Forming method of pressing-resistant plucking-resistant pile base

A technology of uplift-resistant piles and pile formation, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of poor uplift resistance and low pressure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

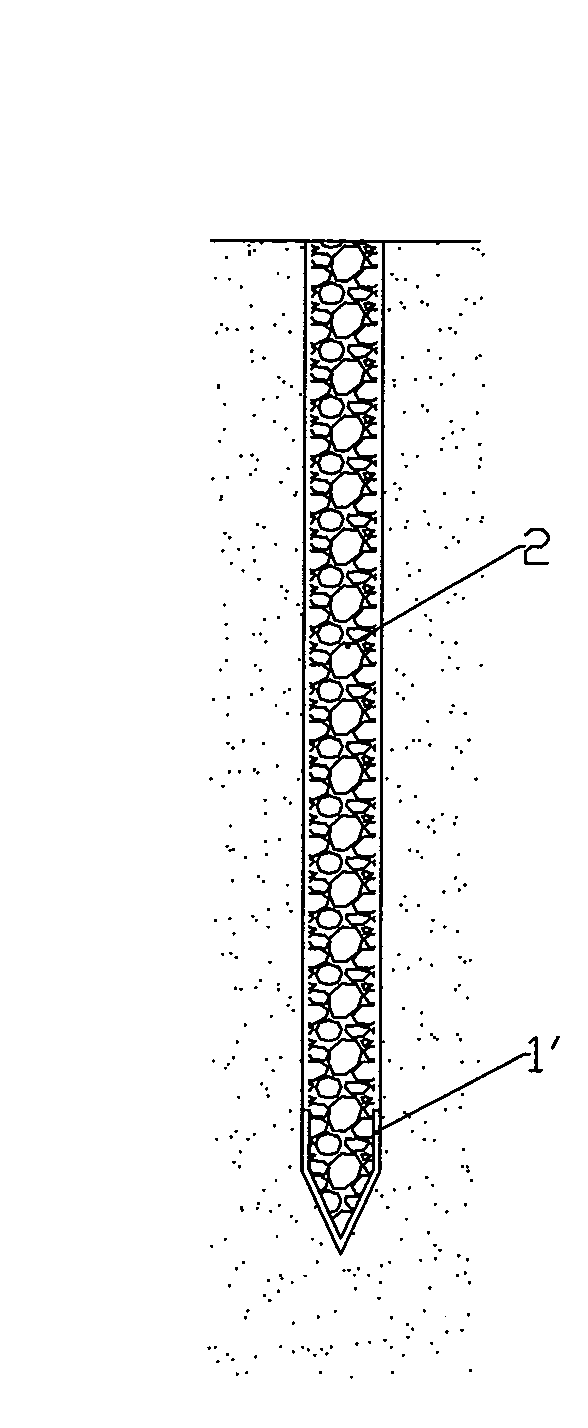

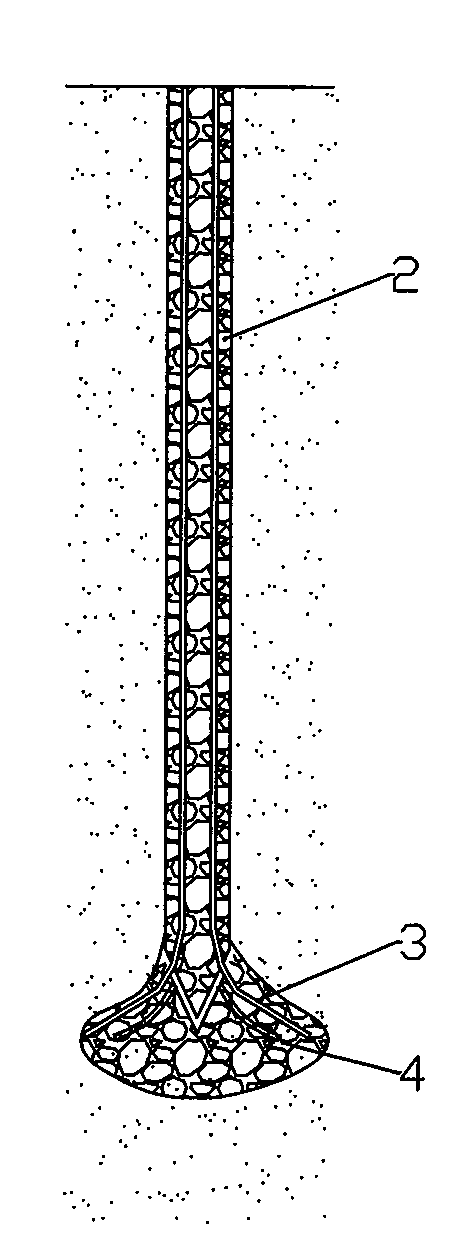

[0015] Such as figure 2 Shown, the pile foundation of the present invention is that a plurality of reinforcing bars 3 protrude outwards at the cylindrical pile foundation main body bottom that is made of concrete 2 and steel bar 3, forms a large head-shaped chassis 4 at the bottom of the pile foundation main body, and the diameter of the chassis 4 The dimension is larger than the main body of the pile foundation. Due to the pressure effect of the soil above the chassis 4 and the shear force effect of the soil, the pile foundation has good pullout resistance in addition to good bearing pressure.

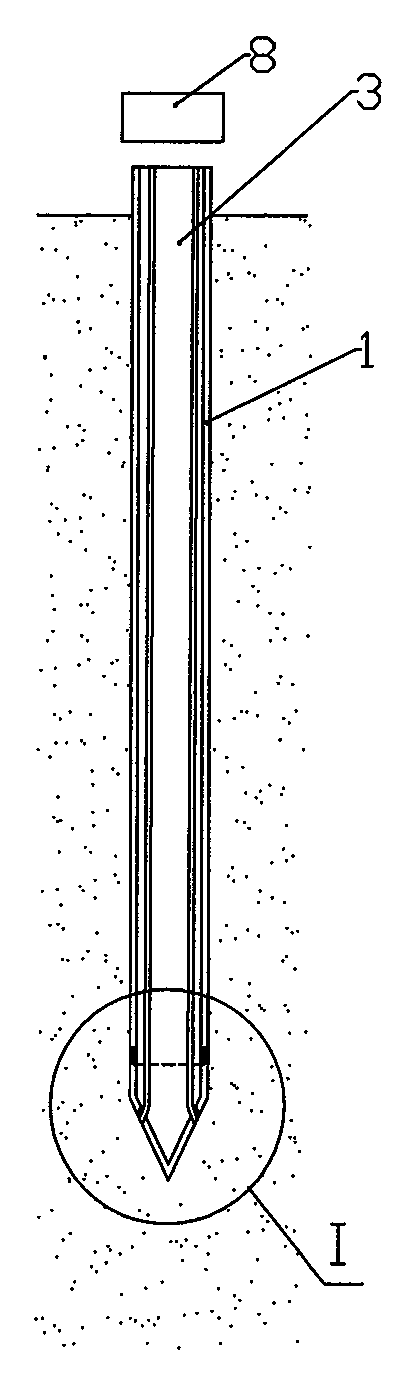

[0016] Since the reinforcing bar protrudes outwards from the bottom of the pile foundation, how to form it is the key and technical difficulty of the present invention. The invention als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com