Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100results about How to "Strong pull-out resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

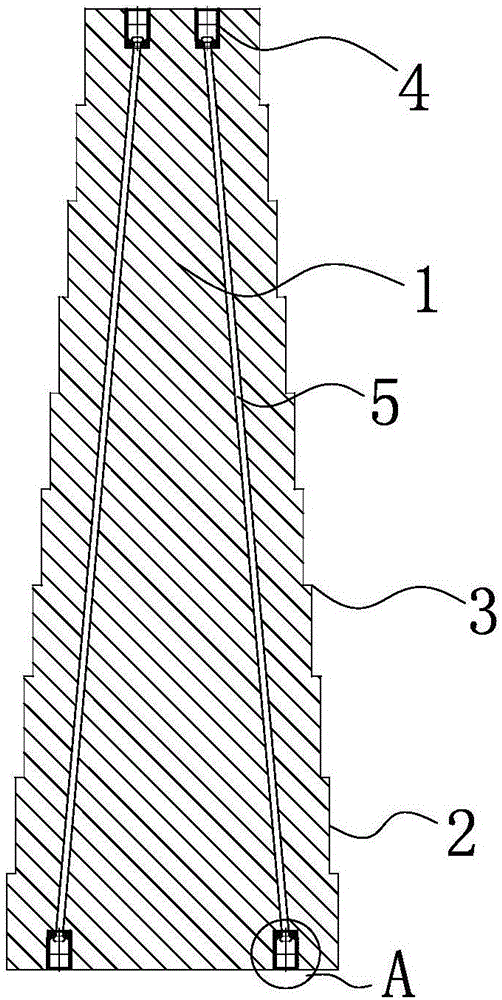

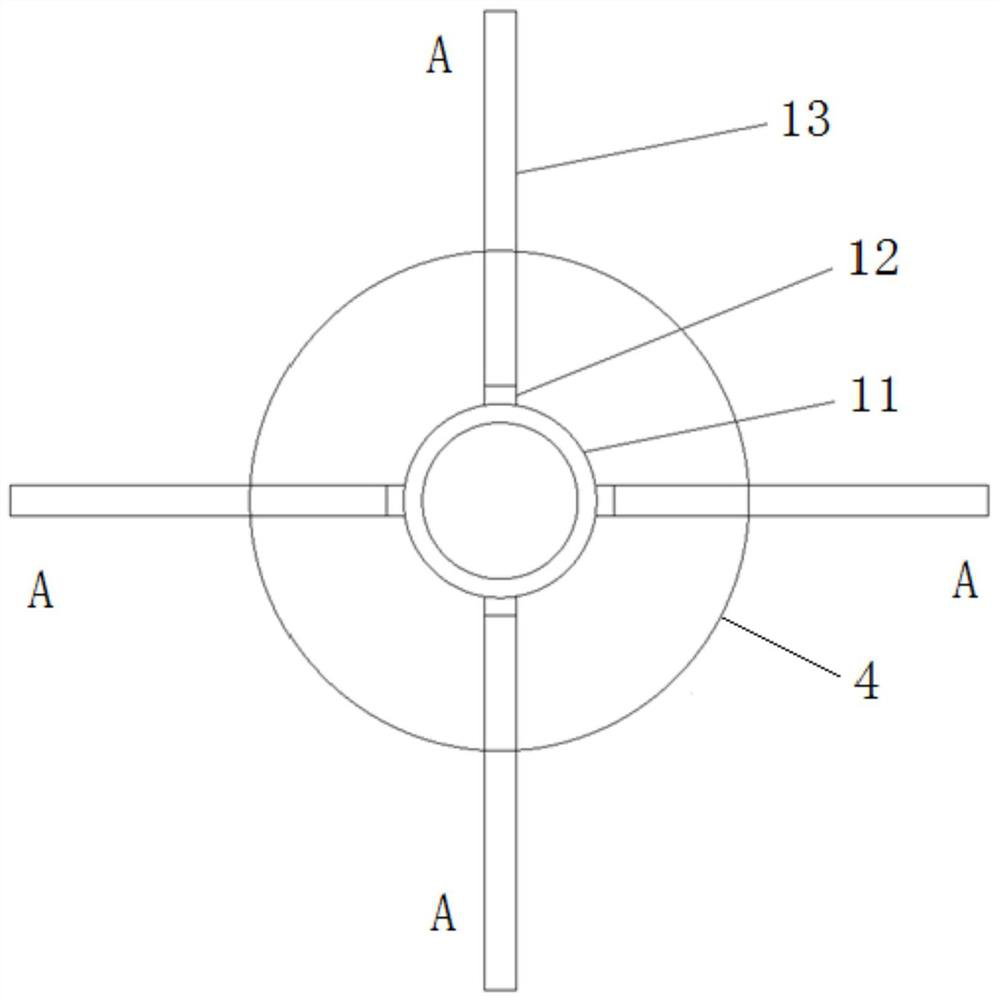

Vertically pulling-resistant type friction pendulum support

InactiveCN101086152AImprove securityImprove applicabilityBridge structural detailsProtective buildings/sheltersEngineeringStructural engineering

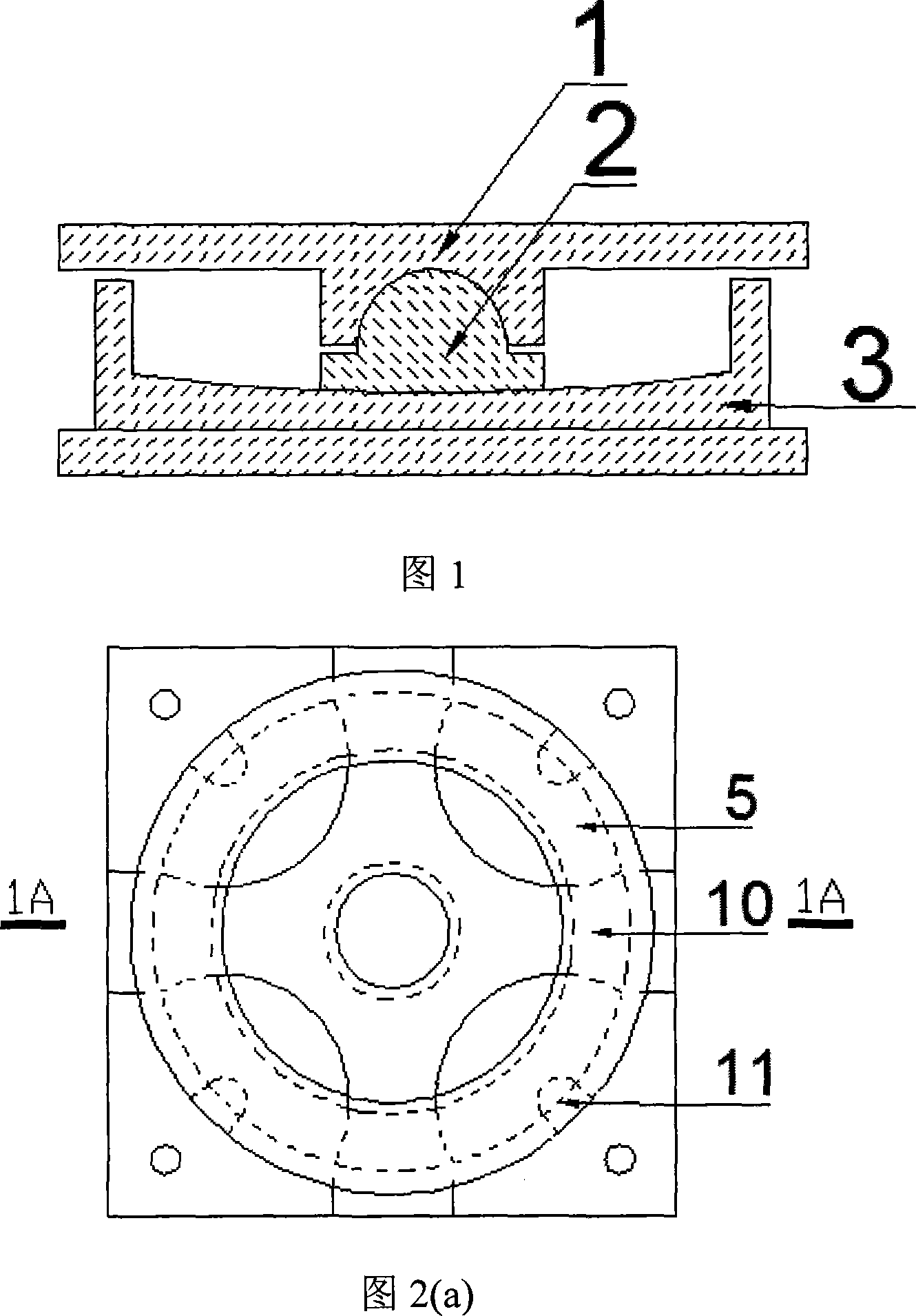

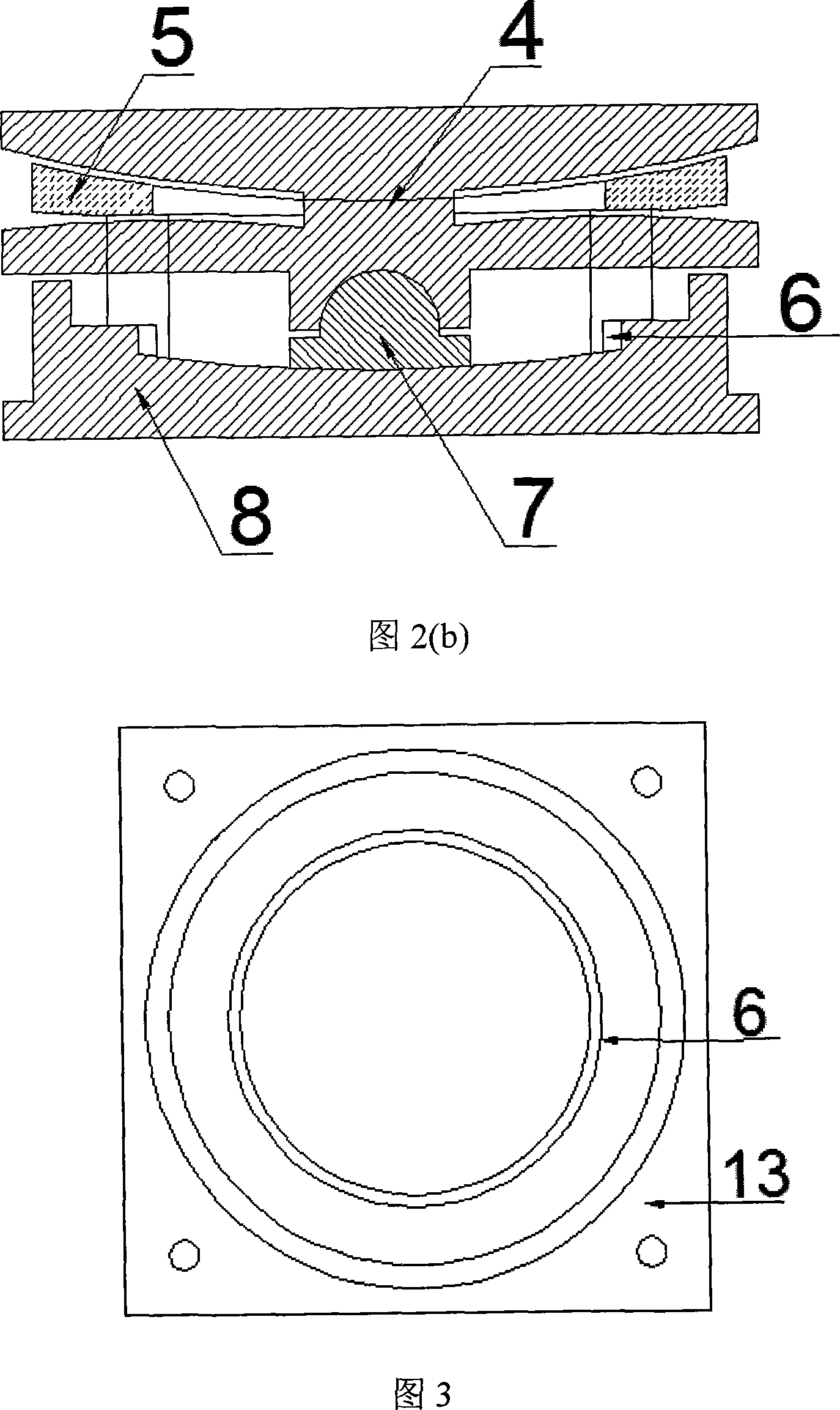

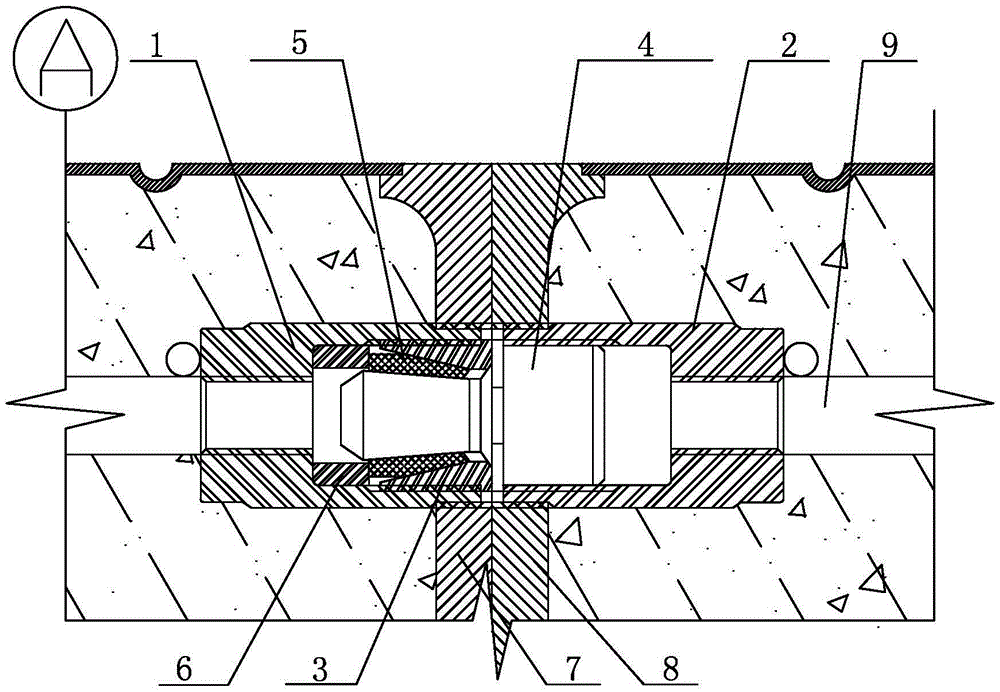

The invention involves a vertical anti-plucking friction pendulum bearing, belongs to architecture structures shock insulation and shock absorbing control field. It mainly consists of the lower connecting steel plate (13) which upper surface is equipped with chute (8), slide block (7), upper cover board (4) and anti-plucking baffle (5). The upper cover board (4) consists of the upper connecting steel plate (9) and lower blocks (10), the both are fixed and connected into one unit. The upper hemispherical protrusion of slide block (7) is matched with the hemispherical groove of lower block (10), the slide block (7) can slide along the bottom of the chute (8) by the driving of lower blocks (10). Compared with prior technology, the invention adds anti-plucking baffle (5) between the upper connecting steel plate (9) and the lower block (10), so the bearing ha strong anti-plucking capacity on the vertical direction, it ensures the structure security under the action of strong earthquake, multidimensional earthquake and wind loads. The invention has simple structure and strong practicability, and it is easy for production and installation.

Owner:BEIJING UNIV OF TECH

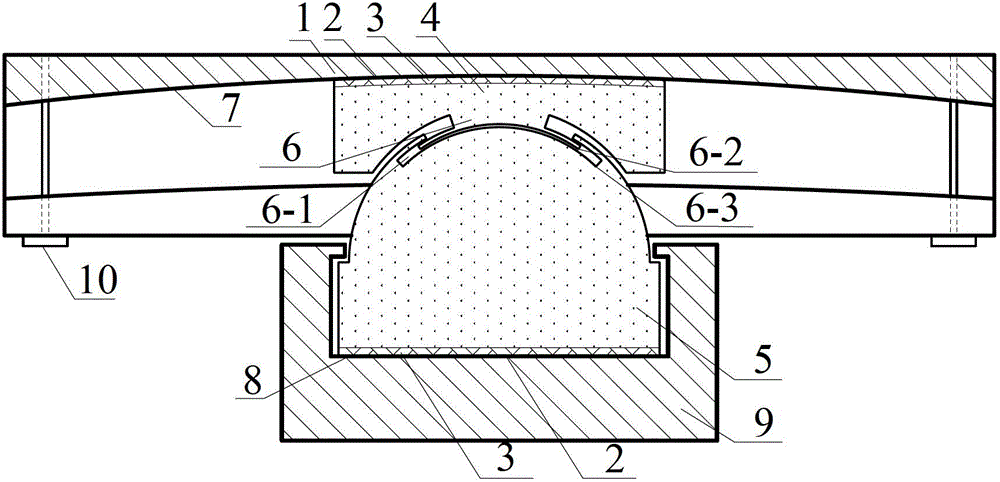

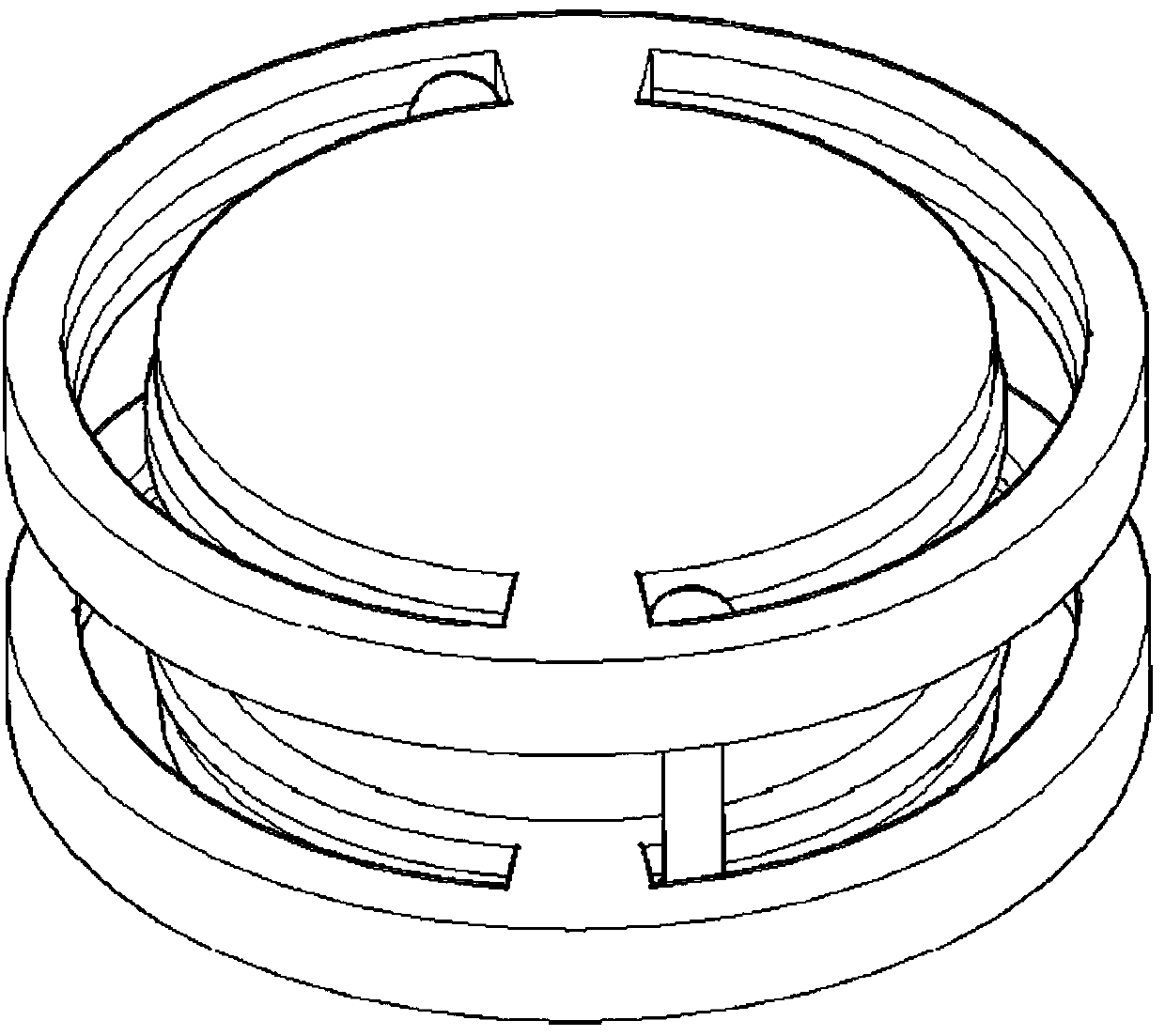

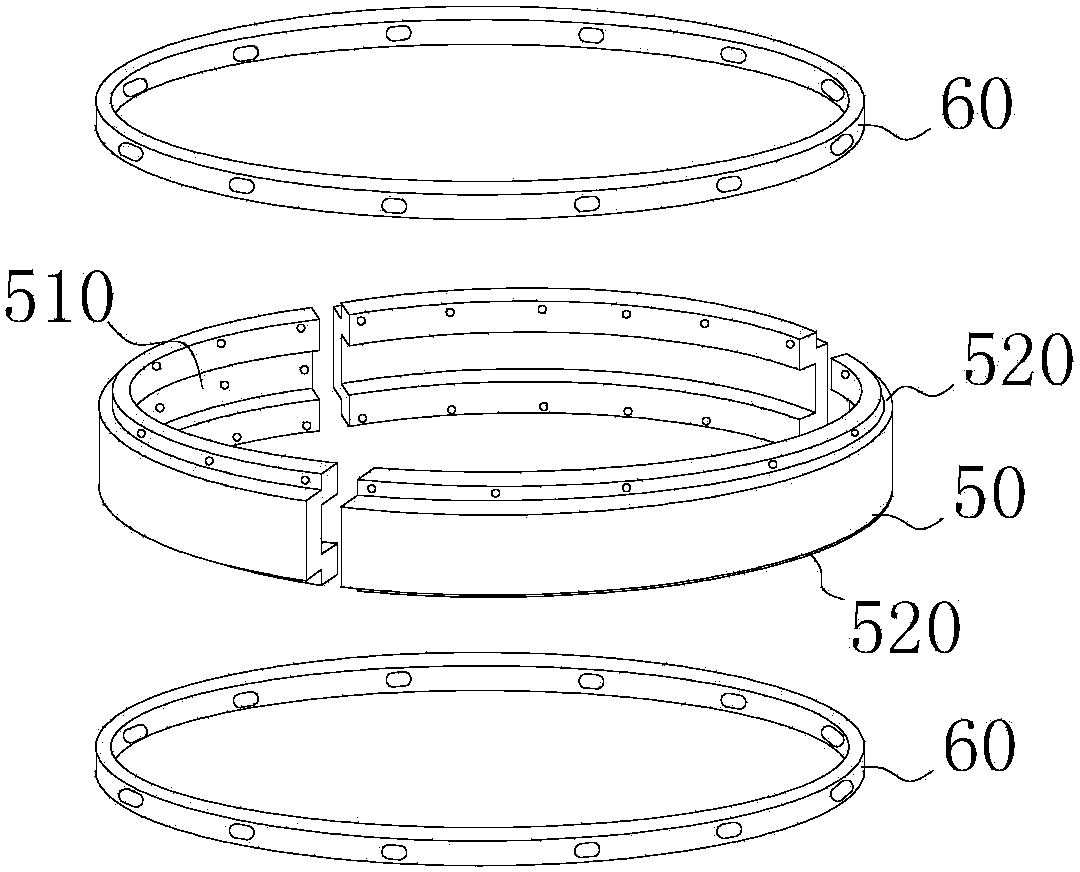

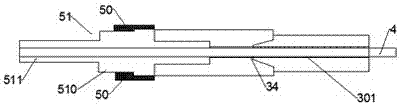

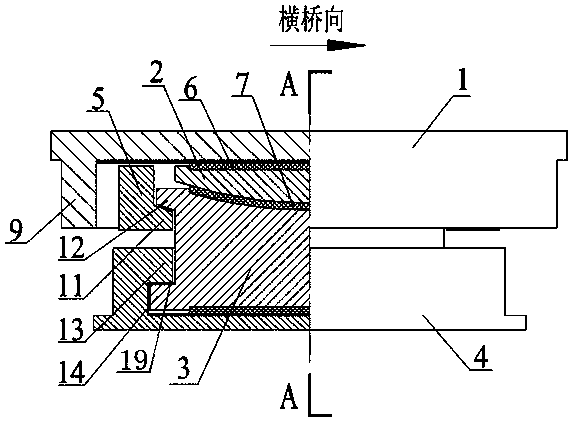

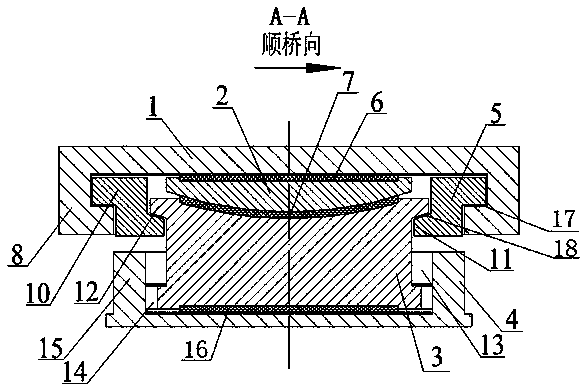

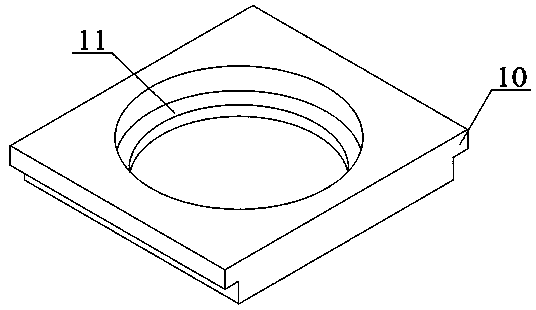

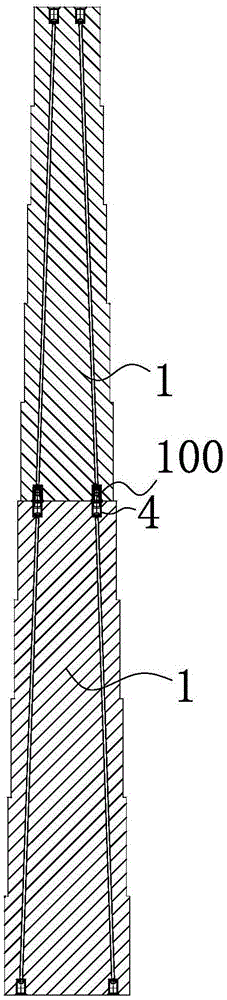

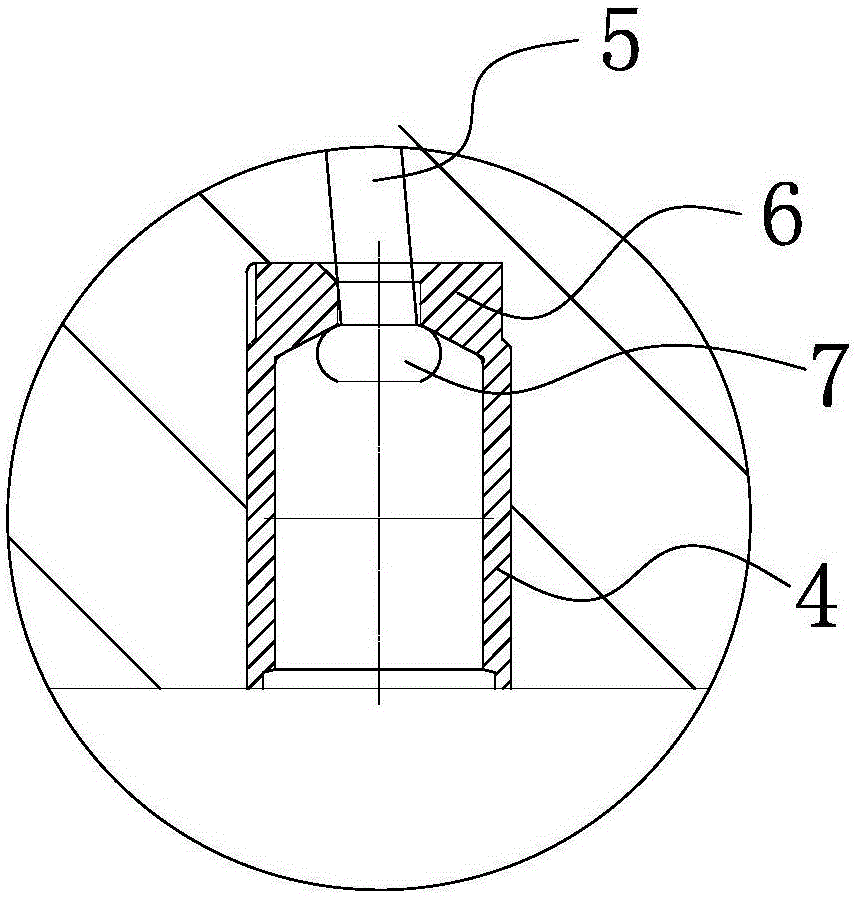

Pulling-resistant bidirectional sliding friction bearing

ActiveCN103147394ASimple structureStrong pull-out resistanceBridge structural detailsShock proofingNormal loadPull force

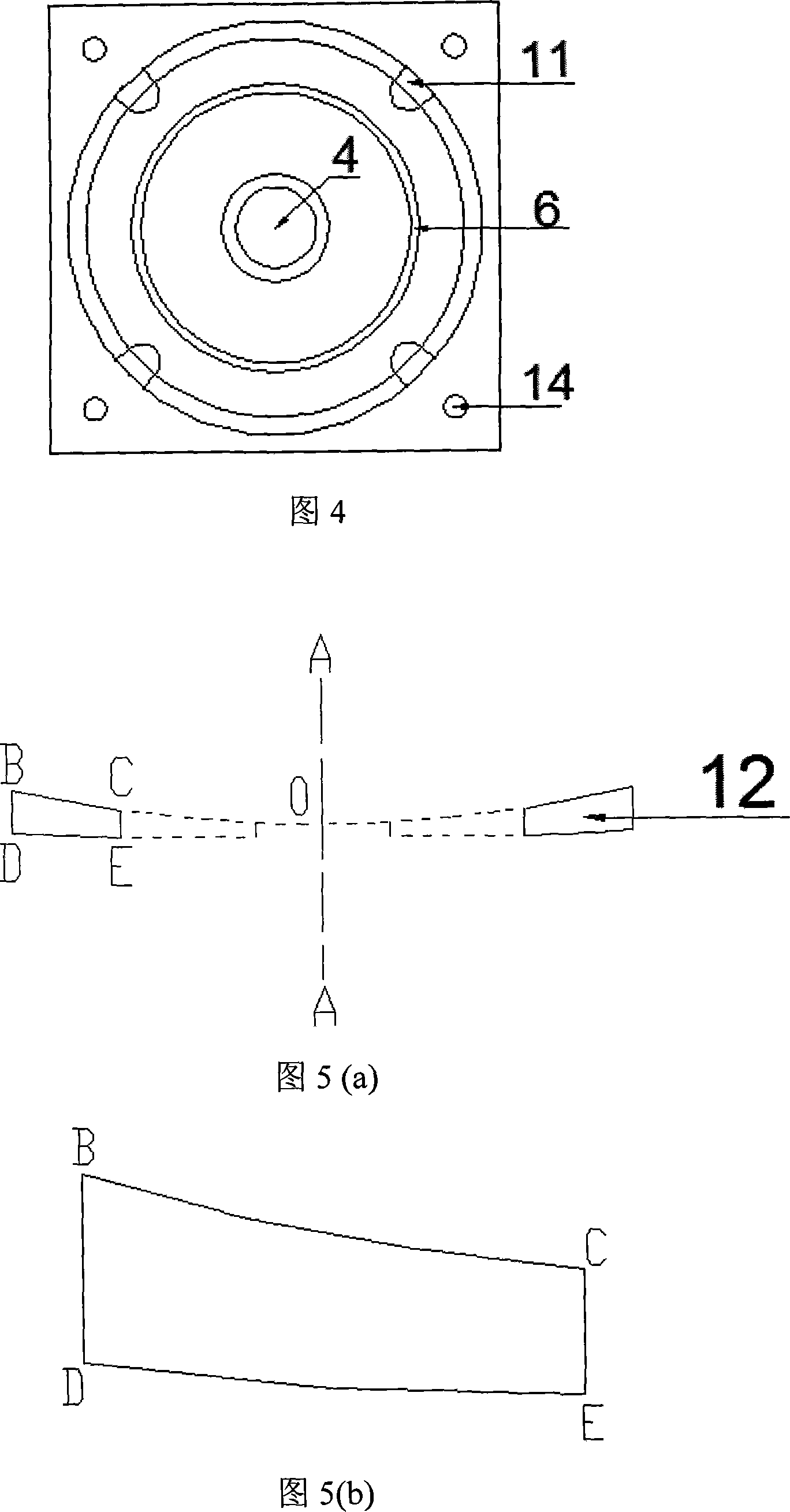

The invention mainly discloses a pulling-resistant bidirectional sliding friction bearing applied to the field of bridge, flume and building engineering. The bearing comprises upper and lower bearing plates, upper and lower sliding blocks, a pulling-resistant system and a limiting pulling-resistant device, wherein the upper sliding block and the lower sliding block can horizontally slide on the upper bearing plate and the lower bearing plate respectively; and a pulling-resistant disc is embedded into a pulling-resistant spherical segment. In the state of a normal load and a small earthquake, the rotation between the pulling-resistant disc and the pulling-resistant spherical segment of the bearing adapts to that of an upper structure under the temperature and the normal load; in the state of a big earthquake, the vibration cycle of a structure system can be changed and the partial earthquake energy can be dissipated by the sliding movement of the sliding block so as to reduce the earthquake response of the upper structure; the pulling-resistant system can be used for preventing the upper structure from being overturned or collapsed due to a pulling force with the control effect caused by larger vertical ground motion component under the action of a near field and a near-fault earthquake; and the bearing is strong in pulling-resistant capability and good in durability, has a definite seismic mitigation and absorption mechanism, and is suitable for various structures such as bridges, flumes, buildings and the like with high seismic performance requirements.

Owner:BEIJING UNIV OF TECH

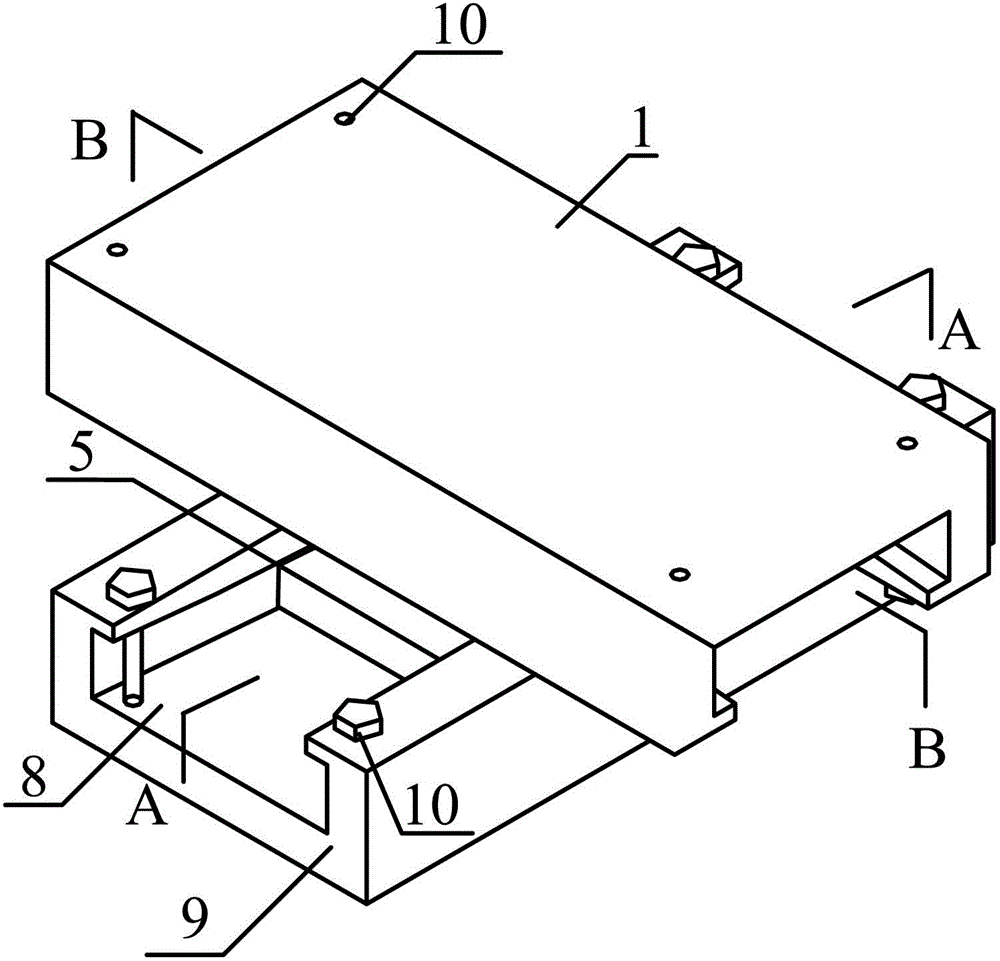

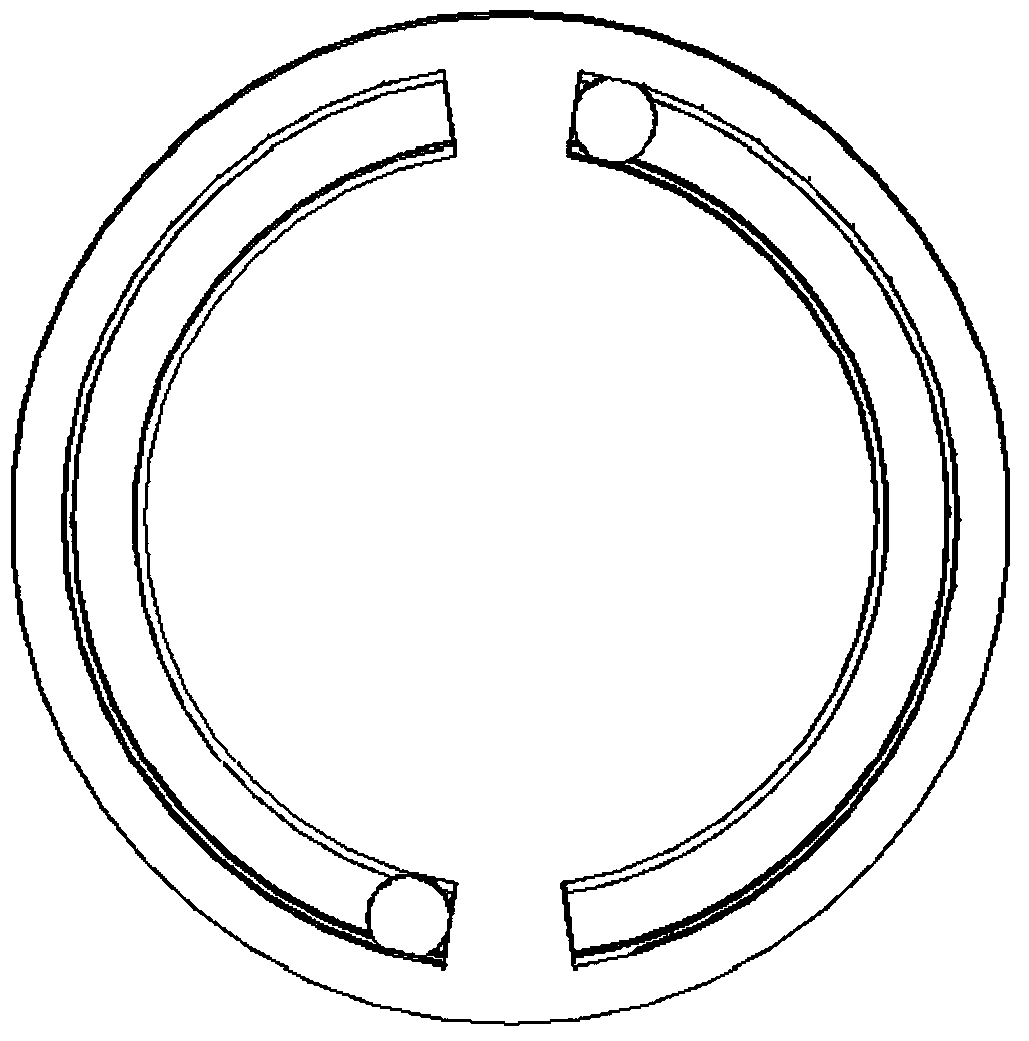

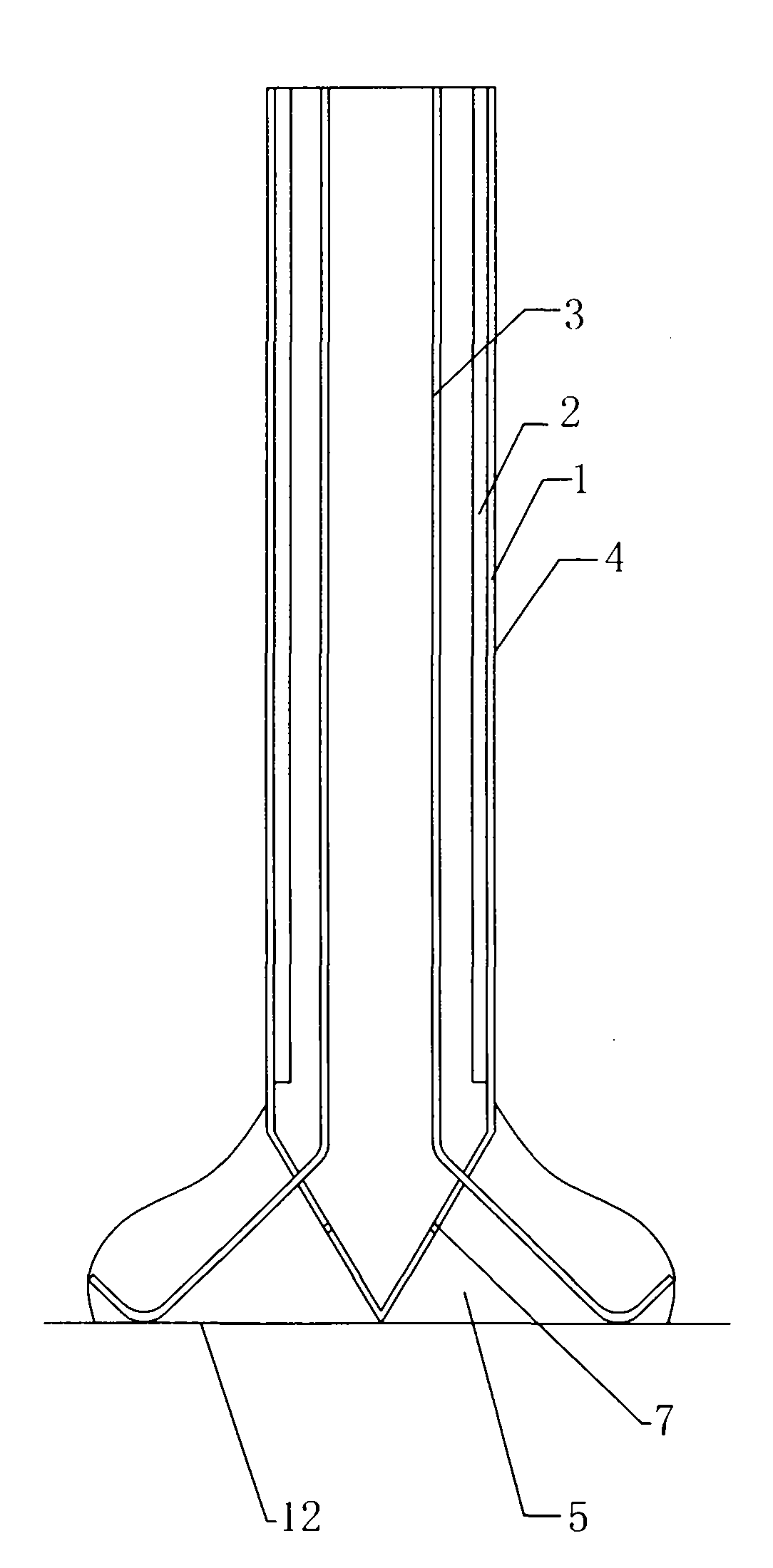

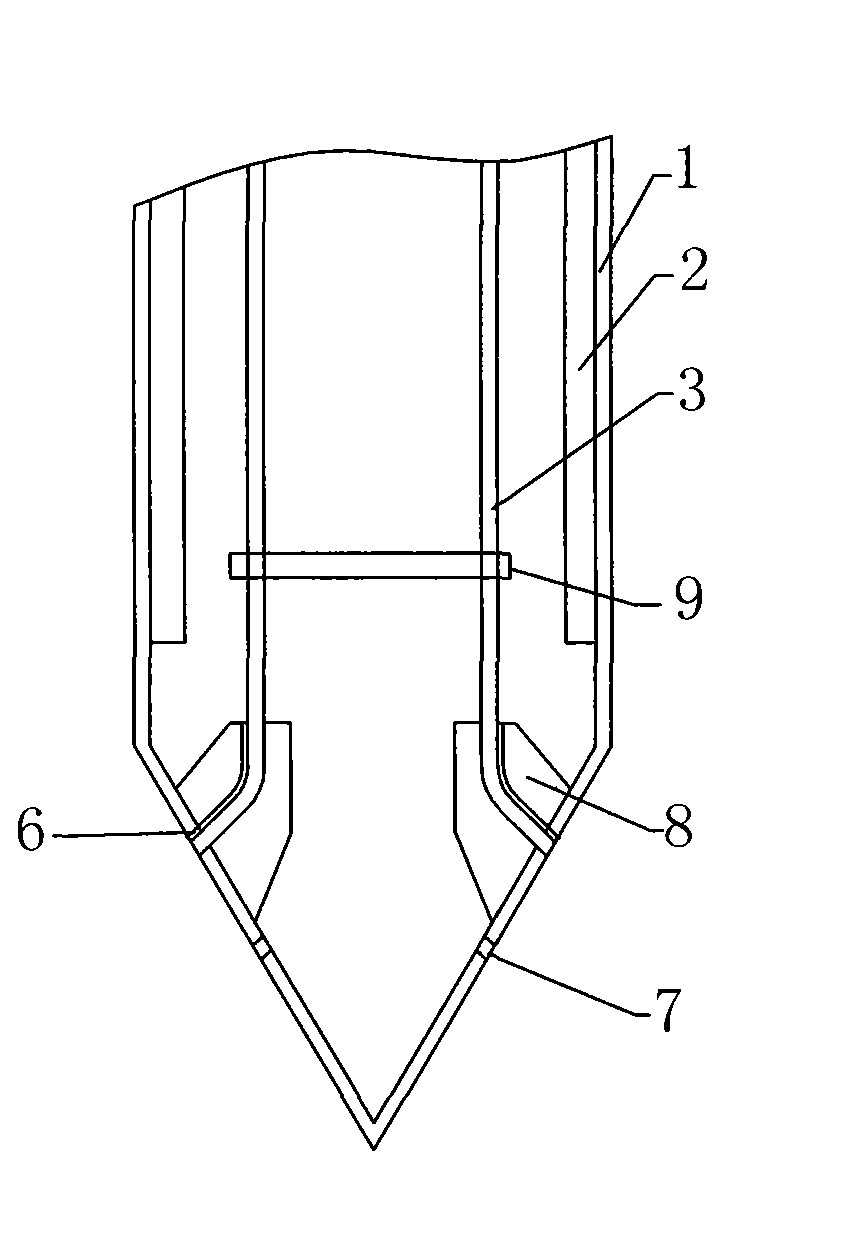

Guide rail type anti-drawing high-damping rubber shock insulation support

InactiveCN104831621ASimple structureStrong pull-out resistanceBridge structural detailsShock proofingVulcanizationPull force

The invention discloses a guide rail type anti-drawing high-damping rubber shock insulation support. A high-damping rubber support body is arranged in the middle position of upper and lower connection plates, and the high-damping rubber support body and the upper and lower connection plates are fixed together through integral vulcanization; two arc slideways are symmetrically arranged at the edges of the upper and lower connection plates, and the space between the two arc slideways is not totally sealed; two steel balls are embedded in the slideways of the upper and lower connection plates and are connected through a steel rod in a welding mode. The guide rail type anti-drawing high-damping rubber shock insulation support meets the requirement of one-way shearing deformation of buildings and bridges under the effect of normal loading, and can meet different seismic performance requirements due to its rigidity and damping characteristics. Especially in rarely met earthquakes, the guide rail type anti-drawing high-damping rubber shock insulation support has an anti-drawing property and can resist vertical pulling force. The guide rail type anti-drawing high-damping rubber shock insulation support is simple in structure, strong in vertical bearing capacity, big in horizontal displacement, good in durability, strong in anti-drawing capability and applicable to one-way horizontal shearing building structures with high vertical anti-drawing property requirements.

Owner:BEIJING UNIV OF TECH

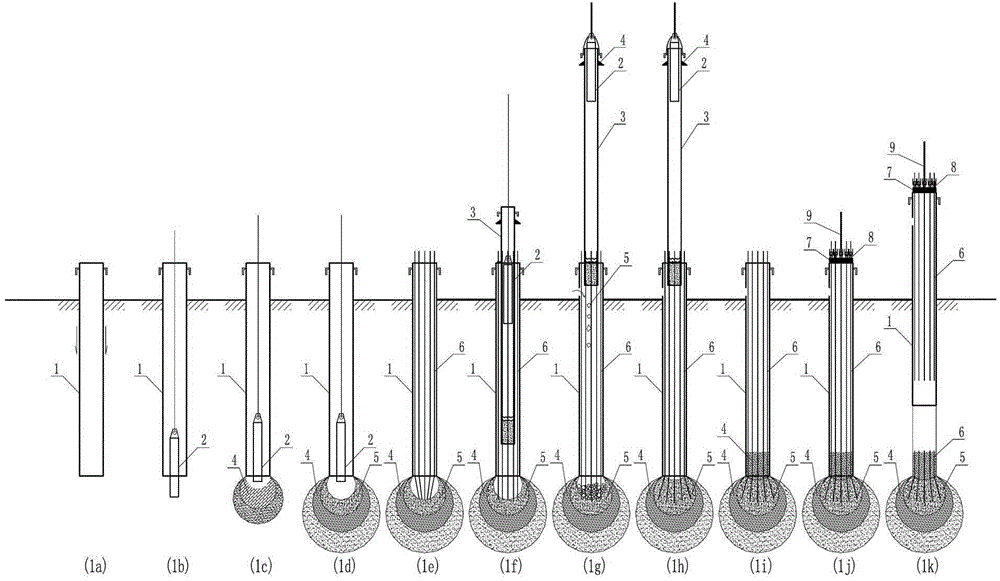

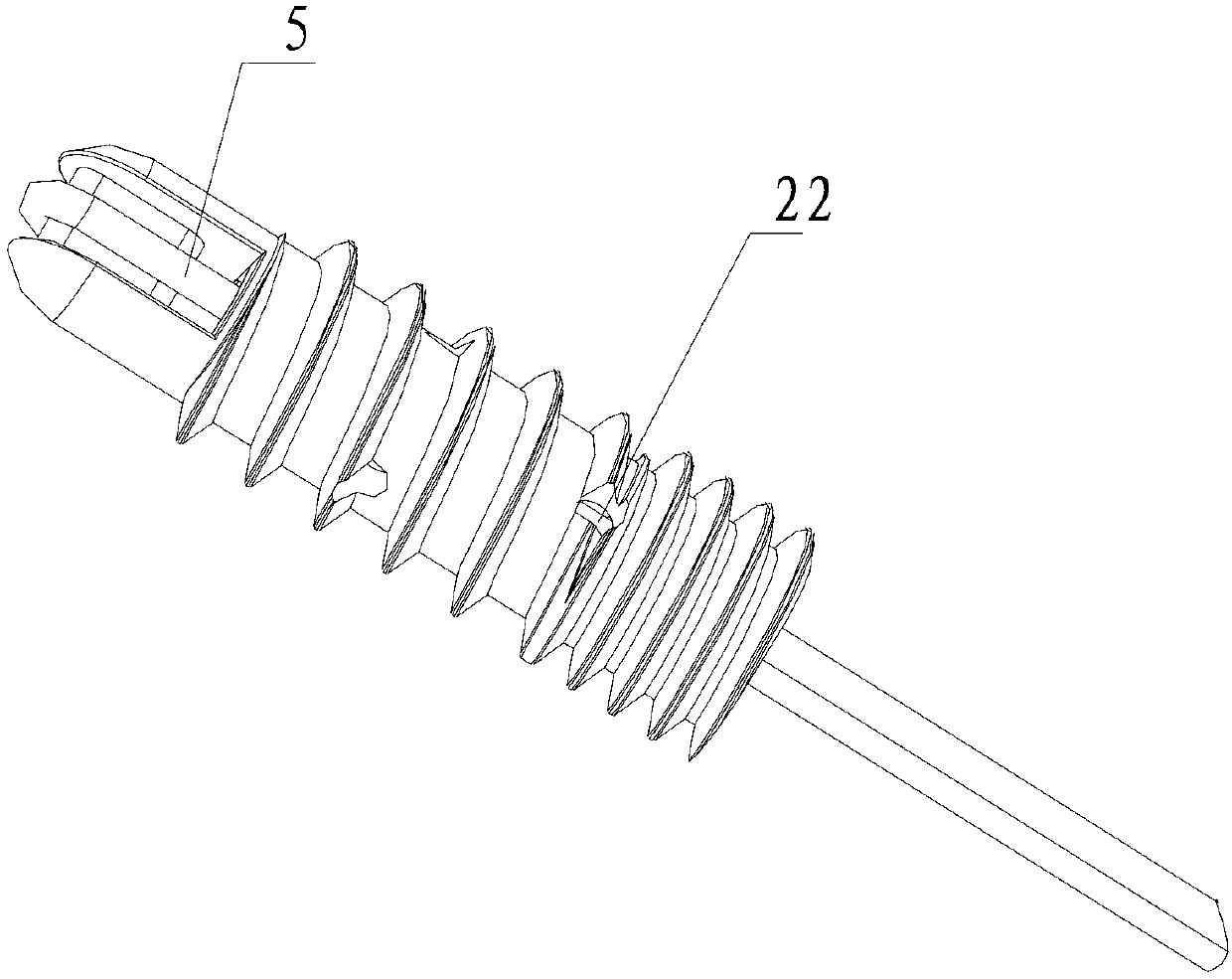

Self-drilling type spiral anchor rod and construction process using self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing

InactiveCN102587366AGood effectImprove construction safetyExcavationsBulkheads/pilesHelical bladeEngineering

The invention discloses a self-drilling type spiral anchor rod and a construction process using the self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing, which are suitable for support engineering of anchor-pulling slopes in weak soil regions. A paste outlet is arranged on a rod body of the spiral anchor rod, the front end of the rod body of the anchor rod is enclosed, a spiral vane is welded at the front end of the rod body of the anchor rod, and a stirring slice is welded behind the spiral vane on the rod body of the anchor rod. The construction process using the self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing comprises the following steps of: injecting cement paste while drilling by rod body of the anchor rod, so that a paste body of the cement paste is ejected out of the paste outlet of the rod body of the anchor rod, mixing the paste body and a soil body cut by using the spiral vane on the front end, uniformly stirring the soil body and the cement paste by using the stirring slice arranged behind the spiral vane, forming an irregular anchor body after curing so that the anchoring force of the anchor rod is increased. Because the drilling and the grouting are integrated, the pressure influence of subsequent grouting on the side wall of a foundation pit is avoided; and meanwhile, the grouting pressure can be effectively controlled so that the grouting quality can be ensured.

Owner:中石化胜利建设工程有限公司

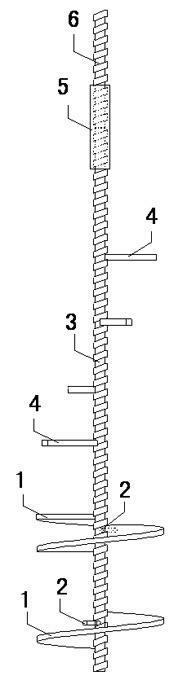

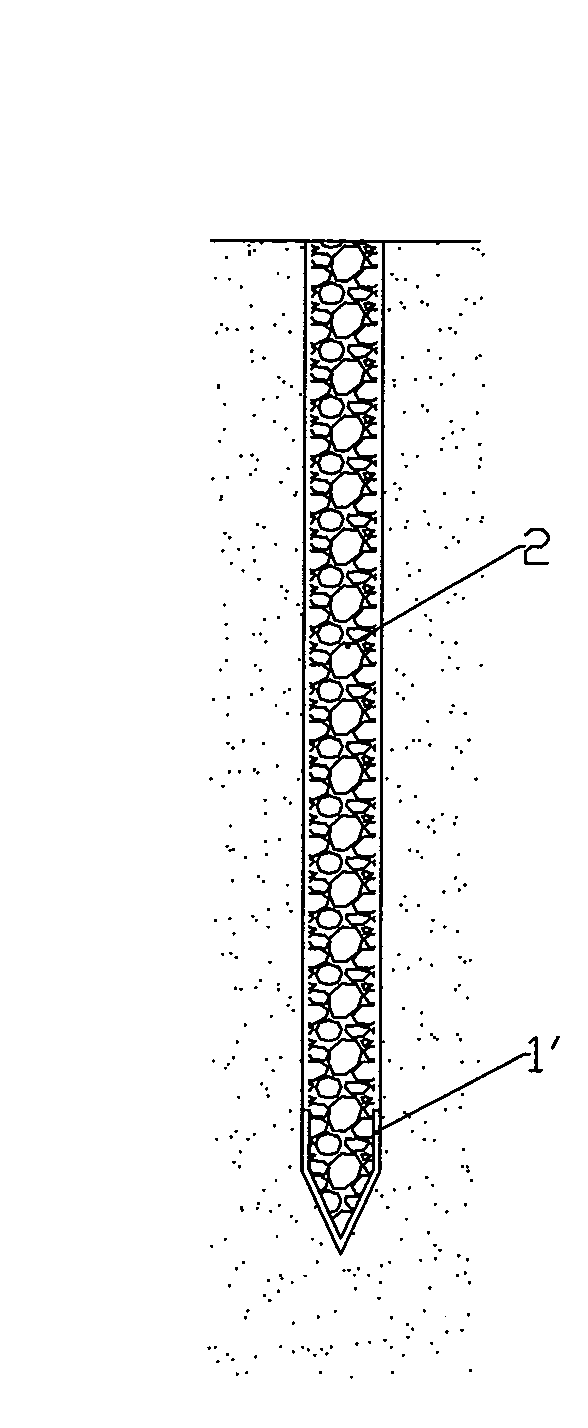

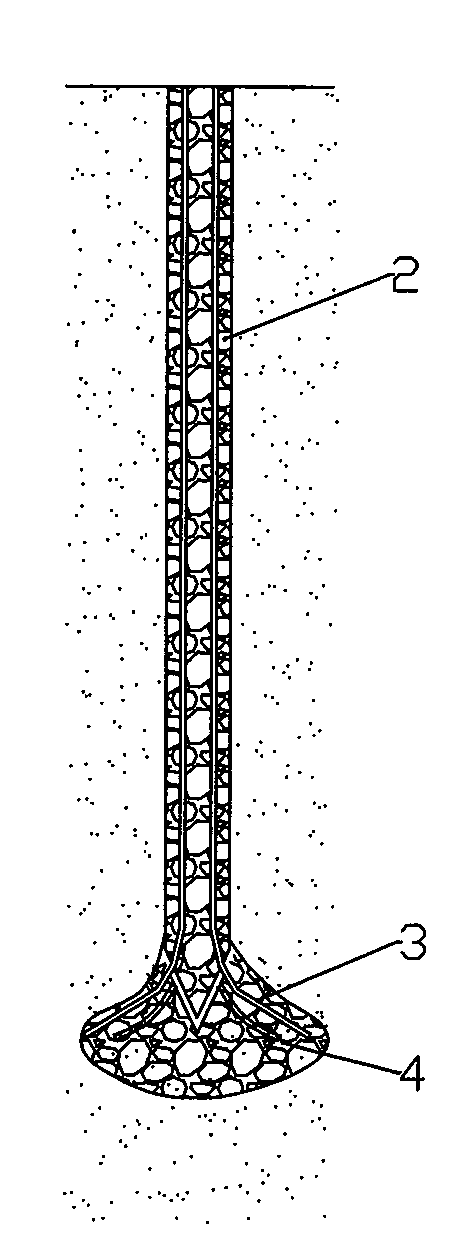

Pressing-resistant plucking-resistant pile and forming method thereof

InactiveCN101012650AImprove stress resistanceStrong pull-out resistanceBulkheads/pilesAcute angleRebar

The invention relates to an anti-pressure and anti-floating pile, comprising a cylinder pile body constituted by reinforced steel bar and concrete, characterized in that the reinforced steel expands outside at the bottom of pile body so as to form a big capitate chassis at the bottom of pile body, whose dimension in radial direction is larger than the pile body. The invention also discloses a pile method that multiple via holes are machined on the pipe wall at the lower end of steel pipe mold and the angle between the axes of via hole and the axes of steel pipe mold is acute angle; multiple reinforced steel bars are set in the steel pipe mold and ends of reinforced steel bars insert into via holes at the lower end of steel pipe mould; steel pipe mold and reinforced steel bars are driven into the foundation to the presetting depth together; Then the steel pipe mold is not driven and reinforced steel bars are driven to protrude with a certain length in outer oblique direction furthermore; and then steep pipe mold is drawn out and concrete is filled in so that concrete is used to fill in the space under steel pipe mold from the bottom of steel pipe mold; reinforced steel bars out of steel pipe mold are covered; finally the pile with larger bottom is formed. The formation is convenience. The pile structure can increase the anti-pressure and anti-floating capacity.

Owner:徐国彬

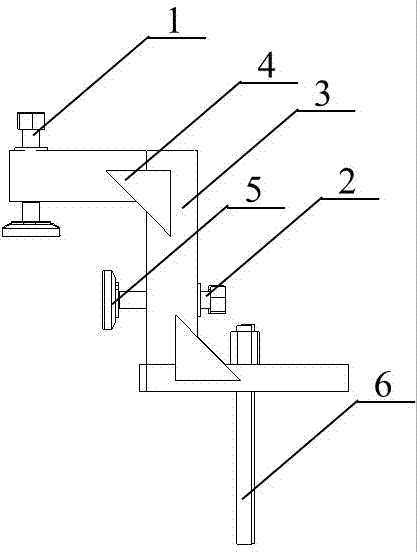

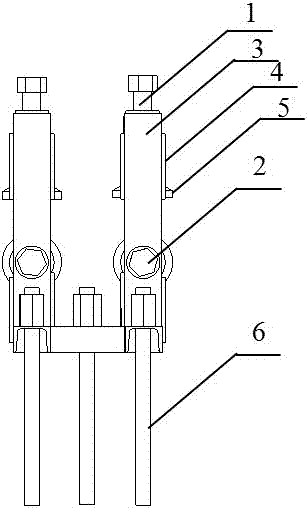

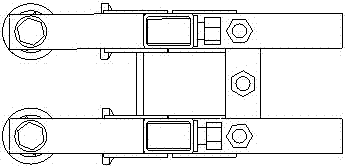

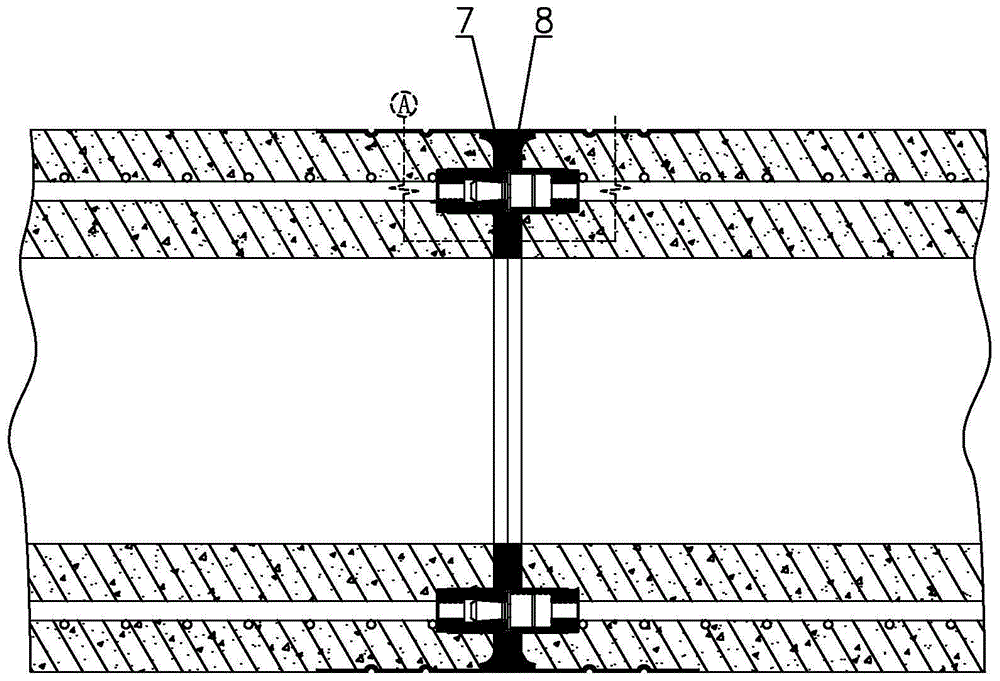

Pressing limiting device and method for slab ballastless track structure

ActiveCN108004855AMeet the needs of compression limitSmall and lightBallastwayStructural engineeringEngineering

The invention discloses a pressing limiting device and method for a slab ballastless track structure, which are used for solving problems of upwarp and warping diseases of the slab ballastless track structure of an operating line, realizing synchronous and integral deviation rectification of the laminated slab ballastless track structure and avoiding the dislocation of the laminated structure andupwarp secondary disease of a track slab in the deviation rectifying process.

Owner:沪杭铁路客运专线股份有限公司 +3

Uplift pile mixed connection structure

ActiveCN105756054AEfficient deliverySolve the problem of impact resistanceBulkheads/pilesAdhesiveStructural engineering

The invention discloses an uplift pile mixed connection structure which comprises a pile head protective sleeve I, a pile head protective sleeve II and a plug connector. The plug connector comprises a first sleeve-shaped fixed positioning sleeve and a second sleeve-shaped fixed positioning sleeve. A clamping piece is arranged in the first fixed positioning sleeve. A plug connection piece is arranged in the second fixed positioning sleeve. The plug connection piece can be inserted into the first fixed positioning sleeve and limited on the clamping piece, and therefore the first pile head protective sleeve and the second pile head protective sleeve can be fixedly connected in a butted mode. Both the first fixed positioning sleeve and the second fixed positioning sleeve are connected with main reinforcement bars and fixedly combined with the pile head protective sleeves through screws. When the uplift pile mixed connection structure is subjected to tensile force, the plug connector effectively connects the upper and lower main reinforcement bars, butt connection of the upper and lower main reinforcing bars on the same axis is achieved, inner stress is effectively transferred, meanwhile, the butted connection faces of the pile head protective sleeve I and the pile head protective sleeve II are in butted connection through a steel adhesive, the uplift resistance is further improved, and the purposes of impact resistance of a pile head end face and shear resistance and corrosion resistance of the connector are thoroughly achieved.

Owner:天海钢棒(张家港)有限公司

Probe penetration implement for detecting and monitoring sea bed soil body

InactiveCN1786350AAvoid damageStrong ability to resist the lateral force of ocean currentsIn situ soil foundationHydraulic motorWater flow

The invention relates to seabed soil mass detecting monitoring feeler lever penetration implement. The pressing penetrating institution bearing platform is fixed on the base of the penetration implement. The oil cylinder fixed on the bearing platform is connected to feeler lever interval lock under the baring platform. Both of them have feeler lever through hole. The chuck of the lock is held at the flute of the feeler lever joint. Oil-way is connected to control oil cylinder oil hydraulic motor. Its circuit is connected to console. The implement can use sea floor pressing penetrating force to press and penetrate feeler lever into seabed. The soil layer around the anchorage bar is destroyed little. The ocean flow side force resistance and pulling resistance are strong. It not only can reduce interference to soil mass, but also can prevent slimness type feeler lever from bending and destroying when it is penetrating into seabed soil mass.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA +1

Novel type pile foundation for sea turn engineering and pile forming method thereof

InactiveCN101914921AHigh strengthIncrease stiffnessCeramic shaping apparatusBulkheads/pilesOcean bottomReinforced concrete

The invention discloses a novel type pile foundation for sea turn engineering and a pile forming method thereof. The novel type pile foundation comprises a steel pipe, the steel pipe is internally provided with a concrete lining pipe; a corrosion preventive is coated outside the steel pipe; the concrete lining pipe is internally provided with a reinforced concrete pile core, and the lower end of a steel bar inside the pile core penetrates out of a through hole positioned on a pointed cone at the lower end of the steel pipe and extends to sea bed rocks; the steel bar wrapped with concrete and penetrating outside the pointed cone passes through a concrete extrusion through hole positioned below the steel bar penetrating through hole on the pointed cone and is connected with the reinforced concrete pile core inside the concrete lining pipe through to form an expanded pile head. The novel type pile foundation for the sea turn engineering forms a chassis in a large head shape and with the radial dimension larger than that of the main body part of the pile foundation at the bottom of the main body of the pile foundation, is closely combined with the sea bed rock and has very high pressure and drawing resisting capability; and in addition, the pile forming method ensures the smooth construction on the sea.

Owner:徐国彬

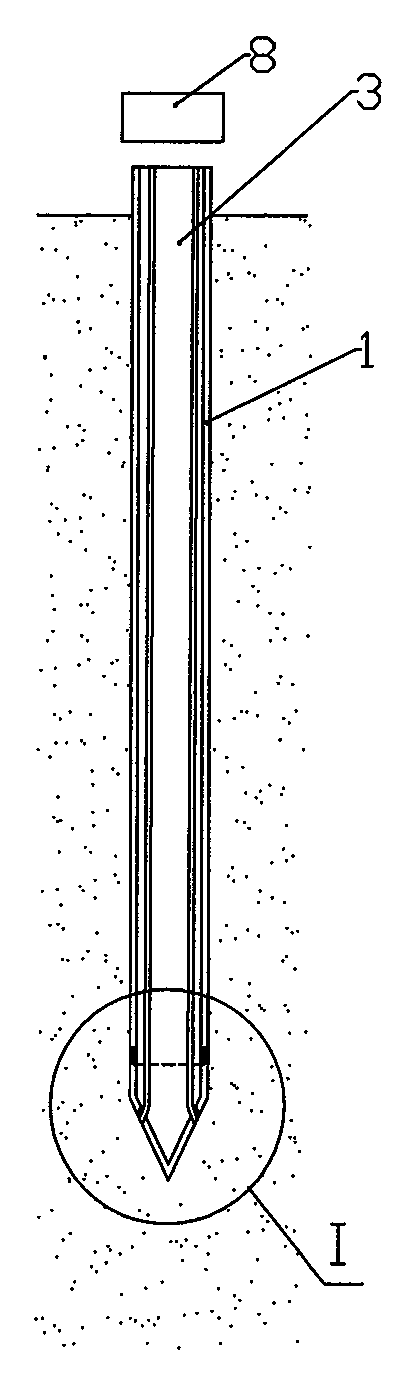

Construction method for uplift pile

ActiveCN102720187APlay a protective effectAvoid punching shearFoundation testingBulkheads/pilesCircular discRebar

The objective of the invention is to provide a construction method for uplift piles. A detection uplift pile capable of providing a high pulling resistance can be formed fast and easily by the method. The construction method comprises the following steps of: 1) sinking outer tubes provided with a hollow steel tube on the inner wall to a designed depth; 2) putting an internal hammer in the outer tubes and hitting the internal hammer out of the outer tubes; 3) filling in the outer tubes with granular filling material in several times and squeezing the filled granular filling material with the internal hammer; 4) filling in the outer tubes with dry rapid-hardening concrete in several times and squeezing the filled dry rapid-hardening concrete with the internal hammer; 5) inserting steel bars separately into the outer tubes through the hollow steel tubes inside the outer tubes; 6) putting an inner tube in the outer tubes and an internal hammer in the inner tubes, and connecting the inner tubes with the internal hammers; 7) filling in the outer tubes with dry rapid-hardening concrete and squeezing the filled dry rapid-hardening concrete by hammering the inner tubes; 8) filling and squeezing repeatedly so as to make the steel bars spread outward and be wrapped and embedded in the dry rapid-hardening concrete; 9) perfusing granular material in the outer tubes; 10) using a steel connecting plate to fix the steel bars and a dowel steel of testing equipment with bolts separately; and 11) recycling the steel connecting plate and steel bars.

Owner:北京波森特岩土工程有限公司

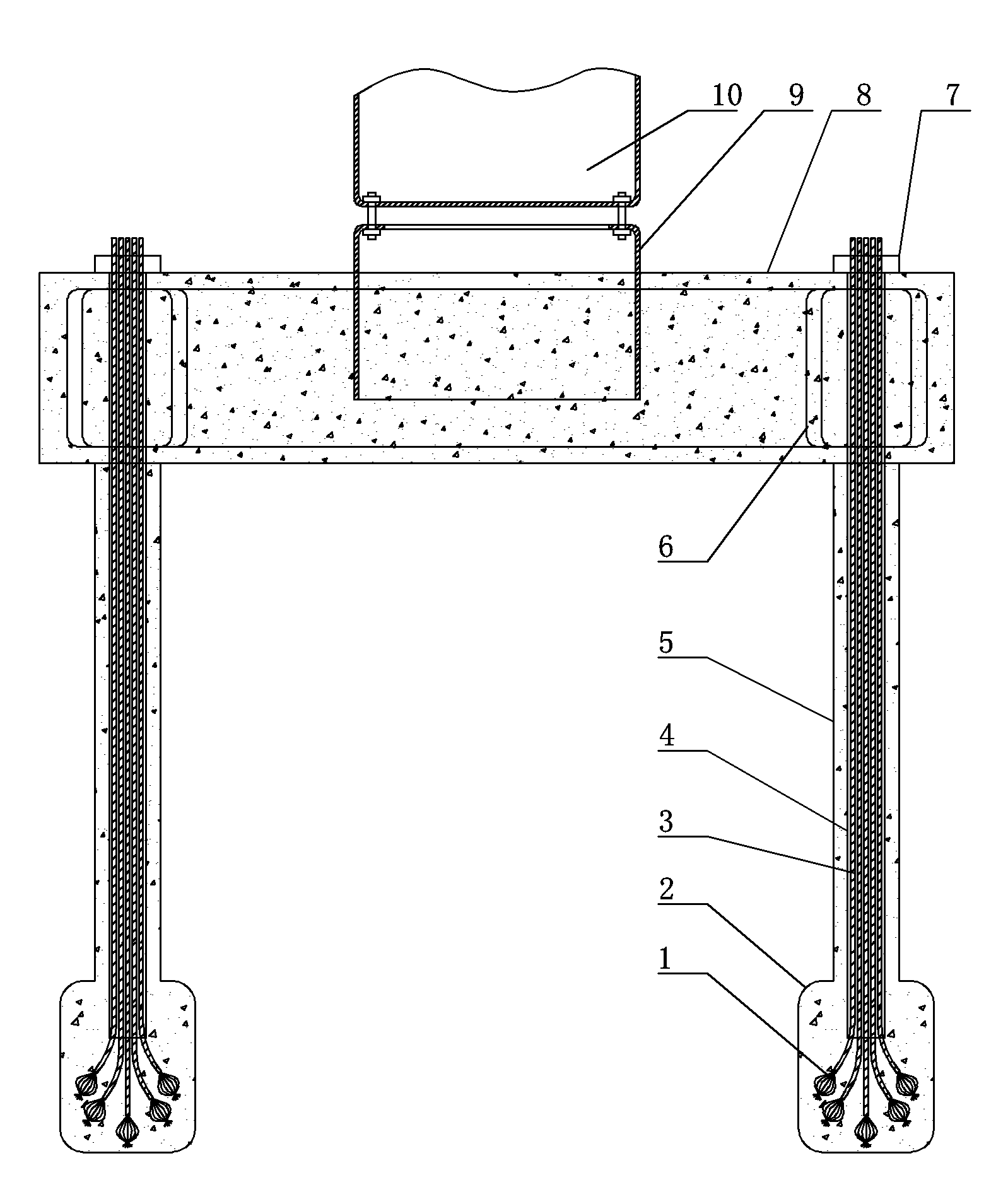

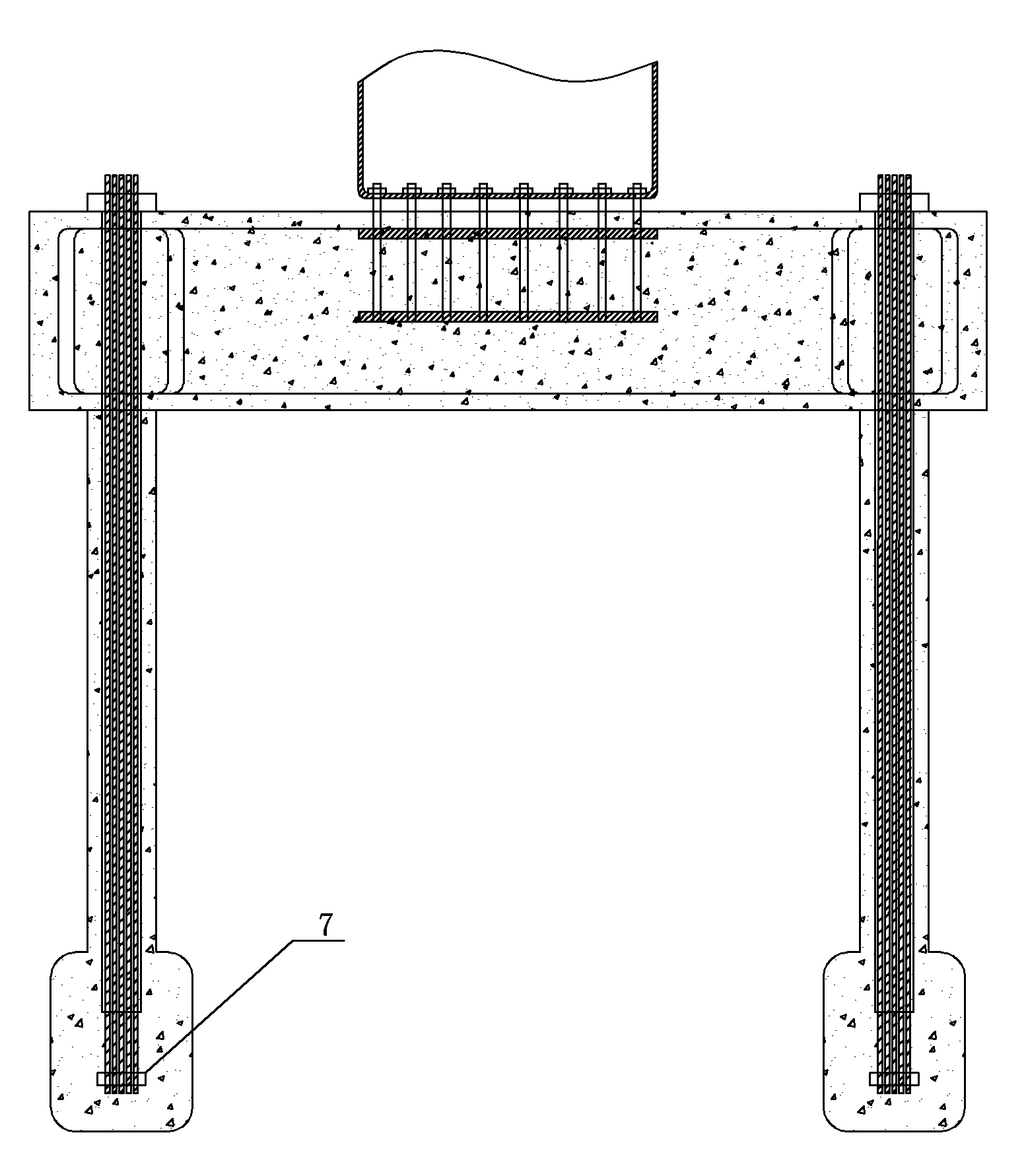

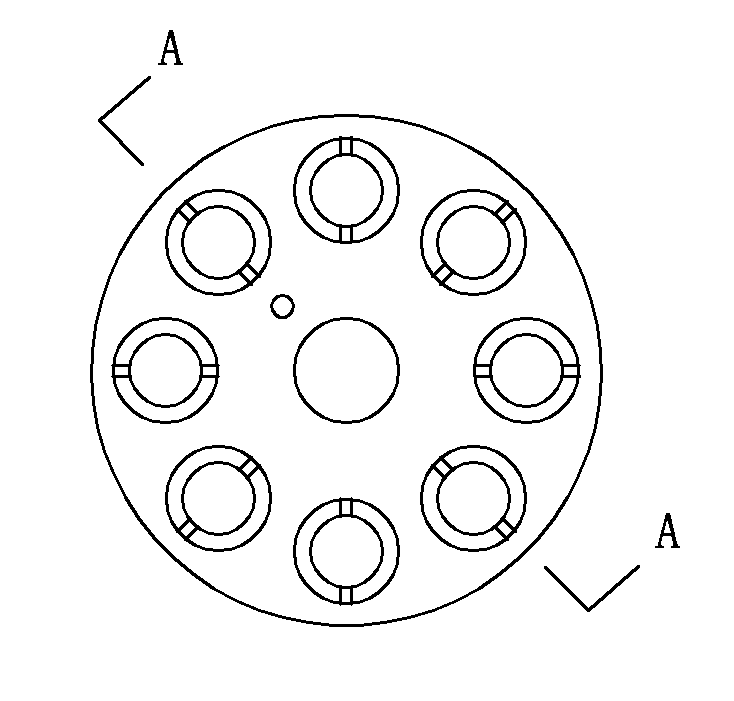

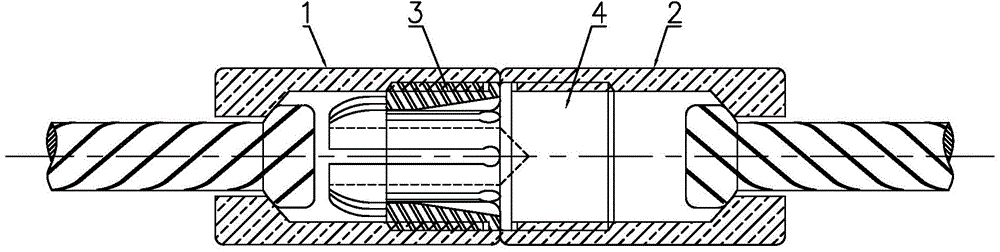

Steel strand prestress base structure of wind driven generator and construction method thereof

InactiveCN103266621AImprove pullout resistanceStable structureFoundation engineeringWind drivenPre stress

The invention provides a steel strand prestress base structure for a wind driven generator and a construction method thereof and relates to improvement of the rock layer and soil layer of base structure of the wind driven generator and the construction method thereof. The rock layer of base structure of the wind driven generator is stable and saves raw materials. The base structure comprises a concrete bearing platform, a fixing portion of the wind driven generator is arranged in the middle in the concrete bearing platform, the upper portion of the concrete bearing platform is connected with the bottom of a fan tower through bolts, straight holes are formed in the lower portion of the edge of the concrete bearing platform and evenly distributed on the circumference with the fixing portion as the center, the bottoms of the straight holes are communicated with bottom expanding holes under the straight holes, steel strands are arranged in the straight holes, anchoring portions of the steel strands arranged in the bottom expanding holes are arranged at the bottom ends of the steel strands, bellows are further arranged on the outside of the steel strands, pouring concrete is arranged in places between the bellows and the straight holes and in the bottom expanding holes, concrete is arranged in the bellows and gaps between the steel strands, and the upper ends of the steel strands are fixed on the concrete bearing platform through a location anchoring disc.

Owner:BEIJING HUADIAN XINNENG CONSULTATION

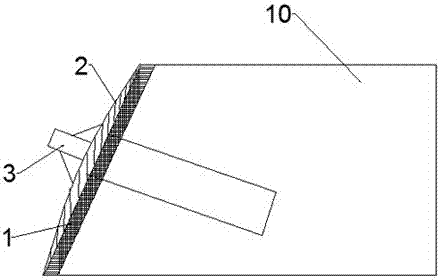

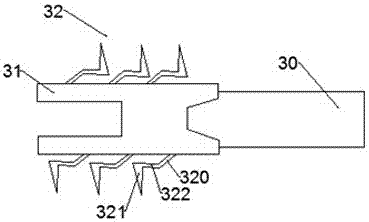

Rapid joint of precast concrete pile

InactiveCN104895052AFlexible dockingMeet the requirements of through-layoutBulkheads/pilesEngineeringRebar

The invention discloses a rapid joint of a precast concrete pile. The rapid joint comprises a stretching positioning sleeve I and a stretching positioning sleeve II which are both of a sleeve shaped structure; limiting ends for limiting end heads of steel bars inside are arranged at the bottom parts of the stretching positioning sleeve I and the stretching positioning sleeve II. The rapid joint further comprises a guide clamp and a reverse spring buckling pin; the guide clamp is in threaded fitting with the stretching positioning sleeve I; the reverse spring buckling pin comprises a screwing base, and at least three reverse buckling teeth fixed on the screwing base, wherein the reverse buckling teeth are extruded to pass through the guide clamp and then sprung back to be limited on the guide clamp; the screwing base is in threaded fitting with the stretching positioning sleeve II. The rapid joint is high in strength, simple to assemble and abut, free of damage on a connecting part body, flexible to abut, high in sealing after abutting, and high in stretching resistance and corrosion resistance.

Owner:袁江

Special grouting material for micro-expanded assembled construction bar connecting sleeve and preparation method thereof

The invention relates to a special grouting material for micro-expanded assembled construction bar connecting sleeve and a preparation method thereof. The grouting material comprises a dry powder of the grouting material and water, wherein the dry powder of the grouting material comprises main materials and additives; the main materials include 30-45% of portland cement, 10-25% of a superfine granulated blast furnace slag powder, and 45-50% of a quartz powder, wherein the sum of the abovementioned three components is 100%; the additives include gypsum, a composite crack resisting shrinkage reducing agent, a defoaming agent, a composite early strength agent, a stabilizing agent, micro steel fibers, a corrosion inhibitor and a polycarboxylate superplasticizer. The preparation method comprises the following steps: weighing raw materials based on matching ratio; uniformly stirring to obtain the dry powder of the grouting material; preparing 100 parts of the dry powder; adding 13-15 parts of water; fully stirring through a mortar stirring machine to obtain the grouting material. The grouting material has the characteristics of being high in mobility, high in intensity, micro-expanded, and high in corrosion resistance; the bar can be firmly combined with the sleeve after grouting; moreover, the grouting material is high in durability.

Owner:LUOYANG INST OF SCI & TECH

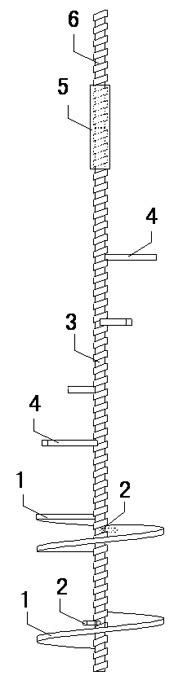

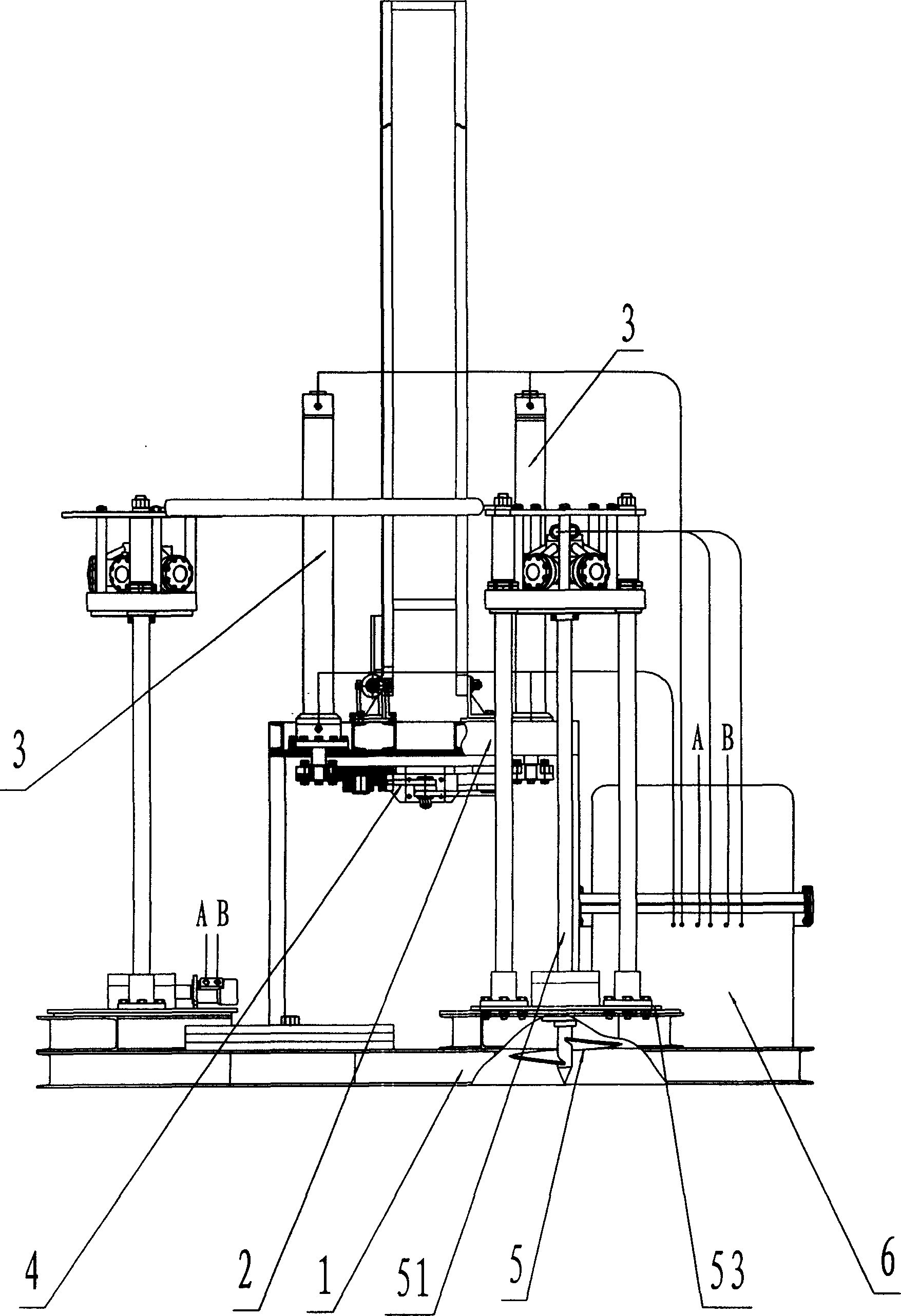

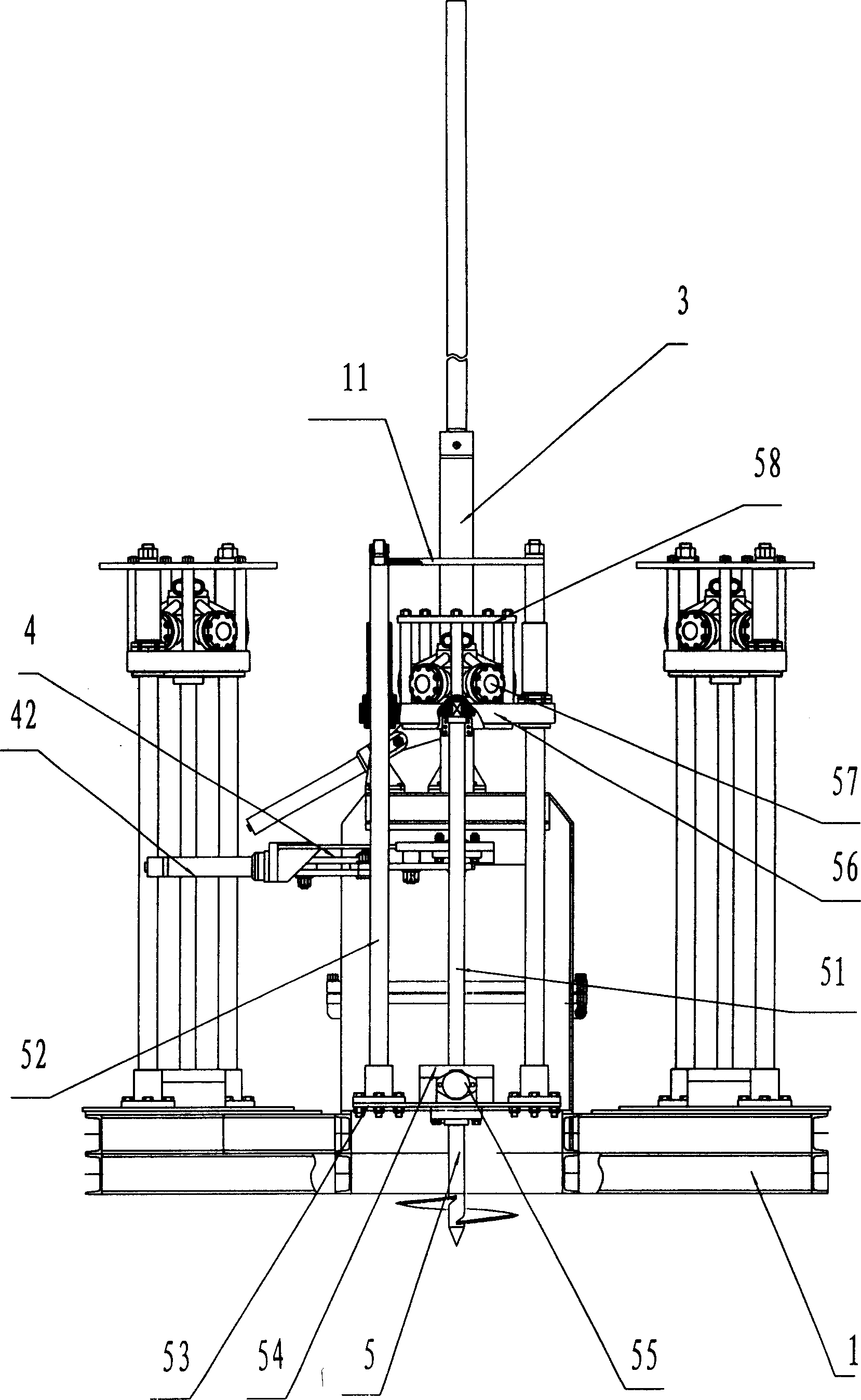

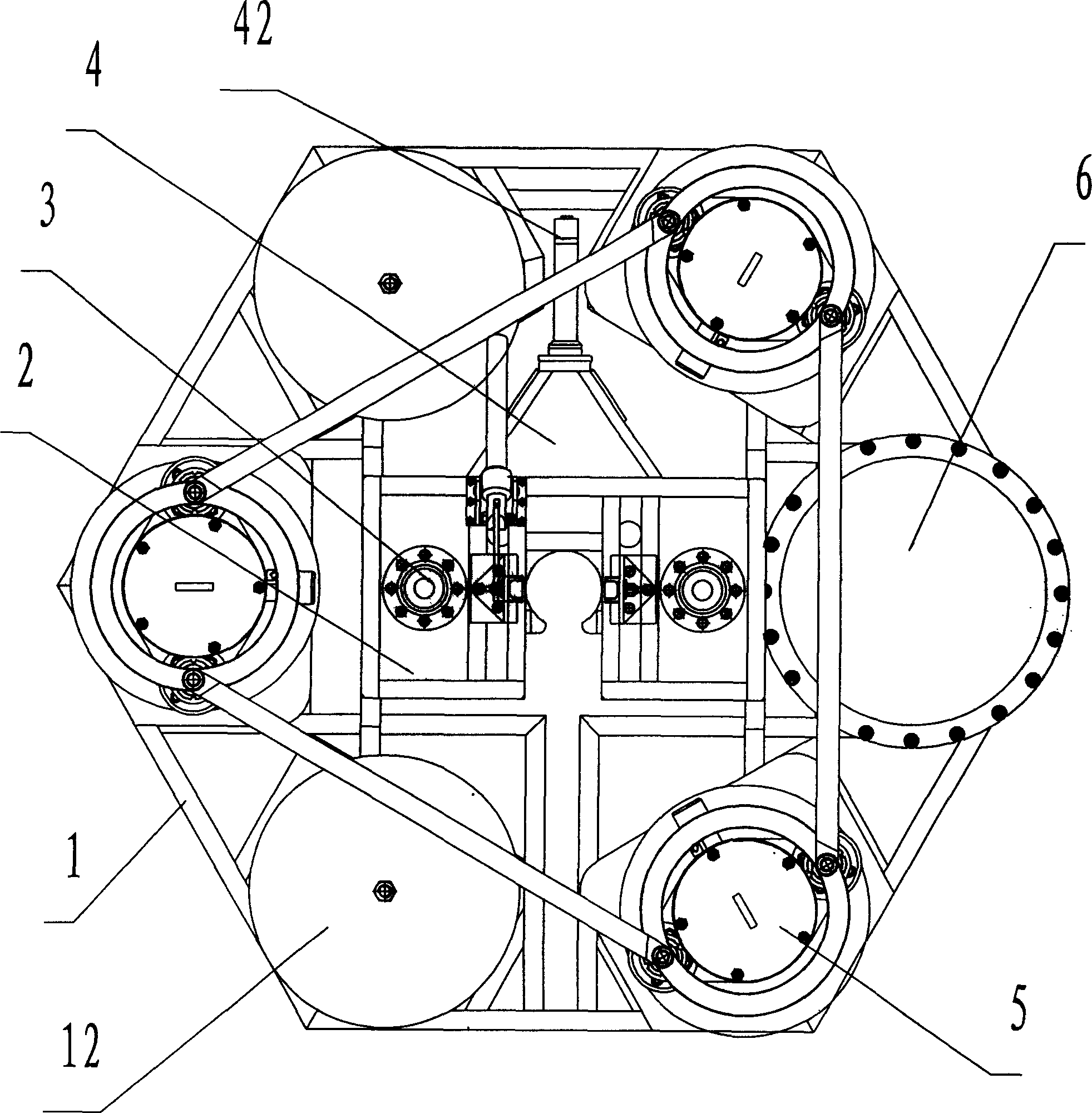

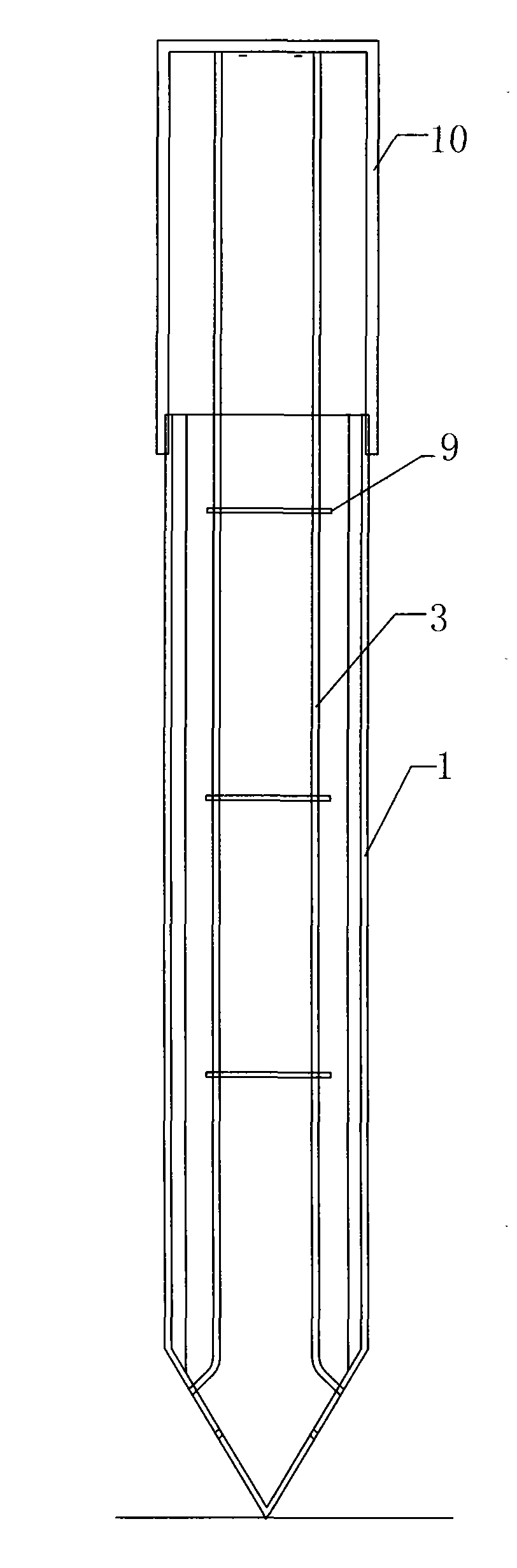

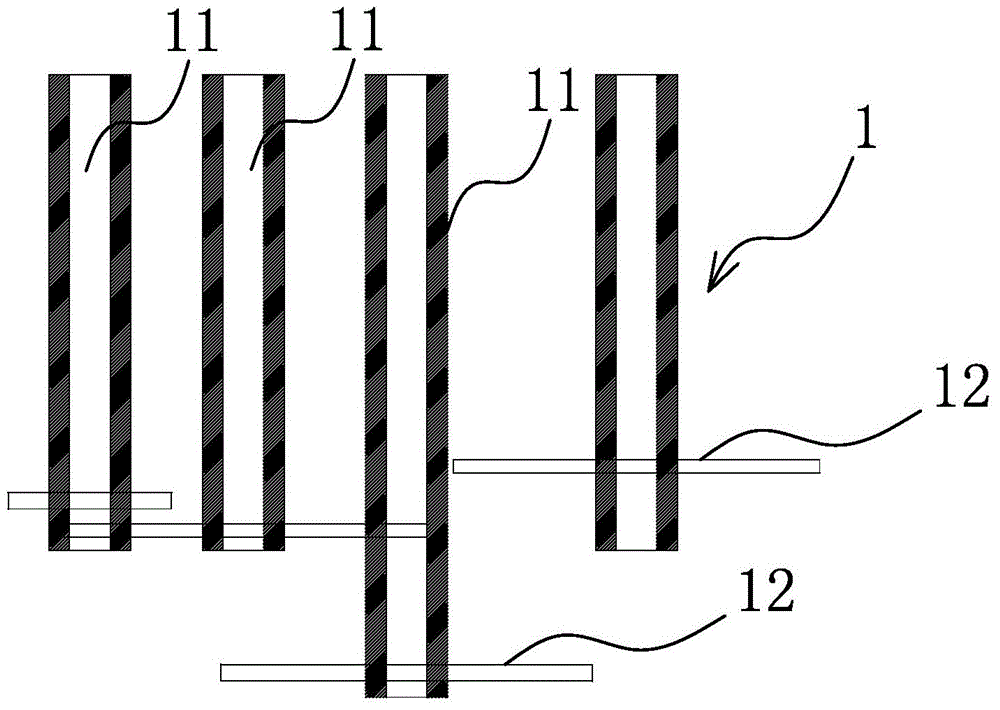

Drill rod distribution structure of cement soil mixing pile driver

ActiveCN105002896AStrong pull-out resistanceReduce drilling difficultyBorehole drivesBulkheads/pilesSoil mixingStructural engineering

The invention belongs to the technical field of construction equipment, and particularly relates to a drill rod distribution structure of a cement soil mixing pile driver. The drill rod distribution structure of the cement soil mixing pile driver solves the problem that an existing cement soil mixing pile driver is low in drilling efficiency and the like. The drill rod distribution structure of the cement soil mixing pile mixer comprises a drill rod assembly with at least three drill rod bodies which rotate in the circumferential direction and are arranged in the vertical direction; each drill rod body is provided with multiple stirring bodies; the projections of the center lines of the drill rod bodies in the drill rod assembly in the vertical direction are not located on the same straight line; the center lines of any three drill rod bodies, with the projections of the center lines in the vertical direction not located on the same straight line, of the drill rod assembly are sequentially connected to form a triangular structure; the drill rod bodies are arranged in the vertical direction in a one-to-one staggered mode. The drill rod distribution structure of the cement soil mixing pile driver has the advantages that stirring is uniform; a manufactured cement soil mixing pile is high in anti-pulling capacity; the drilling difficulty is low; drill holes in an approximate rectangle can be drilled at a time; machine movement or repeated drilling is not needed; the construction cost is saved; stability is good.

Owner:周兆弟

Construction method for concrete piles

The invention aims to provide a construction method for concrete piles. The concrete piles with both higher compression bearing capacity and higher pulling resistance can be rapidly, simply and conveniently formed through the method. The construction method comprises the following steps of: 1), sinking outer tubes to projected depth; 2), respectively putting inner pounders in the outer tubes and knocking out the outer tubes; 3), filling in dispersed stuffing batch by batch and squeezing; 4), filling in harsh concrete batch by batch and squeezing; 5), laying up reinforcement cages of which the bottom parts are respectively provided with main reinforcements; 6), respectively putting inner tubes in the reinforcement cages, and respectively putting inner pounders in the inner tubes; 7), filling in the harsh concrete in the reinforcement cages, and hammering the inner tubes to perform squeezing; 8), repeatedly filling and squeezing the harsh concrete to enable the main reinforcements at the bottom ends of the reinforcement cages to be scattered outwards to be built in the harsh concrete in the manner of wrapping; 9), pouring concrete into the outer tubes to pile heads; and 10), lifting out the outer tubes, and vibrating the concrete to be compact.

Owner:北京波森特岩土工程有限公司

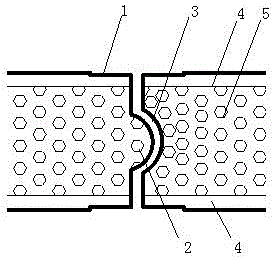

Lightweight partition wall

ActiveCN106431166AEasy constructionHigh smoothness of the outer surfaceWallsCeramicwareEngineeringWall plate

The invention provides a lightweight partition wall convenient quick to construct, comprising more than two lightweight partition wall plates spiced together; a pair of lateral sides of the lightweight partition wall plates are provided with connection structures respectively, to be specific, a first connection structure and a second connection structure, one of the first connection structure and the second connection structure has protrusions that protrude out of the lightweight partition wall plates, the other has cavities recessed into the lightweight partition wall plates, and a grout port is formed in the joint of one first connection structure or second connection structure in two connected lightweight partition wall plates and the other first connection structure or second connection structure; the ends of two surfaces of each lightweight partition wall plate, close to the lateral side, are provided with mounting grooves recessed in the surfaces.

Owner:山东墙盟建筑科技有限公司

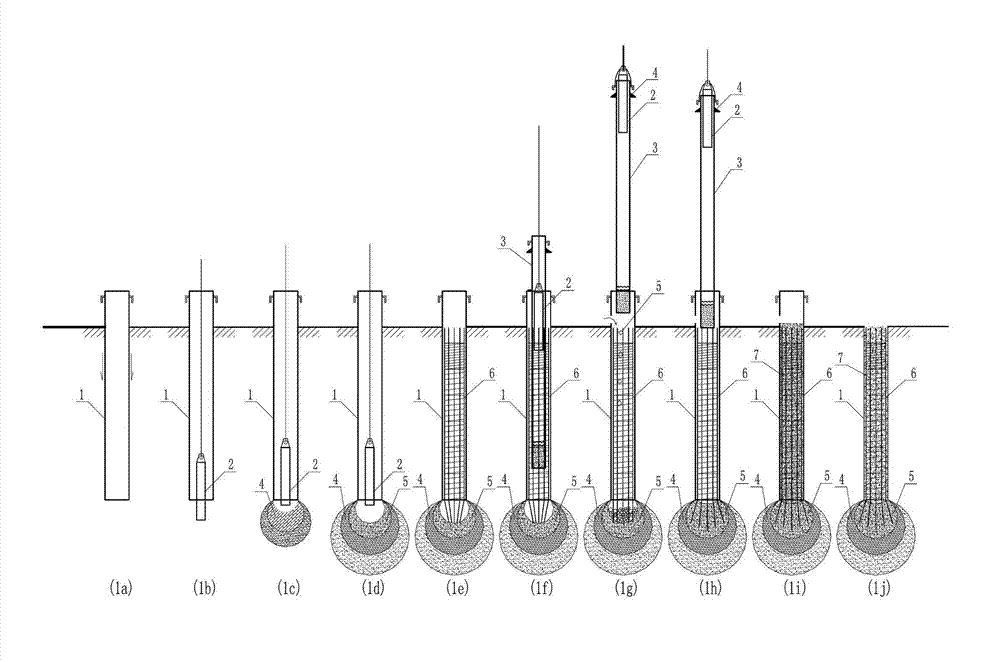

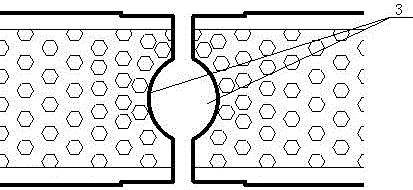

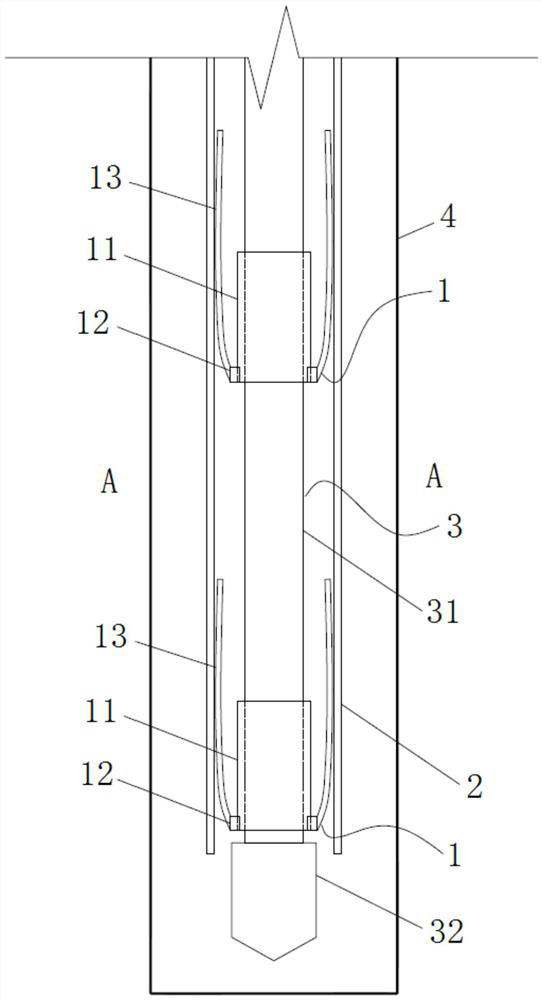

Spiral soil squeezing recompaction cast-in-place concrete pile, pile forming drill bit and construction method

PendingCN111005366AEmission reductionPromote environmental protectionDrill bitsBulkheads/pilesSoil scienceStructural engineering

The invention relates to a spiral soil squeezing recompaction cast-in-place concrete pile, a pile forming drill bit and a construction method. According to the adopted technical scheme, the spiral soil squeezing recompaction cast-in-place concrete pile comprises a primary soil squeezing pile section and a plurality of recompaction sections, the primary soil squeezing pile section is a concrete pile I, concrete piles II arranged inside the recompaction sections, the outer diameter of the concrete piles II is larger than that of the concrete pile I, the concrete piles II are wrapped by a recompaction layer formed by mixing rock soil and concrete, and the concrete pile I and the concrete piles II are of an integrated structure. The spiral soil squeezing recompaction cast-in-place concrete pile can carry out strengthened compaction on a rock soil layer with the large compressibility in the pile depth range, the pile bearing capacity is further improved, and energy conservation and emissionreduction are achieved.

Owner:刘守进 +1

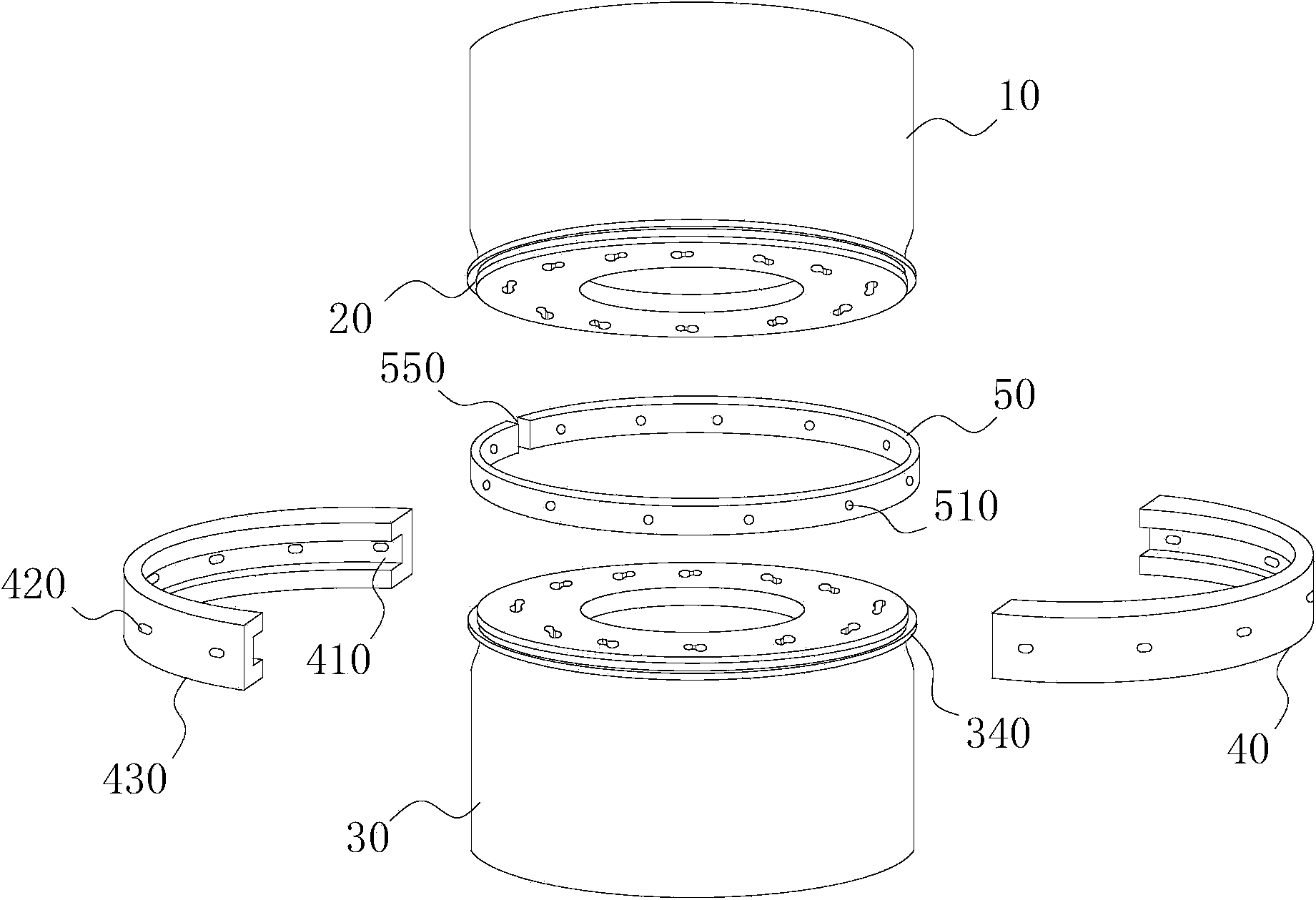

Pile connection structure and pile

The invention discloses a pile connection structure, which comprises an inner hoop element, an outer sheathing hoop, a first end plate and a second end plate, wherein the outer sheathing hoop is arranged on the outer surface of the inner hoop element to tightly hoop the inner hoop element; the end surfaces of the first end plate and the second end plate are connected; the inner hoop element is provided with a first trough; a clamping element is formed by the first end plate and the second end plate and is arranged in the first trough. The pile connection structure disclosed by the invention has strong anti-shearing, anti-pulling and anti-bending capability and strong resistance to corrosion. Meanwhile, the use time of electric welding is reduced, the technical requirement on a construction worker is lowered, and the labor intensity of the worker is lightened.

Owner:钟智谦 +1

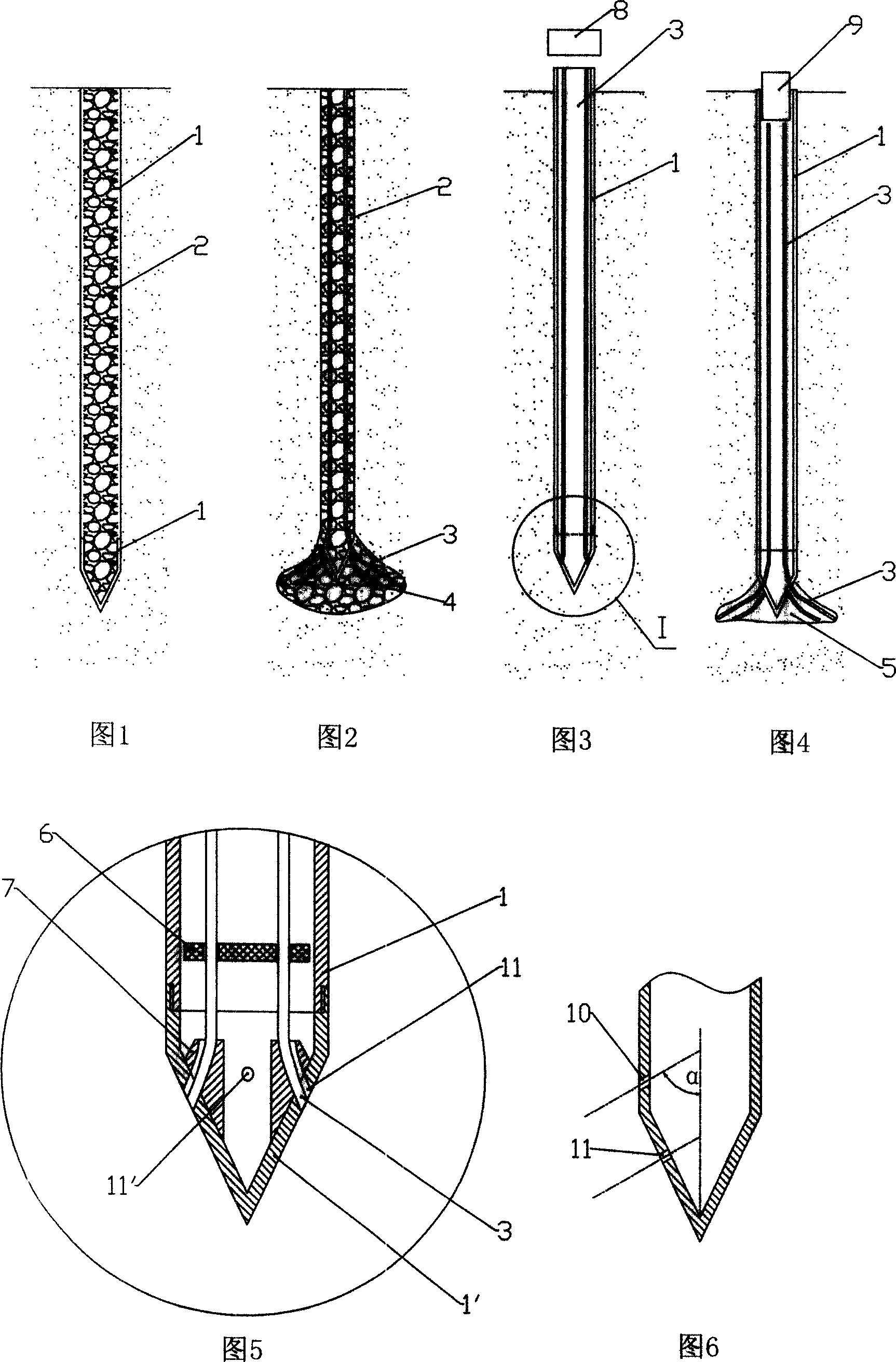

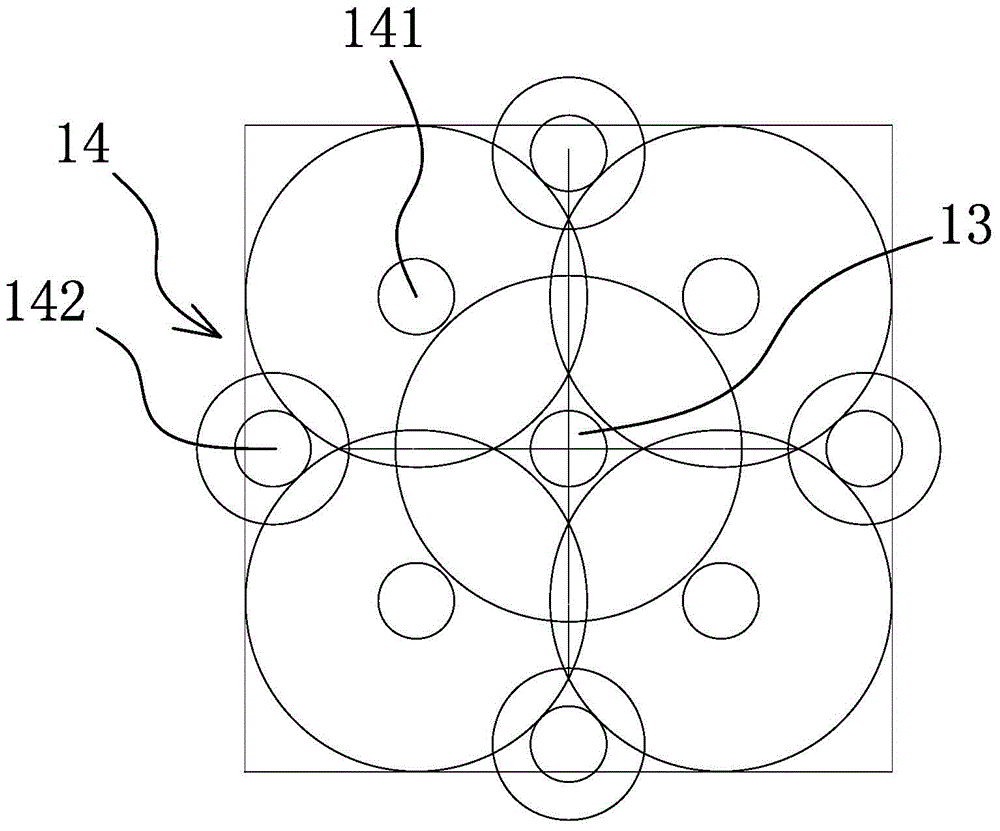

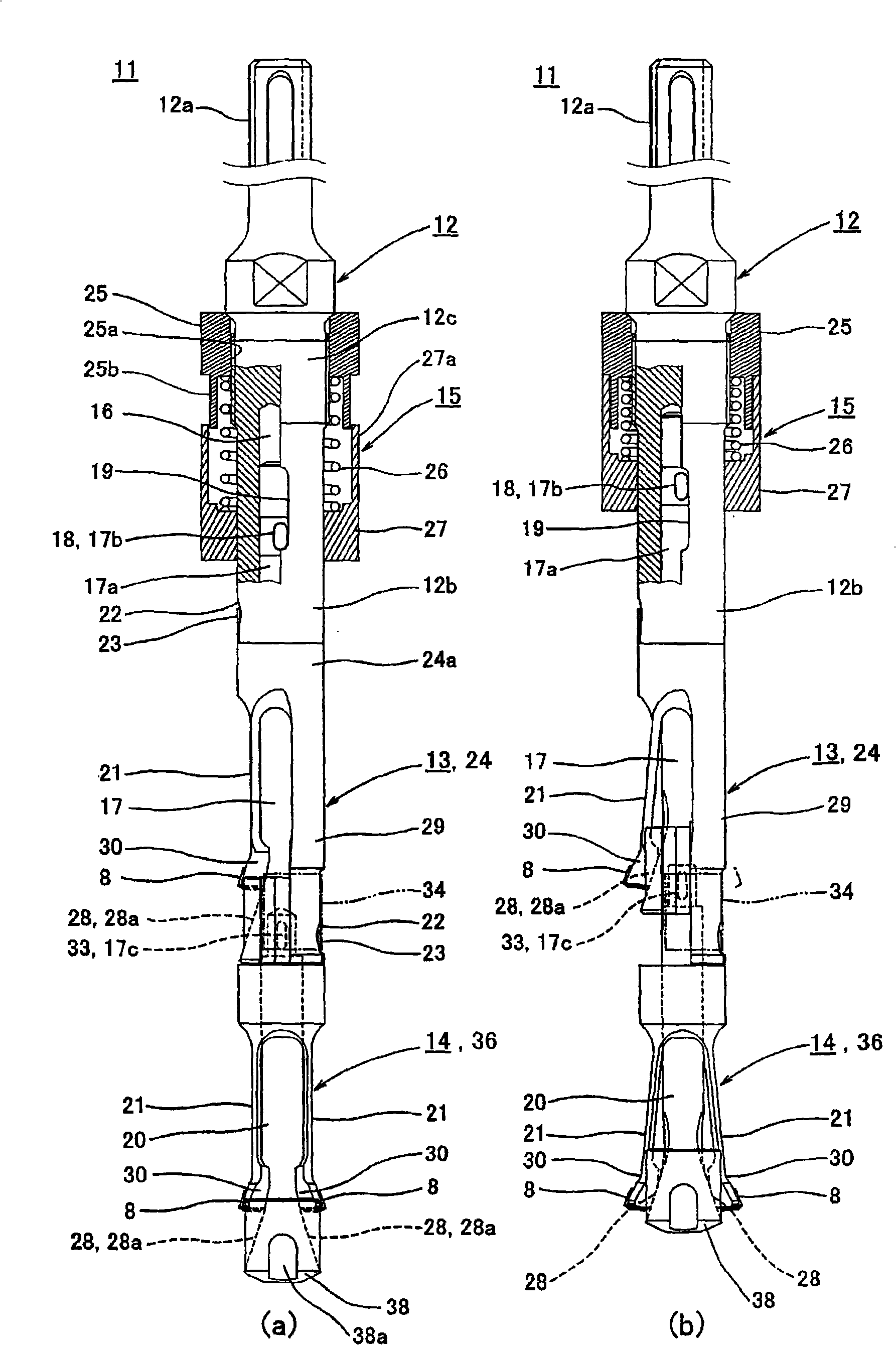

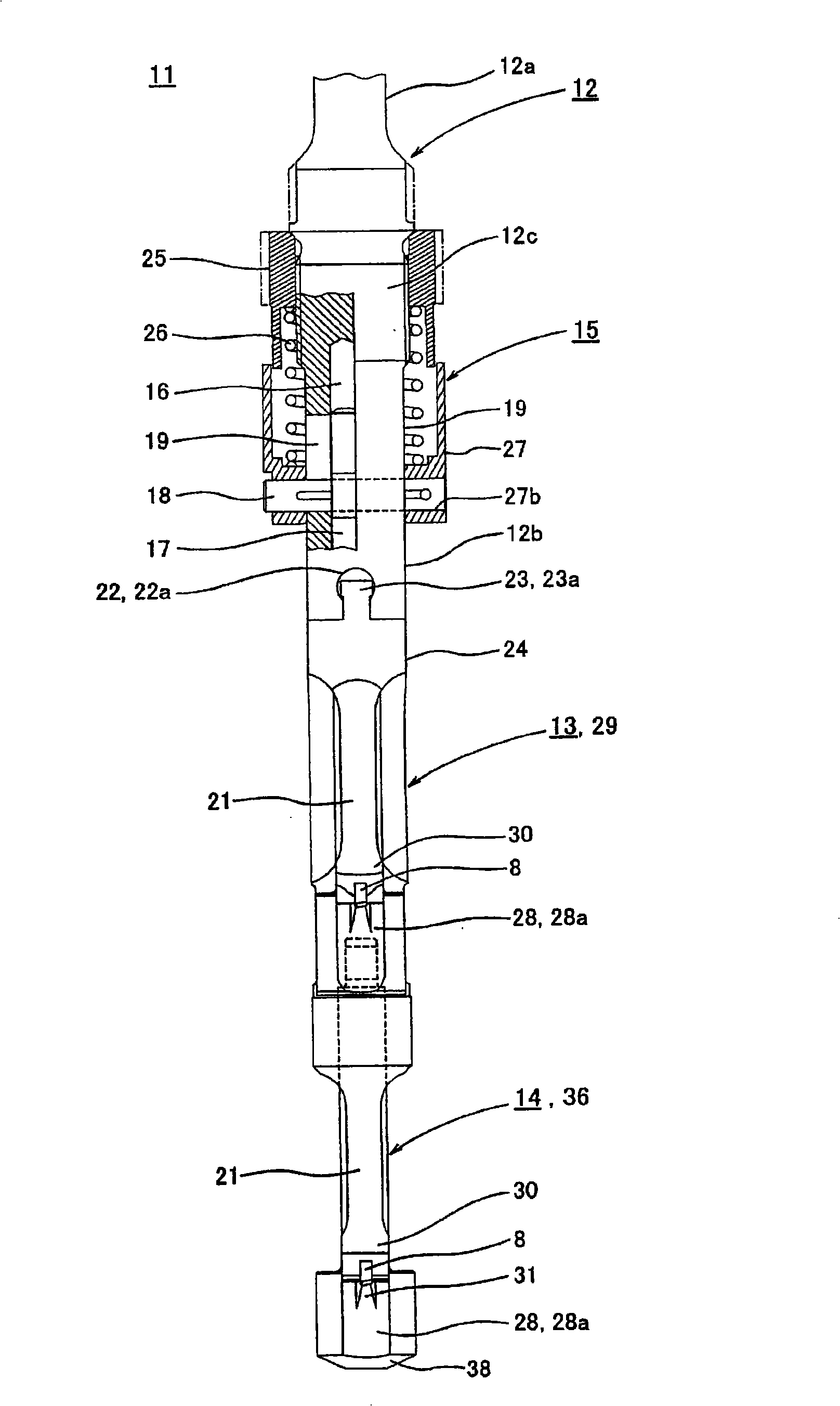

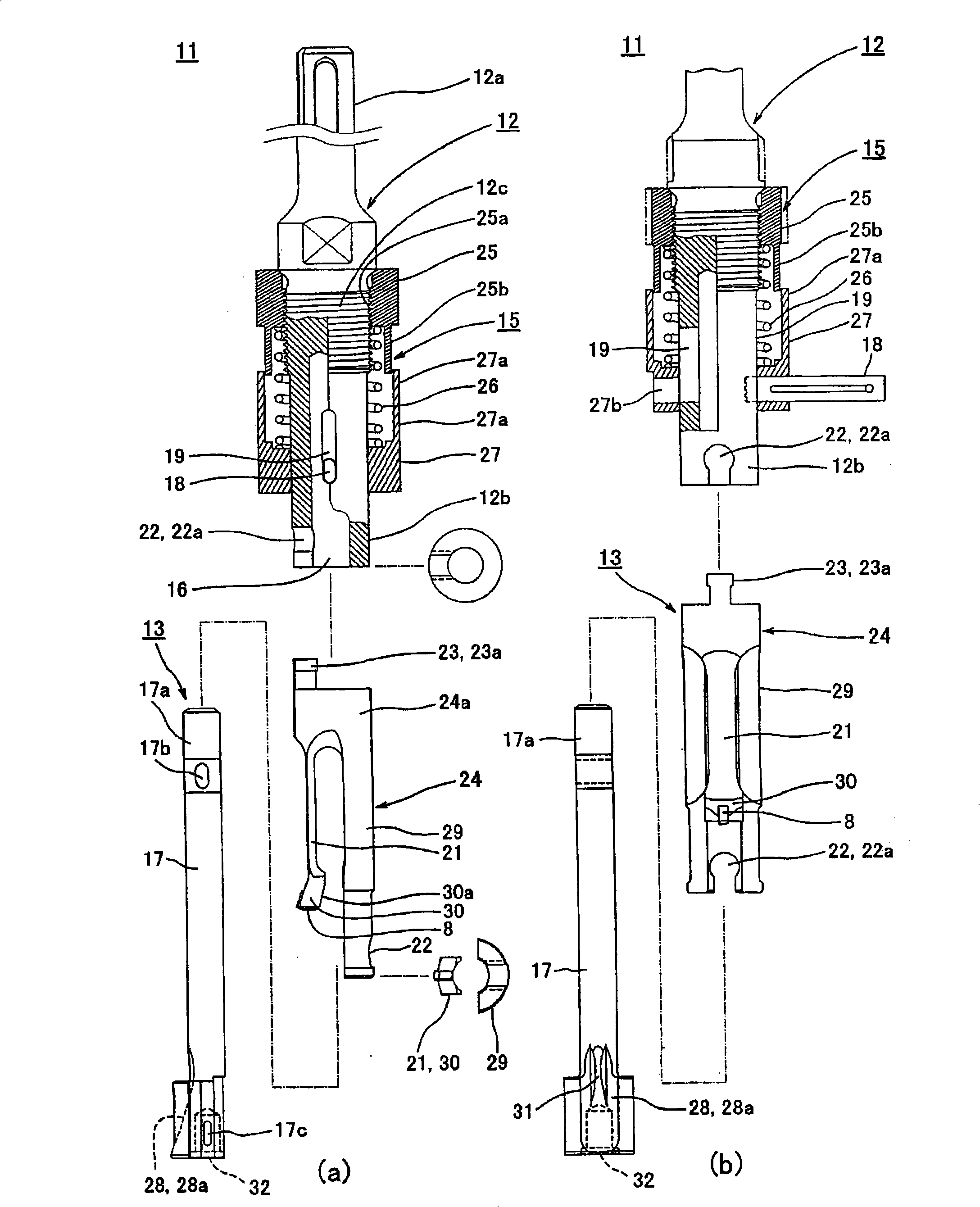

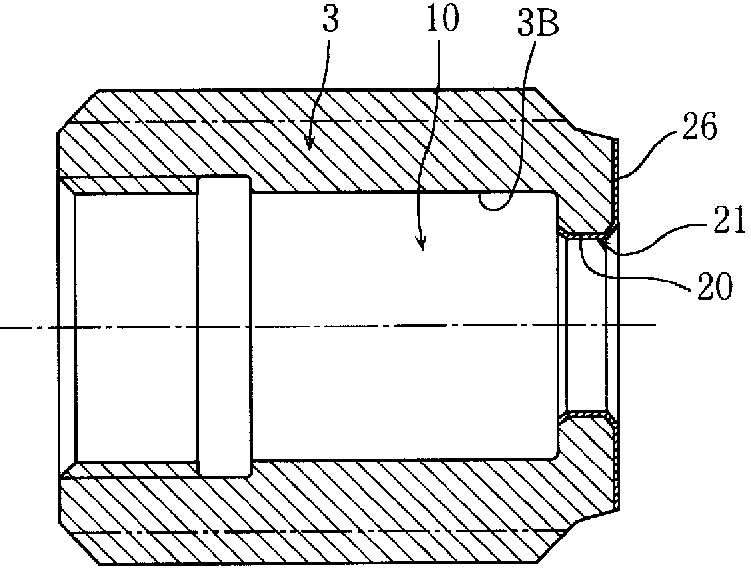

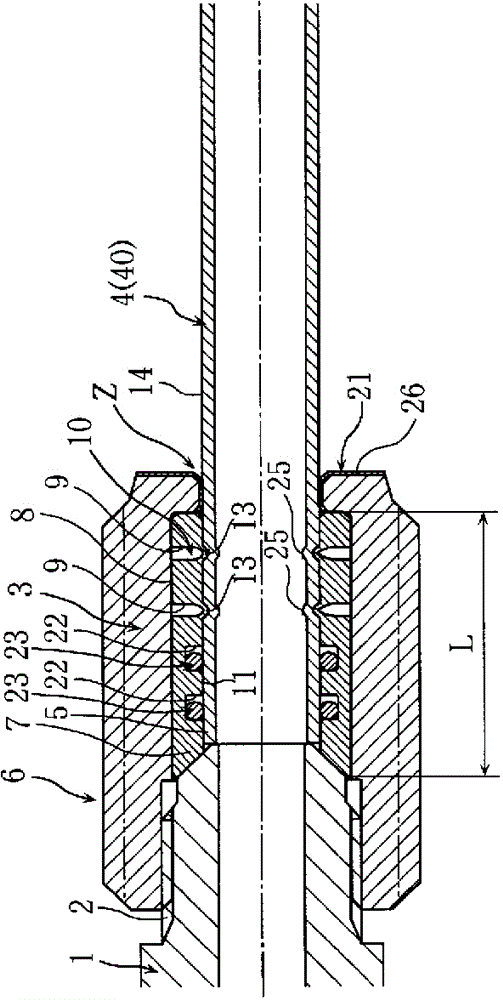

Diameter expanding groove cutting device and expanding/contracting mechanism tool

InactiveCN101292074ASave effortShorten the timeDrill bitsDrilling rodsEngineeringMechanical engineering

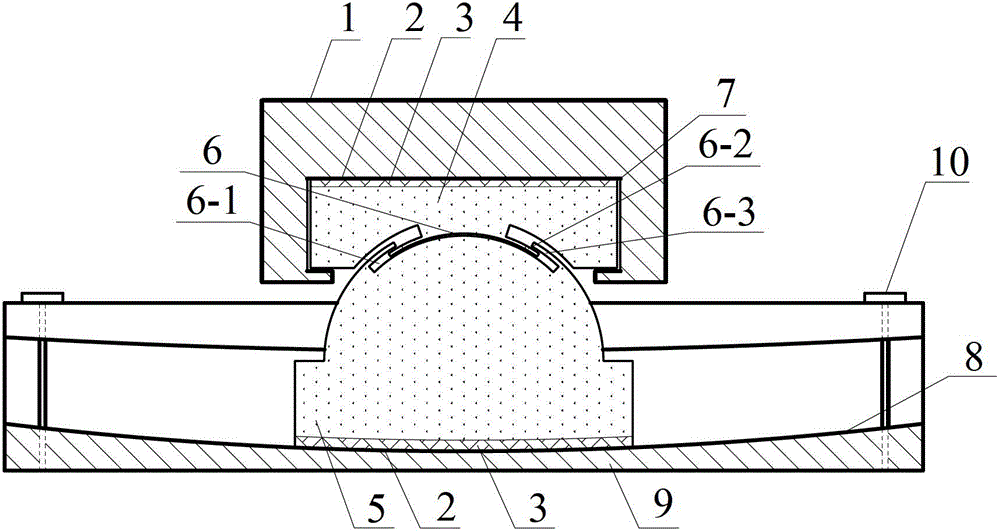

A diameter expanding groove cutting device capable of concurrently cutting a plurality of annular diameter expanding grooves in the inner peripheral wall of an anchor rough hole for anchor reinforcement implanting and an expanding / contracting mechanism tool used for it. The diameter expanding groove cutting device (11) comprises a body (12) having a shank (12a) coupled with a motorized apparatus, an intermediate expanding / contracting mechanism tool (13) provided along the axial direction and kept non-rotatable with respect to the body (12), and a tip-end-side expanding / contracting mechanism tool (14), the cutting device being free to expand or contract, with respective cutting blades (8), expanded and contracted in diameter by contracting and elongating actions, wherein, when rotation around the axis is imparted by the motorized apparatus, cutting blades (8), provided in respective expanding / contracting mechanism tools (13), (14) are used to be able to cut two annular diameter expanding grooves (3) in upper and lower two stages in the inner peripheral wall of the anchor rough hole (2) for anchor reinforcement implanting.

Owner:MIYANAGA KK

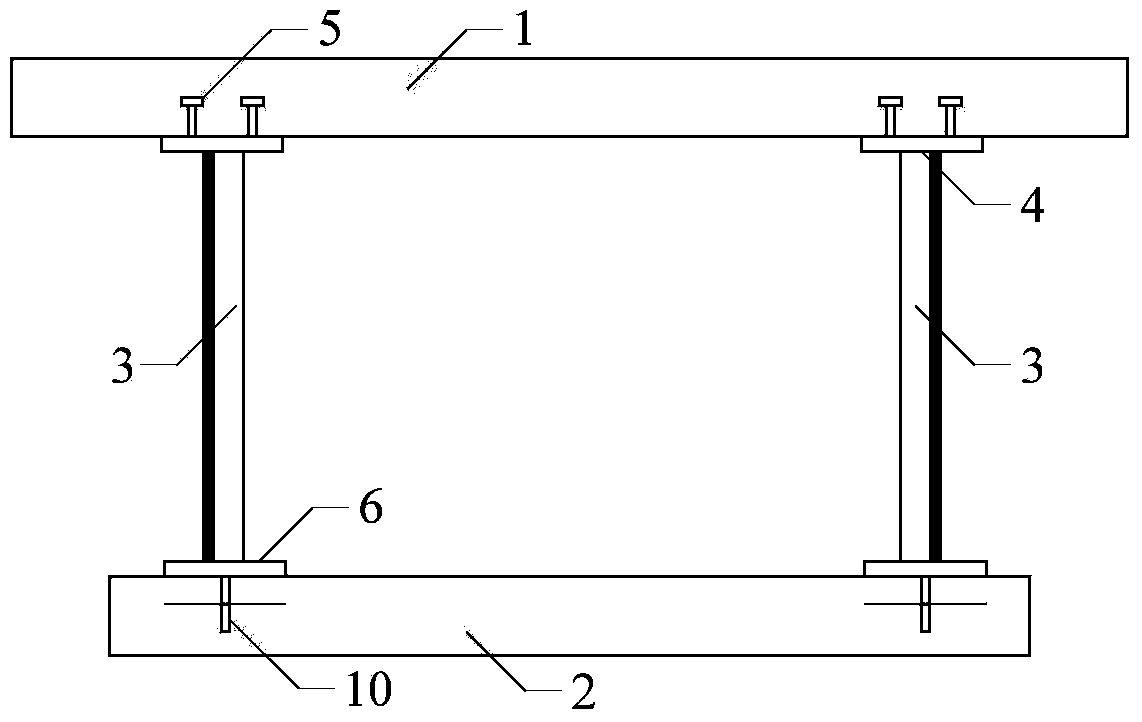

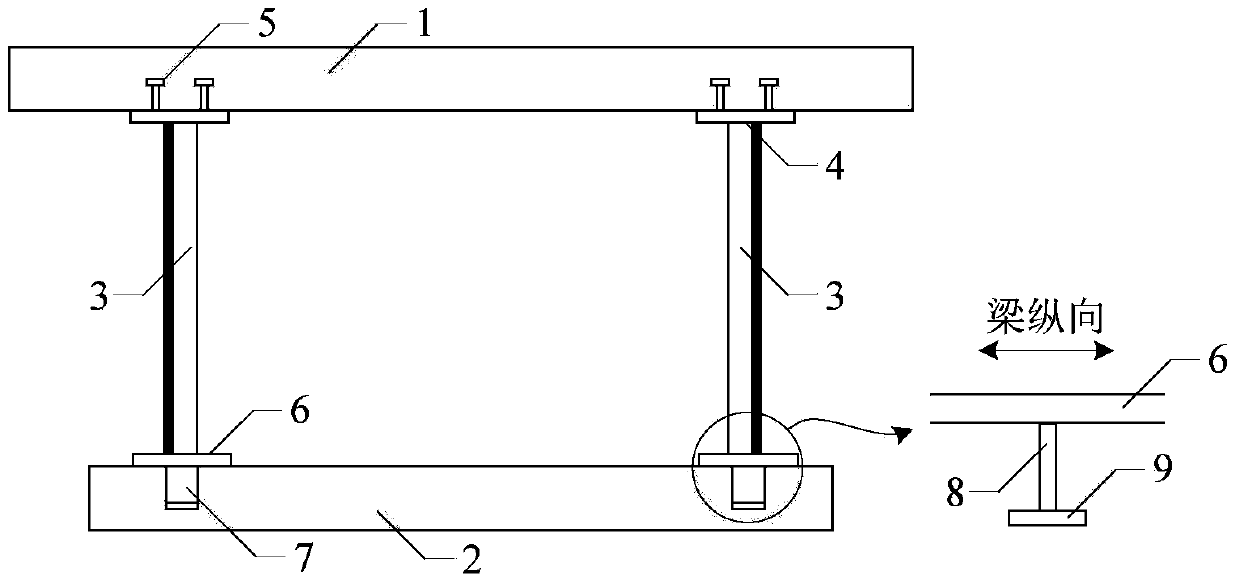

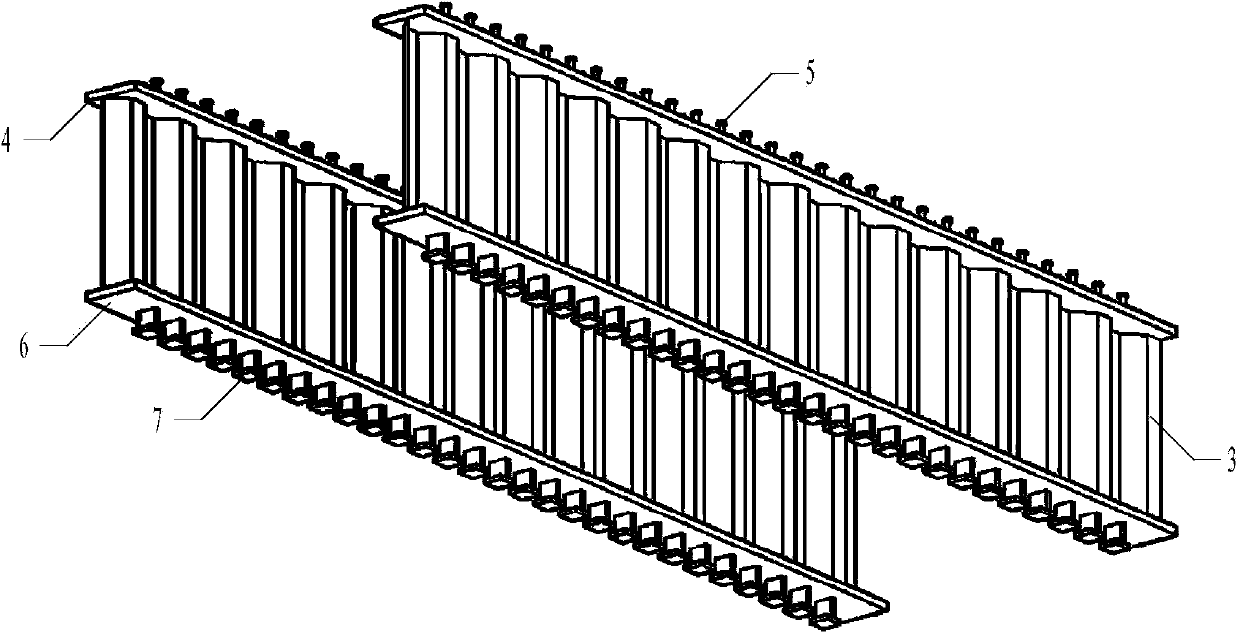

Lower flange anti-pulling composite box girder with corrugated steel webs and construction method

InactiveCN103741584AImprove structural performanceGood for long termBridge erection/assemblySheet steelRebar

The invention relates to a lower flange anti-pulling composite box girder with corrugated steel webs and a construction method of the composite box girder, and belongs to the technical field of bridge structures. The composite box girder comprises an upper flange concrete slab, a lower flange concrete slab, the corrugated steel webs, upper flange steel plates, lower flange steel plates and connectors, the corrugated steel webs are connected with the upper flange steel plates and the lower flange steel plates, the lower flange concrete slab is integrated with the lower flange steel plates through the connectors welded on the lower portions of the lower flange steel plates, and the upper flange concrete slab is integrated with the upper flange steel plates through the stud connectors welded on the upper portions of the upper flange steel plates. The composite box girder is characterized in that the connectors on the lower portions of the lower flange steel plates are T-shaped connectors comprising T-shaped connector webs and T-shaped connector top plates. Without increasing steel dosage, the composite box girder solves the problems that reinforcing meshes in a traditional corrugated steel web lower flange concrete slab with PBL connectors, particularly, transverse reinforcements are difficultly constructed, and construction quality is difficultly ensured.

Owner:TSINGHUA UNIV

Pile connecting structure and pile

ActiveCN103669335AImprove shear resistanceStrong bending resistanceBulkheads/pilesEngineeringSoldering

The invention discloses a pile connecting structure and a pile. The pile connecting structure comprises an outer hoop part, a first end plate and a second end plate, wherein the end face of the first end plate is connected with the end face of the second end plate, the outer side face of the first end plate is provided with a first protruding shoulder, the outer side face of the second end plate is provided with a second protruding shoulder, a first clamping groove is formed between the first protruding shoulder and the second protruding shoulder, an inner hoop part is arranged in the first clamping groove in a clamped mode, the first protruding shoulder, the inner hoop part and the second protruding shoulder form a clamping part, the outer hoop part is provided with a second clamping groove, and the clamping part is arranged in the second clamping groove in a clamped mode. The pile connecting structure and the pile are high in anti-shearing, anti-drawing, anti-bending and anticorrosive capacity; meanwhile, use frequency of electric soldering is reduced, technical requirements for construction workers are reduced, and labor intensity of the workers is lightened.

Owner:钟智谦 +1

Slope reinforcement device used for municipal construction engineering

ActiveCN107326915ASimple structureIncrease prestressExcavationsBulkheads/pilesArchitectural engineeringBuilding construction

The invention provides a slope reinforcement device used for municipal construction engineering. The slope reinforcement device used for municipal construction engineering comprises a concrete frame protective plate and a protective layer, wherein the concrete frame protective plate is arranged on a slope. A plurality of hollowed-out areas are formed in the protective plate and used for planting green plants. The protective layer is a non-woven fabric protective layer and is arranged on the surface of the protective plate. The protective plate is fixed to the slope through an anchor rod. The anchor rod comprises an anchor ribbed rod body, a reinforcement rod head and a plurality of force hook heads, wherein the top end of the anchor ribbed rod body is fixedly connected with the reinforcement rod head, and the force hook heads are welded to the two sides of the reinforcement rod head correspondingly; and the anchor ribbed rod body is made of a steel stranded wire. According to the slope reinforcement device used for municipal construction engineering, the structure of the anchor rod is optimized, and thus the anchor rod is more suitable for shallow fixing. The force hook heads are obliquely welded to the reinforcement rod head, welded to the two sides of the reinforcement rod head in opposite directions correspondingly and obliquely arranged at the inclination angle of 30-45 degrees so that the prestress force applied to the anchor ribbed rod body can be increased easily, the force hook heads can be hooked in the slope more powerfully, and excellent pulling resistance is achieved.

Owner:云林建设集团有限公司

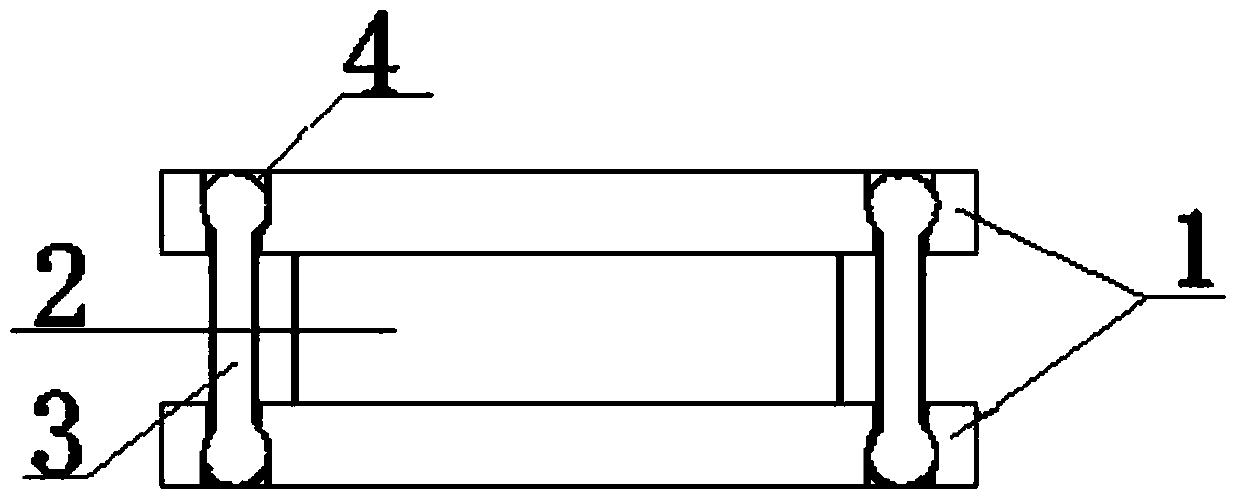

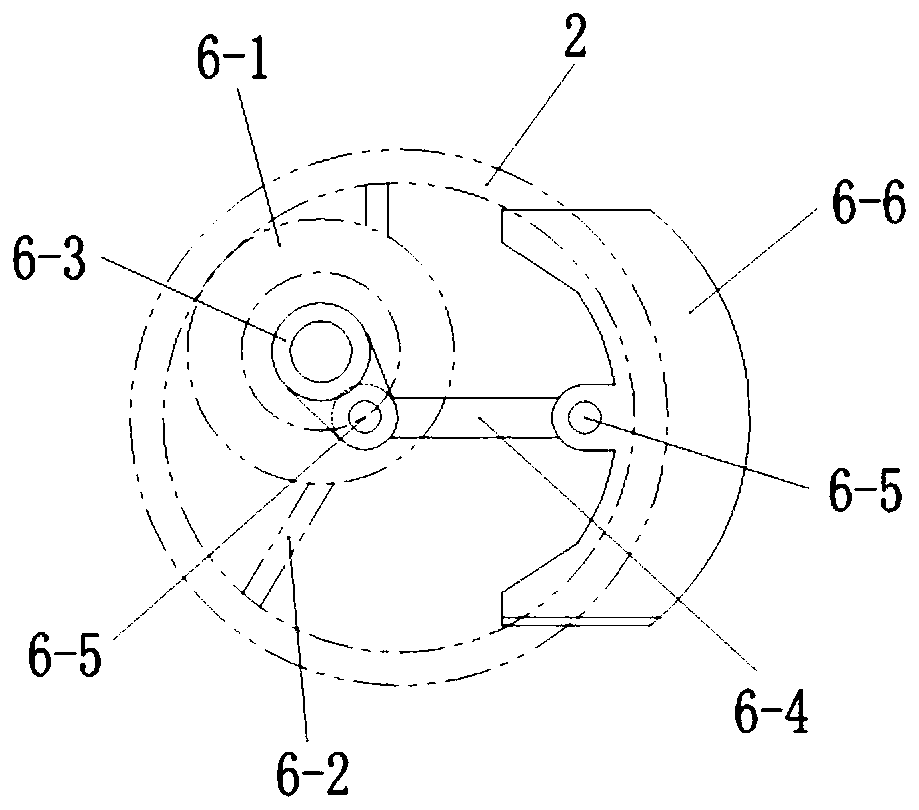

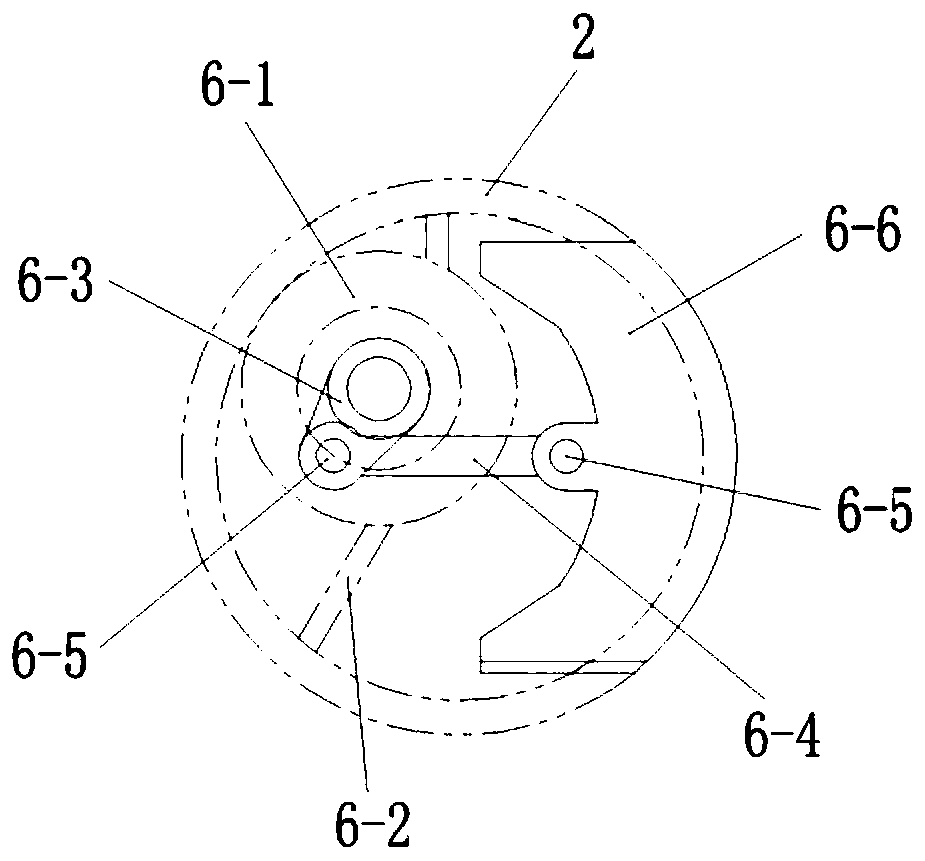

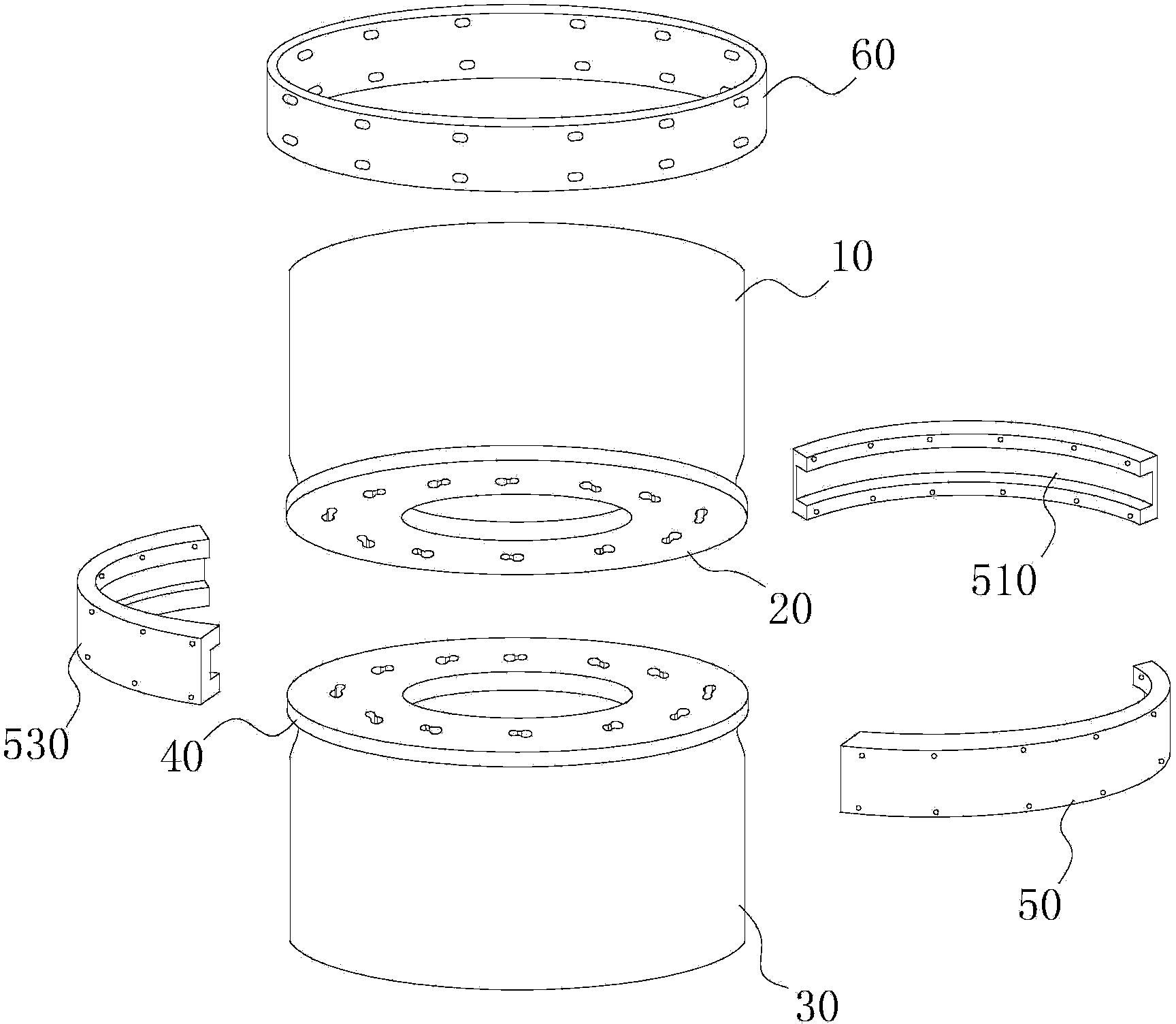

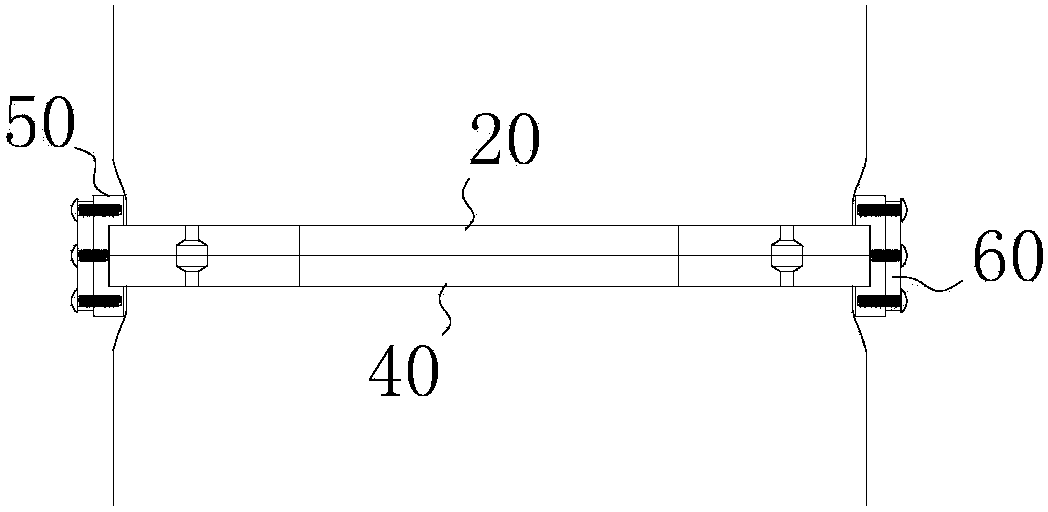

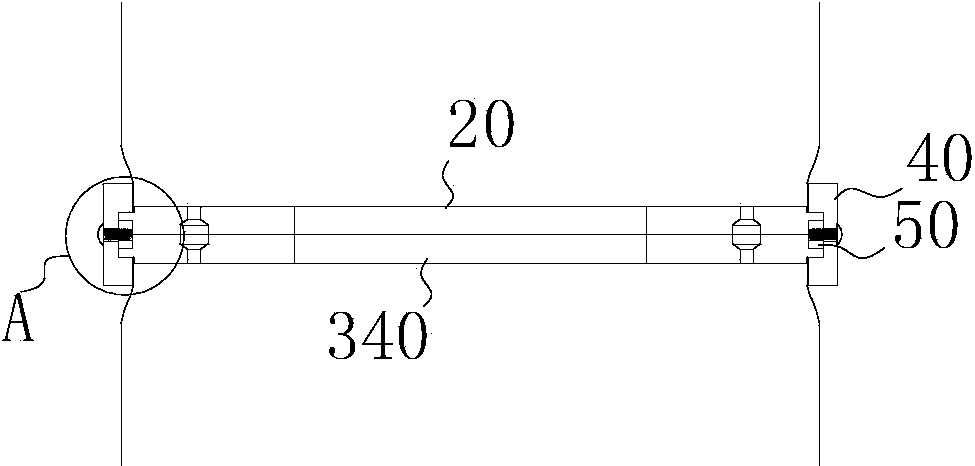

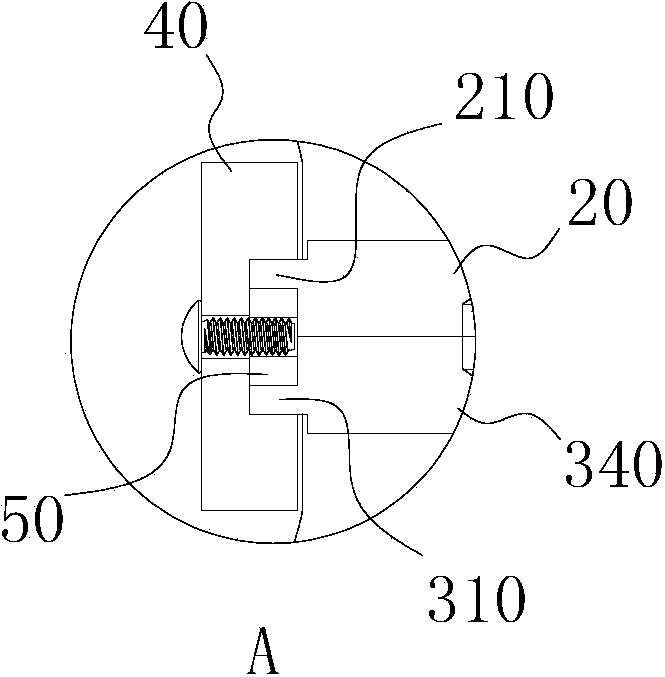

Bi-directional sliding anti-pulling ball type bridge bearing

PendingCN109112957AExtended service lifeEconomical and practicalBridge structural detailsEngineering

The invention discloses a bi-directional sliding anti-pulling ball type bridge bearing, which comprises a support top plate, a ball crown liner, a middle bracket and a lower support plate which are slidably connected from top to bottom. A pull-out member is added between the top plate of the support and the middle bracket, and the upper end of the pull-up member is slidably connected to the planeof the top plate of the support, and a gap is retained between the pull-out member and the rectangular block I of the support top plate, and the pull-out member is retained. The lower end is rotatablyconnected with the upper end of the middle bracket, and the lower end of the middle bracket is slidably connected with the lower support plate plane, and the middle bracket and the lower bracket plate rectangular stopper II retain a certain gap. The design can realize the sliding of the bearing in the transverse direction and along the bridge direction, and the rotation of the bearing around themain and auxiliary directions, and the bearing has good anti-pulling ability, which is suitable for various bridges in special circumstances, and has the advantages of long service life, higher safety, strong economic practicability and high popularization.

Owner:GUIZHOU TRANSPORTATION PLANNING SURVEY & DESIGN ACADEME

Uplift pile

InactiveCN105133599AStrong pull-out resistanceImprove pullout resistanceBulkheads/pilesStructural engineeringSoil horizon

The invention belongs to the technical field of buildings and relates to an uplift pile. The uplift pile comprises a pile body which is formed by connecting a plurality of pile main bodies with the sectional areas gradually increased from top to bottom, and a step part is formed on the joint of every two adjacent pile main bodies. According to the uplift pile, on the basis of the principle that the pulling property of the pile bodies is sequentially enhanced from the soil layer superficial position to the deep position, the pile bodies which are gradually increased are arranged to form the step parts, the pulling resistance can be good in each soil layer, and the pulling property is substantially improved.

Owner:周兆弟

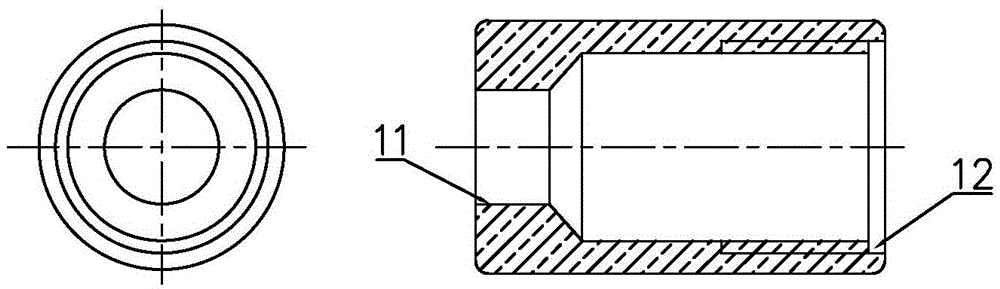

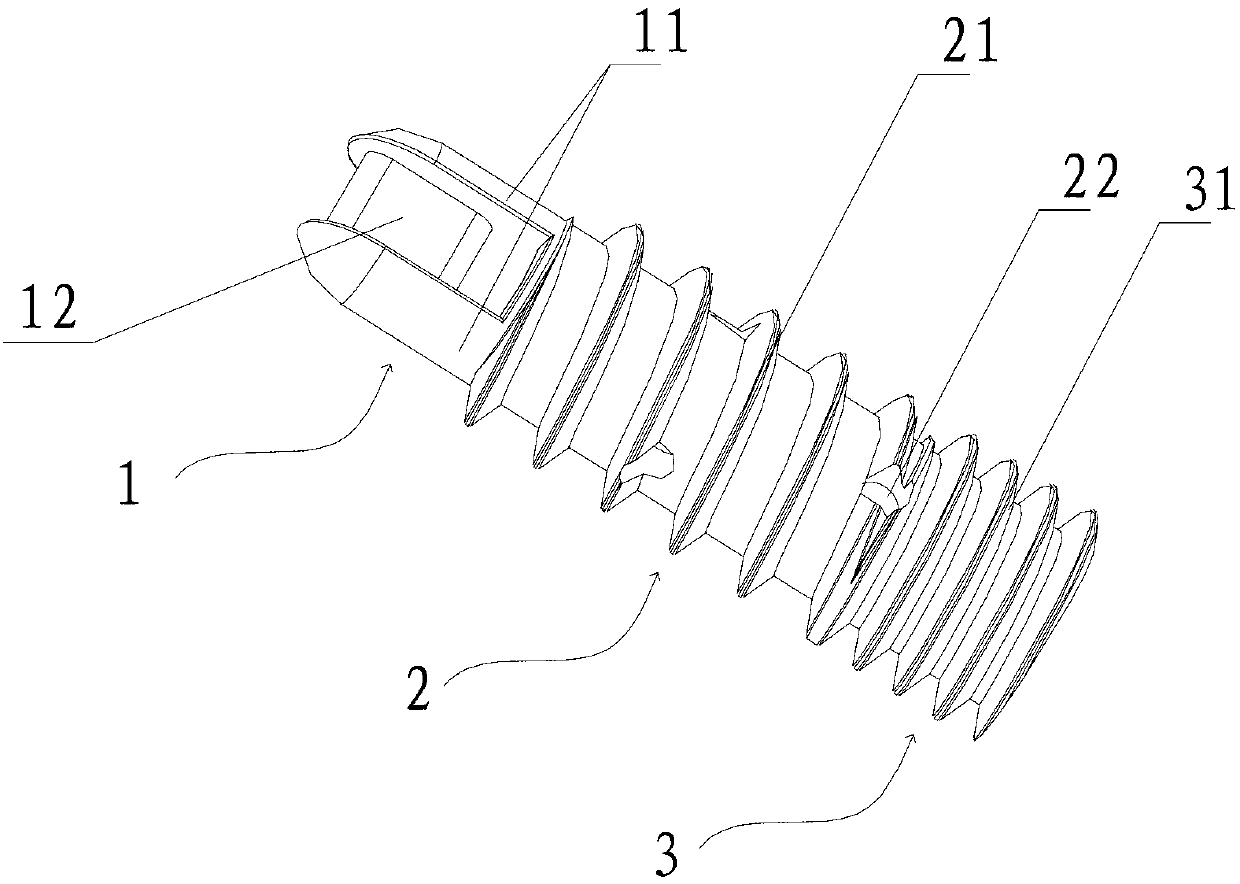

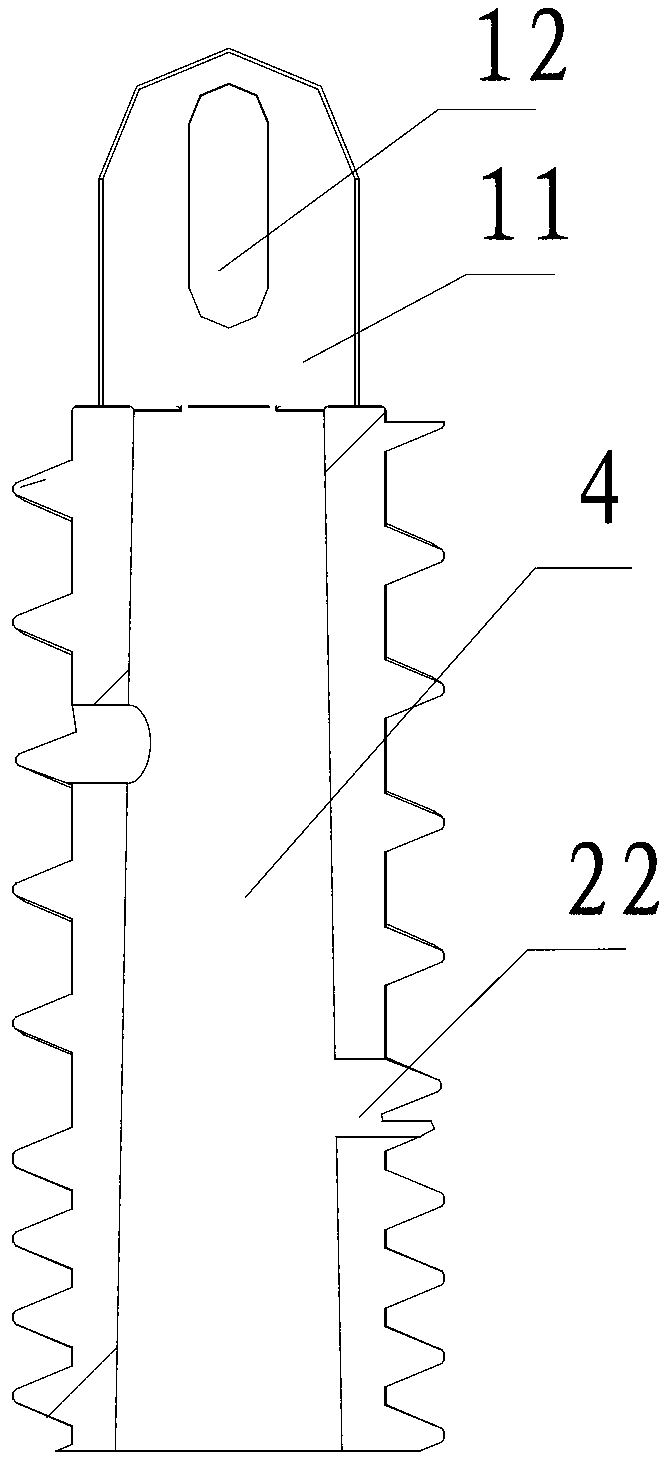

Ligament fastening screw

InactiveCN103271762AStrong pull-out resistanceImprove pullout resistanceFastenersBone ingrowthBiomedical engineering

A ligament fastening screw comprises a screw head (1), a screw body (2) and a screw tail (3), wherein the screw head (1) comprises two baffles (11) which are symmetrically arranged and a transverse plate (12) located between the two baffles, the screw body (2) is provided with deep widening threads (21) and an open pore (22), the screw tail (3) is provided with shallow dense threads (31), and a hollow cavity (4) penetrates through the screw head (1), the screw body (2) and the screw tail (3) to form a channel. The ligament fastening screw overcomes the defects that an existing ligament fastening screw is weak in pullout force, prone to loosening due to inclined pulling and not good in bone bone ingrowth, and has the advantages of being strong in pullout force, not prone to loosening, and good in bone ingrowth state.

Owner:武汉爱思唯科技有限公司

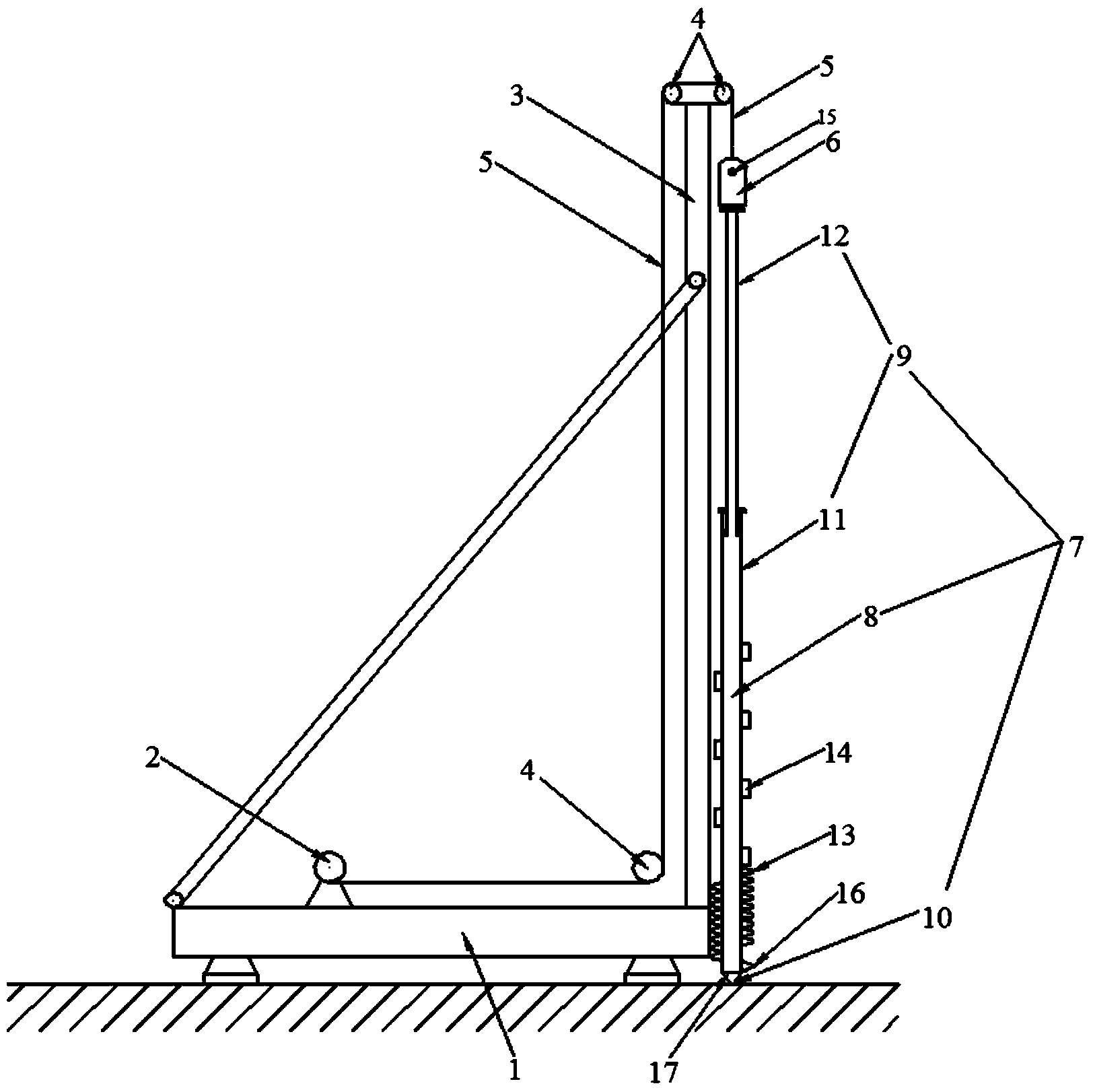

Full-thread pile pouring machine extruding soil body and pile-forming construction method thereof

InactiveCN103526746AImprove bearing capacityStrong pull-out resistanceDrilling rodsDrilling casingsDrill bitDriving mode

The invention provides a full-thread pile pouring machine extruding a soil body and a pile-forming construction method of the full-thread pile pouring machine extruding the soil body. A vertical frame and a winch are arranged on a base, a motor device is arranged on a guide rail of the vertical frame, pulleys are arranged at the top end and the bottom end of the vertical frame, one end of a hauling rope is fixedly connected with the winch, the middle section of the hauling rope is hung on the pulleys, and the other end of the hauling rope is fixedly connected with the top end of the motor device. A drill rod comprises a drill rod shaft and a drill bit, wherein the drill rod shaft is provided with a hollow concrete delivering cavity, and the drill bit is connected to the lower end of the drill rod shaft. A spiral drilling piece is arranged on the outer wall of the lower section of the drill rod shaft in a winding mode, multiple soil scraping pieces are arranged on the outer wall of the middle section in a winding mode and used for scraping, pressing and flatly extruding the inner wall of a pile hole, the motor device is provided with a motor frame and a machine core which is connected with the drill rod in a driving mode, the motor frame is connected with the guide rail of the vertical frame in a sliding mode, and a detachable conical head is connected to the position, adjacent to the drill bit, of the outer wall of the lower section of the drill rod shaft. Full-thread hole forming and pile forming can be achieved, the principle is simple and easy to understand, operation processes are convenient and rapid to perform, and the construction method has the obvious advantage of concrete spraying instantly in comparison with an existing thread pile.

Owner:王志耸

Umbrella-shaped anti-floating anchor rod device and using method

PendingCN113202092AImprove binding abilityGood effectProtective foundationBulkheads/pilesEngineeringStructural engineering

The invention discloses an umbrella-shaped anti-floating anchor rod device. The umbrella-shaped anti-floating anchor rod device comprises an umbrella-shaped anchor sleeve, an outer cylinder and an anchor rod; the umbrella-shaped anchor sleeve sleeves the outer side of the anchor rod; the outer cylinder is located on the periphery of the anchor rod; the umbrella-shaped anchor sleeve is of a telescopic structure, when the umbrella-shaped anchor sleeve is in a contraction state, the umbrella-shaped anchor sleeve is positioned on the inner side of the outer cylinder, and when the umbrella-shaped anchor sleeve is in a stretching state, the umbrella-shaped anchor sleeve extends out of an anchor hole. The defect that in the prior art, the anchoring effect of an anchor rod system is suddenly reduced and even fails when the anchor rod system loosens along with the change of a stratum is overcome; the umbrella-shaped anti-floating anchor rod device has the advantages that the stress condition between the anchor rod system and the stratum is changed, the anchor rod system and an existing stratum are connected into a whole, and the anti-pulling effect is enhanced. The invention further discloses a using method of the umbrella-shaped anti-floating anchor rod device.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

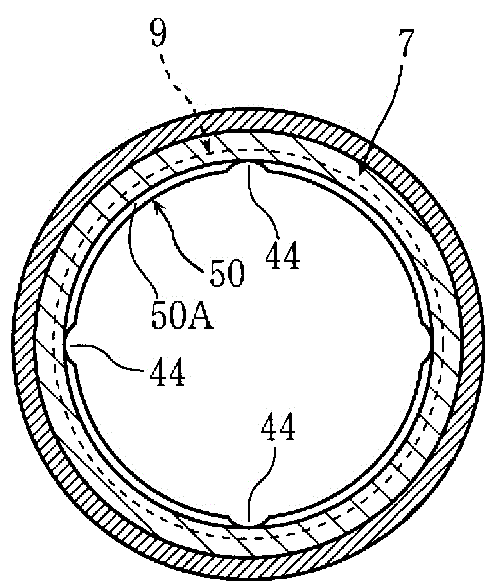

Pipe joint structure

To provide a pipe joint construction with which swift and strong connection is possible without flare work on an end portion when a pipe composed of aluminum, a pipe joint construction provided with a joint main body 1 with a male screw and a cap nut 3 screwed to a male screw 2 of the joint main body 1 to connect an aluminum pipe 4, has a cylindrical compressed deformation sleeve 7, stored in an inner storing space 10 of the cap nut 3 and having a concave peripheral groove 9 on a peripheral face 8, in which a bottom thin wall portion 13 of concave groove, receiving compressing force F in axial direction from the joint main body 1 and the cap nut 3 when the cap nut 3 and the male screw 2 of the joint main body are screwed, is plastically deformed in a radial inner direction to bite into a peripheral face 14 of an inserted aluminum pipe 4 for stopping the aluminum pipe 4.

Owner:INOUE SUDARE +1

Forming method of pressing-resistant plucking-resistant pile base

InactiveCN100585092CImprove stress resistanceStrong pull-out resistanceBulkheads/pilesAcute angleEngineering

The invention relates to an anti-pressure and anti-floating pile, comprising a cylinder pile body constituted by reinforced steel bar and concrete, characterized in that the reinforced steel expands outside at the bottom of pile body so as to form a big capitate chassis at the bottom of pile body, whose dimension in radial direction is larger than the pile body. The invention also discloses a pile method that multiple via holes are machined on the pipe wall at the lower end of steel pipe mold and the angle between the axes of via hole and the axes of steel pipe mold is acute angle; multiple reinforced steel bars are set in the steel pipe mold and ends of reinforced steel bars insert into via holes at the lower end of steel pipe mould; steel pipe mold and reinforced steel bars are driven into the foundation to the presetting depth together; Then the steel pipe mold is not driven and reinforced steel bars are driven to protrude with a certain length in outer oblique direction furthermore; and then steep pipe mold is drawn out and concrete is filled in so that concrete is used to fill in the space under steel pipe mold from the bottom of steel pipe mold; reinforced steel bars out of steel pipe mold are covered; finally the pile with larger bottom is formed. The formation is convenience. The pile structure can increase the anti-pressure and anti-floating capacity.

Owner:徐国彬

Suture anchor and handle thereof

ActiveCN105877798AReduce the difficulty of operationRelieve painSuture equipmentsStaplesEngineeringBones fixation

The invention relates to a suture anchor which comprises a suture anchor body, a thread part, a threading structure and a stress structure, wherein the thread part is arranged at the exterior of the suture anchor body; the threading structure is arranged on the suture anchor body; the stress structure is arranged on the suture anchor body; the thread part is of a thread structure distributed in a high-low manner. By virtue of the thread structure distributed in a high-low manner, the thread structure has stronger anti-pull capacity than a common thread structure; during a process of screwing into a bone, the screwing torque can be reduced, so that not only can medical operation be facilitated, but also pains of patients are reduced; furthermore, the effect of the bone fixation is good, the suture anchor is difficult to loose, secondary injury of the patients is avoided. The invention also relates to a handle matched with the suture anchor, and the handle is simple to use and convenient to install and dismount.

Owner:江苏百易得医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com