Preparation method of low-molecular-weight plant gelatin powder

A plant rubber powder, low molecular weight technology, applied in the field of preparation of low molecular weight plant rubber powder, to achieve the effects of improved solubility, high hydration thickening efficiency, and good salt compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

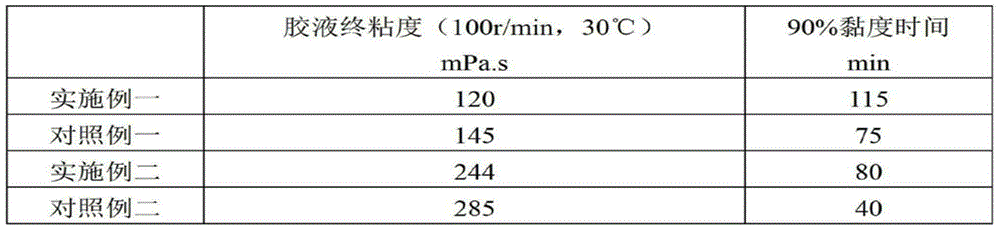

Embodiment 1

[0019] The preparation of embodiment 1 low molecular weight guar gum thickener

[0020] Get Indian imported ("Xuelong brand", 98%) guar gum film, mix with water according to weight ratio 100:40 under room temperature, in hydrator (hydrator is horizontal stirring reactor, Weihai Xintai Chemical Machinery Co., Ltd. Co., Ltd. GSHA type horizontal stirring tank) for 60 minutes of hydration, using a double-sided mechanical viscosifier (Lisheng Chemical Machinery Co., Ltd., LG500 screw extrusion kneader) to viscosify the hydrated guanidine film For processing, elongated guar gum strips were prepared. Spray and mix the thickened guar gum strips with the mannanase solution at a weight ratio of 100:50, keep the temperature of the hydrator at 50°C, and react for 120 minutes. The mannanase used in this reaction The enzyme activity of the liquid is 20U / ml. Then, according to the weight ratio of 100:10, spray the neutral protease liquid in the reaction system, the enzyme activity of the ...

Embodiment 2

[0021] The preparation of embodiment 2 low-molecular-weight cougar gum thickener

[0022] Take coumarin film (taken from Huangshan Vegetable Gum Co., Ltd.), mix it with water at a weight ratio of 100:30 at room temperature, hydrate in a hydrator for 60 minutes, and use a three-roller viscosifier (Lisheng Chemical Machinery Co., Ltd. company, S-405 type) to increase the viscosity of the hydrated coumarin film to prepare a thin and long strip. Spray and mix the thickened coumarin strips with the mannan enzyme solution at a weight ratio of 100:40, keep the temperature of the hydrator at 45°C, and react for 30 minutes. The mannan used in the reaction The enzyme activity of the enzyme liquid is 2.0U / ml. Then, according to the weight ratio of 100:5, spray the neutral protease liquid in the reaction system, the enzyme activity of the neutral protease liquid used is 1.0 U / ml, continue to stir, and react for 10 minutes. The reaction system was quickly dried at 120°C, and the dried gu...

Embodiment 3

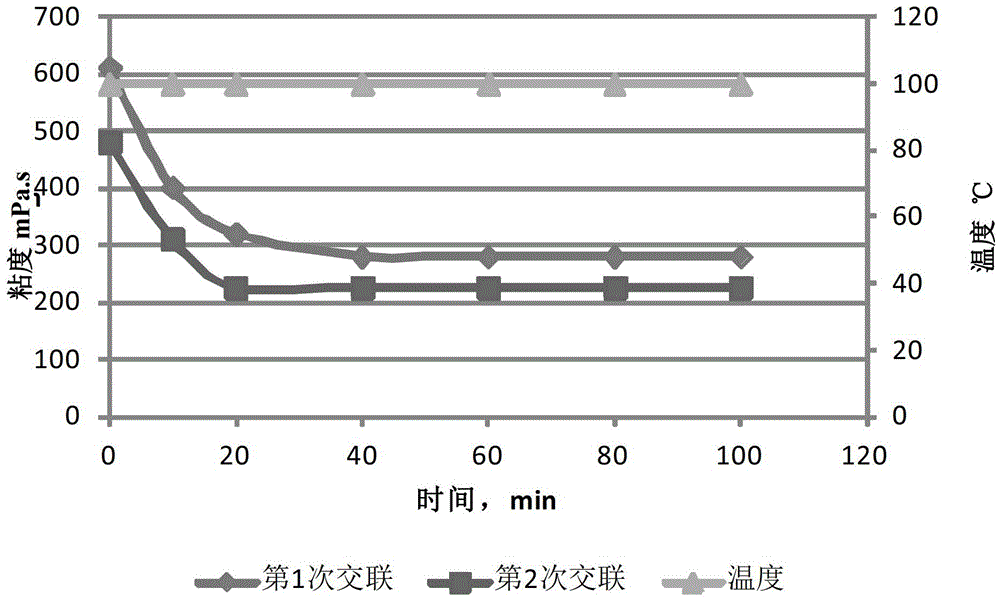

[0033] Embodiment 3 The use of low-molecular vegetable gum fracturing fluid

[0034] Take the low-molecular vegetable gum thickener prepared in Example 1, prepare a fracturing fluid base fluid according to 0.4% low-molecular-weight guar gum thickener, 2.0% KCl, and 0.03% NaOH, ripen for 30 minutes, and take organic boron from Tianhe Fuhua Company Cross-linking agent BCL-61, prepare the gel with the cross-linking ratio of base liquid: cross-linking agent = 100:0.3, measure the temperature and shear resistance of the gel under the shear conditions of 100 ° C and 170 s-1, and the test ends ( After 90 minutes), the pH of the gel system was adjusted to 4.0 with 1.0% hydrochloric acid solution to break the gel, and then left for 24 hours, and then the pH of the system was adjusted to above 10.0 with 2.0% NaOH solution to form a gel, and the above test process was repeated. The temperature and shear performance evaluation of low molecular weight plant gum thickener fracturing fluid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com