Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Shorten swelling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

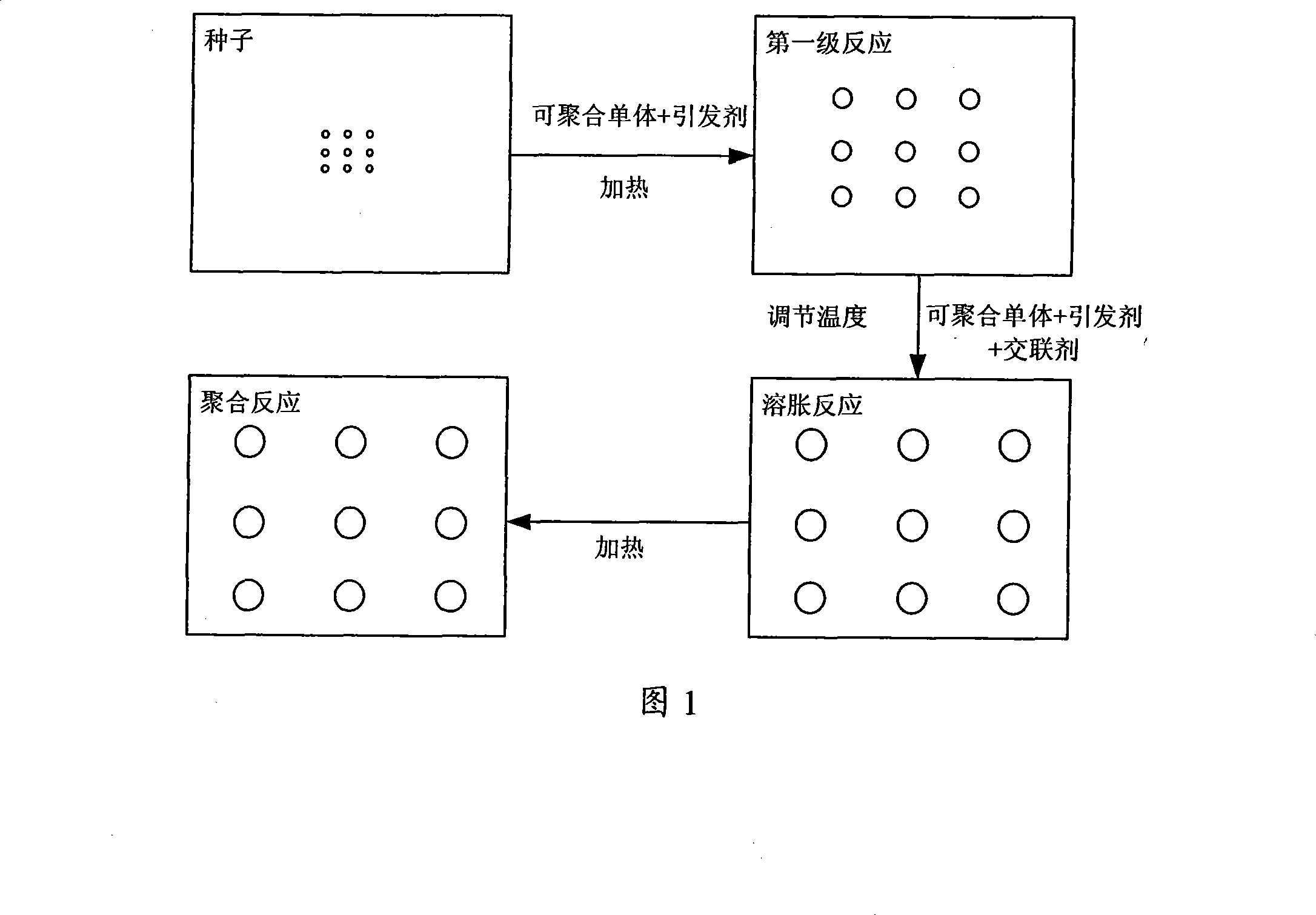

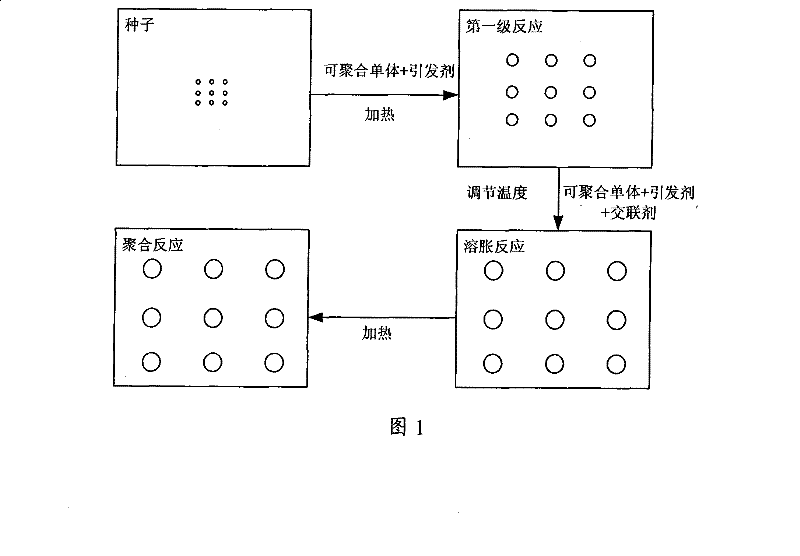

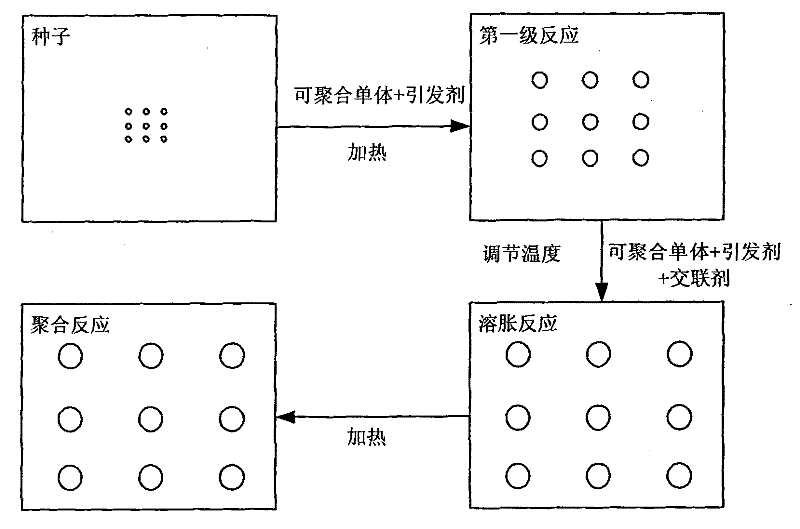

Method for preparing polymer particle

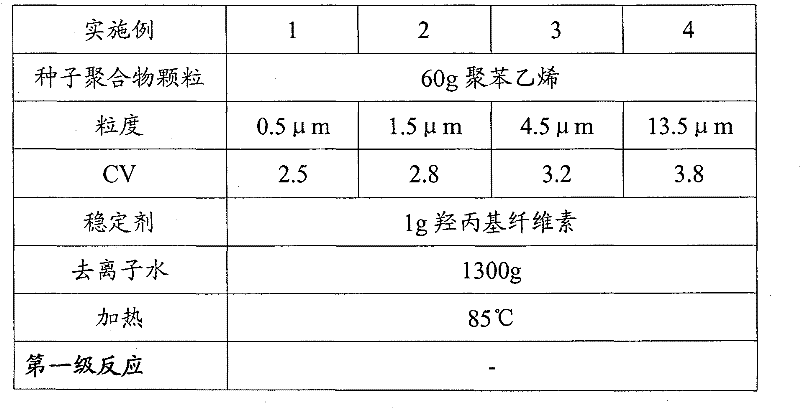

The invention discloses a preparation method of polymer particle, which comprises that suspends monodisperse and swelling seed polymer particles with a first preset value of mass into a water solution containing stabilizer and surface activator, mixes polymerisable monomer with mass of second preset value and initiator with mass as third preset value, to be added into monomer solution at polymerisable temperature, to process reaction, while the reaction degree is controlled at 30-98%, adjusts temperature, adds reactant, swells, while the reactant contains a polymerisable monomer with mass of fourth preset value or a second crosslinkable monomer with mass of fifth preset value, and an initiator with mass of sixth preset value, heats to polymerisable temperature, to process polymerization. The inventive microballoon has better monodispersity, high yield, reaction reproduction support, reduced production cost, and controllable product shape and property, while the invention can prepare porous monodisperse microballoon product.

Owner:深圳市纳微科技有限公司

Method for preparing polymer particle

The invention discloses a preparation method of polymer particle, which comprises suspending monodisperse and swelling seed polymer particles with a first preset value of mass into a water solution containing stabilizer and surface activator, mixing polymerisable monomer with mass of second preset value and initiator with mass as third preset value, be added into a monomer solution at polymerisable temperature to process reaction while the reaction degree is controlled at 30-98%, adjusting temperature, adding reactant, swelling, while the reactant contains a polymerisable monomer with mass offourth preset value or a second crosslinkable monomer with mass of fifth preset value, and an initiator with mass of sixth preset value, and heating to polymerisable temperature to process polymerization reaction. The inventive microballoon has better monodispersity, high yield, reaction reproduction support, reduced production cost and controllable product shape and property, while the inventioncan prepare porous monodisperse microballoon product.

Owner:深圳市纳微科技有限公司

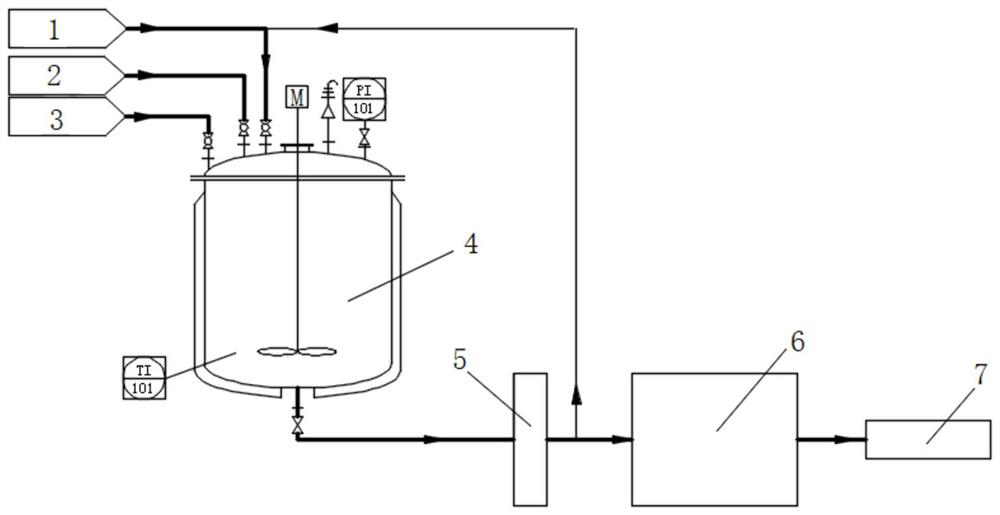

Rapid dissolving method for ultrahigh molecular weight polyacrylonitrile

InactiveCN103497345ADisperse fastEvenly dispersedFibre chemical featuresSpinning solutions preparationPolymer scienceDissolution

The invention relates to a rapid dissolving method for ultrahigh molecular weight polyacrylonitrile. The method comprises the following steps: (1) grinding ultrahigh molecular weight polyacrylonitrile solid particles, sieving with a 50-300 mesh sieve so as to obtain ultrahigh molecular weight polyacrylonitrile powder; (2) slowly adding the ultrahigh molecular weight polyacrylonitrile powder in a solvent with a temperature of 0 to 25 DEG C under mechanical stirring with a rotation speed of 200-1000 revolution per minute, after adding ultrahigh molecular weight polyacrylonitrile powder, heating the solvent to a temperature of 60 to 120 DEG C under mechanical stirring with a rotation speed of 200-1000 revolution per minute, maintaining the temperature for 6 to 12 hours so as to obtain a ultrahigh molecular weight polyacrylonitrile solution, and finally filtering. The rapid dissolving method for ultrahigh molecular weight polyacrylonitrile has the advantages that the dissolving temperature is low, the energy consumption is saved, and the swelling time is greatly reduced so as to quickly finish the dissolution; furthermore, the dissolution operation is convenient, the equipment is simple, and the method is easy to carry out in engineering.

Owner:DONGHUA UNIV

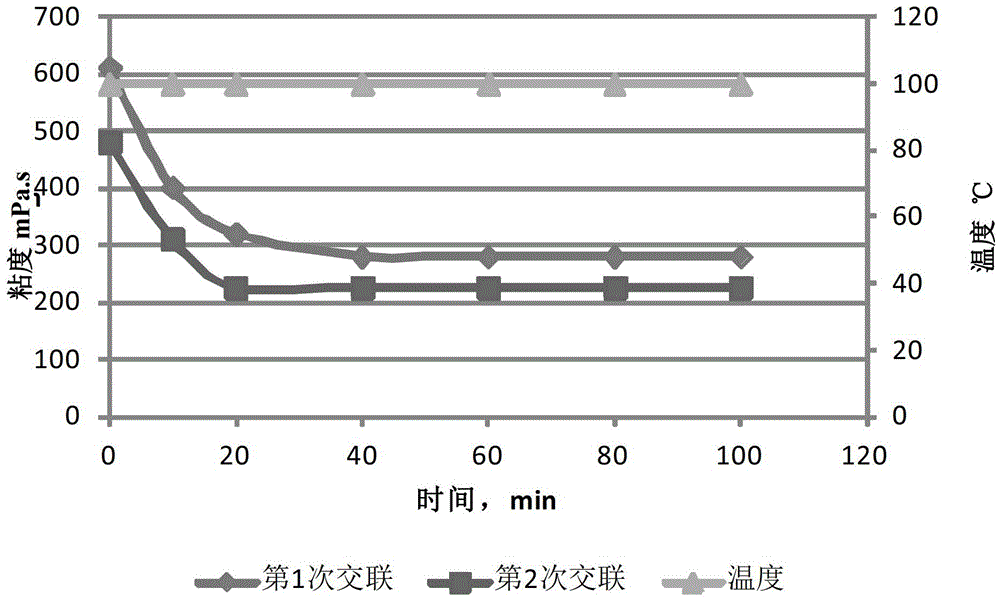

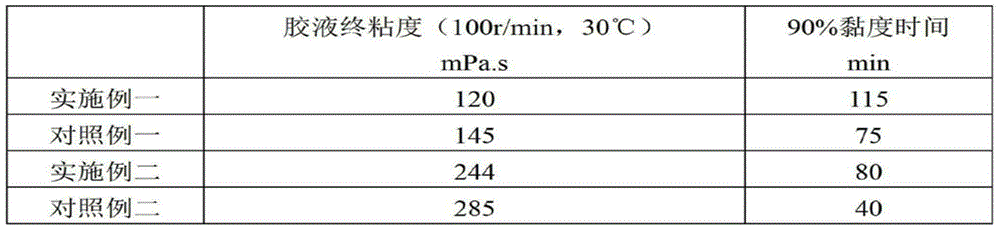

Preparation method of low-molecular-weight plant gelatin powder

InactiveCN103305571ALow water insoluble contentSpecial solubilityFermentationSolubilityNeutral protease

The invention relates to a preparation method of low-molecular-weight plant gelatin powder. The method comprises the following steps of: hydrating, rubbing, rolling and tackifying a plant gelatin sheet; sequentially carrying out enzymolysis treatment by utilizing mannose enzyme liquid and neutral protease liquid; and drying prepared plant gelatin with the certain molecular weight and treating into gelatin powder with the 120-160-mesh size. The plant gelatin sheet prepared by using the method disclosed by the invention can be any one of a guanidine gelatin sheet, a sesbania gelatin sheet and a tonka-bean gelatin sheet. A prepared product has the advantages of low water insoluble matters, high thickening efficiency, rapidness in thickening, protruding salt solubility, temperature stability and corrosion resistance, capability of being repeatedly used, and the like.

Owner:郑建立

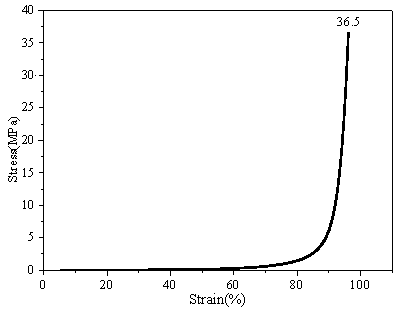

Glucose-sensitive type full interpenetrating network hydrogel and preparation method thereof

InactiveCN108359054AChange responsivenessEasy to preparePeptide/protein ingredientsMetabolism disorderMedicinePolymer network

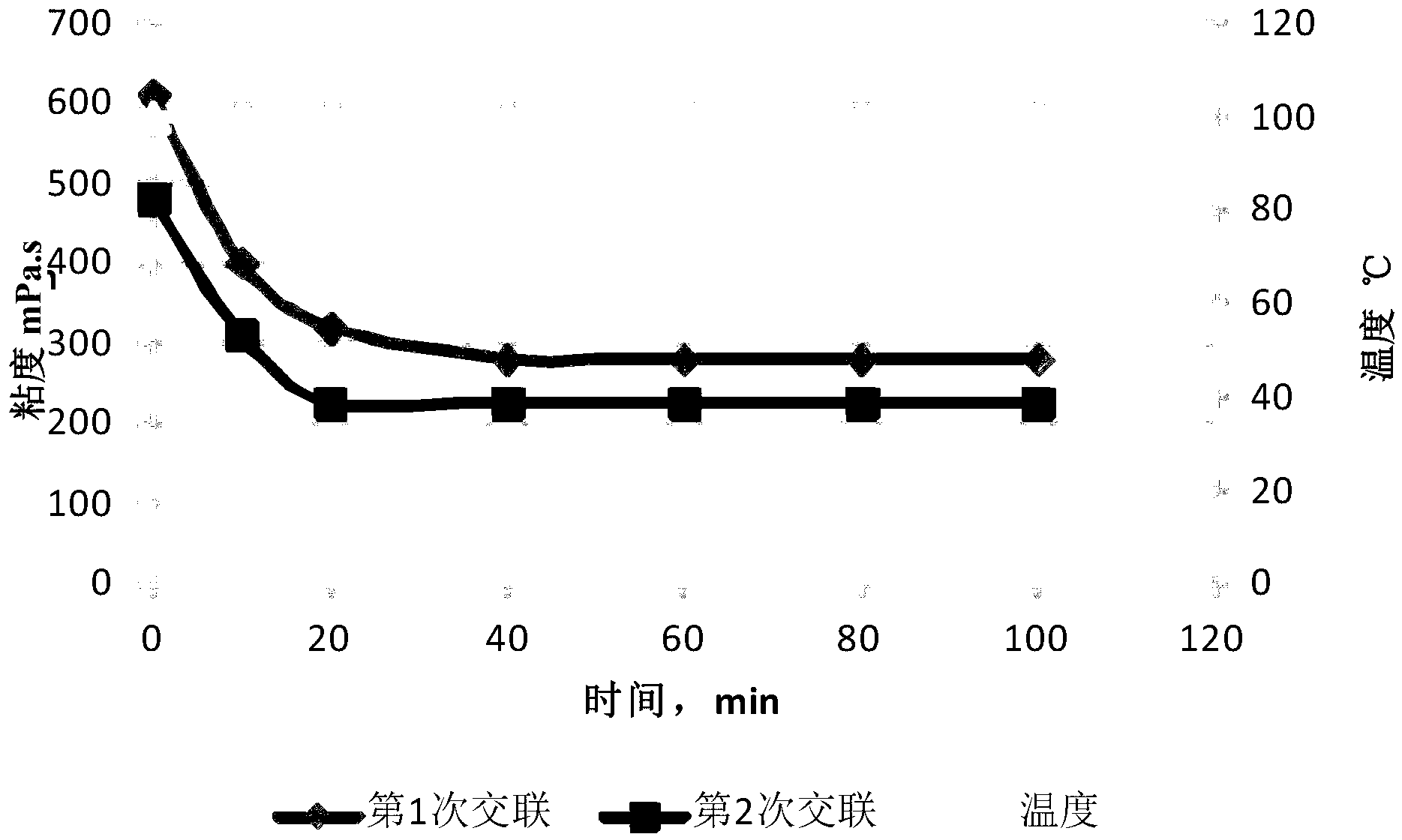

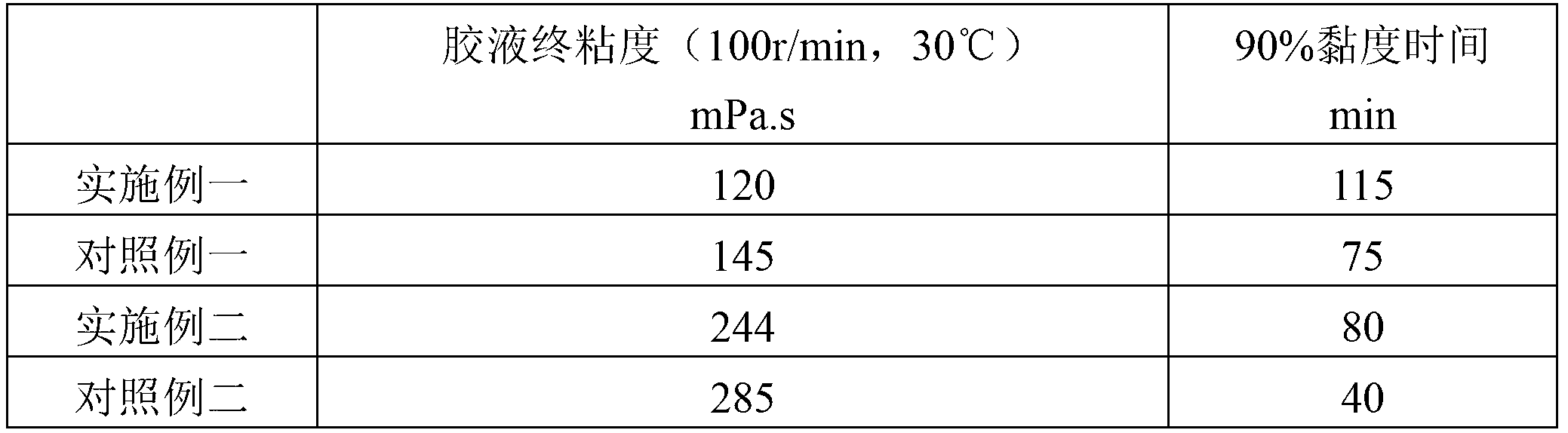

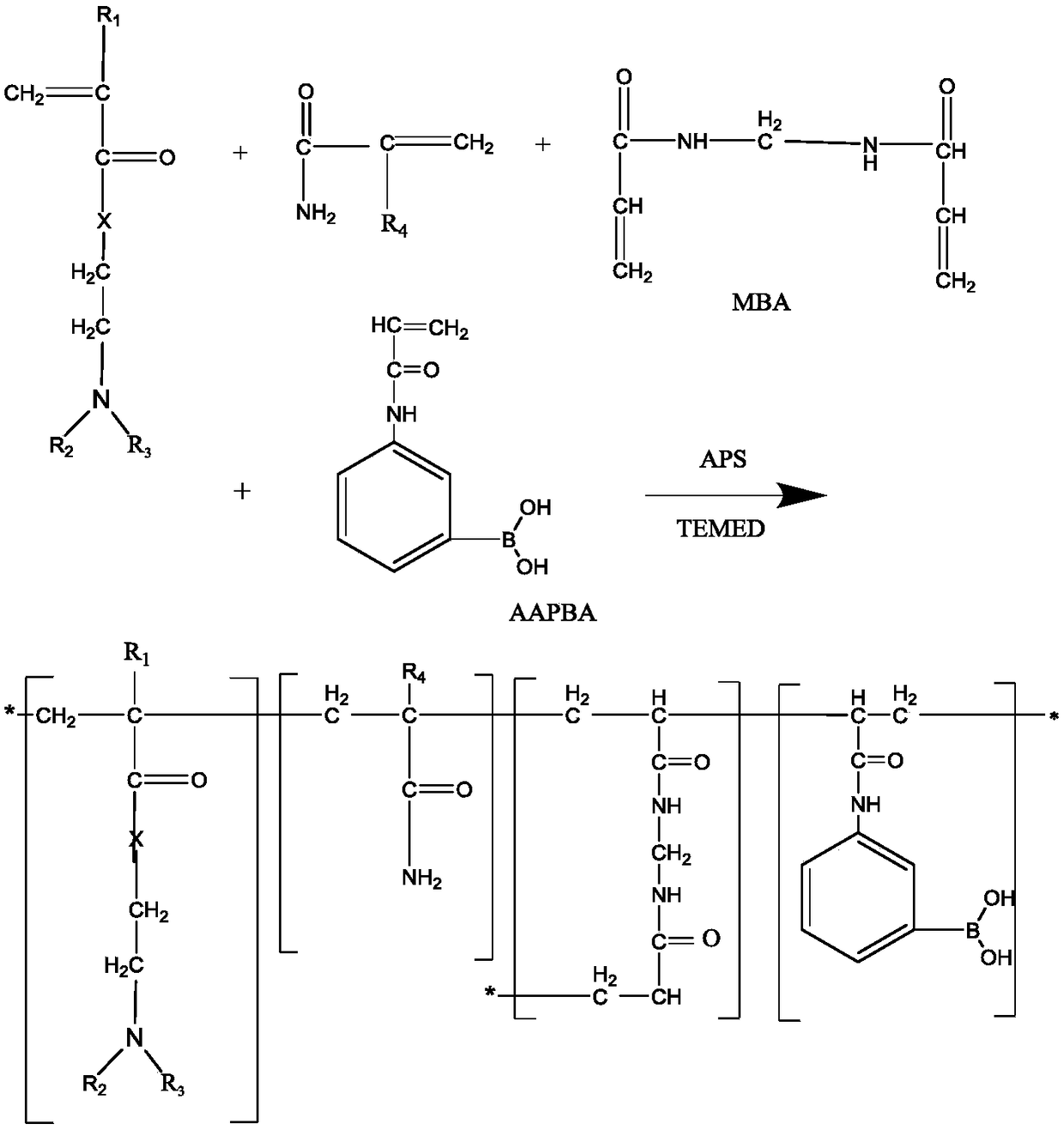

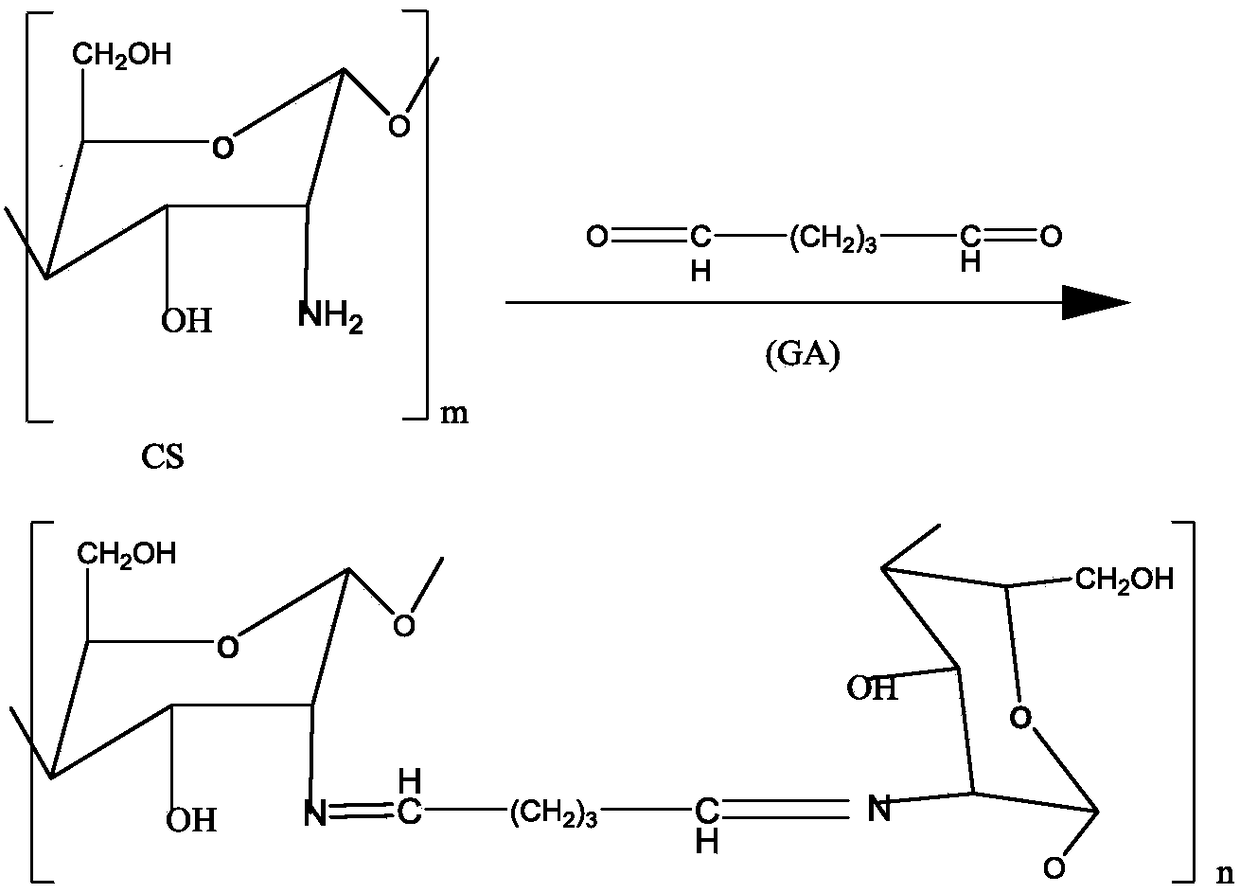

The invention discloses glucose-sensitive type full interpenetrating network hydrogel and a preparation method thereof. The hydrogel comprises two interpenetrating networks including an AAPBA (acrylamidophenylboronic acid) polymer network and a CS (chitosan) crosslinked network. The hydrogel can reduce pKa of PBA, has good response strength and response rate for glucose under the physiological pHand has shortened swelling time and increased swelling degree as compared with gel without CS crosslinked networks, and the IPN structure improves the mechanical strength of the hydrogel. The preparation method of the hydrogel is simple, mild in reaction condition and suitable for industrial production.

Owner:NORTHWEST UNIV

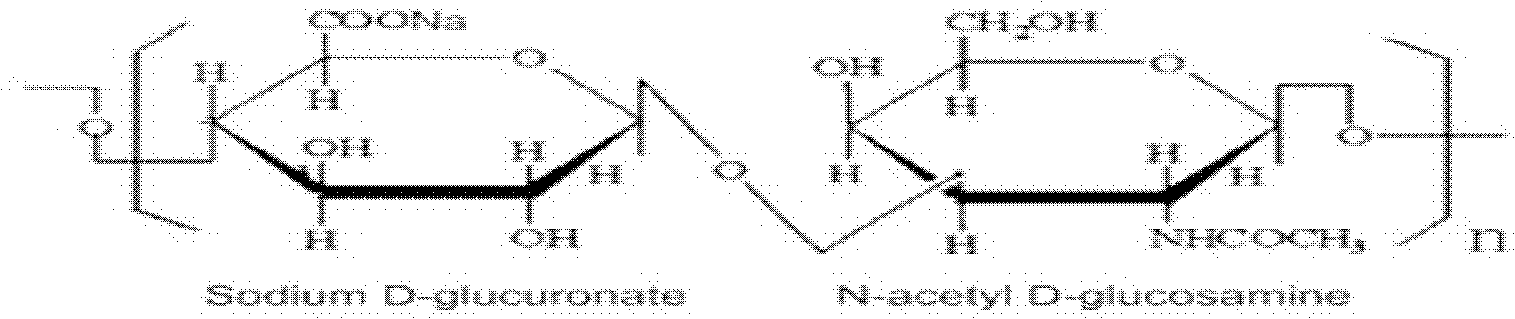

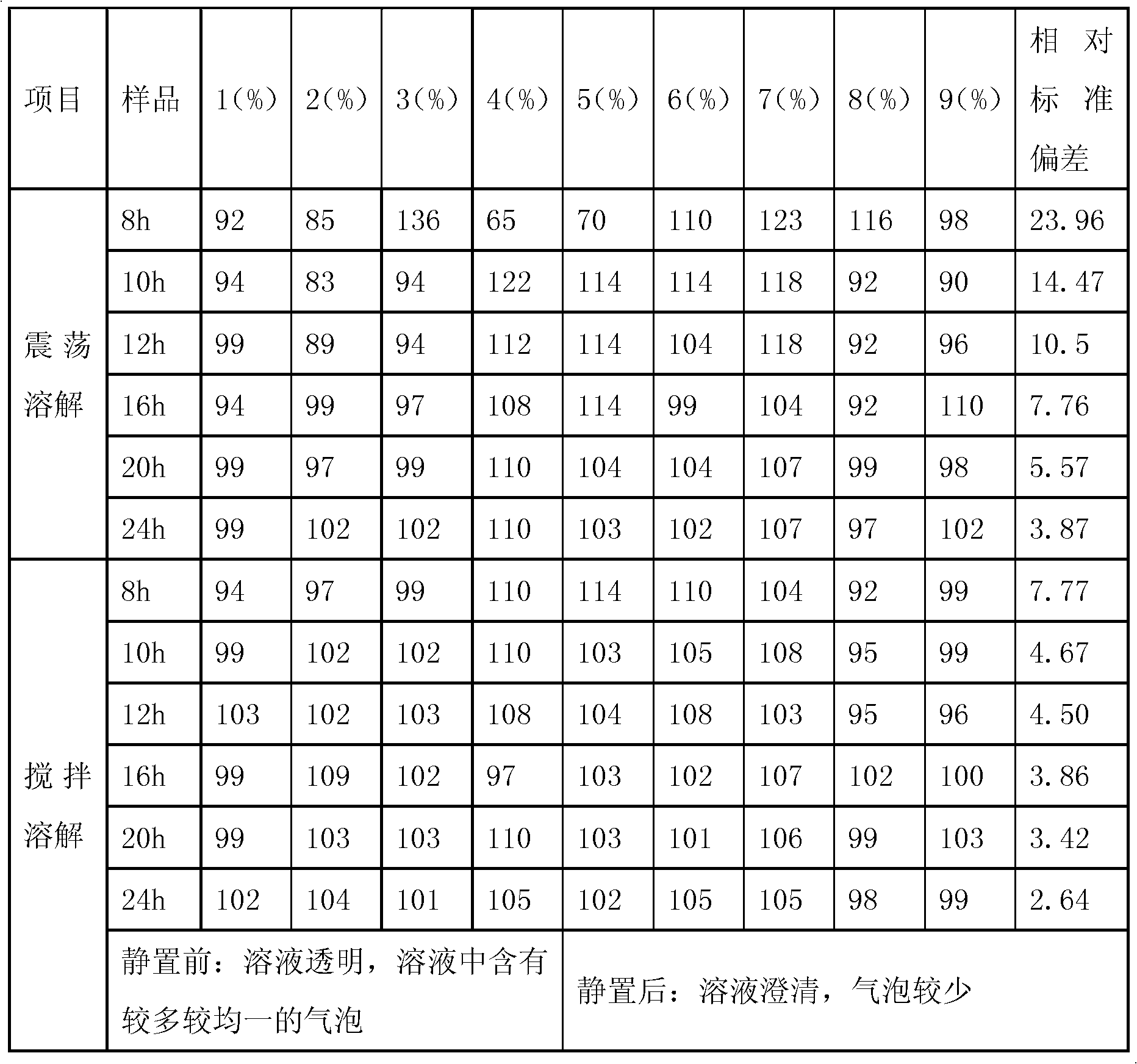

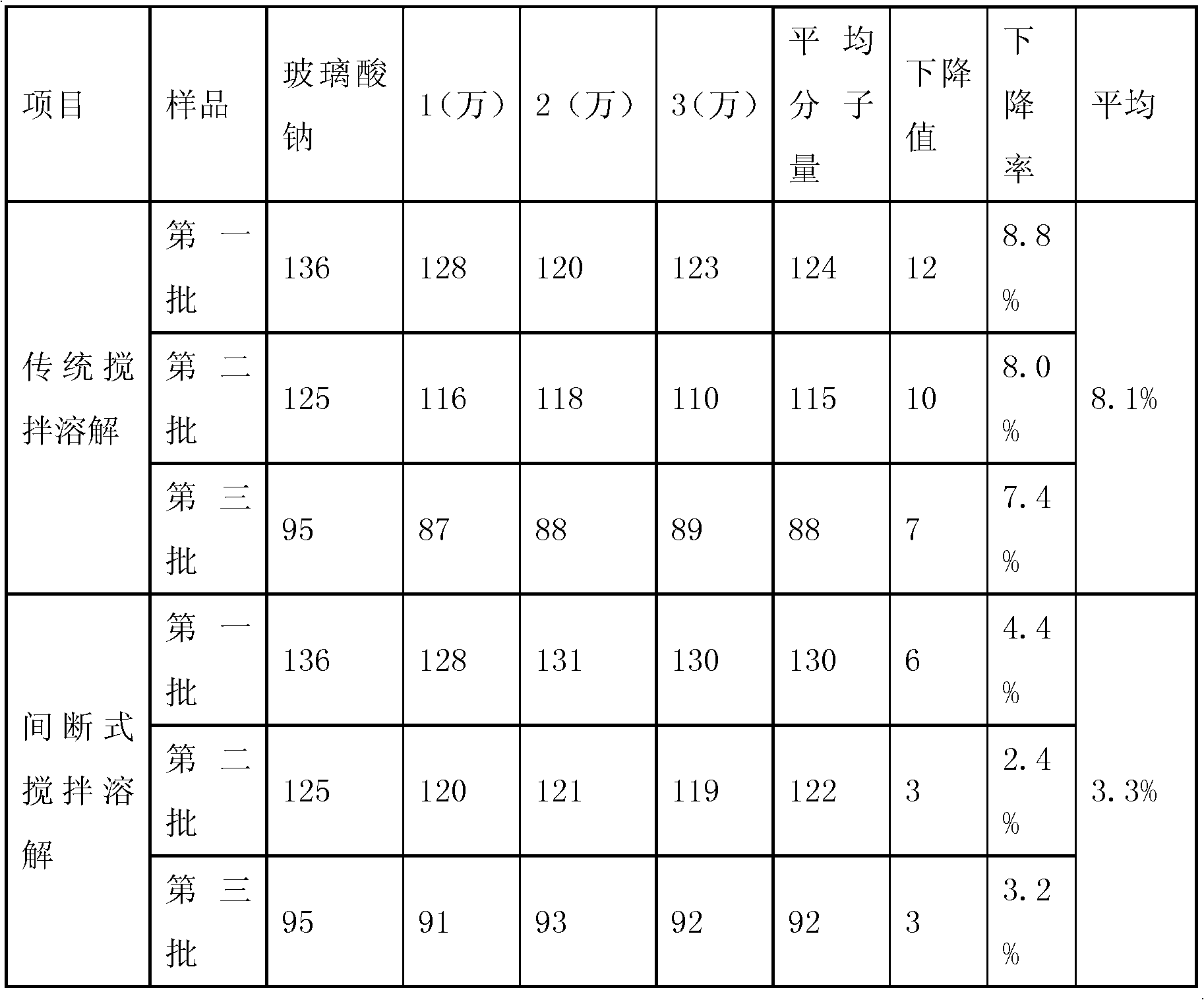

Dissolving method of sodium hyaluronate for solution preparation

ActiveCN102489193AEasy to spreadOvercome the defect of poor uniformityDissolvingHyaluronic acidSodium hyaluronate

The invention relates to a dissolving method of hyaluronic acid for solution preparation. The method comprises the steps of: first adding a PBS solution into a solution preparation tank and starting stirring; adding sodium hyaluronate with a stirring rotating speed less than 150 round / min; closing a feed inlet after addition, filling inert gas in the solution preparation tank, controlling a pressure within a range of from 0 to 0.1MPa, stirring continuously, predissolving for 40-60 min, stopping stirring, carrying out limit swelling for 1-2 h and carrying out intermittent stirring; finally, finishing stirring, protecting the hyaluronic acid solution in inert gas and carrying out standing. The method for dissolving sodium hyaluronate can substantially increase soup dissolving homogeneity, avoid oxidation of product, enhance aseptic guarantee level during product production process and improve product quality; the standing process employs natural sedimentation to reduce bubble amount in an injection; beside, the method substantially shortens a dissolving time during solution preparation, reduces production cost and especially applies to industrialized production.

Owner:SHANGHAI JINGFENG PHARMA

Microgel reinforced dual-network hydrogel and preparation method thereof

The invention discloses a microgel reinforced dual-network hydrogel and a preparation method thereof, and solves the problem that the performance of each batch of products is not uniform due to the fact that the monomer molar ratio of a first network to a second network is difficult to control in an existing two-step method. The preparation method comprises the following steps: dissolving 2-acrylamide-2-methylpropanesulfonic acid, N, N-methylene bisacrylamide, potassium persulfate and acrylamide, carrying out a reaction, taking out a formed first network hydrogel, drying the first network hydrogel, and crushing the first network hydrogel into powder; dissolving acrylamide, potassium peroxodisulfate and N, N-methylene bisacrylamide, mixing the hydrogel powder obtained by grinding with a prepared monomer solution, and reacting for 3 hours at the temperature of 60 DEG C to obtain the microgel reinforced dual-network hydrogel. According to the preparation method, the swelling time of the single-network hydrogel is greatly shortened, the swelling process only needs a short time, and the defect that specific shapes cannot be formed due to the fact that the first-network hydrogel is difficult to creep in an existing two-step method is overcome.

Owner:SHAANXI UNIV OF SCI & TECH

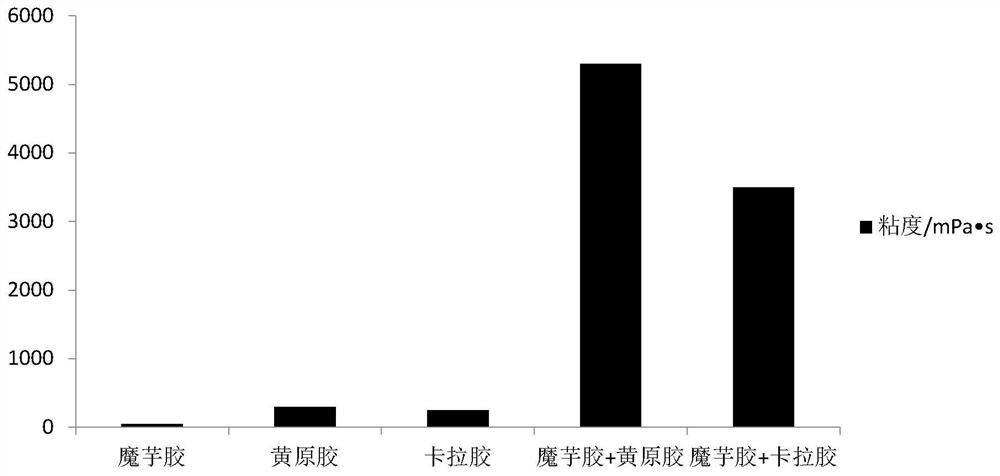

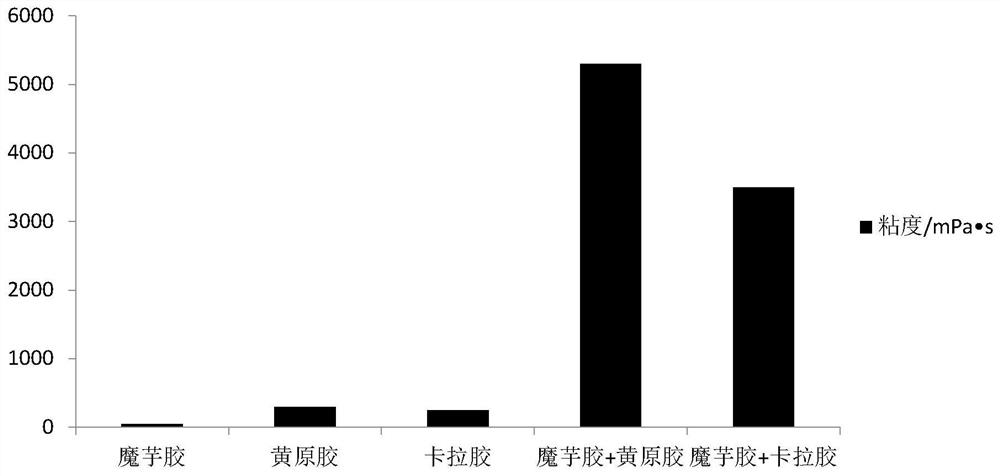

Method for swelling konjaku

The invention discloses a method for swelling konjaku, comprising the steps: placing konjaku powder and water into a vacuum mixer; mixing the konjaku powder and the water for 3-10min under a vacuum degree at 0.02-0.08MPa, and stewing the mixture for 50-60min, so as to obtain the konjaku powder which is completely swelled to be gelatineous. Konjaku can be completely swelled fast and conveniently by the method disclosed by the invention; the swelling time of konjaku is shortened; the internal bubbles of konjaku collosol are reduced, and accordingly a uniform and dense knojaku paste is prepared.

Owner:福建同乐食品开发有限公司

Preparation method of ethylene propylene diene monomer/polyaniline/high density polyethylene composite conducting material

The invention discloses a preparation method of an ethylene propylene diene monomer / polyaniline / high density polyethylene composite conducting material. The preparation method comprises the following steps: (1) adding an aniline monomer to ethylene propylene diene monomer powder, and stirring evenly to obtain the swelled ethylene propylene diene monomer; (2) obtaining ethylene propylene diene monomer / polyaniline composite conducting powder; (3) obtaining ethylene propylene diene monomer / polyaniline / high density polyethylene composite particles; (4) obtaining the ethylene propylene diene monomer / polyaniline / high density polyethylene composite conducting material. The method is capable of obtaining the high-electrical conductivity composite material in case of relatively low polyaniline content; meanwhile, the method provides good processability, and is capable of effectively weakening the influence of the degradation of other properties of the composite material due to the increase of the polyaniline content.

Owner:ZHONGYUAN ENGINEERING COLLEGE

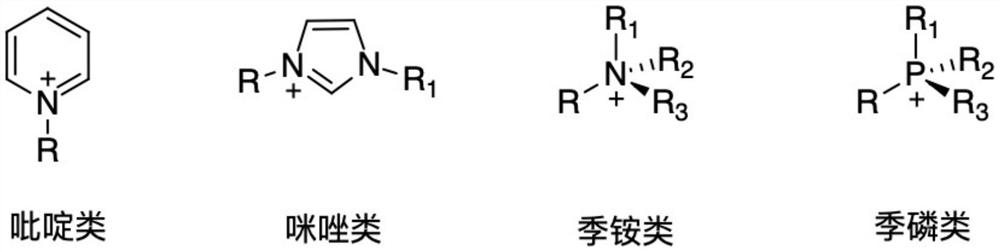

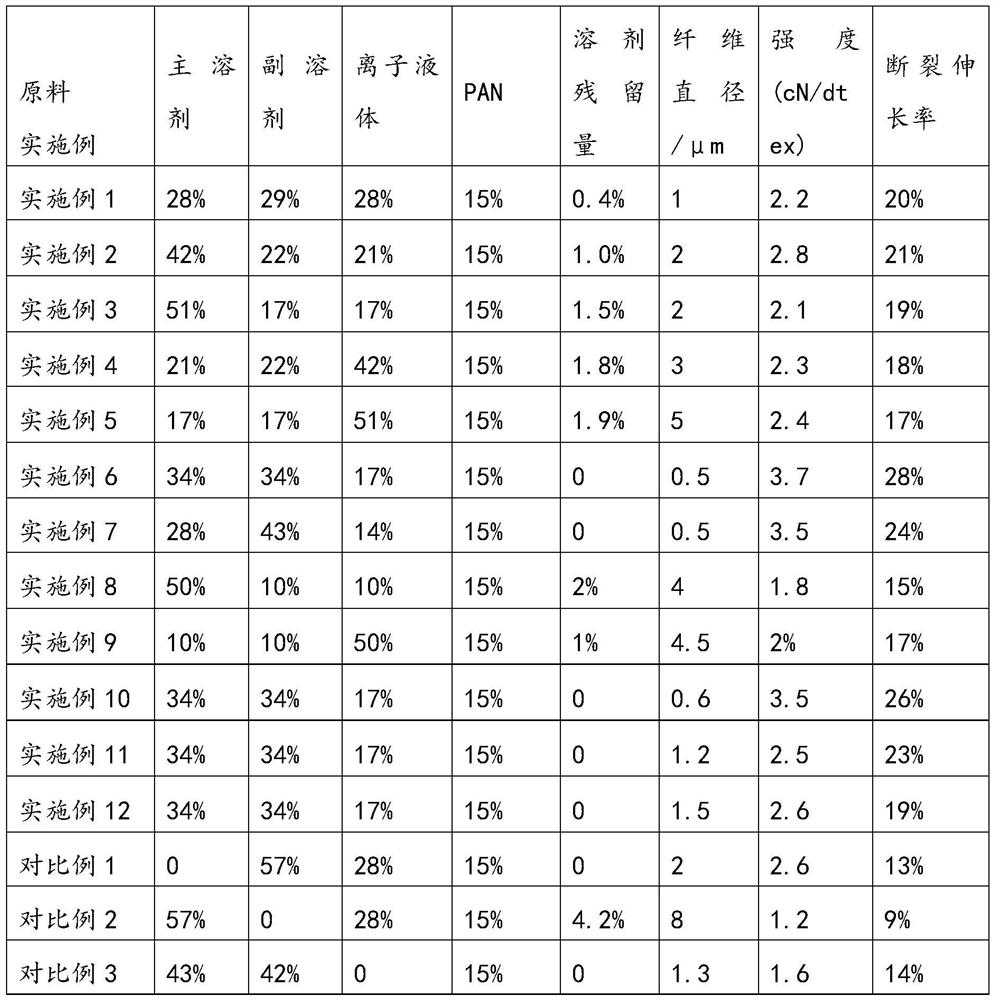

Preparation method of polyacrylonitrile fiber

ActiveCN112831859AImprove spinnabilityNot easy to plug holesMonocomponent synthetic polymer artificial filamentArtifical filament manufacturePolymer scienceSpinning

The invention discloses a preparation method of a polyacrylonitrile fiber. Polyacrylonitrile is firstly swelled and dissolved in an ionic liquid and a high-boiling-point (150-190 DEG C) solvent in a certain proportion under the conditions of high temperature and high pressure, then a volatile or low-boiling-point (30-60 DEG C) solvent is added to obtain a homogeneous spinning solution, then spinning and traction splitting are carried out to prepare the polyacrylonitrile fiber, and the polyacrylonitrile fiber has the advantages that the solvent is not prone to being wrapped in the fiber, and the fiber defect is improved; and the prepared fiber has the technical effects of denser density and thinner diameter.

Owner:SHANDONG RENFENG SPECIAL MATERIALS

Preparation method of composite conductive polylactic acid material

The invention discloses a preparation method of a composite conductive polylactic acid material. The preparation method comprises the following steps of 1 adding an aniline monomer into ethylene propylene diene monomer powder to obtain swelled ethylene propylene diene monomer powder, 2 obtaining ethylene propylene diene monomer / composite conductive polyaniline powder, 3 putting the ethylene propylene diene monomer / composite conductive polyaniline powder obtained in the step 2 and polylactic acid into a high-speed mixing machine to obtain ethylene propylene diene monomer / polyaniline / composite polylactic acid particles into a mold to obtain the composite conductive polylactic acid material. In the preparation method, the assisting effect of ultrasonic waves enables the ethylene propylene diene monomer powder to swell and produce cavatition effect, the diffusion speed of the aniline monomer can be improved, and swelling time can be shortened.

Owner:ZHONGYUAN ENGINEERING COLLEGE

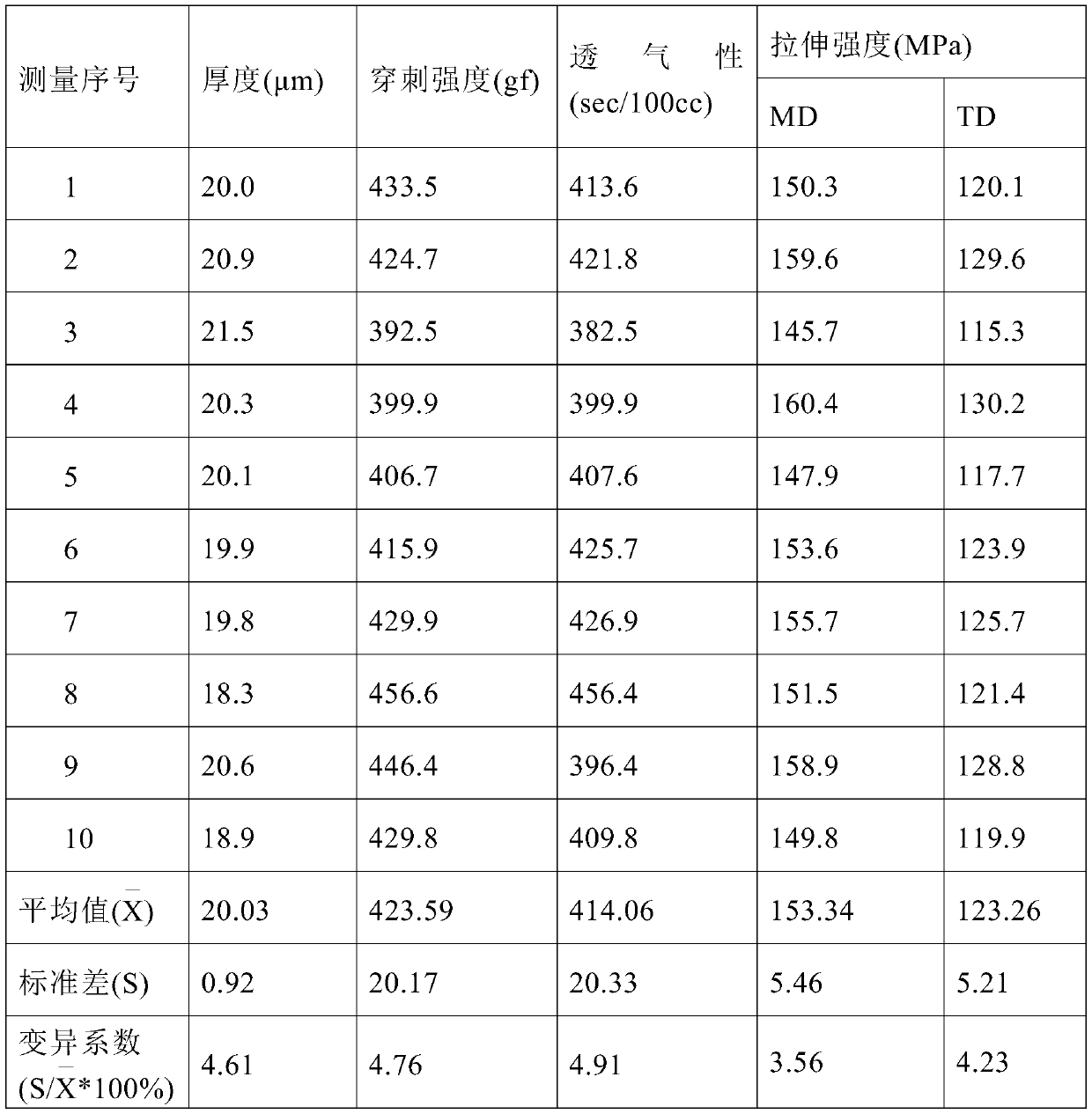

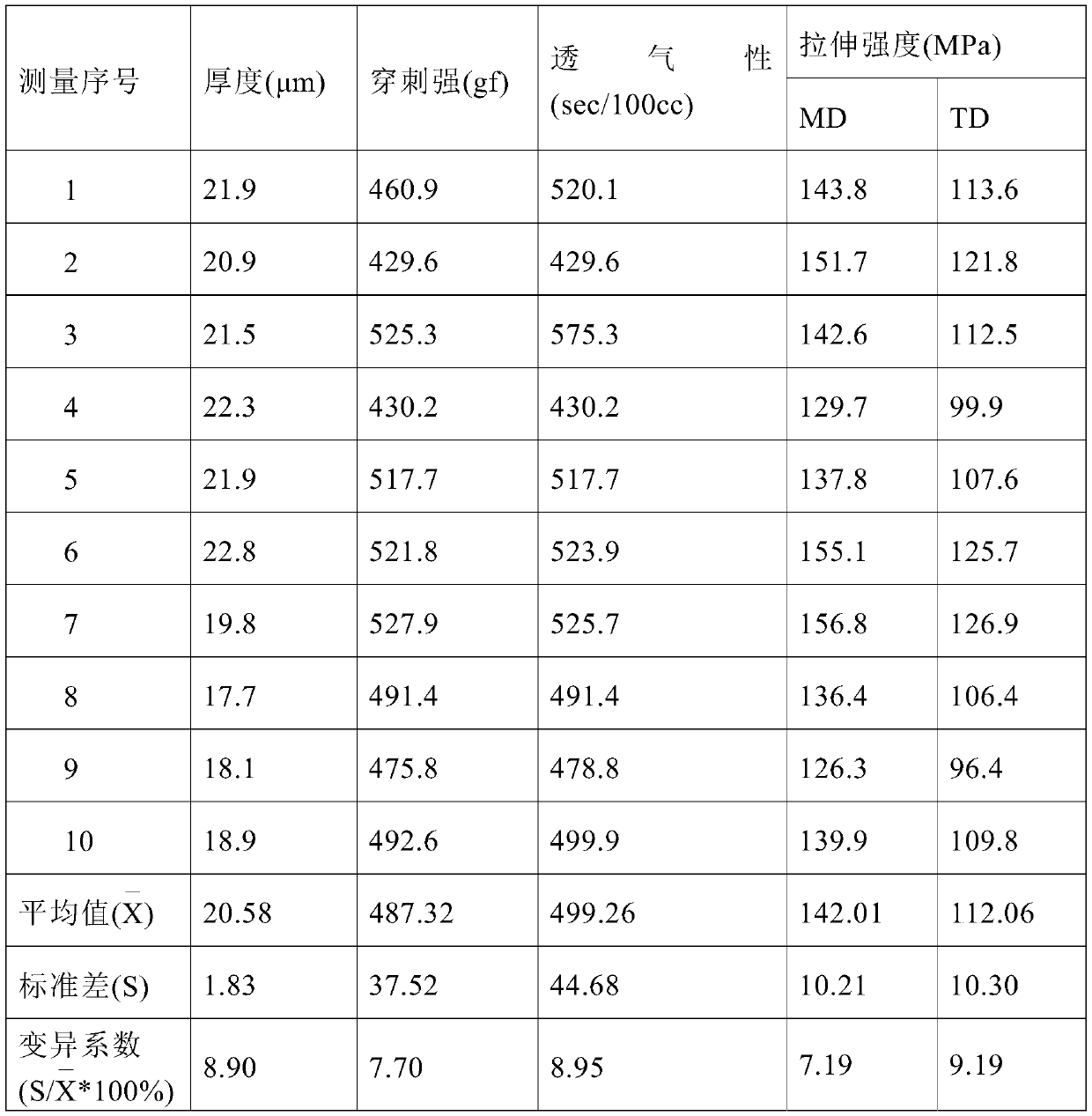

A kind of polyolefin film and preparation method thereof

ActiveCN106432762BImprove uniformityEasy to depositCell component detailsFlat articlesPolymer sciencePolyolefin

Owner:SHANGHAI RES INST OF CHEM IND +1

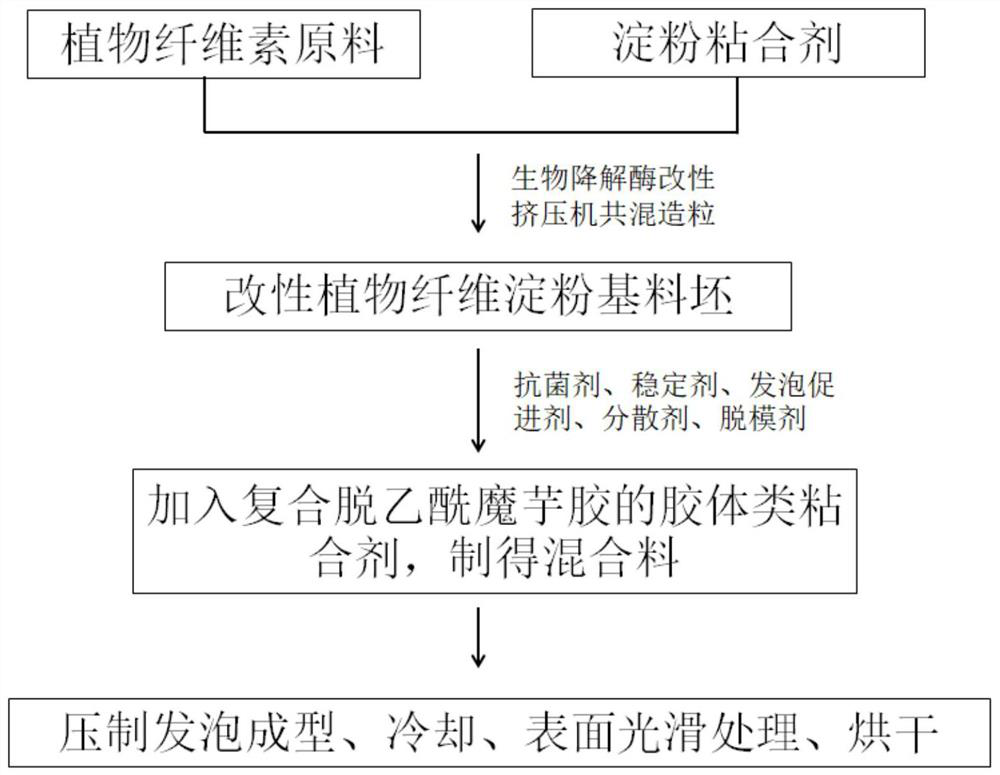

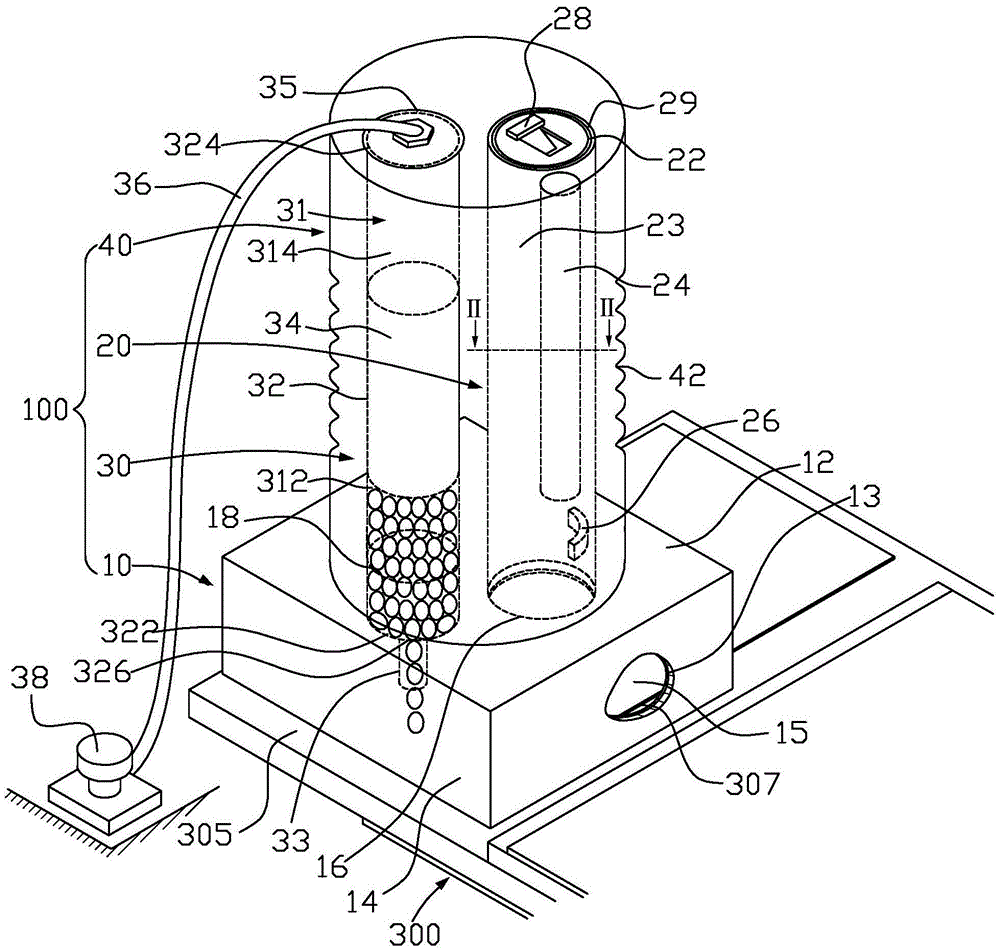

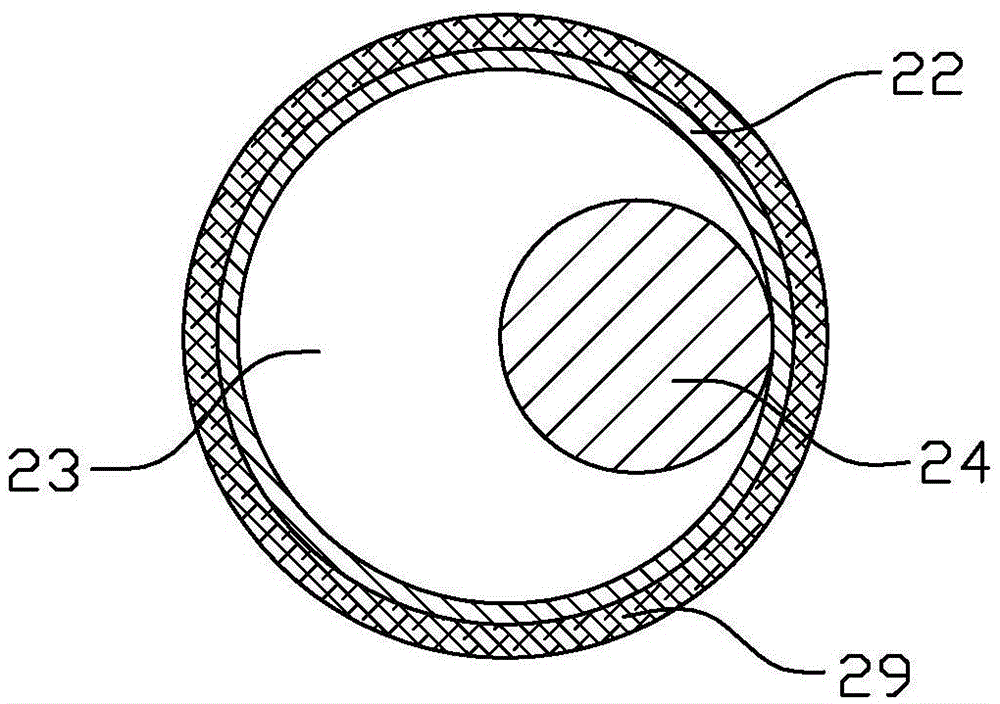

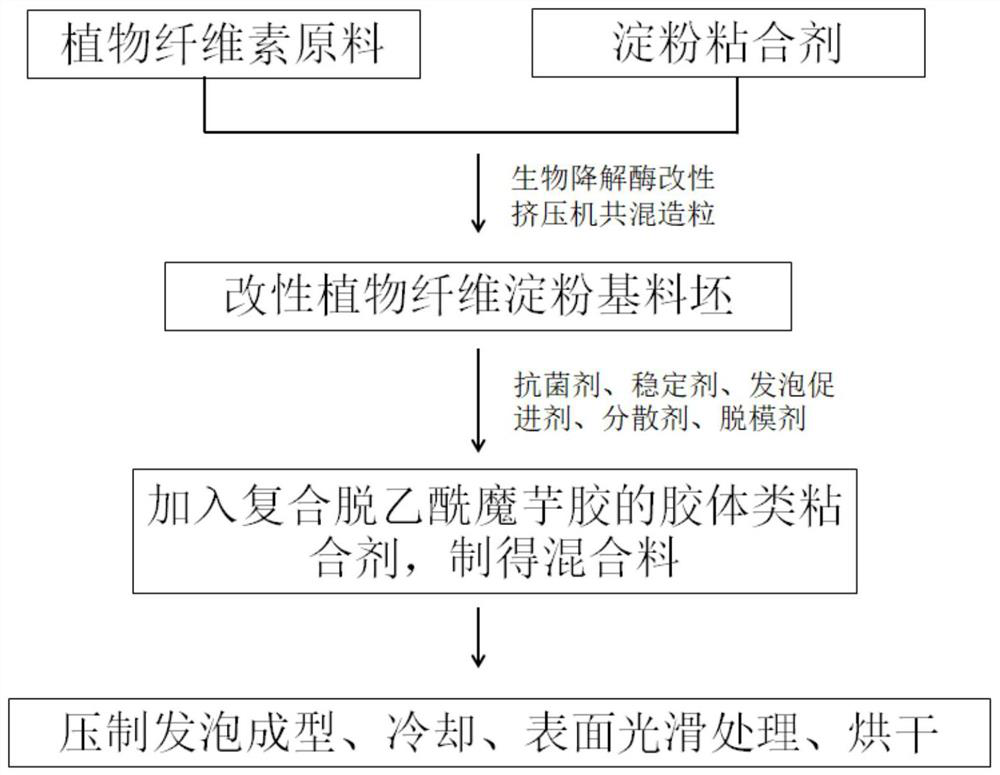

Preparation method of low-cost fully-biodegradable plant fiber starch tableware

ActiveCN113292759AGood antibacterial effectWide range of antibacterialPlatesTablewaresCelluloseAdhesive

The invention relates to a preparation method of low-cost fully-biodegradable plant fiber starch tableware, which comprises the following steps of S1, taking a plant cellulose material containing scutellaria baicalensis dregs to prepare a modified plant fiber starch-based blank, S2, sequentially performing crushing and superfine crushing treatment on the konjac glucomannan to prepare a colloid adhesive of the composite deacetylated konjac glucomannan, S3, mixing a colloid adhesive of composite deacetylated konjac glucomannan with the modified plant fiber starch-based blank to form a mixture, and S4, putting the mixture into a forming mold to be subjected to foaming forming, preparing the tableware, and acquiring the fully-degradable ecological tableware. The tableware is good in antibacterial performance, capable of being fully degraded, low in cost and simple in preparation method.

Owner:CHINA YUNHONG HLDG CO LTD +2

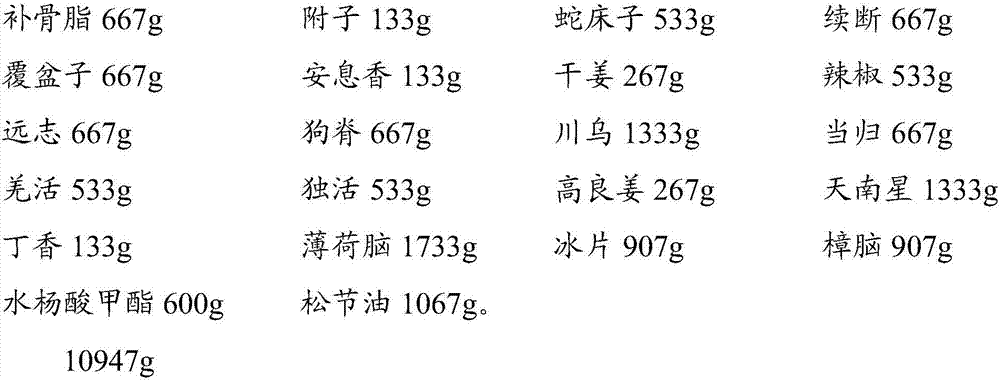

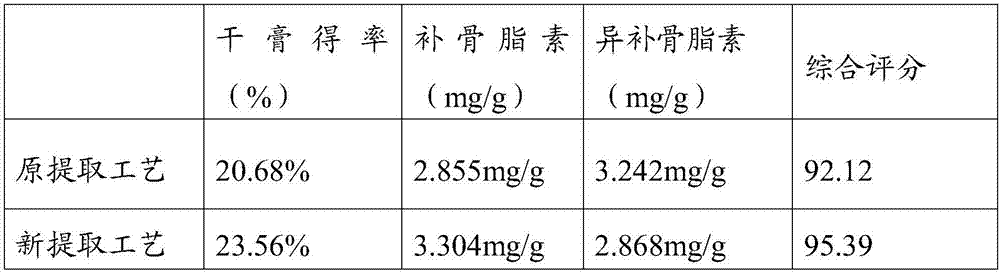

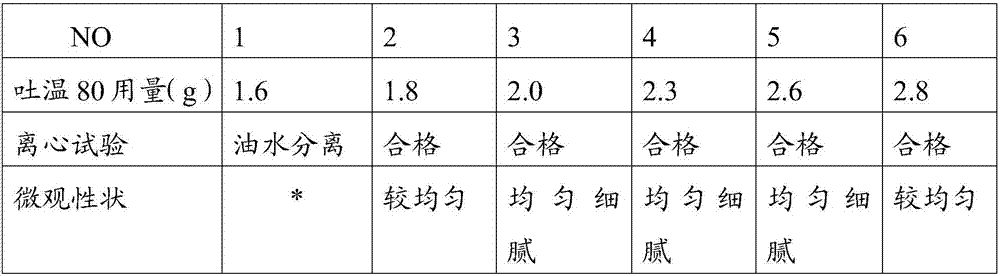

Traditional Chinese medicine topical gel and preparation method thereof

ActiveCN107320442AIncreased psoralen contentGood compatibilityAntipyreticAerosol deliveryMentholRadix Aconiti

The invention relates to a preparation method of traditional Chinese medicine topical gel. The method comprises the following steps: taking fructus psoraleae, radix aconiti carmichaeli, fructus cnidii, radix dipsaci, fructus rubi, benzoin, rhizoma zingiberis, chilli, radix polygalae, rhizoma cibotii, radix aconiti, radix angelicae sinensis, rhizoma seu radix notopterygii, radix angelicae pubescentis, rhizoma galangae, rhizoma arisaematis and flos caryophyllata, adding ethanol for heating reflux extraction, combining extracting solutions, filtering and concentrating into clear paste; take carbomer, adding glycerin, and adding water to obtain a carbomer swelling solution; then adding the clear paste, soaking, mixing uniformly, and then adding triethanolamine to obtain carbomer aqueous gel containing alcohol extracts; dissolving albolene in turpentine and methyl salicylate, and adding menthol, borneol, camphor and laurocapram for dissolving, and then adding Tween-80 to obtain an oily matrix mixture; adding the mixture into the carbopol aqueous gel containing alcohol extracts, and emulsifying uniformly, so as to obtain the traditional Chinese medicine topical gel. The Wentong ointment obtained by the preparation method disclosed by the invention has better efficacy of being analgesic and detumescent and removing stasis than that of the Wentong ointment obtained through the original technology.

Owner:广州中医药大学附属骨伤科医院

Preparation method of polylactic acid composite conductive material

InactiveCN104877318BIncreased diffusion rateShorten swelling timePolymer scienceEthylene-propylene-diene-monomer

The invention discloses a preparation method of a composite conductive polylactic acid material. The preparation method comprises the following steps of 1 adding an aniline monomer into ethylene propylene diene monomer powder to obtain swelled ethylene propylene diene monomer powder, 2 obtaining ethylene propylene diene monomer / composite conductive polyaniline powder, 3 putting the ethylene propylene diene monomer / composite conductive polyaniline powder obtained in the step 2 and polylactic acid into a high-speed mixing machine to obtain ethylene propylene diene monomer / polyaniline / composite polylactic acid particles into a mold to obtain the composite conductive polylactic acid material. In the preparation method, the assisting effect of ultrasonic waves enables the ethylene propylene diene monomer powder to swell and produce cavatition effect, the diffusion speed of the aniline monomer can be improved, and swelling time can be shortened.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A chitin modified pp spunbonded nonwoven fabric

ActiveCN110894642BImprove stabilityAvoid stickingFilament/thread formingMonocomponent polypropylene artificial filamentPolymer scienceNonwoven fabric

The invention discloses a chitin-modified PP spun-bonded non-woven fabric, which contains 0.2-1.5% of chitosan. The chitosan-modified pp spunbonded non-woven fabric has a mildew grade ≤ grade 1, and an antibacterial rate ≥ 99.5%; the chitosan-modified pp spunbonded non-woven fabric prepared by the present invention has added modified chitin, chitin During the modification process, by optimizing the modification process and removing the standing steps, the modification time of chitosan was greatly reduced by 3-5 times, and the production efficiency was improved.

Owner:ZHONGKE TEXTILE RES INST QINGDAO CO LTD +1

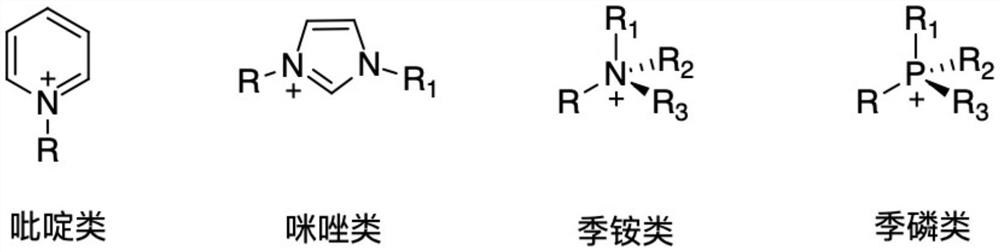

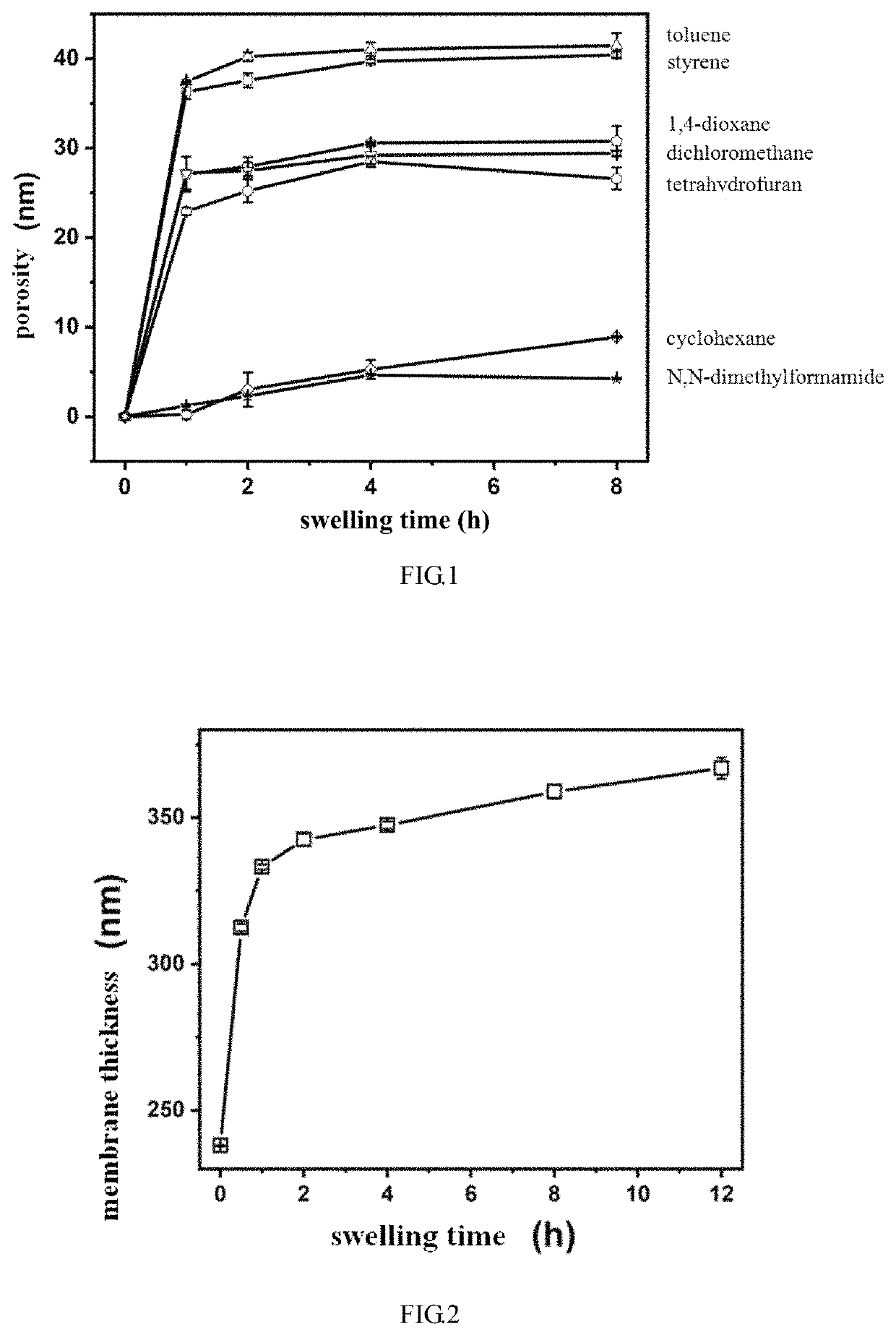

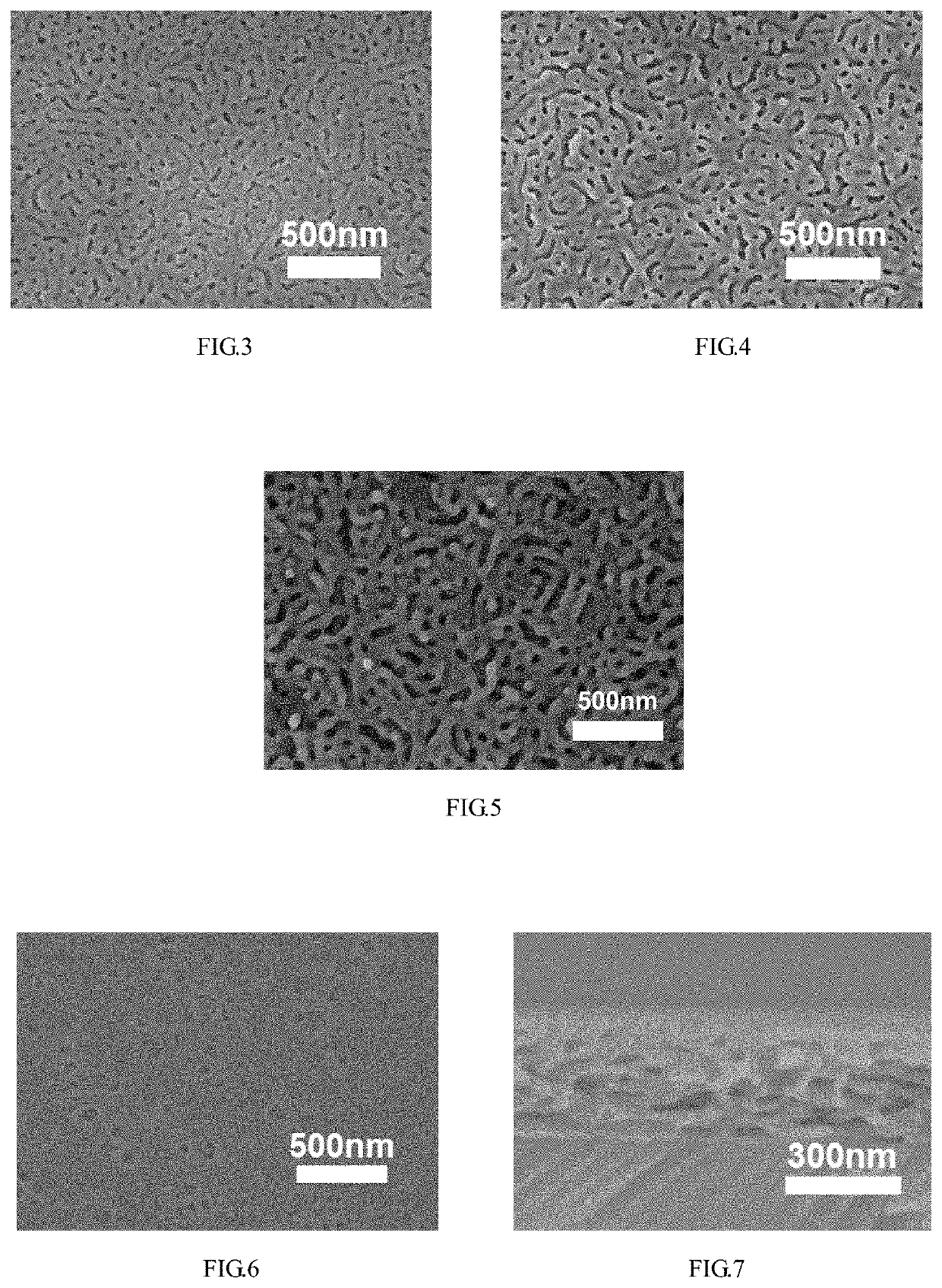

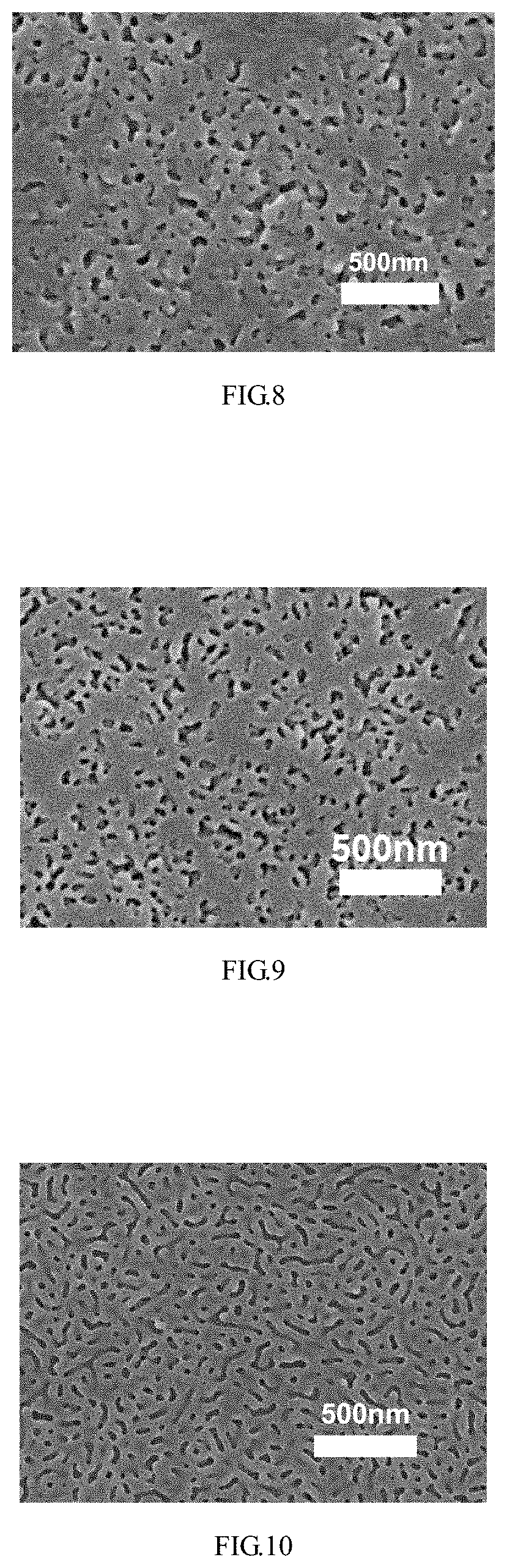

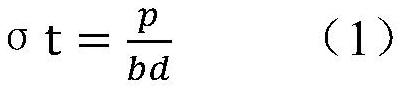

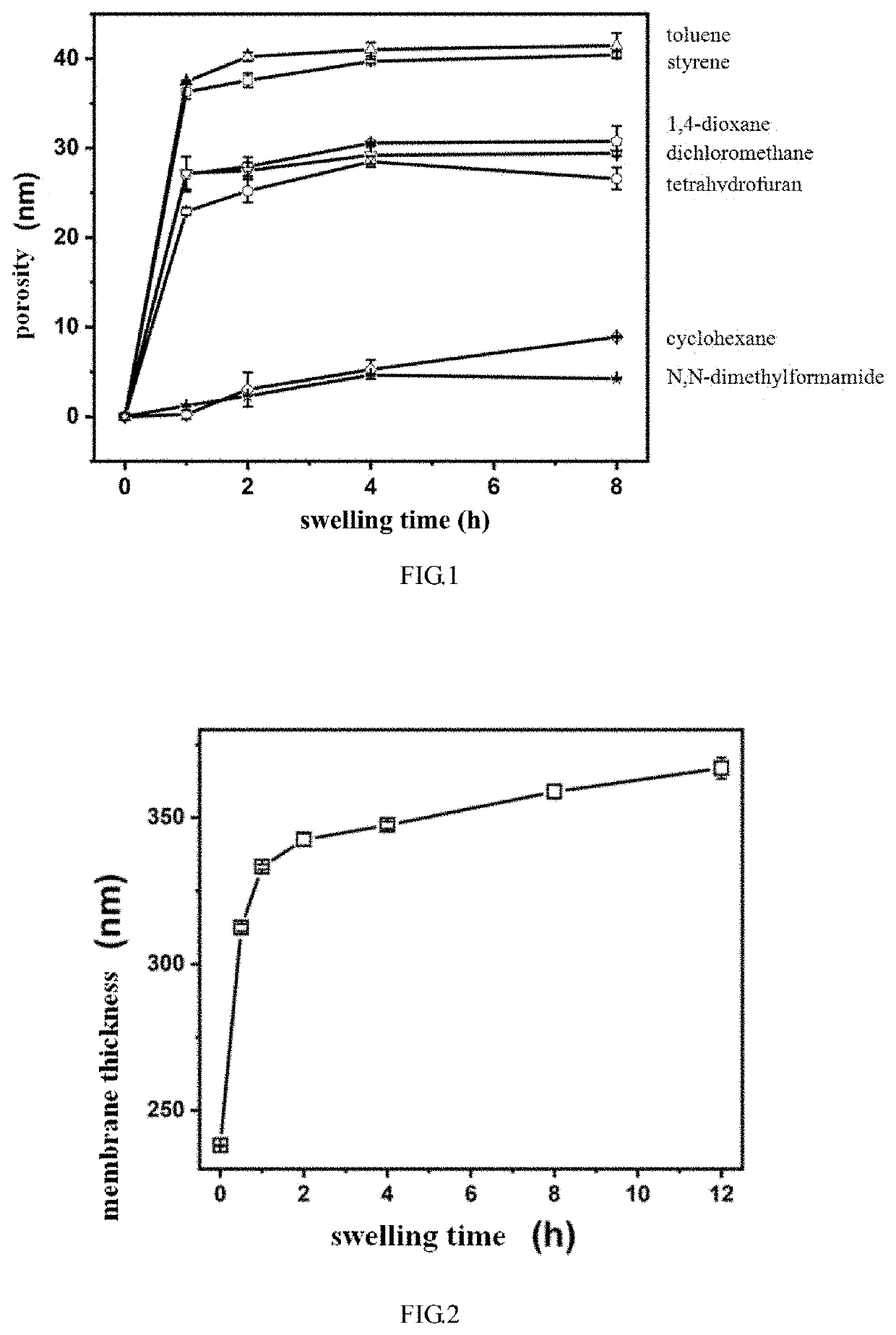

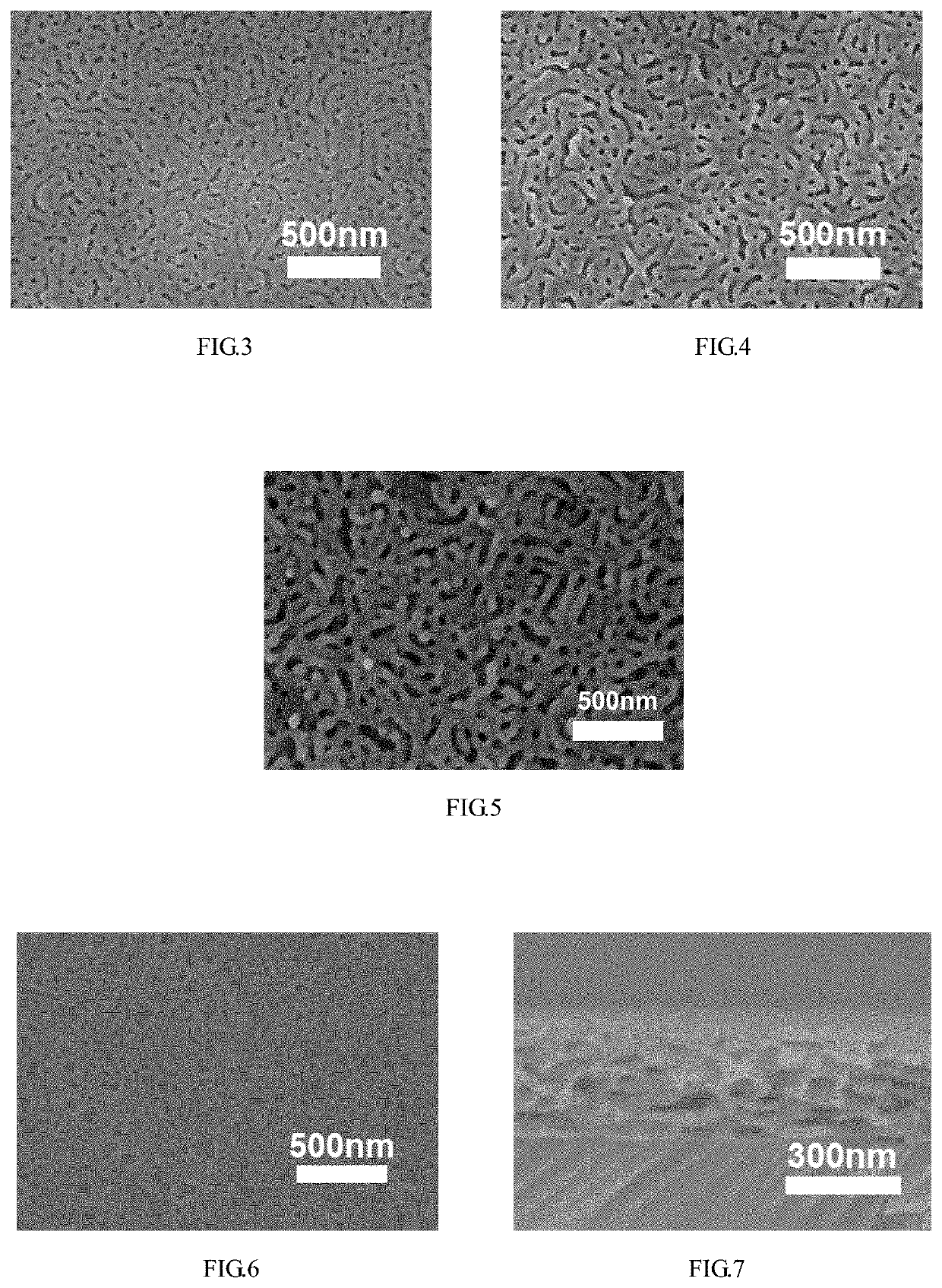

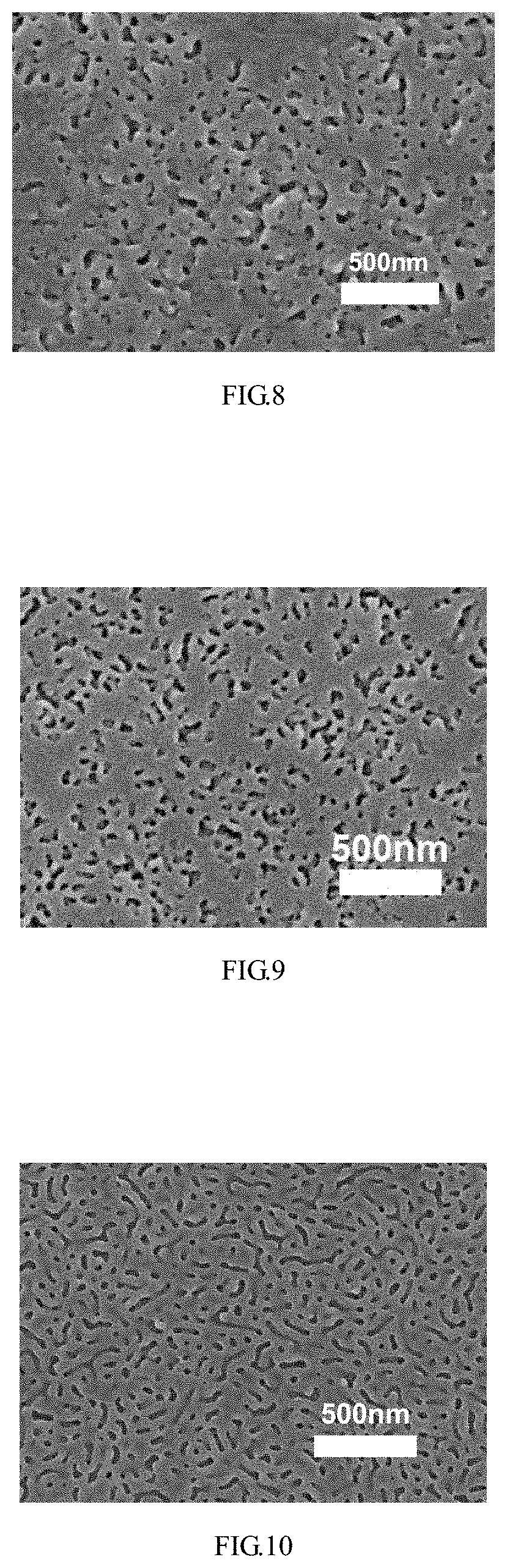

Room-temperature selective swelling method of pore-forming used for preparing separation membranes

ActiveUS11504672B2Reduce the temperatureShorten swelling timeMembranesSemi-permeable membranesPolymer scienceAlcohol

The present invention provides a room-temperature selective swelling method of pore-forming used for preparing separation membranes, comprising: treating a dense membrane of an amphiphilic block copolymer by a composite swelling agent at 15-30° C. for 1 min-24 h, removing the residual solvent, then leaving the membrane at room temperature to dry, so as to obtain an amphiphilic block copolymer separation membrane with a bi-continuous porous structure, wherein the composite swelling agent is composed of 60-96% of a first swelling agent and 4-40% of a second swelling agent, the first swelling agent is an alcohol solvent, the second swelling agent is selected from any one or a mixture of two or more of toluene, styrene, tetrahydrofuran, 1,4-dioxane and so on. In the method of the invention, selective swelling can be achieved at room temperature, abating the energy consumption in membrane-forming process. The method has universality and can be widely used in the pore-forming process of various amphiphilic block copolymers. The swelling level and morphology can be controlled by adjusting the composition of the solvent in the swelling agent and the second swelling agent content in the swelling agent.

Owner:NANJING TECH UNIV

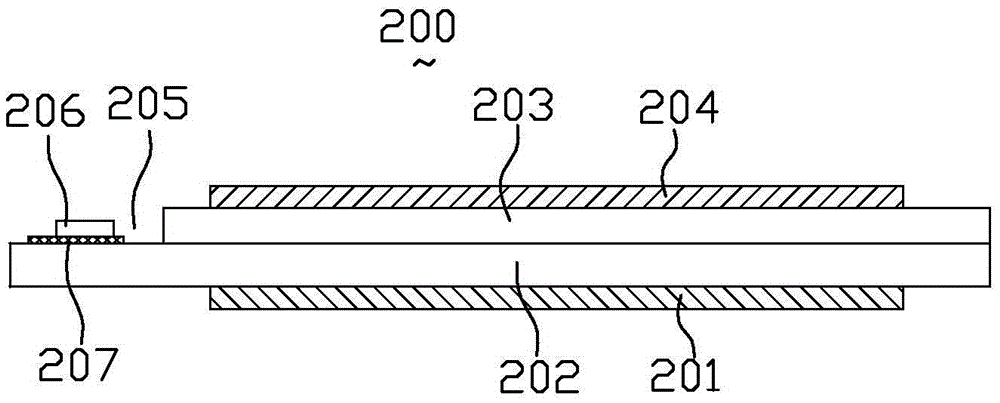

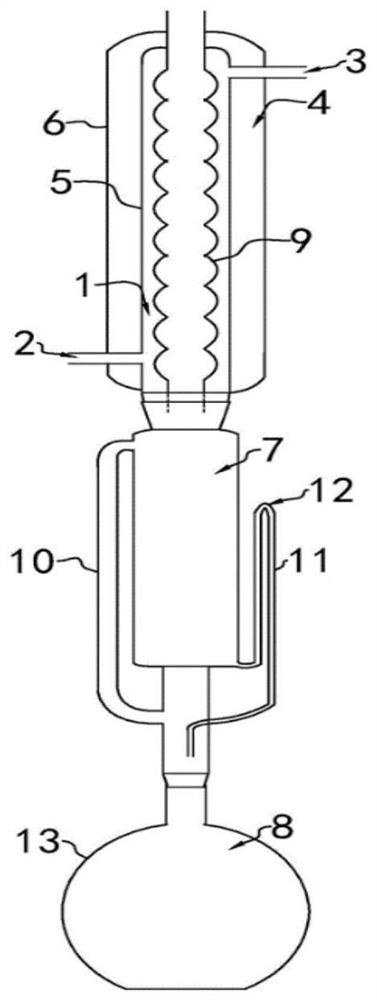

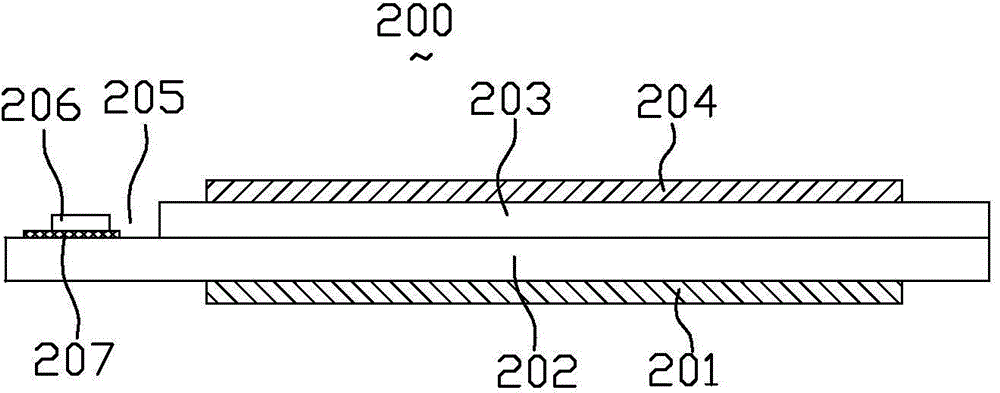

Swelling agent coating heating device and operating method thereof

ActiveCN104624532BShorten swelling timeAvoid harmLiquid surface applicatorsCleaning using toolsAnisotropic conductive filmEngineering

A swelling agent coating and heating device comprises a cover, a heating device and a swelling agent coating device, wherein the cover is of a hollow cuboid structure without a lower bottom surface, a first cavity is formed inside the cover, the cover enables an anisotropic conductive film in a terminal area to be buckled in the first cavity, the heating device and the swelling agent coating device are fixed to the cover and are communicated with the cover, the heating device provides hot air for the first cavity, and the anisotropic conductive film in the first cavity is coated with a swelling agent through the swelling agent coating device. The invention further provides an operation method of the swelling agent coating and heating device. Due to the fact that the swelling agent coating and heating device comprises the cover, the heating device and the swelling agent coating device, the swelling agent does not need to be coated through a manual method, harm to the body caused when an operator makes contact with the swelling agent for a long time can be avoided, meanwhile, the swelling time of the swelling agent is shortened, and working efficiency is effectively improved.

Owner:KUSN INFOVISION OPTOELECTRONICS

A preparation method of low-cost biodegradable plant fiber starch tableware

ActiveCN113292759BGood antibacterial effectWide range of antibacterialPlatesTablewaresCelluloseAdhesive

Owner:CHINA YUNHONG HLDG CO LTD +2

Room-temperature selective swelling method of pore-forming used for preparing separation membranes

ActiveUS20220203305A1Reduce the temperatureShorten swelling timeSemi-permeable membranesMembranesPolymer scienceAlcohol

The present invention provides a room-temperature selective swelling method of pore-forming used for preparing separation membranes, comprising: treating a dense membrane of an amphiphilic block copolymer by a composite swelling agent at 15-30° C. for 1 min-24 h, removing the residual solvent, then leaving the membrane at room temperature to dry, so as to obtain an amphiphilic block copolymer separation membrane with a bi-continuous porous structure, wherein the composite swelling agent is composed of 60-96% of a first swelling agent and 4-40% of a second swelling agent, the first swelling agent is an alcohol solvent, the second swelling agent is selected from any one or a mixture of two or more of toluene, styrene, tetrahydrofuran, 1,4-dioxane and so on. In the method of the invention, selective swelling can be achieved at room temperature, abating the energy consumption in membrane-forming process. The method has universality and can be widely used in the pore-forming process of various amphiphilic block copolymers. The swelling level and morphology can be controlled by adjusting the composition of the solvent in the swelling agent and the second swelling agent content in the swelling agent.

Owner:NANJING UNIV OF TECH

Preparation method of low-molecular-weight plant gelatin powder

InactiveCN103305571BLow water insoluble contentSpecial solubilityFermentationSolubilityNeutral protease

The invention relates to a preparation method of low-molecular-weight plant gelatin powder. The method comprises the following steps of: hydrating, rubbing, rolling and tackifying a plant gelatin sheet; sequentially carrying out enzymolysis treatment by utilizing mannose enzyme liquid and neutral protease liquid; and drying prepared plant gelatin with the certain molecular weight and treating into gelatin powder with the 120-160-mesh size. The plant gelatin sheet prepared by using the method disclosed by the invention can be any one of a guanidine gelatin sheet, a sesbania gelatin sheet and a tonka-bean gelatin sheet. A prepared product has the advantages of low water insoluble matters, high thickening efficiency, rapidness in thickening, protruding salt solubility, temperature stability and corrosion resistance, capability of being repeatedly used, and the like.

Owner:郑建立

Preparation method of EPDM rubber/polyaniline/polypropylene composite conductive material

ActiveCN104861305BIncreased diffusion rateShorten swelling timePolypropylene compositesEthylene-propylene-diene-monomer

The invention discloses a method for preparing an EPDM rubber / polyaniline / polypropylene compound conductive material. The method comprises the following steps: (1) obtaining swelled EPDM rubber powder; (2) obtaining EPDM rubber / polyaniline compound conductive powder; (3) obtaining EPDM rubber / polyaniline / polypropylene compound granules; (4) obtaining the EPDM rubber / polyaniline / polypropylene compound conductive material. According to the method, a composite with high electrical conductivity can be obtained under the condition of lower polyaniline content, meanwhile better processability can be provided, and the influence that other performance of the composite is reduced caused by addition of the polyaniline content is effectively weakened.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Preparation method of swelled natural silk fiber material

InactiveCN108893997AShorten swelling timeImprove swelling efficiencyAnimal fibresLiquid ratioSwelling pressure

The invention provides a preparation method of a swelled natural silk fiber material. The preparation method comprises the following steps: preparing a mixed solution of diethyl ether, hexanediol andwater in a proportion of 1 to (10-15) to (30-50); adding natural silk fibers and the mixed solution into a vacuum stirrer in a solid-liquid ratio of 1 to (10-20), and stirring at a pressure of 0.03MPa-0.05MPa for 3-6 minutes; and carrying out supercritical fluid swelling by taking supercritical carbon dioxide as a swelling agent, so as to obtain the swelled natural silk fiber material, wherein thesolid-liquid ratio of the natural silk fibers to the swelling agent is 1 to (8-12), the supercritical fluid swelling pressure is 6MPa-10MPa, the supercritical fluid swelling temperature is 55-75 DEGC, and the supercritical time is 10-15 seconds.

Owner:苏州先蚕丝绸有限公司

Mixed solvent used for cellulose acetate film as packaging material, method for softening cellulose acetate film and packaging method

ActiveCN110776659BHelpful for qualitativePrevent too softFlexible coversWrappersCelluloseAcetic acid

The invention discloses a mixed solvent used as a packaging material for cellulose acetate film, which comprises the following composition in parts by weight: methanol: 6-20 parts, acetic acid: 6-20 parts, acetone: 1-50 parts, water: 10-20 parts 87 parts, first dissolve the cellulose acetate film into the prepared mixed solution, and make the cellulose acetate film in a swollen state by preparing the solvent in the solution. In this way, the cellulose acetate film can be softened, so that the cellulose acetate film can be attached to the surface of the package in the softened state, and then dried under natural conditions. The cellulose acetate film itself will not be damaged during the swelling process. The molecular structure is damaged. During the drying process, the solvent inside the molecule will volatilize, so that the cellulose acetate film will be released from the swelling state, and the cellulose acetate film will return to its original state and its original mechanical properties. It can be realized that the cellulose acetate film can be completely bonded to the package, including the corners can be completely bonded without wrinkles.

Owner:WENZHOU UNIV

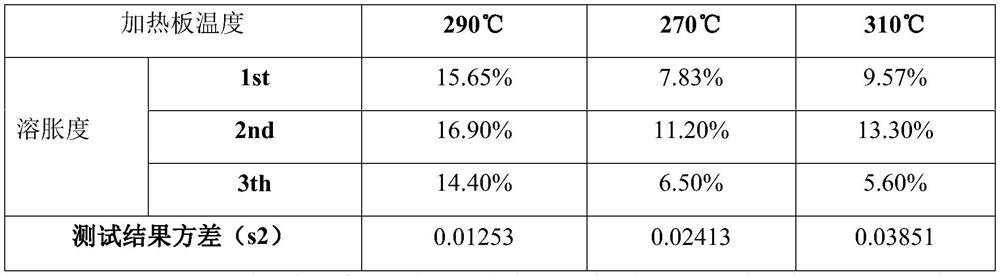

Method for testing swelling degree of solid powdery polymer composite material

PendingCN114858642ATo characterize the degree of impregnationCharacterization Test Degree of ImmersionWeighing by absorbing componentPolymer sciencePolyamide

The invention discloses a method for testing the swelling degree of a solid powdery polymer composite material. The method comprises the following steps: firstly, carrying out compression molding on a solid powdery polymer composite material, cutting into square slices, polishing to be flat by using a grinding tool, then packaging the slices by using a cloth bag, putting into a Soxhlet extractor, adding methyl ethyl ketone, carrying out reflux impregnation, and calculating the swelling degree according to the weight before and after impregnation. The method disclosed by the invention is relatively high in repeatability and stability, stable in test data, capable of better characterizing the impregnation degree of the test sample on methyl ethyl ketone, and suitable for a high-molecular polymer composite material of which the main component is more than 95% of polyamide, polyurethane, polyimide and the like.

Owner:ZHONGFU SHENYING CARBON FIBER

Method for preparing EPDM rubber/polyaniline/polypropylene compound conductive material

The invention discloses a method for preparing an EPDM rubber / polyaniline / polypropylene compound conductive material. The method comprises the following steps: (1) obtaining swelled EPDM rubber powder; (2) obtaining EPDM rubber / polyaniline compound conductive powder; (3) obtaining EPDM rubber / polyaniline / polypropylene compound granules; (4) obtaining the EPDM rubber / polyaniline / polypropylene compound conductive material. According to the method, a composite with high electrical conductivity can be obtained under the condition of lower polyaniline content, meanwhile better processability can be provided, and the influence that other performance of the composite is reduced caused by addition of the polyaniline content is effectively weakened.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Swelling agent coating and heating device and operation method thereof

ActiveCN104624532AShorten swelling timeAvoid harmLiquid surface applicatorsCleaning using toolsAnisotropic conductive filmEngineering

A swelling agent coating and heating device comprises a cover, a heating device and a swelling agent coating device, wherein the cover is of a hollow cuboid structure without a lower bottom surface, a first cavity is formed inside the cover, the cover enables an anisotropic conductive film in a terminal area to be buckled in the first cavity, the heating device and the swelling agent coating device are fixed to the cover and are communicated with the cover, the heating device provides hot air for the first cavity, and the anisotropic conductive film in the first cavity is coated with a swelling agent through the swelling agent coating device. The invention further provides an operation method of the swelling agent coating and heating device. Due to the fact that the swelling agent coating and heating device comprises the cover, the heating device and the swelling agent coating device, the swelling agent does not need to be coated through a manual method, harm to the body caused when an operator makes contact with the swelling agent for a long time can be avoided, meanwhile, the swelling time of the swelling agent is shortened, and working efficiency is effectively improved.

Owner:KUSN INFOVISION OPTOELECTRONICS

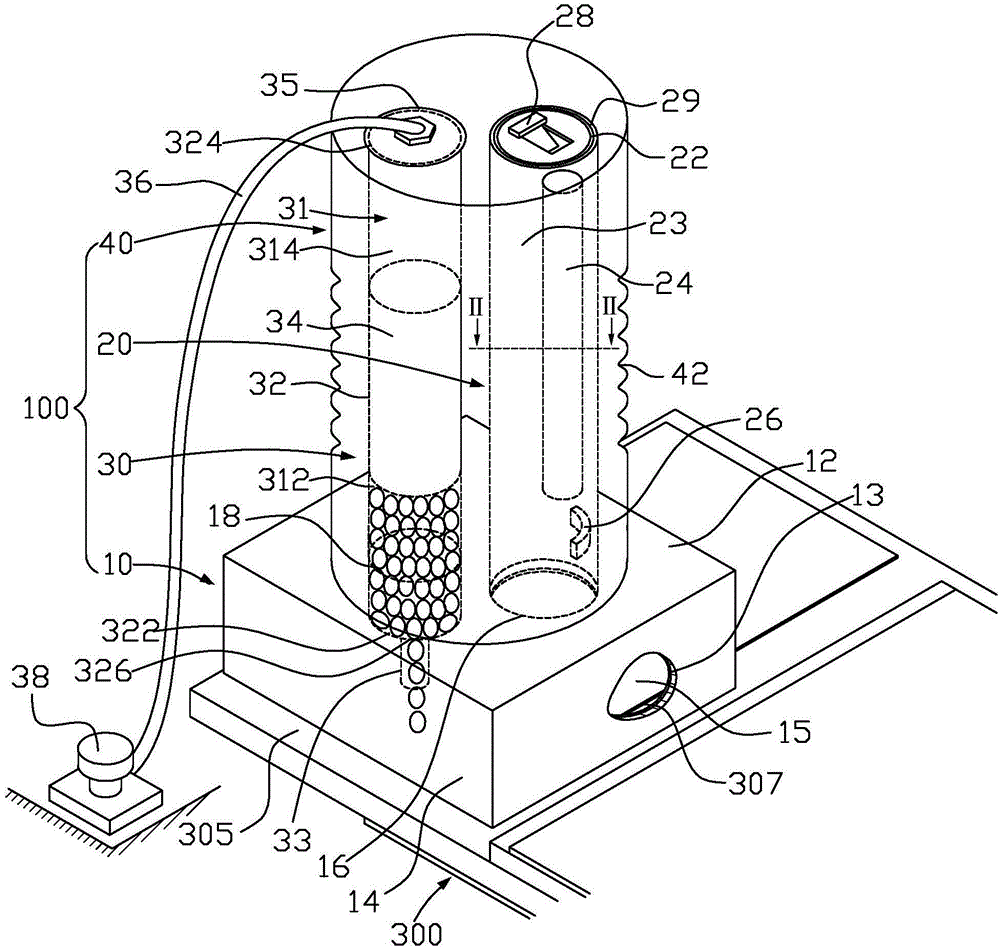

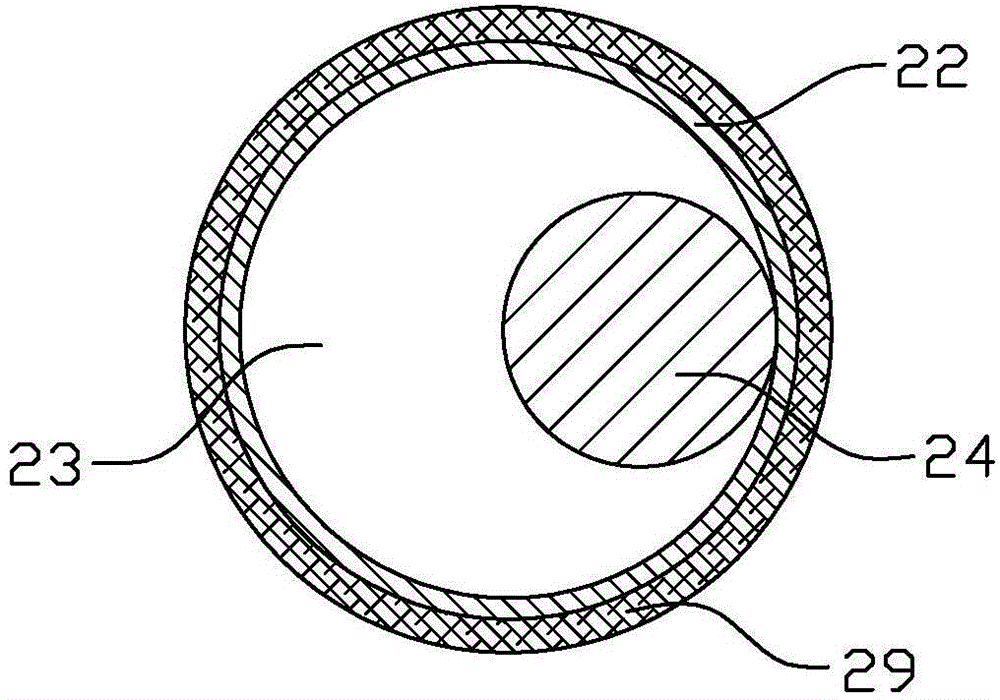

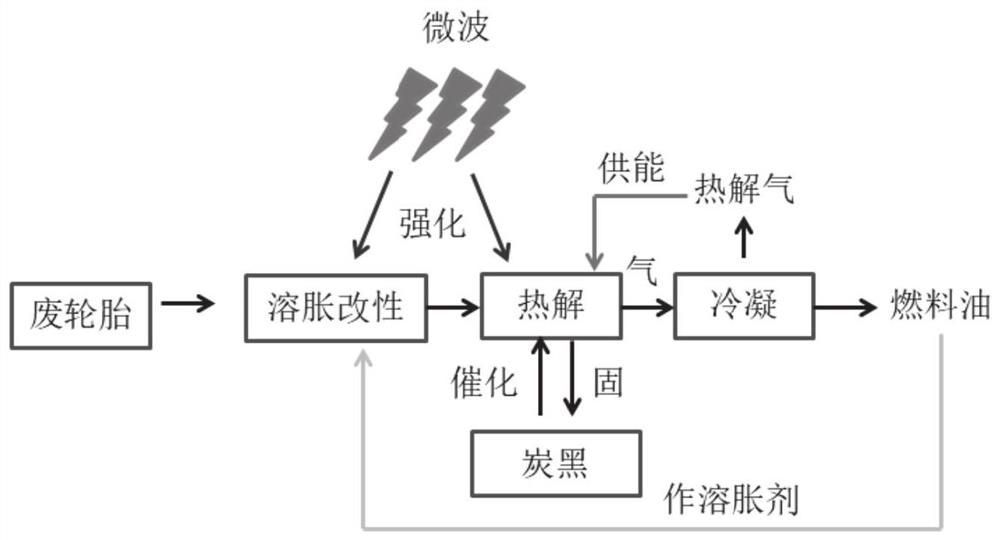

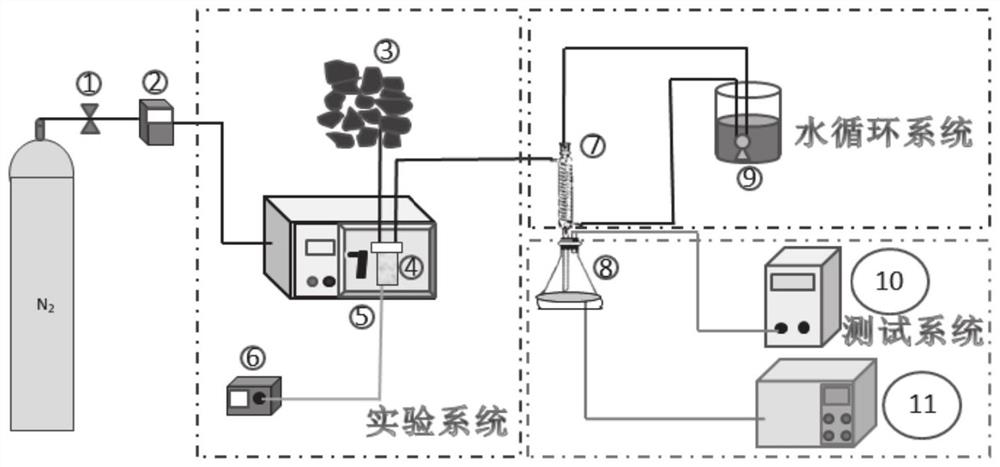

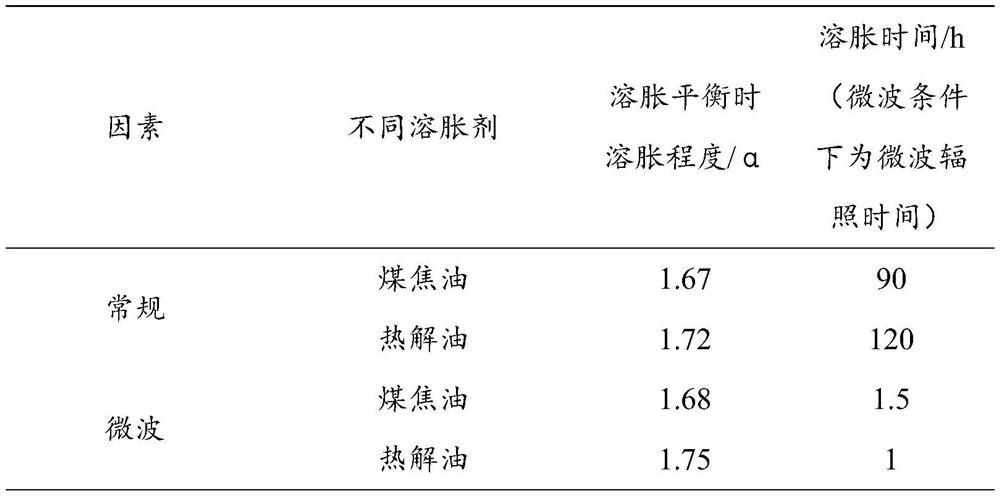

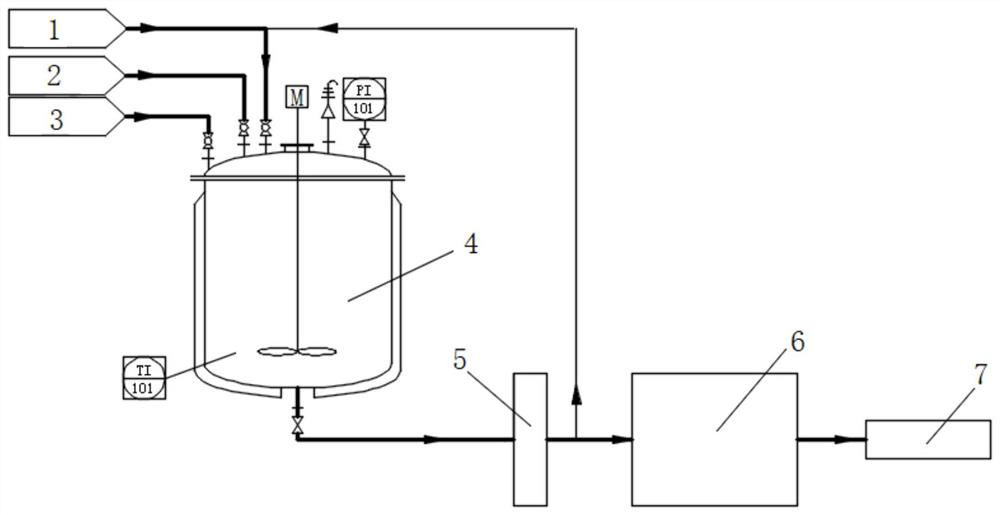

A method for swelling modified and strengthened pyrolysis of waste tires to produce oil and carbon black

ActiveCN113061455BImprove pyrolysis effectShorten swelling timePigmenting treatmentLiquid hydrocarbon mixture productionOligomerPhysical chemistry

The invention discloses a method for swelling modified and enhanced pyrolysis of waste tires to produce oil and carbon black. The waste tires are swollen, and the swollen waste tires are pyrolyzed to prepare pyrolysis oil and carbon black; wherein, during the swelling process of waste tires , using microwave radiation, the swelling agent is the heavy component of the pyrolysis oil. The invention not only reduces the time for making oil from waste tires, but also improves the production efficiency of pyrolysis oil through swelling modification. At the same time, the cracked carbon pores are more developed.

Owner:SHANDONG UNIV

Preparation method of EPDM rubber/polyaniline/high-density polyethylene composite conductive material

InactiveCN104910492BIncreased diffusion rateShorten swelling timeEthylene-propylene-diene-monomerConductive materials

The invention discloses a preparation method of an ethylene propylene diene monomer / polyaniline / high density polyethylene composite conducting material. The preparation method comprises the following steps: (1) adding an aniline monomer to ethylene propylene diene monomer powder, and stirring evenly to obtain the swelled ethylene propylene diene monomer; (2) obtaining ethylene propylene diene monomer / polyaniline composite conducting powder; (3) obtaining ethylene propylene diene monomer / polyaniline / high density polyethylene composite particles; (4) obtaining the ethylene propylene diene monomer / polyaniline / high density polyethylene composite conducting material. The method is capable of obtaining the high-electrical conductivity composite material in case of relatively low polyaniline content; meanwhile, the method provides good processability, and is capable of effectively weakening the influence of the degradation of other properties of the composite material due to the increase of the polyaniline content.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A kind of preparation method of polyacrylonitrile fiber

ActiveCN112831859BImprove spinnabilityNot easy to plug holesMonocomponent synthetic polymer artificial filamentArtifical filament manufacturePolymer scienceSpinning

In the present invention, polyacrylonitrile is first swelled and dissolved in a certain proportion of ionic liquid and high boiling point (150-190°C) solvent under high temperature and high pressure conditions, and then added with volatile or low boiling point (30-60°C) solvent to obtain a homogeneous Spinning liquid, then spinning, drawing and opening to prepare polyacrylonitrile fiber, which has the technical effect of making the solvent less likely to be wrapped inside the fiber and improving fiber defects; the prepared fiber is denser and has a finer diameter.

Owner:SHANDONG RENFENG SPECIAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com