Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Suitable conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

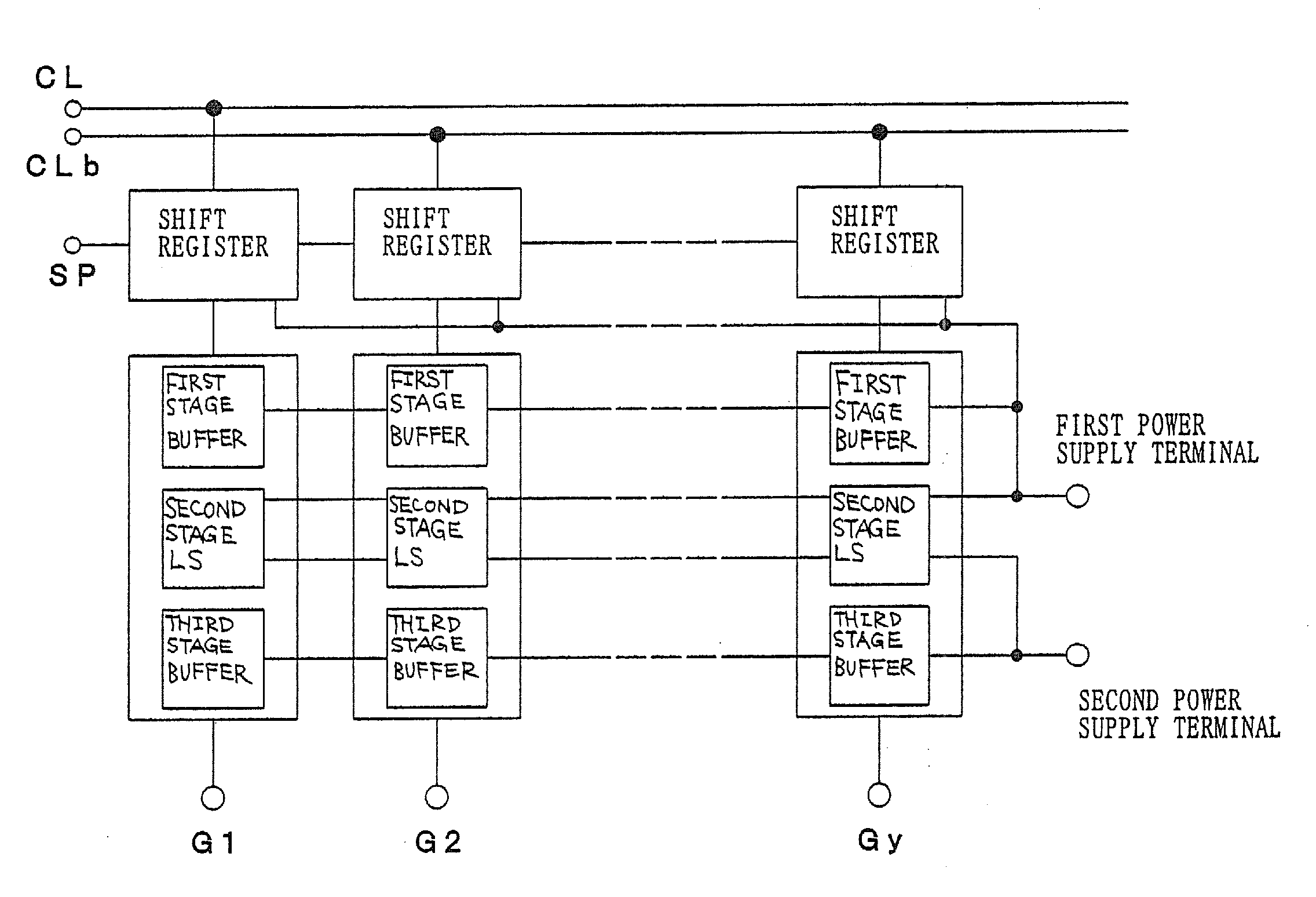

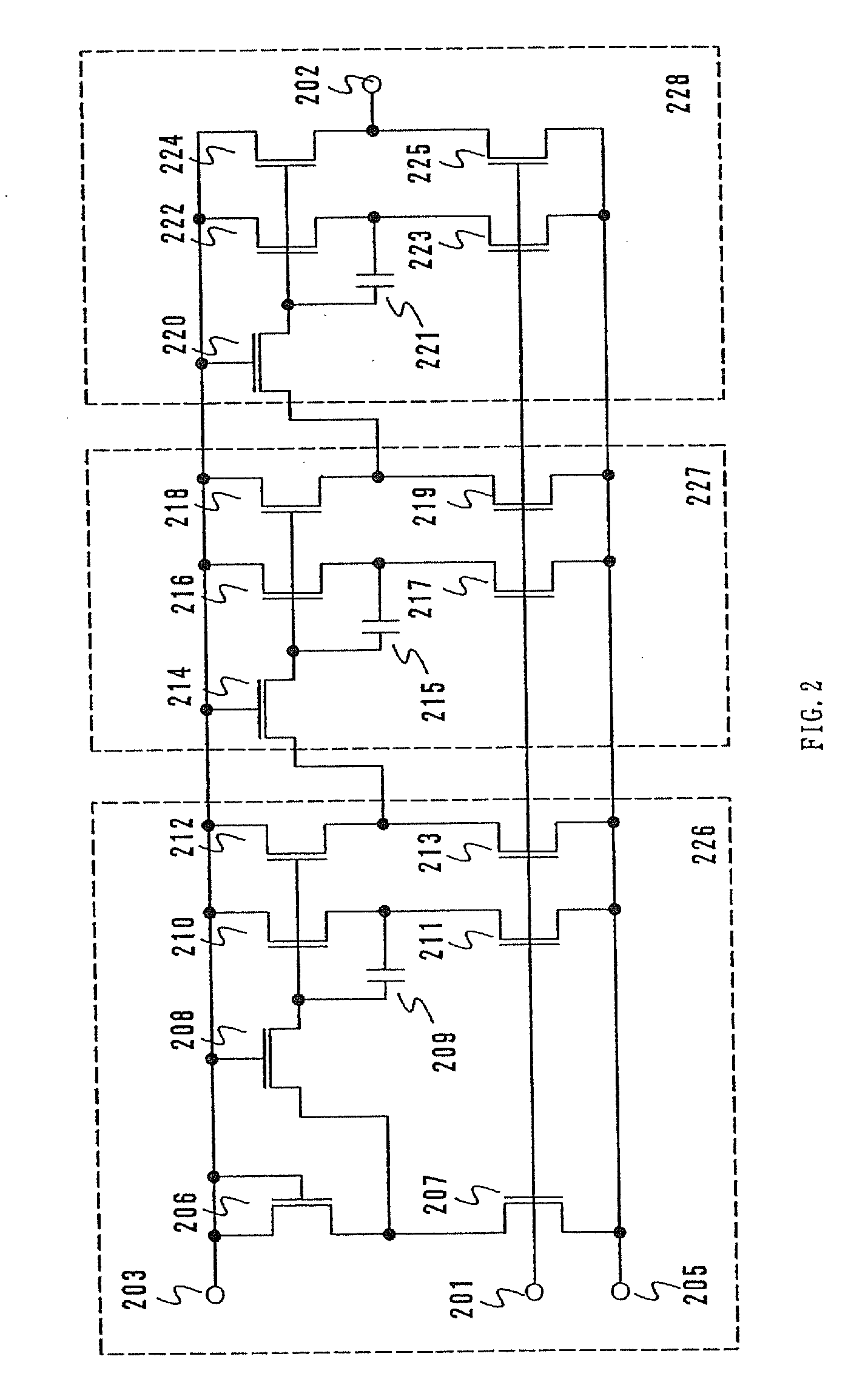

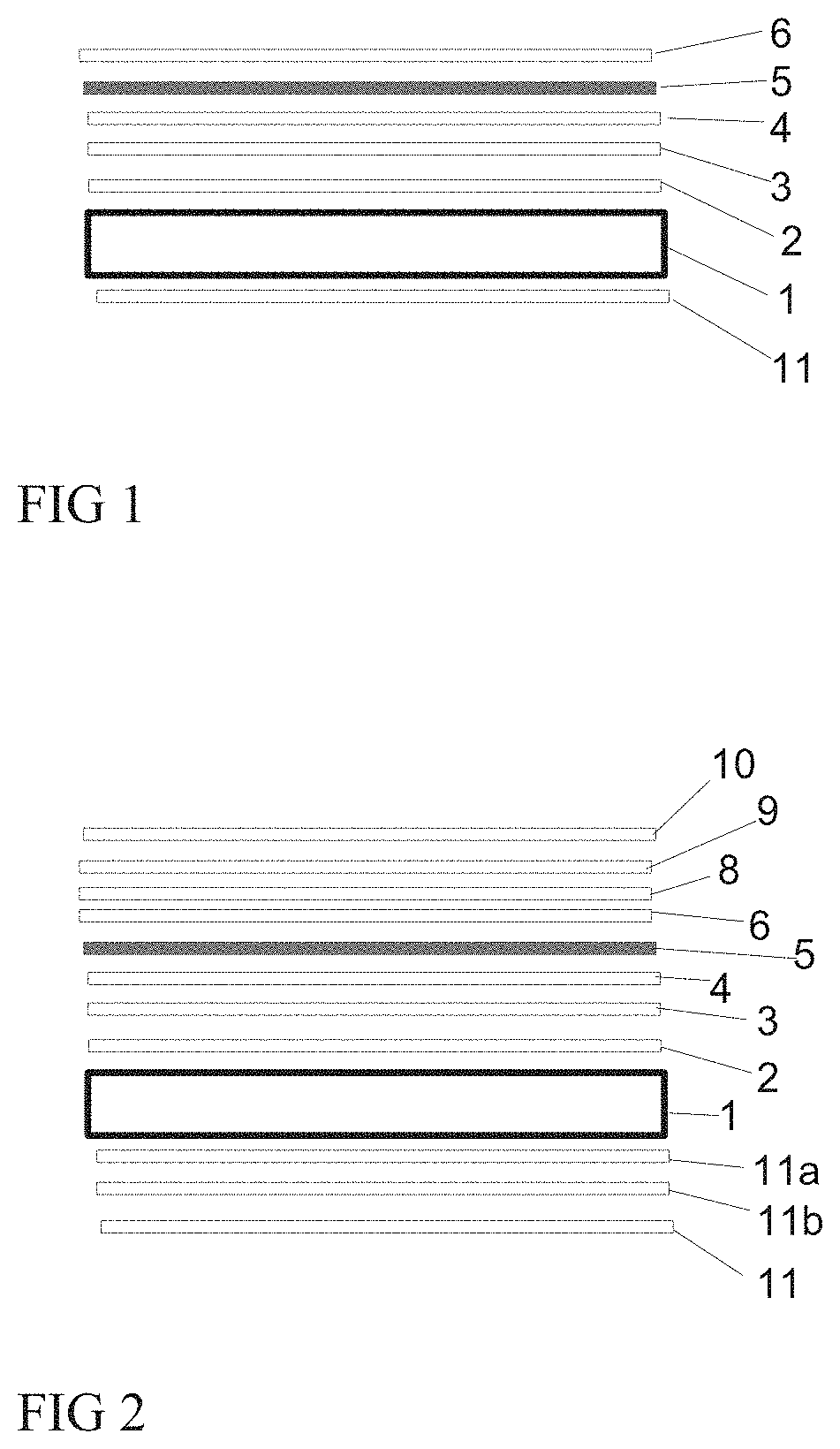

Display device

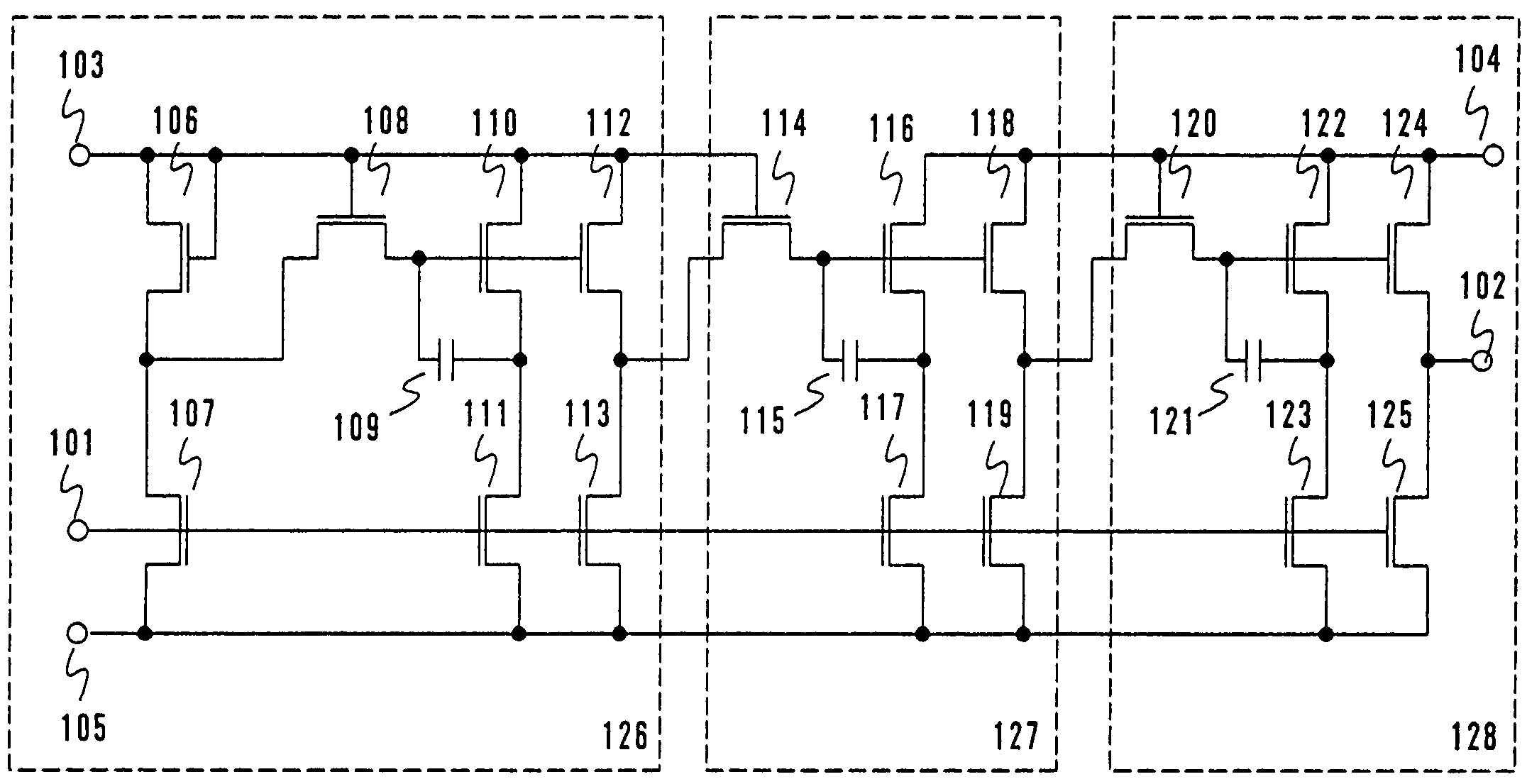

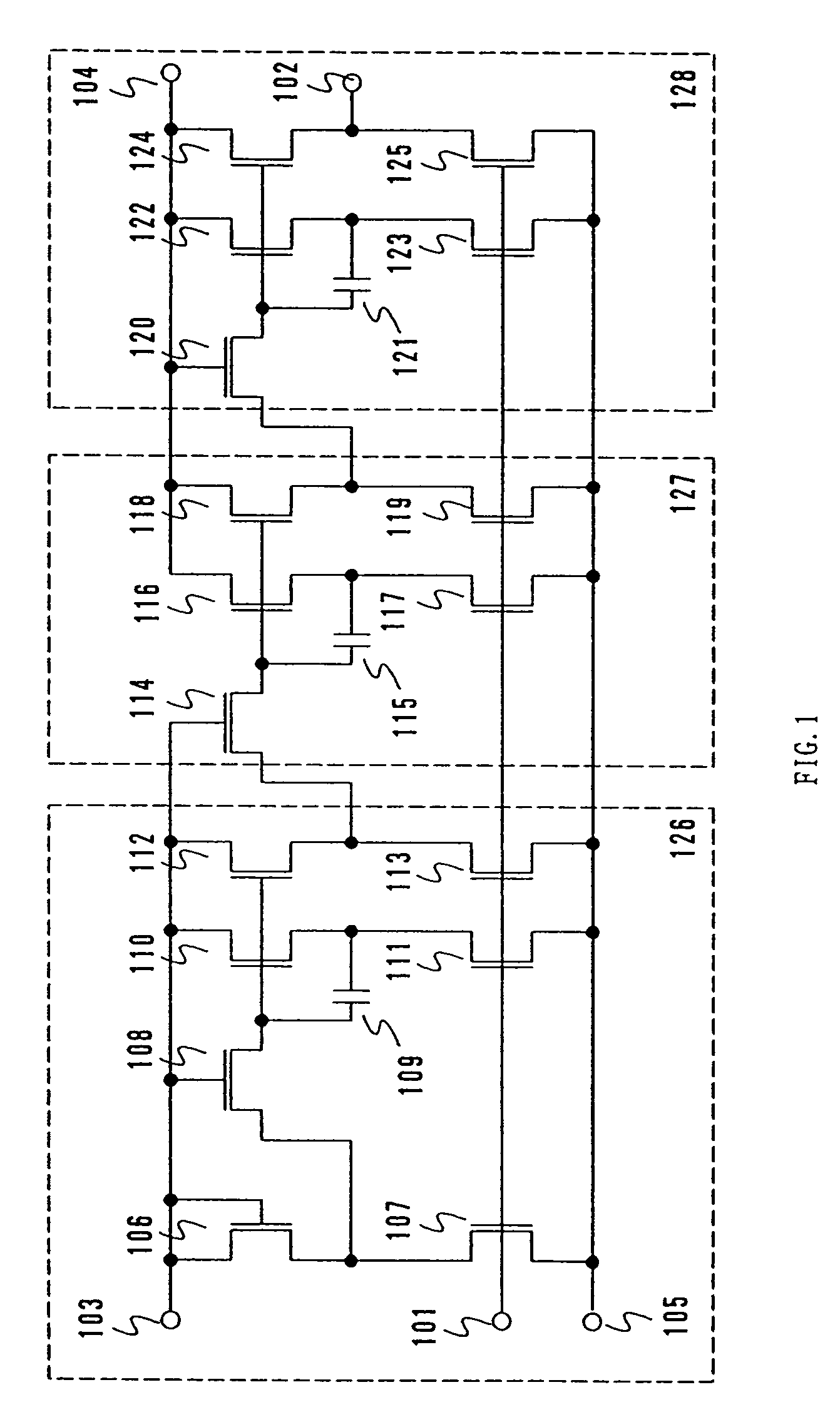

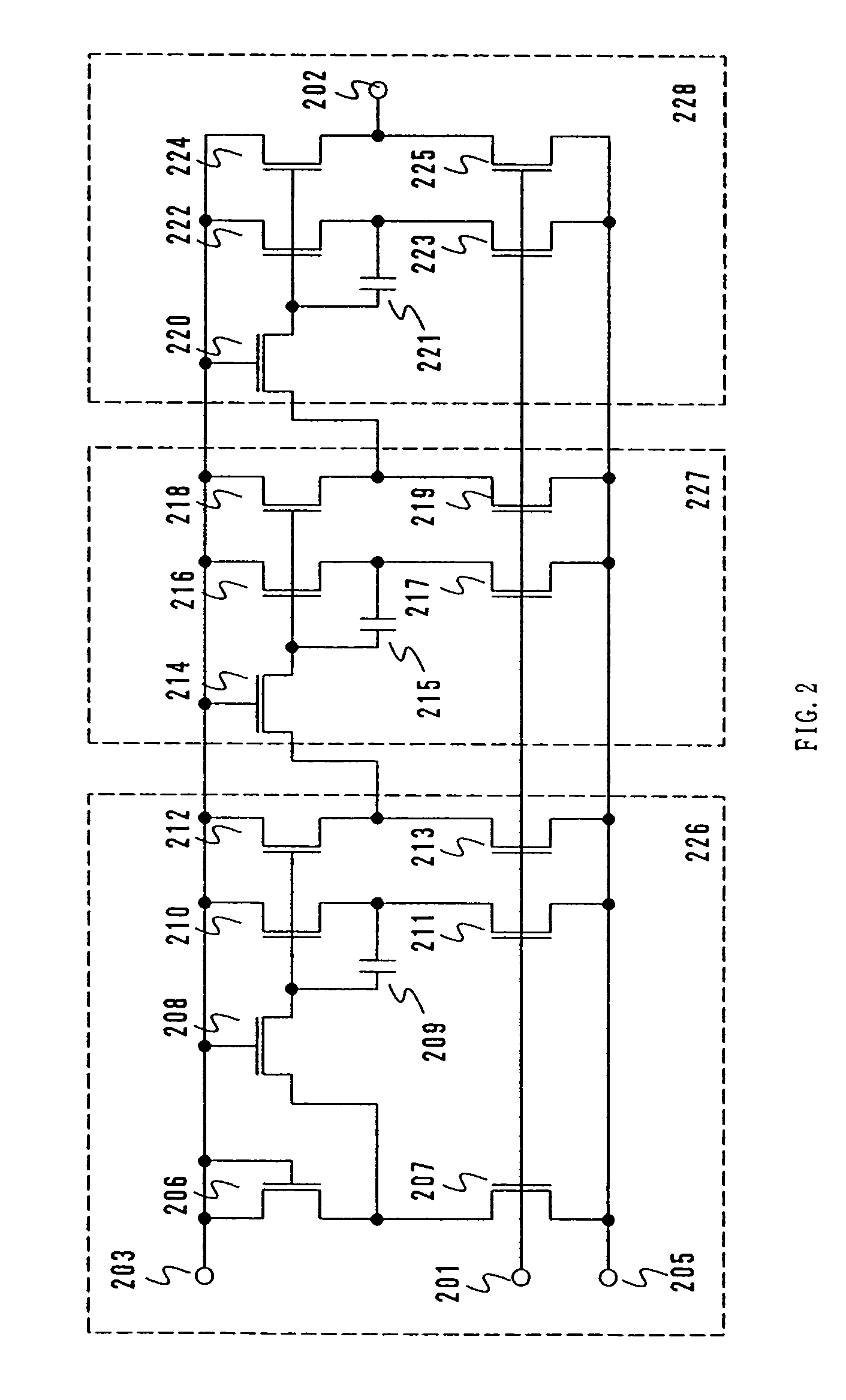

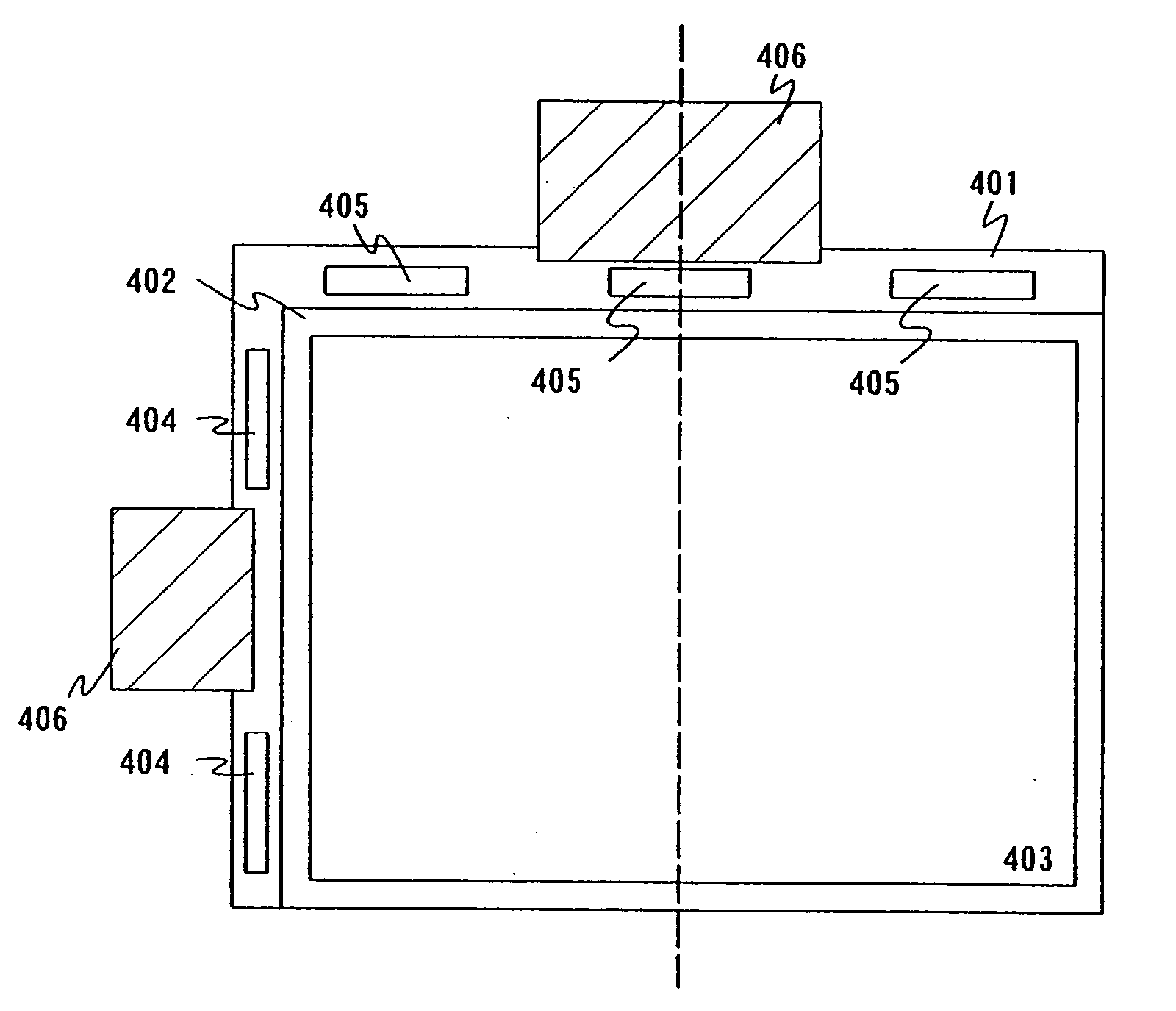

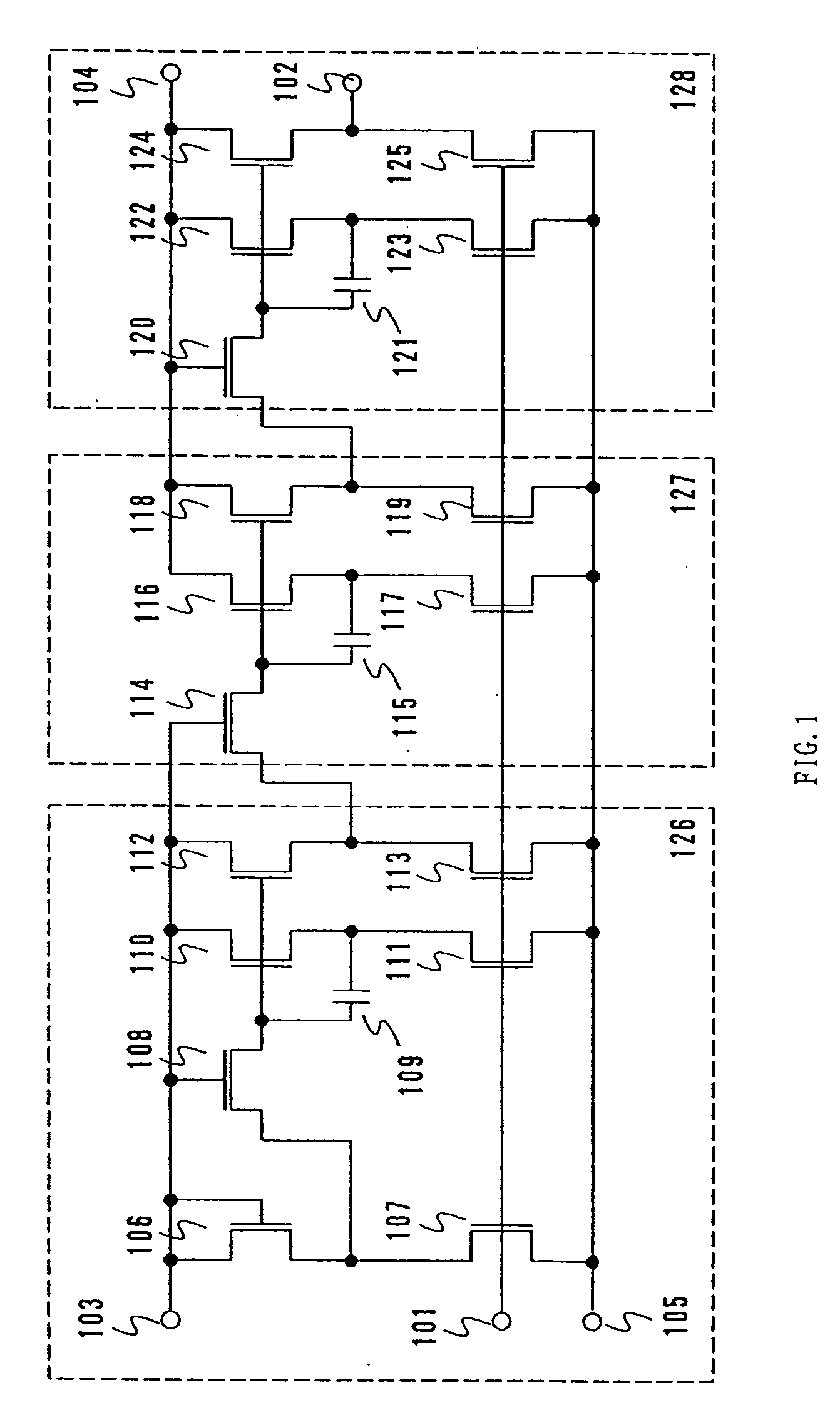

InactiveUS7511709B2High implementation costReduced connection reliabilityTransistorSolid-state devicesDriver circuitShift register

When semi-amorphous TFTs are used for forming a signal line driver circuit and a pixel, a large amplitude is required for driving the pixel, and a large power supply voltage is thus needed. On the other hand, when a shift register is made up of transistors having a single conductivity, a bootstrap circuit is required, and a voltage over a power supply is applied to a specific element. Therefore, not both the driving amplitude and the reliability can be achieved with a single power supply. According to the invention, a level shifter having a single conductivity is provided to solve such a problem.

Owner:SEMICON ENERGY LAB CO LTD

Display device

InactiveUS20050012887A1High implementation costReduced connection reliabilityTransistorSolid-state devicesDriver circuitShift register

When semi-amorphous TFTs are used for forming a signal line driver circuit and a pixel, a large amplitude is required for driving the pixel, and a large power supply voltage is thus needed. On the other hand, when a shift register is made up of transistors having a single conductivity, a bootstrap circuit is required, and a voltage over a power supply is applied to a specific element. Therefore, not both the driving amplitude and the reliability can be achieved with a single power supply. According to the invention, a level shifter having a single conductivity is provided to solve such a problem.

Owner:SEMICON ENERGY LAB CO LTD

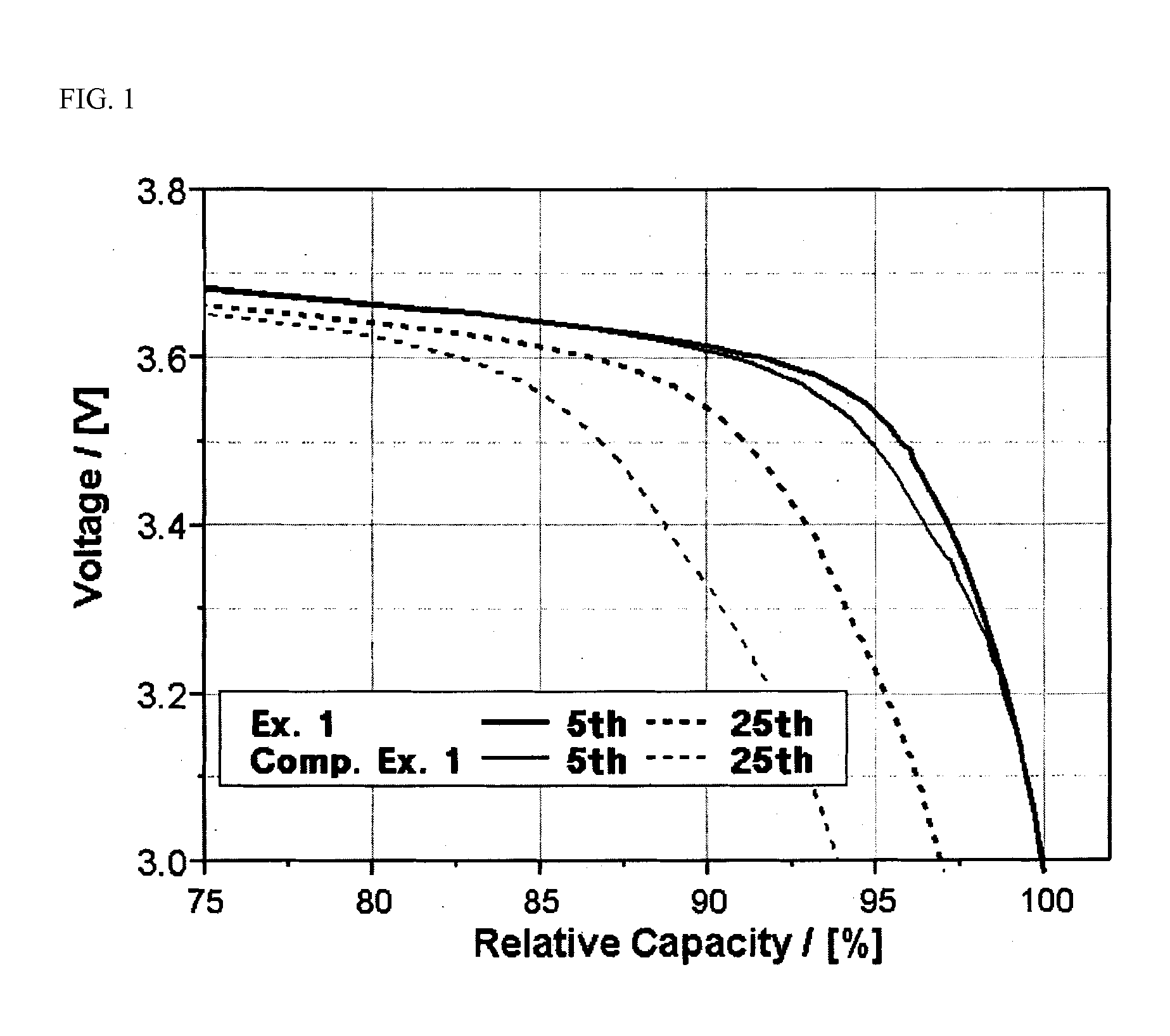

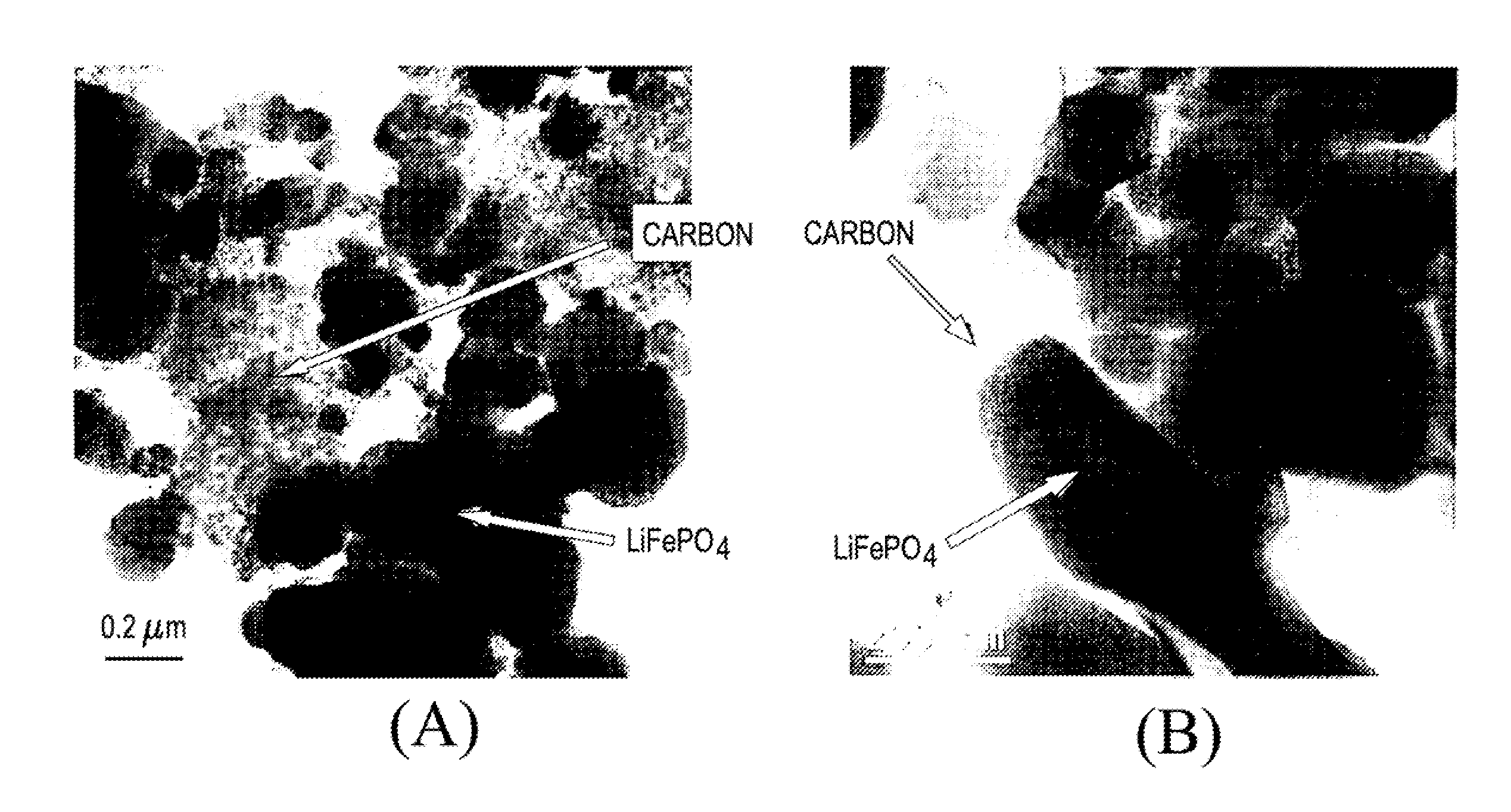

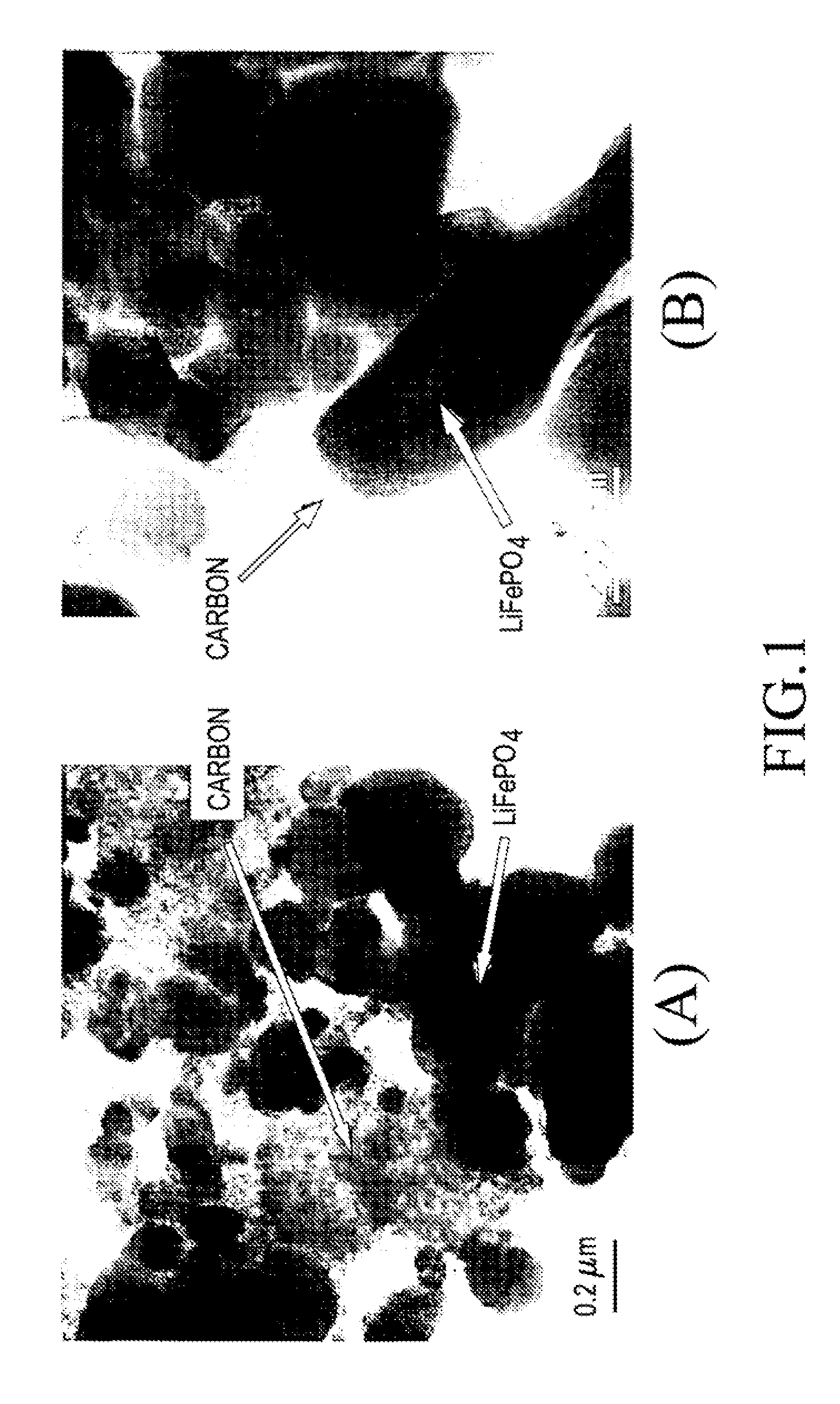

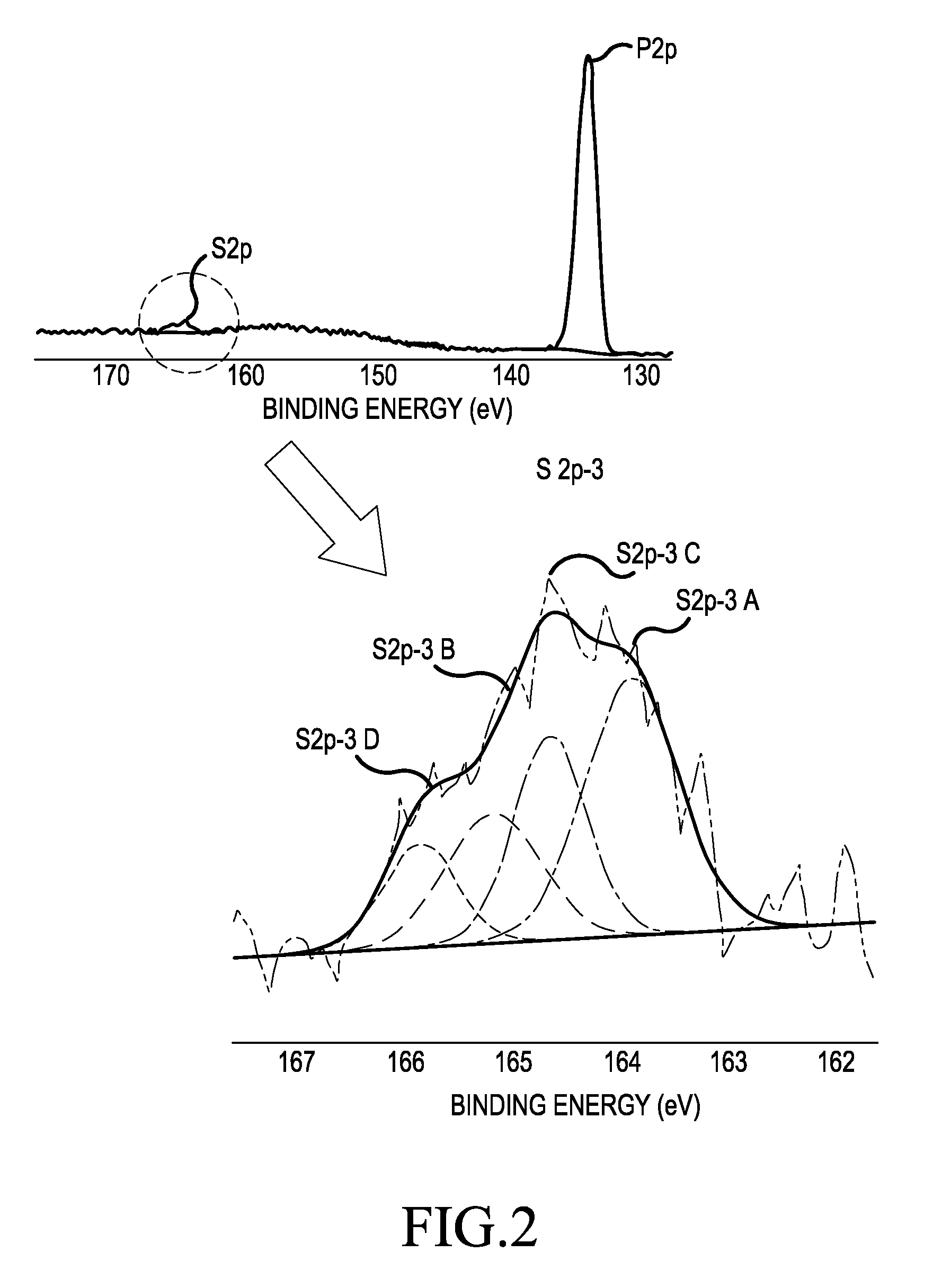

Lithium iron phosphate of olivine crystal structure and lithium secondary battery using the same

ActiveUS20130029226A1Improve conductivityAvoid separationFinal product manufactureNon-aqueous electrolyte accumulator electrodesLithium iron phosphatePhysical chemistry

Disclosed is lithium iron phosphate having an olivine crystal structure wherein carbon (C) is coated on particle surfaces of the lithium iron phosphate, wherein, when a powder of the lithium iron phosphate is dispersed in water, water is removed from the resulting dispersion and the resulting lithium iron phosphate residue is quantitatively analyzed, a ratio of the carbon-released lithium iron phosphate with respect to the total weight of the carbon-coated lithium iron phosphate is 0.005% by weight or less. Advantageously, the olivine-type lithium iron phosphate is not readily separated through uniform thin film coating on the surface of the lithium iron phosphate and exhibits superior conductivity and density, since carbon is coated on particle surfaces of lithium iron phosphate in a state in which the amount of carbon released in water is considerably small.

Owner:LG ENERGY SOLUTION LTD

Carbon-coated lithium iron phosphate of olivine crystal structure and lithium secondary battery using the same

ActiveUS20130216902A1Improve conductivityAvoid separationFinal product manufactureOperating modesChemical LinkageLithium iron phosphate

Disclosed is a lithium iron phosphate with an olivine crystal structure wherein the lithium iron phosphate has a composition represented by the following Formula 1 and carbon (C) is coated on the surface of the lithium iron phosphate by chemical bonding via a heterogeneous element other than carbon. Li1+aFe1−xMx(PO4−b)Xb (1) (wherein M, X, a, x, and b are the same as defined in the specification).

Owner:LG ENERGY SOLUTION LTD

Anode active material and secondary battery comprising the same

ActiveUS20130089791A1Improved dispensabilitySuperior electrode propertyFinal product manufactureNon-aqueous electrolyte accumulator electrodesIonAmorphous carbon

Disclosed are an anode active material for secondary batteries, capable of intercalating and deintercalating ions, comprising a core comprising a crystalline carbon-based material and a composite coating layer comprising one or more materials selected from the group consisting of low crystalline carbon and amorphous carbon, and a metal and / or a non-metal capable of intercalating and deintercalating ions, wherein the composite coating layer comprises a matrix comprising one component selected from one or more materials selected from the group consisting of low crystalline carbon and amorphous carbon and a metal and / or a non-metal capable of intercalating and deintercalating ions, and a filler comprising the other component, incorporated in the matrix, and a secondary battery comprising the anode active material.

Owner:LG ENERGY SOLUTION LTD

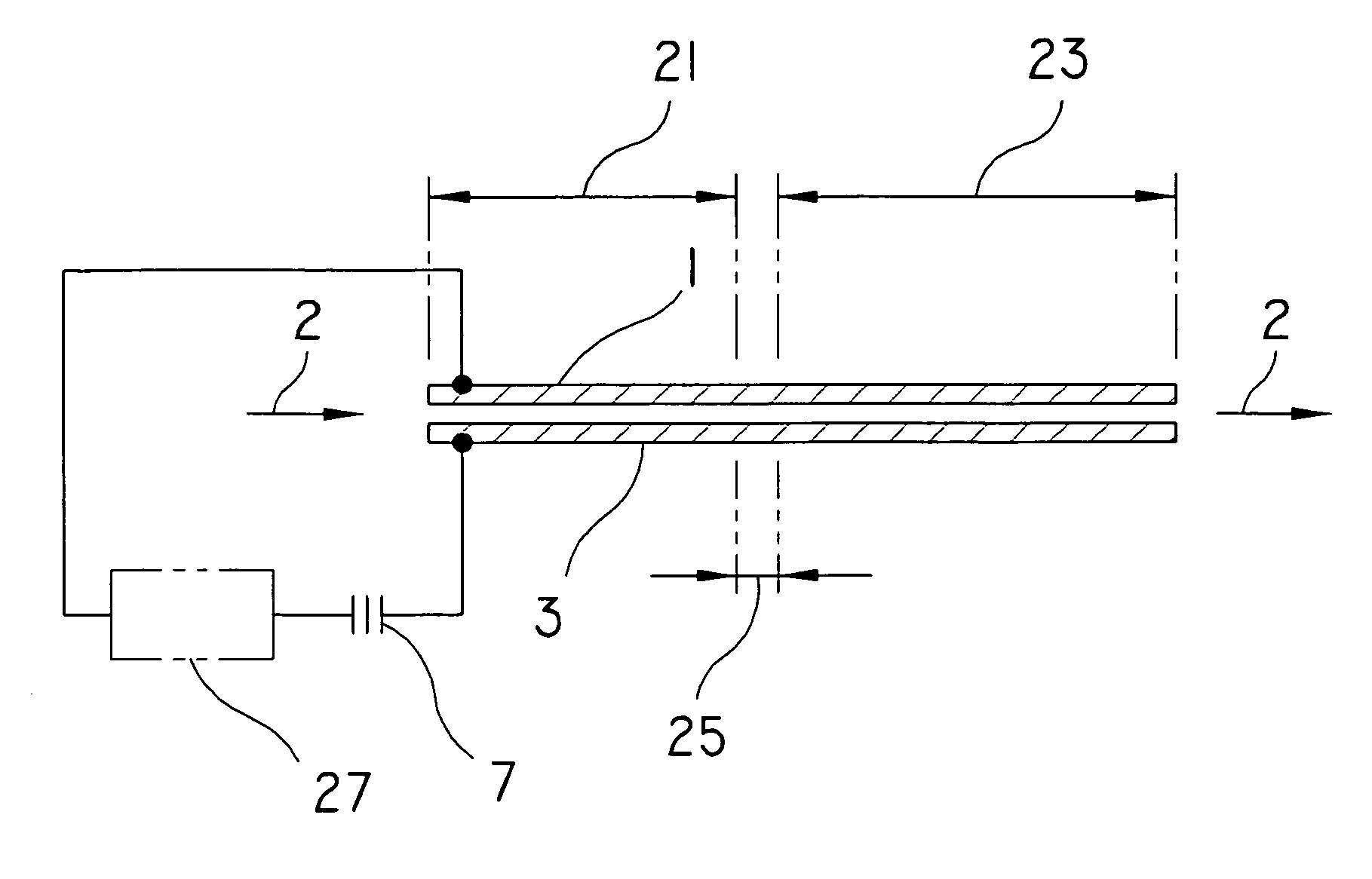

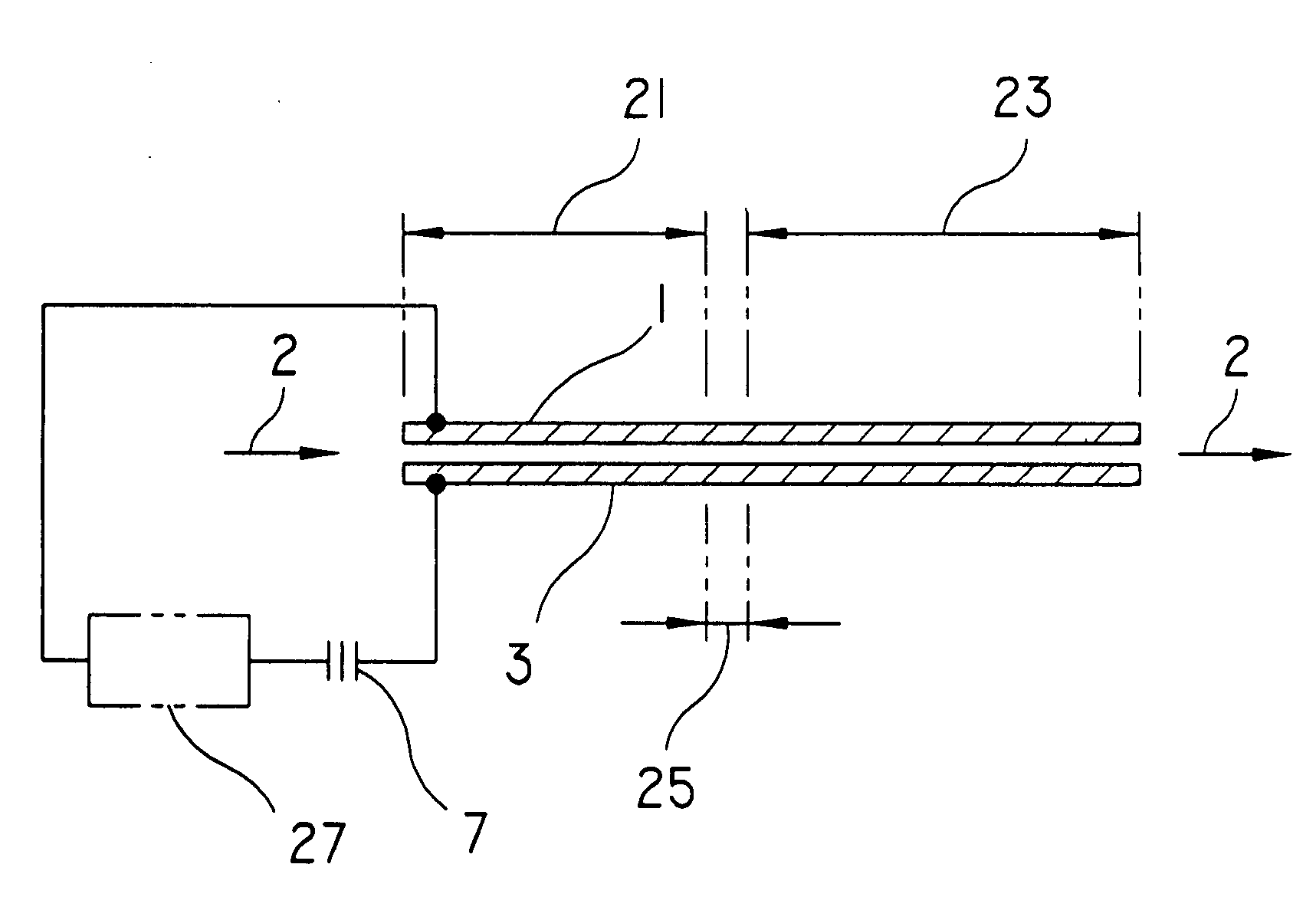

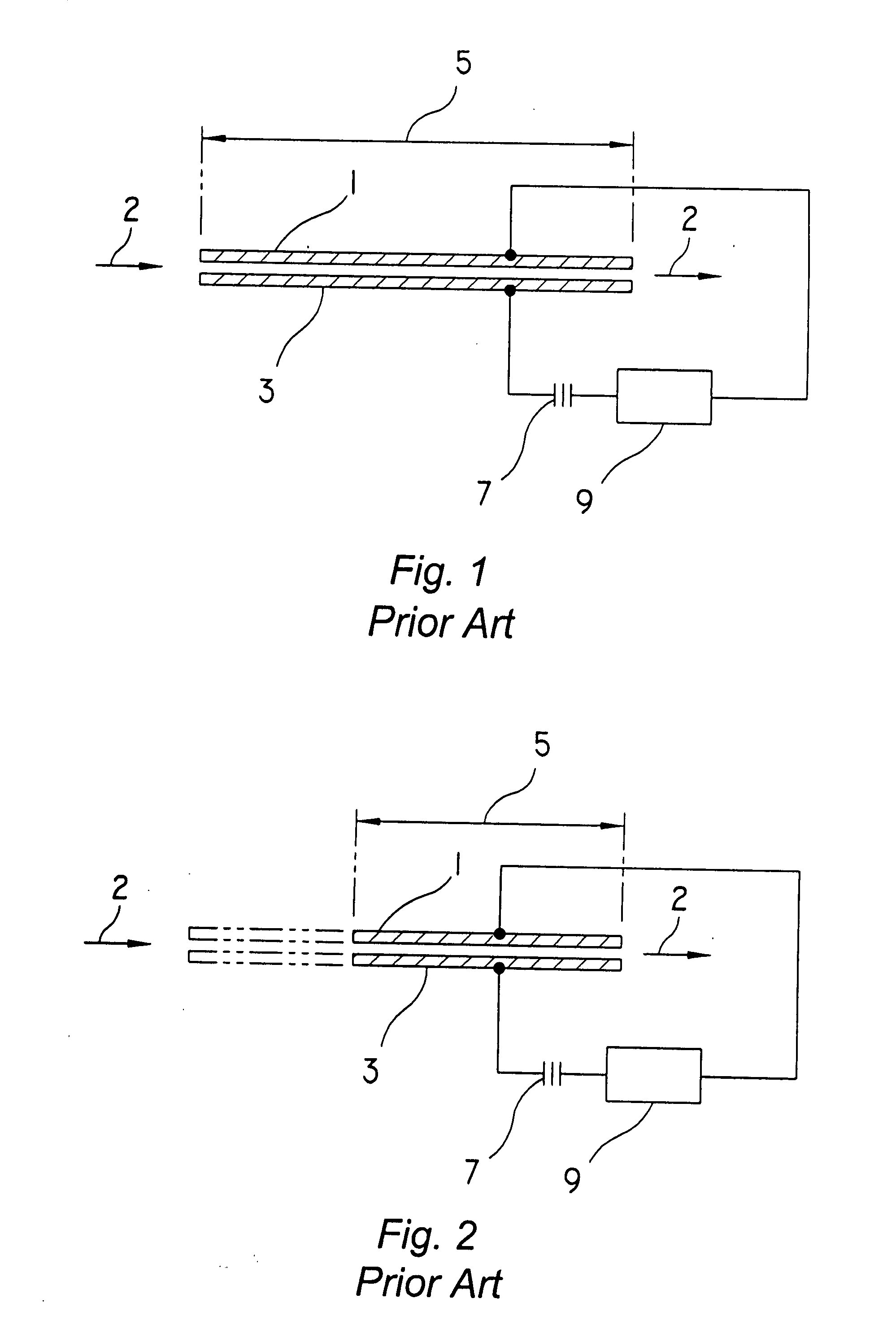

Instant water heater with PTC plastic conductive electrodes

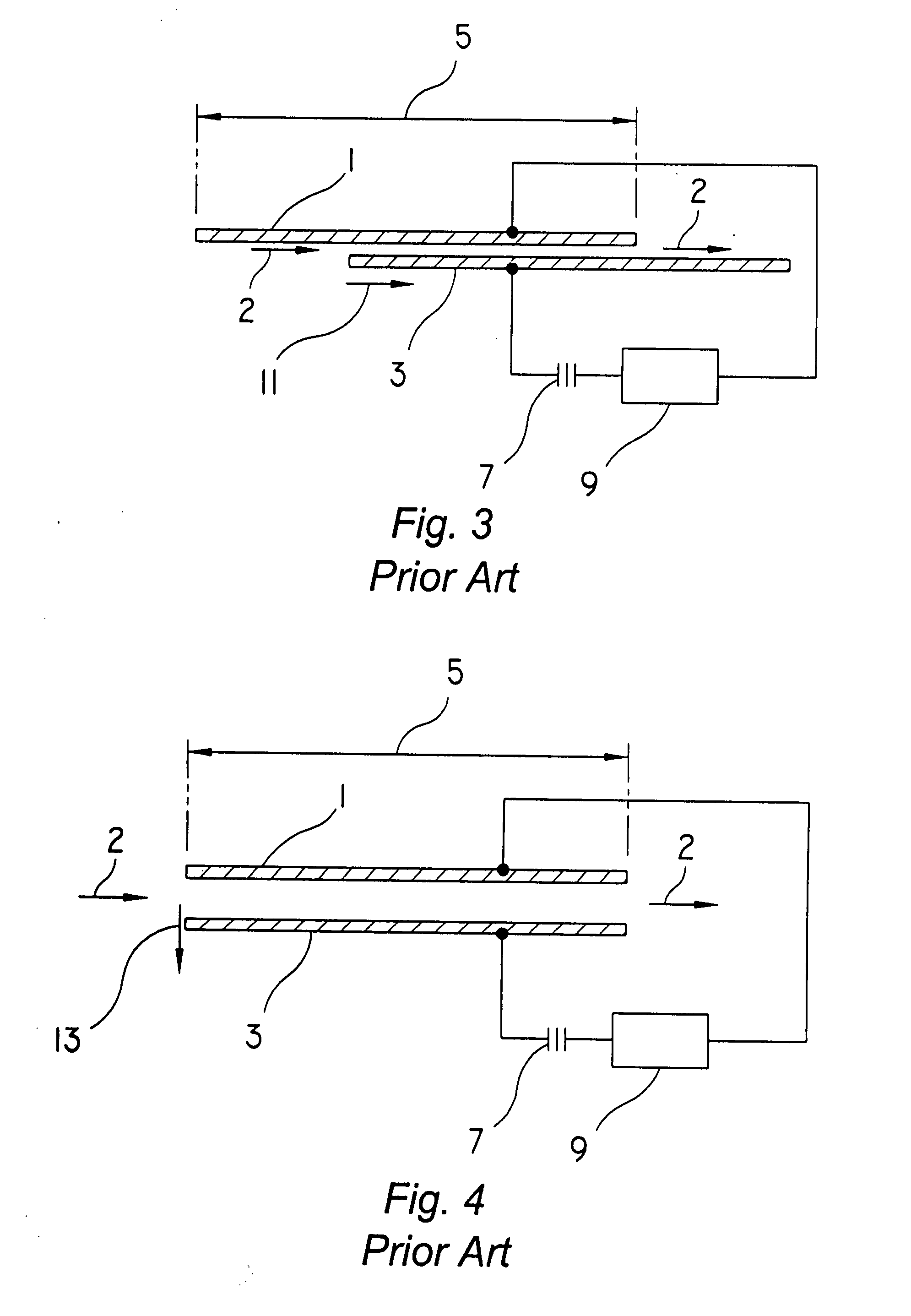

InactiveUS20060239664A1Lower bulk resistanceSuitable conductivitySteam generation heating methodsCooking vesselsEngineeringConductive materials

An instant water heater utilizing positive temperature coefficient plastic electrically conductive material structures for electrodes. The heating of the water is not generated by the electrodes, but instead by the resistance of the water to the electrical current flowing between them. The material of the electrodes undergoes a phase change at certain temperatures when whereby it converts from electrically conductive to electrically non-conductive at a predetermined temperature. The output temperature of the water is determined by a combination of the area of the electrodes that confront one another, the water's conductivity, the flow rate of the water and the current limiting capability of the conductive electrode materials positive temperature coefficient, which reduces or stops the heating of the water when the intended water temperature is achieved.

Owner:CHAPUT IVANHOE

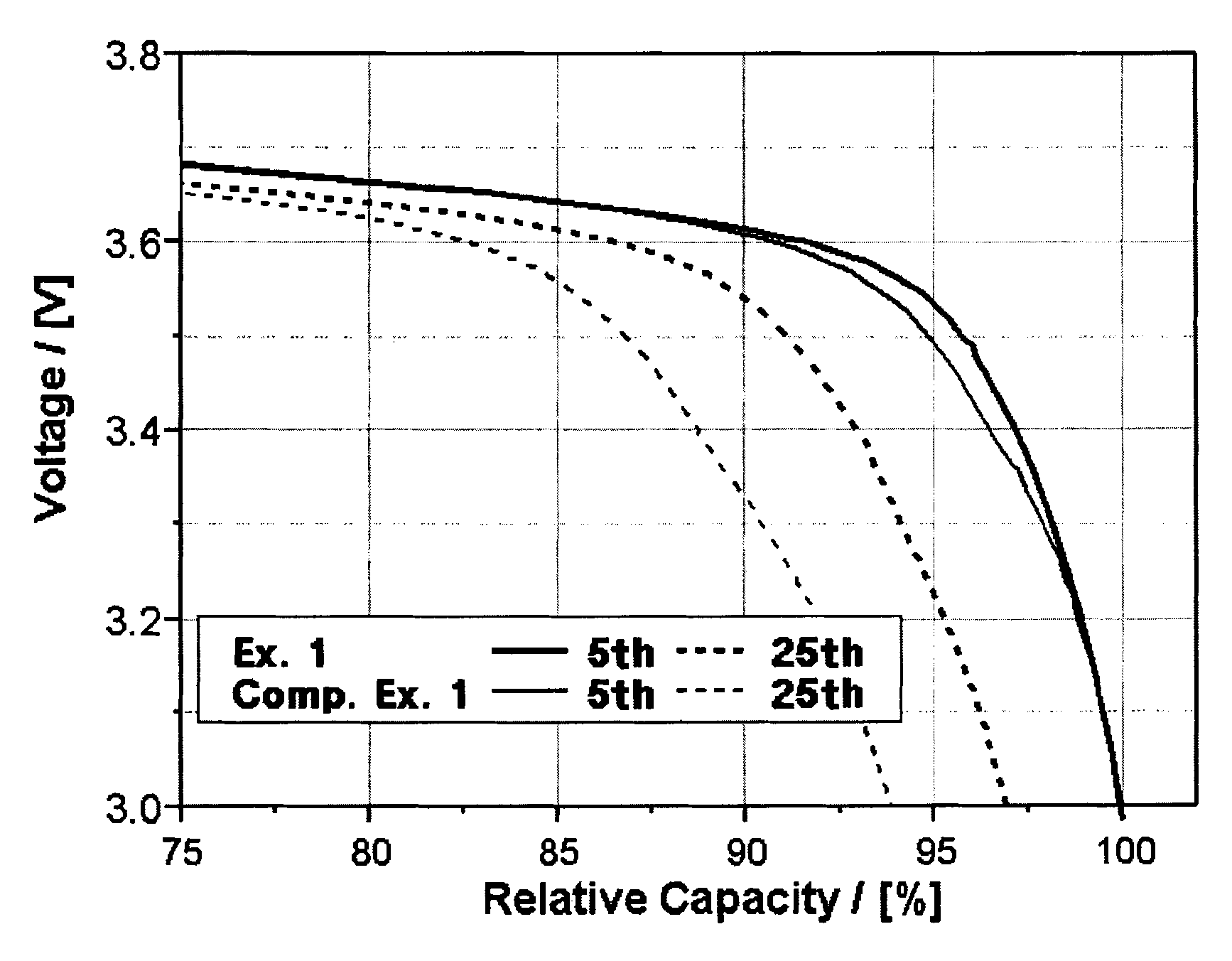

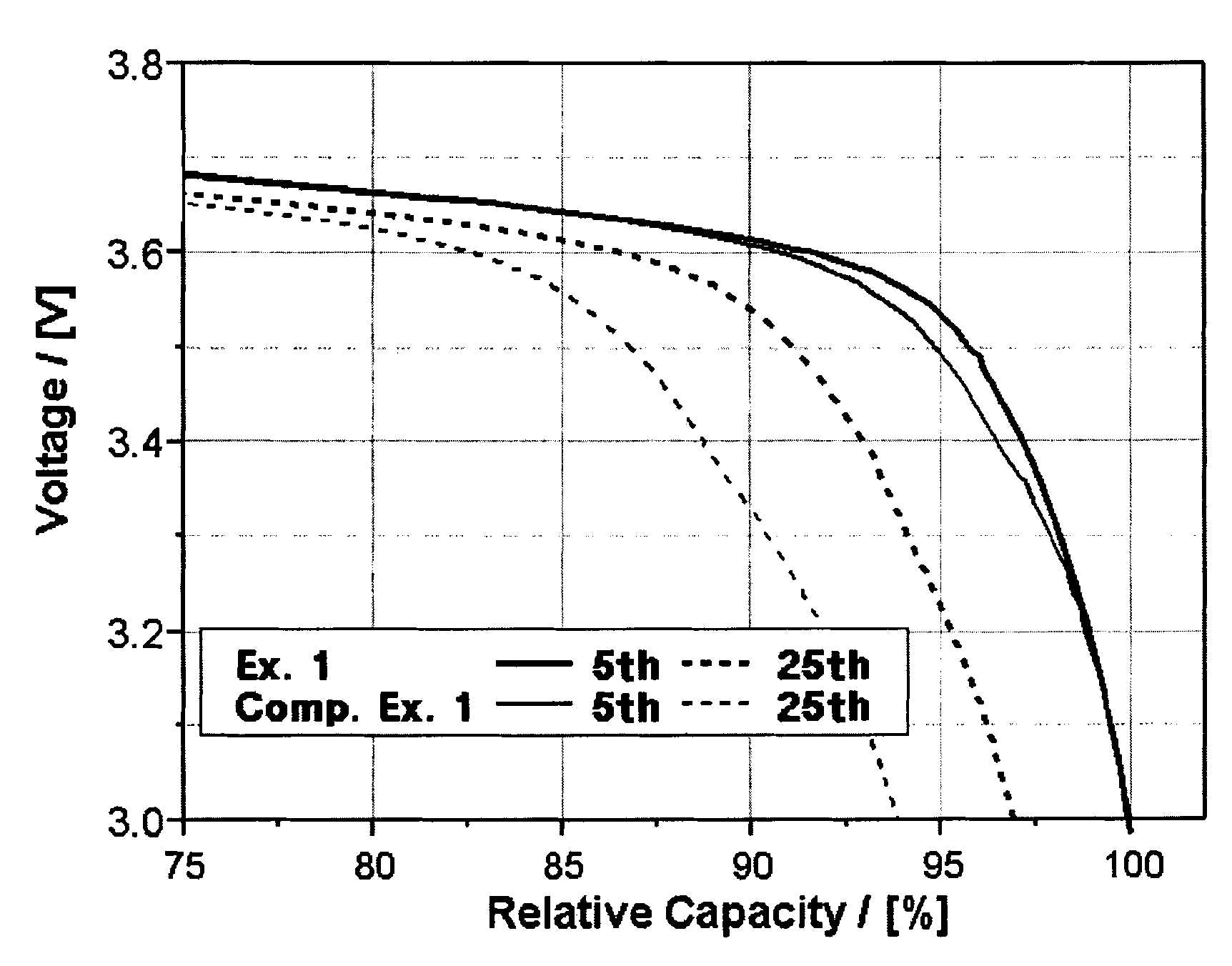

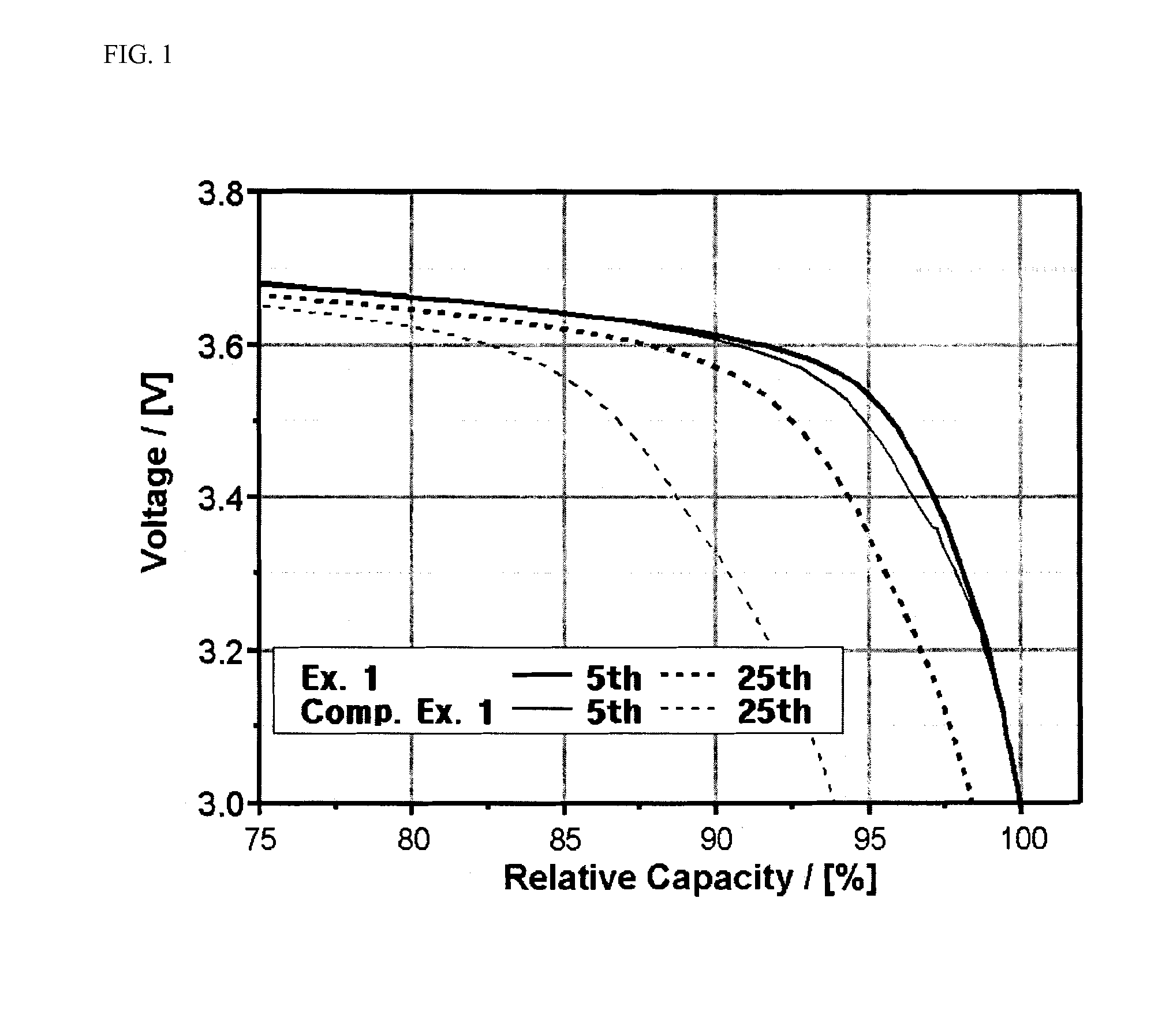

Binder For Secondary Battery Providing Excellent Cycle Property

ActiveUS20130202963A1High bonding strengthSimple materialSecondary cellsNon-aqueous electrolyte accumulator electrodesPolymer scienceElectrolyte

Provided is a binder for secondary battery electrodes wherein the content of a gel comprising a polymer particle obtained by copolymerizing three or more types of monomers is 50 to 100% by weight and a swelling index of the binder to an electrolyte is 1.1 to 5.0. The binder fundamentally improves electrode stability due to the gel content defined above and increases ionic conductivity due to the swelling index, thus providing secondary batteries with superior cycle properties.

Owner:LG CHEM LTD

Anode active material and secondary battery comprising the same

ActiveUS20130260237A1Improve adhesionSuitable conductivityActive material electrodesNon-aqueous electrolyte accumulator electrodesBattery cellMaterials science

Disclosed are an anode active material for secondary batteries, capable of intercalating and deintercalating ions, the anode active material including a core including a crystalline carbon-based material, and a composite coating layer including one or more materials selected from the group consisting of low crystalline carbon and amorphous carbon, and a hydrophilic material, wherein the composite coating layer includes a matrix comprising one component selected from one or more materials selected from the group consisting of low crystalline carbon and amorphous carbon, and a hydrophilic material, and a filler including the other component, incorporated in the matrix, and a secondary battery including the anode active material.

Owner:LG ENERGY SOLUTION LTD

Lithium secondary battery containing silicon-based or tin-based anode active material

ActiveUS7687201B2Improve featuresImprove bindingElectrode carriers/collectorsNegative electrodesLithiumMaterials science

A lithium secondary battery includes an anode mix including a silicon- or tin-based material as an anode active material, a thermosetting agent, and a curing agent and a curing accelerator as a binder. The anode mix is prepared within a short period of time via a simplified manufacturing process by applying the anode mix to a current collector and heating to cure the applied anode mix at a temperature of less than 200° C.

Owner:LG CHEM LTD

Carbon-coated lithium iron phosphate of olivine crystal structure and lithium secondary battery using the same

ActiveUS20130022866A1Improve conductivityIncrease electrode densityPhosphatesFinal product manufactureLithium iron phosphateSulfur

Disclosed is lithium iron phosphate having an olivine crystal structure, wherein the lithium iron phosphate has a composition represented by the following Formula 1 and carbon (C) is coated on the particle surface of the lithium iron phosphate containing a predetermined amount of sulfur (S).Li1+aFe1−xMx(PO4−b)Xb (1)(wherein M, X, a, x, and b are the same as defined in the specification).

Owner:LG ENERGY SOLUTION LTD

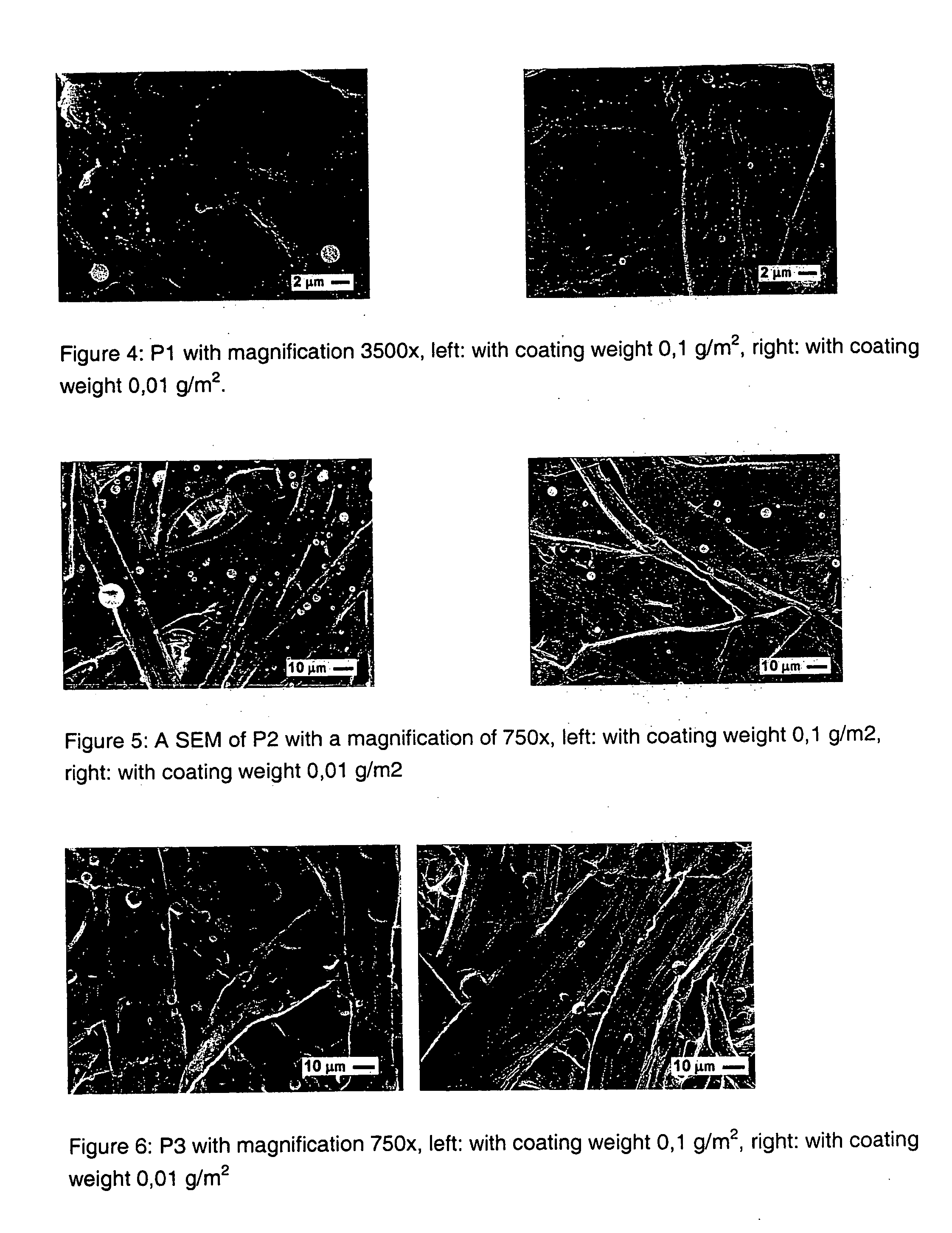

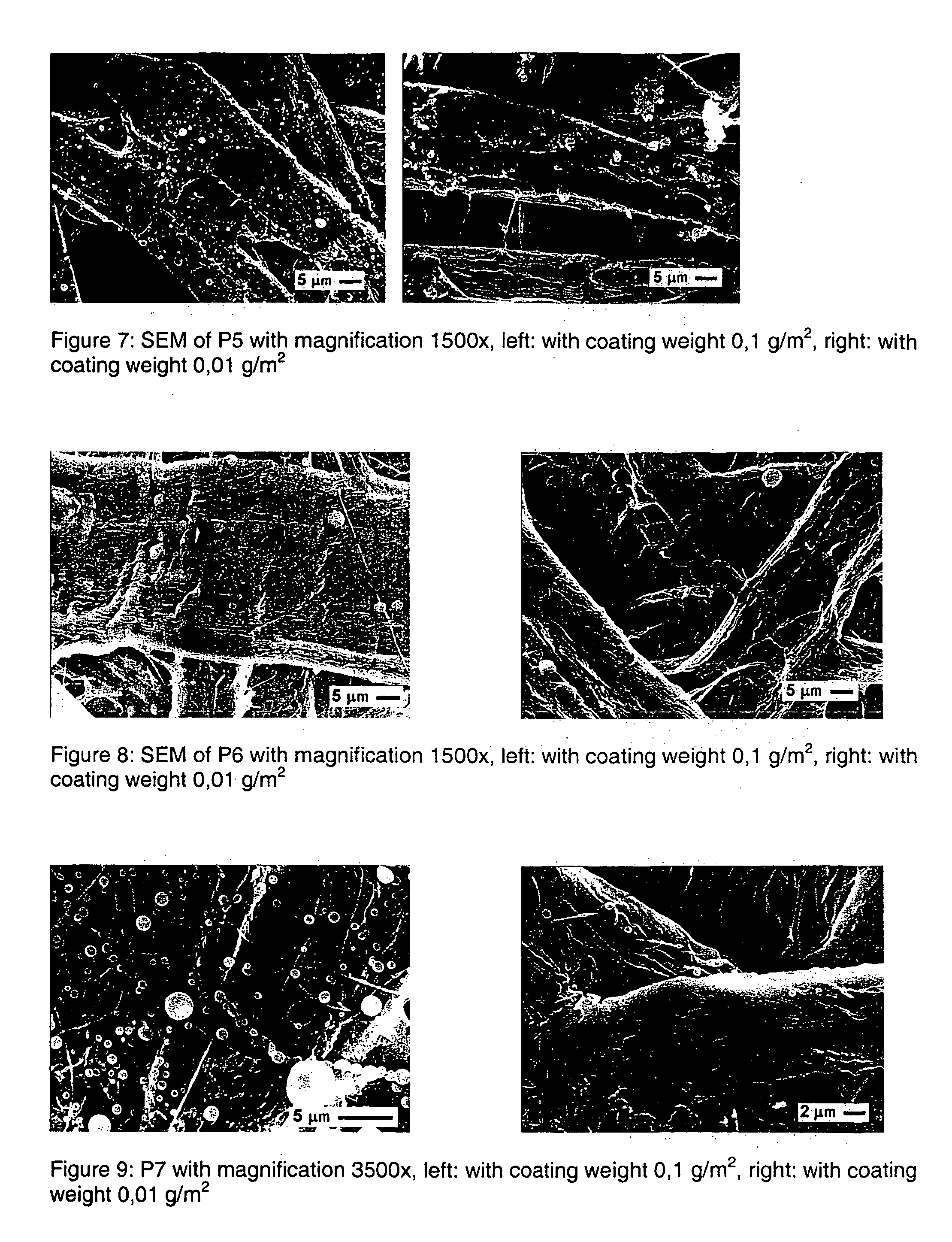

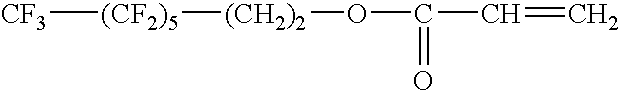

Priming and coating process

ActiveUS20060193994A1Increase production capacitySuitable conductivityBurnersLiquid spraying plantsBiology

Owner:STORA ENSO OYJ

Display device

ActiveUS20090160753A1High implementation costReduced connection reliabilityTransistorSolid-state devicesDriver circuitShift register

Owner:SEMICON ENERGY LAB CO LTD

Wooden Composite Board with Antistatic Properties

ActiveUS20200316919A1SuitableImprove conductivityMaterial nanotechnologyCovering/liningsPolymer scienceMeth-

A wood-based panel includes at least one carrier board and at least one resin layer disposed side of the board. The at least one resin layer includes carbon-based particles, at least one compound of the formula R1aR2bSiX(4-a-b), and / or hydrolysis products. X is H, OH, or a hydrolysable moiety selected from the group including halogen, alkoxy, carboxyl, amino, monoalkylamino or dialkylamino, aryloxy, acyloxy, and alkylcarbonyl. R1 is an organic residue selected from the group including alkyl, aryl, and cycloalkyl, which may be interrupted by —O— or —NH—. R1 has at least one functional group Q1 selected from a group containing a hydroxy-, amino, monoalkylamino, carboxy, mercapto, alkoxy, aldehyde, acrylic, acryloxy, methacrylic, methacryloxy, cyano, isocyano and epoxide group, R2 is a non-hydrolyzable organic moiety selected from the group including alkyl, aryl, alkenyl, alkynyl, cycloalkyl, and cycloalkenyl; A is 0, 1, 2, or 3. B is 1, 2, 3, or 4.

Owner:FLOORING TECH

Cathode for secondary battery

ActiveUS20130119325A1Extend your lifeImprove cycle performanceCell electrodesConductive materialLithiumHalogen

Disclosed is a cathode for secondary batteries comprising a compound having a transition metal layer containing lithium as at least one compound selected from the following formula 1: (1−x)Li(LiyM1−y−zMaz)O2−bAb*xLi3PO4 (1) wherein M is an element stable for a six-coordination structure, which is at least one selected from transition metals that belong to first and second period elements; Ma is a metal or non-metal element stable for a six-coordination structure; A is at least one selected from the group consisting of halogen, sulfur, chalcogenide compounds and nitrogen; 0<x<0.1; 0<y<0.3; 0≦z<0.2; and 0≦b<0.1.

Owner:LG ENERGY SOLUTION LTD

Anode for secondary battery

ActiveUS20130130118A1Improve battery stabilityImprove adhesionNon-aqueous electrolyte accumulator electrodesLi-accumulatorsOvervoltageElectrical battery

Disclosed is an anode for secondary batteries comprising a combination of an anode active material having a relatively low charge / discharge voltage and a relatively low hardness (A) and an anode active material having a relatively high charge / discharge voltage and a relatively high hardness (B), wherein the anode active material (A) is surface-coated with carbon having a high hardness or a composite thereof, and a particle size of the anode active material (B) is smaller than a size of a space formed by the anode active materials (A) arranged in a four-coordination. The anode provides an electrode that prevents lithium precipitation caused by overvoltage, improves ionic conductivity as well as electric conductivity and exhibits superior capacity.

Owner:LG ENERGY SOLUTION LTD

Carbon-coated lithium iron phosphate of olivine crystal structure and lithium secondary battery using the same

ActiveUS9331329B2Improve conductivityAvoid separationFinal product manufactureOperating modesLithium iron phosphateCrystal structure

Owner:LG ENERGY SOLUTION LTD

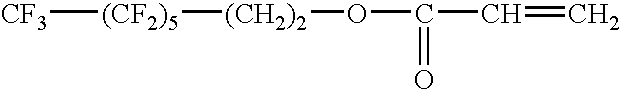

Lithium secondary battery containing silicon-based or tin-based anode active material

ActiveUS20060257740A1Improve conductivityImprove adhesionElectrode carriers/collectorsNegative electrodesPolyesterLithium

Provided is a lithium secondary battery comprising an anode mix including a silicon- or tin-based material as an anode active material, and as a binder, a photo-polymerizable material composed of one or more monomers selected from the group consisting of an epoxy derivative, polyester acrylate and epoxy acrylate, or oligomers or polymers thereof, wherein an anode can be prepared within a short period of time via a simplified manufacturing process by applying the anode mix to a current collector and polymerizing the applied anode mix with light-irradiation, and further, superior charge / discharge cycle characteristics of the battery are provided due to stable maintenance of binding between active materials and between the active material and current collector, regardless of significant volume changes of the anode active material occurring upon charging / discharging the battery.

Owner:LG CHEM LTD

Instant water heater with PTC plastic conductive electrodes

InactiveUS20070223892A1Lower bulk resistanceSuitable conductivityOhmic-resistance electrodesCooking vesselsElectrical resistance and conductanceCurrent limiting

An instant water heater utilizing positive temperature coefficient plastic electrically conductive material structures for electrodes. The heating of the water is not generated by the electrodes, but instead by the resistance of the water to the electrical current flowing between them. The material of the electrodes undergoes a phase change at certain temperatures when whereby it converts from electrically conductive to electrically non-conductive at a predetermined temperature. The output temperature of the water is determined by a combination of the area of the electrodes that confront one another, the water's conductivity, the flow rate of the water and the current limiting capability of the conductive electrode materials positive temperature coefficient, which reduces or stops the heating of the water when the intended water temperature is achieved.

Owner:CHAPUT IVANHOE

Anode for secondary battery

ActiveUS9142836B2Improve adhesionSuitable conductivityLi-accumulatorsNon-aqueous electrolyte accumulator electrodesOvervoltagePhysical chemistry

Disclosed is an anode for secondary batteries comprising a combination of an anode active material having a relatively low charge / discharge voltage and a relatively low hardness (A) and an anode active material having a relatively high charge / discharge voltage and a relatively high hardness (B), wherein the anode active material (A) is surface-coated with carbon having a high hardness or a composite thereof, and a particle size of the anode active material (B) is smaller than a size of a space formed by the anode active materials (A) arranged in a four-coordination. The anode provides an electrode that prevents lithium precipitation caused by overvoltage, improves ionic conductivity as well as electric conductivity and exhibits superior capacity.

Owner:LG ENERGY SOLUTION LTD

Lithium secondary battery containing silicon-based or tin-based anode active material

ActiveUS20060286455A1Improve conductivityImprove adhesionElectrode rolling/calenderingElectrode thermal treatmentPolyesterLithium

Provided is a lithium secondary battery comprising an anode mix including a silicon- or tin-based material as an anode active material, and as a binder, a photo-polymerizable material composed of one or more monomers selected from the group consisting of an epoxy derivative, polyester acrylate and epoxy acrylate, or oligomers or polymers thereof, wherein an anode can be prepared within a short period of time via a simplified manufacturing process by applying the anode mix to a current collector and polymerizing the applied anode mix with light-irradiation, and further, superior charge / discharge cycle characteristics of the battery are provided due to stable maintenance of binding between active materials and between the active material and current collector, regardless of significant volume changes of the anode active material occurring upon charging / discharging the battery.

Owner:LG CHEM LTD

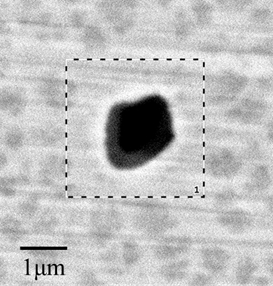

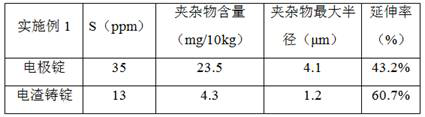

Method for smelting high-tungsten high-cobalt-nickel alloy through electroslag remelting, high-tungsten high-cobalt-nickel alloy and shaped charge liner

ActiveCN112030020AIncrease alkalinityStrong desulfurization abilityIncreasing energy efficiencyCobalt nickel alloyNickel alloy

The invention provides a method for smelting a high-tungsten high-cobalt-nickel alloy through electroslag remelting, the high-tungsten high-cobalt-nickel alloy and a shaped charge liner. The method for smelting the high-tungsten high-cobalt-nickel alloy through electroslag remelting comprises steps that raw materials of an electroslag remelting slag system are subjected to slagging, then an electrode ingot made of the raw materials of the high-tungsten high-cobalt-nickel alloy is smelted, and the high-tungsten high-cobalt-nickel alloy is obtained, wherein the electroslag remelting slag systemcomprises the following raw materials in percentage by mass: 39-44% of CaF2, 24-28% of CaO, 14-18% of Al2O3, 3-5% of MgO and 5-10% of SiO2. The high-tungsten high-cobalt-nickel alloy is prepared by using the method for smelting the high-tungsten high-cobalt-nickel alloy through electroslag remelting. The raw material of the shaped charge liner comprises the high-tungsten high-cobalt-nickel alloy.According to the electroslag remelting slag system provided by the invention, the sulfur content of the alloy can be effectively reduced, the purity of the alloy is improved, and the high-plasticity alloy with good surface quality is obtained.

Owner:UNIV OF SCI & TECH BEIJING

Lithium secondary battery containing silicon-based or tin-based anode active material

ActiveUS7611802B2Improve featuresImprove bindingElectrode rolling/calenderingElectrode thermal treatmentPolyesterLithium

Provided is a lithium secondary battery comprising an anode mix including a silicon- or tin-based material as an anode active material, and as a binder, a photo-polymerizable material composed of one or more monomers selected from the group consisting of an epoxy derivative, polyester acrylate and epoxy acrylate, or oligomers or polymers thereof, wherein an anode can be prepared within a short period of time via a simplified manufacturing process by applying the anode mix to a current collector and polymerizing the applied anode mix with light-irradiation, and further, superior charge / discharge cycle characteristics of the battery are provided due to stable maintenance of binding between active materials and between the active material and current collector, regardless of significant volume changes of the anode active material occurring upon charging / discharging the battery.

Owner:LG CHEM LTD

Carbon-coated lithium iron phosphate of olivine crystal structure and lithium secondary battery using the same

ActiveUS8734676B2Improve conductivityIncrease electrode densityNon-metal conductorsPhosphatesLithium iron phosphateSulfur

Disclosed is lithium iron phosphate having an olivine crystal structure, wherein the lithium iron phosphate has a composition represented by the following Formula 1 and carbon (C) is coated on the particle surface of the lithium iron phosphate containing a predetermined amount of sulfur (S).Li1+aFe1−xMx(PO4−b)Xb (1)(wherein M, X, a, x, and b are the same as defined in the specification).

Owner:LG ENERGY SOLUTION LTD

Cathode for secondary battery

ActiveUS8673171B2Extend your lifeImprove cycle performanceConductive materialNon-aqueous electrolyte accumulator electrodesHalogenElectrical battery

Owner:LG ENERGY SOLUTION LTD

Anode active material and secondary battery comprising the same

ActiveUS8974962B2Improve adhesionSuitable conductivityActive material electrodesNon-aqueous electrolyte accumulator electrodesMaterials scienceIon

Disclosed are an anode active material for secondary batteries, capable of intercalating and deintercalating ions, the anode active material including a core including a crystalline carbon-based material, and a composite coating layer including one or more materials selected from the group consisting of low crystalline carbon and amorphous carbon, and a hydrophilic material, wherein the composite coating layer includes a matrix comprising one component selected from one or more materials selected from the group consisting of low crystalline carbon and amorphous carbon, and a hydrophilic material, and a filler including the other component, incorporated in the matrix, and a secondary battery including the anode active material.

Owner:LG ENERGY SOLUTION LTD

Impregnate with Antistatic Properties

ActiveUS20200317936A1Suitable conductivityImprove conductivitySurface covering paperNon-fibrous pulp additionPolymer scienceCarboxyl radical

An impregnate with antistatic properties for use in laminates or for coating wood-based panels is disclosed. A resin used for impregnating and / or coating paper may include carbon-based particles, at least one compound of the general formula (I) R1aR2bSiX(4-a-b), and / or hydrolysis products thereof. X is H, OH, or a hydrolysable moiety selected from the group including halogen, alkoxy, carboxy, amino, monoalkylamino or dialkylamino, aryloxy, acyloxy, or alkylcarbonyl. R1 is an organic moiety selected from the group including alkyl, aryl, or cycloalkyl, which may be interrupted by —O— or —NH—. R1 has at least one functional group Q1 selected from a group including a hydroxy-, amino, monoalkylamino, carboxy, mercapto, alkoxy, aldehyde, acrylic, acryloxy, methacrylic, methacryloxy, cyano, isocyano or epoxide group. R2 is a non-hydrolyzable organic moiety selected from the group including alkyl, aryl, alkenyl, alkynyl, cycloalkyl, cycloalkenyl; a is 0, 1, 2, or 3, and b is 1, 2, 3, or 4.

Owner:FLOORING TECH

Preparation method of high-reliability sheet-shaped getter without particle falling risk

PendingCN112871125AImprove efficiencyReduce equipment investment and operating costsOther chemical processesAlkali metal oxides/hydroxidesZirconium alloyGetter

The invention relates to a high-reliability sheet-shaped getter without a particle falling risk and a preparation method thereof. The preparation method comprises the following steps: etching a nano-structure on the surface of a sheet-shaped titanium alloy with the thickness of less than 1mm and the titanium weight percentage content of more than 50% or a zirconium alloy with the zirconium weight percentage content of more than 50% by a chemical method so as to obtain a huge specific surface area and further to obtain excellent air suction performance. The method has the advantages that the risk of particle falling is avoided; double surfaces are simultaneously processed, so that the efficiency is improved; the production equipment investment and the operation cost are low; and graphical production can be realized.

Owner:NANJING HUADONG ELECTRONICS VACUUM MATERIAL

Cathode active material for secondary battery

ActiveUS20130119323A1Extend your lifeImprove cycle performanceCell electrodesConductive materialLithiumMetal

Disclosed is a cathode active material for secondary batteries comprising, a compound having a transition metal layer containing lithium as at least one compound selected from the following Formula 1: Li(Li3x±yM1−yPx)O2+z (1) wherein M is an element stable for a six-coordination structure, which is at least one selected from transition metals that belong to the first and second period elements; 0<x<0.1; 0<y<0.3; −4x<z≦4x; and 3x>y is satisfied in a case of 3x−y.

Owner:LG ENERGY SOLUTION LTD

Lithium iron phosphate of olivine crystal structure and lithium secondary battery using the same

ActiveUS8906552B2Improve conductivityAvoid separationPhosphatesFinal product manufactureLithium iron phosphatePhysical chemistry

Disclosed is lithium iron phosphate having an olivine crystal structure wherein carbon (C) is coated on particle surfaces of the lithium iron phosphate, wherein, when a powder of the lithium iron phosphate is dispersed in water, water is removed from the resulting dispersion and the resulting lithium iron phosphate residue is quantitatively analyzed, a ratio of the carbon-released lithium iron phosphate with respect to the total weight of the carbon-coated lithium iron phosphate is 0.005% by weight or less. Advantageously, the olivine-type lithium iron phosphate is not readily separated through uniform thin film coating on the surface of the lithium iron phosphate and exhibits superior conductivity and density, since carbon is coated on particle surfaces of lithium iron phosphate in a state in which the amount of carbon released in water is considerably small.

Owner:LG ENERGY SOLUTION LTD

Impregnate with antistatic properties

ActiveUS11292926B2Suitable conductivityImprove conductivitySurface covering paperNon-fibrous pulp additionPolymer scienceCarboxyl radical

An impregnate with antistatic properties for use in laminates or for coating wood-based panels is disclosed. A resin used for impregnating and / or coating paper may include carbon-based particles, at least one compound of the general formula (I) R1aR2bSiX(4-a-b), and / or hydrolysis products thereof. X is H, OH, or a hydrolysable moiety selected from the group including halogen, alkoxy, carboxy, amino, monoalkylamino or dialkylamino, aryloxy, acyloxy, or alkylcarbonyl. R1 is an organic moiety selected from the group including alkyl, aryl, or cycloalkyl, which may be interrupted by —O— or —NH—. R1 has at least one functional group Q1 selected from a group including a hydroxy-, amino, monoalkylamino, carboxy, mercapto, alkoxy, aldehyde, acrylic, acryloxy, methacrylic, methacryloxy, cyano, isocyano or epoxide group. R2 is a non-hydrolyzable organic moiety selected from the group including alkyl, aryl, alkenyl, alkynyl, cycloalkyl, cycloalkenyl; a is 0, 1, 2, or 3, and b is 1, 2, 3, or 4.

Owner:FLOORING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com