Medical nano-fiber sponge material and preparation method and application thereof

A technology of nanofibers and sponges, which is applied in the field of biomedical materials and wound repair, can solve the problems of poor air permeability, low bionic degree of permeability microstructure, and reduced anti-adhesion, so as to avoid dissolution, excellent healing properties, and promote The effect of vascularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) NaNO 3 and Ca(NO 3 ) 2 4H 2 O was dissolved in 20 mL deionized water at a molar ratio of 1:0.5, NaNO 3 The concentration of the solution is 0.6 mol / liter, adjust the pH value to 12 with ammonia water, stir continuously, and set aside;

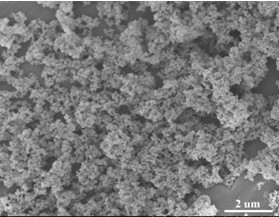

[0038] 2) Add triethyl phosphate and ethyl orthosilicate to 80 mL of absolute ethanol at a molar ratio of 1:25, and the molar concentration of ethyl orthosilicate is 0.5 mol / L. After stirring evenly, add to the above step 1 ) in the inorganic salt mixed solution, stirring continuously for 60 minutes, at 60 o C aged for 72 hours, then dried, and at 550 o Calcined at C to obtain bioactive glass particles, such as figure 1 As shown, the particle size of the particles is 200-300 nm.

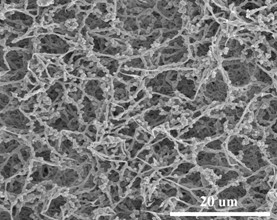

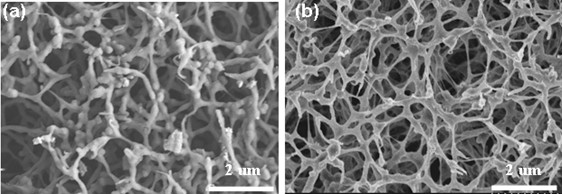

[0039] 3) Add 0.1 g of bioactive glass particles obtained in step 2) to 20 ml of gelatin hydrosol with a mass percentage of 10%, stir and mix well, add 25 ml of absolute ethanol to it, continue stirring evenly, and place in -80 o Stand still in C l...

Embodiment 2

[0046] 1) NaNO 3 and Ca(NO 3 ) 2 4H 2 O was dissolved in 20 mL deionized water at a molar ratio of 1:0.8, NaNO 3 The concentration of the solution is 0.5 mol / liter, adjust the pH value to 11 with ammonia water, stir continuously, and set aside;

[0047] 2) Add triethyl phosphate and ethyl orthosilicate to 80 mL of absolute ethanol at a molar ratio of 1:30, and the molar concentration of ethyl orthosilicate is 0.5 mol / L. After stirring evenly, add to the above step 1 ) in the inorganic salt mixed solution, stirring continuously for 90 minutes, at 80 o C aged for 48 hours, then dried, and at 520 o C and calcined to obtain bioactive glass particles with a particle size of 270-380 nm.

[0048] 3) Add 0.15 g of bioactive glass particles obtained in step 2) to 25 ml of gelatin hydrosol with a mass percentage of 10%, stir and mix well, add 30 ml of absolute ethanol to it, continue to stir evenly, and place in- 80 o Stand still in C low temperature equipment for 20 hours to ob...

Embodiment 3

[0054] 1) NaNO 3 and Ca(NO 3 ) 2 4H 2 O was dissolved in 20 mL deionized water at a molar ratio of 1:1.2, NaNO 3 The concentration of the solution is 0.3 mol / liter, adjust the pH value to 11 with ammonia water, stir continuously, and set aside;

[0055] 2) Add triethyl phosphate and ethyl orthosilicate to 80 mL of absolute ethanol at a molar ratio of 1:20, and the molar concentration of ethyl orthosilicate is 0.5 mol / L. After stirring evenly, add to the above step 1 ) in a mixed solution of inorganic salts, stirring continuously for 90 minutes, at 75 o C aged for 60 hours, then dried, and at 600 o C and calcined to obtain bioactive glass particles with a particle size of 430-620 nm.

[0056] 3) Add 0.18 g of bioactive glass particles obtained in step 2) to 30 ml of gelatin hydrosol with a mass percentage of 8%, stir and mix well, add 25 ml of absolute ethanol to it, continue stirring evenly, and place in -80 o Stand still in C low temperature equipment for 20 hours to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com