Welding robot for aluminum electrolysis cell

A welding robot and aluminum electrolytic cell technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as uneven current distribution in the electrolytic cell, unguaranteed welding quality, and potential safety hazards in production and operation , to achieve the effect of solving reliable welding and work efficiency problems, reliable welding quality, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

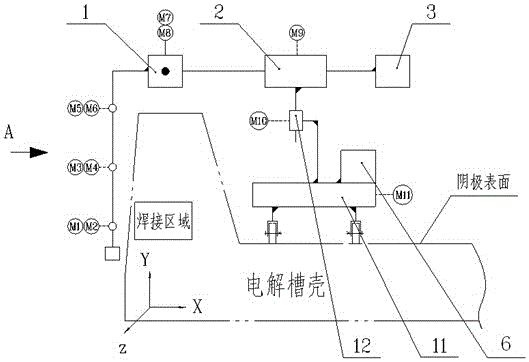

[0015] Such as Figure 1~2 As shown, an aluminum electrolytic cell welding robot is composed of 4, 8, and 9 to form a welding robot arm, 4 is a spiral walking mechanism, 8 is an articulated linkage mechanism, and 9 is a welding device; it is composed of 5, 8, and 7. Arm, 5 is the spiral walking mechanism, 8 is the articulated linkage mechanism, and 7 is the suction cup device; the welding robot arm and the handling robot arm together form a robot assembly 1, which is connected with the debugging platform 2 and can move along the x direction; 3 It is the center of gravity adjustment device, which is linked with the robot component 1 to maintain the balance of the entire robot movement; 12 is the vertical lifting mechanism, which can make the debugging platform 2 move along the y direction; the vertical lifting mechanism 12 is connected with the mobile car 11; the mobile car 11 walks on the electrolytic On the cathode surface of the tank shell, the control unit 6 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com