Microarray die-free forming device based on surface acoustic wave and forming method

A technology of moldless molding and surface acoustic wave, which is applied in the field of micro-molding devices and molding, can solve the problems of restricting the development and application of rapid light-curing micro-molding methods, reducing production efficiency, etc., and achieve mature manufacturing processes, high production efficiency, and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

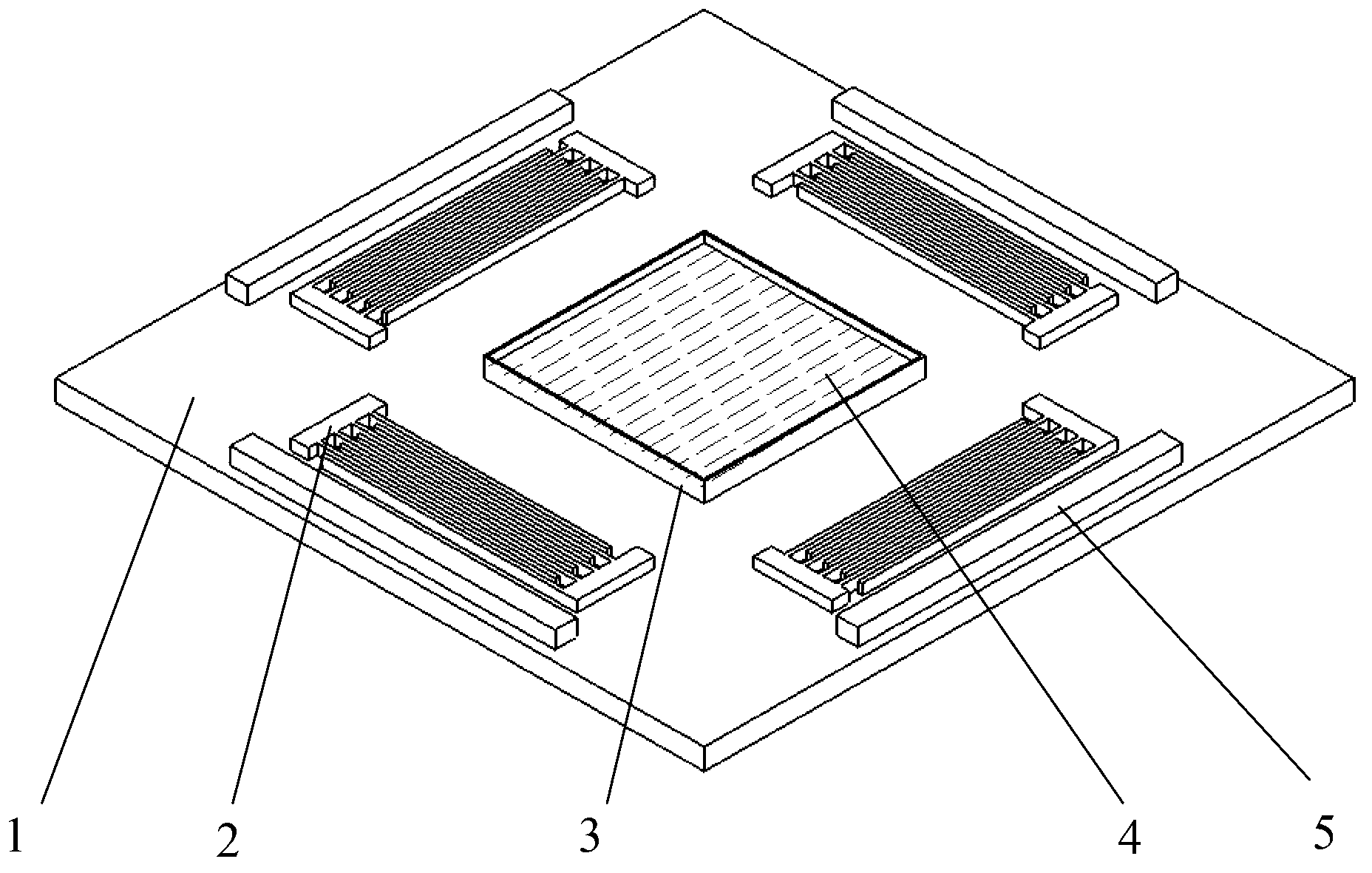

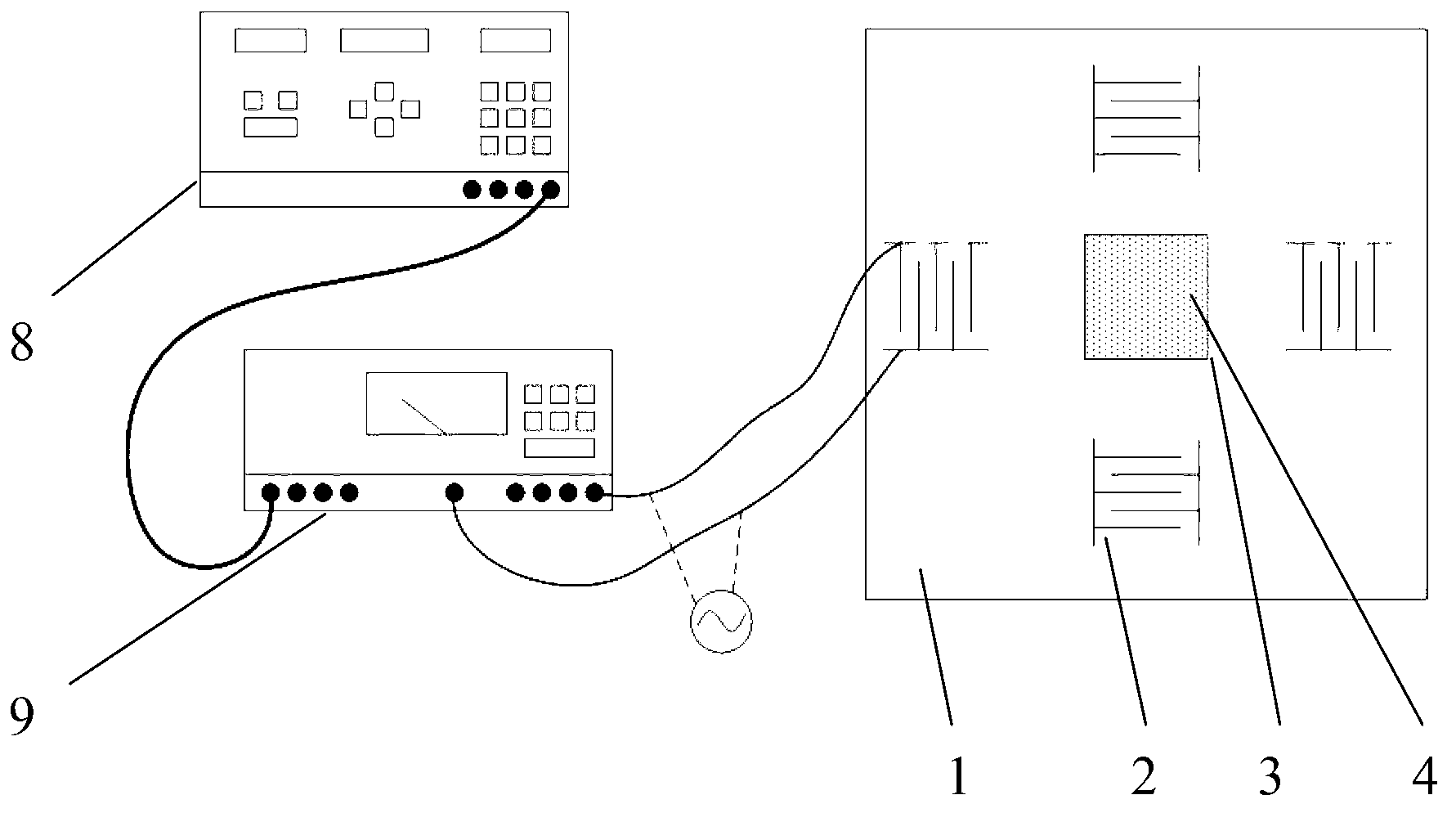

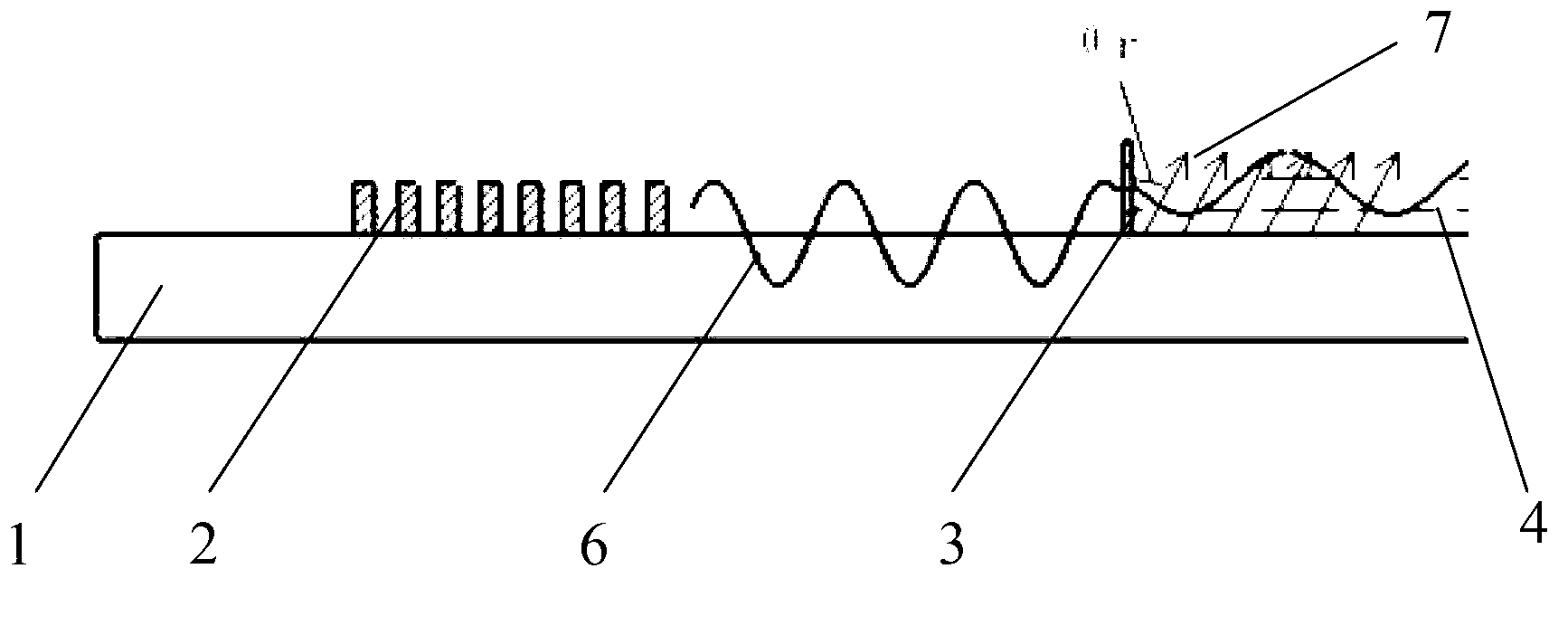

[0032] Such as figure 1 As shown, the present invention has two pairs of interdigital transducers 2 photolithographically etched on a square piezoelectric substrate 1, and each pair of interdigital transducers 2 is arranged symmetrically with the central axis of the square piezoelectric substrate 1 as the axis. A square glass liquid tank 3 is placed in the middle of the piezoelectric base plate 1 and cemented with the piezoelectric base plate 1 , and the formed liquid material 4 is placed in the glass liquid tank 3 .

[0033] The square glass liquid tank 3 is a bottomless glass liquid tank, and its glass wall surface is bonded to the square piezoelectric substrate plate 1. The formed liquid material 4 contained in the glass liquid tank 3 has a thickness less than or equal to 5mm.

[0034] The side length of the square molten glass tank 3 is less than o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com