Laser scanning device and method for making three-dimensional object

A laser scanning device, a technology for three-dimensional objects, applied in optics, optical components, instruments, etc., can solve the problems of slowing down the forming speed of three-dimensional objects, affecting the forming accuracy of three-dimensional objects, and difficult to achieve high precision and high forming speed. The effect of increasing the molding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

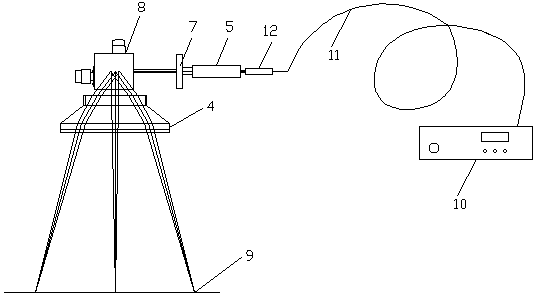

Embodiment approach 1

[0037]Embodiment 1: The beam adjustment system includes a fixed magnification beam expander, an F-Theta lens, and a diaphragm, and the laser, a fixed magnification beam expander, a galvanometer system, and an F-Theta lens form a first optical path unit, and the F -Theta lens is used to form a focused spot of uniform size on the working plane by the laser beam reflected by the galvanometer system. The fixed magnification beam expander is arranged between the laser and the galvanometer system. The aperture, so that the aperture is set between the fixed magnification beam expander and the vibrating mirror system, when scanning the filling area, the aperture is lowered, so that the aperture does not appear in the first optical path unit.

Embodiment approach 2

[0038] Embodiment 2: The beam adjustment system includes a dynamic focusing module and a diaphragm, the dynamic focusing module includes a dynamic diverging mirror and a focusing mirror, and the laser, the dynamic diverging mirror, the focusing mirror and the vibrating mirror system form a second optical path unit, and the The above-mentioned dynamic diverging mirror and focusing mirror are sequentially arranged between the laser and the galvanometer system. When scanning the contour area, the diaphragm is raised so that the diaphragm is arranged between the dynamic diverging mirror and the focusing mirror. stop, so that the stop does not appear in the second optical path unit.

[0039] The apertures in Embodiment 1 and Embodiment 2 can be raised and lowered by motor control. When the aperture rises, that is, the aperture appears in the first optical path unit and / or the second optical path unit, which is equivalent to starting the filter function. When the diaphragm drops, it...

Embodiment approach 3

[0040] Embodiment 3: The beam adjustment system includes a variable magnification beam expander and an F-Theta lens, the variable magnification beam expander is arranged between the laser and the galvanometer system, and the F-Theta lens is used to The laser beam reflected by the vibrating mirror system forms a focused spot of uniform size on the working plane, and the first spot and the second spot are respectively obtained by adjusting the magnification of the variable magnification beam expander.

[0041] Preferably, in order to further improve the accuracy and molding speed of the three-dimensional object, the first light spot and the second light spot should satisfy the formula: d 2 ≤2d 1 , where d 1 is the first spot size, d 2 is the second spot size.

[0042] In specific implementation, the laser is CO 2 A laser or a fiber laser, and of course other types of lasers can also be used.

[0043] In the laser scanning device for manufacturing three-dimensional objects o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com