Method for preparing porous ceramic support

A technology of porous ceramics and supports, used in ceramic products, final product manufacturing, fuel cell components, etc., can solve the problems of large amount of feed, only suitable for mass production, and prolong the experimental period, and achieve fast forming speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

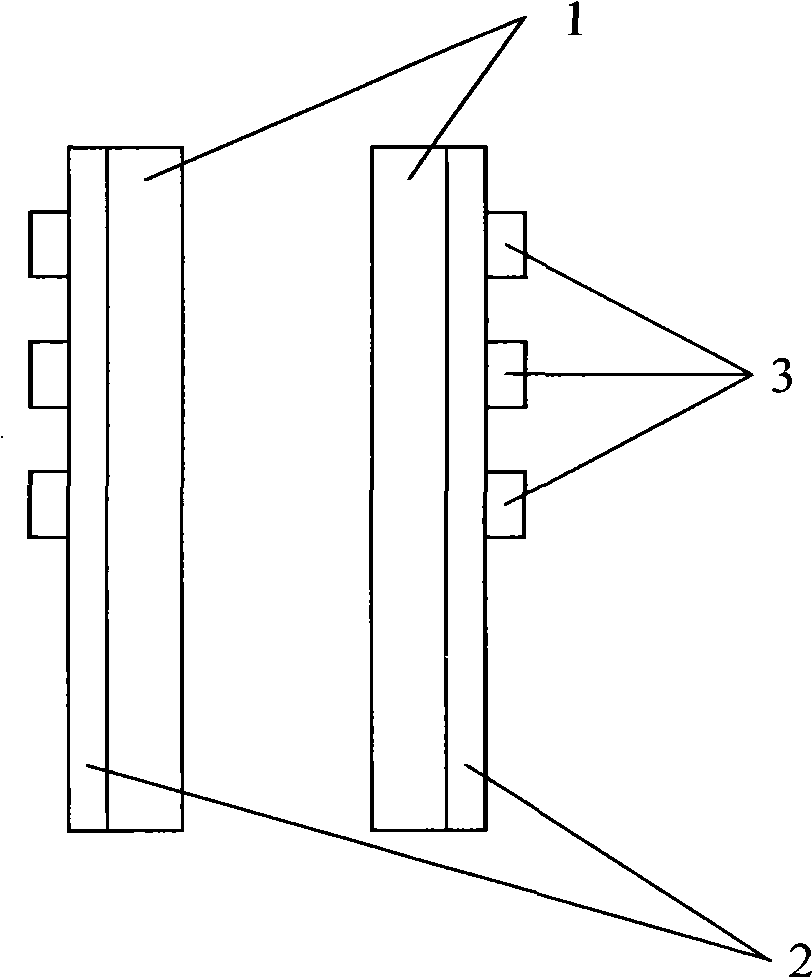

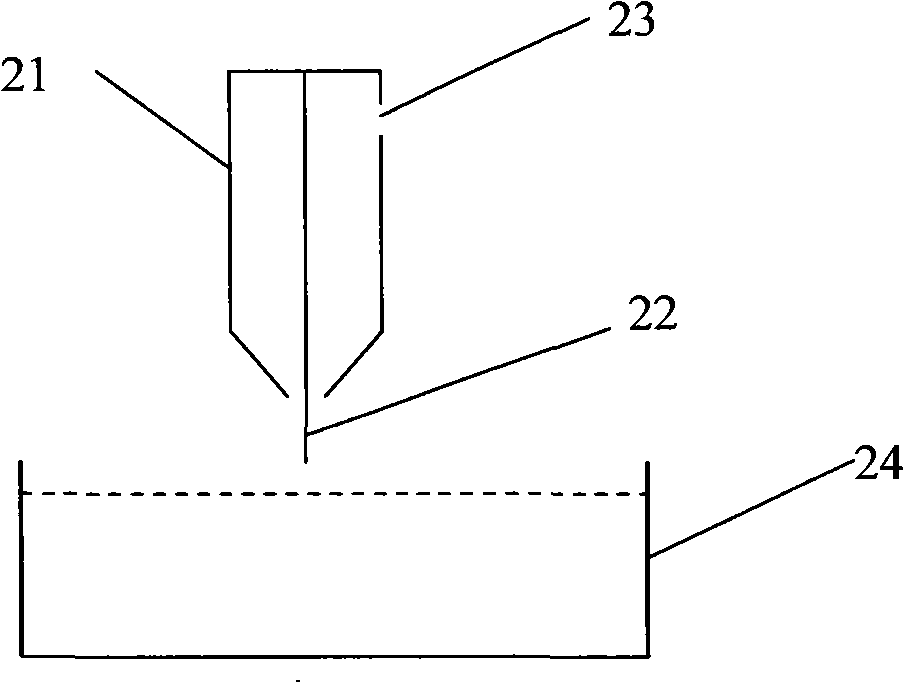

Image

Examples

Embodiment 1

[0026] Accurately weigh 15g of 3%mol yttria-stabilized zirconia (PSZ) ceramic powder in an agate mortar, then add 3g of flour to grind evenly. Weigh 0.75g polysulfone (PSF) and dissolve it in 2.25g N-methylpyrrolidone (NMP), then add it to the pretreated PSZ ceramic powder, and grind it with a mortar to obtain a muddy slurry. Evenly coat the surface of the glass rod, and then use the rolling method to roll back and forth on the glass plate for about 5 minutes. After the tube wall is uniform, soak it in pure water for 3 minutes, and then take out the glass rod to get the tube. Type green body. Finally, the obtained green body was sintered in a high-temperature furnace at 1200° C. for 4 hours to obtain a PSZ tubular porous ceramic support body with a porosity of about 74%.

[0027] In this embodiment: the weight of the pore-forming agent is 20% of the weight of the ceramic powder; the weight percentage of the molding agent, solvent, and pretreated ceramic powder is 3.57%: 10.71...

Embodiment 2

[0030] Accurately weigh 7.5g of nickel oxide (NiO) and 7.5g of 8% mol yttrium oxide stabilized zirconia (YSZ) ceramic powder in a ball mill jar, then add 1.5g of flour, then add an appropriate amount of absolute ethanol, and place in a planetary Mill on a ball mill for 1 hour, and finally dry in an oven for later use. Weigh 1.0g polyethersulfone (PES) and dissolve it in 2.5g N-methylpyrrolidone (NMP), then add it to the pretreated NiO-YSZ mixed ceramic powder, and grind it with a mortar to obtain a muddy slurry , evenly coat the slurry on the surface of the glass rod, and then use the rolling method to roll back and forth on the glass plate for about 5 minutes. After the tube wall is uniform, soak it in pure water for 10 minutes, and finally take out the glass rod A tubular green body with a wall thickness of about 1.0 mm is obtained.

[0031] In this embodiment: the weight of the pore-forming agent is 10% of the weight of the ceramic powder; the weight percentage of the mold...

Embodiment 3

[0035] First prepare the PSZ long-tube porous ceramic support with a length of about 15 cm according to the composition ratio and method of Example 1, then utilize the impregnation method to prepare a film of nickel oxide (NiO) and gadolinium-doped cerium oxide (GDC) mixture on its surface, Pre-fired at 1150°C for 4 hours to obtain a NiO-GDC anode, and then prepared a GDC film on its surface by impregnation method, and then sintered at 1450°C for 4 hours to form a GDC electrolyte layer, and finally painted on the surface of the sintered GDC electrolyte layer Barium Strontium Cobalt Iron (Ba 0.5 Sr 0.5 co 0.8 Fe 0.2 o 3 ) cathode, and after sintering at 970°C for 2 hours, a thin-film SOFC single cell supported by PSZ porous ceramics is obtained.

[0036] The output performance of this single cell is measured by the four-electrode method. In the test, the silver wire is used as the wire, the silver paste is used as the connecting material, hydrogen saturated with water vapor a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com