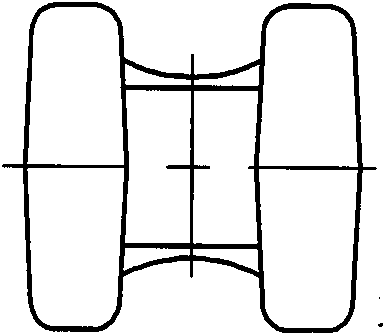

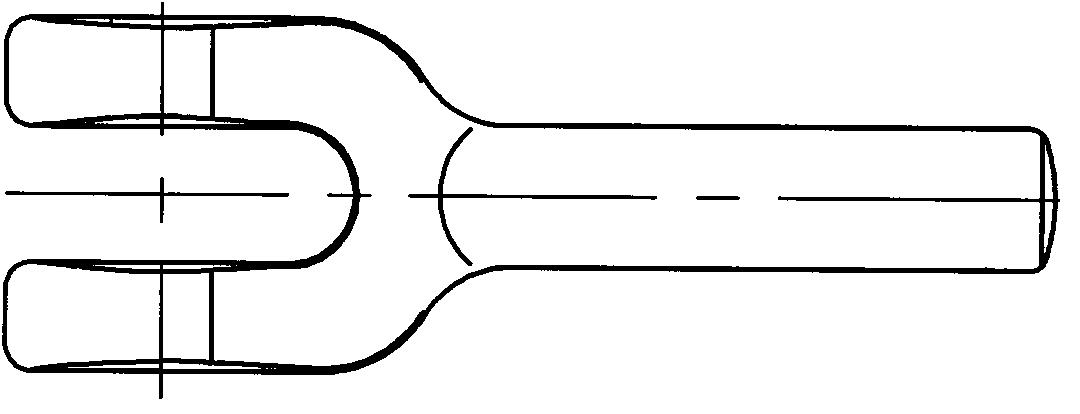

Preforging mould structure for processing shaft fork part stamp forgings

A technology for die forgings and parts, which is applied in the field of pre-forging die structure for the processing of die forgings such as shafts and forks. It can solve the problems of insufficient filling of the fork head, achieve the effects of small flash width, reduce equipment tonnage, and increase die life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Embodiment: For the FB bushing fork type of automobile and the AK1202 type shaft fork, the downward extension H of the parting surface of the pre-forging die is 2.2 mm and 5.5 mm, and the container ship lashing 1604, 1608 type shaft fork is adopted by using the pre-forging die The downward extension H of the parting surface is 3.1 mm, and it is still processed on the hot die forging press equipment of the original tonnage, which completely eliminates the defects of insufficient upper surface. It is 88% to 92%, and the problem of the offset of the blank in the operation arrangement no longer exists. It can be seen that a seemingly inconspicuous improvement has achieved extremely large and excellent results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com