Method for granulating urea by using melt marble cutting technology and obtained urea granules

A cutting technology and urea granulation technology, applied in the field of urea granule preparation, can solve problems such as high cost, need to be cleaned regularly, reduce production capacity, etc., achieve good sphericity, avoid the problem of particle agglomeration, and improve the effect of sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In the present embodiment, the steps of granulating urea with melt marble cutting technology are as follows:

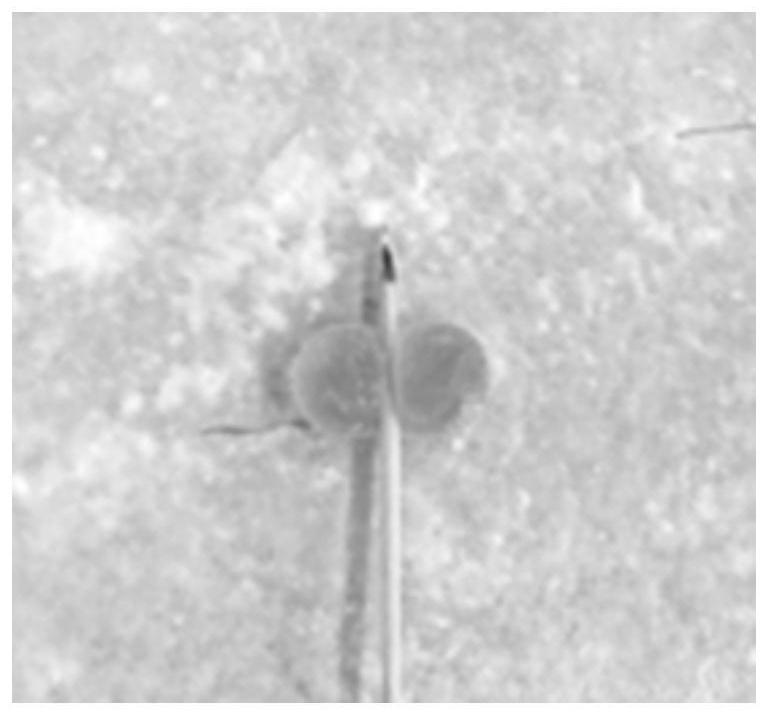

[0048] (1) Industrial urea powder and PTFE powder are dosed according to the mass ratio of 100:1, and the PTFE powder is coated on the surface of urea melt by premixing and melting to form urea melt marbles. The specific operation is: industrial urea powder and 0.04g of the mixture formed by mixing the PTFE powder evenly is placed on the superphobic urea melt cutting table 1 and operates a temperature-controllable heating and cooler 3, so that the super urea molten cutting table 1 is heated to 150°C, and the After the industrial urea powder is heated, melted and aggregated into a urea melt, the PTFE powder is evenly coated on the surface of the urea melt to form a urea melt marble (see figure 1 );

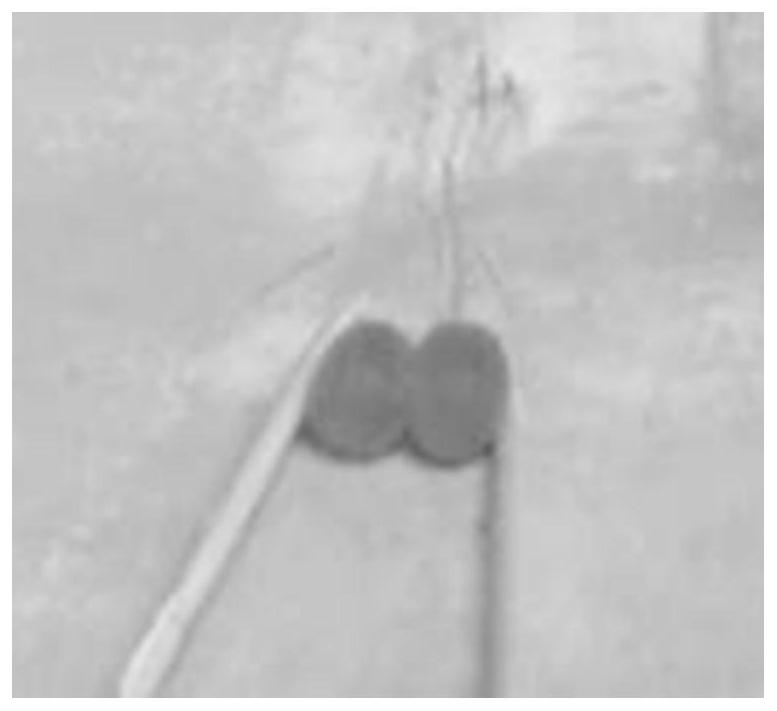

[0049] (2) Cut the urea melt marbles obtained in step (1) using a needle-shaped cutter with superphobic urea melt properties to obtain two independent urea melt pa...

Embodiment 2

[0056] In the present embodiment, the steps of granulating urea with melt marble cutting technology are as follows:

[0057] (1) Industrial urea powder and PTFE powder are dosed according to the mass ratio of 100:1, and the PTFE powder is coated on the surface of urea melt by premixing and melting to form urea melt marbles. The specific operation is: industrial urea powder and 0.04g of the mixture formed by mixing the PTFE powder evenly is placed on the superphobic urea melt cutting table 1 and operates a temperature-controllable heating and cooler 3, so that the super urea molten cutting table 1 is heated to 150°C, and the After the industrial urea powder is heated, melted and aggregated into a urea melt, the PTFE powder is evenly coated on the surface of the urea melt to form a urea melt marble;

[0058] (2) Cut the urea melt marbles obtained in step (1) using a plane cutter with superphobic urea melt performance, to obtain two independent urea melt particles coated with PTF...

Embodiment 3

[0064] In the present embodiment, the steps of granulating urea with melt marble cutting technology are as follows:

[0065](1) Industrial urea powder and PTFE powder are dosed according to the mass ratio of 40:1, and the PTFE powder is coated on the surface of urea melt by premixing and melting to form urea melt marbles. The specific operation is: industrial urea powder and 1.00g of the mixture formed by mixing the PTFE powder evenly is placed on the superphobic urea melt cutting table 1 and operates a temperature-controllable heating and cooling device 3, so that the super urea molten cutting table 1 is heated to 150°C. After the industrial urea powder is heated, melted and aggregated into a urea melt, the PTFE powder is evenly coated on the surface of the urea melt to form a urea melt marble;

[0066] (2) Cut the urea melt marbles obtained in step (1) using a honeycomb orifice cutter with superphobic urea melt performance, to obtain multiple independent urea melt particles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com