Pressing limiting device and method for slab ballastless track structure

A slab ballastless track and limiting device technology, applied in tracks, roads, ballast layers, etc., can solve the problems of the gap between the track slab and the filling layer, the impact of the track structure, and the limited pull-out strength, etc. Plate warpage, high safety and stability, and the effect of preventing relative displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

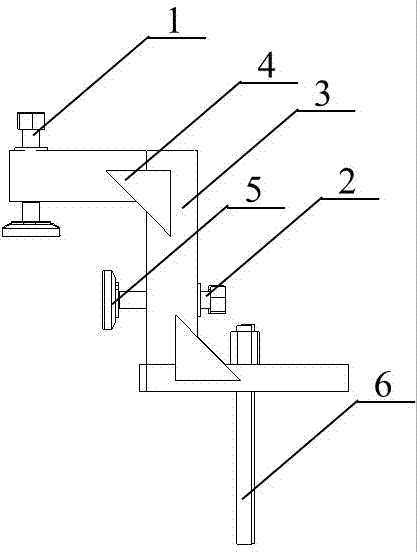

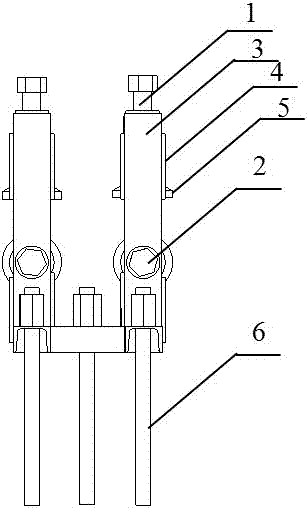

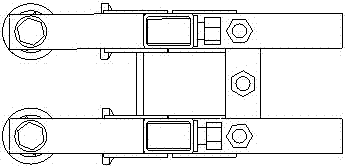

[0036] Embodiment 1: A compression limiting device and method for preventing the arching disease of the slab ballastless track structure

[0037] Consists of the following steps:

[0038] Step 1: Arrange the compression limit device on the concrete support layer exposed outside the ballastless track slab. The compression limit device is evenly and symmetrically distributed on the line, and the mark corresponds to the planting position of each compression limit device. Twist drill drilling, the drilling diameter is 27mm, the drilling depth is 200mm~250mm, the diameter of the implanted threaded steel bar is 25mm, the length of the threaded steel bar is 320mm, the implantation depth is 200mm, and the permeable planting glue is poured into the drilled hole , the amount of pouring is half of the drilling depth, the planting glue is gradually penetrated into the concrete of the supporting layer, the threaded steel bar is put into the drilling hole, and the air around the steel bar i...

Embodiment 2

[0043] Embodiment 2: A compression limiting device and method for preventing warpage of slab ballastless track structure

[0044] Consists of the following steps:

[0045] Step 1: Arrange the compression limit device on the concrete support layer exposed outside the ballastless track slab. The compression limit device is evenly and symmetrically distributed on the line, and the mark corresponds to the planting position of each compression limit device. Twist drill drilling, the drilling diameter is 27mm, the drilling depth is 200mm~250mm, the diameter of the implanted threaded steel bar is 25mm, the length of the threaded steel bar is 320mm, the implantation depth is 200mm, and the permeable planting glue is poured into the drilled hole , the amount of pouring is half of the drilling depth, the planting glue is gradually penetrated into the concrete of the supporting layer, the threaded steel bar is put into the drilling hole, and the air around the steel bar is discharged in ...

Embodiment 3

[0050] Embodiment 3: A compression limit device and method for lateral deviation correction operation of slab ballastless track structure

[0051] Consists of the following steps:

[0052] Step 1: Arrange the compression limit device on the concrete support layer exposed outside the ballastless track slab. The compression limit device is evenly and symmetrically distributed on the line, and the mark corresponds to the planting position of each compression limit device. Twist drill drilling, the drilling diameter is 27mm, the drilling depth is 200mm~250mm, the diameter of the implanted threaded steel bar is 25mm, the length of the threaded steel bar is 320mm, the implantation depth is 200mm, and the permeable planting glue is poured into the drilled hole , the amount of pouring is half of the drilling depth, the planting glue is gradually penetrated into the concrete of the supporting layer, the threaded steel bar is put into the drilling hole, and the air around the steel bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com