Full-automatic leather printing and cutting machine and printing and cutting method implemented by same

A fully automatic and automatic printing technology, which is applied in the fields of leather surface mechanical treatment, leather punching/punching/cutting, small raw leather/big raw leather/leather/fur mechanical treatment, etc. Problems such as processing cost and left-right asymmetry of patterns can be solved to improve processing efficiency and processing accuracy, reduce processing costs, and solve graphic printing asymmetry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

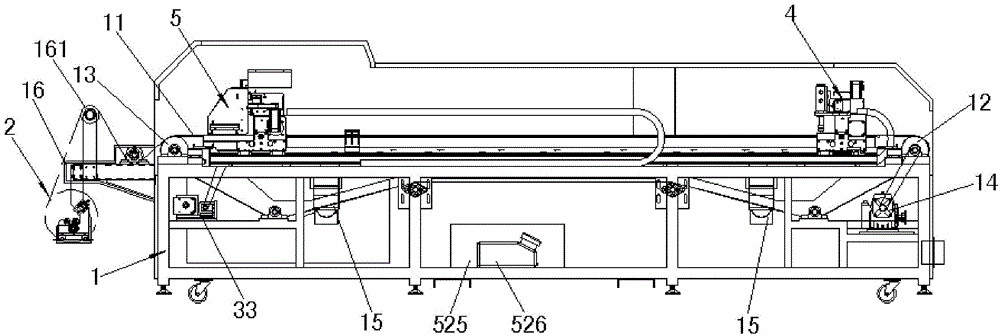

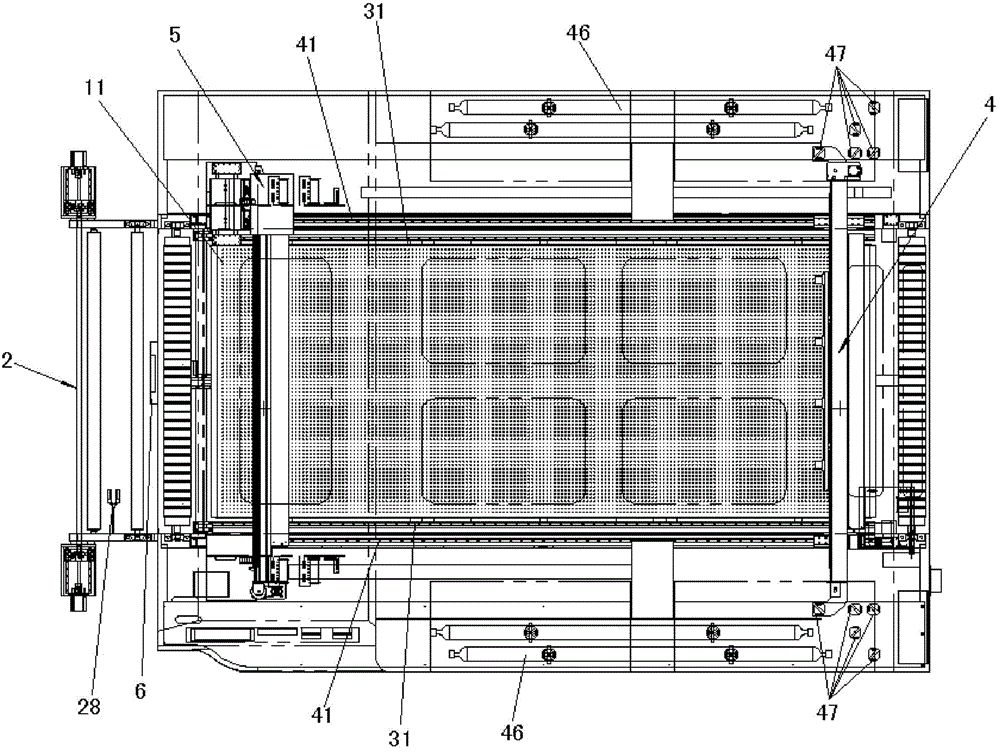

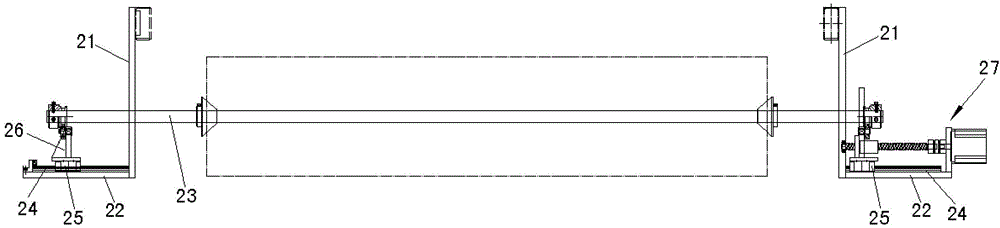

[0027] see Figure 1-14 As shown, the present invention relates to a fully automatic leather printing and cutting machine, including a frame 1, a material rack 16 is provided at the front end of the frame 1, and a material rack roller 161 is also provided on the material rack 16, specifically including automatic deviation correction Mechanism 2, automatic feeding manipulator 3, automatic laser cutting mechanism 4, automatic printing mechanism 5, control system. The printing mechanism 5 is all arranged on the frame 1, and the control system is arranged in the frame 1 and connected with the automatic feeding manipulator 3, the automatic laser cutting mechanism 4, and the automatic printing mechanism 5.

[0028] Compared with the existing technology, the present invention sets up an integrated automatic deviation correction mechanism, an automatic feeding manipulator, an automatic laser cutting mechanism, an automatic printing mechanism, and is controlled by a computer control sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com