Ultralow dielectric constant film with sandwich structure and preparation method thereof

An ultra-low dielectric constant, sandwich technology, applied in the field of ultra-low dielectric constant film and its preparation, can solve problems such as low dielectric constant, achieve low dielectric constant, excellent heat resistance, and easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

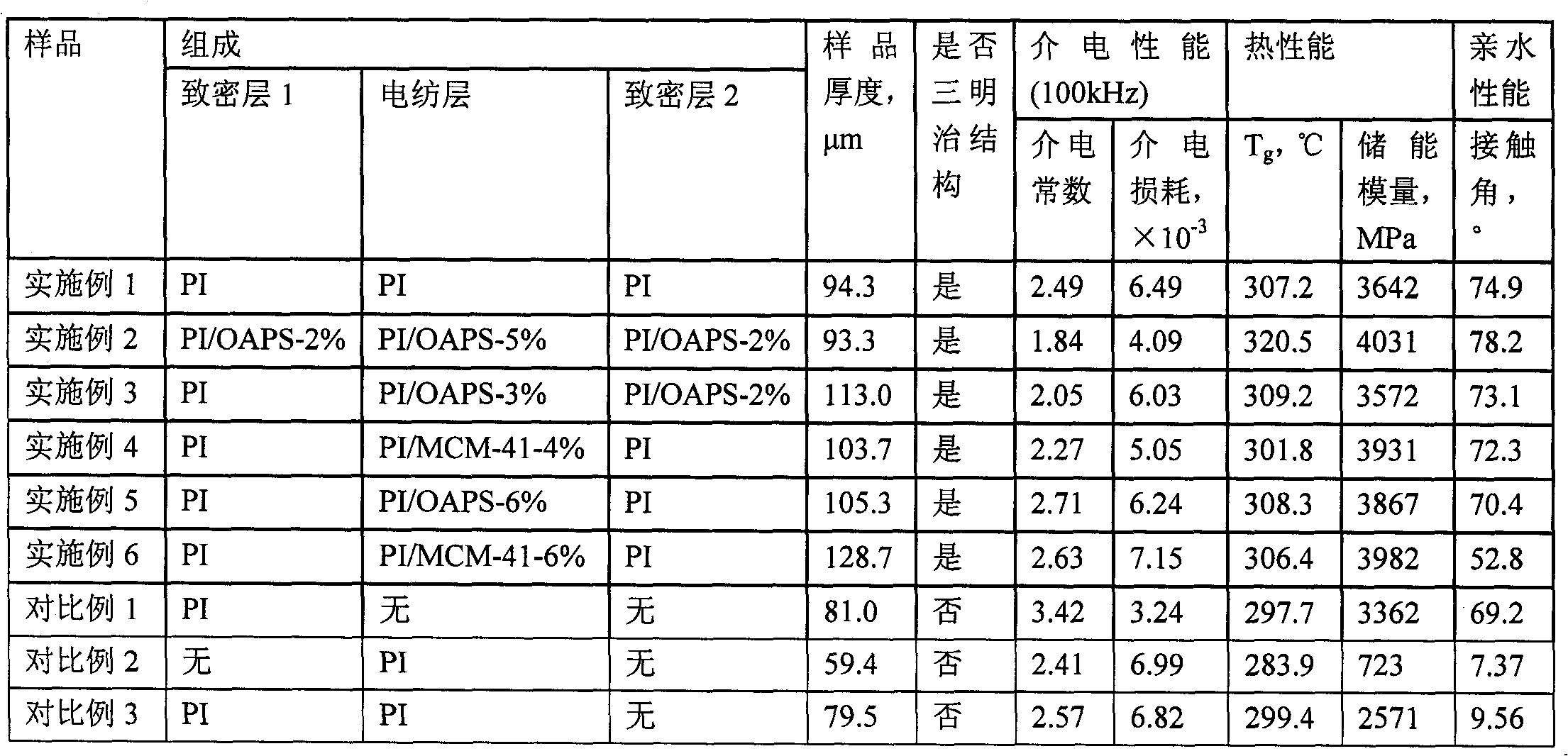

Examples

preparation example Construction

[0035] b) The preparation method of mesoporous molecular sieve (MCM-41) is as follows:

[0036] Dissolve 120g of cetyltrimethylammonium bromide in 2L of deionized water, stir at room temperature for 30min to fully dissolve; add 2.5L of absolute ethanol and 680g of ammonia water (25%), stir for 25min; add 180ml of normal Ethyl silicate, stirred at room temperature for 6h; then aged at room temperature for 1 hour. Suction filtration, washing until neutral, and drying to obtain the original powder; put the original powder in a muffler furnace, and roast at 1°C / min to 580°C for 6 hours under an air atmosphere to obtain MCM-41.

[0037] c) Organic monomers: pyromellitic dianhydride (PMDA): Sinopharm Chemical Reagent Co., Ltd.; 3,3',4,4'-benzophenone tetracarboxylic dianhydride (BTDA): SIGMA-ALDRICH China Co., Ltd. ; 4,4'-diaminodiphenyl ether (ODA): Sinopharm Chemical Reagent Co., Ltd.; p-phenylenediamine (p-PDA): Sinopharm Chemical Reagent Co., Ltd.;

[0038] d) Solvent: N, N-di...

Embodiment 1

[0044] Synthesis of polyamic acid solution for dense layer preparation:

[0045] Under the protection of nitrogen, after dissolving 0.9649g ODA in 50ml NMP, slowly add 1.5535gBTDA, after the addition, react at 20°C for 15 hours to obtain a polyamic acid solution with a solid content of 0.05g / ml.

[0046] Preparation of polyamic acid dense base film:

[0047] Drop 6ml of the above polyamic acid solution onto a glass plate placed horizontally, and cast to form a film; remove the solvent at 60°C for more than 18 hours. Then immerse it in hot water and cook for 5-10 minutes, and scrape it off gently to get a dense polyamic acid film.

[0048] Synthesis of polyamic acid solution for electrospun membrane preparation:

[0049] Under the protection of nitrogen, after dissolving 3.9752g ODA in 58ml DMF, slowly add 6.5248gBTDA, after the addition, react at 15°C for 20 hours to obtain a polyamic acid solution with a solid content of 0.18g / ml.

[0050] Preparation of electrospun membra...

Embodiment 2

[0057] Synthesis of polyamic acid / OAPS hybrid solution for dense layer preparation:

[0058] 1) Dissolve 0.0233gOAPS in 40mlDMSO;

[0059] 2) Under the protection of nitrogen, add 0.5516g ODA to the above dispersion liquid; after the ODA is completely dissolved, slowly add 0.6129g PMDA, and react at 20°C for 18 hours after the addition, to obtain a solid content of 0.03g / ml and an OAPS content of 2 % of a homogeneous polyamic acid / OAPS hybrid solution.

[0060] Preparation of polyamic acid / OAPS hybrid dense base film:

[0061] Drop 6ml of the above-mentioned polyamic acid / OAPS hybrid solution on a glass plate placed horizontally, and cast to form a film; remove the solvent at 60°C for more than 18 hours. Then immerse it in hot water and cook for 5-10 minutes, and scrape it off gently to get a dense polyamic acid / OAPS hybrid film.

[0062] Synthesis of polyamic acid / OAPS hybrid solution for electrospun membrane preparation:

[0063] 1) Dissolve 0.5250g OAPS in 79ml DMF;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com