Battery separator producing system and method

A battery separator and production system technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of uneven moisture content on the upper and lower surfaces of AGM separators, affecting the quality of AGM separators, affecting the performance of AGM separators, etc. , to achieve the effect of reducing drying time, less heat absorption and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes the battery separator production system of the present invention in further detail with reference to preferred embodiments and the accompanying drawings.

[0056] The production process of AGM separator 1 mainly includes separator forming process, drying process, quality inspection process and winding process. Between quality inspection process and winding process, AGM separator 1 can also be processed (for example: cut into Requires wide AGM partitions, etc.).

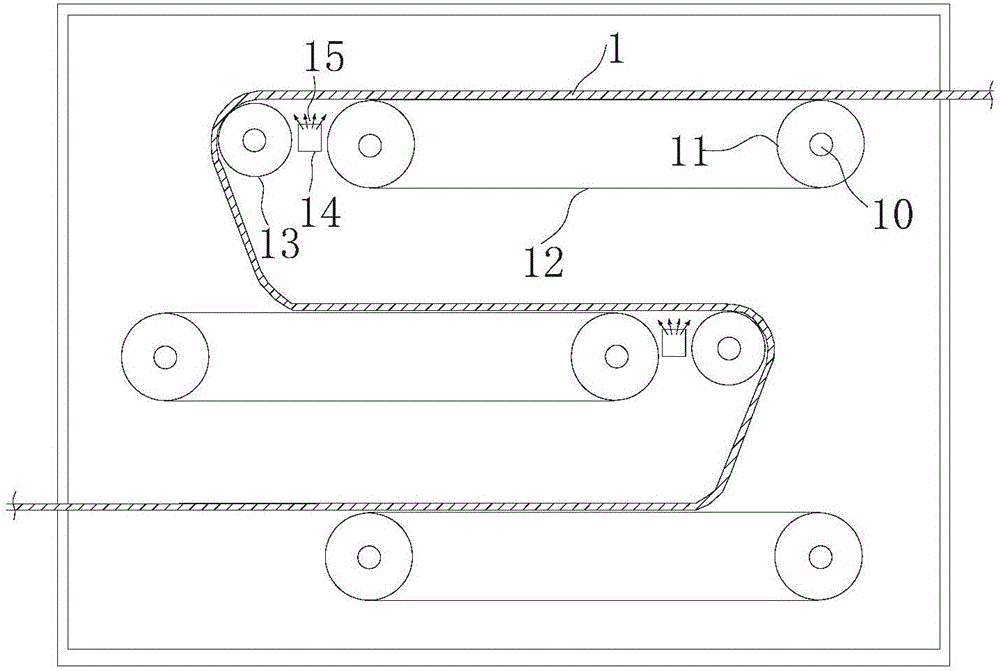

[0057] The battery separator production system of the present invention includes an AGM separator forming device A, a drying device B, a light inspection device C, and a winding device D which are sequentially connected, such as figure 1 Shown.

[0058] Such as figure 2 As shown, the AGM partition forming device of the present invention includes a conveyor mesh belt 2 installed on the frame, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com