Vertically pulling-resistant type friction pendulum support

A technology of friction pendulum support and anti-pull type, which is applied in the direction of building types, bridge parts, bridges, etc., can solve the problems of non-pull-out resistance, and achieve the advantages of easy manufacture and installation, enhanced safety and applicability, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

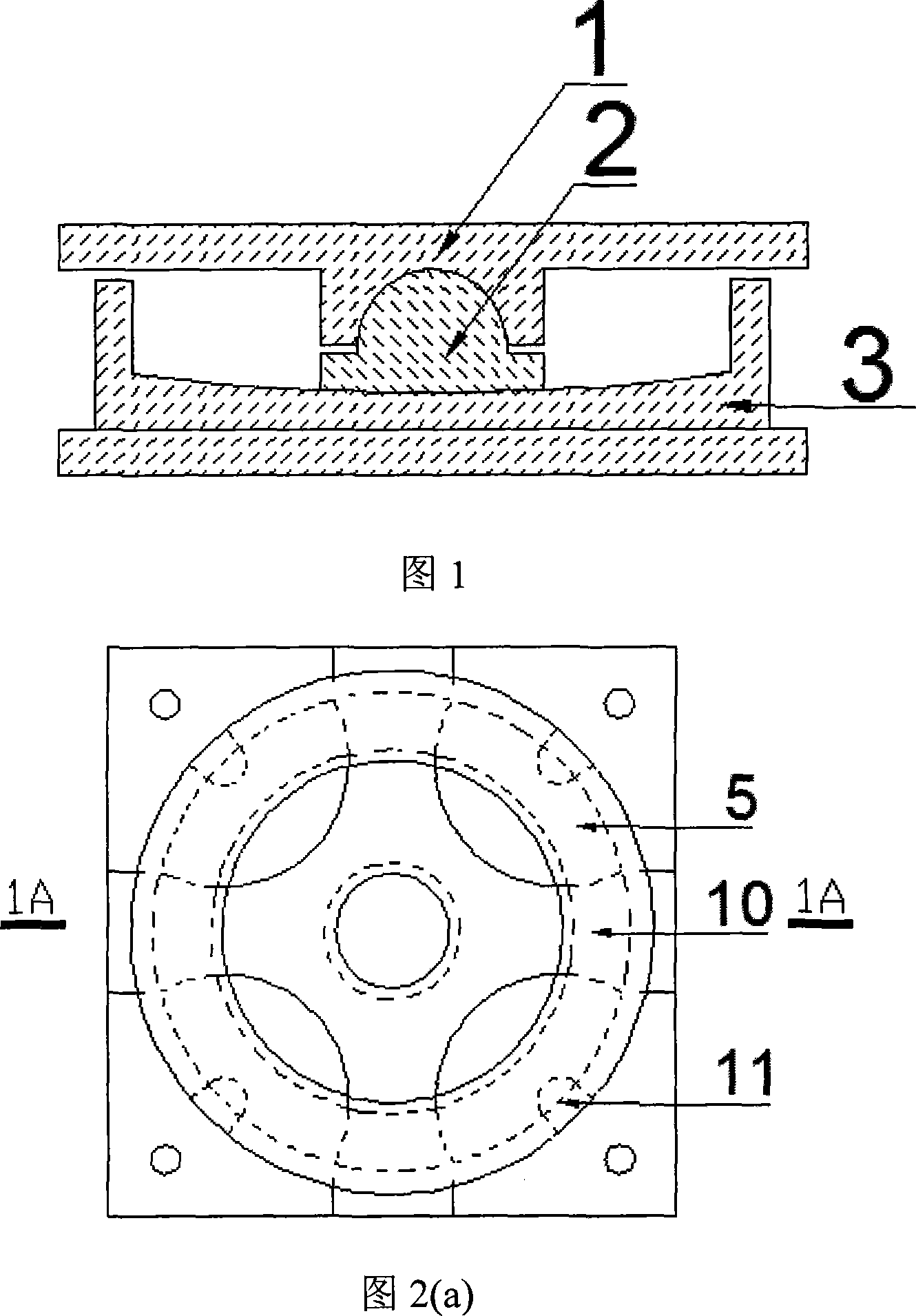

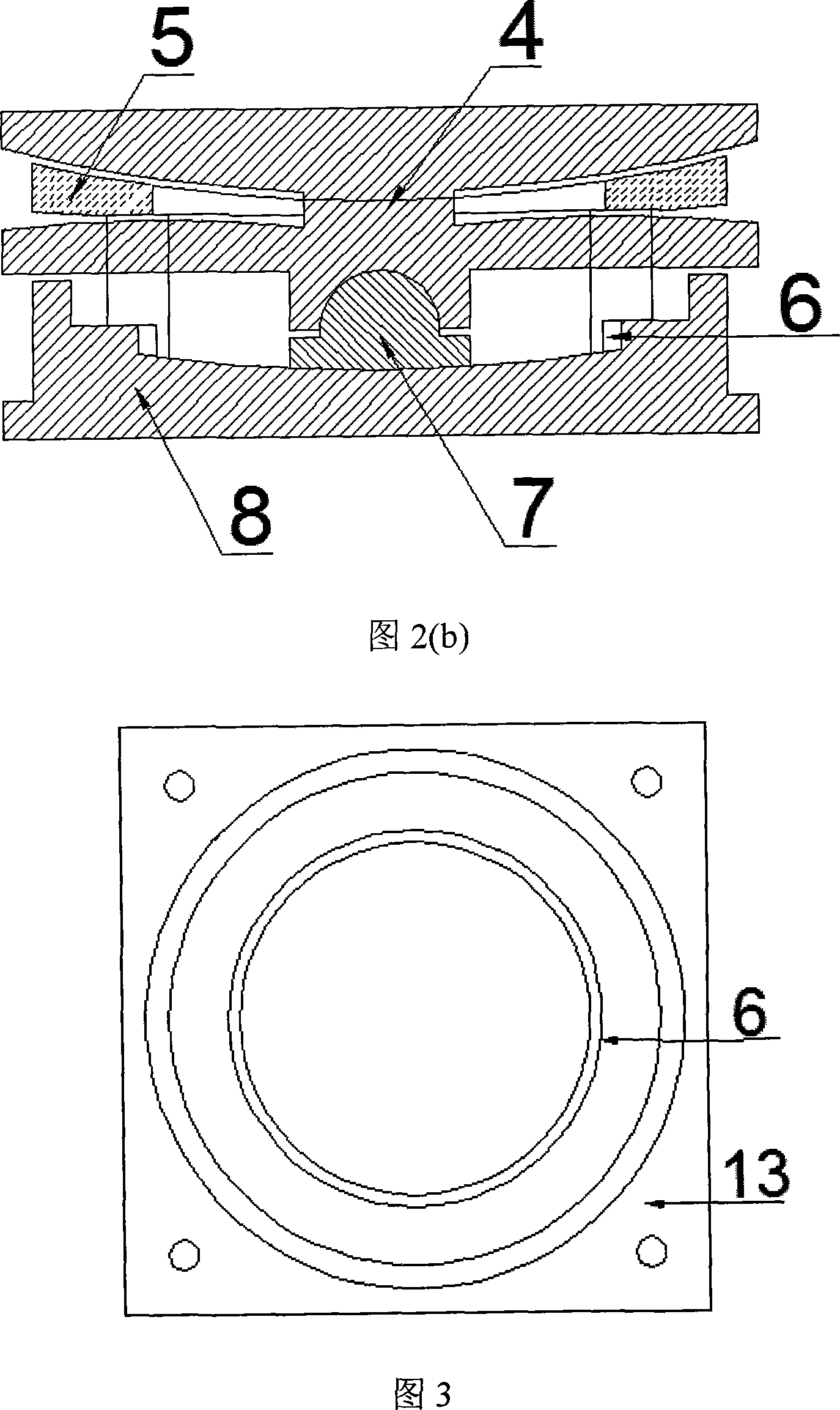

[0024] This embodiment will be described in detail below with reference to FIGS. 2 to 6 .

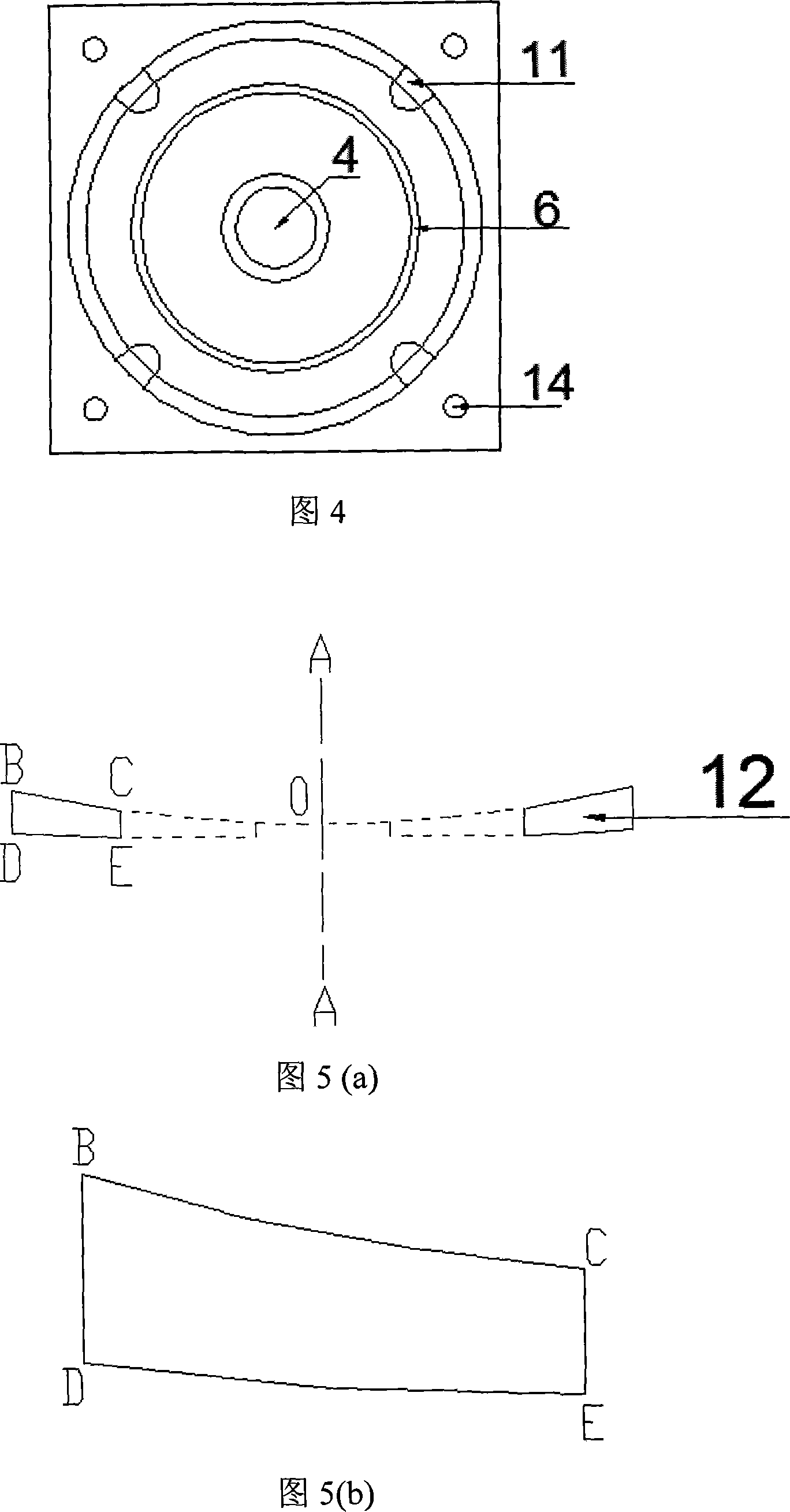

[0025] The technical solution of this embodiment is shown in FIG. 2 , which mainly includes a lower connecting steel plate 13 with a chute 8 on the upper surface, a buffer rubber strip 6 , a slider 7 , an upper cover plate 4 and an anti-pull baffle 5 . The upper cover plate 4 includes an upper connecting steel plate 9 and a lower stopper 10, the two are fixedly connected as one, the upper part of the slider 7 is a hemispherical protrusion, which matches the hemispherical groove of the lower stopper 10, and the slider 7 is in the lower Driven by the block 10 , it can slide along the bottom surface of the chute 8 . Between the upper connecting steel plate 9 and the lower block 10, an anti-pull baffle 5 is arranged, and the anti-pull baffle 5 includes an annular baffle 12 and a short column 11, and the short column 11 passes through the lower baffle 10, which One end is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com