Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "The upper and lower surfaces are flat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

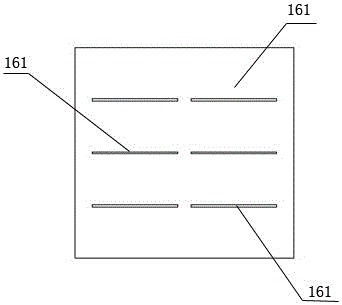

Vacuum auxiliary molding technique produced by large-sized sandwich composite material

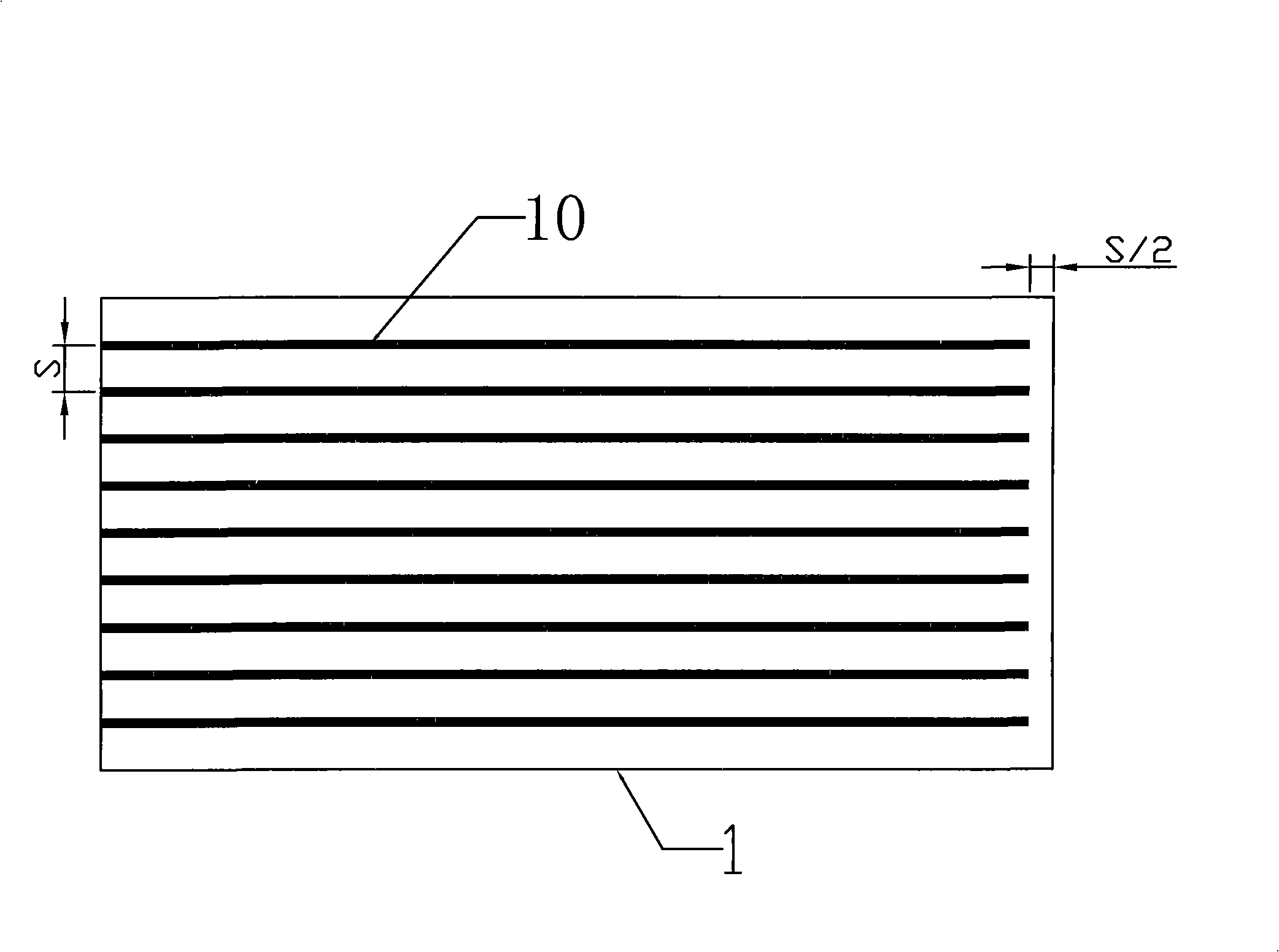

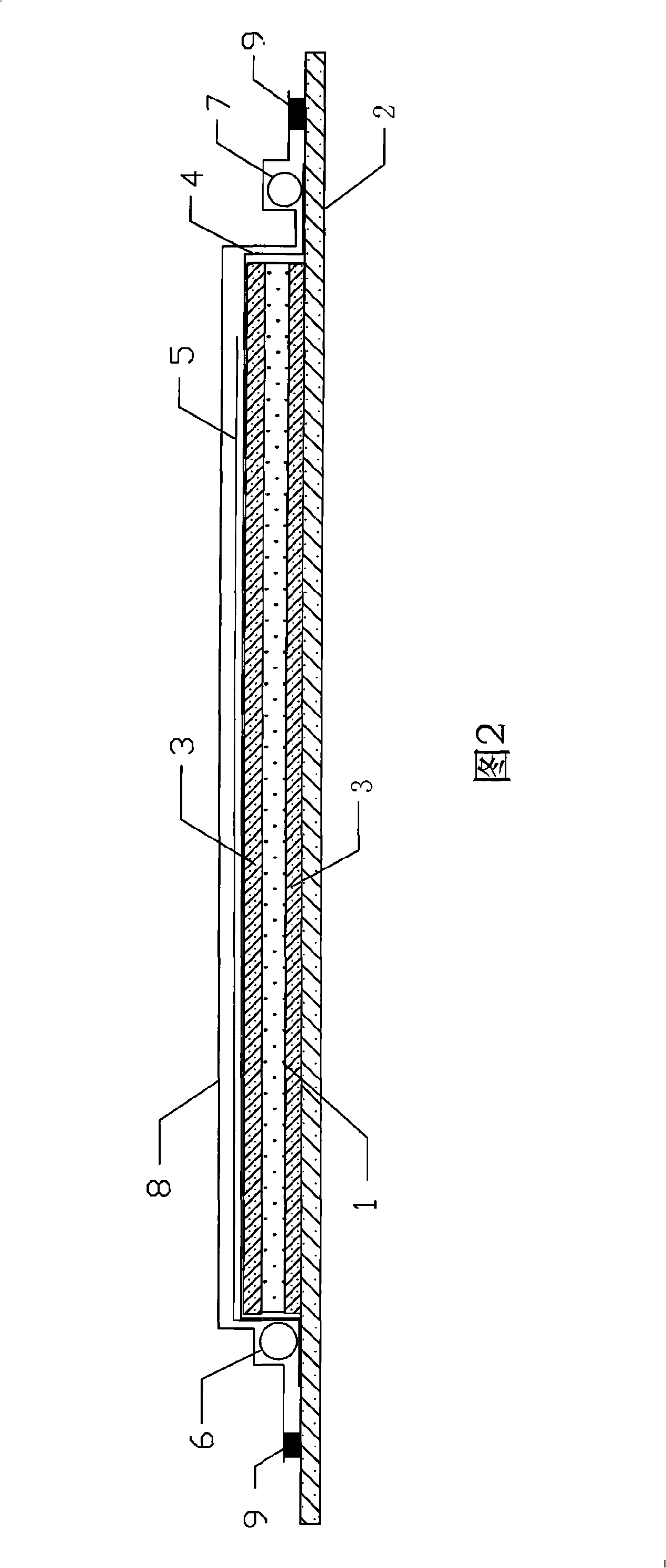

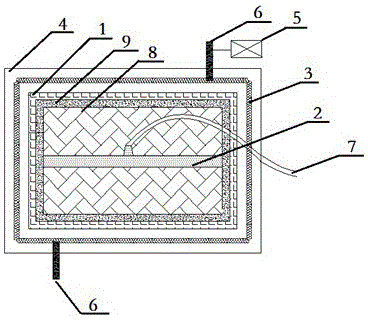

The invention provides a vacuum assistant resin infused method for molding a large part of sandwich composite materials as follows: a set of grooves parallel to each other are arranged at the bottom of the foam core material; fiber fabrics are paved on a processed die according to the specified thickness, and then the grooved foam core material is arranged on the already-paved fiber fabrics, wherein, the machined surface of the grooves of foam core material contacts to the already-paved fiber fabrics, and then the fiber fabrics with a specified thickness are paved on the foam core material; a conduction pipe is arranged at one foam core material end with grooves and a vacuum pipe is arranged at the other end; sealed vacuum bag film and sealed adhesive tape are adopted to seal the fiber fabrics; when the vacuum pressure in the sealed bag film is equal to or less than negative 0.095Mpa, resin solution is inducted to the resin conduction system consisting of the conduction pipe and the conduction cloth after being poured with glue; after the resin immerses the fiber fabrics completely, glue pouring and evacuation are stopped; after the poured-in resin is heat-released and solidified, sandwich composite materials are obtained after 24 hours solidification under indoor temperature condition.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Fiber-reinforced modified-reaction injection-molding nylon sheet and preparation method thereof

ActiveCN101525433AGuaranteed continuityThe upper and lower surfaces are flatFlat articlesCarbon fibersPolymer science

The invention relates to a fiber-reinforced modified-reaction injection-molding nylon sheet and a preparation method thereof, belonging to the field of composite material preparation. An amide monomer is used as a basal raw material; a catalyst, an auxiliary catalyst, an auxiliary antioxidant, a stabilizing agent, a surface conditioning agent, and the like are added; and the materials are injected into a high-temperature mold cavity with preset fibers by an RIM and thermally pressed and molded to prepare the reinforced modified-reaction injection-molding nylon sheet. The prepared sheet comprises the following ingredients by mass percentage: 30 to 95 of amide monomer, 3 to 70 of fiber, 0.01 to 2 of catalyst, 0.01 to 10 of auxiliary catalyst, 0.1 to 2 of antioxidant, 0.1 to 2 of stabilizing agent and 0.1 to 1 of surface conditioning agent, wherein the amide monomer is caprolactam or dodecalactam, the fiber is one of glass fiber, carbon fiber or aramid fiber and is in the form of fiber cloth, short-cut fiber or compound fiber. Compared with common reaction injection nylon and monomer cast nylon sheets, the reaction injection-molding nylon sheet has stronger carrying capability, low manufacture cost and easy popularization and application.

Owner:株洲时代工程塑料科技有限责任公司

Production of frame tube of bicycle with magnesium alloy, frame tube and frame

InactiveCN1817730ANo pollution in the processStrong specific strengthCycle framesEngineeringUltimate tensile strength

Owner:于克儒

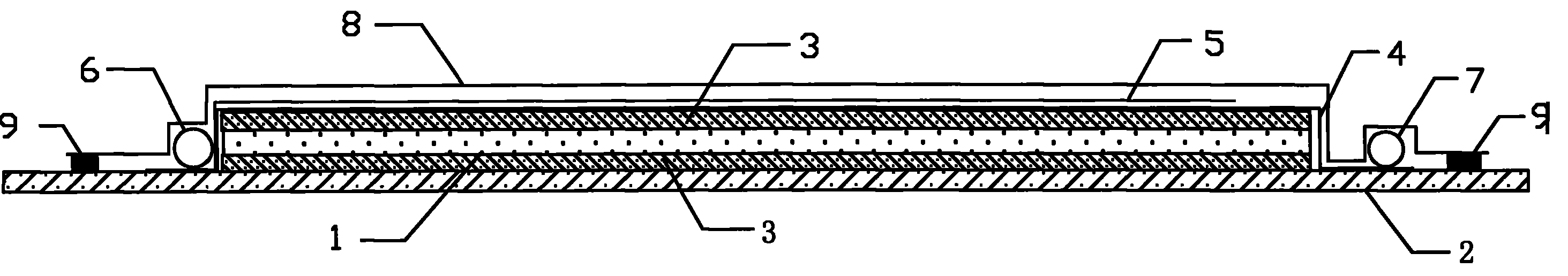

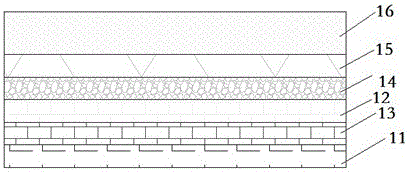

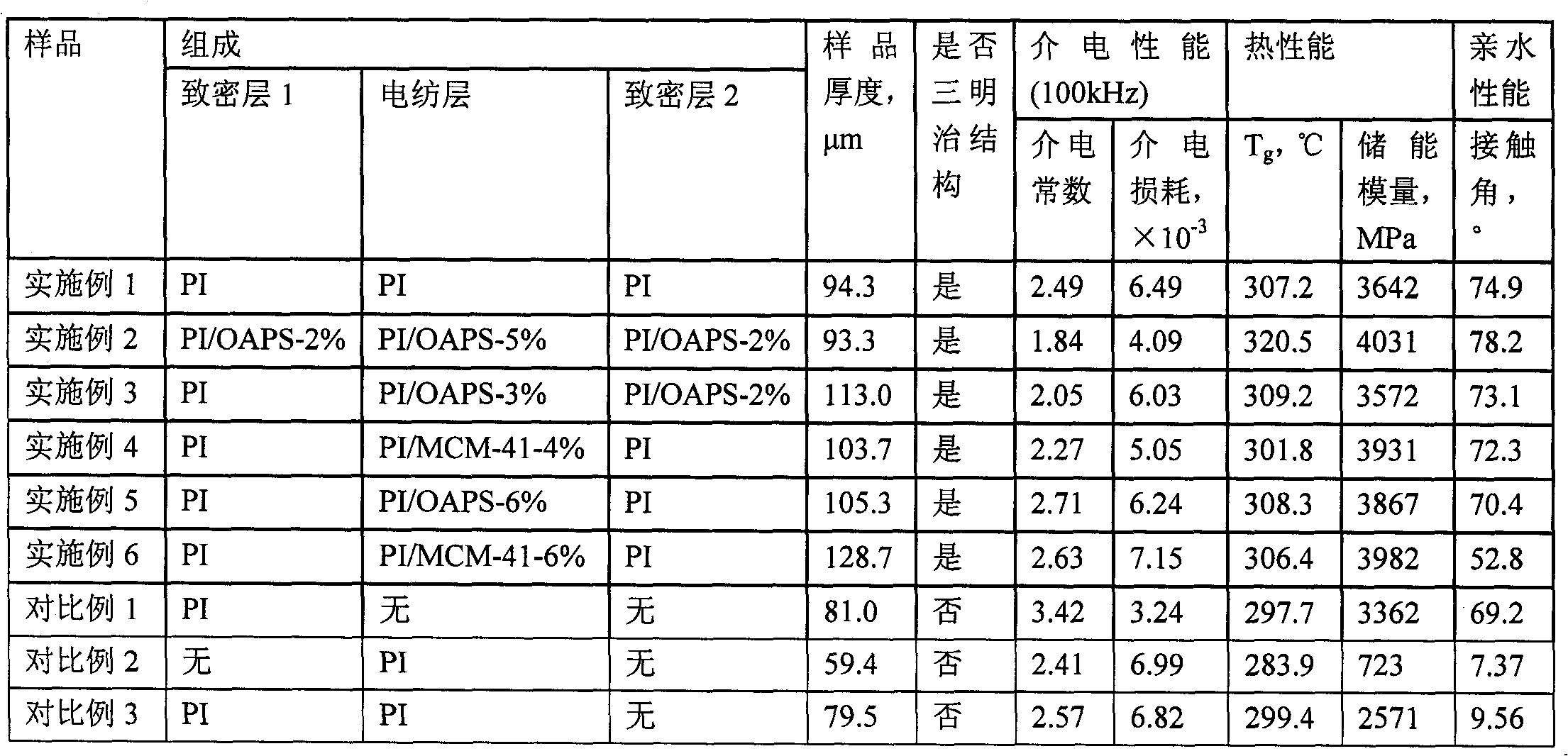

Ultralow dielectric constant film with sandwich structure and preparation method thereof

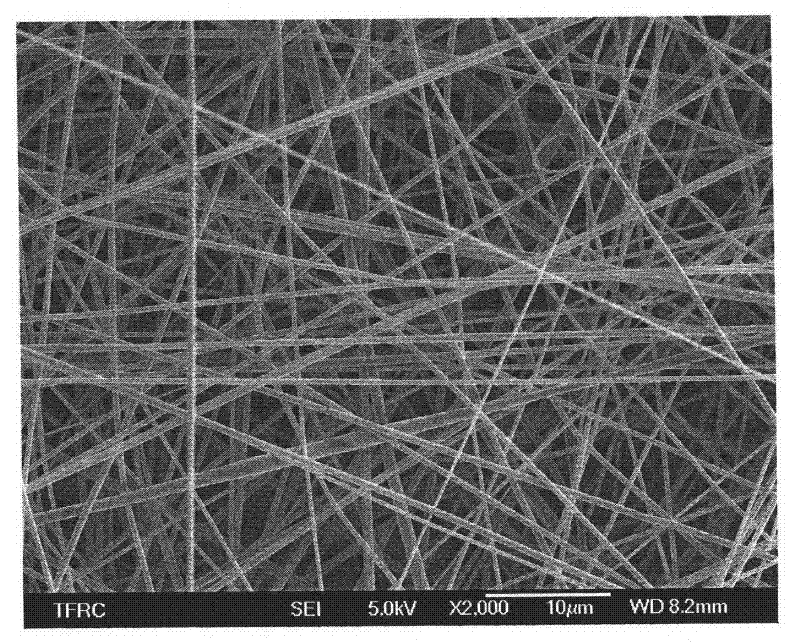

InactiveCN102189724ALow dielectric constantEasy to implementSynthetic resin layered productsElectrospinningLow-k dielectric

The invention belongs to the field of polymer dielectric materials and discloses an ultralow dielectric constant film with a special sandwich structure and a preparation method thereof. The ultralow dielectric constant film with the sandwich structure comprises a three-layer structure, namely a compact layer 1, an electrospinning layer and a compact layer 2 sequentially. The invention also discloses the preparation method for the ultralow dielectric constant film with the sandwich structure, which comprises the following two key steps of: directly performing electrospinning on a compact bottom film; and performing pressurization heat treatment. Through the adjustment of a material structure, multiple problems of a single electrospinning film are solved, lower dielectric constants are kept, the ultralow dielectric constant film which is provided with upper and lower smooth and compact surfaces and has the sandwich structure can be obtained, the defects of a rough surface and an over-high water adsorption ratio of the conventional electrostatic spinning film are overcome, and the preparation method is similar to that of the conventional single electrospinning film and is easy to implement.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Integrally formed carriage plate for van and manufacturing technology

ActiveCN105128487AImprove performanceWaterproofSynthetic resin layered productsLaminationManufacturing technologyVacuum pressure

The invention relates to an integrally formed carriage plate for a van and a manufacturing technology. The outer layer of the carriage plate is made of glass steel, and a PVC foam plate is adopted as an interlayer. The technology comprises the following steps that 1, demoulding material processing and room-temperature curing are performed; 2, a surfacing mat, a composite mat, the PVC foam plate and a diversion composite mat are laid; 3, omega tubes and a winding pipe are fixed, sealing adhesive tapes are bonded, and a demoulding cloth and a vacuum bag are laid to form a vacuum system; 4, the vacuum system is connected with a resin collector in a sealed mode, and the leakproofness of the vacuum system is detected; 5, vacuum pressure maintaining is performed; 6, resin is prepared and poured in a vacuum mode; 7, solidifying, demoulding and postprocessing are performed. Compared with prior art, the PVC foam plate is used as the interlayer, and therefore the advantages of being capable of achieving water resistance, flame retardance, acid and alkali resistance, moth proofing, light mass, high hardness, heat preservation, sound insulation and shock absorption; vacuum infusion and integrally forming are achieved, and therefore the two surfaces of the carriage plate are smooth.

Owner:JIANGSU YUEKE NEW MATERIAL

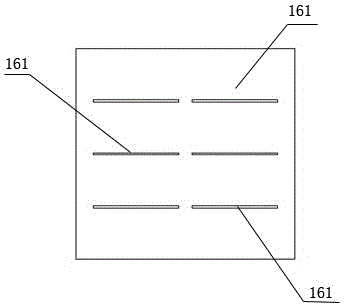

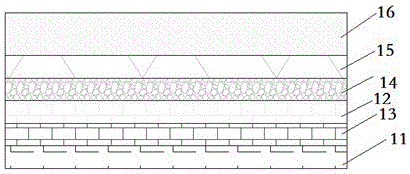

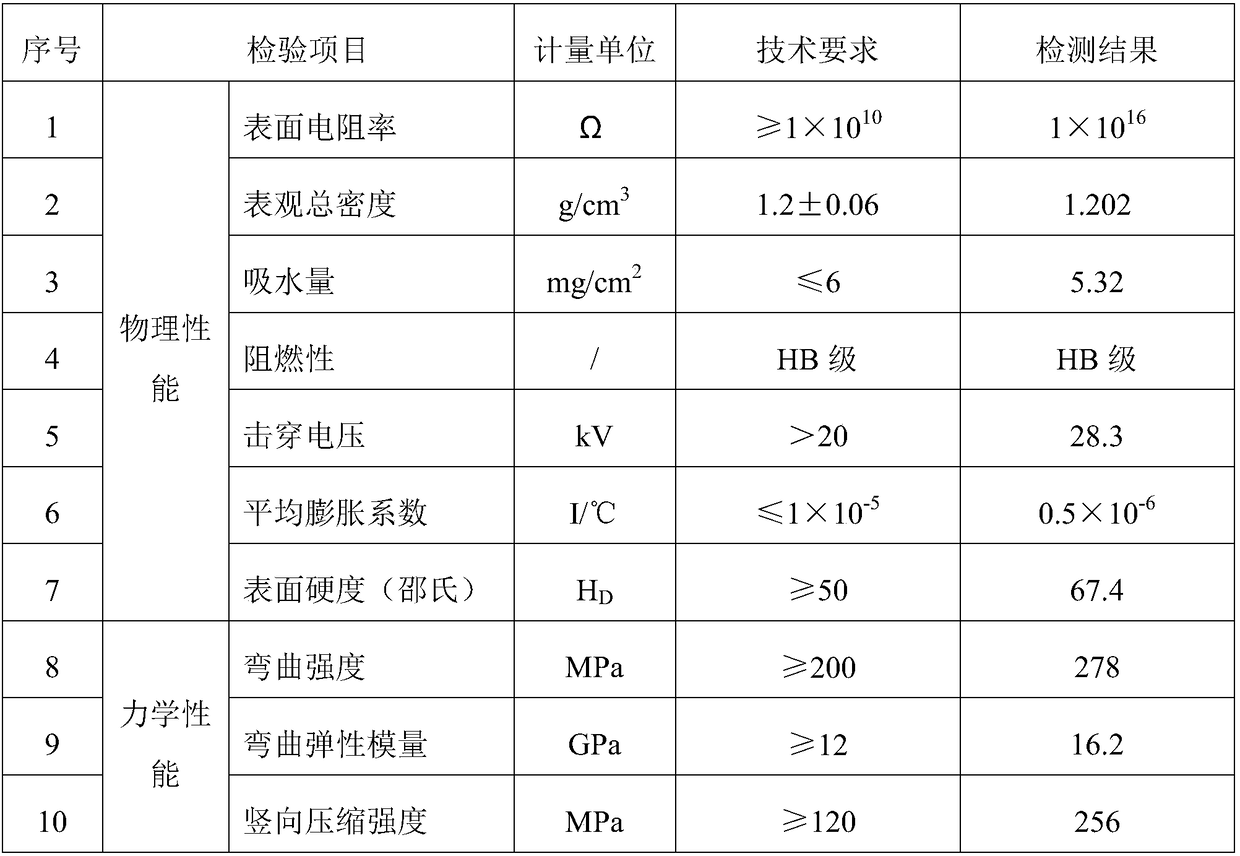

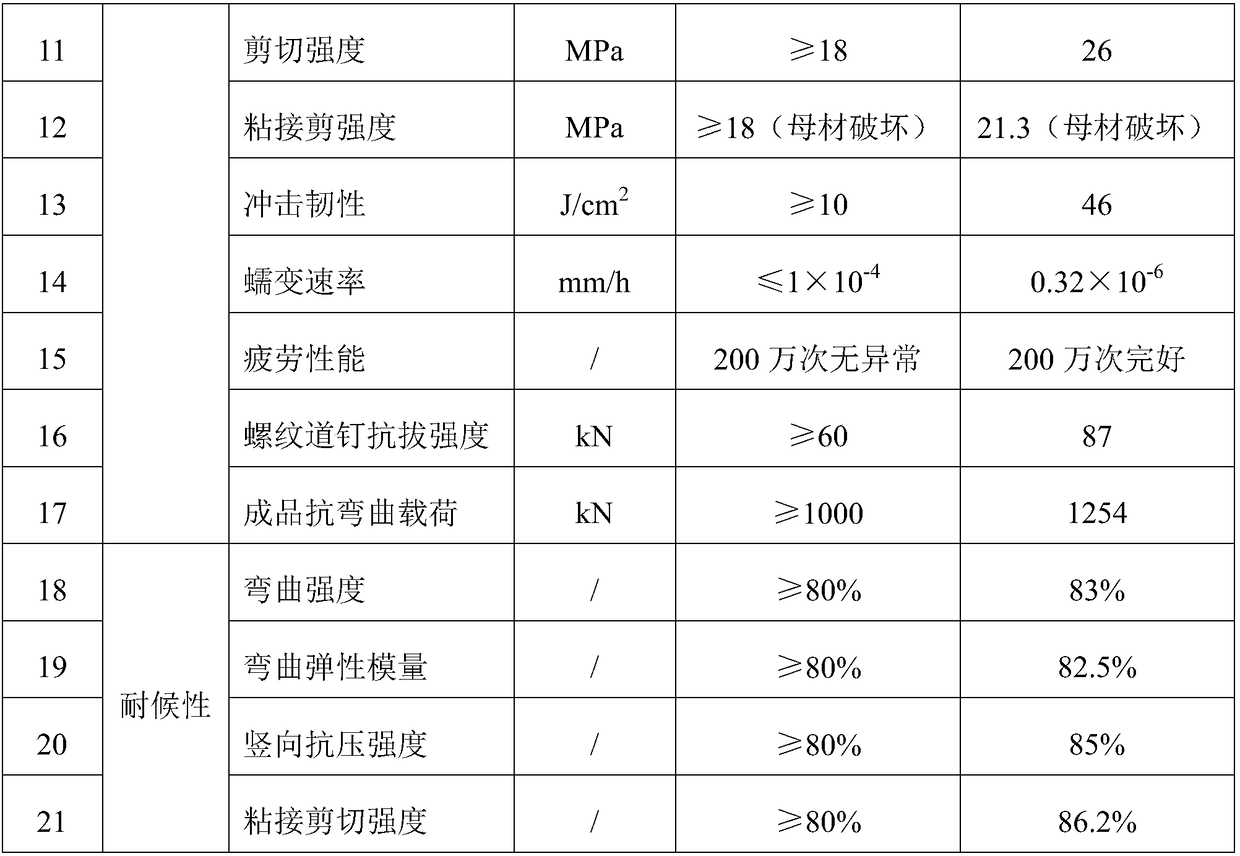

Fiber-reinforced polyurethane foamed and synthesized sleeper and preparation method thereof

The invention discloses a fiber-reinforced polyurethane foamed and synthesized sleeper and a preparation method thereof. The sleeper comprises a body formed by polyurethane resin in a one-time lamination manner, wherein multiple layers of composite felts with a transverse reinforcing effect are transversely arranged in the body, and a fiber yarn layer with a longitudinal reinforcing effect penetrates into the polyurethane resin between two adjacent composite felts; the fiber yarn layer and the composite felts account for 65%-75% of the total weight of the sleeper; the polyurethane resin accounts for 25%-35% of the total weight of the sleeper, and the density of the sleeper is 0.6g / cm<3>-1.6g / cm<3>; and the sleeper is prepared through combination of a double-steel belt laminating machine and a multilayer synchronous glue injection primary formation. According to the fiber-reinforced polyurethane foamed and synthesized sleeper, gum dipping is relatively adequate and uniform, so that thetransverse strength of the sleeper is enhanced, and the cracking phenomenon of a product during punching and indenting can be avoided; and the production process is simple, the equipment input is reduced, the production cost is lowered, and the production efficiency is improved.

Owner:铁科腾跃科技有限公司

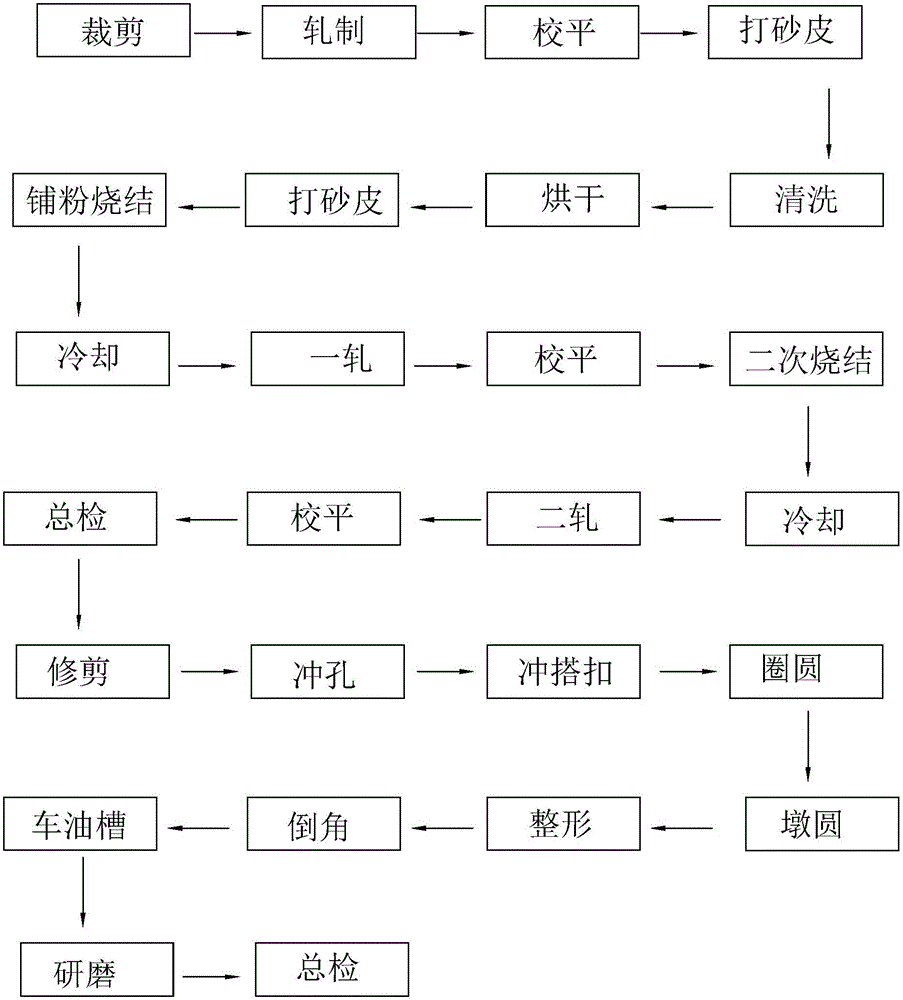

Wrapped bearing bush processing method

The invention discloses a wrapped bearing bush processing method. A big steel plate is cut into multiple small blank plates, anti-rust oil on the blank plates is removed by means of a JQ-107 cleaning agent through ultrasonic cleaning, the cleaned blank plates are dried and then polished with sand paper, unleaded copper powder is spread on the polished blank plates, then the blank plates are placed in a sintering furnace to be sintered at 920-940 DEG C, and the rotating speed of a mesh belt in the furnace is 350-400 mm / min; the blank plates after primary sintering are rolled by 0.05-0.1 mm, and the leveled blank plates are placed in the furnace again for secondary sintering at 940-950 DEG C for 20-40 min, and the rotating speed of the mesh belt in the furnace is 350-400 mm / min; secondary rolling is conducted on the blank plates after secondary sintering by 0.02-0.04 mm, the blank plates after secondary rolling are punched, and the punched blank plates are rolled into the shape of a bearing bush. The wrapped bearing bush produced with the method is stable in structure, and the service life of the wrapped bearing bush is prolonged greatly.

Owner:浙江凯蒂滑动轴承有限公司

Cover structure of washing machine

ActiveCN101565891ASmooth structureThe upper and lower surfaces are flatOther washing machinesTextiles and paperLaundry washing machineButton pressing

The invention relates to a cover structure of a washing machine, which comprises a shell; a base is arranged at the bottom of the shell, an opening is correspondingly arranged in an inner bucket, a surface frame is arranged at the opening, and the surface frame and the cover are articulated through at least one articulated element; a torsion spring or an elastic piece which applies an action force on the opening direction to the cover is arranged at the articulating position; the cover and the surface frame are buckled by a locking way; a hook is arranged in the cover, and the surface frame is provided with a buckling position corresponding to the hook and connected with the hook by a buckling way; the hook is also connected with the button or a spanner, and the button or the spanner is arranged on the cover; one end of at least one articulated element are connected with the surface frame, and the other end thereof is connected with the torsion force controller and the cover; and the button is pressed or the push spanner is pushed to cause the hook and the buckling position to be separated so that the cover can be automatically and slowly opened. The middle part of the cover is an integrated structure without twice articulation, the upper surface and the lower surface of the cover are flat and neat, and easy to clean; and the button controls the cover structure to be turned up, and the button exposes on the top surface of the cover, therefore, a control circuit of the washing machine can not be influenced even if water enters a slot between the button and the cover.

Owner:GUANGDONG GALANZ GRP CO LTD

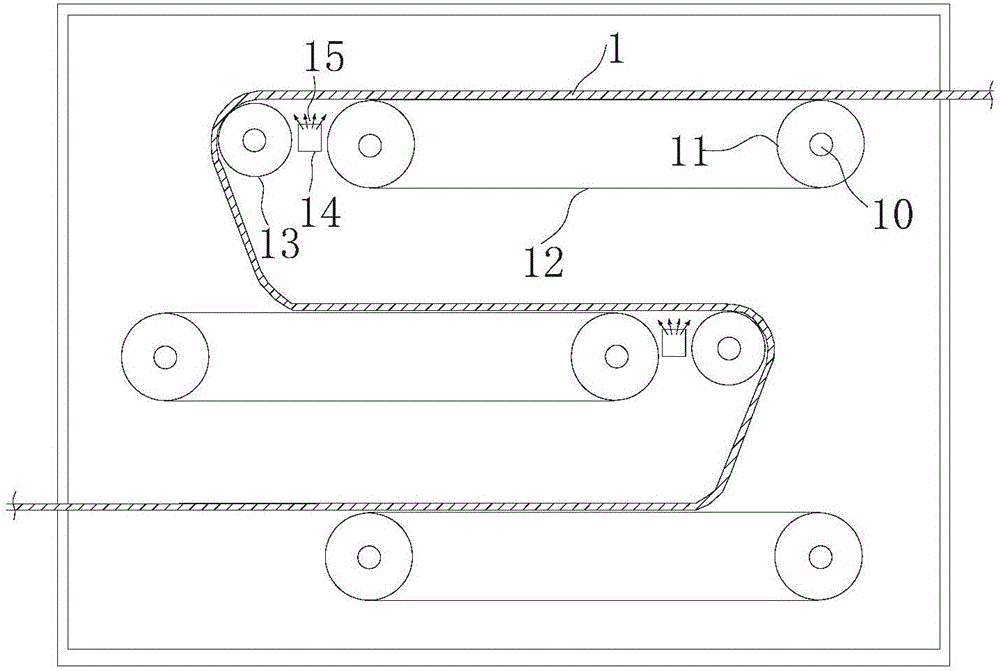

Battery separator producing system and method

ActiveCN105006540AFast molding speedShorten drying timeCell component detailsPulp and paper industrySlurry

The invention discloses a battery separator producing system and method. The battery separator producing system comprises an AGM separator molding device, a drying device and an optical inspection device which are sequentially connected. The AGM separator molding device comprises a conveying net belt, two sets of vacuum water suction boxes and a circulation net belt, wherein the conveying net belt is used for driving an AGM separator, the vacuum water suction box is used for dewatering the AGM separator, and the circulation net belt is arranged above the conveying net belt and abuts against the top face of the AGM separator. The first set of vacuum water suction boxes act with the bottom face of the conveying net belt, and the second set of vacuum water suction boxes act with the side, opposite to the AGM separator, of the circulation net belt. The optical inspection device comprises a lamp box internally provided with a light emitting element. The side, facing the AGM separator, of the lamp box is provided with an inclined light inlet window. An air inlet is formed in the bottom of the lamp box and communicated with an air feeder. The top of the lamp box is provided with an air outlet facing the AGM separator. The slurry drying time can be shortened, the upper and lower planes of the molded AGM separator are flat, and the AGM separator performance is improved.

Owner:ZHEJIANG CHANGTONG SCI & TECH

Magnesium alloy clothes hanger and its production process

InactiveCN1810568APromote environmental protectionImprove rigidityLuggage carriersRoom temperatureUltimate tensile strength

The magnesium alloy clothes hanger has high mechanical performance, light weight and low cost, and the production process with high production efficiency and high product quality includes descaling magnesium alloy rod, heating in a furnace at 400 deg.c for 24 hr, air cooling to room temperature, re-heating in a furnace at 300-400 deg.c for 3 hr, extruding to form shapes, mechanical forming and welding to assembly, and annealing to eliminate stress or artificially ageing. Owing to the heat treatment, the magnesium alloy clothes hanger has well matched strength, plasticity and comprehensive performance, and may be used in various non-motored vehicle.

Owner:于克儒

Small-caliber steel pipe lateral impact sample flattening method

ActiveCN101271048ASimple processing technologyEasy to usePreparing sample for investigationStrength propertiesEngineeringSmall caliber

The invention provides a small-aperture steel pipe horizontal shock sample flattening method which includes the following steps: cushion block making: each cushion block is tempered and quenched into a martensitic structure, the range of which is HRC35 to 40; mould making: a plurality of cushion blocks are subsequently laminated and numbered from narrow to wide, used together or singly, and form flattening moulds; two cushion blocks with the first numbers form a first set of mould which is arranged on a chuck below a flattening test machine; and then a sample to be tested is arranged on the first set of mould; the inner surface of the sample to be tested contacts the first set of mould; the center lines of the sample to be tested and the mould are aligned; and then the flattening test machine starts to pressurize and load on the upper part of the sample to be tested, until a flat part appears and the sample to be tested is flattened. The method has the advantages that each cushion block can be independently removed, is convenient in use and simple to be processed; the materials are widely available and the consumption is small. The method can make the horizontal shock power of small pipes possible, bring convenience for follow-up testing and improve production efficiency.

Owner:TIANJIN PIPE GROUP CORP

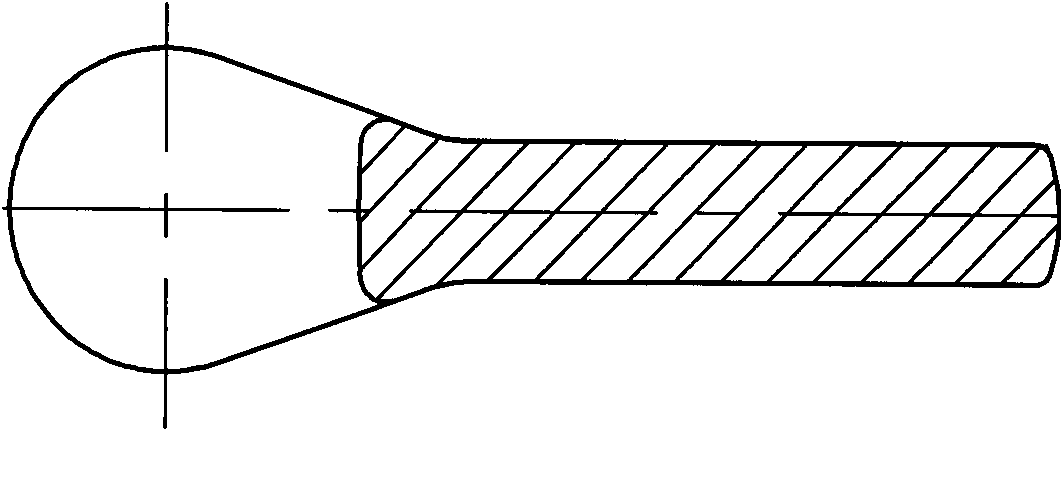

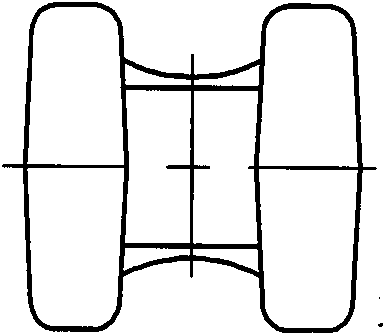

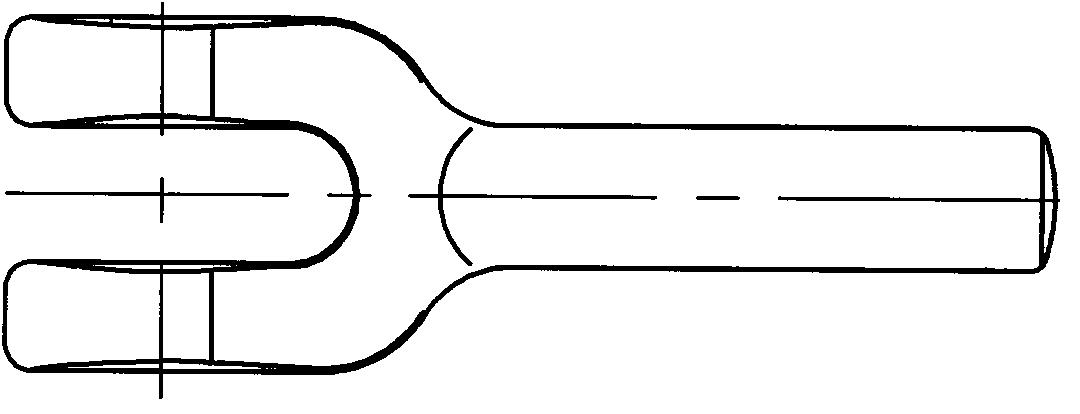

Preforging mould structure for processing shaft fork part stamp forgings

ActiveCN102371326ASmall loadExtend your lifeRailway componentsForging/hammering/pressing machinesHorizontal projectionForging

The invention relates to a mould structure for processing mechanical parts, in particular to a preforging mould structure for processing shaft fork stamp forgings. The preforging mould structure for processing the shaft fork part stamp forgings comprises a preforging upper mould and a preforging lower mould which are used for horizontally arranging a shaft fork part forging and pressing mould and is characterized in that: on the outer edge of the shaft fork part, mould joints of the preforging upper and lower moulds are positioned on the upper and lower symmetrical central surfaces of the part; and on the mould joint of an inner circle of a fork lug part, namely a U-shaped inner circle, the preforging upper mould is extended downward one circle, and the preforging lower mould is recessed downward one circle of the corresponding height. Due to the mould structure, under the condition of the same amount of the used materials, a cavity can be filled by metal conveniently, rejection rate of a forging is reduced, a flash width is smaller, a horizontal projection area is smaller, equipment tonnage can be reduced, the bearing load of the mould is smaller, the service life of the mould can be prolonged, and due to slight flash, materials and cost can be saved, and problems that blank is deflected and is not placed stably before can be solved.

Owner:江苏南洋中京科技有限公司

Dual ring rolling production process of thin-sheet wind driven generator

InactiveCN103192010ASpecifications and sizes are easy to controlThe upper and lower surfaces are flatMetal rollingElectricityRoll forming

The invention discloses a dual ring rolling production process of a thin-sheet wind driven generator, and belongs to the technical field of machine manufacturing. The task of the invention is that when a wind driven flange forged piece with higher quality, larger diameter and smaller thickness is manufactured, the upper surface and the lower surface are smooth, without warping, the dimension is easy to control, and the production yield is high. The key points of the technical scheme are that the production process comprises a dual blank preparation section, a dual blank performing section, and a dual ring rolling forming section. The quality of the single blank is the same as that of two thin-sheet wind driven generator flange blanks; the height of the circular ring-shaped fine blank is the same as that of circular ring-shaped fine blanks of the two thin-sheet wind driven generator flange blanks; and the circular ring-shaped fine blank is divided into two parts by a saw belt, and then the two parts are cut into qualified parts. When the wind driven flange forged piece with higher quality, larger diameter and smaller thickness is manufactured, the dimension is easy to control, the technical effects of the upper surface and the lower surface are smooth, without warping, and the production yield is high are achieved. The production process is simple in structure.

Owner:SHANXI TIANBAO GRP CO LTD

High-power semiconductor laser transition heat sink and preparation method thereof

ActiveCN103326234AGood effectImprove thermal conductivityLaser detailsSemiconductor laser structural detailsHigh power lasersHeat conducting

The invention provides a high-power semiconductor laser transition heat sink and a preparation method thereof. The transition heat sink comprises a substrate, a metal transition layer and a welding flux adhering layer. The substrate consists of an SiC wafer, a titanium metal transition layer or a chromium metal transition layer and a gold welding flux adhering layer are sequentially arranged on the upper surface and the lower surface of the SiC wafer respectively in an evaporation mode, the upper surface and the lower surface of the SiC wafer are an A face and a B face respectively, and an insulated slot is manufactured in the A face. The preparation method includes the steps of conducting wire-electrode cutting on the SiC wafer to cut the SiC wafer into a wafer, washing the wafer, conducting surface metallization on the SiC wafer, etching the insulated slot in the A face of the metallized wafer, and forming the single laser transition heat sink in a dividing mode. The heat-conducting property of the high-power semiconductor laser transition heat sink based on the SiC wafer is better than the heat-conducting property of a transition heat sink of an aluminum nitride ceramic substrate, the size is accurate, and the size can be determined flexibly according to the packaging need of a high-power laser.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

Efficient wood grinder

InactiveCN108942464AThe upper and lower surfaces are flatReduce glitchesGrinding carriagesGrinding feedersCardboardWood grinder

The invention discloses an efficient wood grinder which comprises a workbench (1). An input conveying belt (2), a round grinding mechanism (3) and a fine grinding mechanism (4) are sequentially arranged on the upper surface of the workbench (1) in the wood grinding direction. The fine grinding mechanism (4) comprises an output conveying belt (41) arranged in the wood grinding direction. A grindingpaper layer (42) is arranged on the upper surface of the output conveying belt (41), and a grinding paper board mechanism (43) is arranged over the grinding paper layer (42) in the direction parallelto the wood grinding direction and is connected with the output conveying belt (41) through a connecting frame (44). The output conveying belt (41) is arranged below the round grinding mechanism (3).The input conveying belt (2), a rack (31) and the output conveying belt (41) are all arranged on the upper surface of the workbench (1). The efficient wood grinder has the advantages of being good inwood grinding quality and high in work efficiency.

Owner:湖州韵高木业有限公司

Vacuum auxiliary molding technique produced by large-sized sandwich composite material

The invention provides a vacuum assistant resin infused method for molding a large part of sandwich composite materials as follows: a set of grooves parallel to each other are arranged at the bottom of the foam core material; fiber fabrics are paved on a processed die according to the specified thickness, and then the grooved foam core material is arranged on the already-paved fiber fabrics, wherein, the machined surface of the grooves of foam core material contacts to the already-paved fiber fabrics, and then the fiber fabrics with a specified thickness are paved on the foam core material; aconduction pipe is arranged at one foam core material end with grooves and a vacuum pipe is arranged at the other end; sealed vacuum bag film and sealed adhesive tape are adopted to seal the fiber fabrics; when the vacuum pressure in the sealed bag film is equal to or less than negative 0.095Mpa, resin solution is inducted to the resin conduction system consisting of the conduction pipe and the conduction cloth after being poured with glue; after the resin immerses the fiber fabrics completely, glue pouring and evacuation are stopped; after the poured-in resin is heat-released and solidified,sandwich composite materials are obtained after 24 hours solidification under indoor temperature condition.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

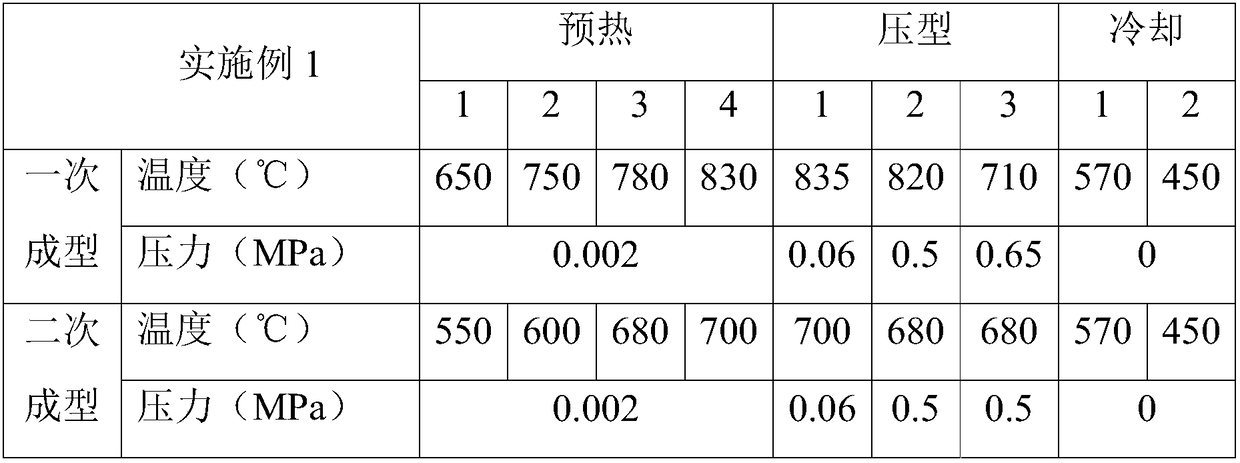

Curved glass and molding method thereof

ActiveCN109206000AImprove production yieldImprove appearance qualityGlass reforming apparatusGlass productionVertical projectionMaterials science

The invention discloses a curved glass and a molding method thereof. The method includes: (1) taking a glass substrate with a thickness of h0 for one-shot forming to obtain a curved glass green body with a vertical projection height of h1; (2) subjecting the curved glass green body to secondary forming to obtain curved glass with a vertical projection height of h2, wherein in horizontal projection, the length perpendicular to the axial direction is 2L, and h2 / L is greater than or equal to 1 / 6 and less than or equal to 1, (h1-h0):(h2-h0)=(0.6-0.9):1. The method is beneficial to reducing the residual stress inside the molded curved glass, reducing or avoiding the possibility of pits, press marks and other defects, and improving the yield rate of molded curved glass, endows the curved glass product with smooth upper and lower surfaces, and optimizes the appearance quality of the curved glass.

Owner:BYD CO LTD

One-time forming compartment panel for van truck and its manufacturing process

ActiveCN105128487BImprove performanceWaterproofSynthetic resin layered productsLaminationManufacturing technologyVacuum pressure

The invention relates to an integrally formed carriage plate for a van and a manufacturing technology. The outer layer of the carriage plate is made of glass steel, and a PVC foam plate is adopted as an interlayer. The technology comprises the following steps that 1, demoulding material processing and room-temperature curing are performed; 2, a surfacing mat, a composite mat, the PVC foam plate and a diversion composite mat are laid; 3, omega tubes and a winding pipe are fixed, sealing adhesive tapes are bonded, and a demoulding cloth and a vacuum bag are laid to form a vacuum system; 4, the vacuum system is connected with a resin collector in a sealed mode, and the leakproofness of the vacuum system is detected; 5, vacuum pressure maintaining is performed; 6, resin is prepared and poured in a vacuum mode; 7, solidifying, demoulding and postprocessing are performed. Compared with prior art, the PVC foam plate is used as the interlayer, and therefore the advantages of being capable of achieving water resistance, flame retardance, acid and alkali resistance, moth proofing, light mass, high hardness, heat preservation, sound insulation and shock absorption; vacuum infusion and integrally forming are achieved, and therefore the two surfaces of the carriage plate are smooth.

Owner:JIANGSU YUEKE NEW MATERIAL

Splice bamboo plate and its making method

InactiveCN100400249CEasy to processThe upper and lower surfaces are flatWood treatment detailsVeneer manufactureAdhesiveEngineering

Owner:龙开琼

Splice bamboo plate and its making method

InactiveCN1693042AEasy to processThe upper and lower surfaces are flatWood treatment detailsVeneer manufactureAdhesiveEngineering

Owner:龙开琼

AGM partition production system

ActiveCN108232084AImprove molding qualityThe upper and lower surfaces are flatCell component detailsWater storage tankSlurry

The invention relates to production equipment, in particular to an AGM partition production system. The AGM partition production system comprises a molding device and a drying device, wherein the molding device comprises a material uniformizing-conveying device and a conveying-water absorbing device; the material uniformizing-conveying device comprises a material uniformizing groove; a plurality of stirring flow control devices are arranged in the material uniformizing groove; the stirring flow control devices comprise separation plates arranged on the bottom surface of the inner wall of the material-uniformizing groove, flow control plates arranged on the top of the inner wall of the material-uniformizing groove, and stirring devices arranged between the separation plates and the flow control plates; the conveying-water absorbing device comprises a frame, a conveying net belt, a flattening belt and a water-absorbing device; the water-absorbing device comprises a water-absorbing tank,a water storage tank and a water-absorbing pump; the water storage tank is connected with the water-absorbing tank through a water-absorbing pipe; the drying device comprises a conveying mechanism; the conveying mechanism comprises a rotating shaft, a chain wheel, a transmission chain and a mandrel. The AGM partition production system is easy to operate; the slurry uniformity of an AGM partition is high, the frictional force between a conveying belt and the AGM partition is reduced, and the AGM partition can be prevented from sticking to the conveying belt.

Owner:ZHEJIANG CHANGTONG SCI & TECH

A kind of microchannel heat sink and its manufacturing method

ActiveCN109411427BReduce processing difficultyReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesHeat flowHemt circuits

The invention discloses a microchannel heat radiator. A microchannel and a shunting network are arranged in the microchannel heat radiator, a surface is provided with a liquid inlet and a liquid outlet, and an external surface of the microchannel is provided with a metal layer. According to the microchannel heat radiator provided by the invention, the surface of the microchannel heat radiator is provided with the metal layer, thus, a grounding requirement of a high-frequency system is satisfied well, arranging a deep TSV hole on the microchannel heat radiator is also avoided, processing difficulty and manufacturing cost of the microchannel heat radiator are reduced, and reliability of integration density of a circuit and reliability of a structure are guaranteed; with the metal layer, upper and lower surfaces of the microchannel heat radiator provided by the invention are flat and have no cavity, so, a plurality of high heat-flux density chips can be integrated on the surfaces of the microchannel heat radiator, and the circuits can be designed flexibly under the premise of guaranteeing heat dissipation performance of products.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Fiber-reinforced modified-reaction injection-molding nylon sheet and preparation method thereof

ActiveCN101525433BGuaranteed continuityThe upper and lower surfaces are flatFlat articlesCarbon fibersPolymer science

The invention relates to a fiber-reinforced modified-reaction injection-molding nylon sheet and a preparation method thereof, belonging to the field of composite material preparation. An amide monomer is used as a basal raw material; a catalyst, an auxiliary catalyst, an auxiliary antioxidant, a stabilizing agent, a surface conditioning agent, and the like are added; and the materials are injected into a high-temperature mold cavity with preset fibers by an RIM and thermally pressed and molded to prepare the reinforced modified-reaction injection-molding nylon sheet. The prepared sheet comprises the following ingredients by mass percentage: 30 to 95 of amide monomer, 3 to 70 of fiber, 0.01 to 2 of catalyst, 0.01 to 10 of auxiliary catalyst, 0.1 to 2 of antioxidant, 0.1 to 2 of stabilizingagent and 0.1 to 1 of surface conditioning agent, wherein the amide monomer is caprolactam or dodecalactam, the fiber is one of glass fiber, carbon fiber or aramid fiber and is in the form of fiber cloth, short-cut fiber or compound fiber. Compared with common reaction injection nylon and monomer cast nylon sheets, the reaction injection-molding nylon sheet has stronger carrying capability, low manufacture cost and easy popularization and application.

Owner:株洲时代工程塑料科技有限责任公司

Ultralow dielectric constant film with sandwich structure and preparation method thereof

InactiveCN102189724BLow dielectric constantImprove heat resistanceSynthetic resin layered productsRough surfacePolymer dielectrics

The invention belongs to the field of polymer dielectric materials and discloses an ultralow dielectric constant film with a special sandwich structure and a preparation method thereof. The ultralow dielectric constant film with the sandwich structure comprises a three-layer structure, namely a compact layer 1, an electrospinning layer and a compact layer 2 sequentially. The invention also discloses the preparation method for the ultralow dielectric constant film with the sandwich structure, which comprises the following two key steps of: directly performing electrospinning on a compact bottom film; and performing pressurization heat treatment. Through the adjustment of a material structure, multiple problems of a single electrospinning film are solved, lower dielectric constants are kept, the ultralow dielectric constant film which is provided with upper and lower smooth and compact surfaces and has the sandwich structure can be obtained, the defects of a rough surface and an over-high water adsorption ratio of the conventional electrostatic spinning film are overcome, and the preparation method is similar to that of the conventional single electrospinning film and is easy to implement.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Environment-friendly bolt type power electronic rectification chip forming process

PendingCN111739808AReduce contentImprove the environmental indexSolid-state devicesSemiconductor/solid-state device manufacturingGraphiteSoldering

The invention discloses an environment-friendly bolt type power electronic rectification chip forming process which comprises the following steps: (1) preparing a plurality of tin-copper alloy soldering lugs and lead-tin alloy soldering lugs, wherein the weight percentage of tin in the tin-copper alloy soldering lugs is 96%-98%, and the weight percentage of copper in the tin-copper alloy solderinglugs is 4%-2%; (2) sequentially filling the tin-copper alloy soldering lugs, the lead-tin alloy soldering lugs, a cathode molybdenum plate, a siliceous rectification chip and an anode molybdenum plate into a die hole of each graphite sintering die; (3) feeding the plurality of graphite sintering dies into a vacuum chamber of a horizontal vacuum sintering furnace; and (4) carrying out sintering and molding by using the horizontal vacuum sintering furnace. According to the invention, tin-copper (97:3) alloy replaces lead-tin (95:5) alloy material to be used as the cathode and anode surface weld-aid layers of the rectification chip product, so that the environmental protection index of the product is greatly improved, the application market of the product is expanded, the production efficiency of the product is greatly improved, and the phenomenon that the traditional lead enameling process affects the health is avoided.

Owner:HUANGSHAN HENGYUE ELECTRONICS

Magnesium alloy clothes hanger and its production process

InactiveCN100395144CPromote environmental protectionImprove rigidityLuggage carriersRoom temperatureUltimate tensile strength

The magnesium alloy clothes hanger has high mechanical performance, light weight and low cost, and the production process with high production efficiency and high product quality includes descaling magnesium alloy rod, heating in a furnace at 400 deg.c for 24 hr, air cooling to room temperature, re-heating in a furnace at 300-400 deg.c for 3 hr, extruding to form shapes, mechanical forming and welding to assembly, and annealing to eliminate stress or artificially ageing. Owing to the heat treatment, the magnesium alloy clothes hanger has well matched strength, plasticity and comprehensive performance, and may be used in various non-motored vehicle.

Owner:于克儒

A high-power semiconductor laser transition heat sink and its preparation method

ActiveCN103326234BGood effectImprove thermal conductivityLaser detailsSemiconductor laser structural detailsHigh power lasersHeat conducting

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

Preforging mould structure for processing shaft fork part stamp forgings

ActiveCN102371326BBoth upper and lower surfaces are smoothThe upper and lower surfaces are flatRailway componentsForging/hammering/pressing machinesMechanical componentsRejection rate

Owner:江苏南洋中京科技有限公司

Nailless flat riveting structure of copper bar and its process method

ActiveCN108832447BThe upper and lower surfaces are flatNice appearanceLine/current collector detailsCable/conductor manufactureMetallurgyEngineering

The invention provides a copper bar nail-free flat riveted structure and a process method thereof. The copper bar nail-free flat riveted structure comprises an upper copper bar and a lower copper barwhich are arranged perpendicularly; two layers of concentric stepped circular holes which pass through the upper copper bar the thickness direction of the upper copper bar are formed in the upper copper bar; one side surface of the lower copper bar is provided with circular riveting joints which are suitable for being riveted into the circular holes with smaller diameters in the stepped circular holes; and process counterbores are formed in the circular riveting joints. According to the copper bar nail-free flat riveted structure and the process method thereof of the invention, riveting can berealized with no nails needed, other connecting parts are not required, the upper surface and lower surface of the copper bar nail-free flat riveted structure are flat, the appearance of the copper bar nail-free flat riveted structure is beautiful, the installation of other parts is not disturbed, and riveting means can be enriched.

Owner:CHANGZHOU BORI ELECTRIC POWER AUTOMATION EQUIP

Production of frame tube of bicycle with magnesium alloy, frame tube and frame

InactiveCN100469651CNo pollution in the processStrong specific strengthCycle framesEngineeringUltimate tensile strength

Owner:于克儒

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com