Flowing friction additional material manufacturing device and additional material manufacturing method

A technology of additive manufacturing and flow friction, applied in the field of additive manufacturing, can solve the problems of large machining allowance and low material utilization rate, and achieve the effects of low material utilization rate, high efficiency, low-cost manufacturing, and material structure refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

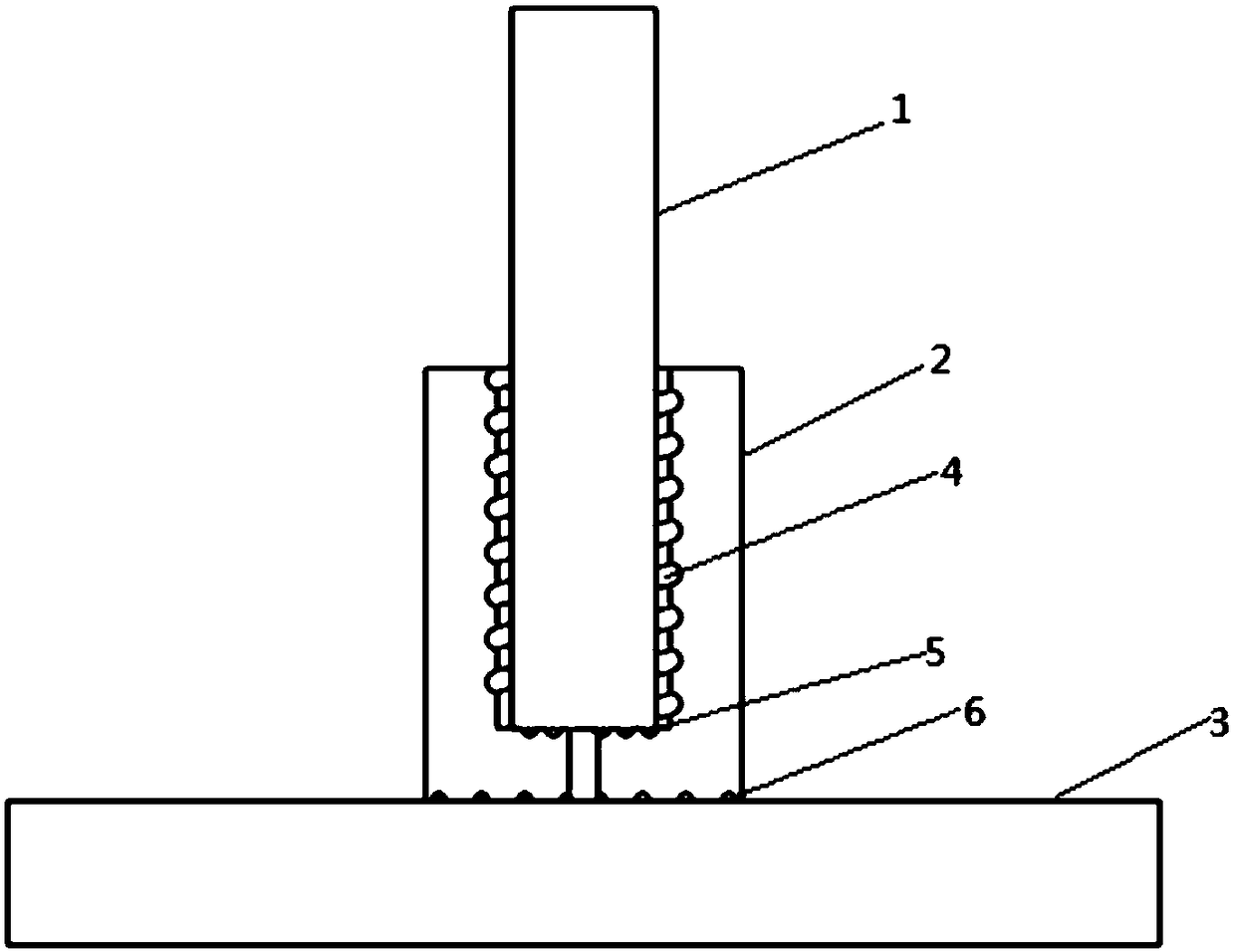

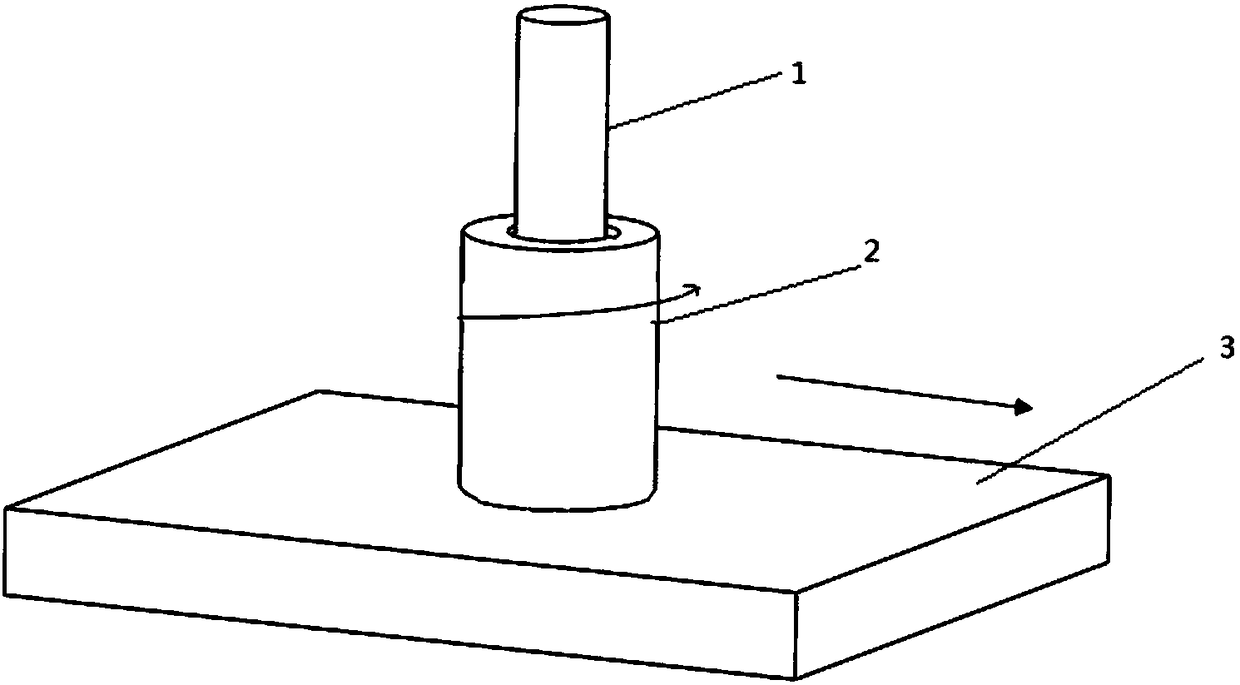

[0032] Such as figure 1 As shown, a flow friction additive manufacturing device includes a shoulder 2, a base material 1 and a base 3, the shoulder 2 is cylindrical, the base material 1 is also cylindrical, and the base 3 is a plate with a cavity inside the shoulder , the lower end of the shaft shoulder below the cavity is provided with a central through hole communicating with the cavity, the cylindrical base material is placed in the cavity inside the shaft shoulder, and the outer end surface of the shaft shoulder is placed on the surface of the matrix to be added; The side wall of the cavity is designed with a spiral groove, that is, the spiral groove 4 on the side wall of the cavity, and the bottom surface of the cavity is also designed with a spiral groove, that is, the spiral groove 5 on the bottom surface of the cavity. The rotation direction of the spiral groove structure depends on the rotation direction of the shoulder during the additive manufacturing process, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com