Preparation method of polyacrylonitrile fiber

A polyacrylonitrile fiber and ionic liquid technology, applied in the direction of fiber chemical characteristics, rayon manufacturing, single-component synthetic polymer rayon, etc., can solve the problems of increased internal defects of fibers, complex process flow, and low production efficiency , to achieve the effects of low solvent residue, lower dissolution temperature, and lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

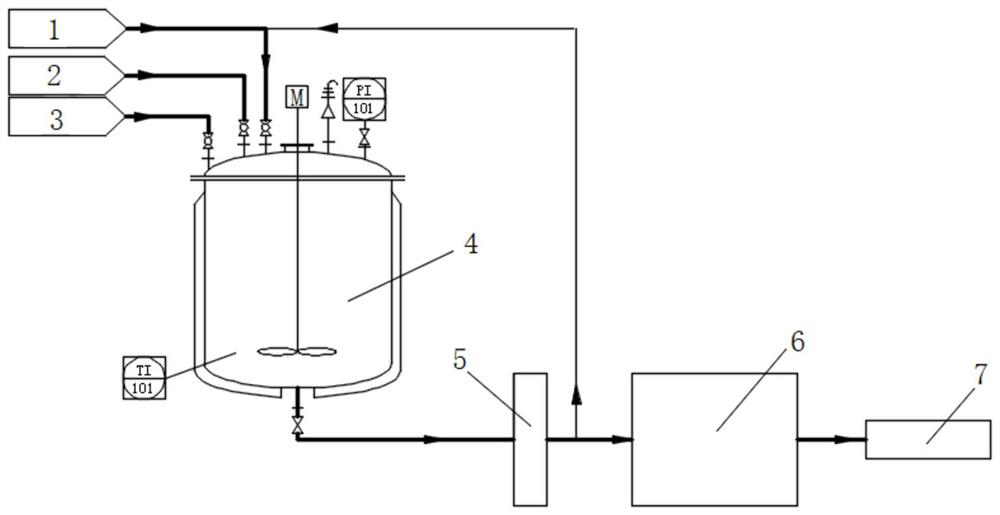

Method used

Image

Examples

Embodiment 10

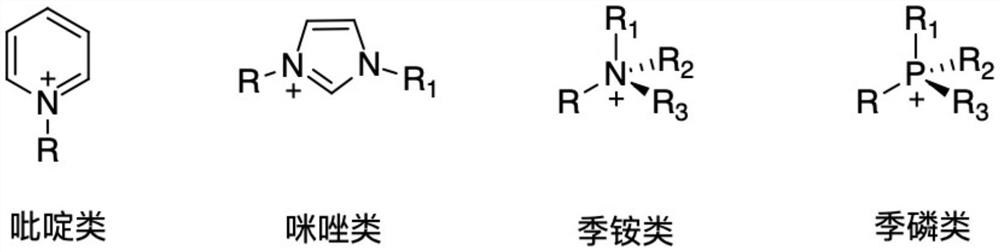

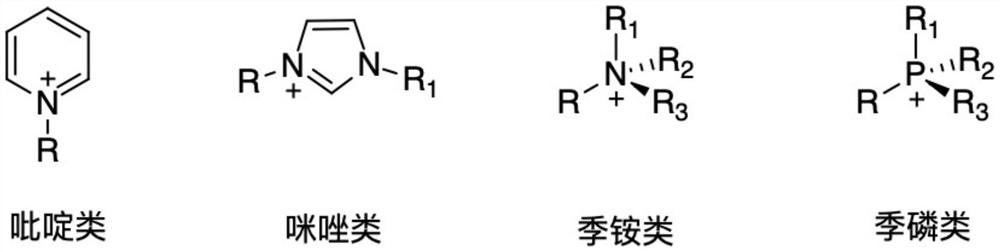

[0031] The main solvent (i.e. the benign solvent of polyacrylonitrile) is dimethylformamide, the secondary solvent is dichloromethane, and the ionic liquid is 1-ethyl-3-methylimidazolium tetrafluoroborate, according to the raw materials in the table Ratio, preparation method is identical with embodiment 1.

Embodiment 11

[0033] The main solvent (i.e. the benign solvent of polyacrylonitrile) is dimethylformamide, the secondary solvent is n-hexane, and the ionic liquid is 1-ethyl-3-methylimidazolium tetrafluoroborate, according to the raw material composition in Table 1 Ratio, preparation method is identical with embodiment 1.

Embodiment 12

[0035] Taking the main solvent (i.e. the benign solvent of polyacrylonitrile) as dimethyl sulfoxide, the secondary solvent as dichloromethane, and the ionic liquid as N-alkylpyridine chloroaluminate as an example, according to the ratio of raw materials in Table 1, prepare Method is identical with embodiment 1.

[0036] See Table 1 for the performance tests of the polyacrylonitrile fibers prepared in Examples and Comparative Examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com