Pile connecting structure and pile

A technology for connecting structures and connecting holes, which can be used in basic structure engineering, sheet pile walls, buildings, etc., and can solve problems such as poor shear resistance, tensile resistance and bending resistance, easy corrosion of welds, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

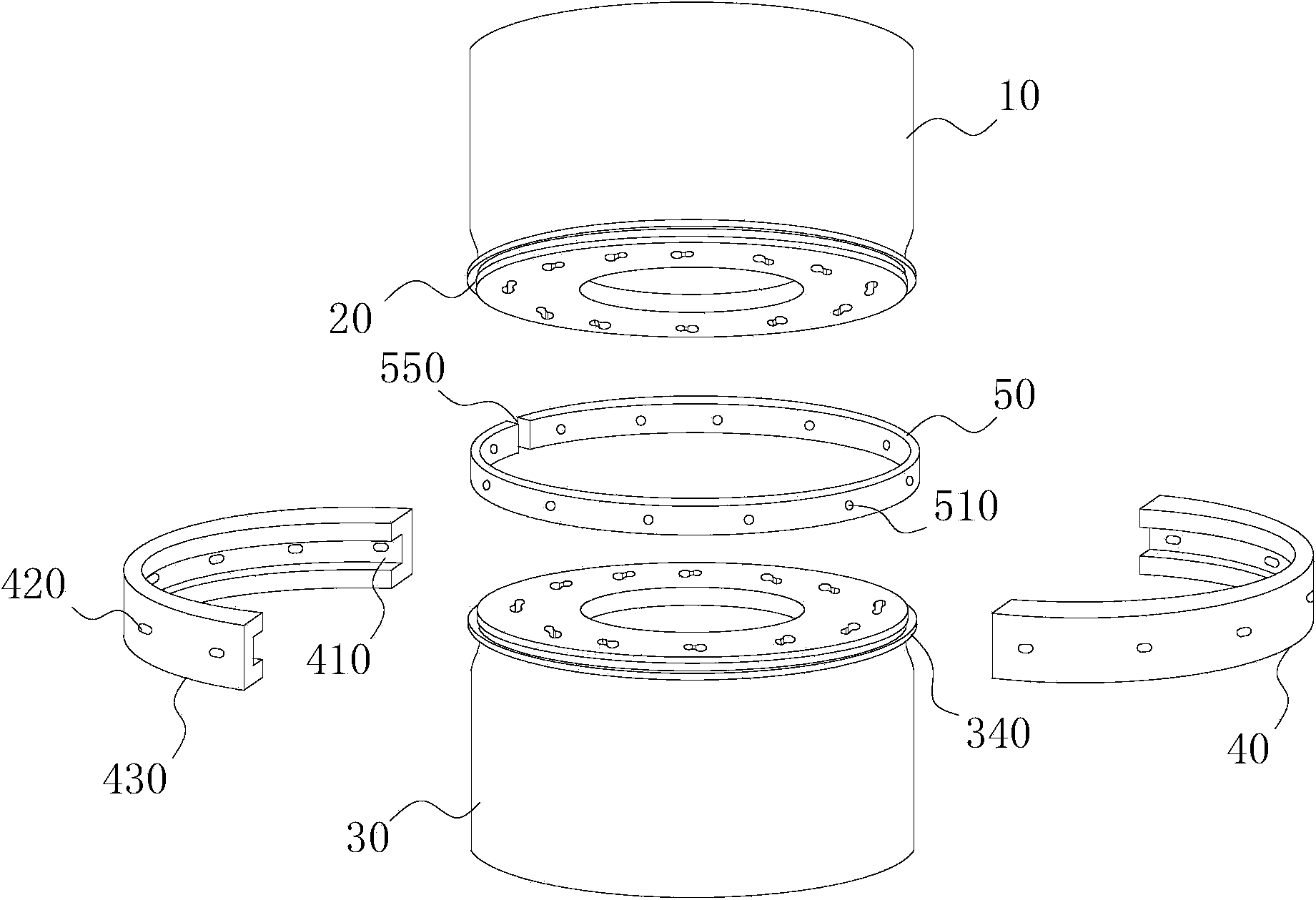

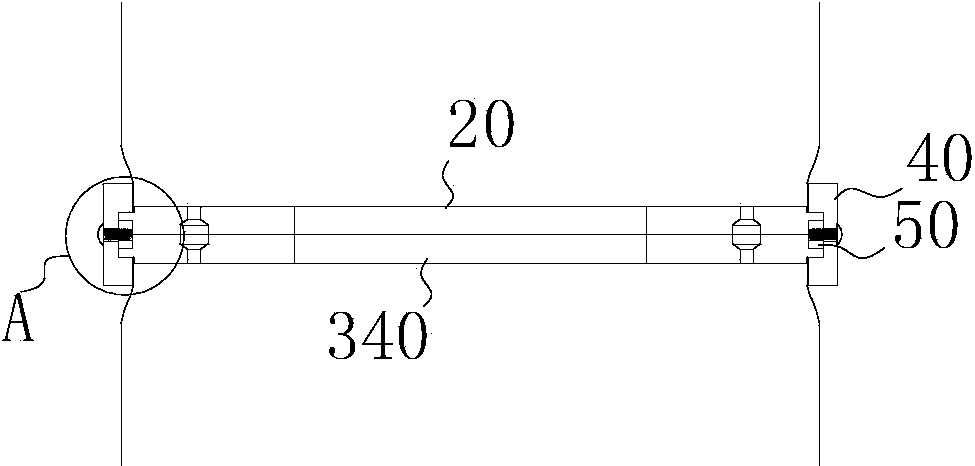

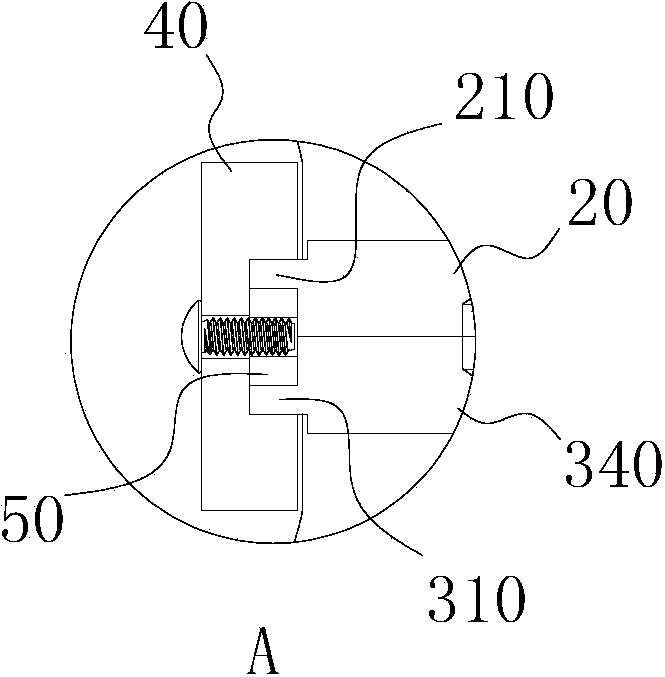

[0034] Please refer to Figures 1 to 3 . The pile connection structure is arranged between adjacent piles, and the piles used in engineering construction are formed by connecting the piles of multiple sections end to end. The pile connection structure includes an outer hoop 40 and a first end plate 20 and a second end plate 340 whose end faces are connected. The first end plate 20 is integrally formed with the first pile 10, the second end plate 340 is also integrally formed with the second pile 30, the inner hoop 50, the outer hoop 40, the first end plate 20 and The shape of the second end plate 340 matches the section of the pile, so that the pile connection structure is suitable for any prefabricated piles with end plates, including prestressed concrete pipe piles, prestressed concrete hollow square piles and concrete solid square piles.

[0035]The outer surface of the first end plate 20 is provided with a first shoulder 210 , and the outer surface of the second end plat...

Embodiment 2

[0050] Please refer to details Figure 12 . The pile connection structure in the second embodiment is substantially the same as the pile connection structure in the first embodiment, the difference is that the pile connection structure includes at least two inner hoops 50, and the inner hoops 50 are arranged side by side with the first card slot within 330. Moreover, the second connection hole 510 of the first inner hoop 50 is misaligned with the second connection hole 510 of the second inner hoop 50 . The pile connection structure includes at least two inner hoops 50, and two or more inner hoops 50 are layered and arranged side by side in the first slot 330 to enhance the shear resistance and improve the safety factor. At the same time, the second connection hole 510 provided on the first inner hoop 50 and the second connection hole 510 provided on the second inner hoop 50 are arranged in a misaligned manner to enhance the overall strength. The upper and lower sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com