A kind of polyolefin film and preparation method thereof

A technology of polyolefin and polyolefin resin, which is applied in the field of polyolefin film and its preparation, can solve problems affecting resin dissolution, insufficient swelling, complex feeding equipment, etc., and achieve flexible control, reduce local swelling, and reduce process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

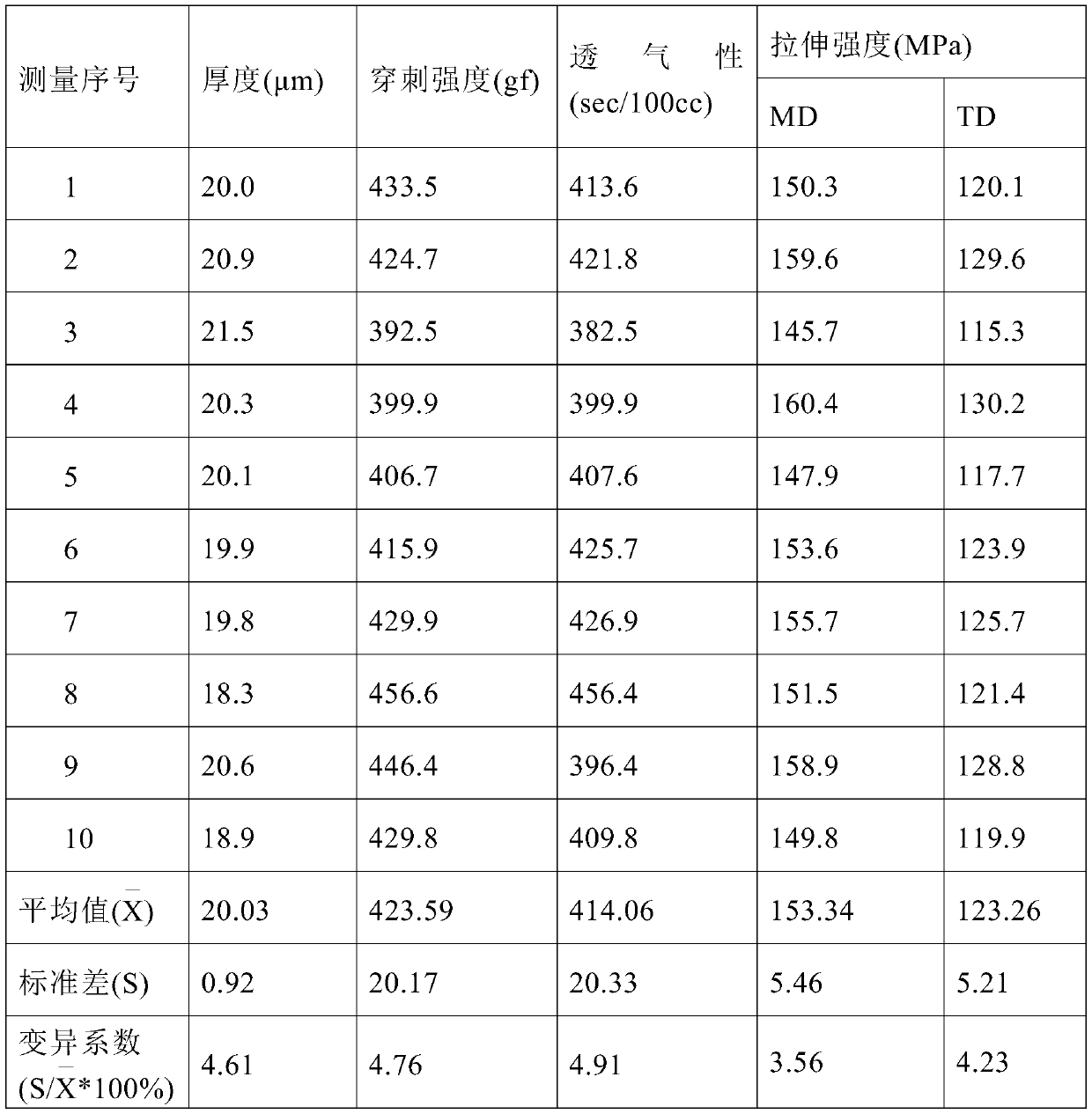

Embodiment 1

[0026] Polyethylene with a viscosity average molecular weight of 500,000 and a solvent of decahydronaphthalene. Heat up to 85°C in a swelling kettle and stir for 20 minutes, cool down, and filter. The filtered polyethylene mass fraction is 40%, 4,4'sulfurized-bis(6-tert-butyl 3-tetrayl)phenol is 0.05% of polyethylene, and the rest is solvent, which contains 50% white oil and 50% Paraffin oil. Extruded by a twin-screw extruder at 170°C, cooled at room temperature, stretched horizontally and vertically simultaneously by biaxial stretching equipment, the thickness of the stretched film reaches 20um, extracted with dichloromethane, stretched at 110°C, Set at 100°C.

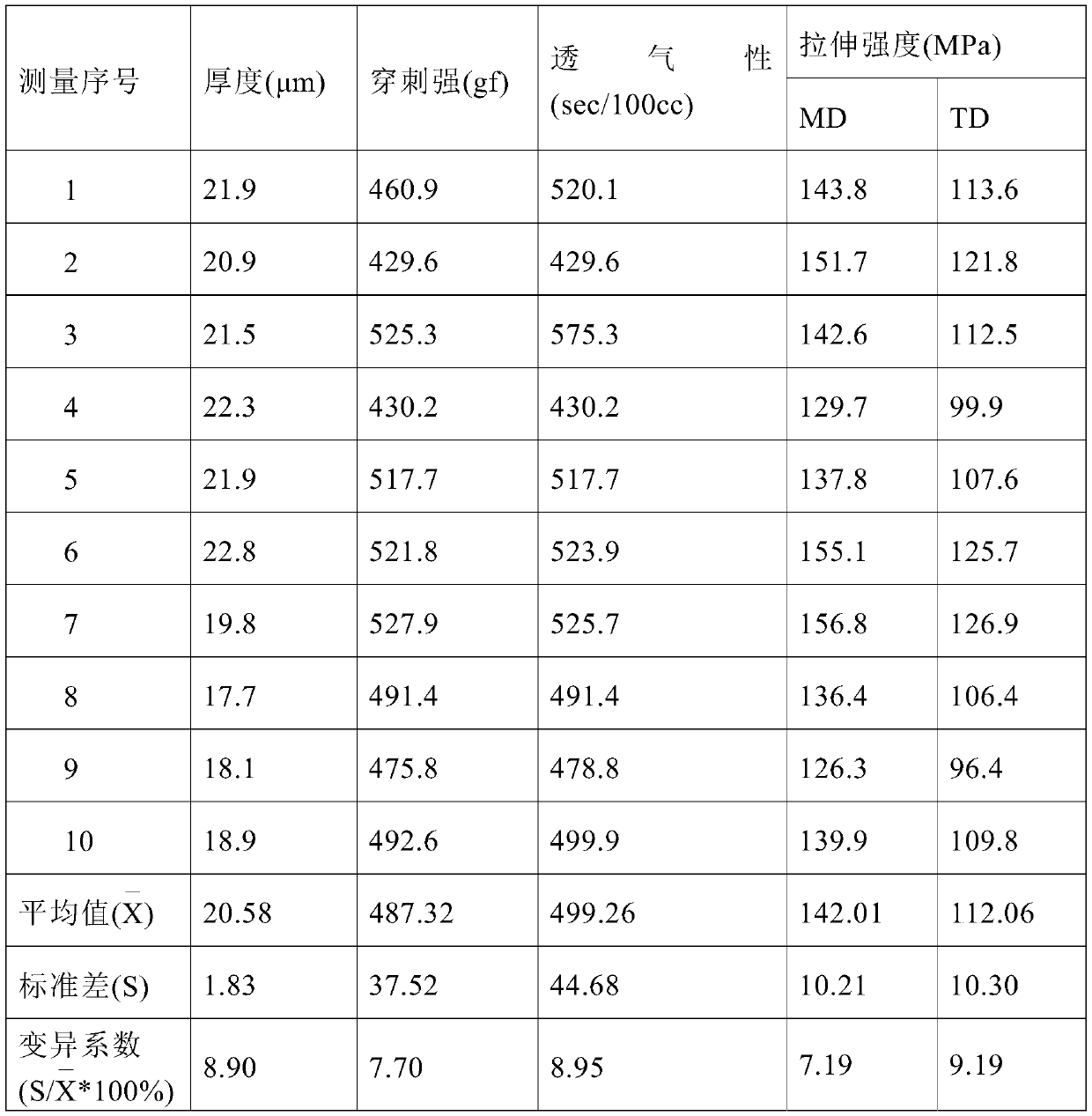

Embodiment 2

[0028]Polypropylene with a viscosity average molecular weight of 1,000,000 and a solvent of decahydronaphthalene. Heat up to 90°C in a swelling kettle and stir for 30 minutes, cool down, and filter. The filtered polypropylene mass fraction is 10%, the viscosity-average molecular weight is 500,000 polyethylene 25%, two (2-hydroxyl-3-tert-butyl 5-tetrayl) pyrenetetrane is 0.2% of polypropylene and polyethylene %, the rest is paraffin oil. After being extruded at 200°C by a twin-screw extruder, cooled at 90°C, and stretched horizontally and vertically simultaneously by biaxial stretching equipment, the thickness of the stretched film reaches 20um, extracted with ethanol, stretched at 120°C, and stretched at 110 ℃ set the shape.

Embodiment 3

[0030] Ultra-high molecular weight polyethylene with a viscosity average molecular weight of 4,000,000 and a solvent of xylene. Heat up to 100°C in a swelling kettle and stir for 50 minutes, cool down, and filter. The mass fraction of ultra-high molecular weight polyethylene after filtration is 5%, the polyethylene with a viscosity average molecular weight of 700,000 is 20%, octadecyl 3-(3',5'-di-tert-butyl-4'-phenyl) N-propyl ester is 0.5% of ultra-high molecular weight polyethylene and polyethylene, and the rest is paraffin oil. Extruded at 210°C by a twin-screw extruder, cooled at 30°C, stretched horizontally and vertically by biaxial stretching equipment, the thickness of the stretched film reaches 20um, extracted with isopropanol, stretched at 125°C , set at 120°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com