Preparation method of low-cost fully-biodegradable plant fiber starch tableware

A plant fiber starch, biodegradable technology, applied in the direction of dishes, etc., can solve the problems of the hygienic situation of degradable tableware or packaging products that are difficult to control, the anti-mildew technology is difficult to solve, and the health of consumers is affected, and the impact strength is achieved. High, non-deformable plasticity, the effect of shortening the swelling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

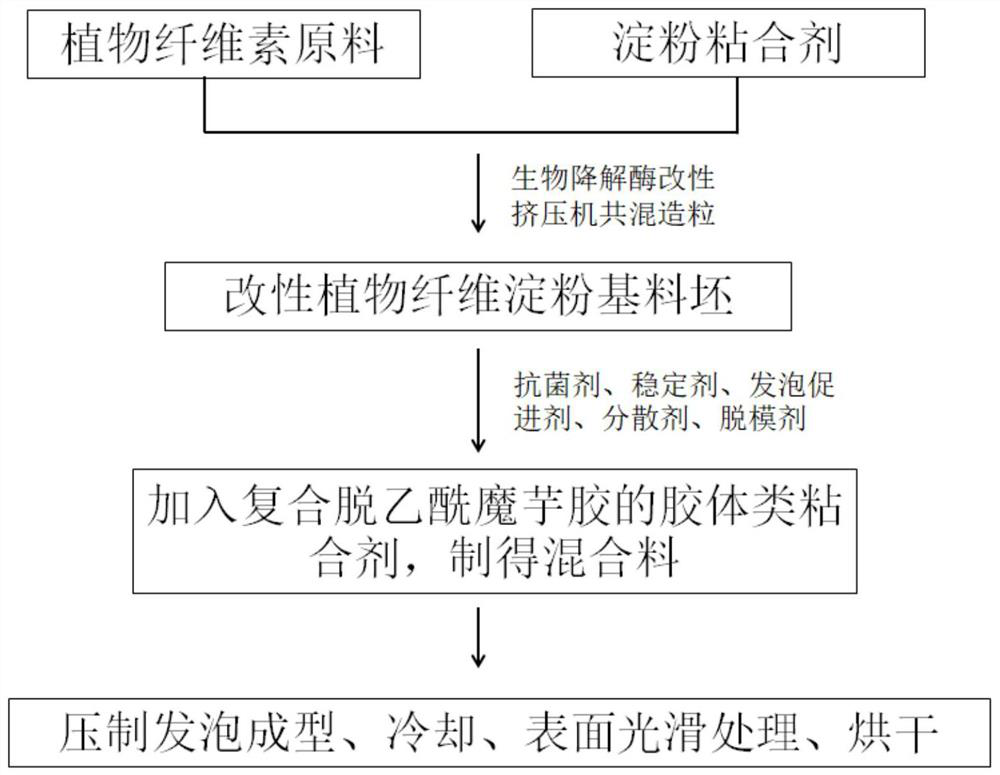

[0035] This embodiment provides a method for preparing low-cost biodegradable plant fiber starch tableware, such as figure 1 shown, which includes the following steps:

[0036] S1: Take the plant cellulose material containing Scutellaria baicalensis dregs, add water and stir it into a pulp, filter it with a 100-mesh sieve, and then dry, pulverize, and sieve the solid residue in turn, and then use an airflow ultrafine pulverizer for ultrafine pulverization Treatment (equipment pressure 0.7-1.0MPa, system air volume 3-5m 3 / min, classifier speed 2000~2500r / min), then add starch binder and biodegradation enzyme, adjust the temperature to 50-70°C (preferably 60°C), and adjust the water content to 20%-30% ( Preferably 25%) after stirring in a mixer for 12-20min (preferably 15min), stirring speed 800-1000r / min;

[0037] Send into twin-screw extruder again and carry out blending, extrude, make modified plant fiber starch base stock, and twin-screw extruder extrusion temperature is ...

Embodiment 2

[0046] The only difference between this example and Example 1 is that, and in parts by weight, the fully degradable ecological tableware includes the following components: 70 parts of plant cellulose material, 0.5 part of biodegradable enzyme, starch binder 18 parts, 2 parts of colloidal binder compounded with deacetylated konjac gum, 1 part of antibacterial agent, 0.5 part of stabilizer, 0.8 part of foam accelerator, 0.8 part of dispersant, and 0.2 part of release agent.

Embodiment 3

[0048] The only difference between this example and Example 1 is that, and in parts by weight, the fully degradable ecological meal consists of the following components: 65 parts of plant cellulose materials, 0.4 parts of biodegradable enzymes, starch-based adhesive 15 parts of agent, 0.5 part of colloidal binder of composite deacetylated konjac gum, 0.6 part of antibacterial agent, 1 part of stabilizer, 0.6 part of foam accelerator, 0.5 part of dispersant, and 1 part of release agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com