Novel type pile foundation for sea turn engineering and pile forming method thereof

A wind engineering and pile foundation technology, which is applied in the field of new pile foundations for offshore wind engineering, can solve the problems that the pile foundation cannot be formed underwater, the concrete is washed away, and the pile foundation is huge, etc. Effect of strength and stiffness, strong compressive and pullout resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

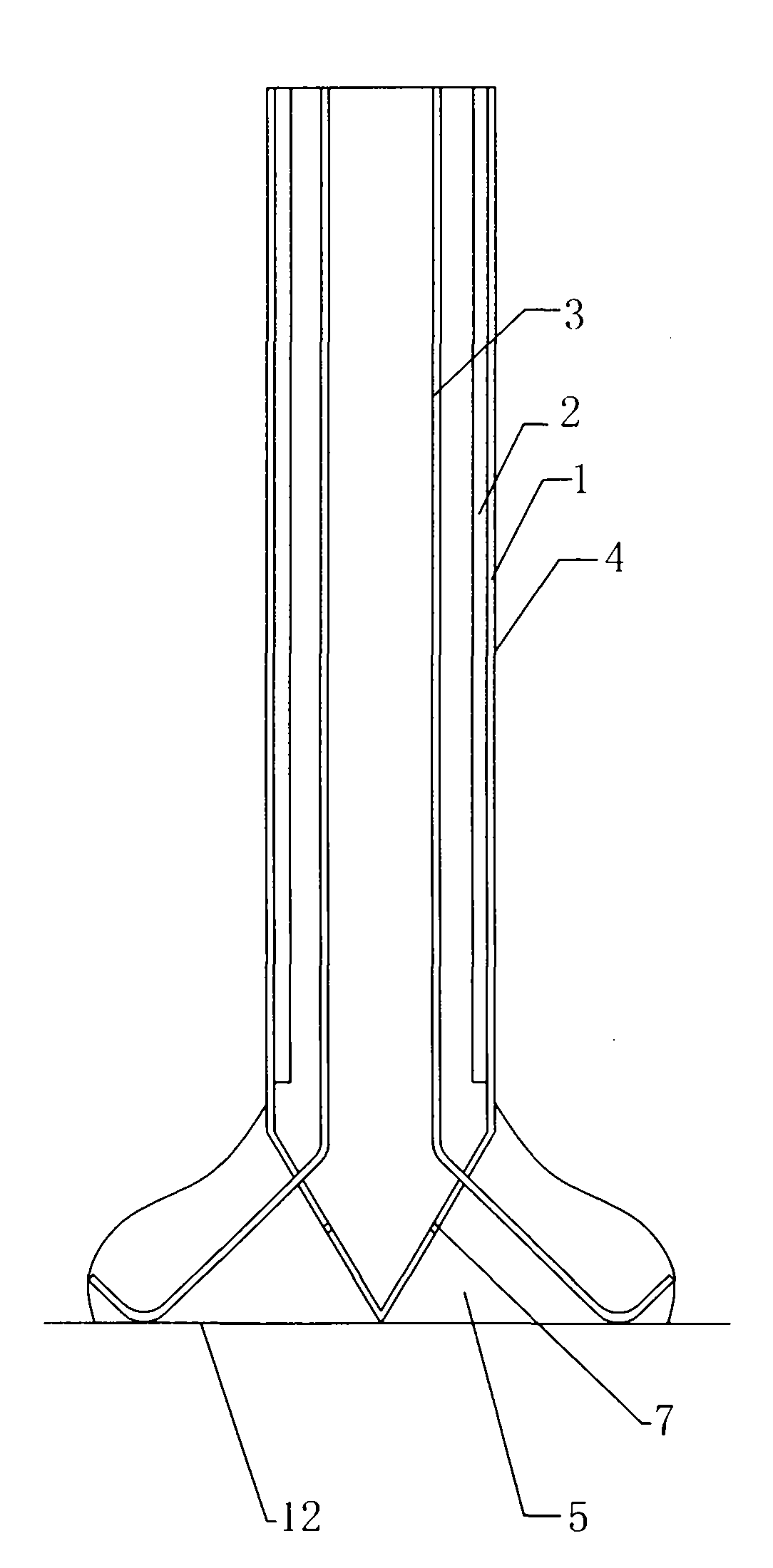

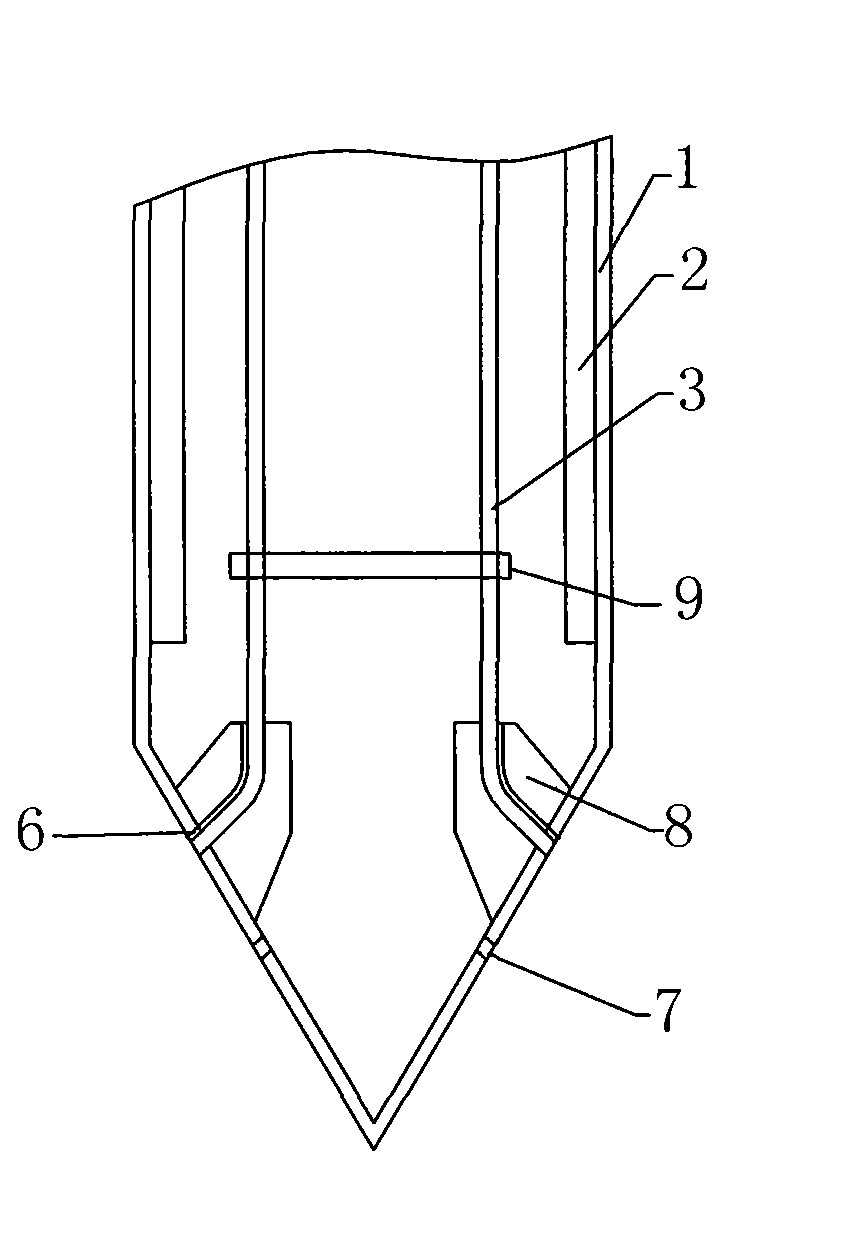

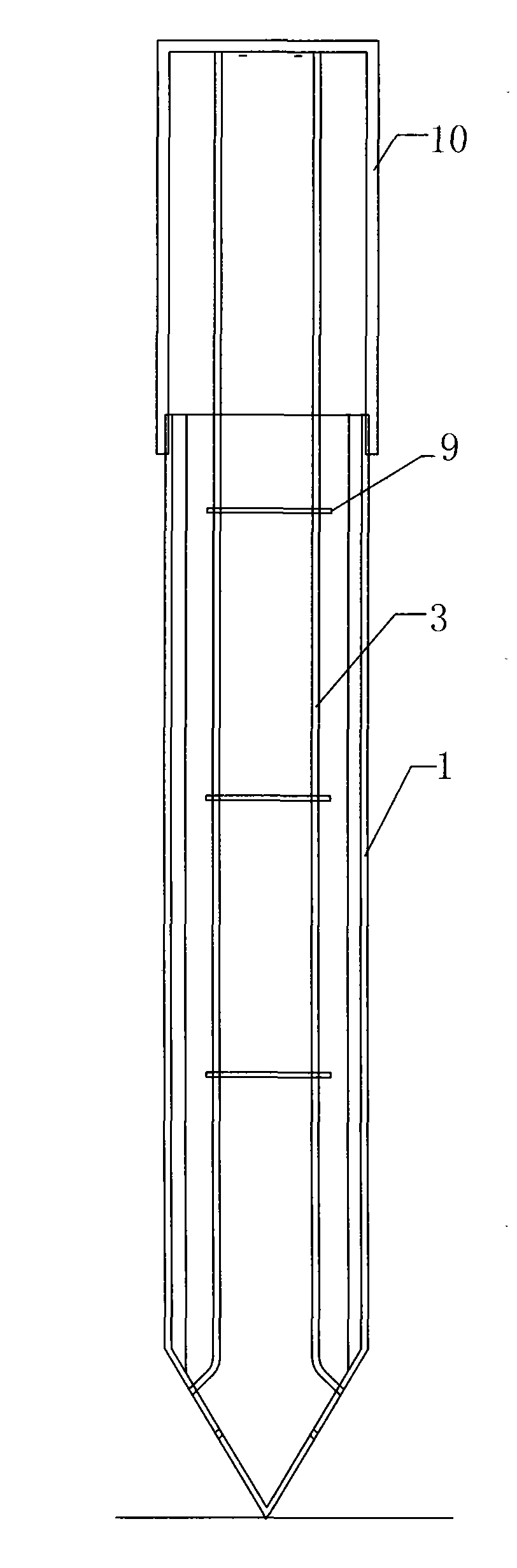

[0027] As attached to the manual figure 1 As shown, the present invention is a new type of pile foundation for offshore wind engineering, including steel pipe 1, steel pipe 1 inner wall composite concrete lining pipe 2, steel bar 3 and reinforced concrete pile core formed by concrete pouring, and the steel pipe is coated with fluorine resin for anticorrosion Layer 4 to improve its corrosion resistance. And the steel bar 3 lower end in the pile core is from the sharp cone of the steel pipe 1 lower end such as figure 2 The shown oblique through hole 6 passes through and expands to reach the bedrock 12 of the seabed. Outside the pointed cone, concrete wraps the pierced steel bar 3 and passes through the concrete extruded through hole 7 on the pointed cone below the through hole for passing through the steel bar. It is integrated with the reinforced concrete pile core in the pipe, the concrete is filled under the steel pipe 1 and the concrete solidifies itself, forming a large h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com