Exterior wall grinding robot

A technology of robots and grinding mechanisms, applied in the direction of grinding frames, grinding machine parts, grinding machines, etc., can solve the problems of large environmental pollution, insufficient labor resources, and low construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

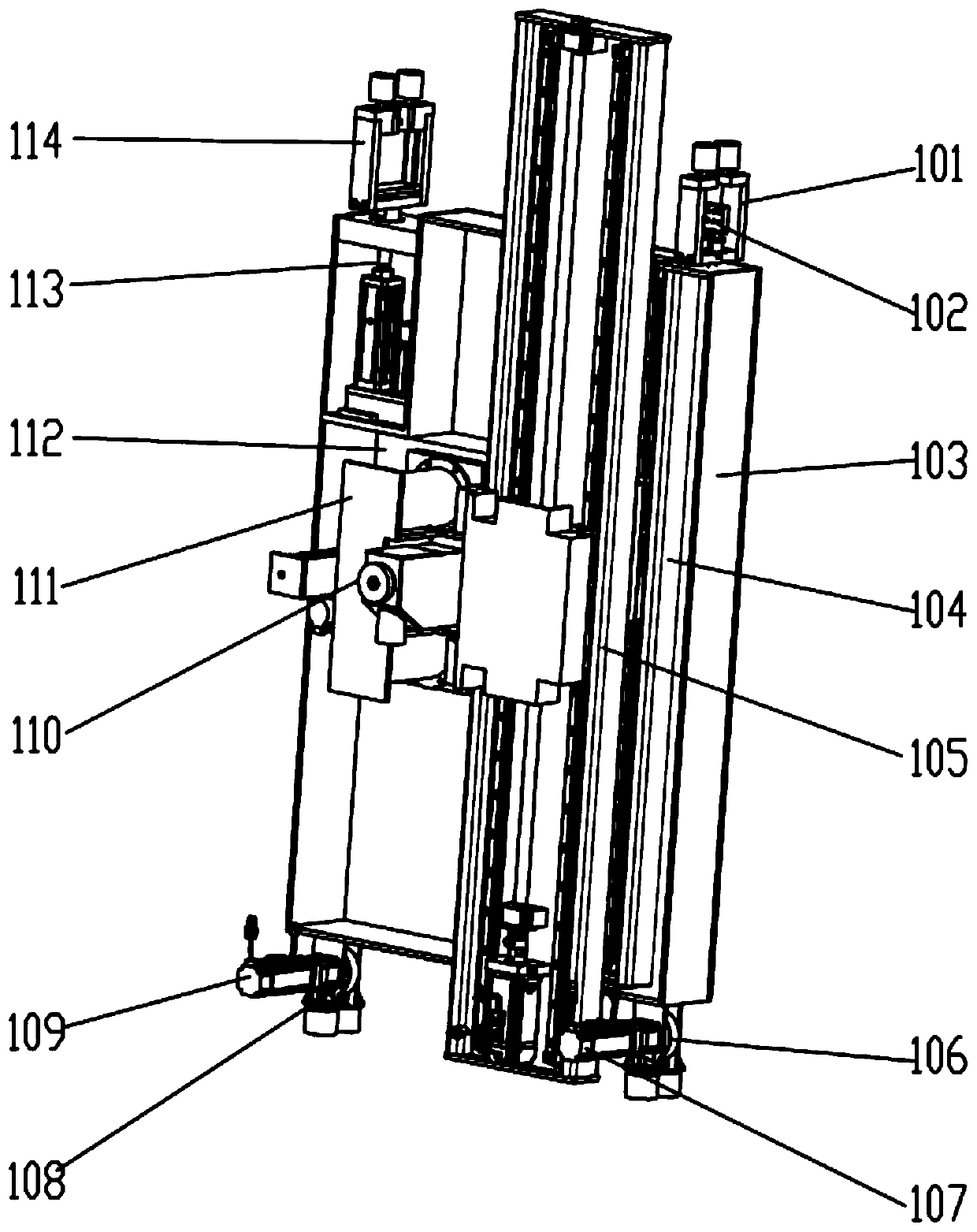

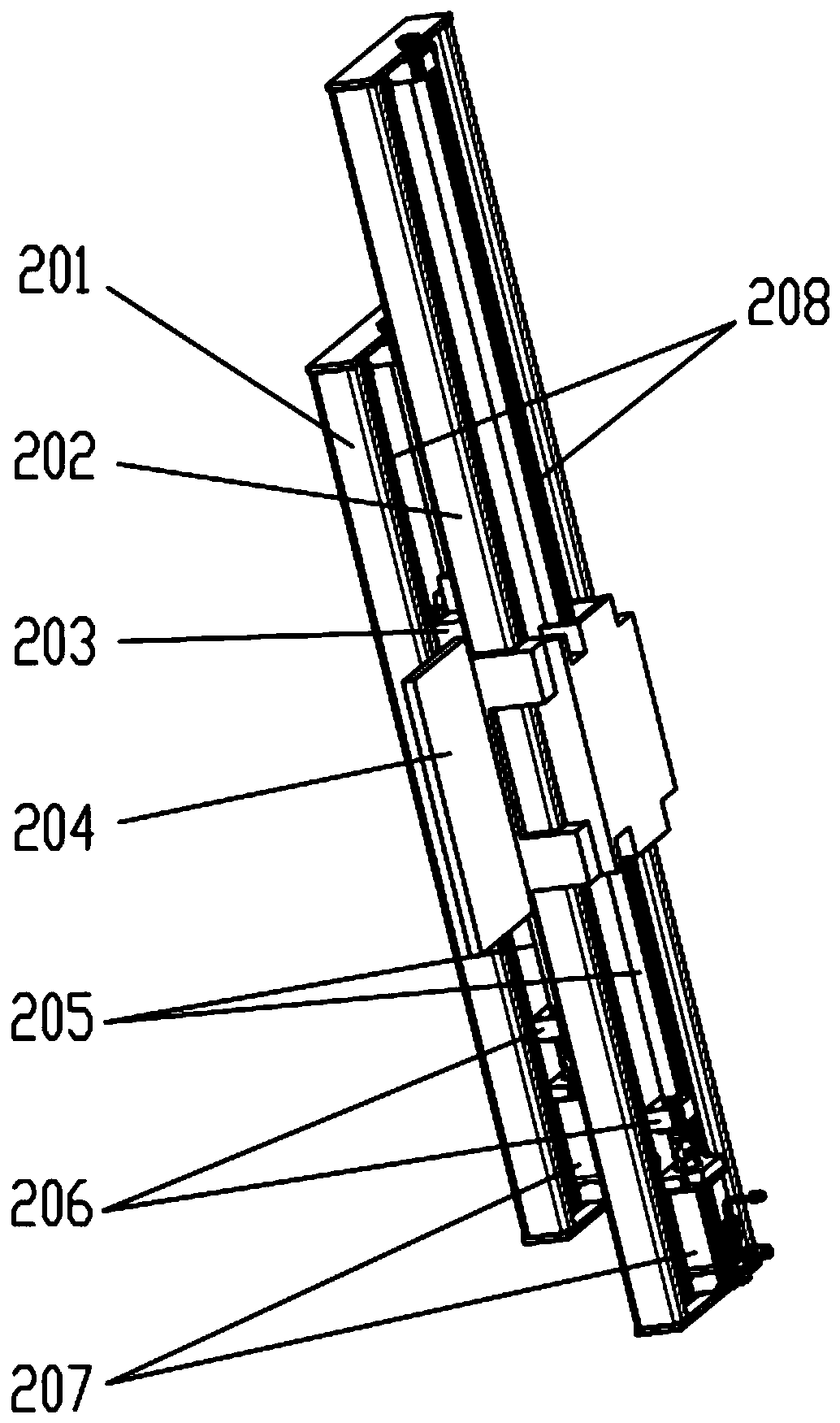

[0034] A three-axis external wall grinding robot based on a climbing frame. The robot is mainly composed of a mobile platform, a lifting mechanism, a telescopic platform, a grinding mechanism, a driving mechanism, a collector, a walking wheel, a clamping mechanism, and a control system. The mobile platform is used as the main frame for the integration of all mechanisms. The lifting mechanism is set as a two-stage lifting mechanism. The slider module on the outermost lifting mechanism of the lifting mechanism is connected to the telescopic platform. The telescopic platform is equipped with a grinding mechanism. The driving mechanism drives the mobile platform to move on the guide rail of the climbing frame. The current collector is set on the upper right guide rail travel wheel mechanism. The clamping mechanism and the left upper guide rail travel wheel mechanism are integrated together. The special travel wheels include the upper guide rail travel wheel mechanism and the lower g...

Embodiment 2

[0056] figure 1 Be climbing frame and robot figure of the present invention, among the figure: upper guide rail 2 and lower guide rail 4 are connected together with climbing frame 1, and robot 3 just moves along upper guide rail 2 and lower guide rail 4.

[0057] figure 2 It is a three-dimensional view of the robot of the present invention. In the figure: the mobile platform 103, as the main frame of the robot, plays a role in supporting all mechanisms. The upper left of the mobile platform 103 is the clamping mechanism 113 and the upper left traveling wheel mechanism 114. The wheel mechanism 114 is combined together, the upper right of the mobile platform 103 is the upper right traveling wheel mechanism 101 and the collector 102, the collector 102 is arranged on the structure of the upper right traveling wheel mechanism 101, the middle part of the mobile platform 103 is a lifting mechanism, and the lifting mechanism consists of the first One-level lifting mechanism 104 and ...

Embodiment 3

[0070] as attached Figures 1 to 2 As shown, the embodiment of the present invention provides a three-axis external wall grinding robot based on a climbing frame. The climbing frame is attached to the external wall of a building. Using the feature of the climbing frame, a robot is set on the climbing frame. It becomes possible to replace manual work, and the robot 3 walks on the guide rails (upper guide rail 2 and lower guide rail 4) of the climbing frame 1, wherein the driving wheels of the left and right lower traveling wheel mechanisms (108 and 106) are not only used as actuators for driving walking, And still as the wheel bearing weight, the wheels on both sides keep the robot on the track, and the side wheels of the traveling wheel mechanism (114 and 101) on the left and right keep the robot on the track. The robot also includes a lift platform (the first level lift mechanism 104 and the second level lift mechanism 105) except that the left and right up and down travel wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com