Medical nano-fiber sponge material and preparation method and application thereof

A nanofiber, sponge technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) NaNO 3 and Ca(NO 3 ) 2 4H 2 O was dissolved in 20 mL deionized water at a molar ratio of 1:0.5, NaNO 3 The concentration of the solution is 0.6 mol / liter, adjust the pH value to 12 with ammonia water, stir continuously, and set aside;

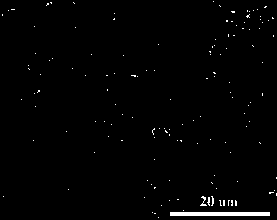

[0038] 2) Add triethyl phosphate and ethyl orthosilicate to 80 mL of absolute ethanol at a molar ratio of 1:25, and the molar concentration of ethyl orthosilicate is 0.5 mol / L. After stirring evenly, add to the above step 1 ) in the inorganic salt mixed solution, stirring continuously for 60 minutes, at 60 o C aged for 72 hours, then dried, and at 550 o Calcined at C to obtain bioactive glass particles, such as figure 1 As shown, the particle size of the particles is 200-300 nm.

[0039] 3) Add 0.1 g of bioactive glass particles obtained in step 2) to 20 ml of gelatin hydrosol with a mass percentage of 10%, stir and mix well, add 25 ml of absolute ethanol to it, continue stirring evenly, and place in -80 o Stand still in C l...

Embodiment 2

[0046] 1) NaNO 3 and Ca(NO 3 ) 2 4H 2 O was dissolved in 20 mL deionized water at a molar ratio of 1:0.8, NaNO 3 The concentration of the solution is 0.5 mol / liter, adjust the pH value to 11 with ammonia water, stir continuously, and set aside;

[0047] 2) Add triethyl phosphate and ethyl orthosilicate to 80 mL of absolute ethanol at a molar ratio of 1:30, and the molar concentration of ethyl orthosilicate is 0.5 mol / L. After stirring evenly, add to the above step 1 ) in the inorganic salt mixed solution, stirring continuously for 90 minutes, at 80 o C aged for 48 hours, then dried, and at 520 o C and calcined to obtain bioactive glass particles with a particle size of 270-380 nm.

[0048] 3) Add 0.15 g of bioactive glass particles obtained in step 2) to 25 ml of gelatin hydrosol with a mass percentage of 10%, stir and mix well, add 30 ml of absolute ethanol to it, continue to stir evenly, and place in- 80 o Stand still in C low temperature equipment for 20 hours to ob...

Embodiment 3

[0054] 1) NaNO 3 and Ca(NO 3 ) 2 4H 2 O was dissolved in 20 mL deionized water at a molar ratio of 1:1.2, NaNO 3 The concentration of the solution is 0.3 mol / liter, adjust the pH value to 11 with ammonia water, stir continuously, and set aside;

[0055] 2) Add triethyl phosphate and ethyl orthosilicate to 80 mL of absolute ethanol at a molar ratio of 1:20, and the molar concentration of ethyl orthosilicate is 0.5 mol / L. After stirring evenly, add to the above step 1 ) in a mixed solution of inorganic salts, stirring continuously for 90 minutes, at 75 o C aged for 60 hours, then dried, and at 600 o C and calcined to obtain bioactive glass particles with a particle size of 430-620 nm.

[0056] 3) Add 0.18 g of bioactive glass particles obtained in step 2) to 30 ml of gelatin hydrosol with a mass percentage of 8%, stir and mix well, add 25 ml of absolute ethanol to it, continue stirring evenly, and place in -80 o Stand still in C low temperature equipment for 20 hours to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com