Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

115results about How to "Solve work efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

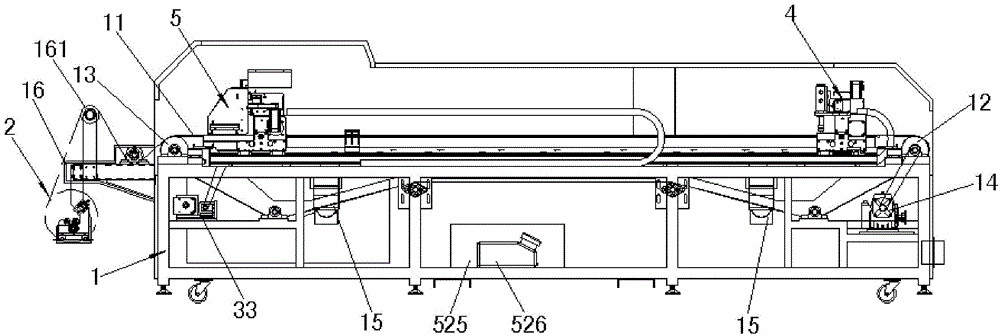

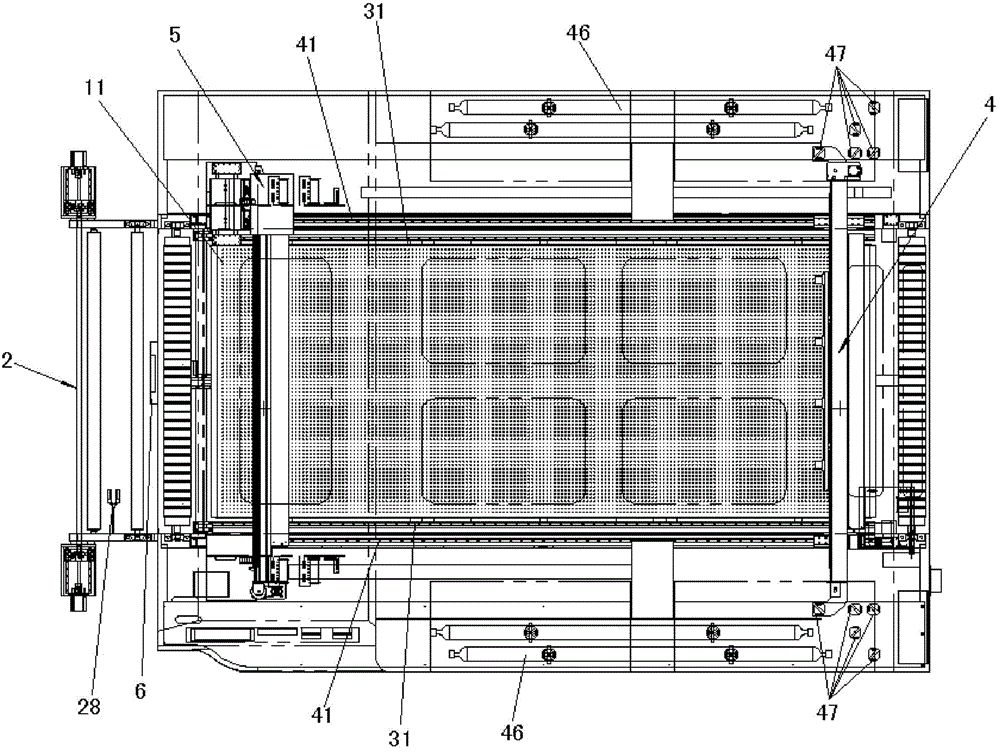

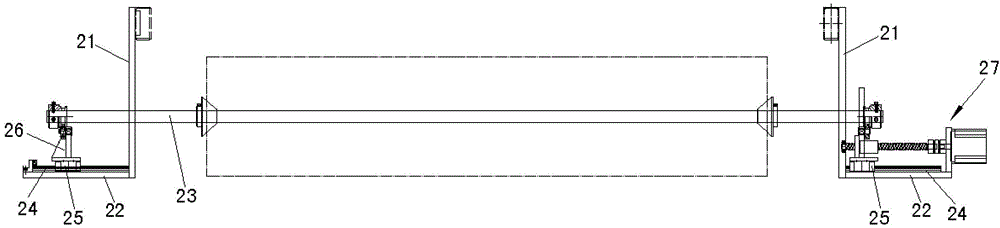

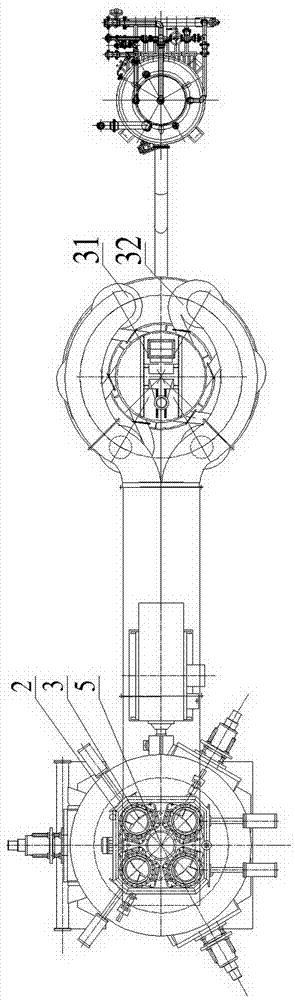

Full-automatic leather printing and cutting machine and printing and cutting method implemented by same

InactiveCN104818350ASolve processabilitySolve the large number of laborLeather clicking/perforating/clickingTypewritersComputer control systemGraphics

The invention discloses a full-automatic leather printing and cutting machine which comprises a framework, an automatic rectifying mechanism, an automatic feeding manipulator, an automatic laser cutting mechanism, an automatic printing mechanism and a control system. A frame and a frame shaft are arranged at the front end of the framework, the frame shaft is arranged on the frame, the automatic rectifying mechanism is arranged at the front end of the framework, the automatic feeding manipulator, the automatic laser cutting mechanism and the automatic printing mechanism are arranged on the framework, and the control system is arranged in the framework and is connected with the automatic feeding manipulator, the automatic laser cutting mechanism and the automatic printing mechanism. The full-automatic leather printing and cutting machine has the advantages that manual production can be truly replaced by machines, accordingly, the leather processing efficiency and processing precision can be greatly improved, and the processing cost can be reduced; optional patterns can be accurately printed by the printing mechanism by the aid of the computer control system, and the problem of asymmetric pattern printing in existing leather processing procedures can be effectively solved.

Owner:DONGGUAN DEL LASER TECH

Using method of production line for preparing junked tire fine rubber powder

InactiveCN107471490ASolve the problem of storage spontaneous combustionReduce storage spontaneous combustion problemsPlastic recyclingGrain treatmentsSpontaneous combustionProduction line

The invention relates to the technical field of resource recycling comprehensive utilization, in particular to a using method of a production line for preparing junked tire fine rubber powder. The using method is characterized in that a driving grinding grate assembly and a driven grinding roller assembly are designed to complete the grinding technological process by combining the advantages of a movable-fixed tool and a movable-movable tool, and water vapor is used for completing the technological processes of conveying, sterilization, separation, sorting, protection and the like in the production process of the junked tire fine rubber powder; the water vapor is used as a pneumatic transmission carrier of the junked tire fine rubber powder, and compared with the modes of mechanical conveying and the like, the advantages of reducing cost, saving energy, achieving automation and relieving labor intensity are achieved; and the water vapor serves as a sterilization medium of the junked tire fine rubber powder, microbial cells can be effectively killed, reproducing growth can be restrained, the phenomenon that microbial strains are decomposed into small-molecular-weight combustibles through fermentation and metabolism is avoided, the firefighting safety level is increased, and the problem of spontaneous combustion caused by storage of rubber powder sediments at a normal temperature is solved.

Owner:南京市高淳橡塑二厂

Stenter convenient to clean for printing and dyeing

InactiveCN107326594AEasy to cleanClean up reachCleaning using toolsCleaning using gasesCouplingArchitectural engineering

The invention discloses a stenter convenient to clean for printing and dyeing. The stenter comprises a box body, the surface of the box body is fixedly connected with a supporting rod, the surface of the supporting rod is fixedly connected with a motor, and the output shaft of the motor is fixedly connected with a first rotating shaft through a coupler, wherein the surface of the first rotating shaft is fixedly connected with a first retractable pipe the inner wall of which is provided with a sliding groove, the inner wall of the sliding groove is connected with a locating block in a sliding mode, and the surface of the locating block is fixedly connected with a first retractable rod the surface of which is in threaded connection with a first fixing bolt. According to the stenter convenient to clean for printing and dyeing, when the stenter needs to be cleaned, a padlock is unlocked, a second tong base is flicked under the action of a spring and rotates on the surface of a connecting shaft, and the opening angles of a first tong base and the second tong base are expanded, so that an effect of conveniently cleaning a clamping device of the stenter is achieved, and the problem is effectively solved that since normal stenters are not provided with cleaning devices, the working efficiency of the stenters is affected at a certain degree.

Owner:秦泽坤

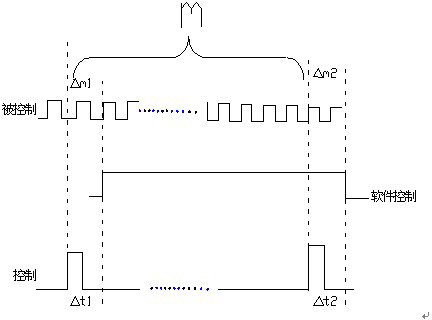

Error counter for electric energy meter and error counting method

ActiveCN102636769AEasy to handleReduce the amount of settingsElectrical measurementsSoftware designFuzzy control system

The invention discloses an error counter for an electric energy meter. The error counter comprises a single chip, a 10M constant-temperature crystal oscillator, a 5-frequency divider and a 100-frequency divider, wherein four counters are carried by the single chip, and two of the counters are provided with a capturing function. For the error counter provided by the invention, the capturing interrupting and pulse modulation means are adopted, the fuzzy control principle is adopted, and an error counting method with setting parameters subjected to optimized treatment is further adopted, so that the precision for collecting pulses is guaranteed from aspects of hardware design and software design. In addition, the error counter provided by the invention is especially used for solving the problem of controlling the measuring precision and measuring time of low-frequency pulse by the low-frequency pulse. Under the condition of ensuring the measuring precision, the working efficiency is greatly improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

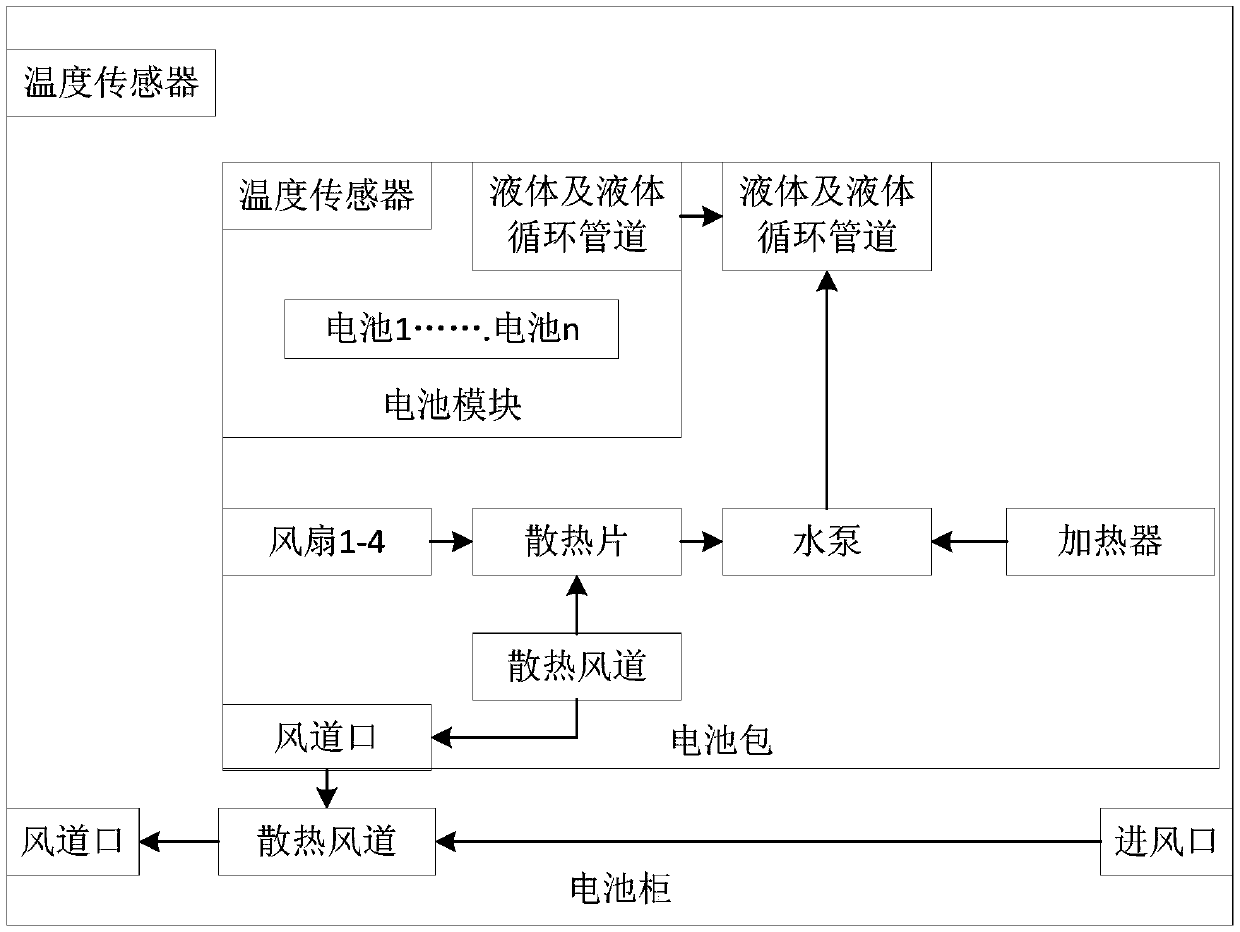

Battery energy storage equipment and thermal management system thereof

PendingCN107799848AGuaranteed to workRealize temperature regulationSecondary cellsElectrical batteryComputer module

The invention relates to battery energy storage equipment and a thermal management system thereof, belonging to the technical field of battery energy storage. According to the thermal management system, all battery modules are separately provided with a liquid circulation branch, a liquid circulation pipeline is arranged in a battery pack formed by the at least two battery modules, all the liquidcirculation branches are in parallel connection with the liquid circulation pipelines of the corresponding battery packs; water pumps are respectively arranged on the liquid circulation pipelines. Theliquid circulation branches corresponding to the battery modules are controlled to be communicated with the liquid circulation pipelines according to the temperature of all the battery modules, so that a circulating system is formed; therefore, the temperature of all the battery modules can be adjusted, a battery is enabled to work in a suitable temperature range to the utmost extent, and the service life of the whole battery energy storage equipment is further prolonged.

Owner:HENAN SENYUAN ELECTRIC CO LTD

Air conditioning system and the controlling method thereof

InactiveCN106642773AImprove economy and reliabilityImprove energy efficiency ratioMechanical apparatusCompression machines with non-reversible cycleRefrigerantEngineering

The invention discloses an air conditioning system and the controlling method thereof. The air conditioning system comprises a refrigerant circulation circuit which is provided with an indoor heat exchanger, an outdoor heat exchanger and a compressor. Besides, the refrigerant circulation circuit is provided with a supercharging device for driving refrigerant cycle that can be in series with the compressor. The controlling method of the air conditioning system is divided into the working mode of the compressor, the alternate mode of the compressor and the refrigerant pump, the mode of the refrigerant pump and the co-working mode of compressor and refrigerant pump according to the difference between the length of the connecting pipe between the indoor heat exchanger and the outdoor heat exchanger and height between the indoor heat exchanger and the outdoor heat exchanger. The air conditioning system and the method thereof have solved the low working efficiency and the energy efficiency ratio problems causing by the low environmental temperature and the long distance between the indoor and outdoor machine and the like, thereby being more reliable and economical.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

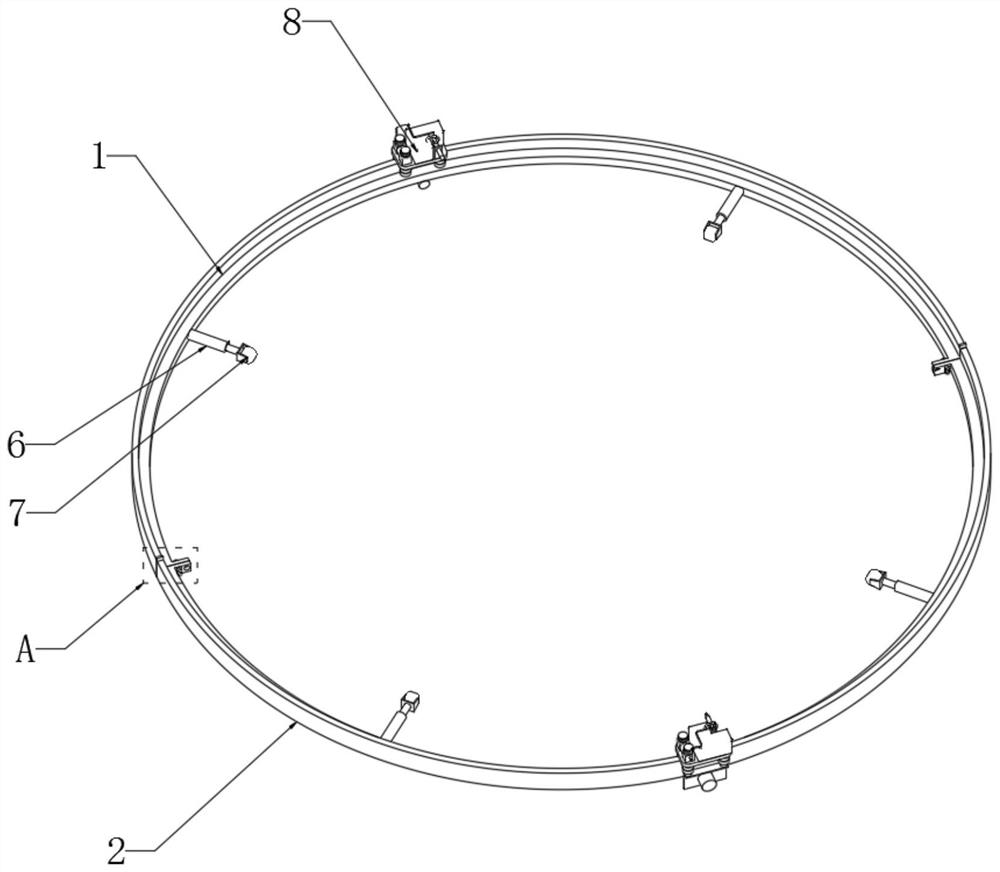

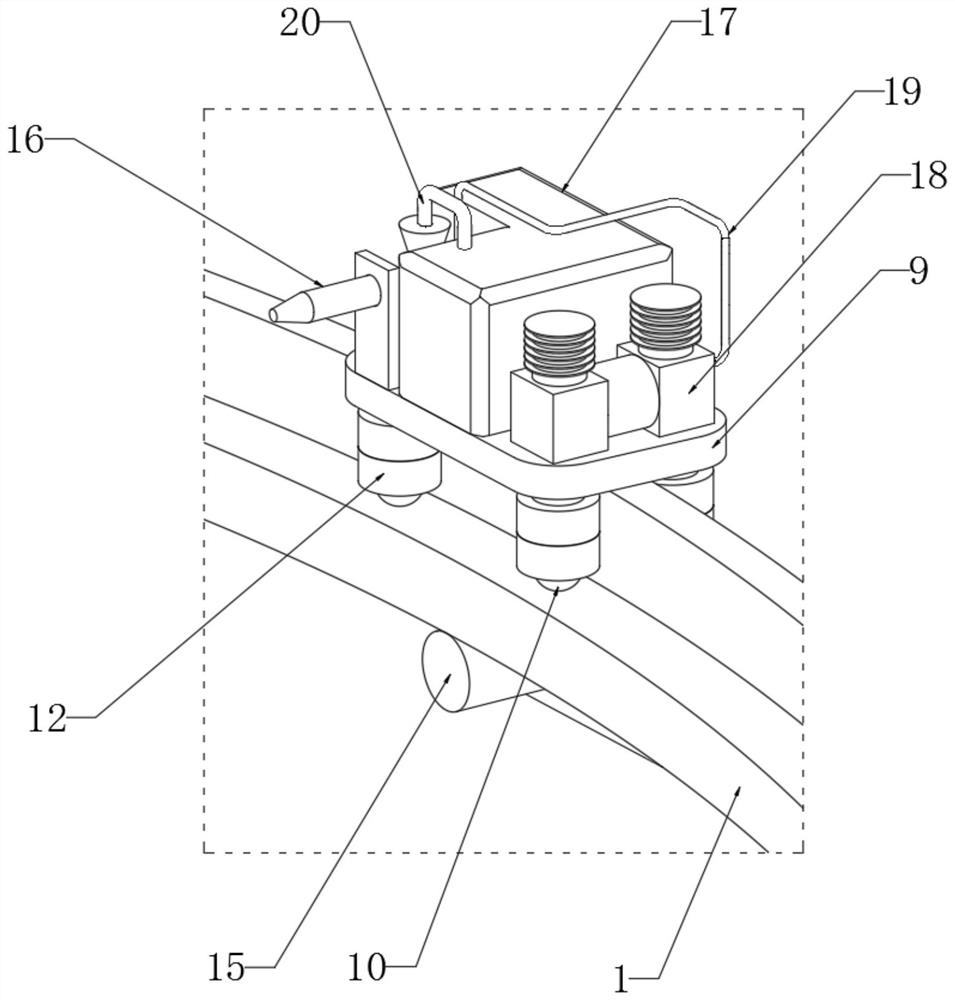

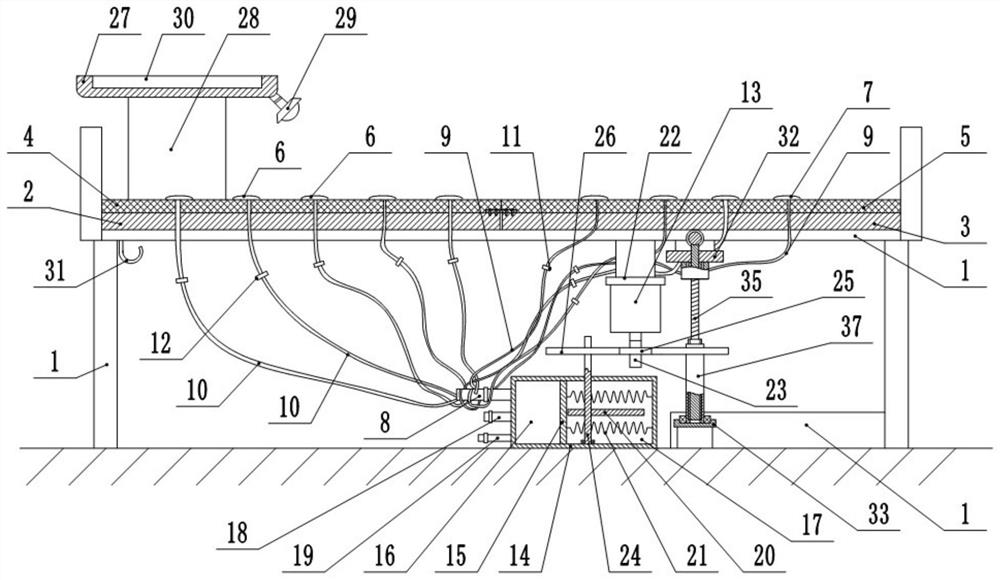

Automatic painting device for wind power tower drum

PendingCN113000259ARealize automatic painting operationAddress riskSpraying apparatusAir pumpElectric machinery

The invention discloses an automatic painting device for a wind power tower drum, and relates to the field of wind power generation equipment maintenance devices. The following solution aiming at solving the problems of high safety risk of operators and low operation efficiency in the existing manual maintenance of an outer wall protective paint of a wind power tower is provided, the automatic painting device comprises a first semi-ring and a second semi-ring, wherein the first semi-ring and the second semi-ring are both semicircular, fixing lugs are arranged at the two ends of the first semi-ring and the two ends of the second semi-ring correspondingly, paint spraying vehicles are arranged at the top ends of the first semi-ring and the second semi-ring correspondingly, each paint spraying vehicle comprises an installing plate, a motor, a spray gun, a paint box and an air pump, fixing bolts are arranged between every two adjacent fixing lugs, hoisting holes are formed between every two adjacent fixing lugs, and proximity switches are arranged at the tops of the two ends of the first semi-ring correspondingly. The automatic painting device is novel in structure, and effectively solves the problems of high safety risk of the operators and low operation efficiency in the existing manual maintenance of the outer wall protective paint of the wind power tower.

Owner:HUANENG CLEAN ENERGY RES INST +3

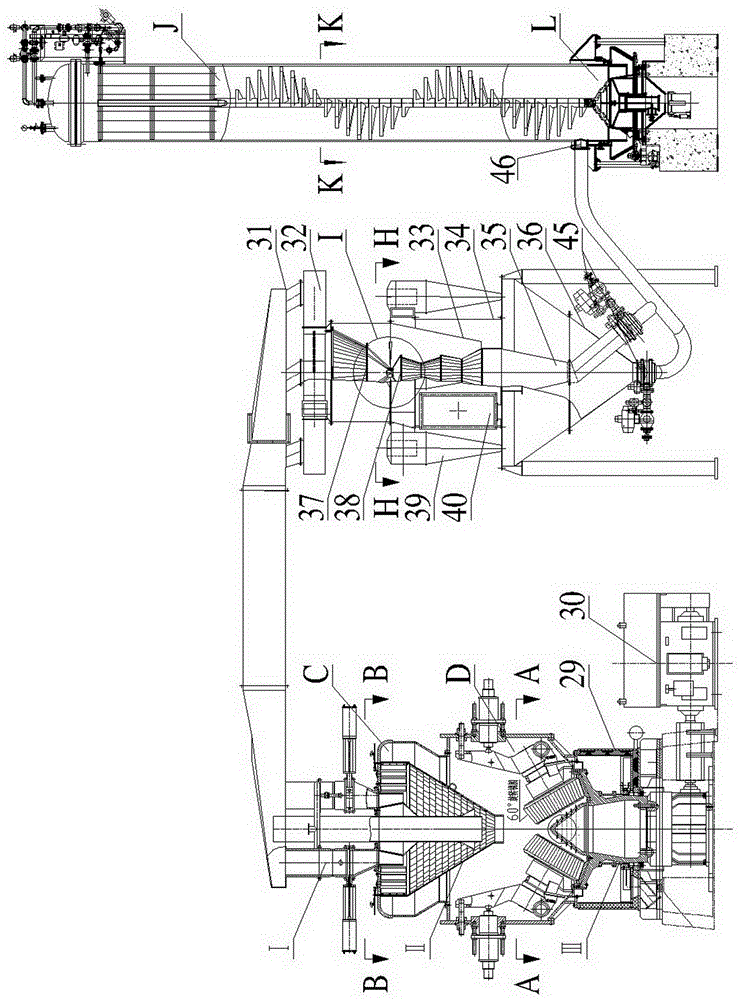

Production line for preparing used-tire fine rubber powder

ActiveCN107521000ASolve the problem of storage spontaneous combustionReduce storage spontaneous combustion problemsPlastic recyclingGrain treatmentsSpontaneous combustionFire protection

The invention relates to the technical field of recycling and comprehensive utilization of resource, in particular to a production line for preparing used-tire fine rubber powder. The production line is characterized by comprising a distributing groove component, a separator component, a grinding component, a classifier component, a plenum pulse bag gathering component, a spiral stair blade separating component and a rotary table component. The way that the technological process of conveying, sterilization, separation, separation, protection, etc. in the production process of used-tire fine rubber powder is completed by water vapor is ideal. Compared with mechanical conveying, the water vapor as a pneumatic conveying carrier of used-tire fine rubber powder has the advantages of reducing the cost, saving energy, realizing automation and reducing labor intensity. The water vapor as a sterilization medium of used-tire fine rubber powder can effectively kill microorganisms, inhibit reproduction and growth of the microorganisms, and avoid microbial bacterial fermentation and metabolism so as not to decompose out small molecular weight of combustible matters. The safety level of fire protection is improved, and the problem of spontaneous combustion of rubber dust accumulators during storage at normal temperature is solved.

Owner:安徽成泰化学科技有限公司

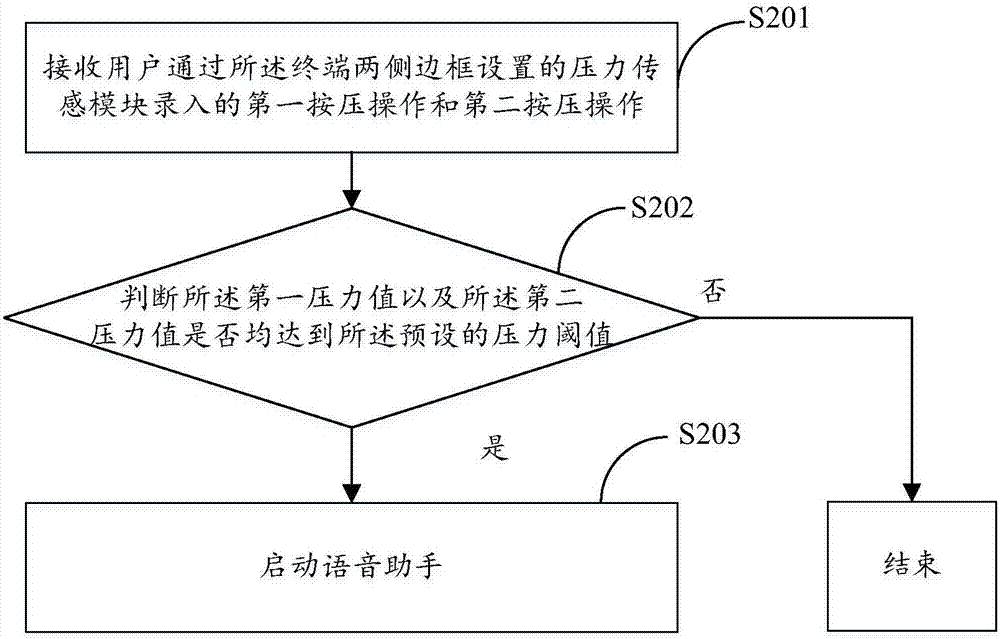

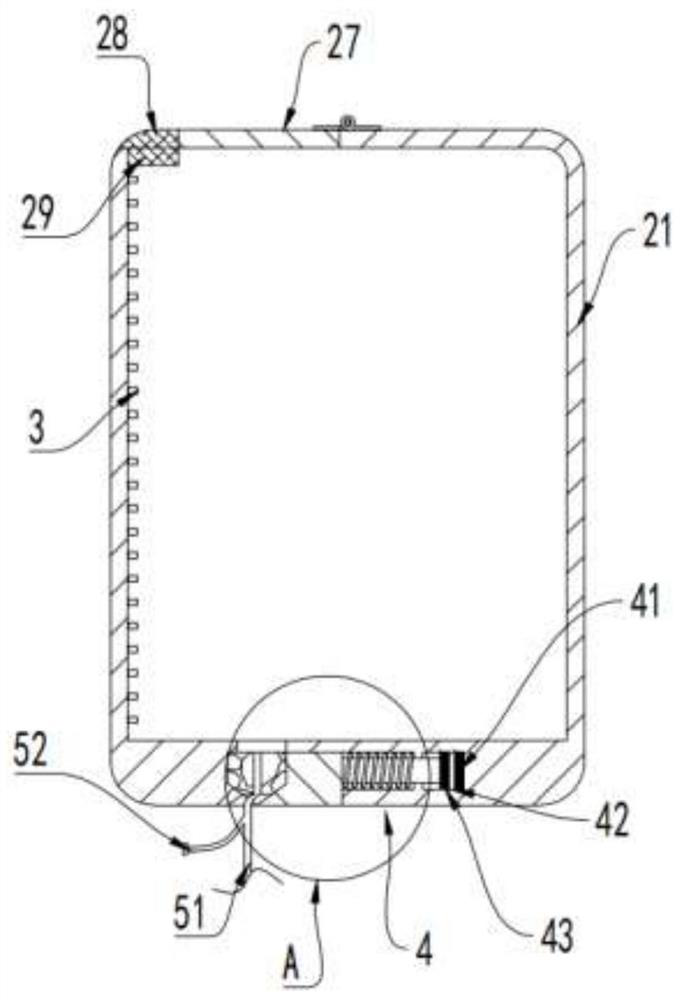

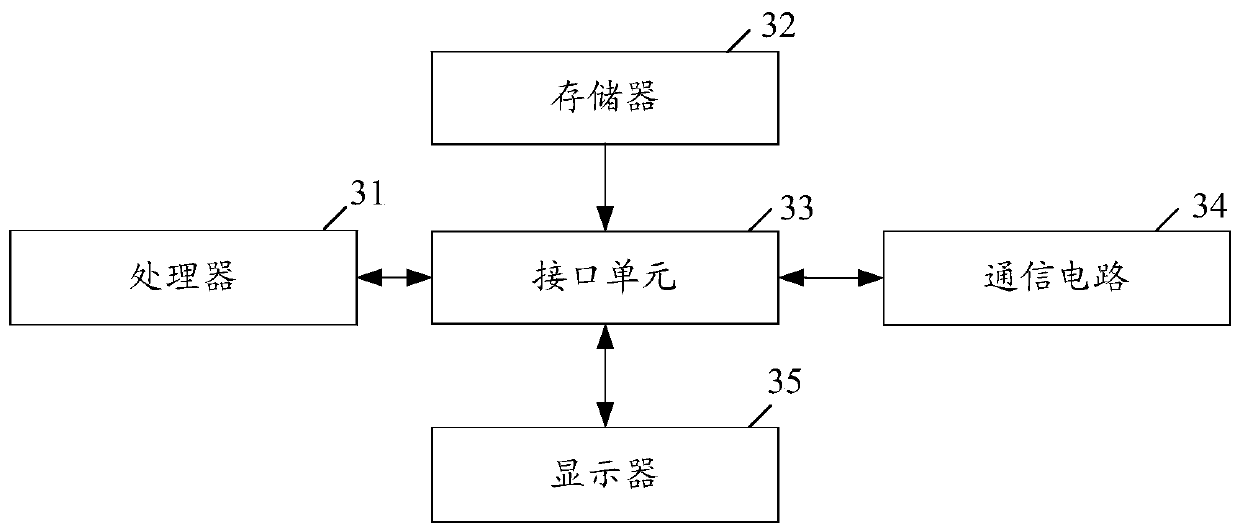

Voice assistant starting method, voice assistant starting device, computer device and computer readable storage medium

InactiveCN107423098ASolve learning efficiencySolve work efficiencyProgram loading/initiatingInput/output processes for data processingPressure senseSpeech sound

The invention is applicable to the field of mobile terminal applications, and provides a voice assistant starting method, a voice assistant starting device, a computer device and a computer readable storage medium. The voice assistant starting device is applied to a terminal, and a pressure sensing module is arranged on a frame of the terminal. The voice assistant starting method includes the steps: receiving compression operation inputted by a user through the pressure sensing module when the terminal is in a call state; judging whether the compression operation meets preset voice assistant starting conditions or not; stating a voice assistant when the compression operation meets the preset voice assistant starting conditions. As the intelligent terminal is provided with the pressure sensing module, the voice assistant starting device determines whether the compression operation of the pressure sensing module by the user meets the preset voice assistant starting conditions or not in the call process of the user, the voice assistant is started when the compression operation meets the preset voice assistant starting conditions, and the normal call quality of the user is improved, so that learning and working efficiency of the user is improved.

Owner:MEIZU TECH CO LTD

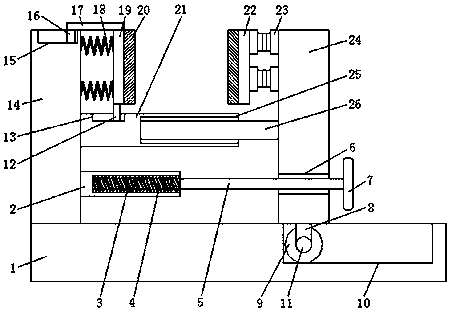

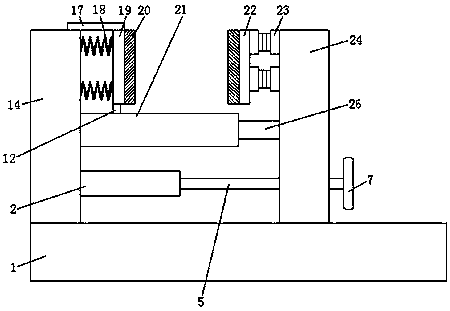

Metal cutting machine tool clamping device facilitating clamping

InactiveCN109955084AEasy clampingReduce vibrationPositioning apparatusMetal-working holdersMetal machiningLap joint

The invention provides a metal cutting machine tool clamping device facilitating clamping, and relates to the field of metal machining machine tools. The metal cutting machine tool clamping device facilitating clamping comprises a base, a fixing plate is fixedly connected to the upper surface of the base, an adjusting rod is fixedly connected to the right side of the fixing plate, and a threaded groove is formed in the right end of the adjusting rod and is internally in threaded connection with a screw. The end, away from the threaded groove, of the screw is fixedly connected with a rotation rod. The upper surface of the base is in lap joint with a movable plate. A movable hole communicating with the right side is formed in the left side of the movable plate. According to the metal cuttingmachine tool clamping device facilitating clamping, through leather pads arranged on the surfaces of a first clamping plate and a second clamping plate, after a workpiece is clamped, workpiece surface damage is avoided; and through springs arranged between the fixing plate and the first clamping plate, vibration of the workpiece during machining is buffered, and it is guaranteed that defects areavoided after the workpiece is machined.

Owner:朱爱芳

Electric vehicle charging navigation system design based on voice recognition

InactiveCN110986986AEnsure driving safetySolve work efficiencyInstruments for road network navigationElectric vehicle charging technologyNavigation functionNavigation system

The invention discloses an electric vehicle charging navigation system design based on voice recognition, which is used for solving the problem that an existing electric vehicle charging navigation path cannot provide a satisfactory charging path for a user through voice interaction. The system comprises a voice recognition module used for collecting and processing voice signals in a vehicle; a vehicle information acquisition module used for providing necessary vehicle information for a vehicle-mounted controller module; a vehicle-mounted controller module which is a core module for user datastorage and path planning; a man-machine interaction module used for providing a visual interface and a manual interaction entry for the user; a voice broadcasting module used for providing necessaryfeedback information for a voice command of the user; and a cloud server module used for acquiring traffic information and charging station state information. According to the embodiment of the invention, the electric vehicle charging navigation function is realized through voice interaction with the user, a satisfactory navigation scheme can be effectively provided for the user of an electric vehicle, and the traffic risk caused by manual interaction in the driving process is reduced.

Owner:YANSHAN UNIV

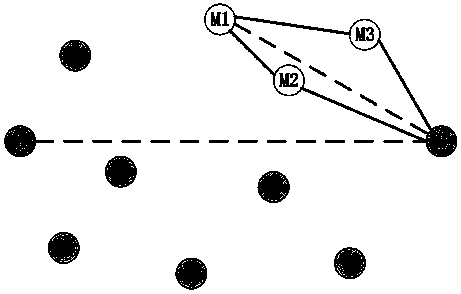

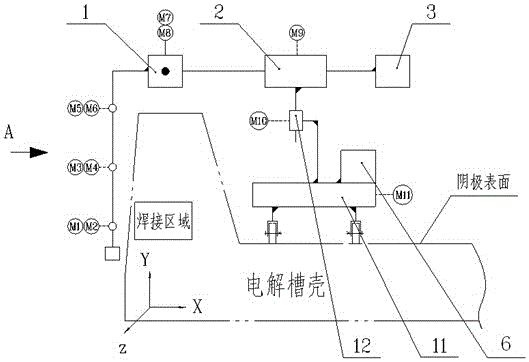

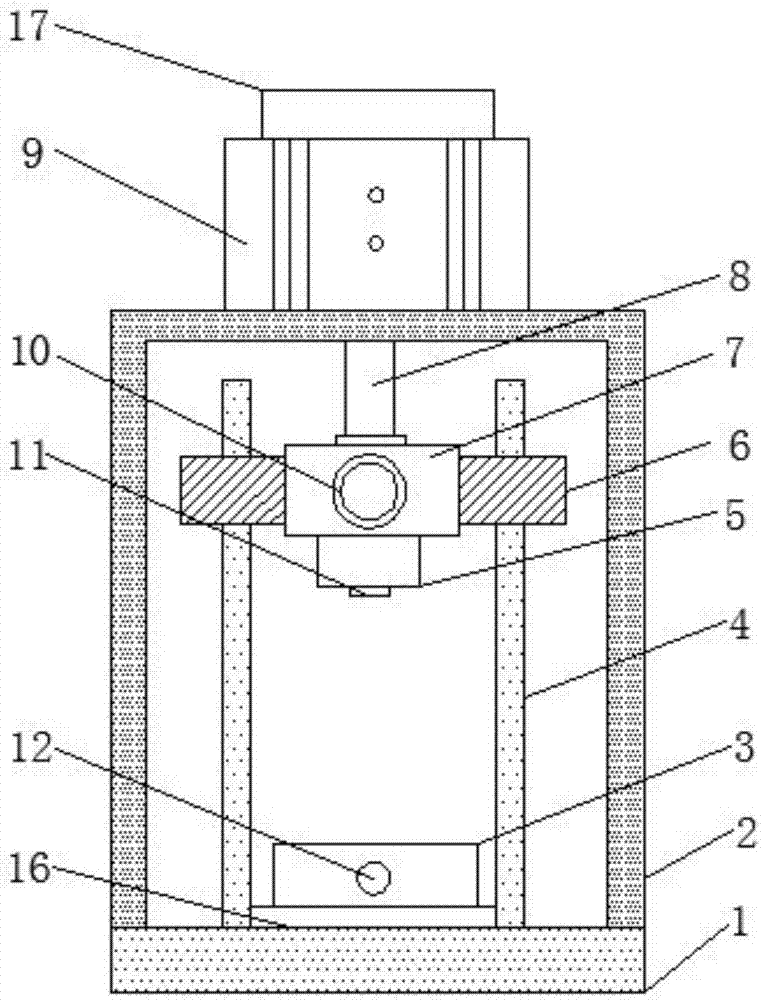

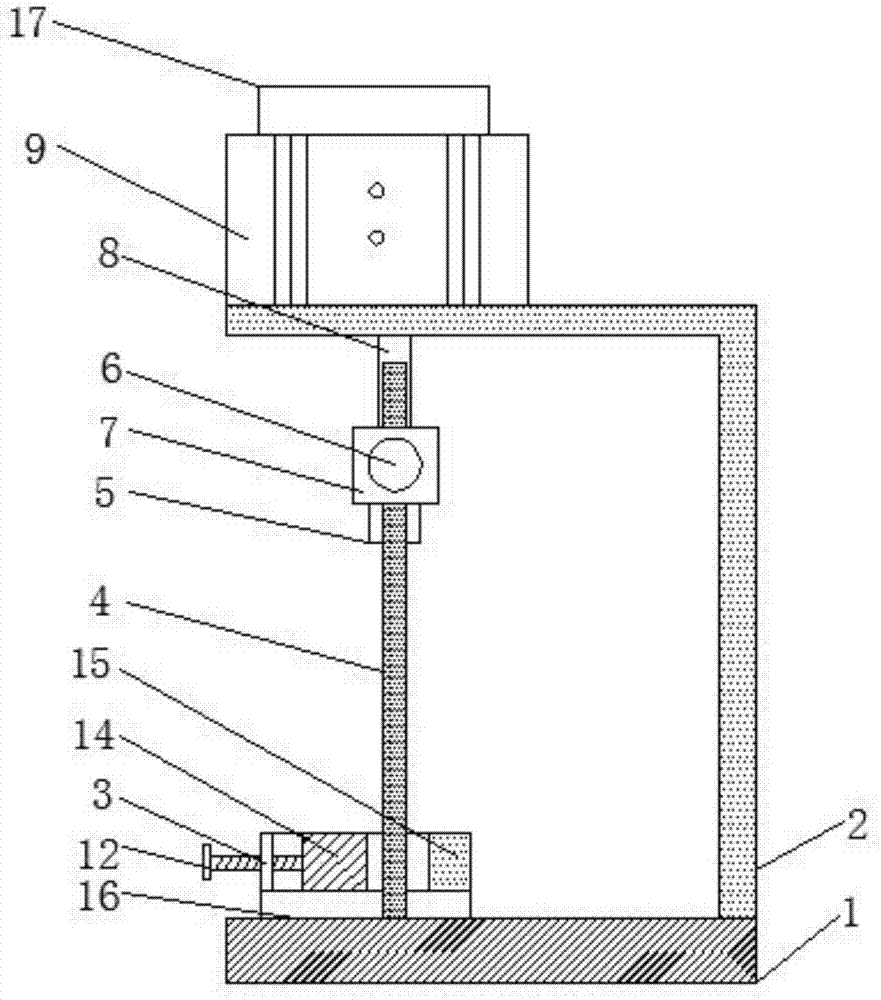

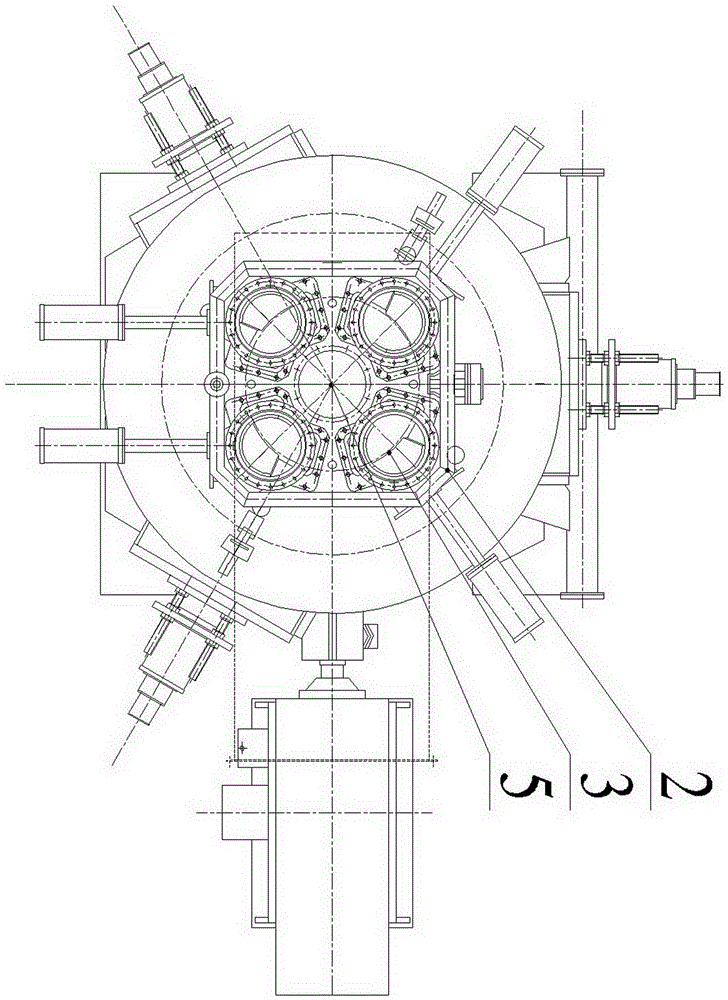

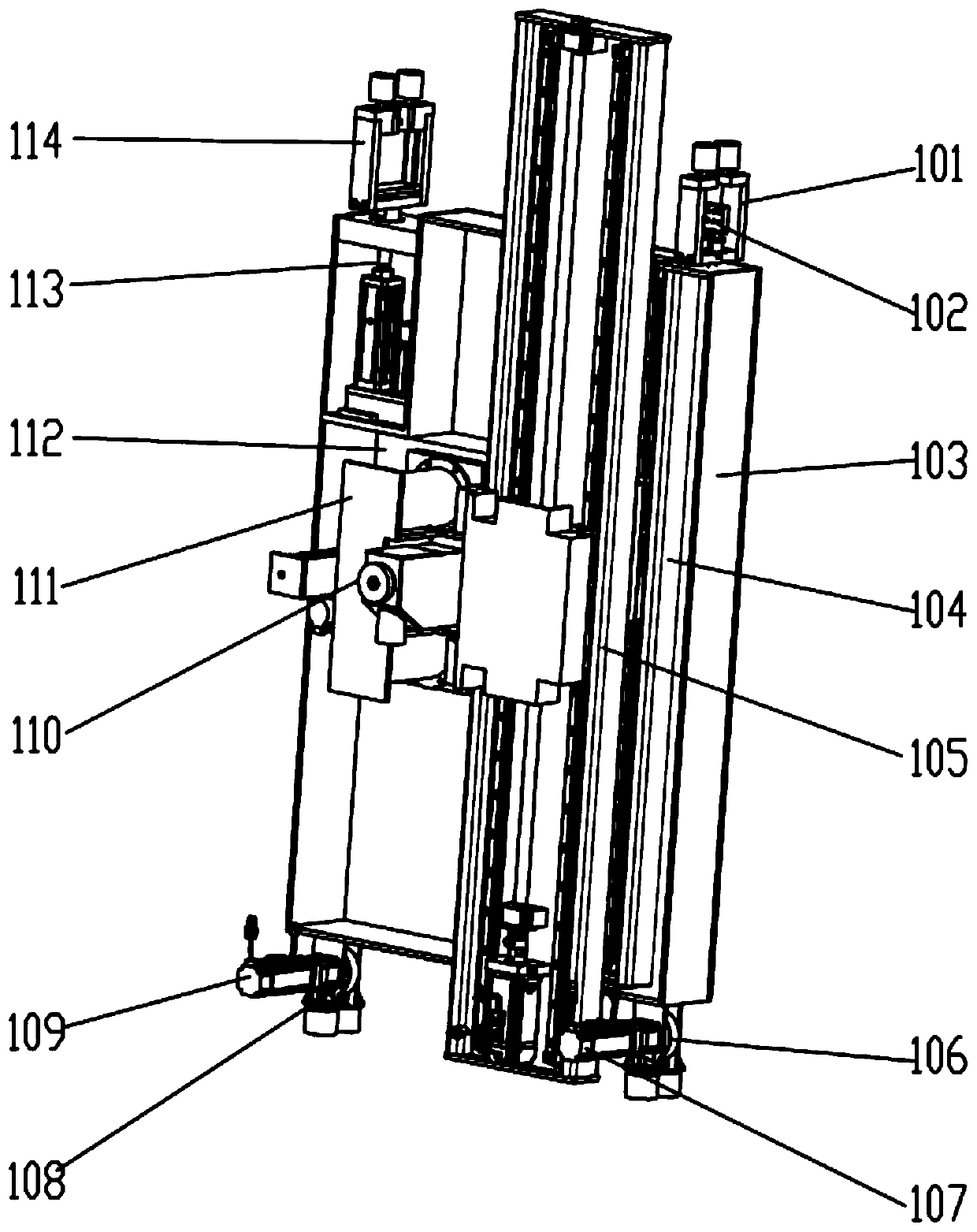

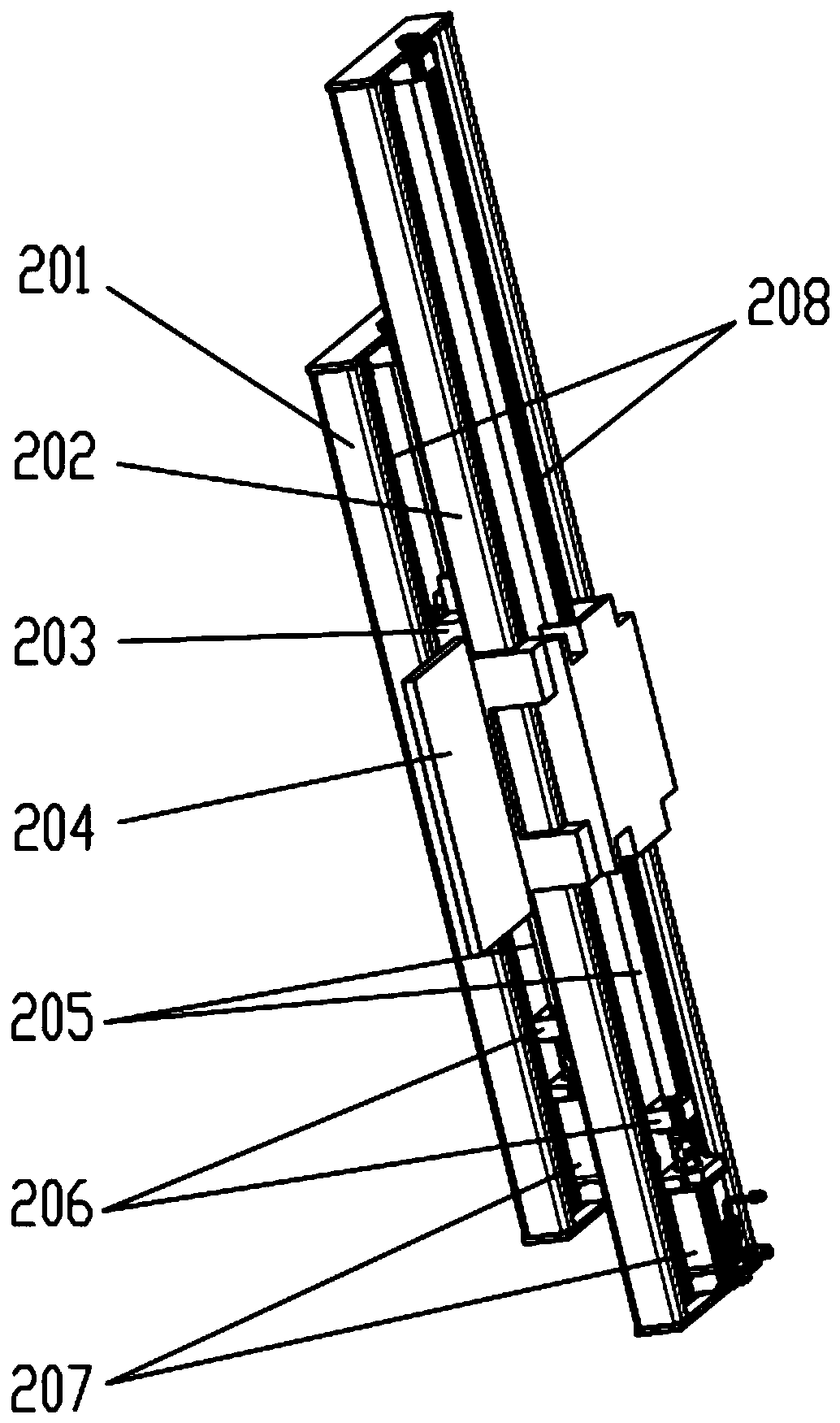

Welding robot for aluminum electrolysis cell

ActiveCN105328372ASolve welding efficiencySolve work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesElectrolysisPower flow

The invention discloses a welding robot for an aluminum electrolysis cell. The welding robot comprises a robot assembly (1) composed of a welding mechanical arm and a carrying mechanical arm. The robot assembly (1) is connected with a debugging platform (2). One side of the debugging platform (2) is provided with a gravity center adjustment device (3) linked with the robot assembly (1). A vertical lifting mechanism (12) is arranged below the debugging platform (2) and connected with a movable trolley (11). The movable trolley (11) travels on the cathode surface of the cell shell of the electrolysis cell and is provided with a control unit (6). According to the welding robot, the length of a metal block is shortened, and a hole in a spacing rod can be right clamped. Operation of the welding robot is very simple and easy. Not only is the welding work efficiency is high, but also the welding quality is reliable. The uniformity of electric current distribution of the electrolysis cell is improved, and potential safety hazards in production running are reduced.

Owner:GUIYANG AL-MG DESIGN & RES INST

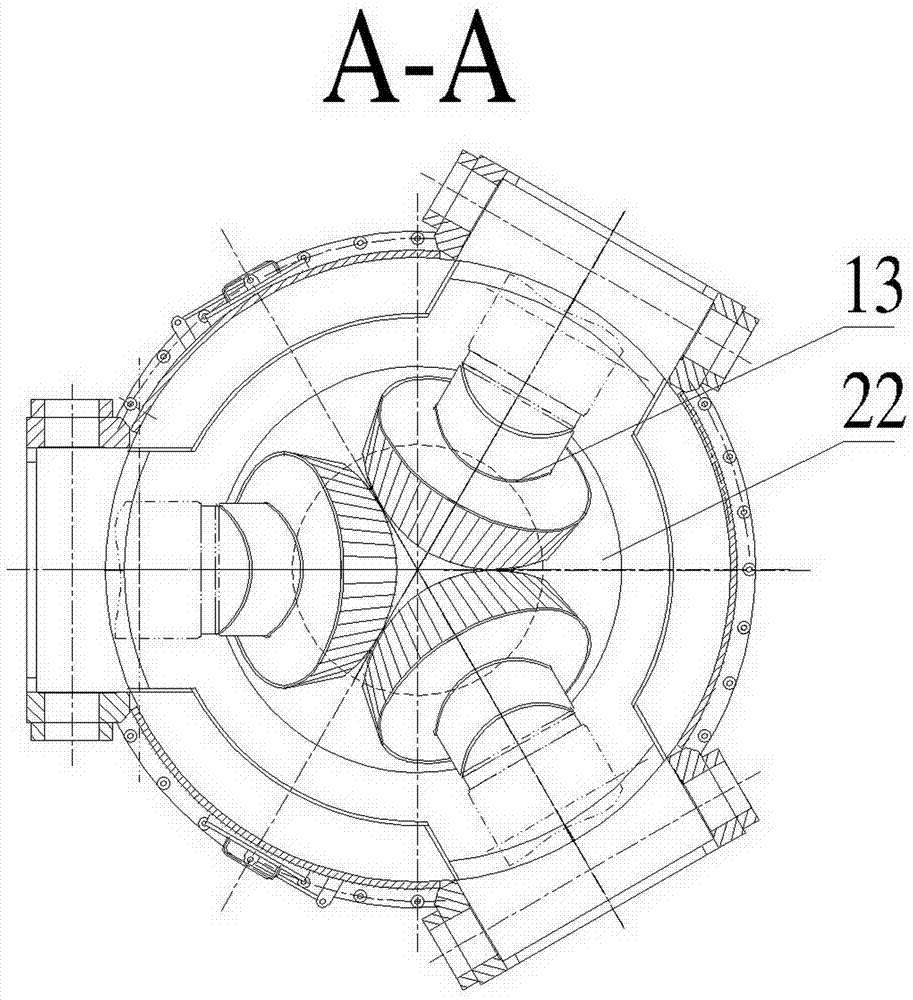

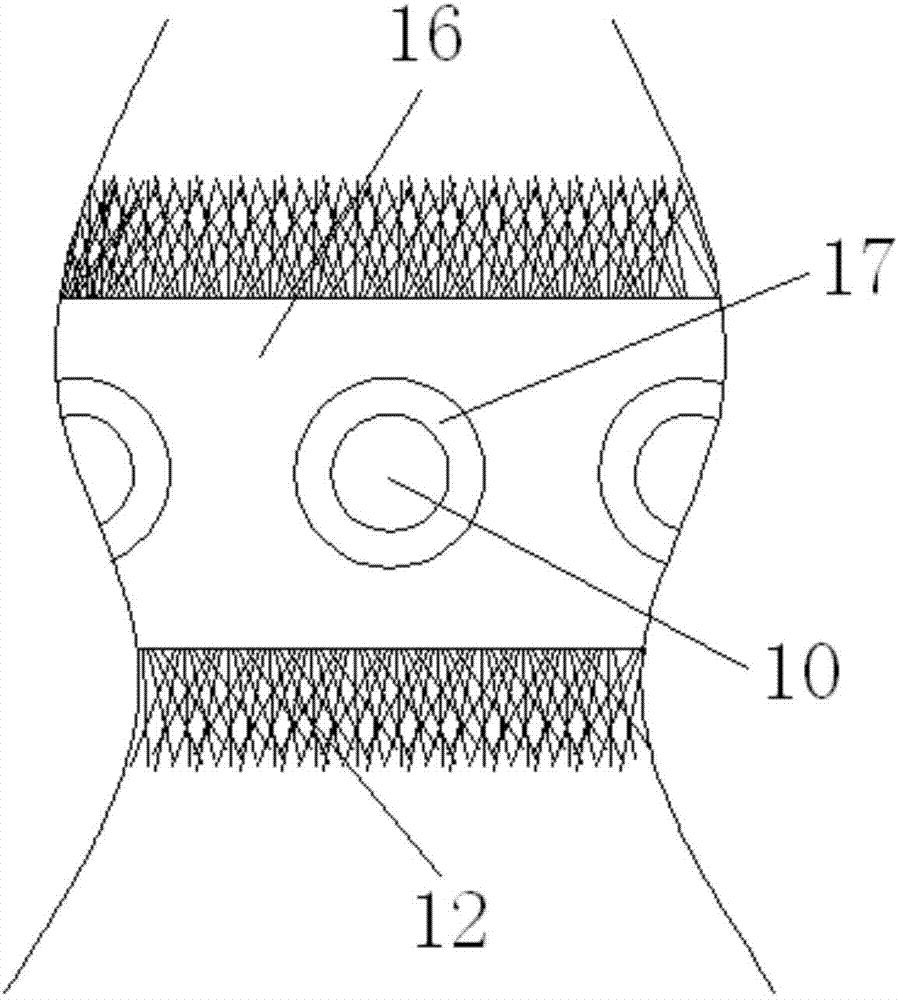

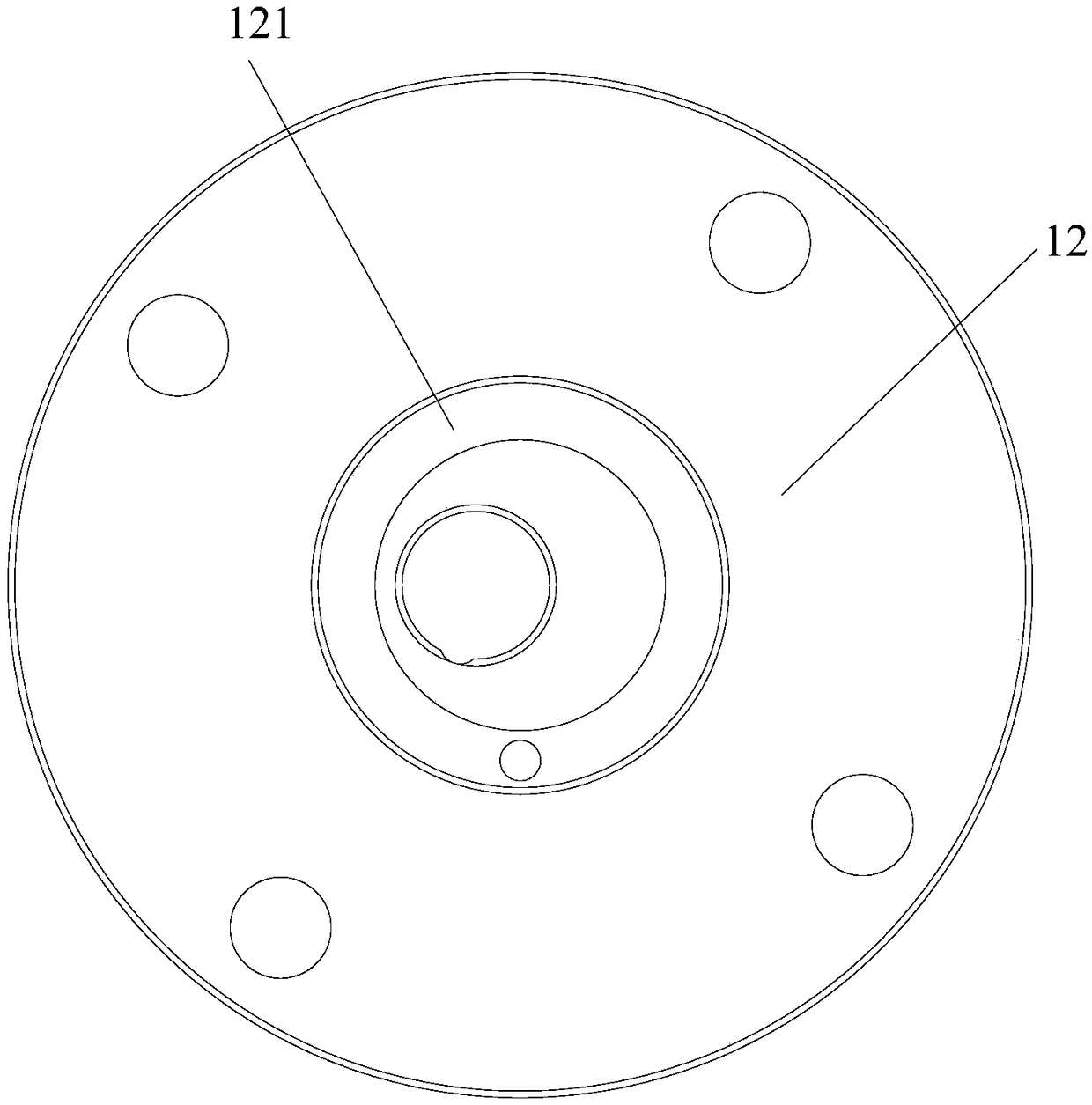

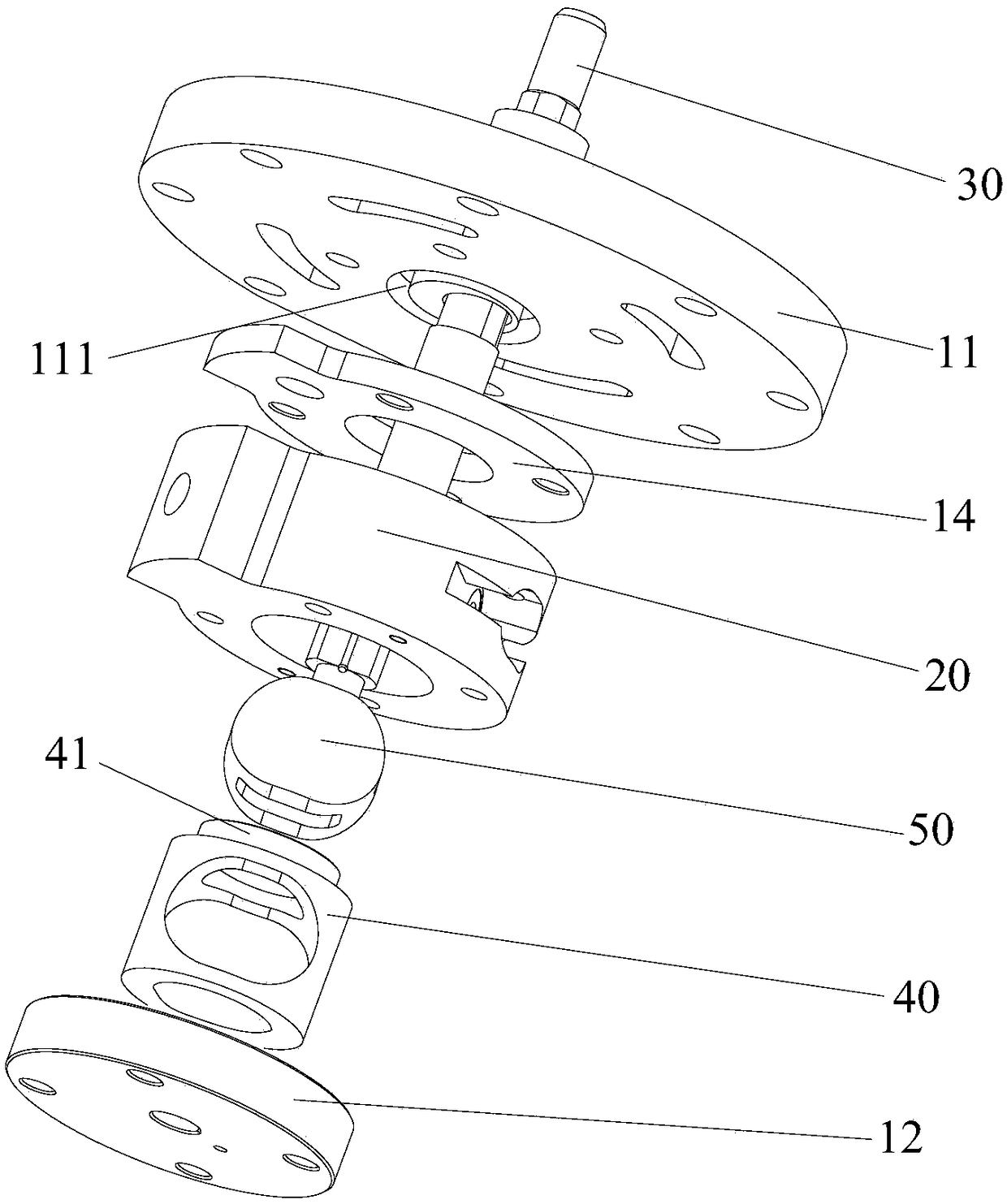

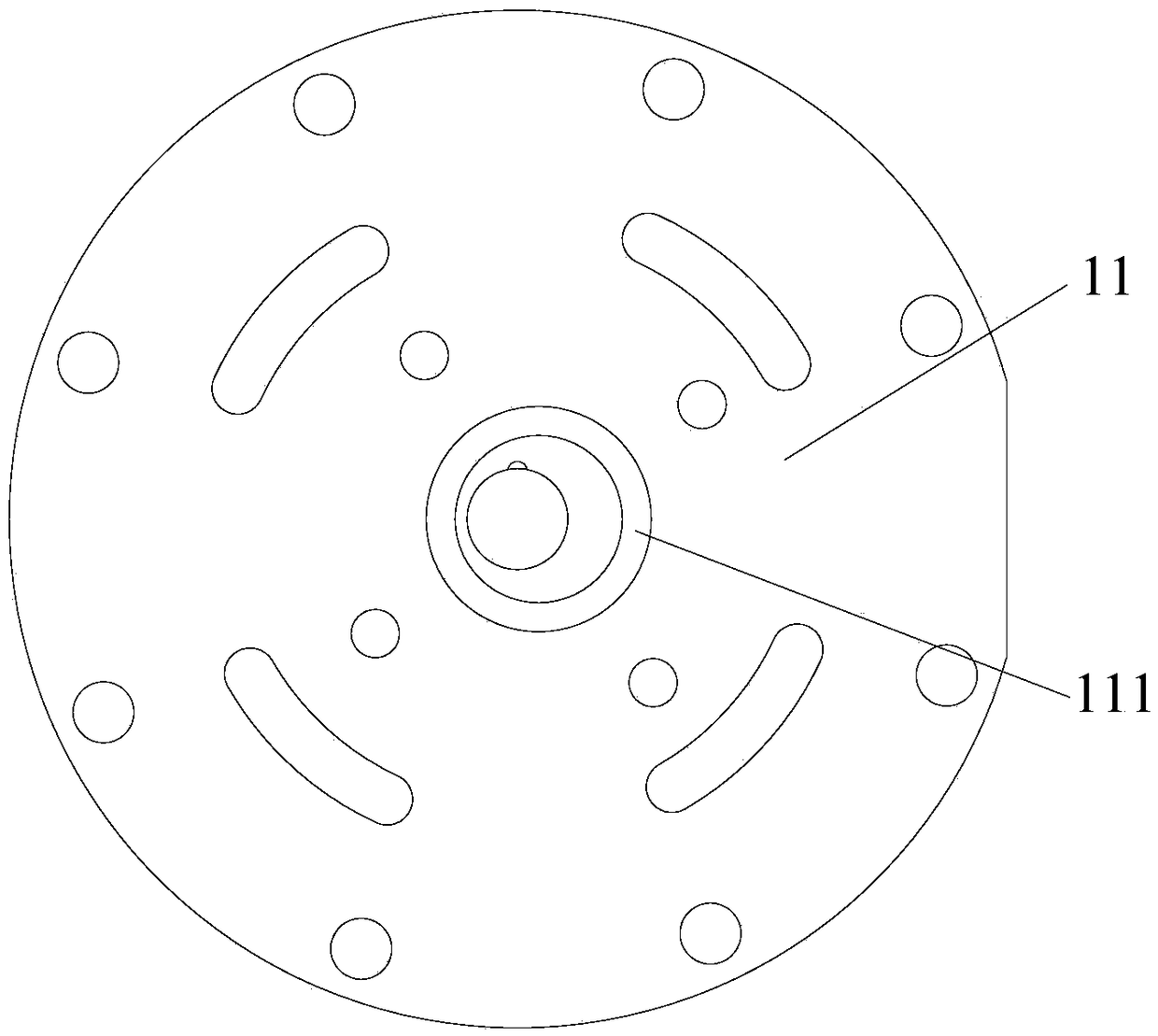

Pump body assembly, fluid machine and heat exchange equipment

PendingCN108799105AImprove operational reliability and performanceImprove operational reliabilityRotary piston pumpsRotary piston liquid enginesPistonEngineering

The invention provides a pump body assembly, a fluid machine and heat exchange equipment. The pump body assembly comprises an upper flange, an upper wearing ring, an air cylinder and a piston assembly, wherein the upper wearing ring is positioned in the air cylinder, and the upper flange is positioned above the air cylinder; the piston assembly is arranged in the air cylinder and comprises a piston sleeve and a piston slidably disposed within the piston sleeve, the upper wearing ring is provided with a central hole, and the upper end face of the piston sleeve is provided with a first extendingpart extending into the central hole of the upper wearing ring and in limiting fit with the lower end face of the upper flange to prevent radial displacement of the piston sleeve relative to the upper flange. The pump body assembly effectively solves the problem that a piston sleeve of a pump body assembly in the prior art is prone to generate eccentric rotation and affects the working efficiencyof the pump body assembly.

Owner:GREE ELECTRIC APPLIANCES INC

Pump body assembly, fluid machinery and heat exchange equipment

PendingCN108799104ASolve work efficiencyImprove operational reliabilityPiston ringsPlungersEngineeringPiston

The invention provides a pump body assembly, fluid machinery and heat exchange equipment. The pump body assembly comprises a lower flange, a lower anti-friction ring, an air cylinder and a piston assembly, wherein the lower anti-friction ring is positioned in the air cylinder, and the lower flange is positioned below the air cylinder; the piston assembly is arranged in the air cylinder; the pistonassembly comprises a piston sleeve and a piston which is arranged in the piston sleeve in a sliding mode; a center hole is formed in the lower anti-friction ring; the surface, which faces towards thelower flange, of the piston sleeve is provided with a limiting bulge; and the limiting bulge extends into the center hole of the lower anti-friction ring, and is in limiting fit to the lower flange to prevent the piston sleeve from displacement in a radial direction relative to the lower flange. The pump body assembly effectively solves the problems that the piston of the pump body assembly in the prior art is liable to have eccentric rotation and the working efficiency of the pump body assembly is affected.

Owner:GREE ELECTRIC APPLIANCES INC

Pump body assembly, fluid machine and heat-exchanging equipment

PendingCN108869279AImprove operational reliability and performanceImprove operational reliabilityRotary piston pumpsRotary piston liquid enginesPistonEngineering

The invention provides a pump body assembly, a fluid machine and heat-exchanging equipment. The pump body assembly comprises an upper flange, an upper limiting board, a cylinder and a piston assembly,wherein the upper limiting board is positioned between the upper flange and the cylinder; the piston assembly is arranged in the cylinder; the piston assembly comprises a piston bush and a piston which is arranged in the piston bush in a slide manner; the upper end face of the piston bush is matched with the lower end face of the upper limiting board in a limiting manner in order to prevent the piston bush from moving in a radial direction relative to the upper flange. By adopting the pump body assembly, the problem of influence on the working efficiency of the pump body assembly since the piston bush is liable to rotate eccentrically in the prior art is solved effectively.

Owner:GREE ELECTRIC APPLIANCES INC

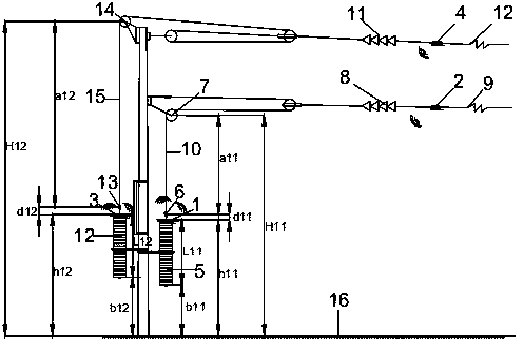

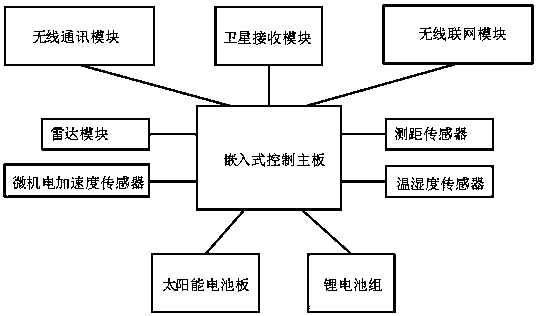

Online monitoring device for anchor sections of overhead lines

InactiveCN110320021AQuality improvementImprove securityMachine part testingTime informationPoint change

The invention discloses an online monitoring device for anchor sections of overhead lines. The device comprises a first host 1, a first slave 2, a second host 3 and a second slave 4. According to thedevice, through a micro-electro-mechanical acceleration sensor, a distance measuring sensor, a temperature and humidity sensor, a satellite data receiving module, a wireless communication module, a wireless networking module and a radar module, the height change of a balance weight string of an overhead line compensator is monitored in real time, the overhead line acceleration value change, hard point change, oscillation amplitude change, disconnection and compensator lag fault information and ambient temperature and humidity, position and time information are monitored in real time, and the data is preprocessed and then sent to a cloud data analysis and processing center, so that a support is provided for an overhead line maintenance mechanism. According to the device, the problems that the states of the overhead lines cannot be acquired in a full time period in vehicle detection and artificial patrol modes and the feedback speed is low are solved, so that the maintenance work is moretargeted and the efficiency is higher, and thus the quality of a tractive power supply system is improved, and the train operation safety is improved.

Owner:郑州意达信息技术有限公司

Dressing change bed facilitating abdominal dressing change

ActiveCN111920609AIncrease in sizeEasy dressing changePneumatic massageNursing bedsDressing changeEngineering

The invention relates to the field of medical sickbeds, and discloses a dressing change bed facilitating abdominal dressing change, which comprises a bed frame, a left bed board and a right bed boardare arranged on the bed frame, the left bed board is hinged with the right bed board, a left mattress and a right mattress are respectively arranged on the left bed board and the right bed board, a right expansion unit is fixedly connected to the right mattress, and the right expansion unit comprises a plurality of right expansion airbags; an inflation mechanism used for inflating the right expansion unit is arranged below the bed frame and comprises an inflation pipe, the inflation pipe is communicated with a plurality of inflation branch pipes I, control valves I are installed on the inflation branch pipes I, and the ends, away from the inflation pipe, of the inflation branch pipes I are communicated with the corresponding right expansion air bags respectively. According to the invention, the volume of the inflated right expansion air bag of the right expansion unit is increased, and the rear waist of the patient is pushed to leave the right mattress, so that a space is reserved between the rear waist of the patient and the right mattress, medical personnel can change medicine conveniently, the patient is prevented from exerting force autonomously, the medical personnel are prevented from exerting force to lift the abdomen of the patient, and the working efficiency of the medical personnel is improved.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

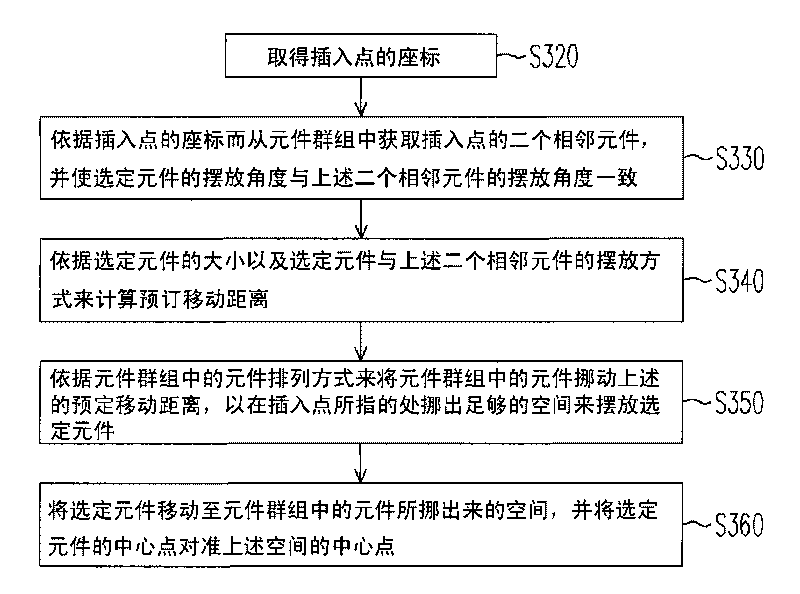

Layout method capable of automatically arranging insertion elements

InactiveCN101751486ASolve work efficiencyAvoid errorsSpecial data processing applicationsEngineeringInsertion point

The invention provides a layout method capable of automatically arranging insertion elements. In the method, firstly, a coordinate of an insertion point is obtained, and the insertion point represents the insertion position at which a selected element is pre-inserted into an element group, wherein the elements in the element group are arranged vertically or horizontally. Secondly, two adjacent elements of the insertion point are obtained from the element group according to the coordinate of the insertion point, and the putting angle of the selected element is consistent with that of the two adjacent elements. Thirdly, the pre-set movement distance can be calculated according to the size of the selected element and the putting mode of the selected element and the two adjacent elements. Fourthly, the elements in the element group are moved for the preset movement distance according to the arrangement mode of the elements in the element group, so as to form an enough space at the position pointed by the insertion point for putting the selected element. Finally, the selected element is moved to the spaced formed by moving the elements in the element group, and the central point of the selected element is aligned with that of the space.

Owner:INVENTEC CORP

Medical infusion equipment convenient to use

InactiveCN112569425ASolve work efficiencyEasy to compare and viewDrug and medicationsInfusion devicesIntensive care medicineFluid administration

The invention discloses medical infusion equipment convenient to use, which belongs to the field of medical treatment, and comprises a seat, an infusion mechanism, an infusion tube, a flow guide blockand a cleaning mechanism; the seat is arranged on the ground of an infusion area, the infusion mechanism is arranged right above the seat, and the bottom of the infusion mechanism is provided with the infusion tube through the flow guide block; a cleaning mechanism is further arranged in the liquid conveying mechanism. After the medical staff confirms by comparing with a patient information areaoutside the infusion box according to the doctor's advice information, liquid medicine to be infused is poured into the infusion box for one-time infusion; after infusion of a patient in an infusion area is completed, clear water is introduced into the infusion box through the cleaning mechanism, residual liquid medicine in the box is diluted and cleaned; and after the liquid level in the water tank reaches the liquid detection switch at the top of the siphon, the water supplementing electromagnetic valve is closed, and the drainage electromagnetic valve is opened; finally, the cleaning liquidin the tank automatically flows out from the end part of the siphon under the siphon action until no water remains in the tank.

Owner:夏厦

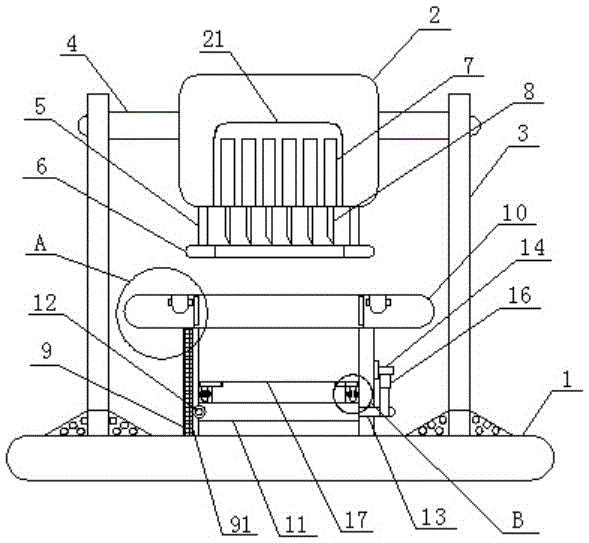

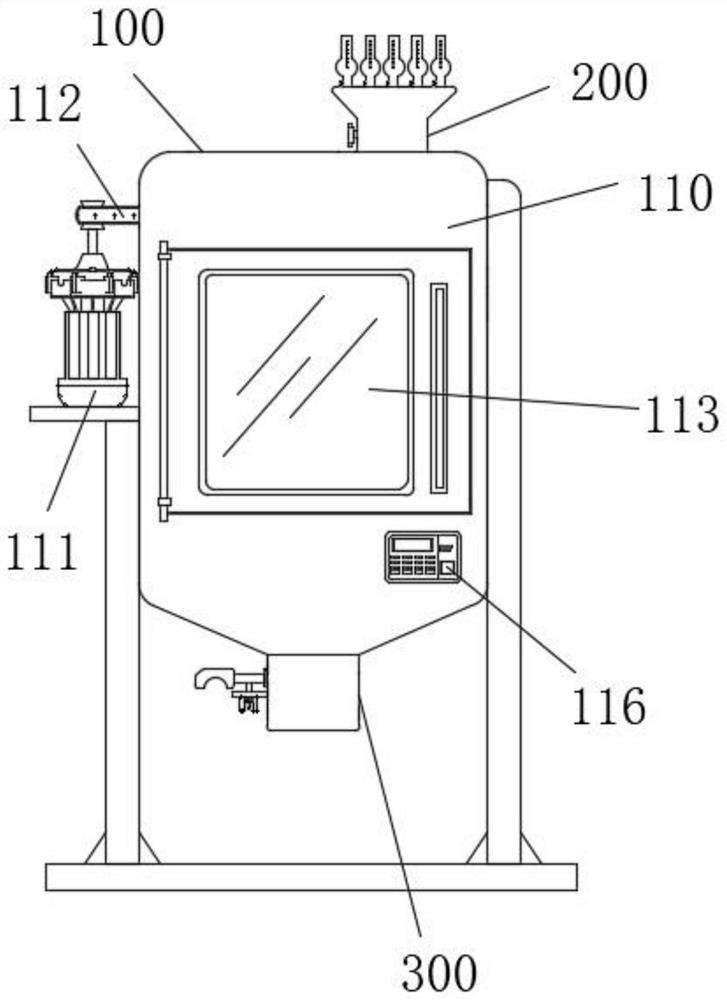

Efficient embroidery machine convenient to use

ActiveCN106436084ASolve work efficiencyQuality improvementAuxillary devicesFeedersSoftware engineeringElectric machinery

The invention discloses an efficient embroidery machine convenient to use. The machine comprises a base and an embroidery machine body. The embroidery machine body is located over the base. A storage bin is arranged in the middle of the upper surface of the base. A worktable is installed at the top end of the storage bin. A sliding groove is formed in one side face in the storage bin. A supporting table is arranged at the bottom of the storage bin. The other end of the supporting table is provided with an extending rod, one end of the extending rod penetrates through the inner side wall of the storage bin, a circular slide way is arranged on the side wall, away from a movable wheel, of the storage bin, and a rotary motor is installed in a motor installation groove. An embroidery template is placed on the upper surface of the supporting table, and a groove is formed in the side wall of the worktable. The problems that a common computer embroidery machine is only provided with one embroidery template which is inconvenient to replace, and work efficiency of the computer embroidery machine is affected are solved. Work efficiency is improved, and economic practicability is very high.

Owner:贵州榜香郁苗绣服饰开发有限公司

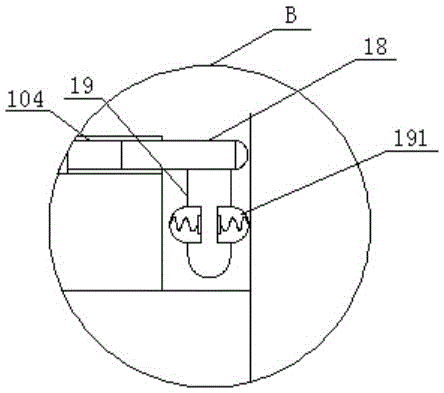

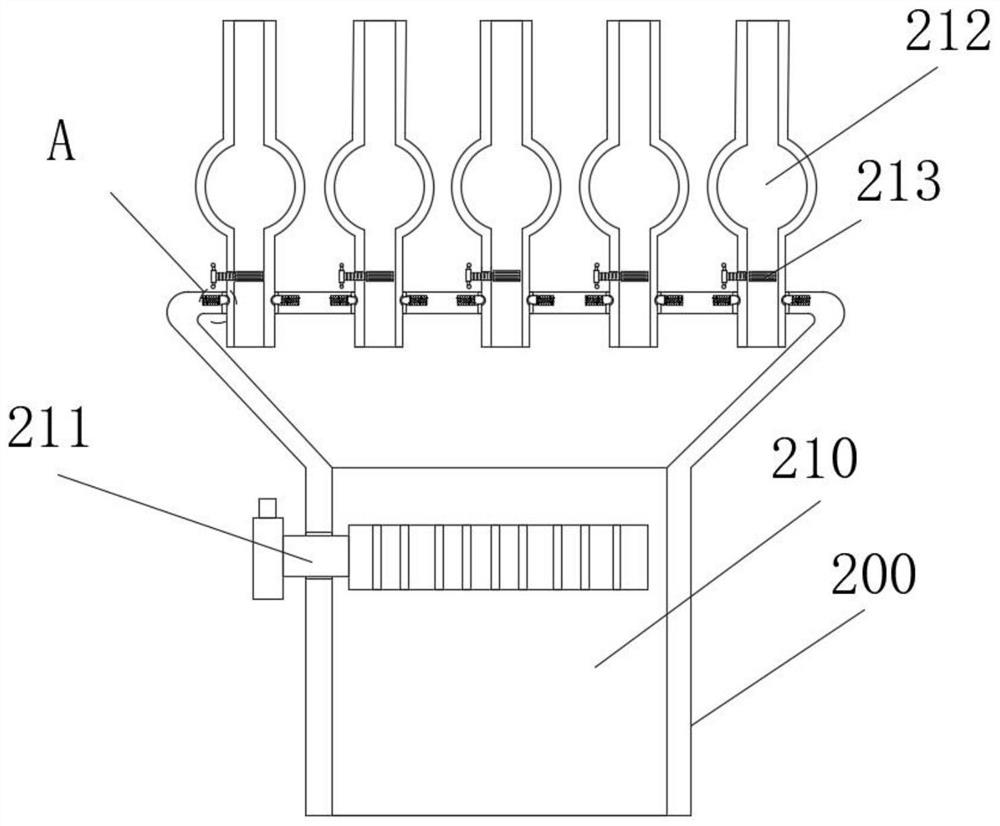

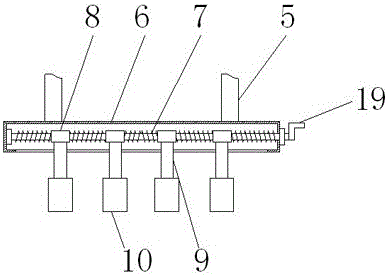

Multi-press head and semi-automatic terminal crimping machine

InactiveCN107994441ASolve work efficiencyQuick changeLine/current collector detailsSemi automaticEngineering

The invention discloses a multi-press head and semi-automatic terminal crimping machine. The multi-press head and semi-automatic terminal crimping machine comprises a base, wherein a rack, two slidingrails and a crimping bottom disc are arranged at a top end of the base, the crimping bottom disc is arranged between the two sliding rails, the rack is arranged at one side of each sliding rail, a terminal fixing rear plate, a terminal fixing sliding way and a terminal fixing front plate are arranged at a top end of the crimping bottom disc, the terminal fixing rear plate is arranged at one sideof the terminal fixing sliding way, and an adjustment screw rod is arranged in the terminal fixing front plate in a penetrating way. A press head fixing square block is arranged at an outer side of amovable sliding block, a plurality of press head seats can be fixed on the press head fixing square block, only the press head fixing square block is needed to be rotated when the press head is neededto be replaced, a terminal press head at the bottom end is adjusted, so that the terminal press head of the terminal crimping machine can be rapidly replaced, and the problem that the press head is not conveniently replaced according to different terminals during application of the terminal crimping machine to affect the efficiency of crimping operation is solved.

Owner:CHONGQING RUIRUN ELECTRONICS

Efficient planing device used for bamboo and wood processing

InactiveCN108544621AImprove practicalityEasy to useTree debarkingCane mechanical workingEngineeringSlide plate

The invention discloses an efficient planing device used for bamboo and wood processing. The device comprises a shell. The rear side of the inner wall of the shell is fixedly connected with a motor. The output end of the motor is fixedly connected with a turnplate. The front face of the turnplate is movably connected with a connecting plate. The top of the connecting plate is movably connected with a slide plate. The top of the slide plate is in sliding connection with a slide bar. The bottom of the slide bar penetrates through the slide plate and extends to the bottom of the slide plate to befixedly connected with the bottom of the inner wall of the shell. The top of the slide bar is fixedly connected with a positioning block. According to the efficient planing device, by arranging the shell, the motor, the turnplate, the connecting plate, the slide plate, the slide bar, the positioning block, a power plate, fixing blocks, movable plates, slide sleeves, slide rods, a workbench, supporting plates, clamp plates, a wood plate, a first air cylinder, a second air cylinder and a plane cutter which are used in cooperation, the problems that an existing planing device fails to clamp bamboo and wood tightly, the bamboo and wood are prone to warp up in the planing process, and consequentially, the working efficiency of the planing device is lowered are solved.

Owner:安吉铸卫竹木制品有限公司

Automatic seasoning feeding and stirring device for food pickling

InactiveCN111804182ASolve work efficiencyEasy to disassemble and cleanRotary stirring mixersTransportation and packagingElectric machineryIndustrial engineering

The invention relates to the technical field of pickled food, and especially relates to an automatic seasoning feeding and stirring device for food pickling. The device comprises a device main body, wherein the device main body comprises a device shell; a motor is fixedly mounted on one side of the device shell through a mounting plate; a conveying belt is arranged at the top end of the motor; andone side of the conveying belt extends into the device shell through a through groove. An automatic feeding mechanism is arranged, so the problem that an existing seasoning stirring device is found in the using process, when various seasonings are added by workers, workers often need to manually add various seasonings, and the working efficiency of workers is influenced is solved; due to the factthat a seasoning proportioning tank and scale marks are arranged, the workers can proportion seasonings very conveniently; and the workers can disassemble and clean a seasoning proportioning tank very conveniently due to the fact that a clamping ball, a clamping groove and a reset spring are further arranged.

Owner:湖南津山口福食品有限公司

Pump body assembly, fluid machine and heat-exchange equipment

PendingCN108799108ASolve work efficiencyImprove operational reliabilityRotary piston pumpsRotary piston liquid enginesPistonFlange

The invention provides a pump body assembly, a fluid machine and heat-exchange equipment. The pump body assembly comprises an upper flange, an upper limiting plate, an air cylinder and a piston assembly, wherein the upper limiting plate is located between the upper flange and the air cylinder; the piston assembly is arranged in the air cylinder and comprises a piston sleeve and a piston slidably arranged in the piston sleeve; and a first extending part is arranged on the upper end surface of the piston sleeve, stretches into a center hole of the upper limiting plate and is in limiting fit withthe lower end surface of the upper flange, so that the piston sleeve is prevented from displacing in the radial direction relative to the upper flange. According to the pump body assembly, the fluidmachine and the heat-exchange equipment provided by the invention, the problem that in the prior art, the working efficiency of apump body assembly is affected since apiston sleeve of the pump body assembly is easy to eccentrically rotate is effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

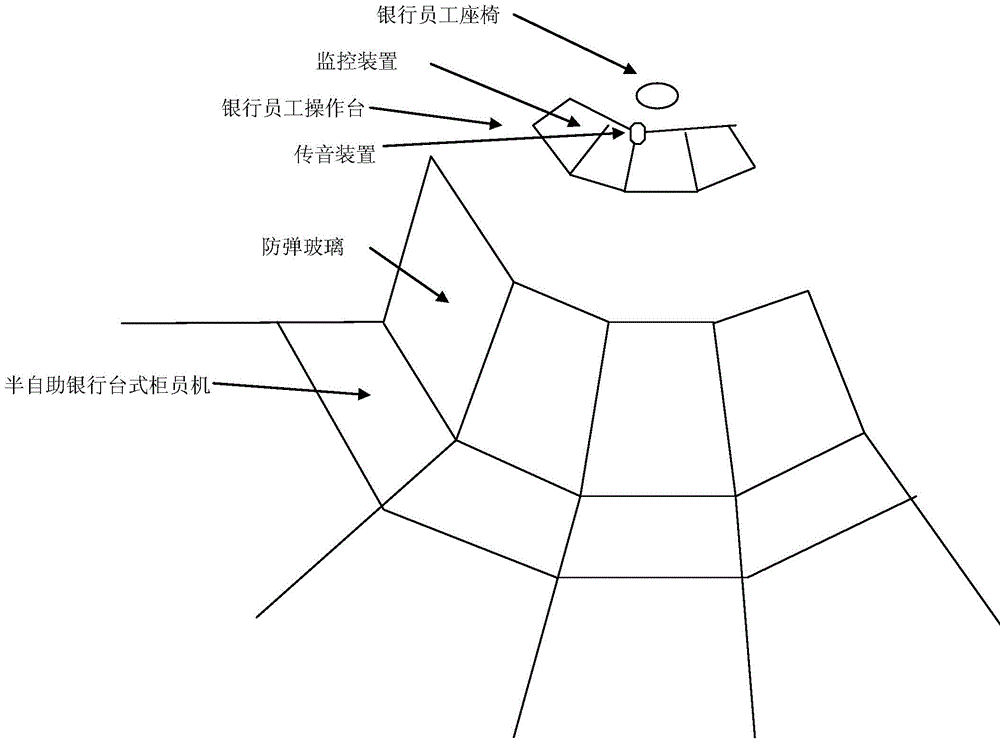

Semi-self-service bank desk type teller machine set

The invention discloses a semi-self-service bank desk type teller machine set. The semi-self-service bank desk type teller machine set comprises at least two semi-self-service bank desk type teller machines, bullet-proof glass, a bank employee operation desk, a monitoring device and a sound transmission device. A bank employee can serve a plurality of customers at the bank employee operation desk simultaneously. The bank employee operation desk is provided with arc-shaped display screens, wherein the number of the display screens is equal to that of the semi-self-service bank desk type teller machines. The bank employee at the bank employee operation desk checks the business handling process of the customer through the display screens and the bullet-proof glass and gives a prompt. Each semi-self-service bank desk type teller machine comprises a main machine, a teller machine desk, a touch screen, three groups of card reading devices, three groups of currency counting devices, three groups of noncontact type card reading devices, a group of worn coin and A4 paper conveying devices, a printer / scanner, a two-dimensional scanning device and a USB (universal serial bus) digital certificate interface. The main machine of each semi-self-service bank desk type teller machine is used for handling a banking business for the customer and controlling all the parts of each semi-self-service bank desk type teller machine.

Owner:广东奔腾达电子有限公司

Pump body assembly, fluid machine and heat exchange equipment

PendingCN108799106ASolve work efficiencyImprove operational reliabilityRotary piston pumpsRotary piston liquid enginesEngineeringRadial displacement

The invention provides a pump body assembly, a fluid machine and heat exchange equipment. The pump body assembly comprises a lower flange, a lower wearing ring, an air cylinder and a piston assembly,wherein the lower wearing ring is positioned in the air cylinder, and the lower flange is positioned below the air cylinder; the piston assembly is arranged in the air cylinder and comprises a pistonsleeve and a piston slidably disposed within the piston sleeve, and the lower end face of the piston sleeve is in limiting fit with the lower wearing ring to prevent radial displacement of the pistonsleeve relative to the lower flange. The pump body assembly effectively solves the problem that a piston sleeve of a pump body assembly in the prior art is prone to generate eccentric rotation and affects the working efficiency of the pump body assembly.

Owner:GREE ELECTRIC APPLIANCES INC

Vending processing method, system and device and cashier processing method and device

InactiveCN111383405ASolve work efficiencyMany manpowerCustomer communicationsCharacter and pattern recognitionOperating systemIndustrial engineering

The invention discloses a vending processing method, system and device and a cashier processing method and device; the invention includes acquiring image information of a consumer entering a store under the condition that the cashier mode is switched to a self-service cashier mode; determining identity information of the consumer according to the image information; and based on the identity information of the consumer, guiding the consumer to a cashier desk through voice or other forms to perform cashier guidance of self-service settlement. According to the invention, the work efficiency of ashop owner can be improved, more manpower is released to the shop owner, and time and money are saved for the shop owner.

Owner:ALIBABA GRP HLDG LTD

Using method of steam protecting grinding machine for preparing waste tire fine rubber powder

ActiveCN107521001ASolve work efficiency and timely sortingAddress Contaminant SpillsPlastic recyclingGrain treatmentsWaste tiresEngineering

The invention relates to the technical field of resource recycling and comprehensive utilization, in particular to a using method of a steam protecting grinding machine for preparing waste tire fine rubber powder. The using method is characterized in that the advantages of a movable-fixed tool and a movable-movable tool in the prior art are combined, in the working process, a driving grinding grate assembly rotates, friction force generated during cutting of waste tire rubber drives three grinding rollers to rotate, then, three grinding roller work faces are generated, that is, the working conditions that millstones cut each other, and the millstones and a grinding bowl and a conical grate which are on the working face of the driving grinding grate assembly cut each other occur, accordingly, the working efficiency is improved, and sorting is conducted in time. Steam is adopted as a medium to complete the production technological processes including rubber powder conveying, protecting, heat preservation, sorting, separating and the like, and the purposes of improving the rubber powder production quality, reducing the cost and achieving environment friendliness are realized.

Owner:吴雨潞

Exterior wall grinding robot

PendingCN111251104ASolve pollutionSolve labor costsGrinding carriagesGrinding drivesEngineeringVertical climbing

The invention provides an exterior wall grinding robot. The exterior wall grinding robot comprises a vertical climbing frame. A plurality of guide rail units are arranged in the climbing frame in parallel. Each guide rail unit comprises an upper guide rail and a lower guide rail which are horizontally fixed in parallel in an up-down mode, A robot doing horizontal reciprocating movement along the guide rail units is arranged between the upper guide rails and the lower guide rails. A grinding mechanism moving in the X-axis, Y-axis and Z-axis directions is mounted in the robot. The robot is usedfor replacing manual operation. The problem of labor cost is solved. Moreover, the problem of personal safety possibly caused by aloft work is solved. The problem of working efficiency caused by the large grinding area and alternate construction through manual operation and the climbing frame is solved. The grinding mechanism of the exterior wall grinding robot is provided with a dust suction mechanism, and the problem of pollution to the environment is also solved.

Owner:上海雅跃智能科技有限公司

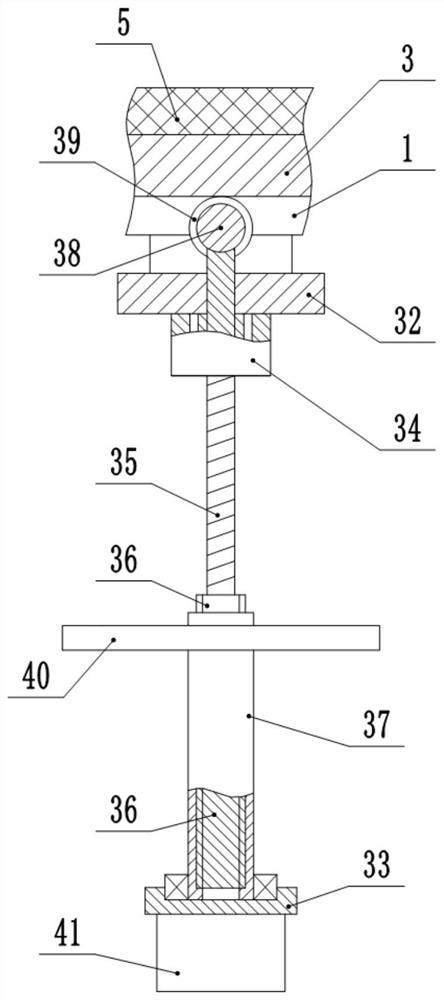

Tillage disk assembly

InactiveCN107517600ASolve work efficiencyEasy to moveTilling equipmentsArchitectural engineeringScrew thread

The invention discloses a tillage tray assembly, comprising a body, a tilling rod is fixedly connected to the left side of the body, an adjusting sleeve is sleeved on the surface of one end of the tilling rod, and an adjusting member is fixedly connected to the top of the adjusting sleeve , the bottom of the adjustment sleeve is fixedly connected with a first connecting rod, the bottom of the first connecting rod is fixedly connected with a connecting frame, the interior of the connecting frame is movably connected with a threaded rod through a fixed shaft, and one end of the threaded rod is Passing through the connecting frame and extending to the outside of the connecting frame, the surface of the threaded rod is threadedly connected with a threaded sleeve. The invention can rotate the threaded rod through the setting of the rotating handle, and through the setting of the threaded rod, the threaded rod rotates while driving the threaded sleeve to move, and then the threaded sleeve drives the movable rod and the rotary tiller to move the distance between the rotary tiller. At the same time, it solves the problem that the distance between the rotary tillers cannot be adjusted, which affects the working efficiency of the tiller.

Owner:黄怀

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com