Using method of steam protecting grinding machine for preparing waste tire fine rubber powder

A technology for waste tires and rubber powder, applied in the field of resource recycling and comprehensive utilization, can solve the problems of easy blocking of sieve holes, sorting efficiency, heat can not be cooled, quality index decline, etc., to solve work efficiency and timely sorting, and solve pollutants The effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

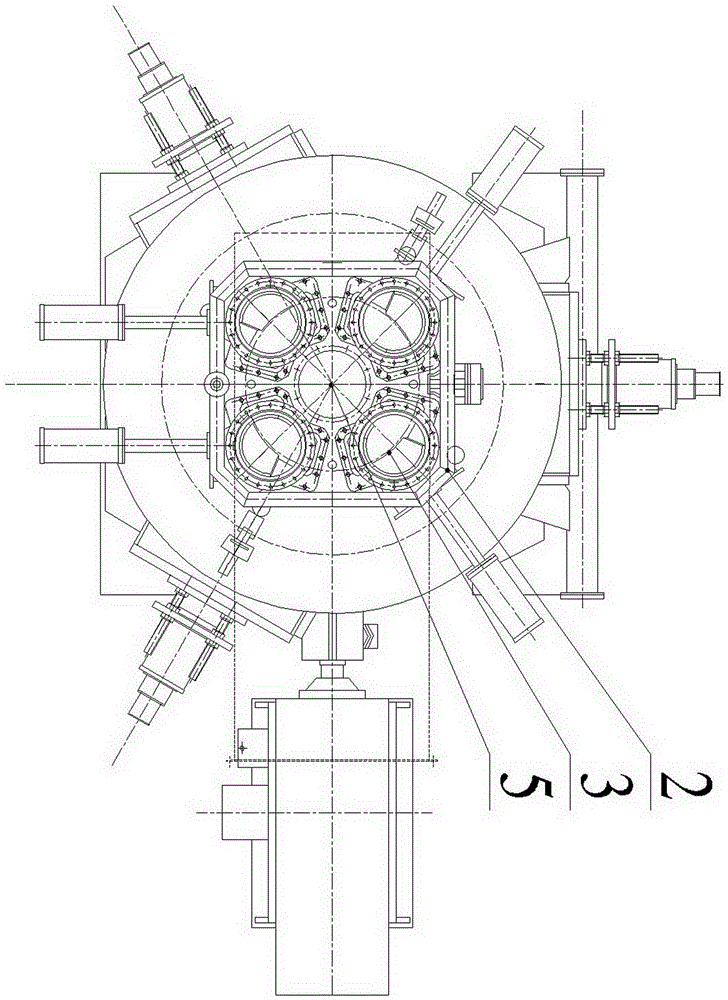

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 Shown, a kind of use method of preparing waste tire fine rubber powder steam protection mill is characterized in that:

[0031] Step 1. Before feeding, use 105°C steam to purge distribution tank assembly I, separator assembly II, and grinding assembly III. At this time, the electric butterfly valve 4 is opened, and the annular header 2 is in a closed state. The steam flows from steam inlet I18, steam The inlet II19 enters, and is discharged through the Venturi tube 3 and the header 1.

[0032] Step 2, after the purging is completed, the tray 23 of the active grinding grate assembly 17 is driven by the driving device 30 to rotate, and the appropriate grinding pressure is applied to the grinding disc 16 by adjusting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com