Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Rotation speed adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

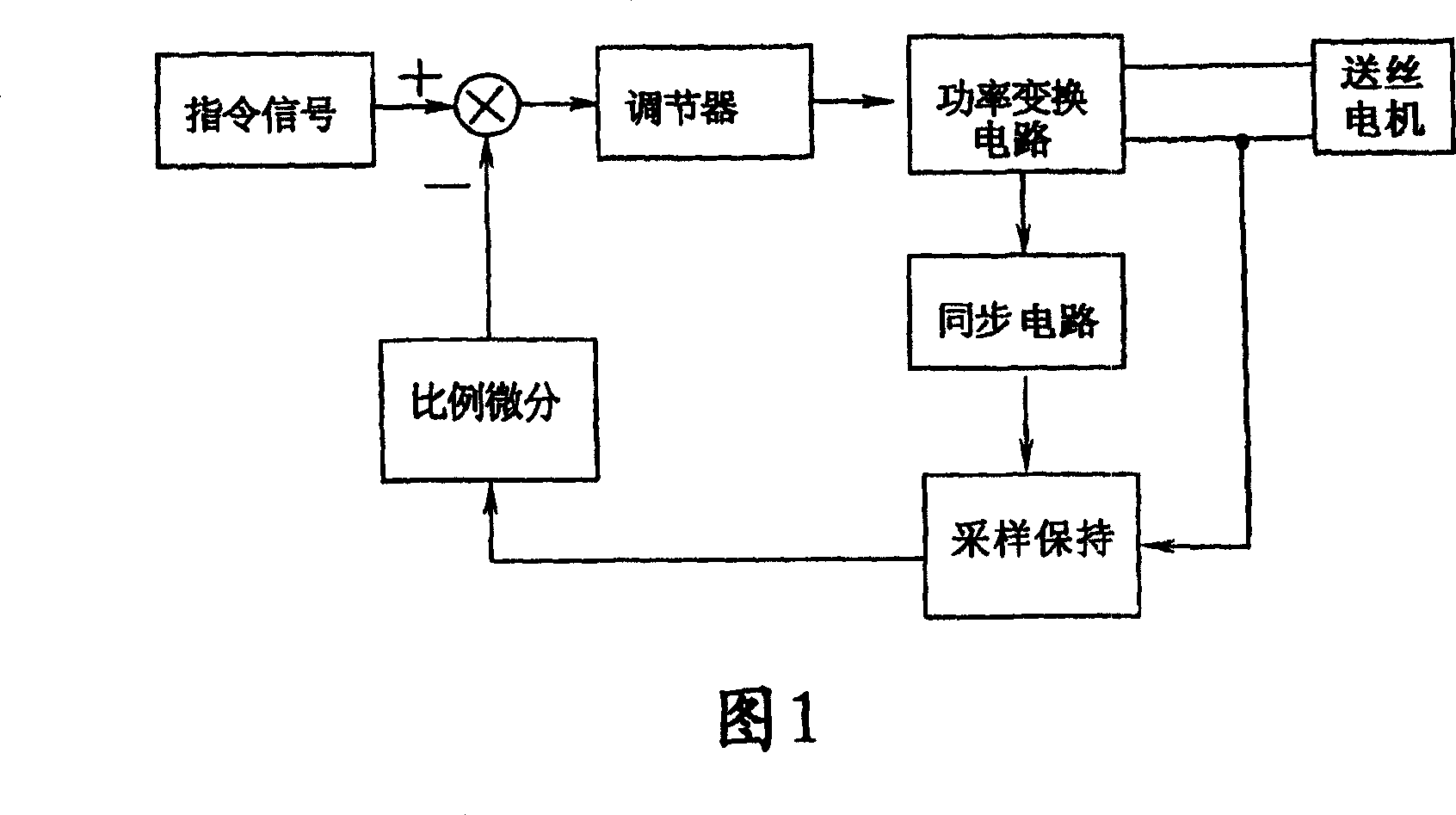

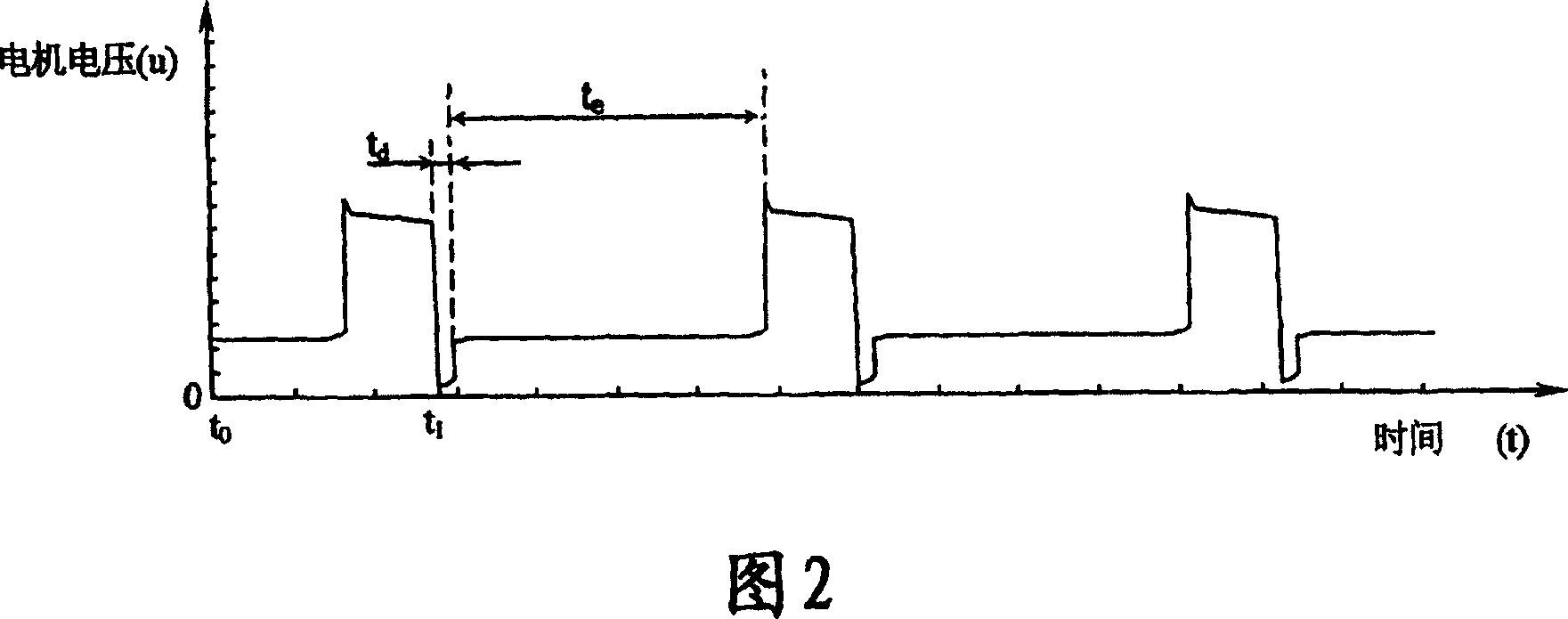

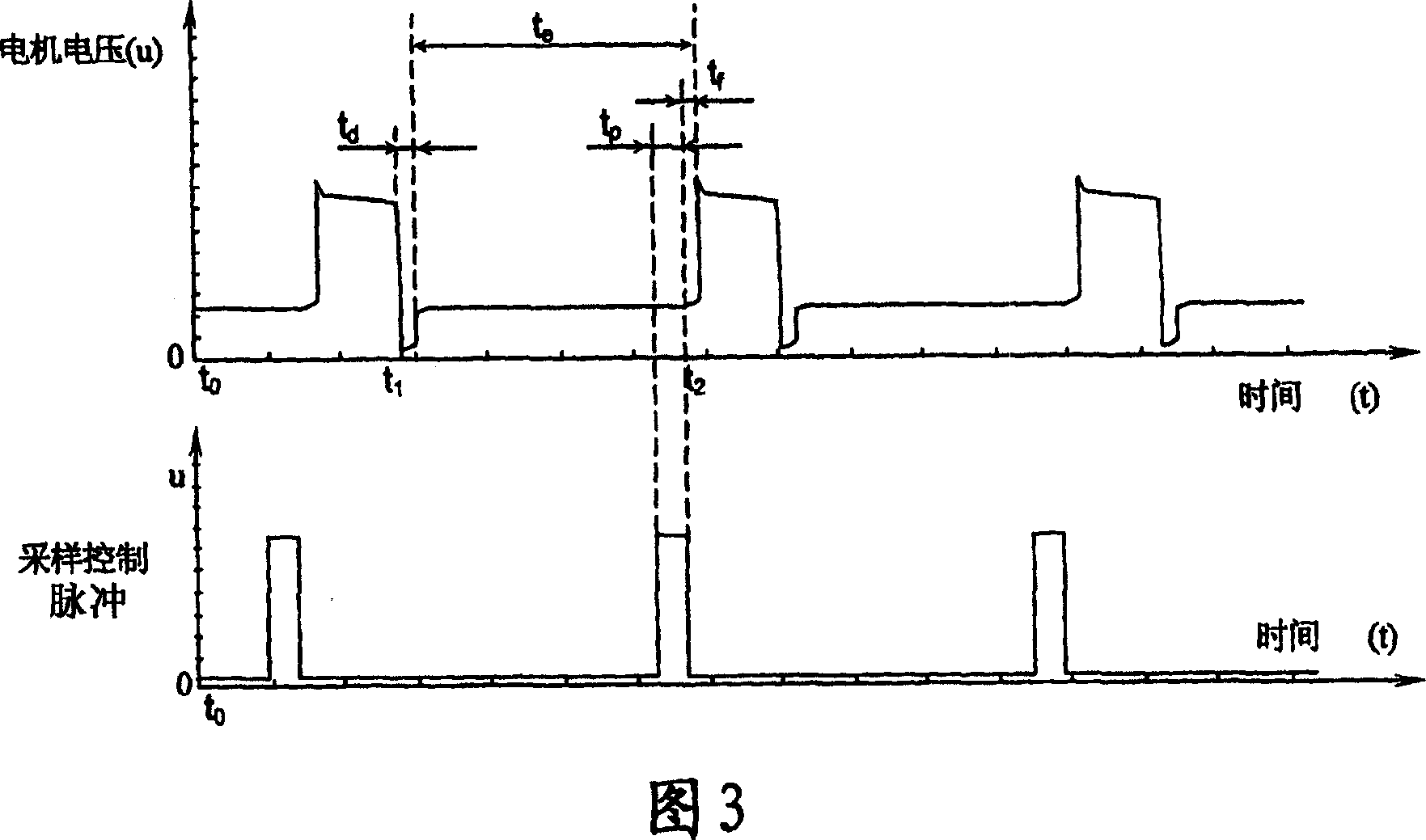

Method and system for regulating feeding wire speed

ActiveCN101051808AAccurately reflect the rotation speedRotation speed adjustmentField or armature current controlArc welding apparatusWire speedEngineering

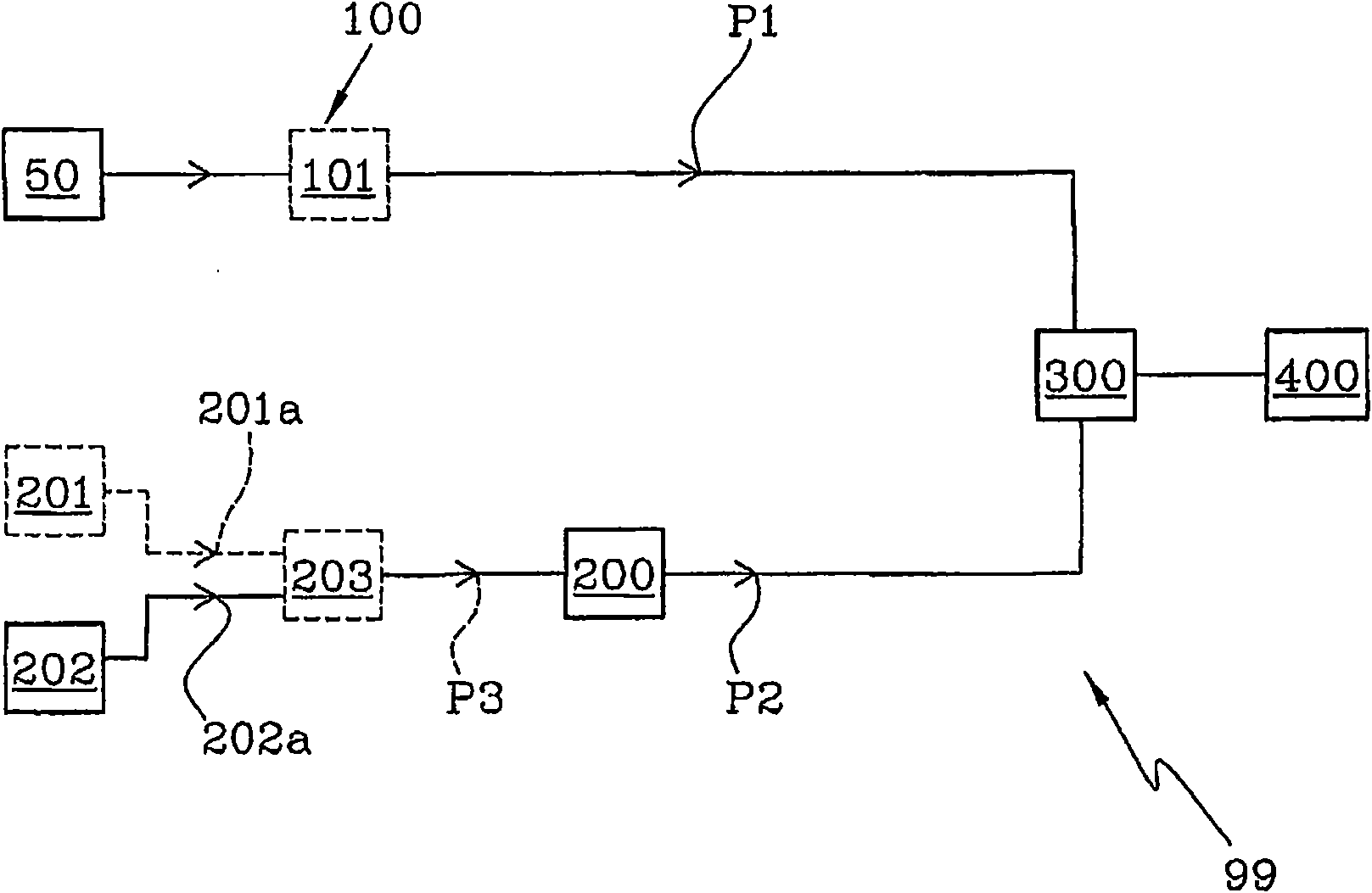

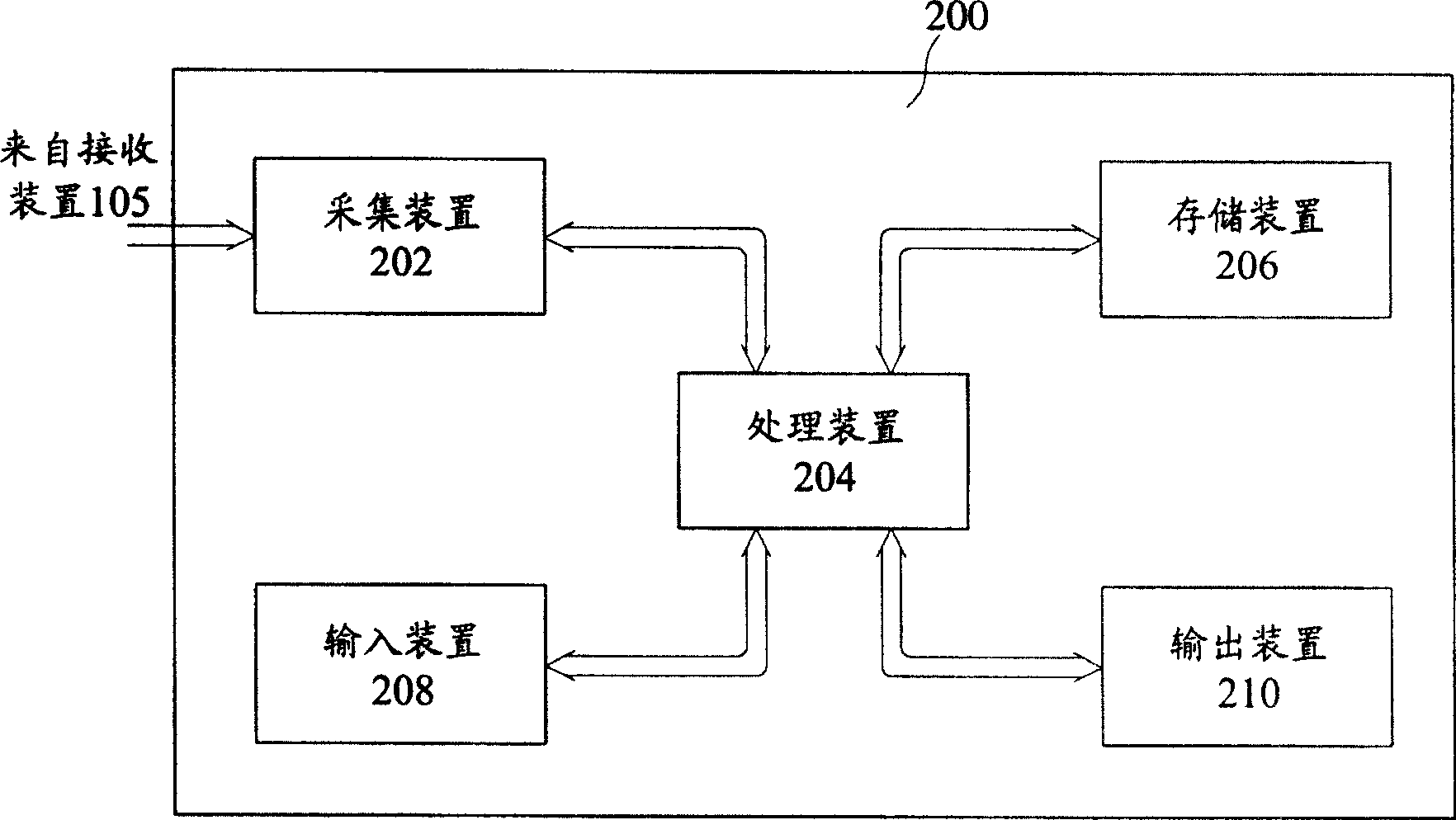

The system includes following parts: when sampling control device outputs control pulse, the sample and hold device is in use for sampling and holding the sampled signals; regulating device is in use for magnifying error of instruction signal and the said sampled and held signal; modulation device is in use for outputting signal of pulse width modulation, and the said signal is in use for controlling output from the drive unit based on signal outputted from the regulating device; the drive unit is in use for revolving driving the motor for delivering wire based on pulse signal outputted from the modulation device; the sample and control device is in use for outputting sample and control pulse signal before the moment when the drive unit provides energy to the motor for delivering wire; starting device is in use for controlling operating states of the modulation device and the drive unit.

Owner:PANASONIC WELDING SYST TANGSHAN

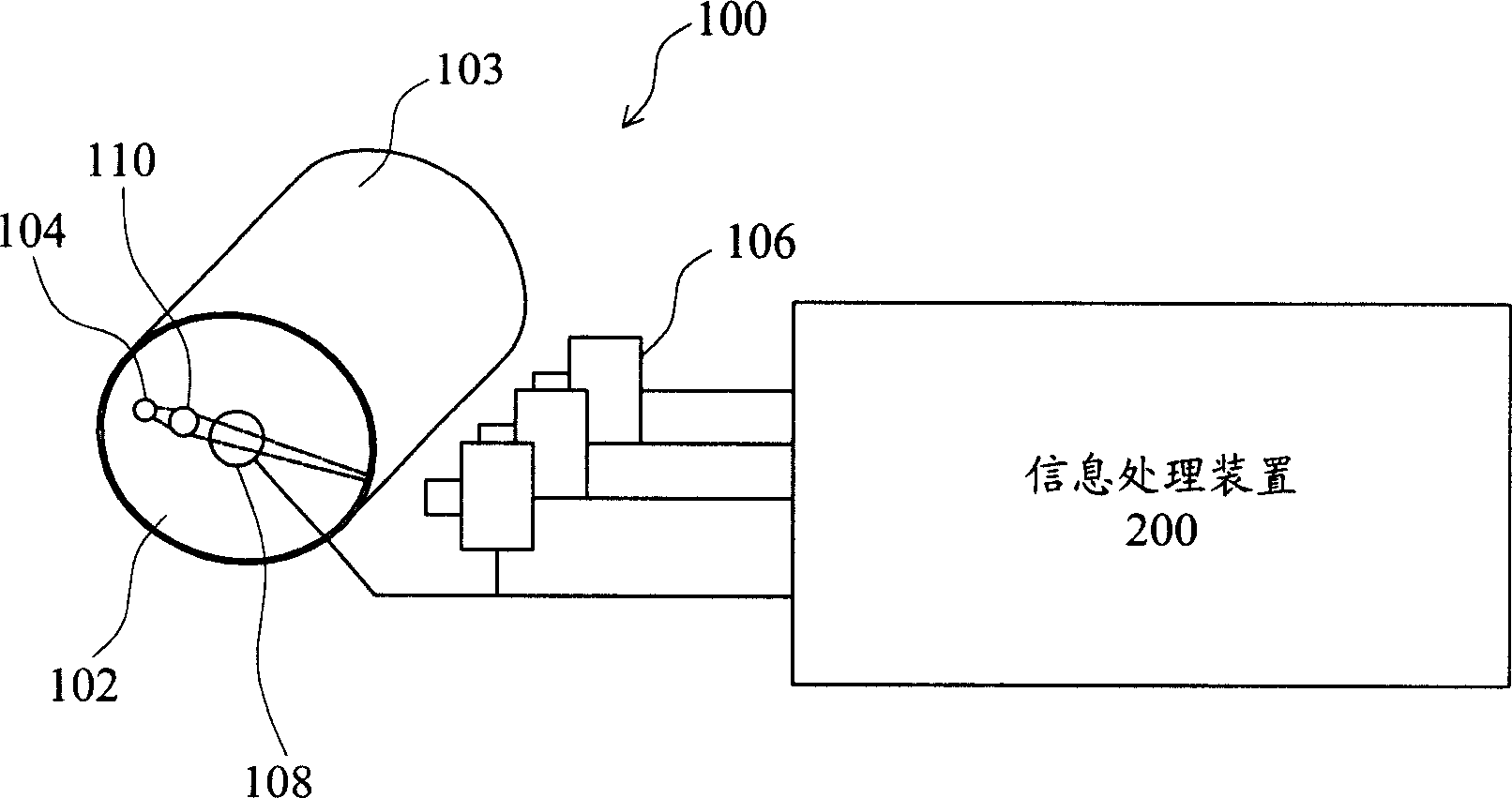

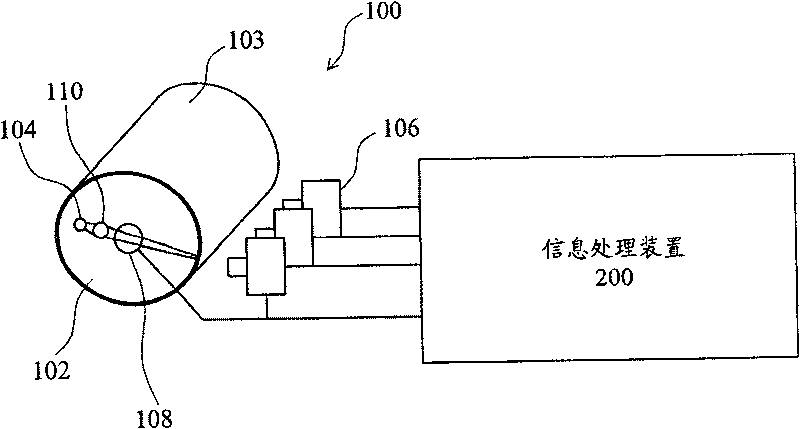

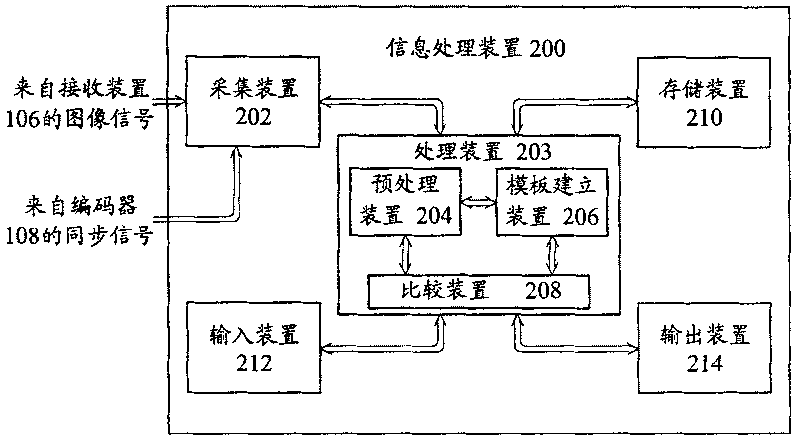

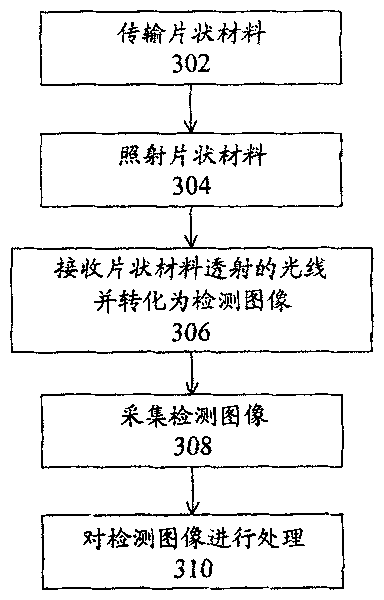

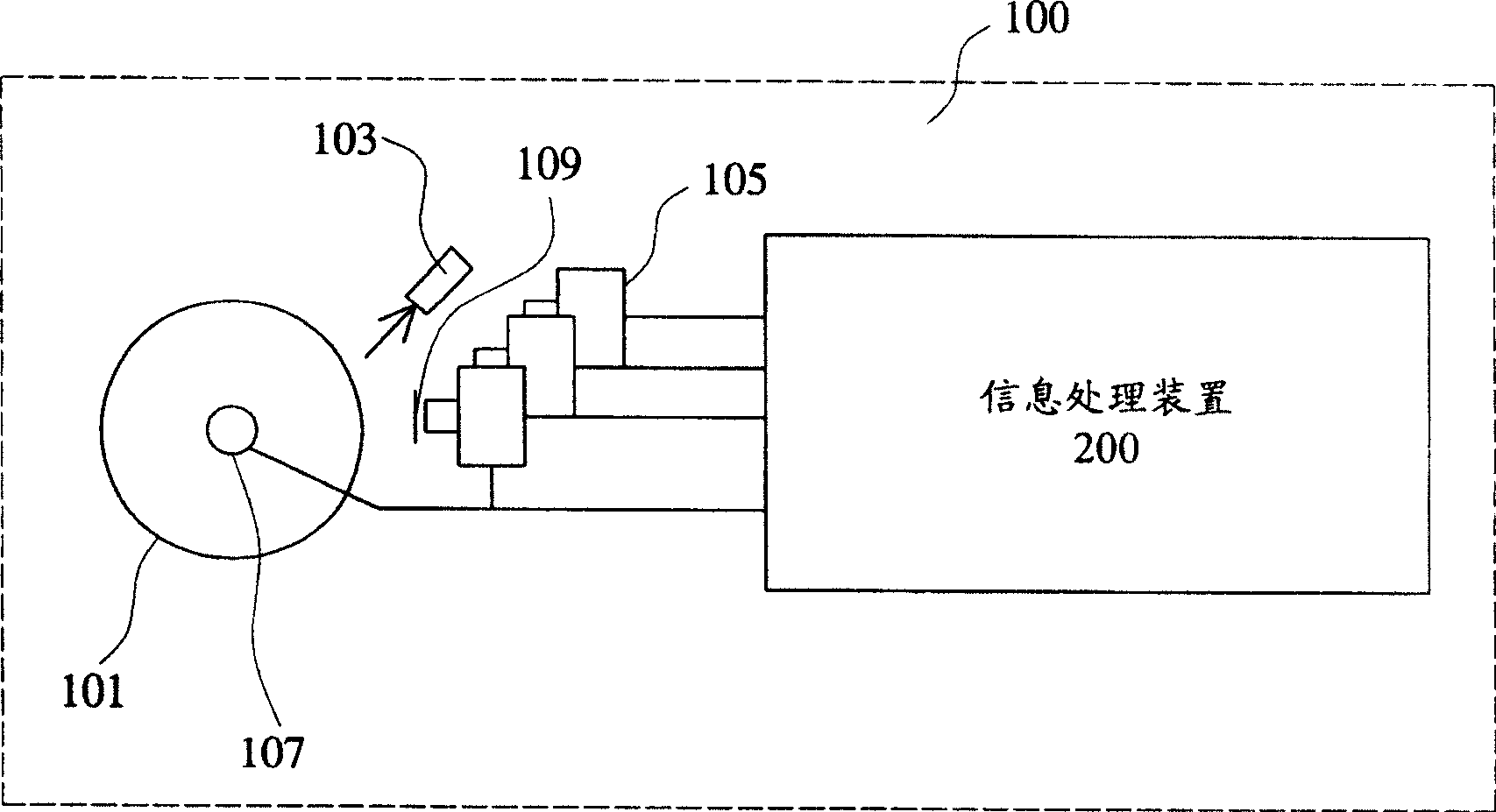

Apparatus and method for detecting sheet-like material

InactiveCN1670513ASimple structureLow costPaper-money testing devicesMaterial analysis by optical meansFlaked MaterialEngineering

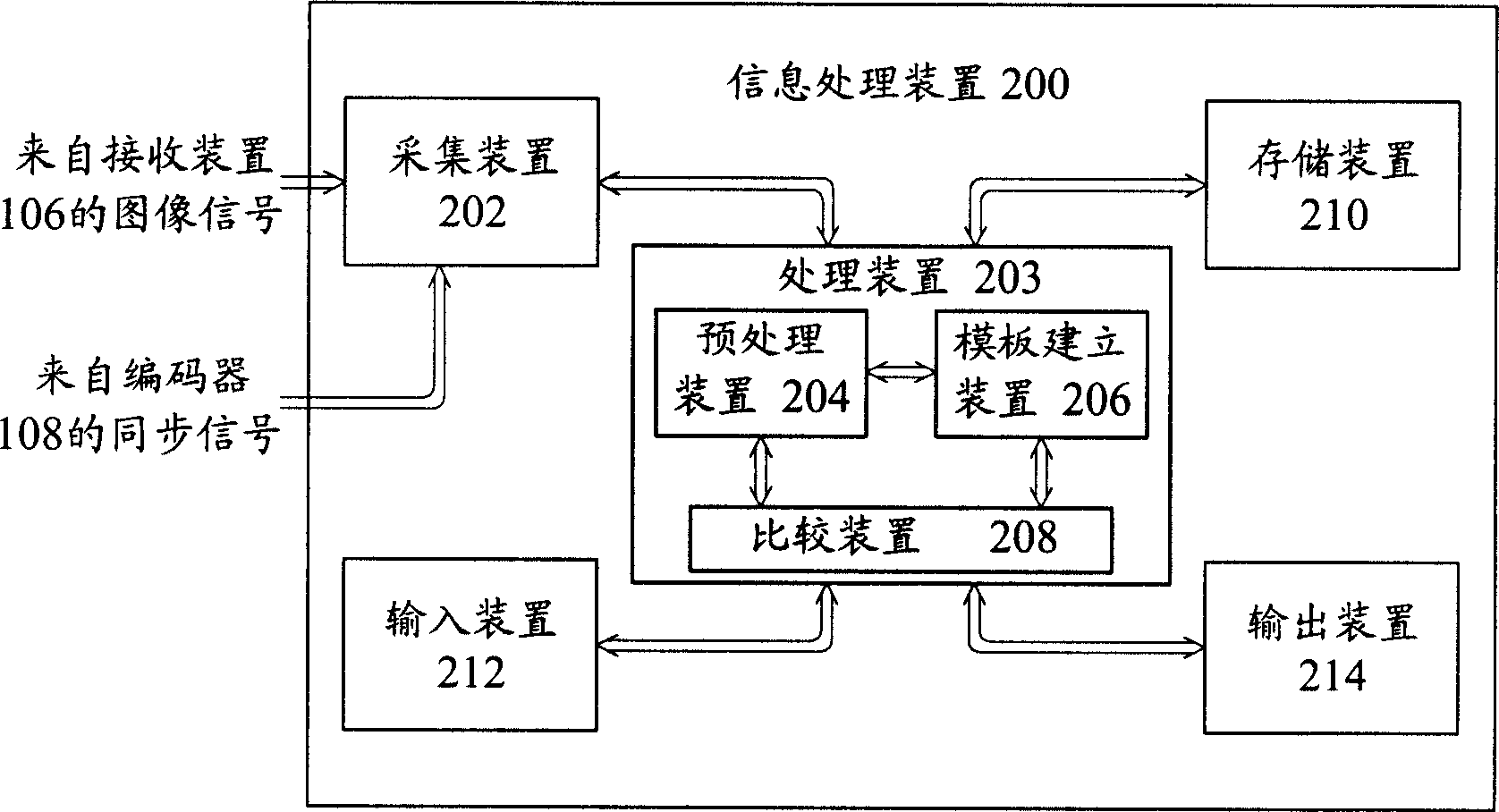

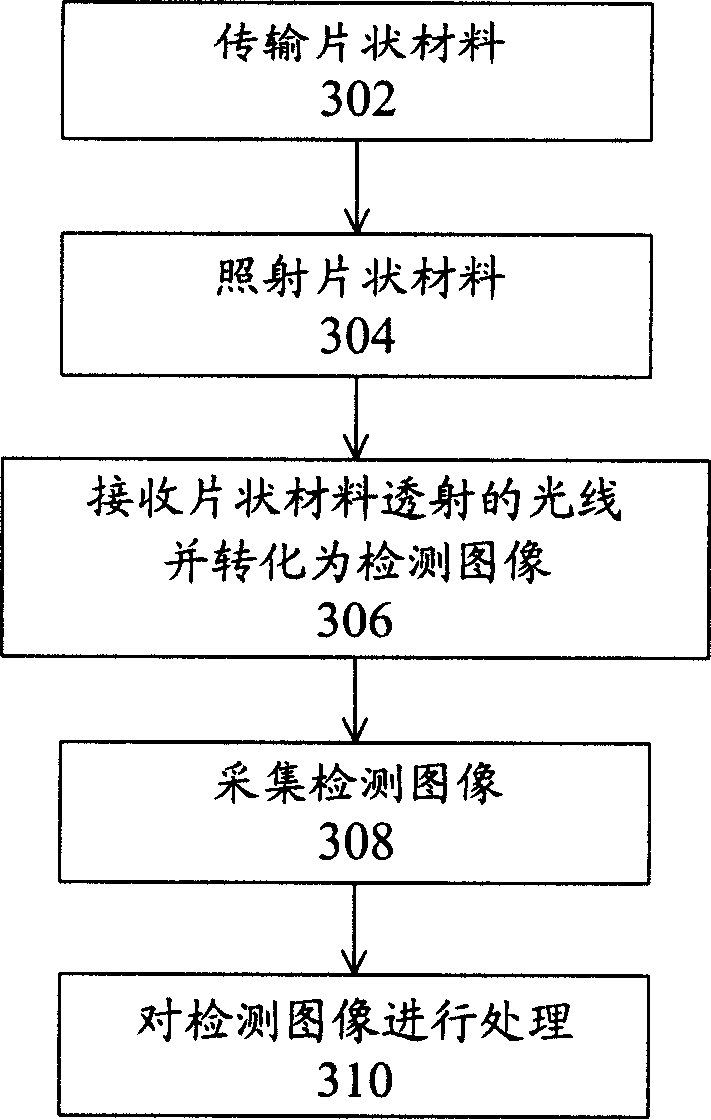

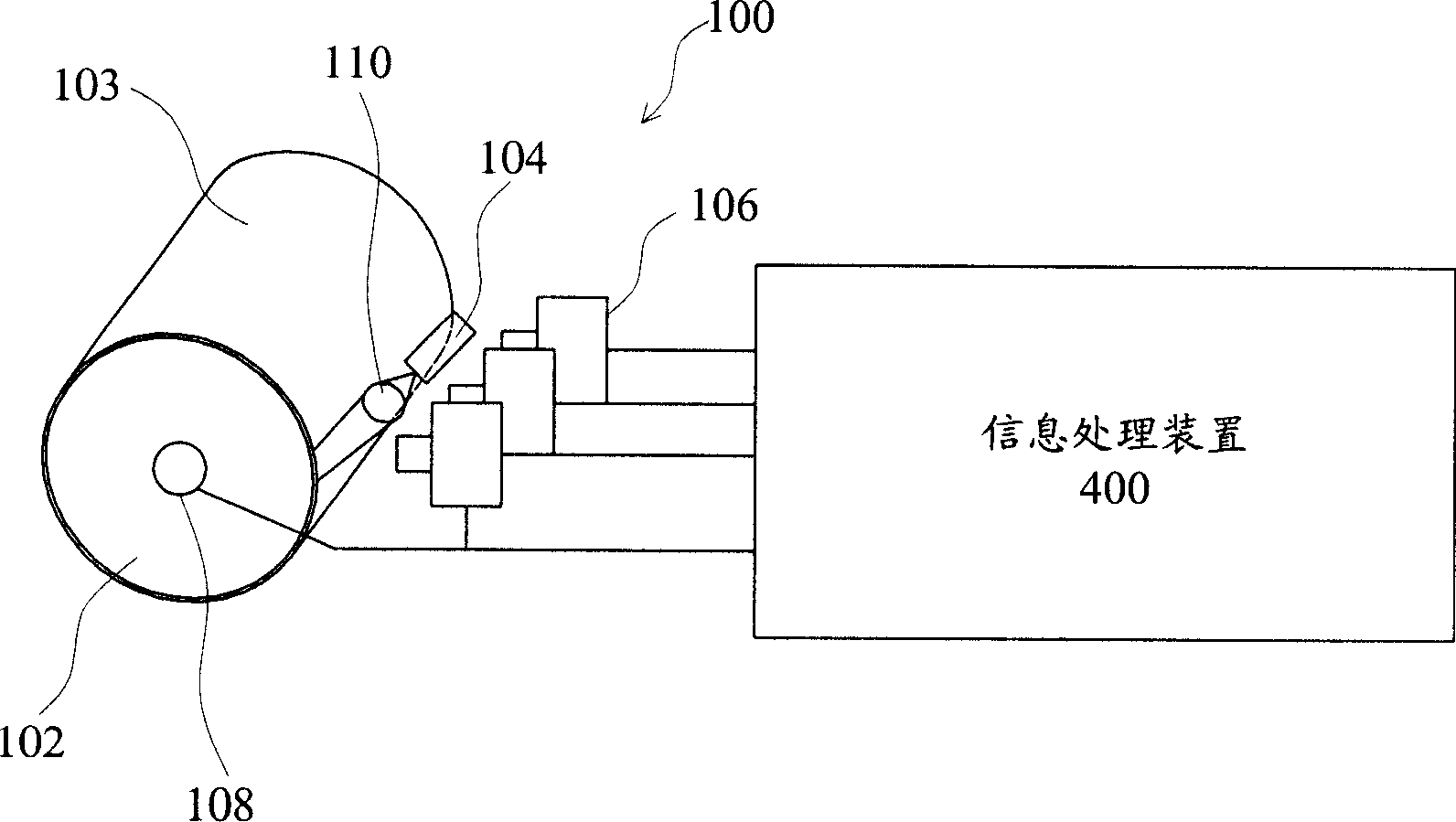

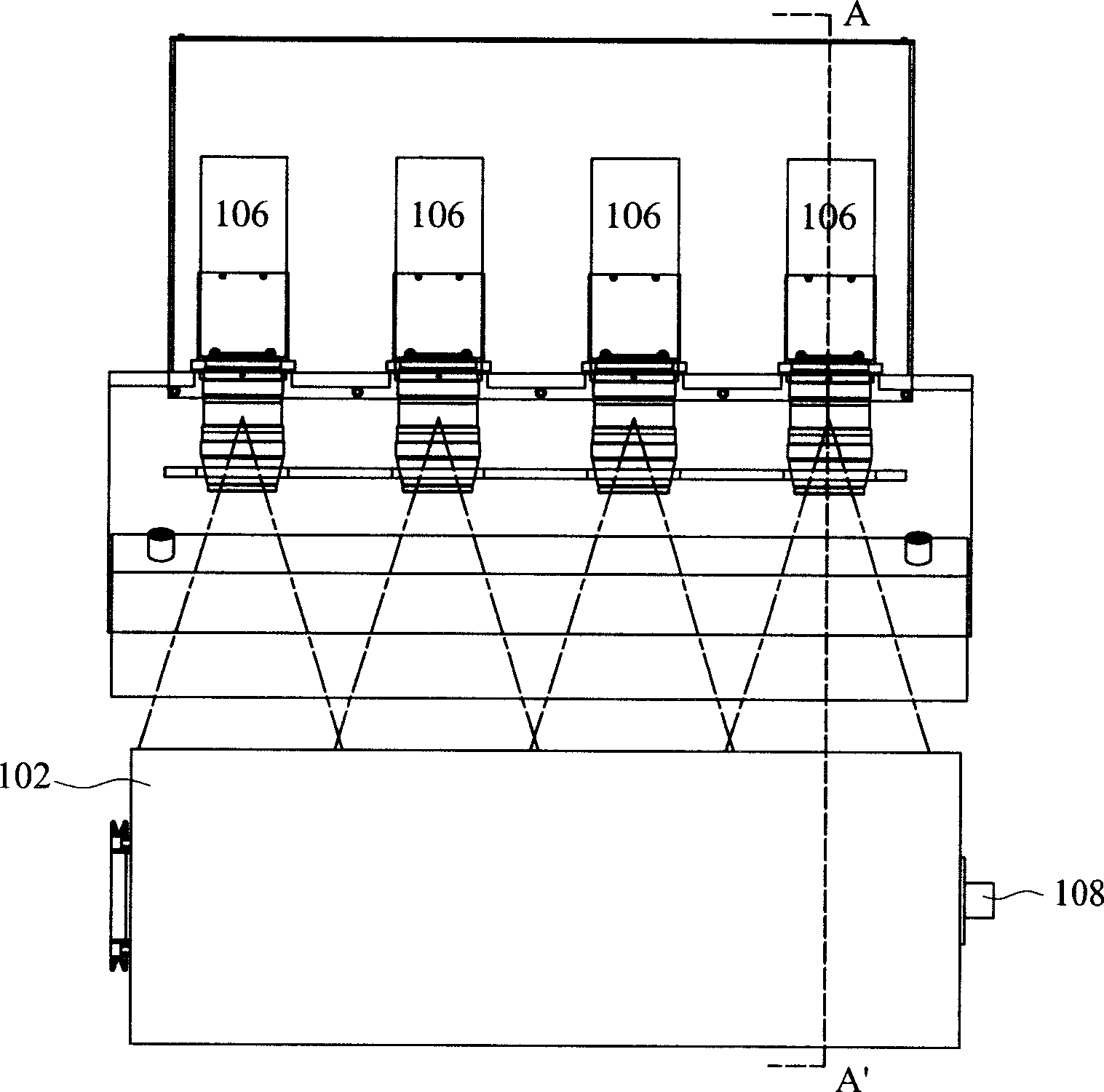

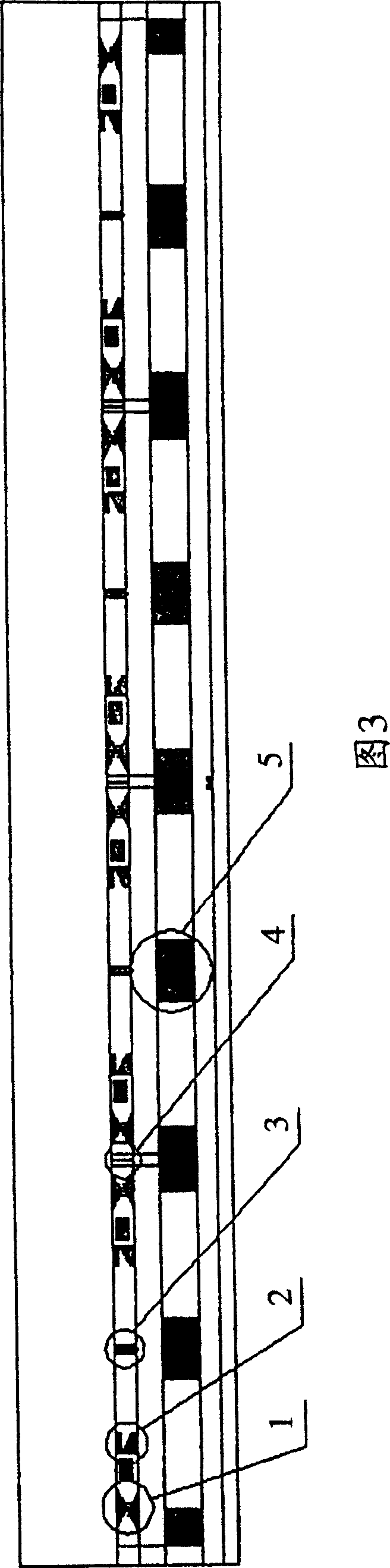

This invention provides a device and method to test slice materials, wherein, the device comprises transmission device, irradiation device, and receiving device and information process device. The transmission device is to transmit the slice materials; the irradiation device is located on one side of the slice material to irradiate the slice materials; the receiving device is located on the other side of the slice materials, comparing to the irradiation device, to receive transmission light from slice material and to convert the received light into relative test images; the information process device is to collect and process image measurement and compare the tested image and the mode board to test the transmission image quality.

Owner:CHINA BANKNOTE PRINTING & MINTING

Apparatus and method for detecting sheet-like material

InactiveCN1670514AAvoid Modeling DifficultiesAvoid Mistakes Checking ChromaMaterial analysis by optical meansPattern printingColor printingIrradiation

This invention provides a device and method to test slice materials, wherein, the device comprises transmission device, irradiation device, and receiving device and information process device. The transmission device is to load and transmit slice materials; the irradiation device is to irradiate the light on the slice materials; the receiving device is to receive the diffused and reflected light from slice and to convert the relative light into relative test images; the information process device is to collect and process test images and to compare the tested images and mode to test slice material color printing quality.

Owner:CHINA BANKNOTE PRINTING & MINTING

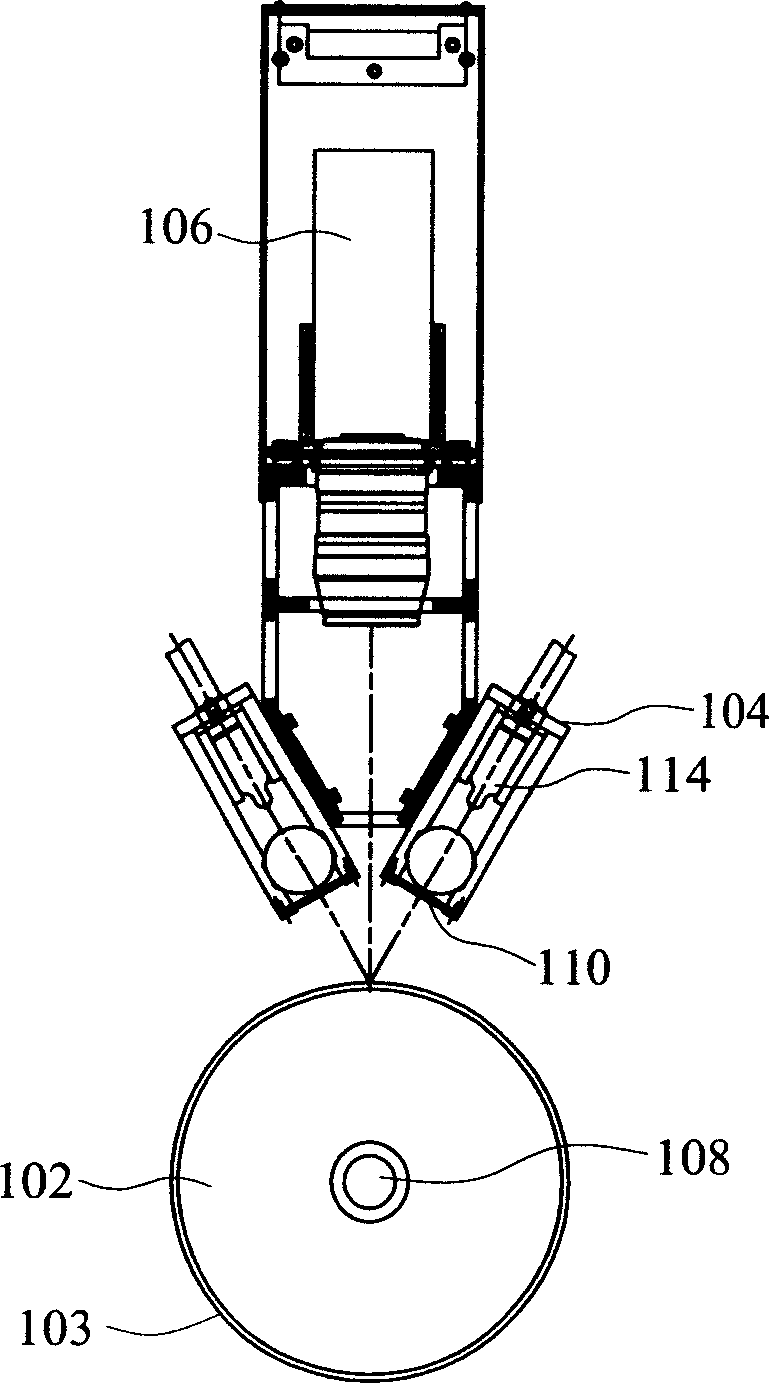

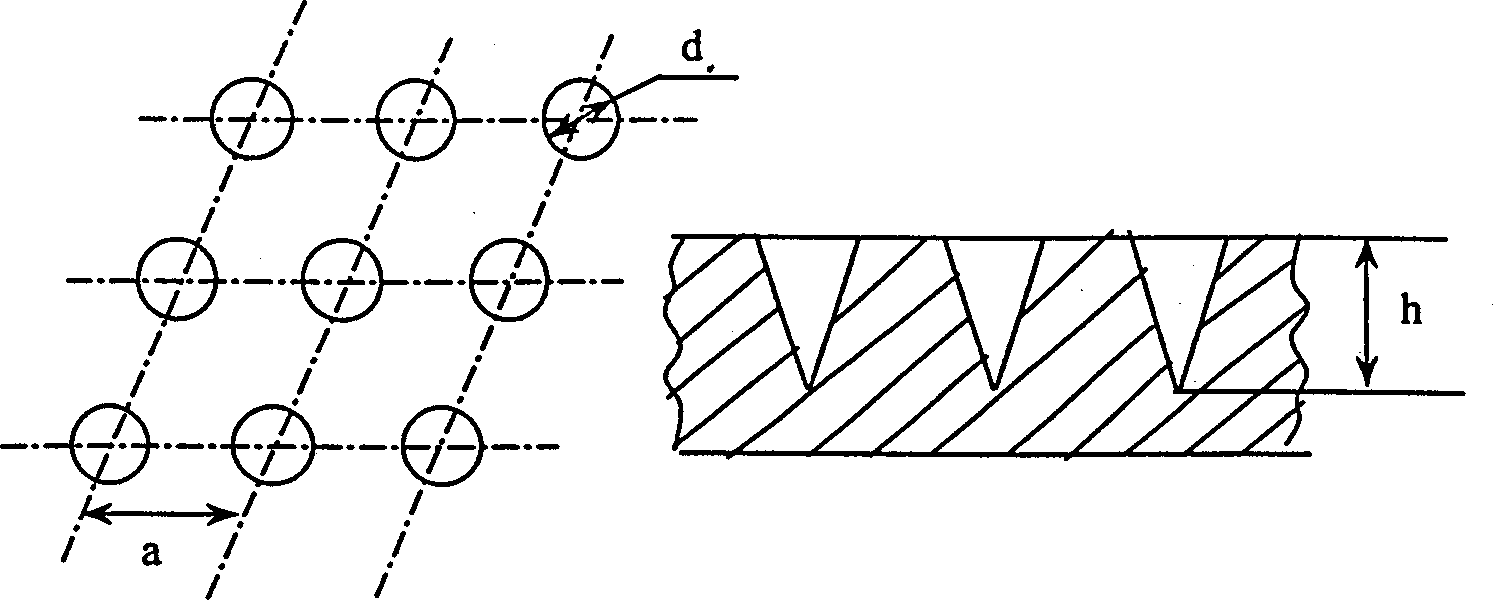

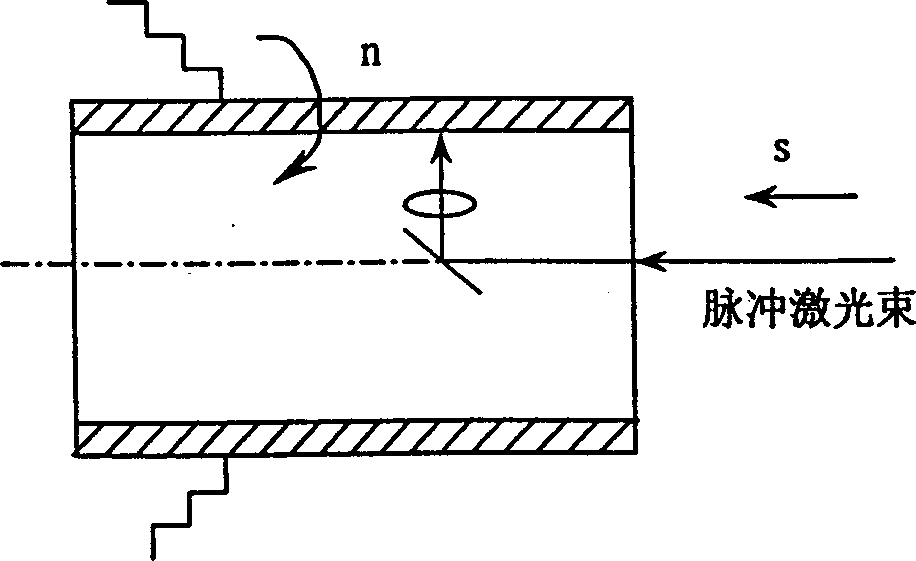

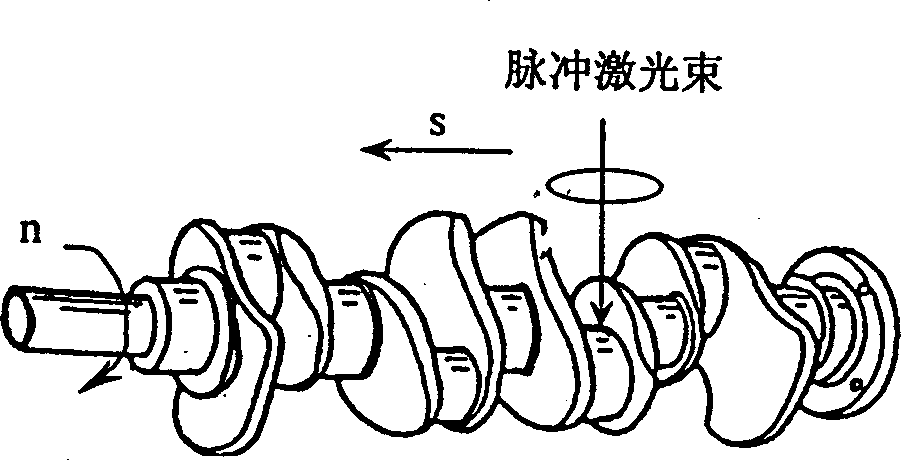

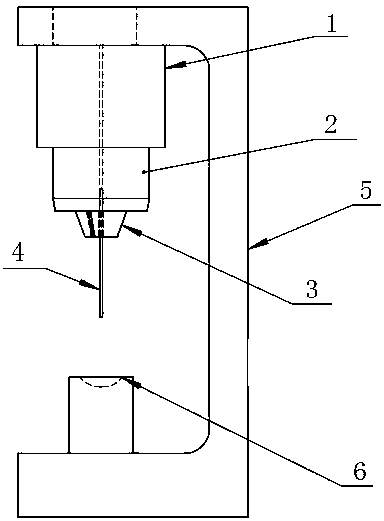

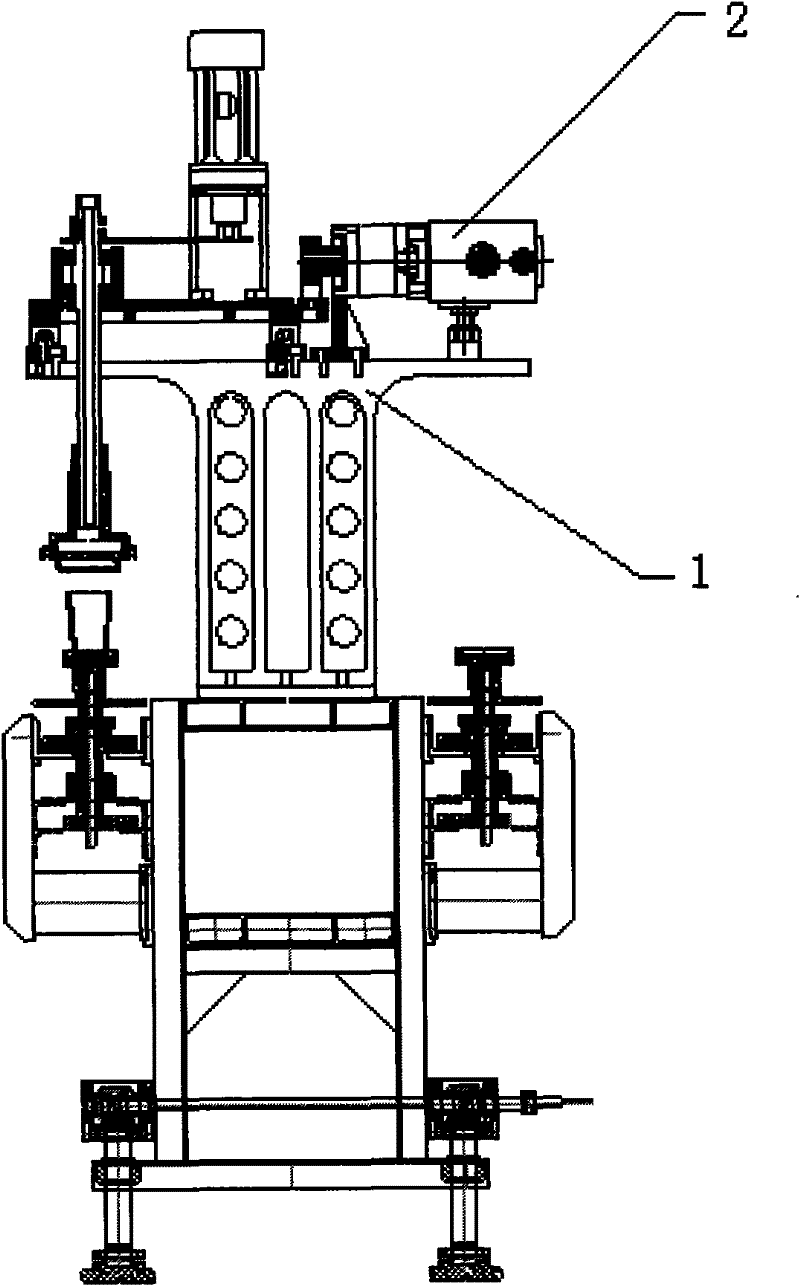

Microconcave digital controlled laser formation method and device on working surface of friction pair

InactiveCN1385277AConsistent depthAdjustable speedLaser beam welding apparatusNumerical controlEngineering

The present invention discloses a micropit numerical control laser forming method on the working surface of friction pair, and is characterized by that the components of the friction pair are rotated, the pulse laser bean can be used and relatively moved along the rotated components of the friction pair, then the focused pulse laser-bean can be used for making micropits on the working surface of friction pair components. Said invention possesses the following advantages: 1. can form micropits with thousands which are mutually independent and identical in depth on the working surface of frictino pair; 2. contactless processing, energy of laser beam and its movement can be regulated, and the rotating speed of components of friction pair also can be regulated; 3. it does not result in deformation of workpiece.

Owner:杭州电子工业学院

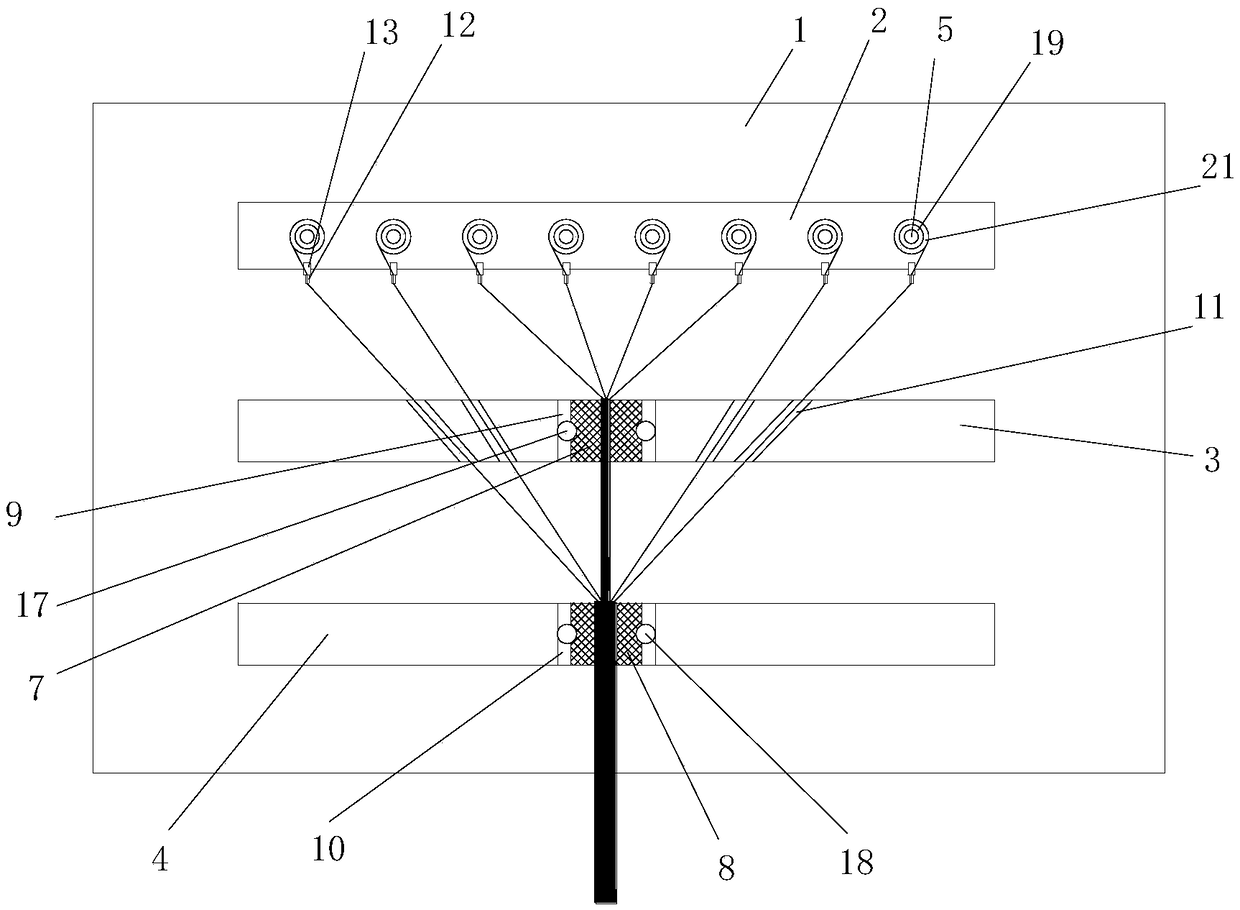

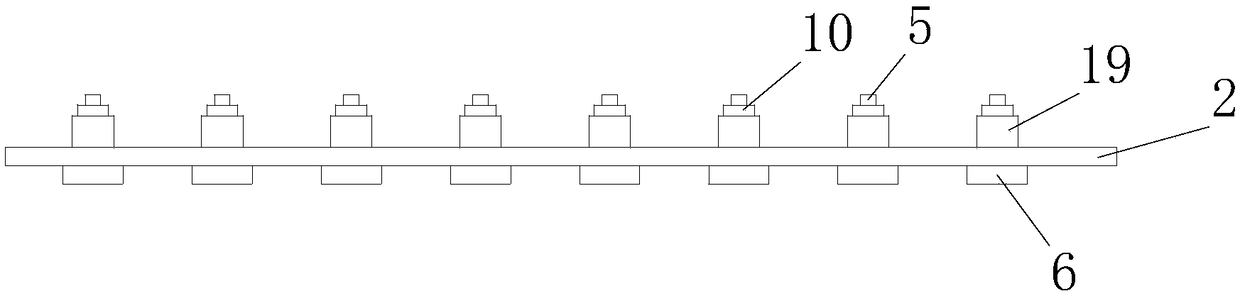

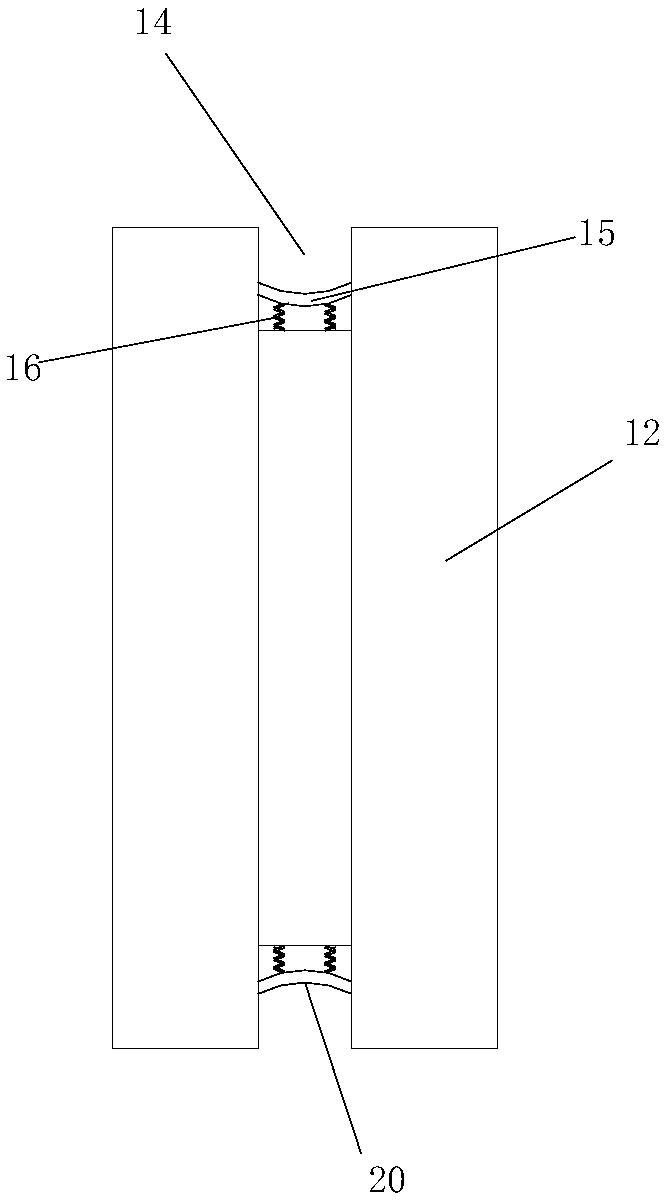

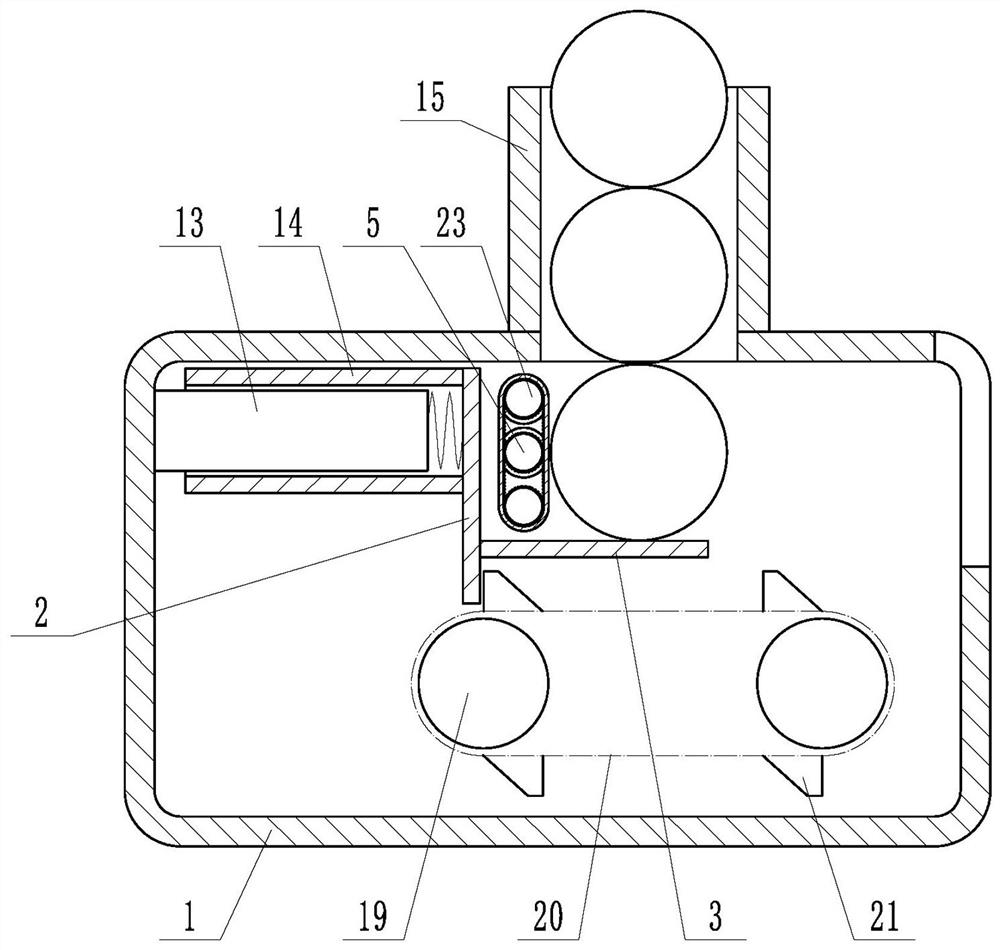

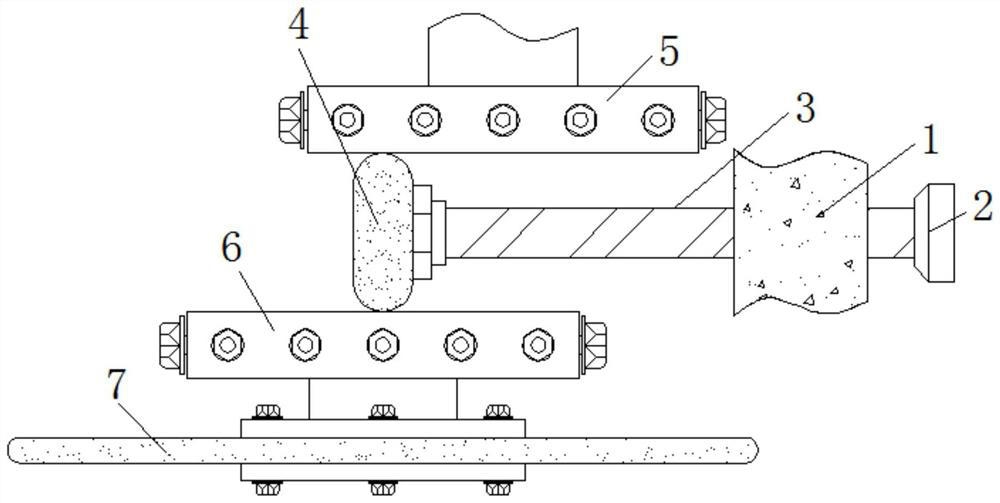

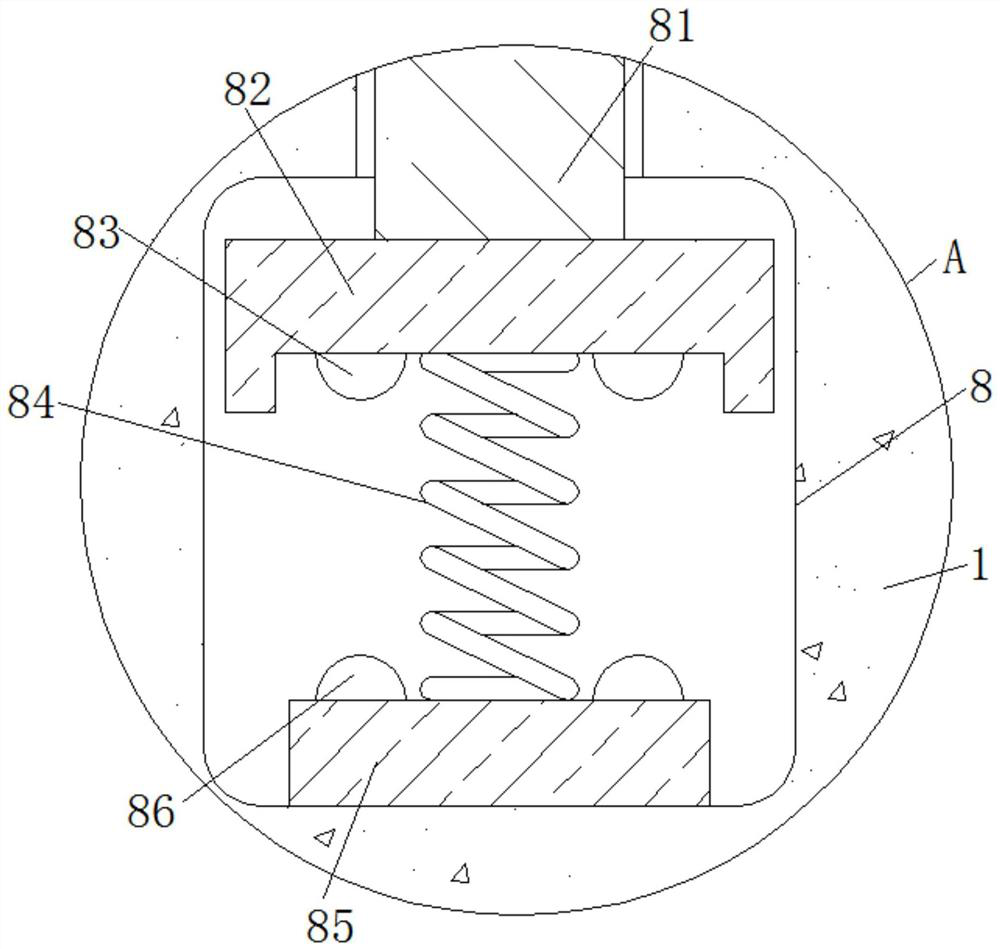

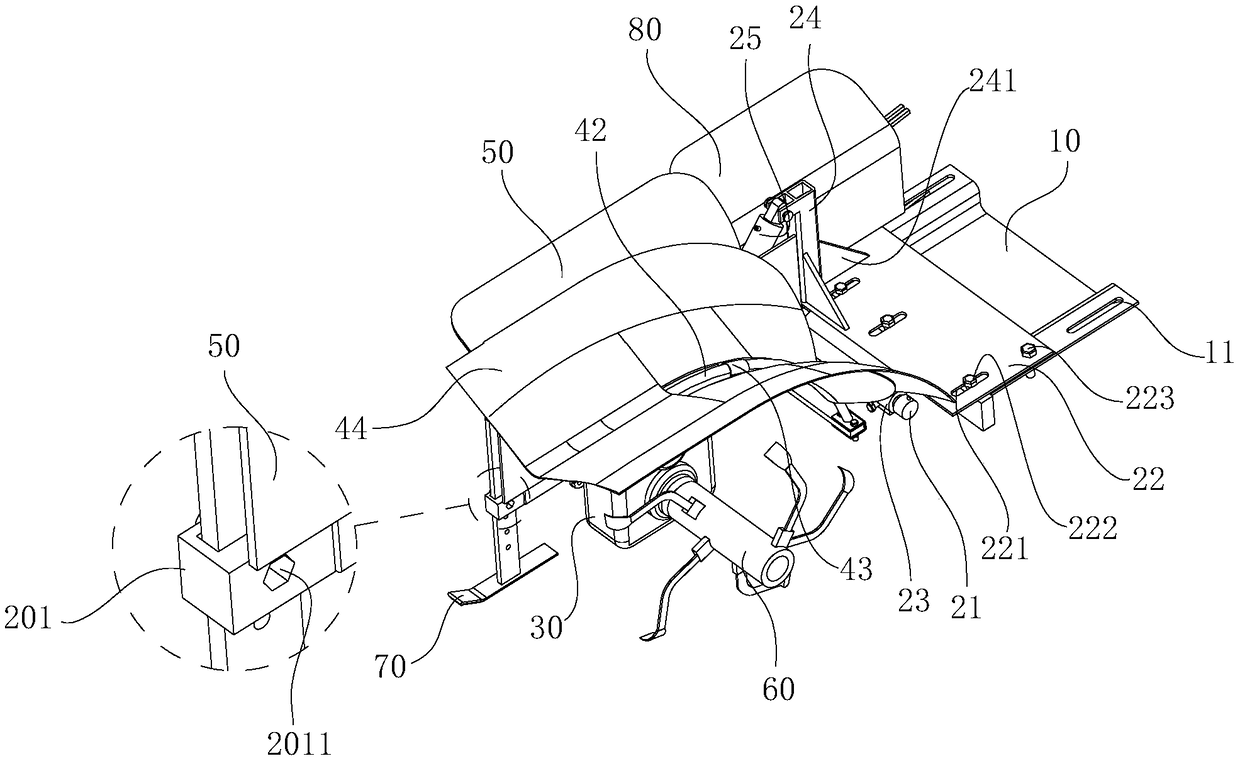

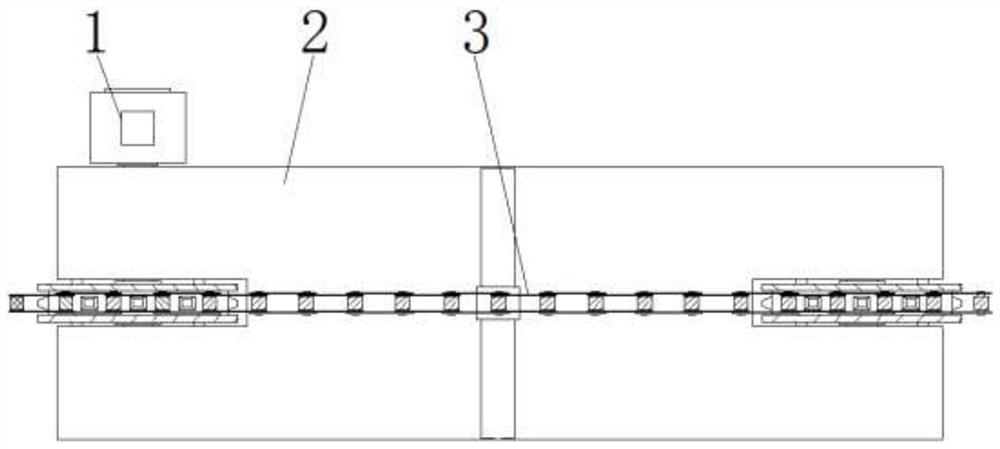

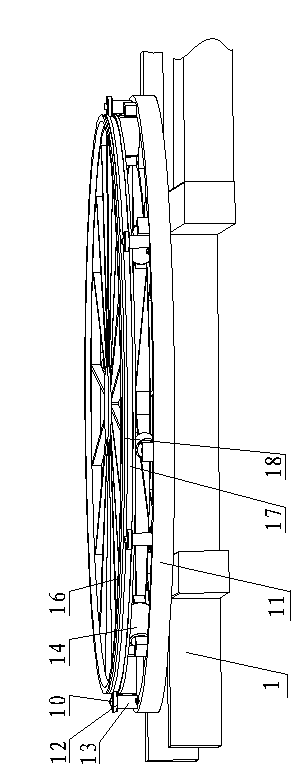

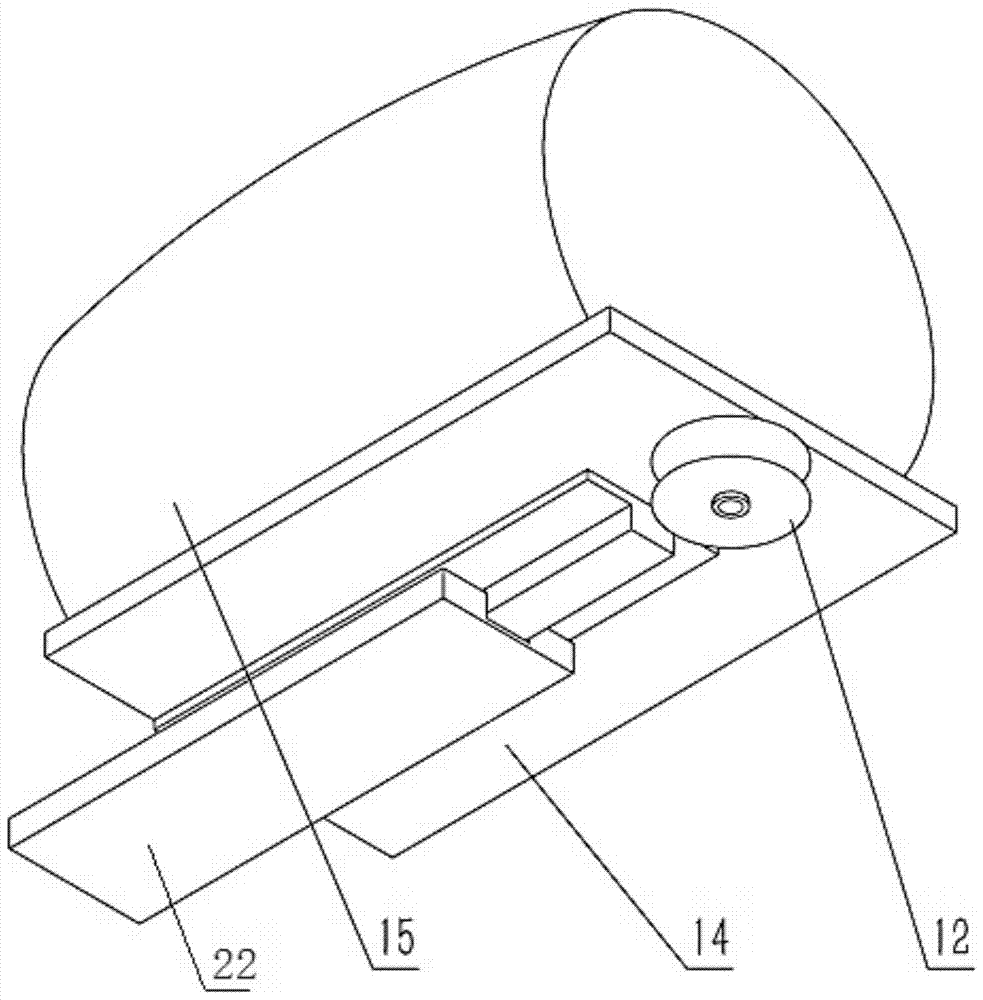

Anti-breakage wire stranding machine

PendingCN108766671AAvoid disconnectionImprove processing efficiencyApparatus for feeding conductors/cablesEngineeringMechanical engineering

The invention provides an anti-breakage wire stranding machine. The anti-breakage wire stranding machine comprises a workbench, a wire uncoiling rack, a first wire stranding rack, a second wire stranding rack, a plurality of wire uncoiling shafts, a plurality of driving mechanisms, a plurality of guiding assemblies, a first wire stranding mould and a second wire stranding mould, wherein a run-through first wire stranding hole is formed in the first wire stranding rack; a plurality of run-through split wire holes are formed in each of the two sides of the first wire stranding hole in the firstwire stranding rack; a run-through second wire stranding hole is formed in the second wire stranding rack; first ends of the plurality of wire uncoiling shafts are rotationally mounted on the wire uncoiling rack, and the plurality of wire uncoiling shafts are linearly distributed; the plurality of driving mechanisms are connected with the first ends of the plurality of wire uncoiling shafts and are used for driving the wire uncoiling shafts to rotate; the plurality of guiding assemblies are mounted on the wire uncoiling rack, and the plurality of guiding assemblies correspond to the pluralityof wire uncoiling shafts one by one; the first wire stranding mould is mounted inside the first wire stranding hole; the second wire stranding mould is mounted inside the second wire stranding hole. Through adjustment of the wire uncoiling speeds by the driving mechanisms, the problem that wire bodies are broken due to excessive tensions is solved.

Owner:安徽双马机械设备有限公司

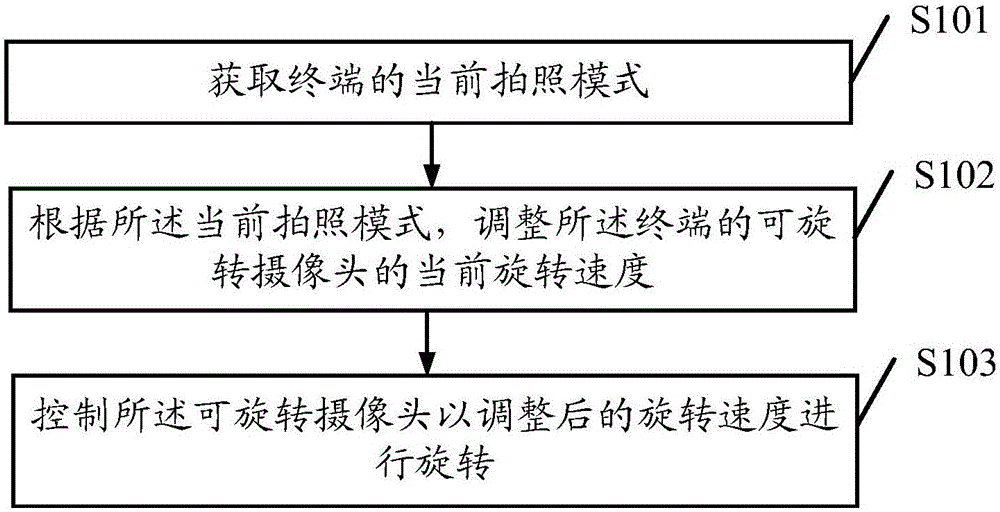

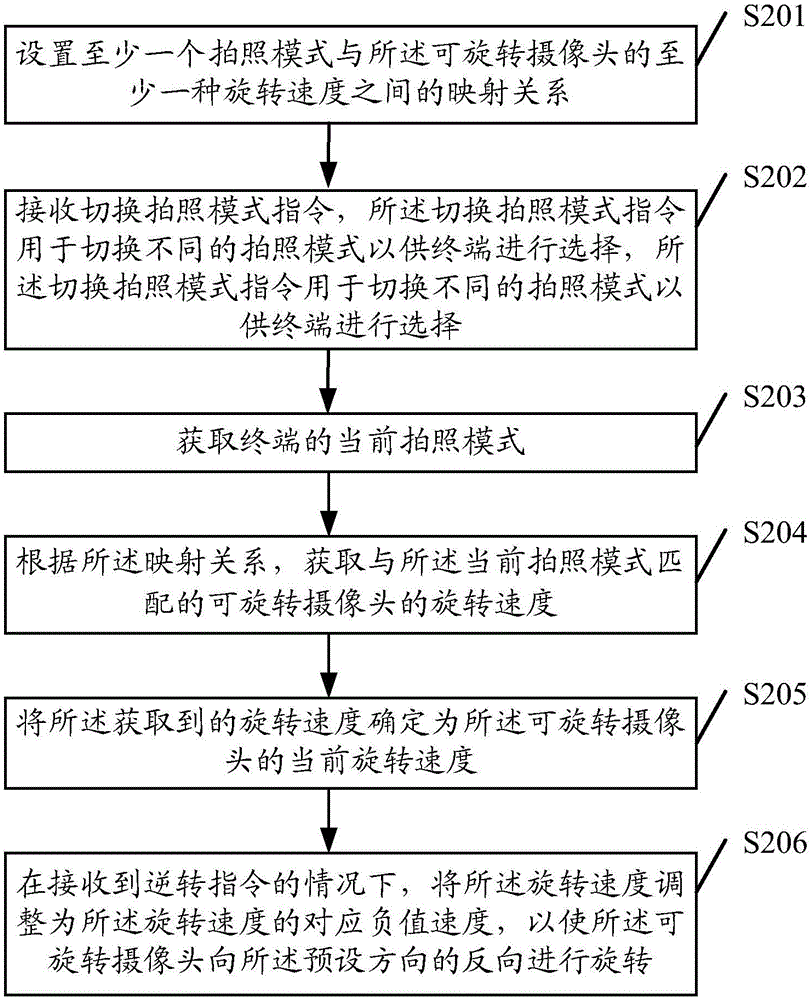

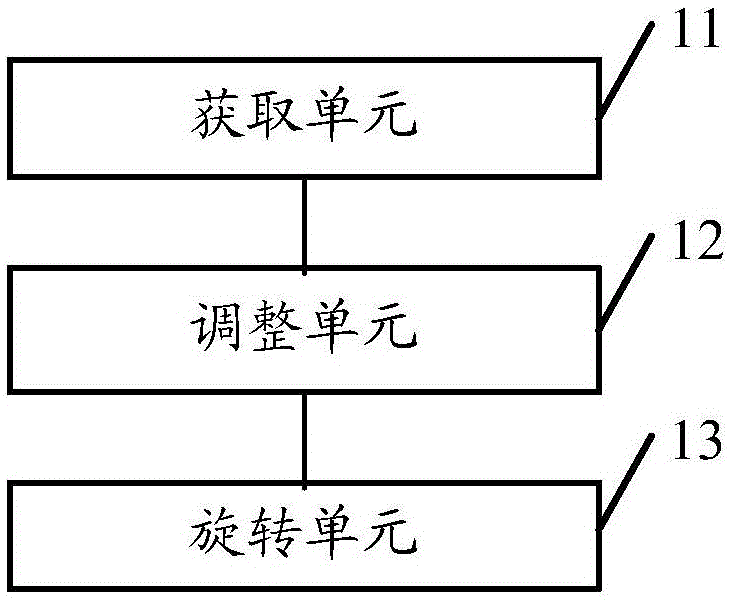

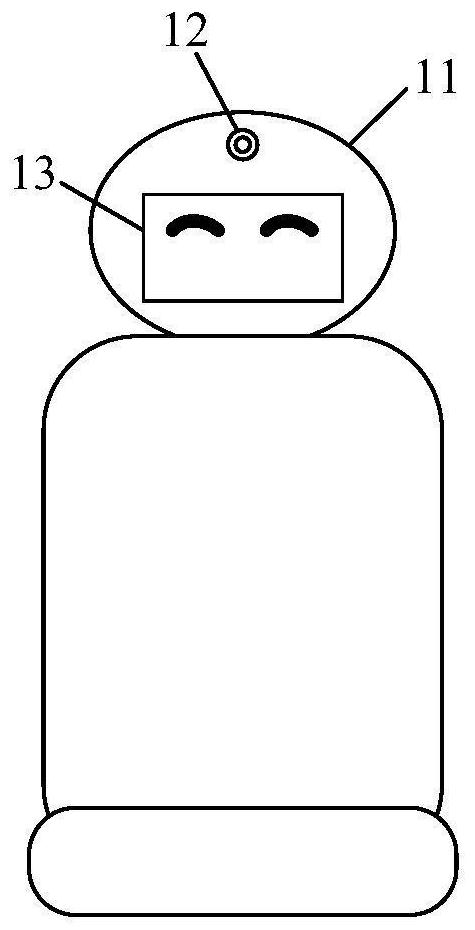

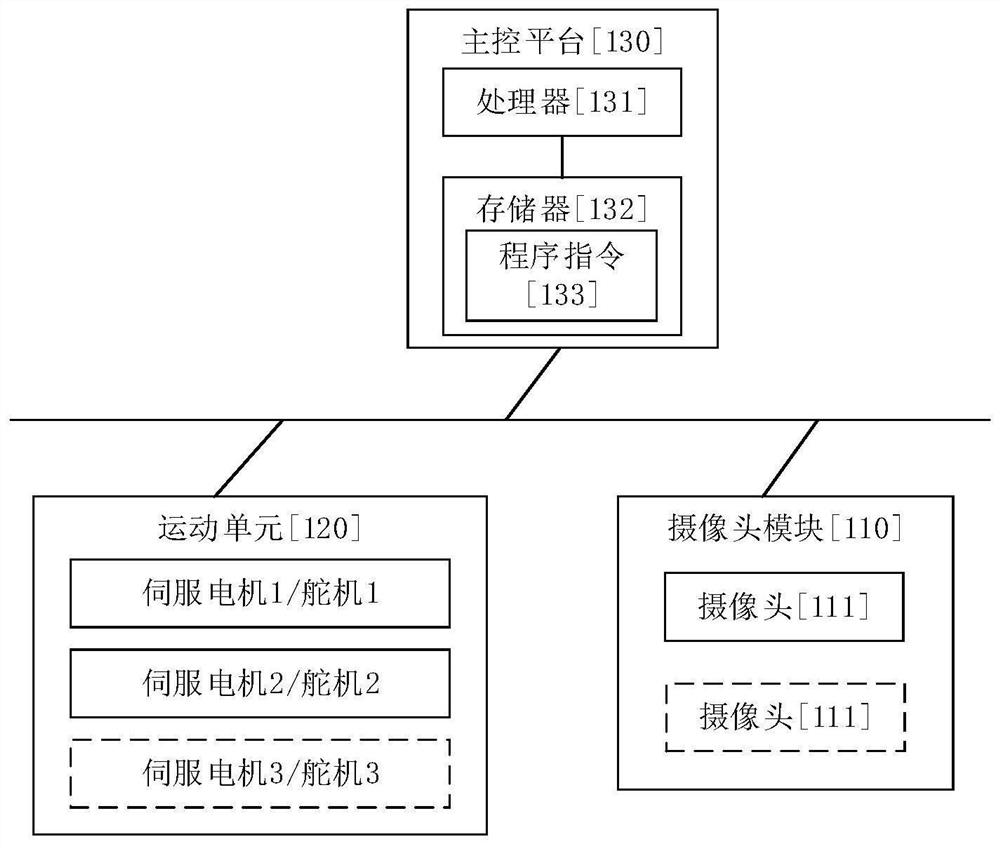

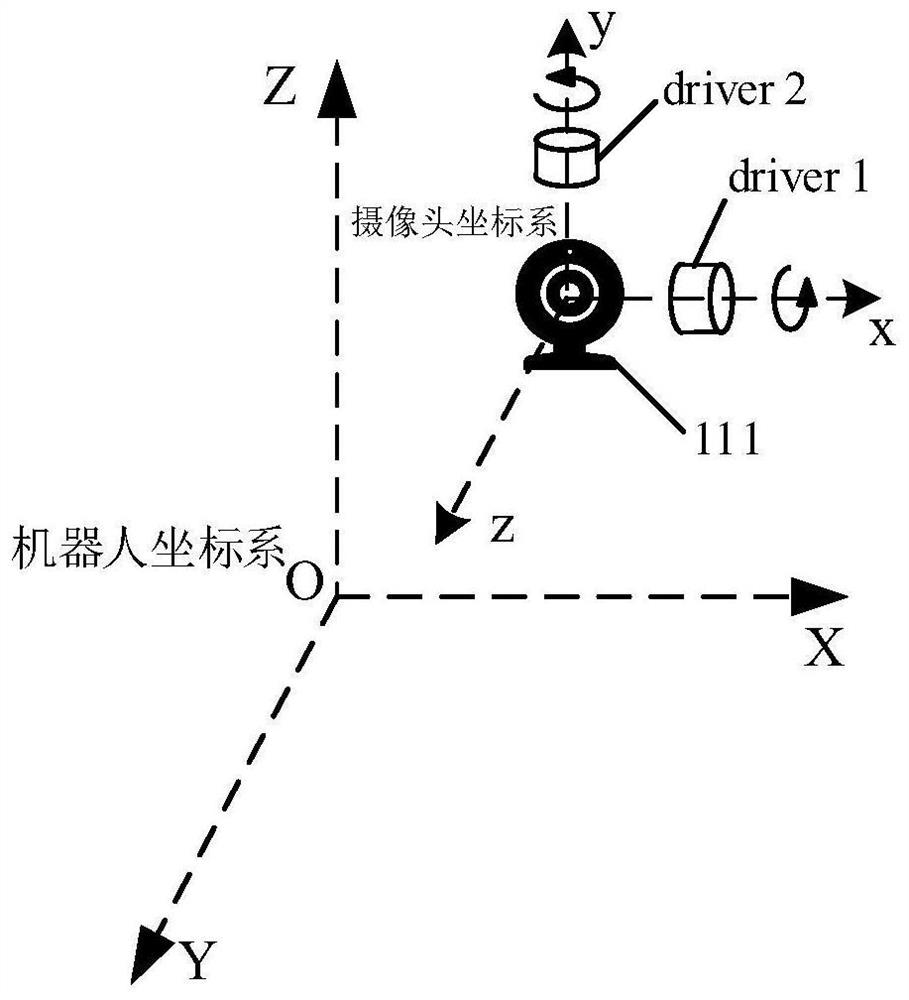

Method for controlling rotation of camera and terminal

ActiveCN105072326ARotation speed adjustmentTelevision system detailsColor television detailsEngineeringControl theory

The present invention discloses a method for controlling rotation of a camera and a terminal. The method comprises acquiring a current photographing mode of the terminal; adjusting current rotating speed of a rotatable camera of the terminal according to the current photographing mode; and controlling the rotatable camera to rotate at the adjusted rotating speed. The terminal is also correspondingly provided. With adoption of the method and the terminal, the rotating speed of the rotatable camera of the terminal can be precisely and flexibly adjusted according to the selected photographing modes.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

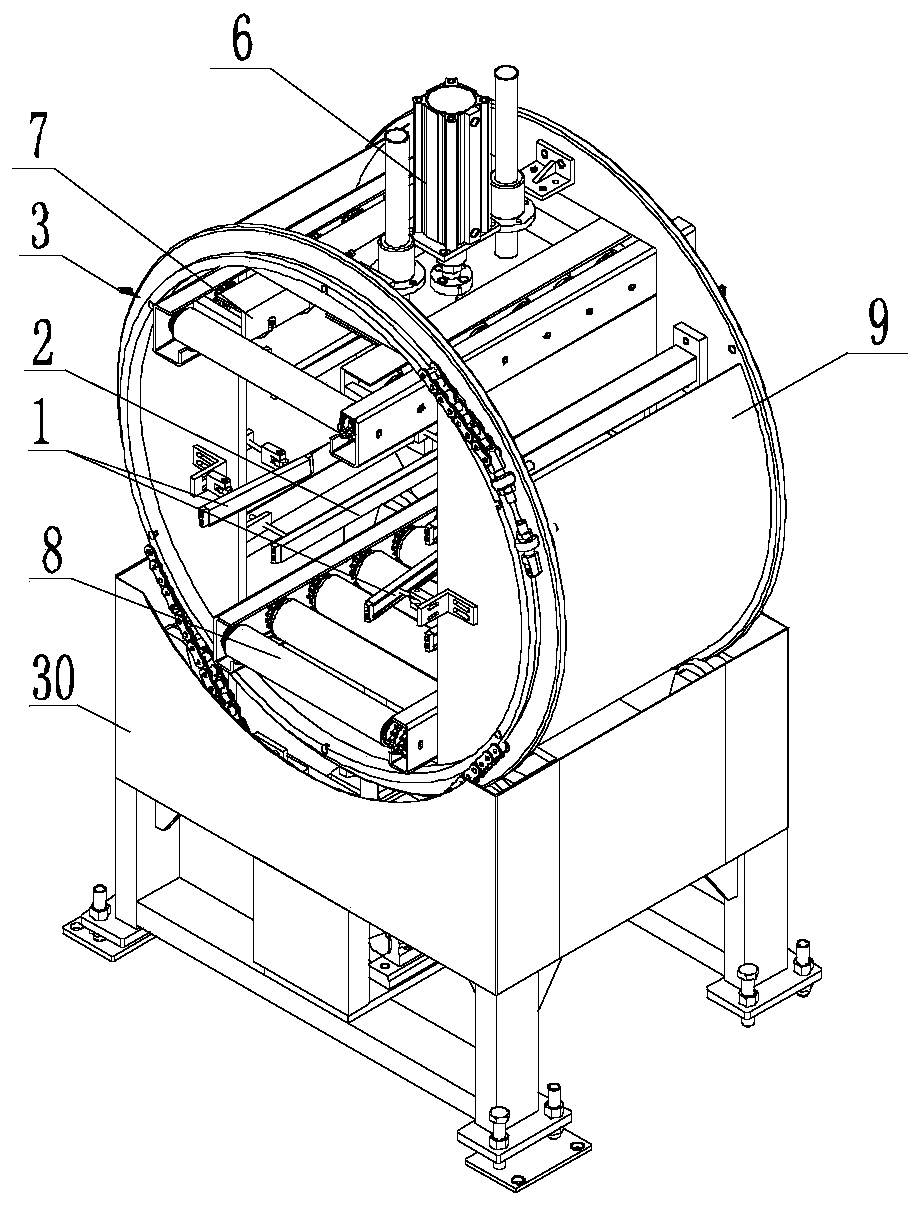

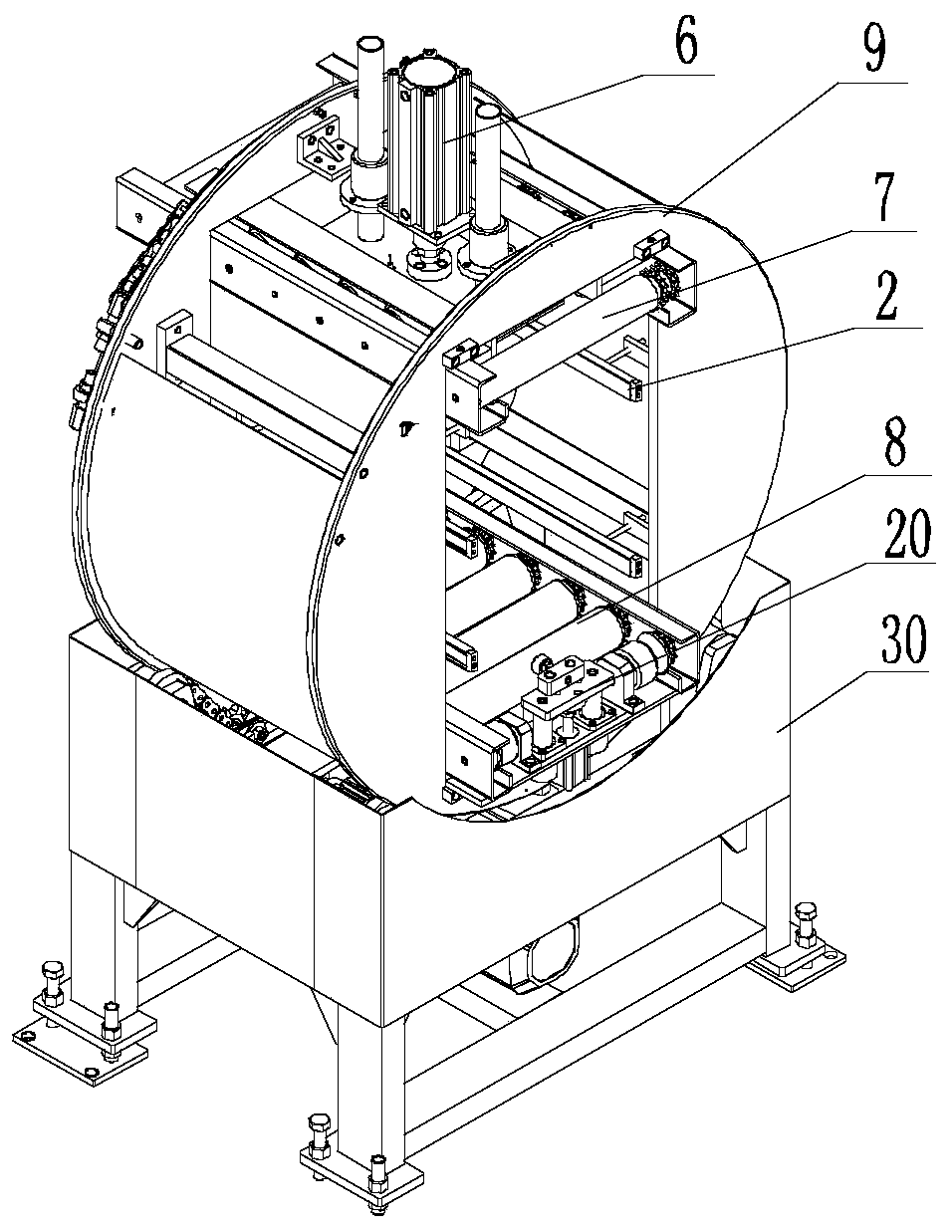

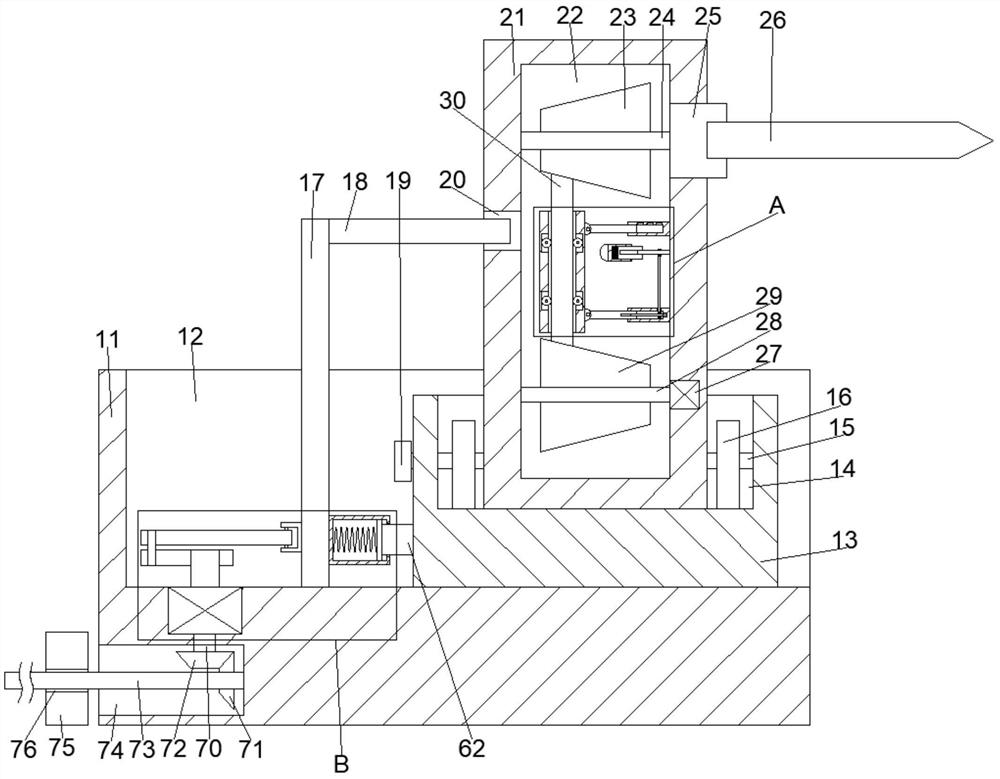

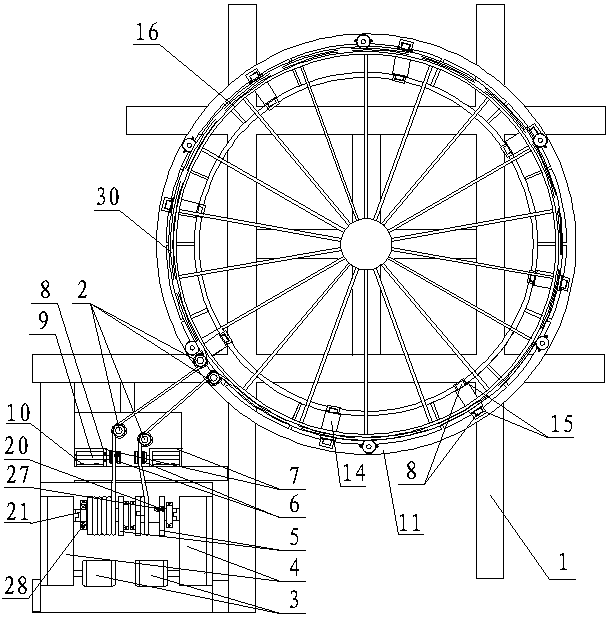

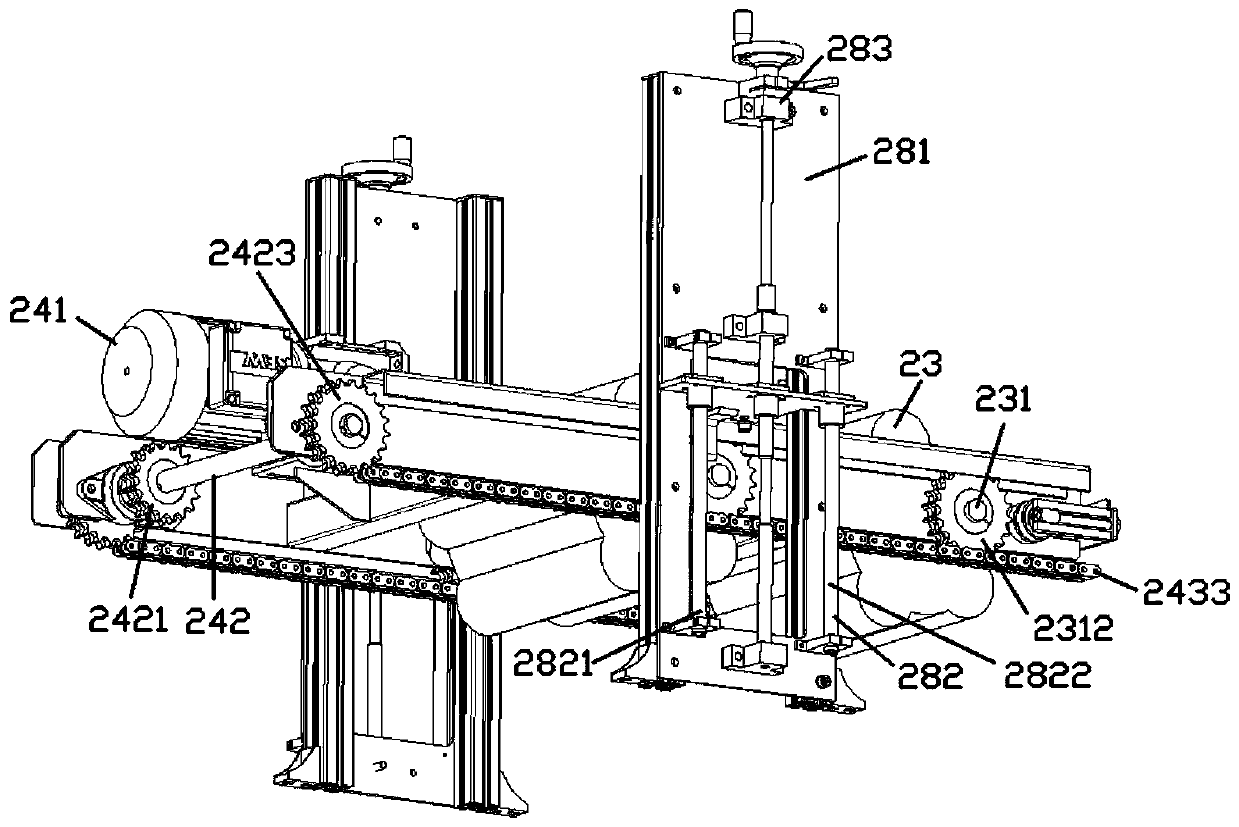

Workpiece overturning equipment for vehicle production line

The invention belongs to the technical field of vehicle production lines, and particularly relates to workpiece overturning equipment for a vehicle production line. The workpiece overturning equipmentcomprises a pressing mechanism, an output roller way, an input roller way, an overturning table, a pressing mechanism, an overturning driving mechanism and a base mechanism. The overturning table isarranged on the base mechanism in a manner of rotating around a horizontal shaft, the overturning driving mechanism is arranged in the base mechanism and is connected with the overturning table and used for driving the overturning table to rotate, the output roller way and the input roller way which are oppositely arranged are arranged in the overturning table, the pressing mechanism is arranged on the overturning table, located on the outer side of the output roller way and used for pressing a workpiece conveyed into the overturning table through the input roller way, and when the overturningtable rotates to enable the output roller way to be located below, the workpieces are output through the output roller way. The pressing mechanism is used for pressing a workpiece, the motor is directly used for driving the workpiece to rotate, and the structure saves more space and materials and adjustment is more convenient from the perspective of design and calculation. A tray is not needed, and accurate positioning is not needed either.

Owner:中国科学院沈阳计算技术研究所有限公司

Circular aging bunker

The invention belongs to a circular aging bunker which comprises a ceiling, a feed belt, a material distribution belt, a discharge belt, a material conveying belt and a stand column. A hole is formed in the center of the ceiling. A discharge plate is arranged under the hole. A hanging rod is arranged at an outlet of the material distribution belt. A rail is arranged on the ceiling over the hanging rod. A distance measuring sensor is arranged on the lower face, at an outlet, of the material distribution belt. A rotary rack is arranged below the discharge plate. A supporting rack is arranged at the upper portion of the stand column. The rotary rack is internally provided with a material distribution belt motor. A supporting rod is arranged at the lower end of the stand column. A movable plate is arranged on the plane of the outer side of the supporting rod. A spiral conveyor is arranged on one side of the movable plate. Blade teeth are arranged on blades of the spiral conveyor. A V-shaped rack is arranged on the other side of the movable plate. A push plate is arranged between rack rods. Reinforcing ribs are arranged between the outer rack rod and the movable plate. A driving wheel is arranged below the outer rack rod. The outer rack rod is provided with a movable plate motor. The inner rack rod is provided with a driven wheel. By adoption of the circular aging bunker, the construction cost is greatly saved, automatic material distribution is completed, and the quality of produced bricks is improved.

Owner:HAMI HAOBANG BUILDING MATERIAL

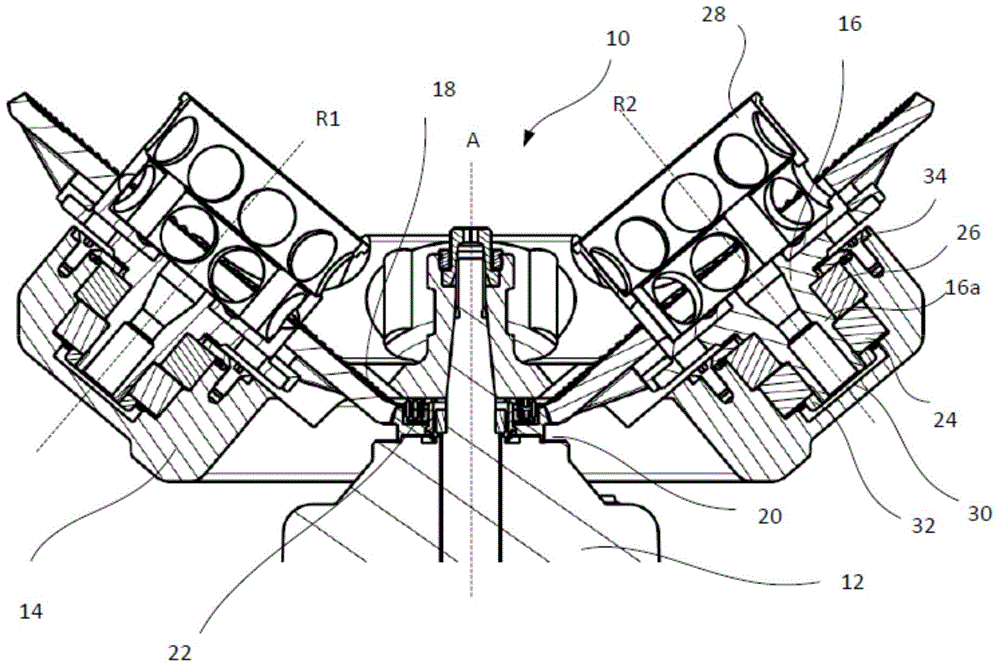

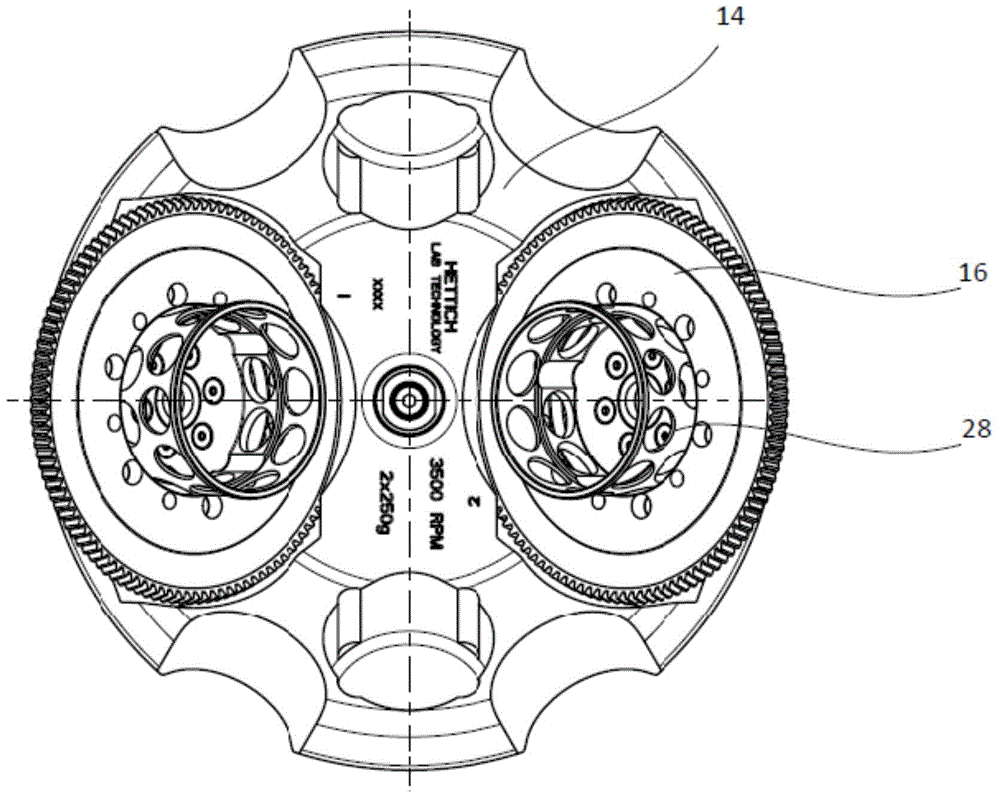

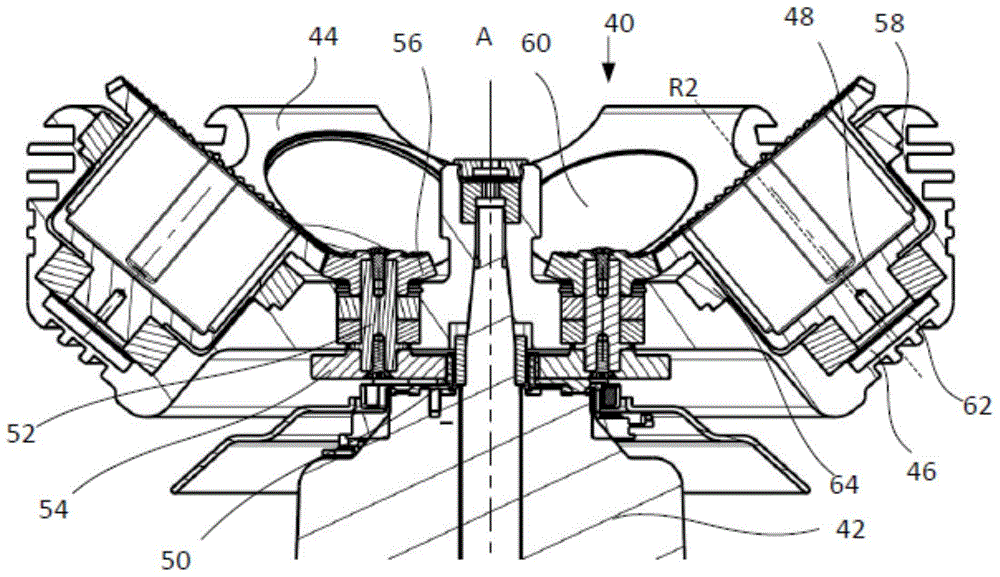

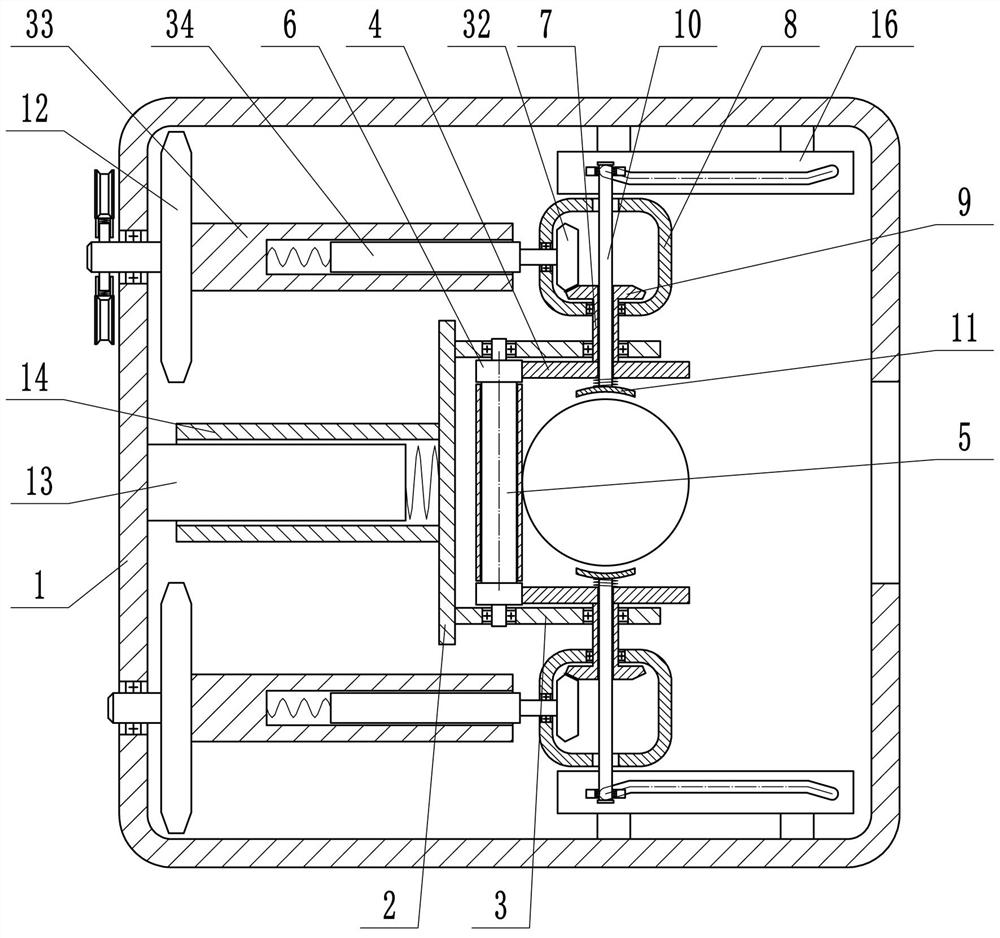

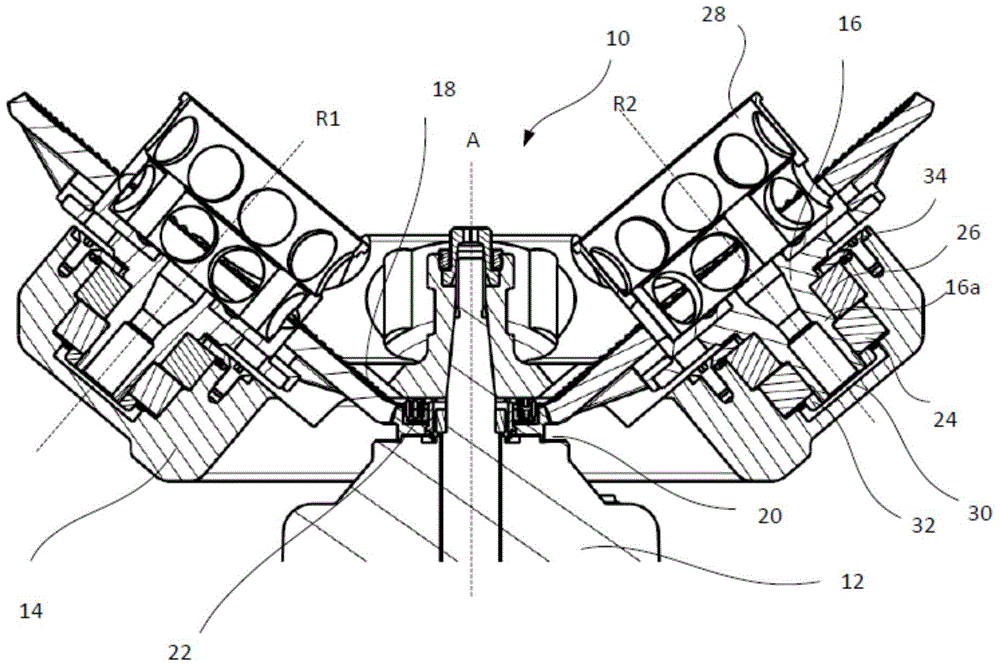

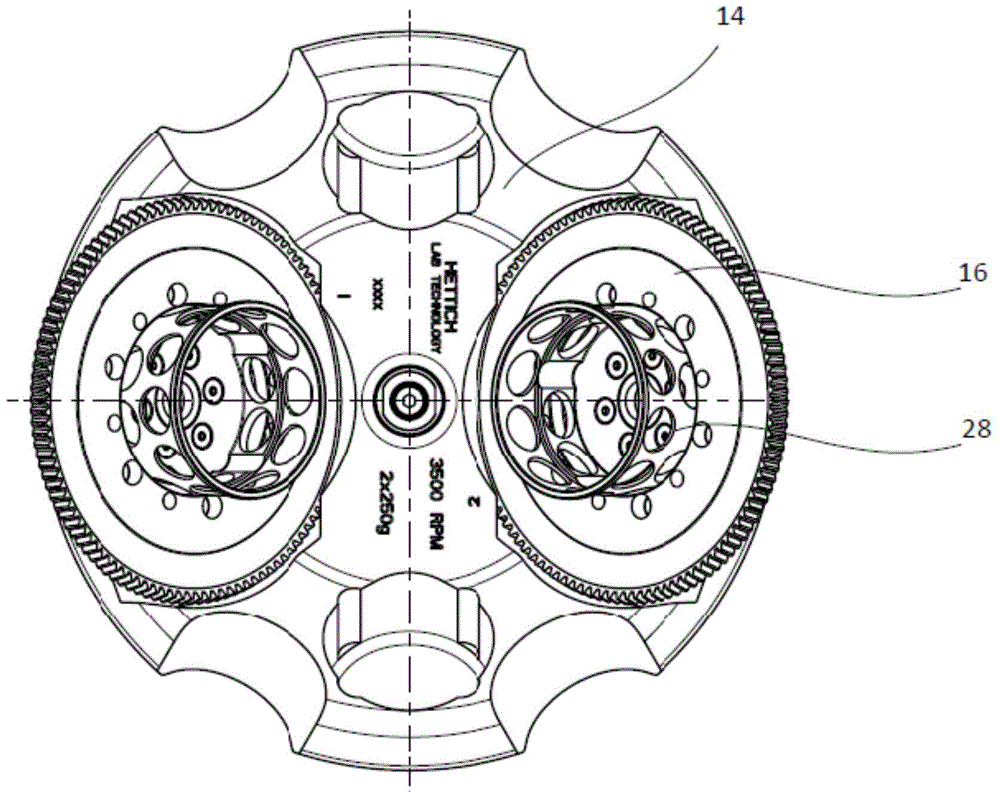

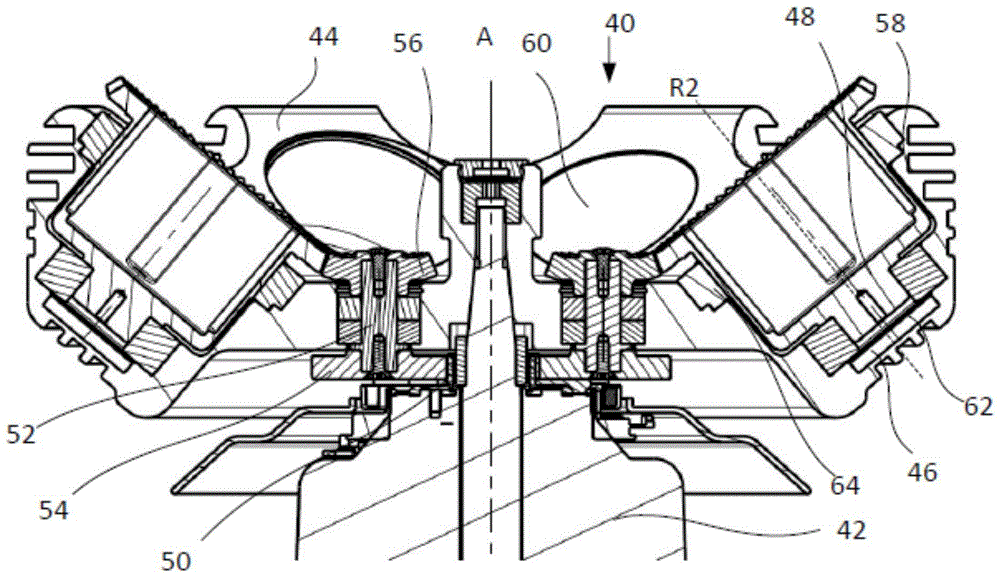

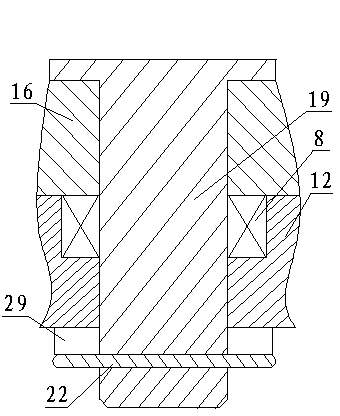

Apparatus for homogenization and separation of samples

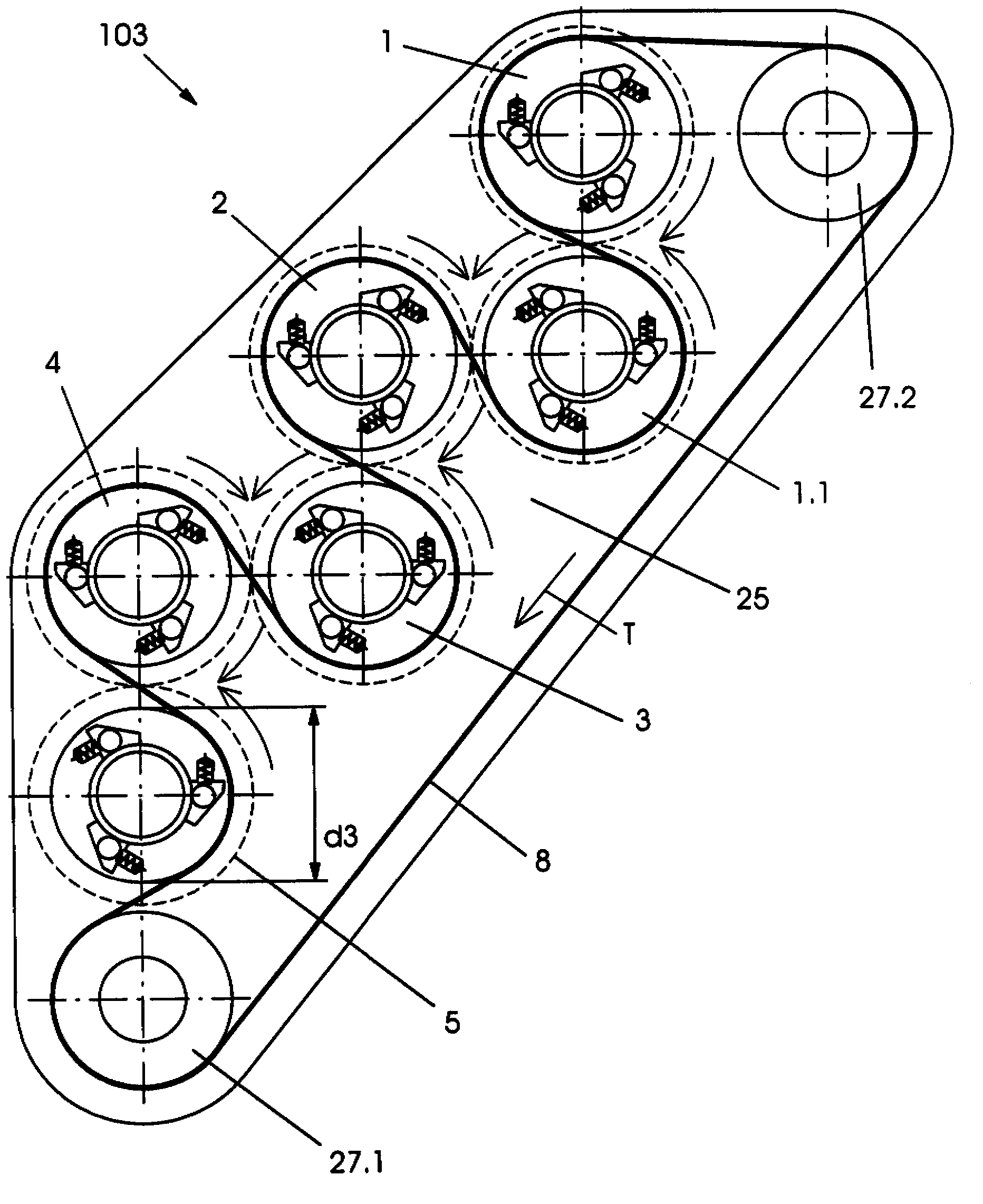

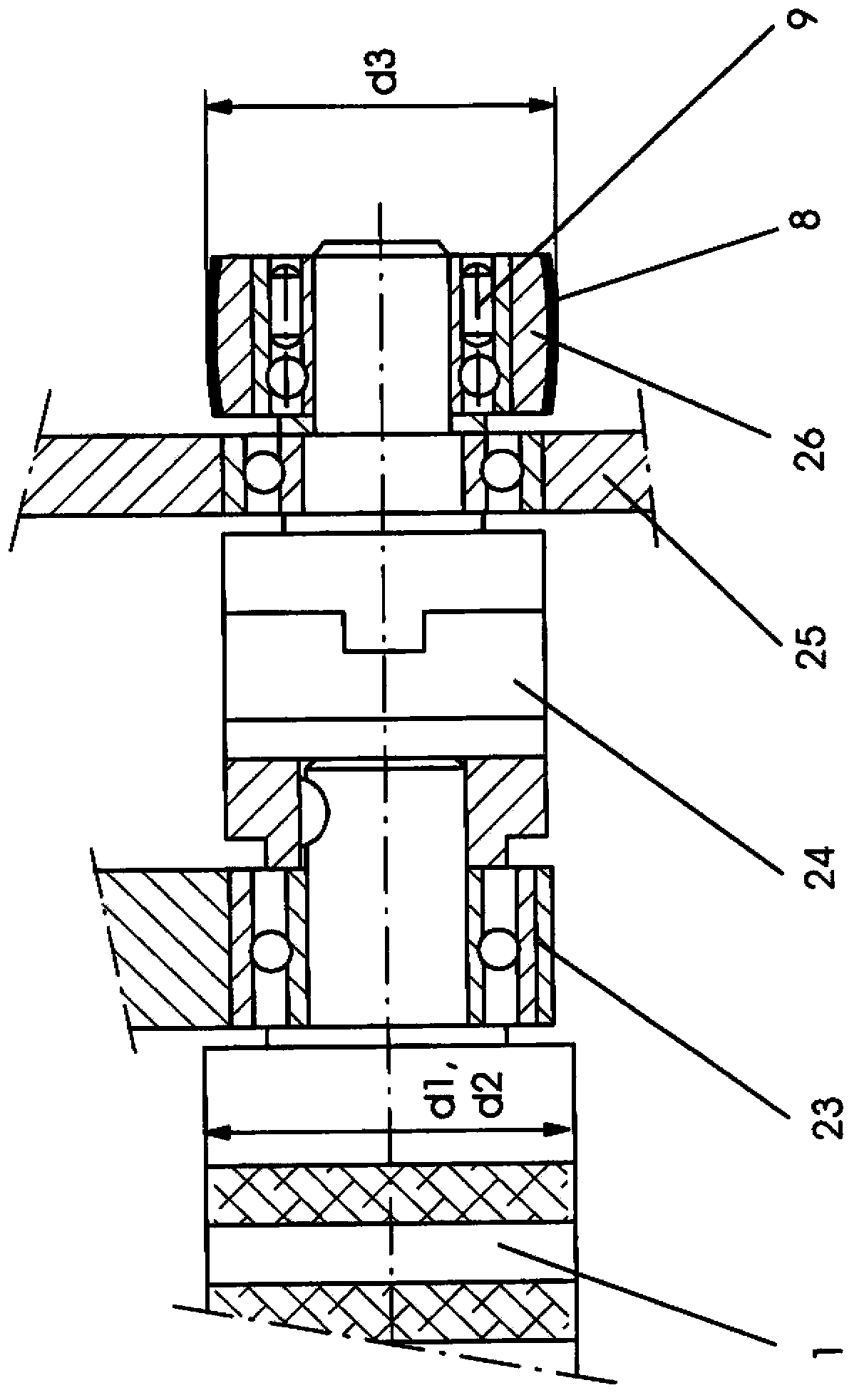

ActiveCN104619405ALong operating timeIncrease centrifugal forceRotating receptacle mixersTransportation and packagingCentrifuge rotorEngineering

The invention relates to an apparatus for homogenization and separation of media (10), comprising a centrifuge (40, 70) having a centrifuge rotor (14, 44, 74) which is rotatable about a motor axis (A) of a centrifuge motor (12, 42, 72) and has a rotor body to which at least one rotation unit (16, 48, 80) is connected such that the latter is additionally configured so as to be rotatable about a rotation unit axis of rotation different from the motor axis (A), and this rotation unit can be driven by means of a rotation unit drive, with provision of means by which at least two different speeds of rotation of the rotation unit (16, 48, 80) can be set, and the rotation unit (16, 48, 80) is also provided in its peripheral region with a tooth system (8) by which the rotation unit (16, 48, 80) can be driven. It is a feature of the invention that the rotation unit drive has a tooth system associated with the centrifuge motor.

Owner:ANDREAS HETTICH GMBH & CO KG +1

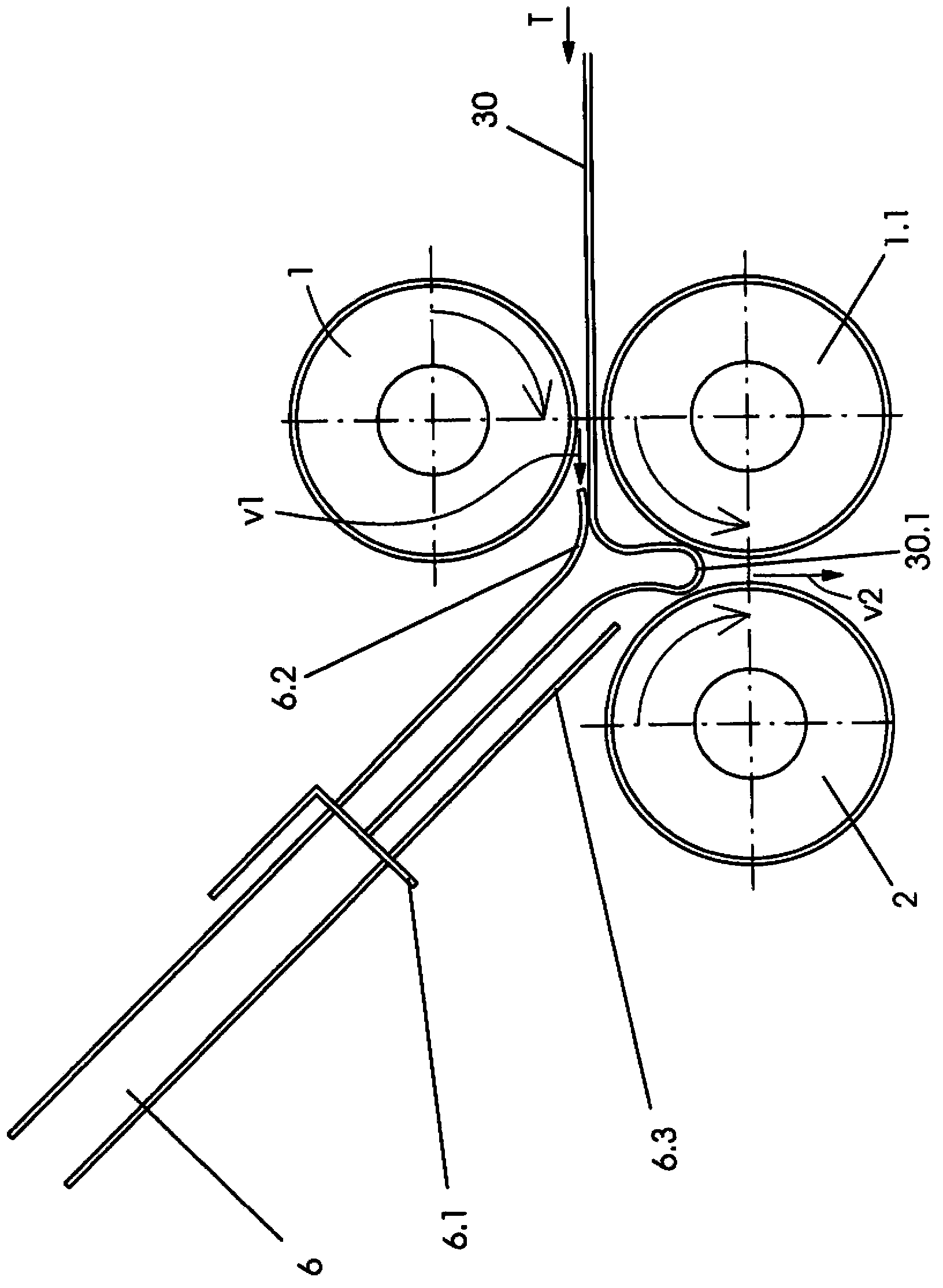

Method for folding and buckle plate folding machine

The invention relates to a method for folding applied for a buckle plate folding machine. The buckle plate folding machine has at least one first roller pair, a first later folding buckle plate at the paper running direction and a later folding roller pair at the paper running direction, wherein the the peripheral speed of one roller in the folding roller pair is always higher than the peripheral speed of of the other folding roller. A paper is drawn to pass through a folding station in a tension state through the speed difference. The invention also relates to the folding machine employing the method, wherein the application schemes of a standard rolling unit and a special rolling unit are set. According to the invention, the drive line or the folding roller diameter of the folding machine is adjusted.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

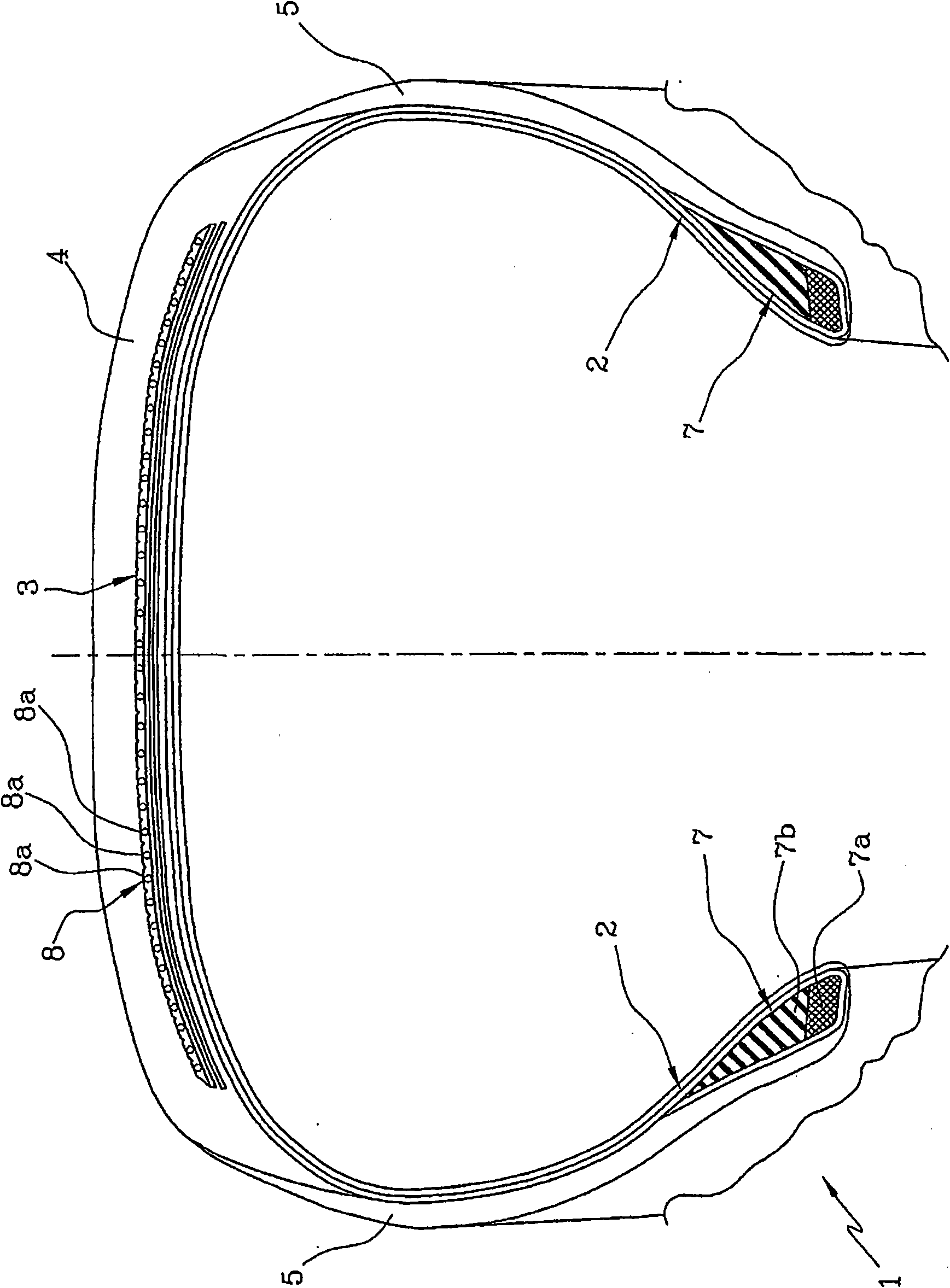

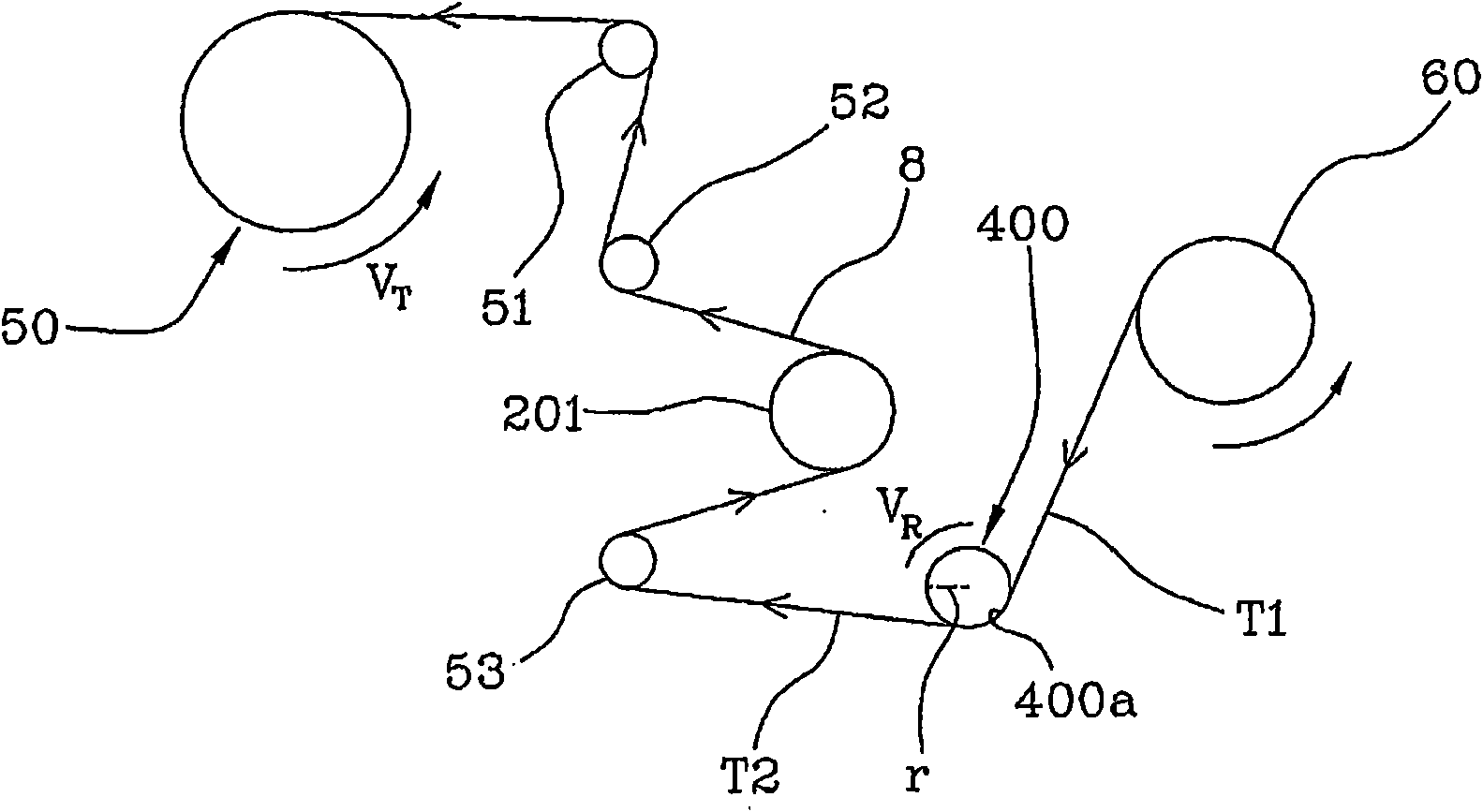

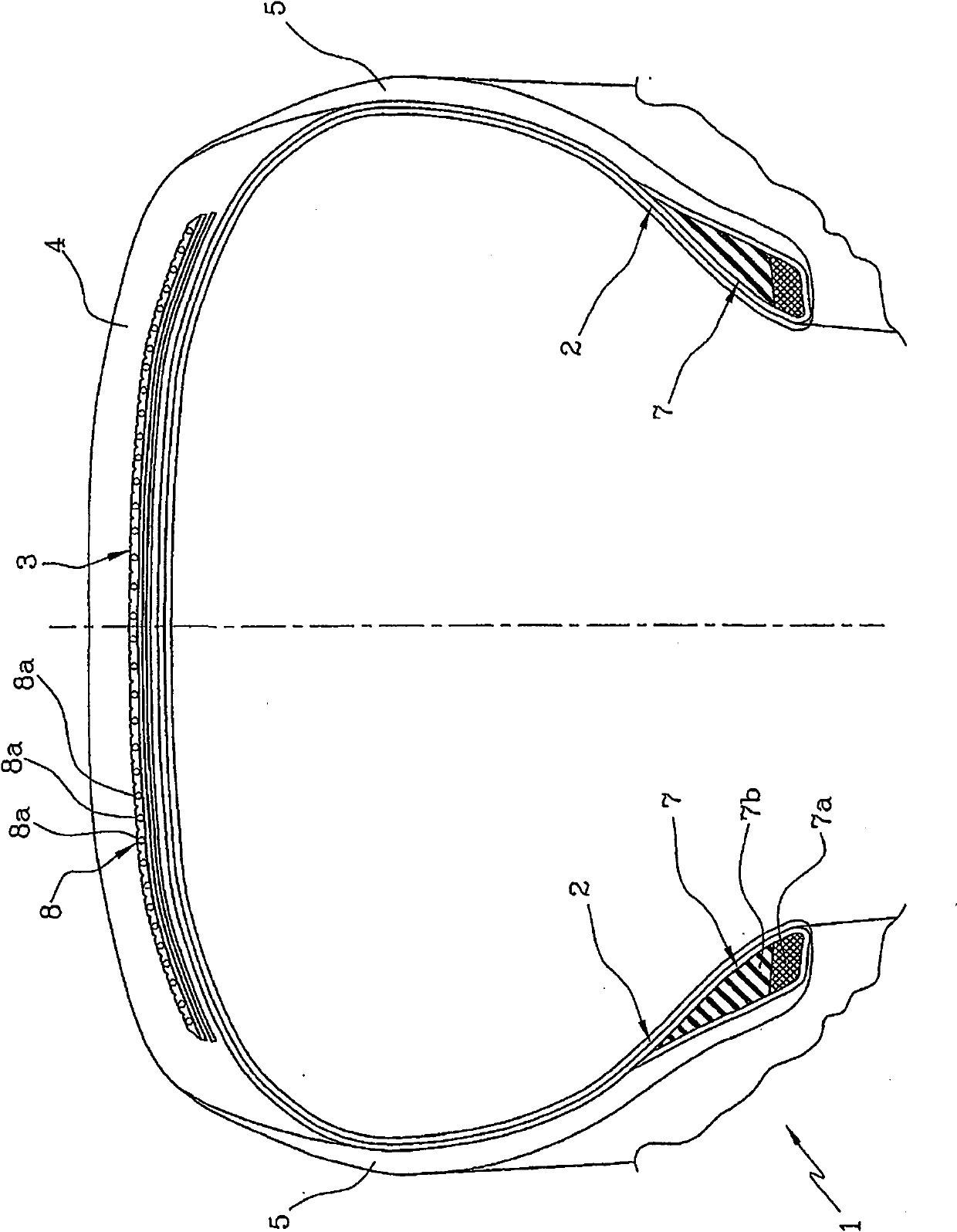

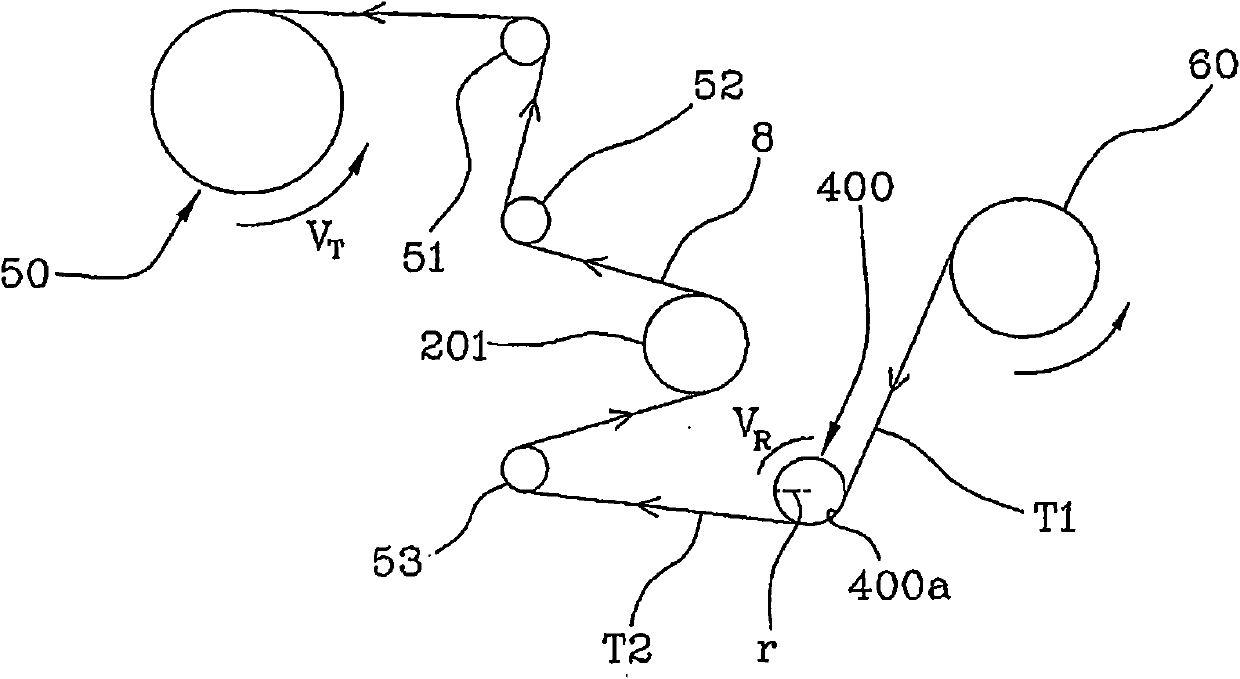

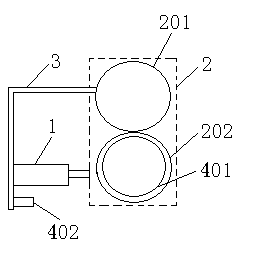

Method for laying down at least an elastic element in a process for producing tyres for vehicles, process for producing tyres for vehicles and apparatus for laying down at least one elastic element

Method of laying down at least one elastic element in a process for producing tyres for vehicles, said method comprising the following steps: determining a first parameter representative of a laying speed at which at least one elastic element is laid down around a tyre forming drum; determining a second parameter representative of a percent elongation to be applied to said elastic element; adjusting, as a function of said first and second parameters, a rotation speed of a control roller positioned upstream of said forming drum and having a radially external surface at least partly in engagement with said elastic element for controlling the laying profile of said at least one elastic element. Also described is a process for producing tyres for vehicles and an apparatus for carrying out said laying method.

Owner:PIRELLI TYRE SPA

Target tracking method and device

PendingCN112132136AAvoid lossAccurate target tracking capabilityTelevision system detailsImage analysisLinear classifierCyclic shift

The embodiment of the invention provides a target tracking method and device, which can generate a sampling frame in a Tth frame image acquired by a camera device, the sampling frame comprises a firstarea of interest of a target face, cyclic shift is performed on the sampling frame in the Tth frame image to obtain n training samples, each training sample corresponds to a classification label. A nonlinear classifier is trained by using the n training samples and the classification labels corresponding to the n training samples, the response degree of the input samples and the first area of interest is outputted by the nonlinear classifier, and cyclic shift is performed on the sampling frame in the (T + 1) th frame of image to obtain n shift samples, A target sample is determined with the highest response degree with the first area of interest from the n shift samples by using a nonlinear classifier, the first area of interest is updated according to the target sample, and the visual angle of the camera device is adjusted according to the position of the first area of interest. The technical scheme can adapt to scenes such as multiple faces and high dynamics in the visual field of the camera device, and is high in robustness.

Owner:HUAWEI TECH CO LTD

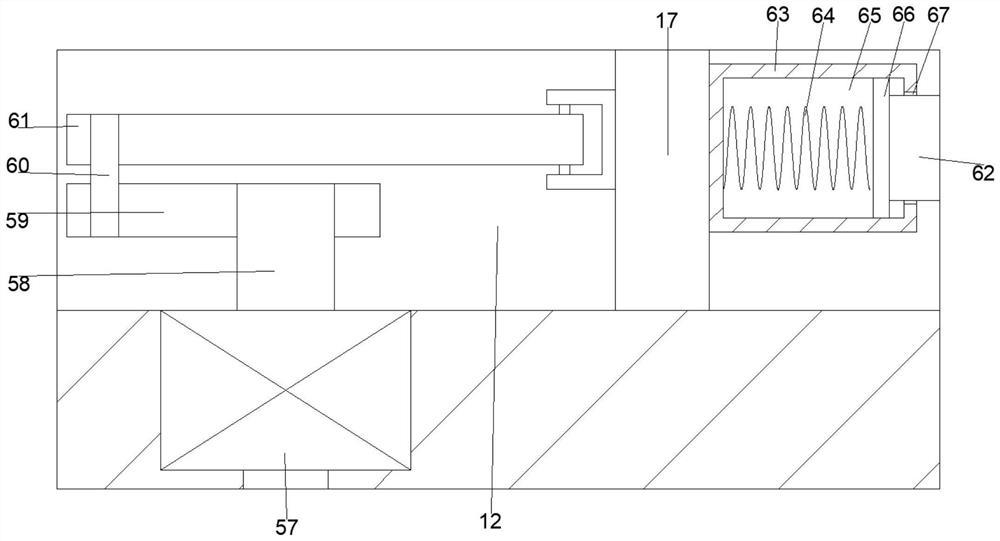

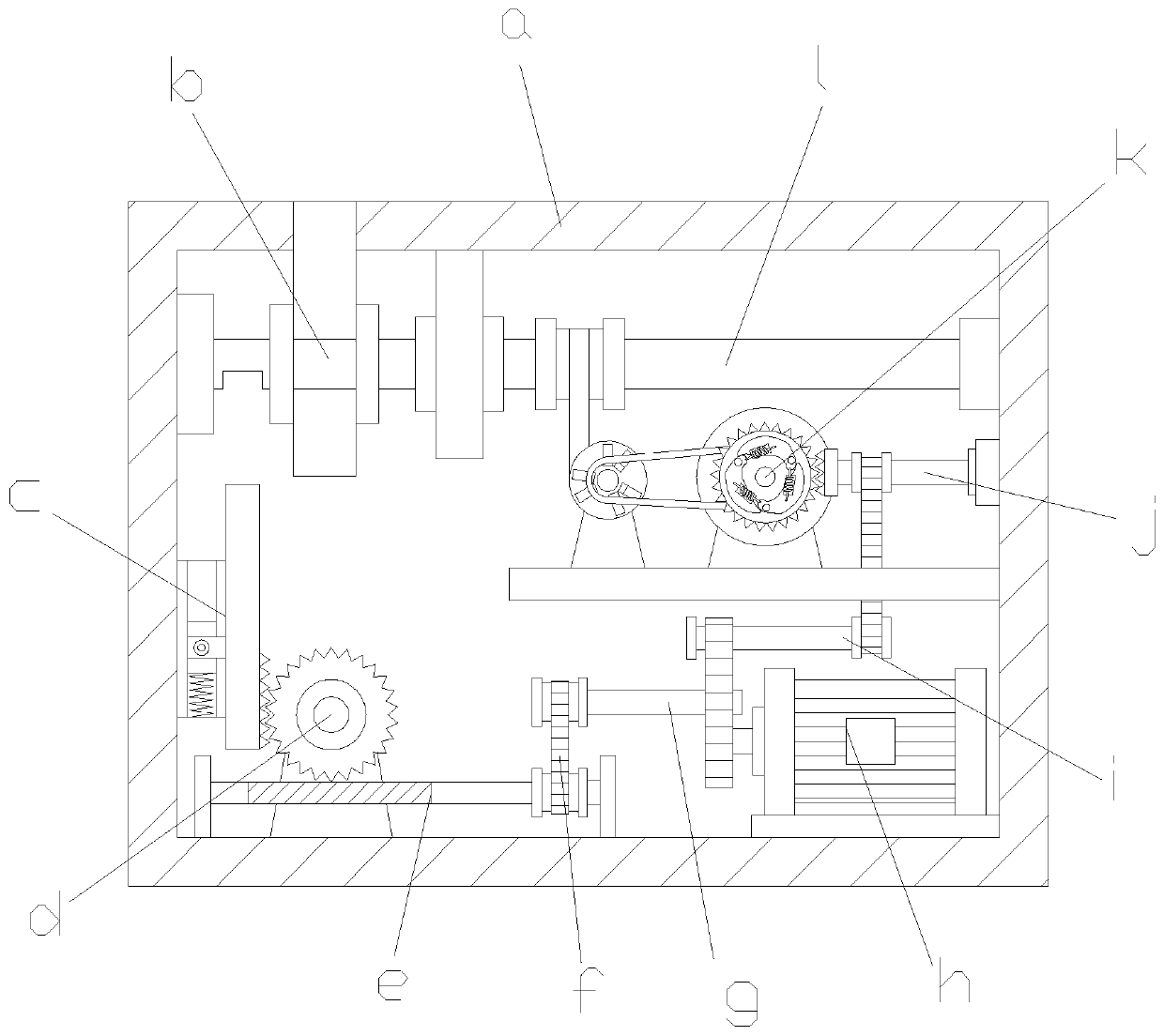

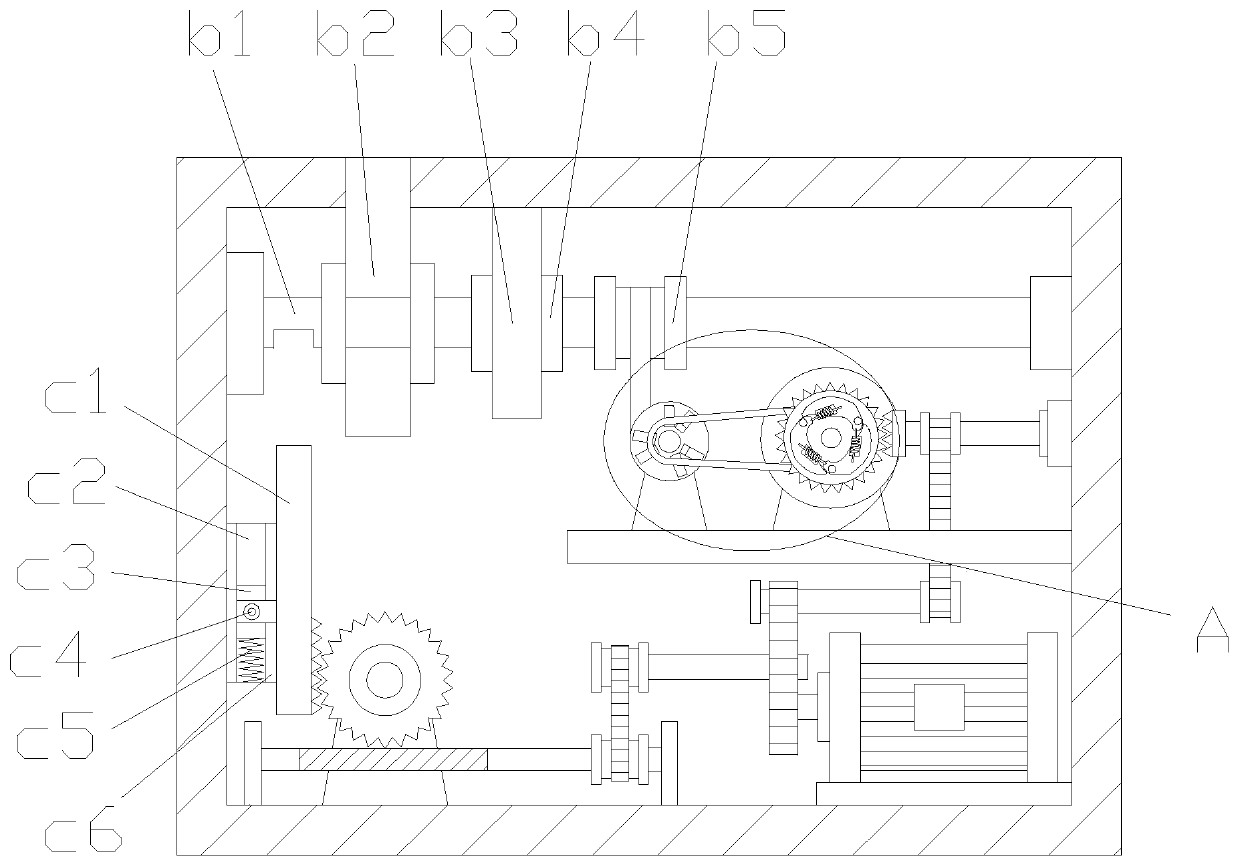

Electric drill equipment capable of automatically adjusting speed according to hardness

InactiveCN113043051AAvoid getting stuckRotation speed adjustmentFeeding apparatusDriving apparatusJackshaftReciprocating motion

The invention discloses electric drill equipment capable of automatically adjusting the speed according to the hardness. The electric drill equipment comprises a moving box, a reciprocating pushing cavity with an upward opening and a rightward opening is formed in the moving box, a clamping box is slidably connected to the lower wall of the reciprocating pushing cavity left and right, and a hinged plate located on the left side of the clamping box is slidably connected to the lower wall of the reciprocating pushing cavity left and right; and the lower wall of the reciprocating pushing cavity is rotationally connected with a crankshaft located on the left side of the hinged plate, a spring block is fixedly connected to the right end face of the hinged plate, a spring cavity is formed in the spring block, the right wall of the spring cavity communicates with a sliding cavity with a rightward opening, a clamping cavity with an upward opening is formed in the clamping box, and the left wall and the right wall of the clamping cavity are rotatably connected with a two-way screw. According to the electric drill equipment capable of automatically adjusting the speed according to the hardness, a drill bit can be driven to perform left-right reciprocating motion while being fed towards one side at a constant speed, so that the drill bit is prevented from being clamped, and meanwhile, the movement of a push block is controlled through the compression state of a spring.

Owner:曹县法恩亚家具有限公司

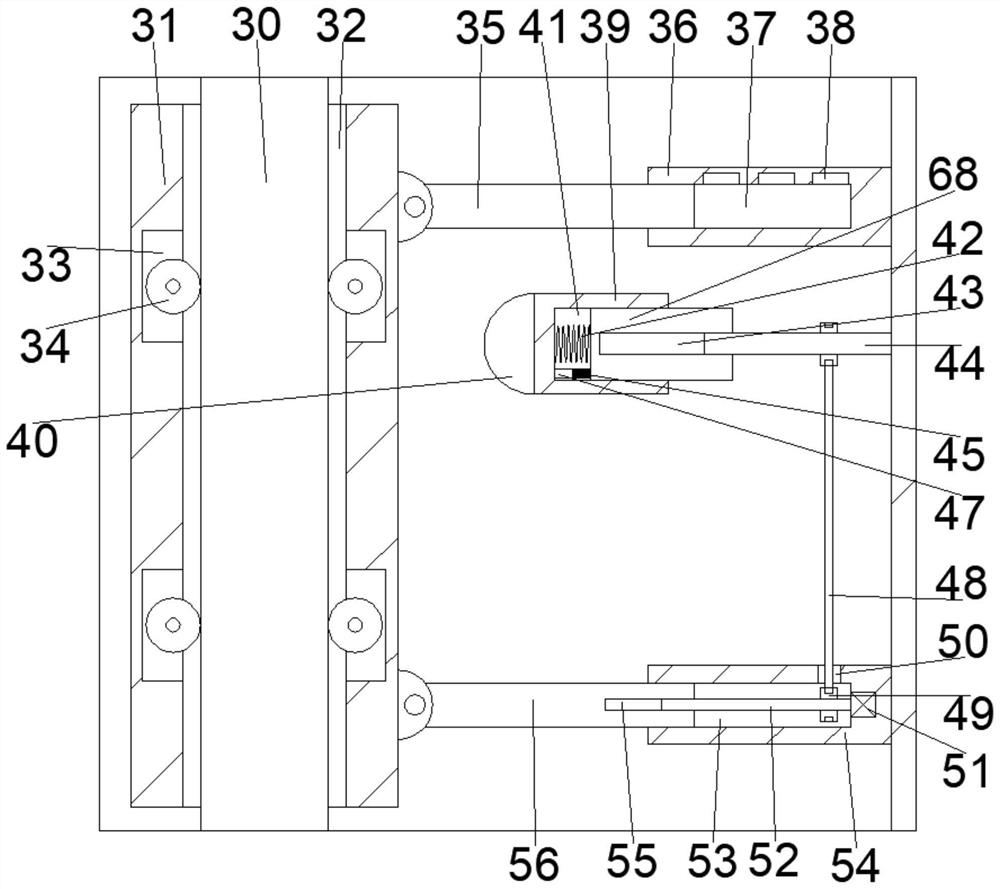

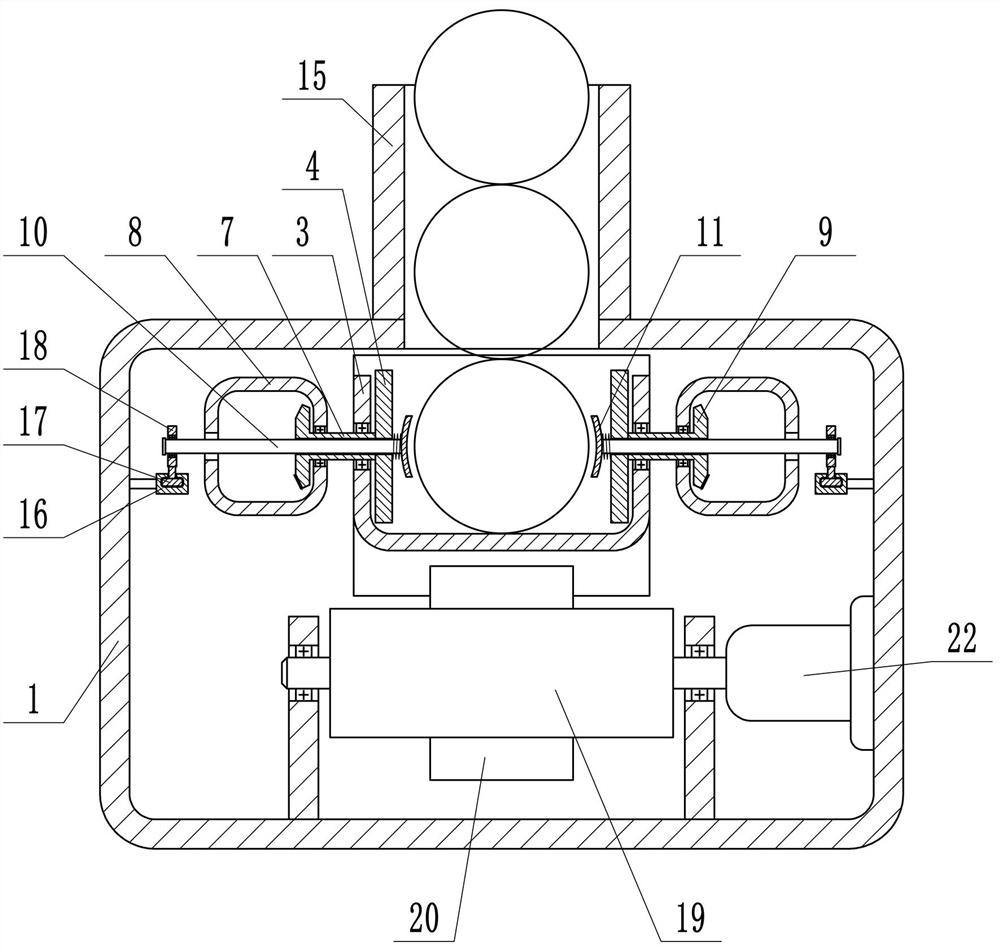

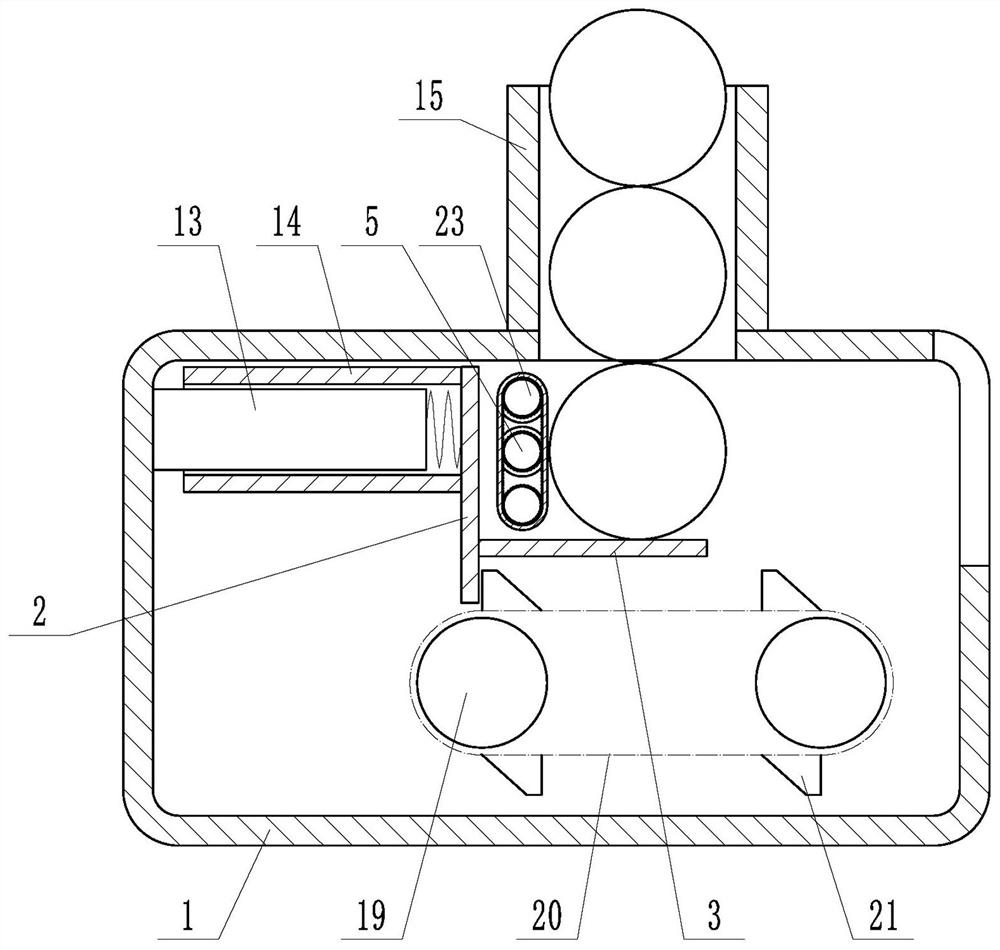

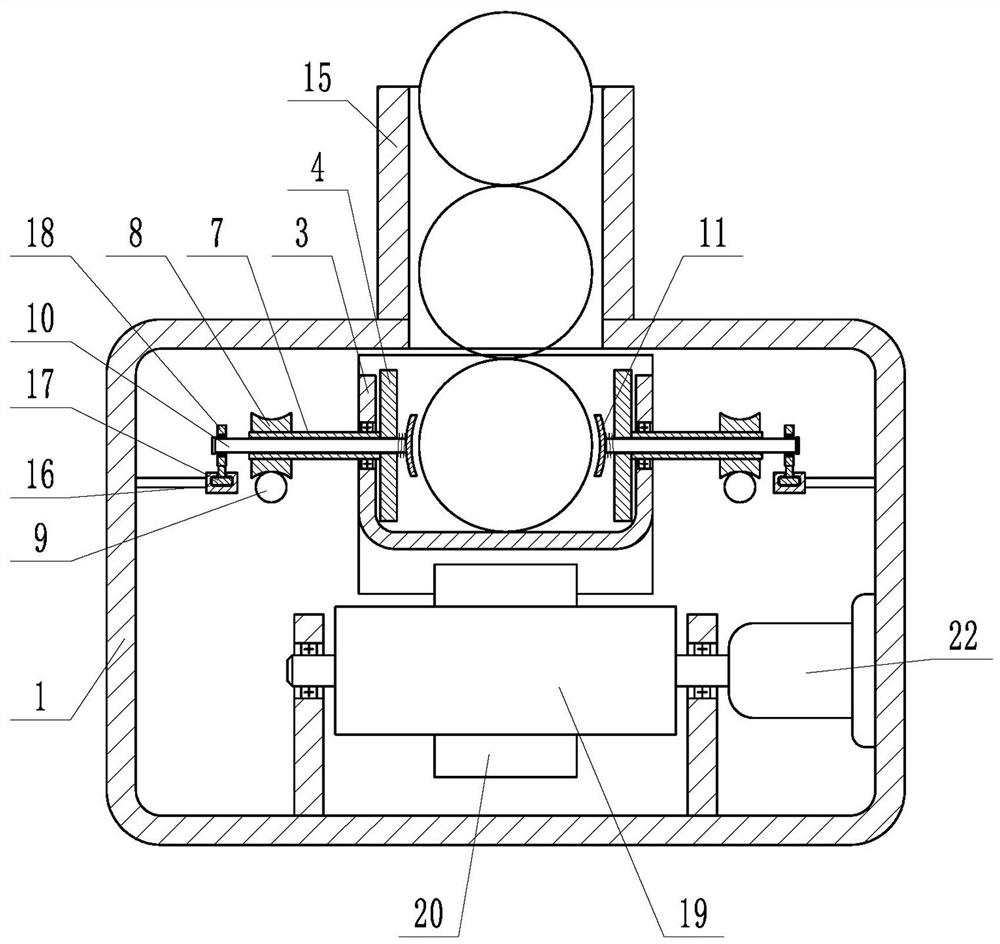

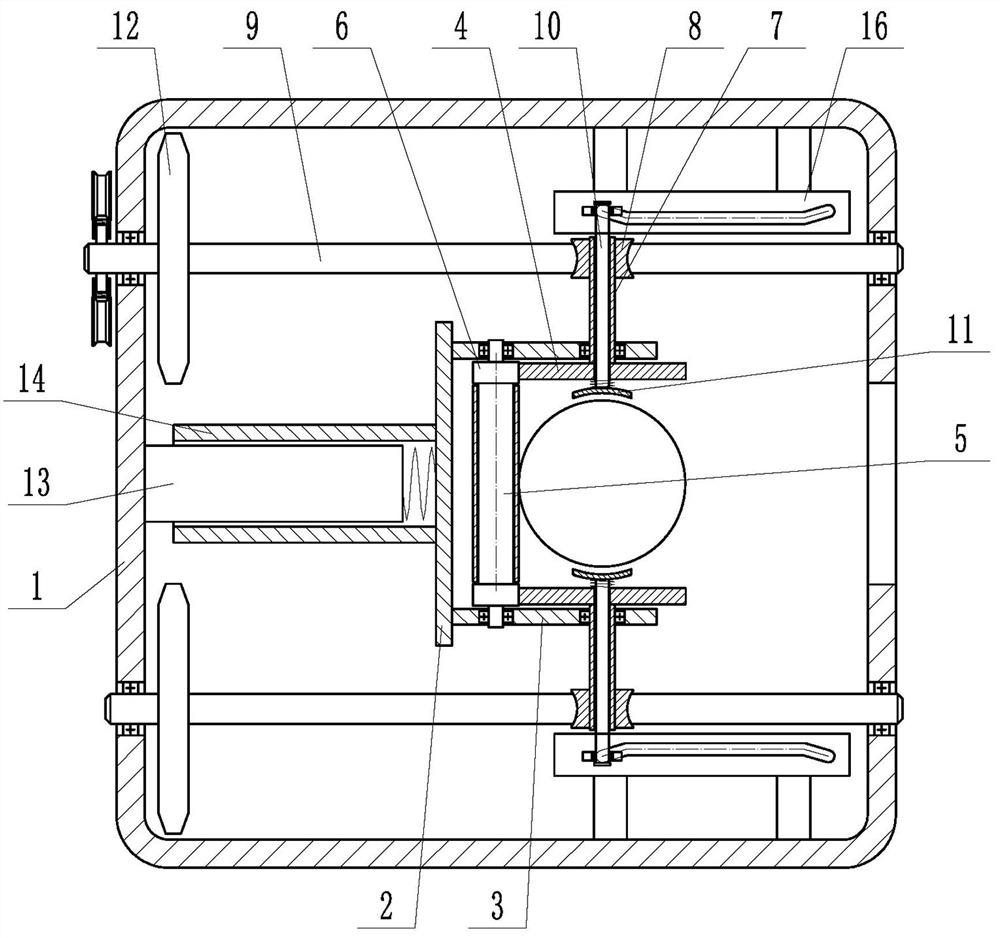

Table tennis training device

The invention provides a table tennis training device which effectively solves the problems that an existing pitching machine cannot pitch high-speed rotating balls and the track rotating speed of thetable tennis balls is not easy to control. According to the invention, the table tennis training device comprises a rectangular shell, a vertical plate is arranged in the shell, a U-shaped plate is fixed on the right side surface of the vertical plate, and the table tennis balls are placed in the U-shaped plate; big gears are arranged on front and rear side plates of the U-shaped plate, a rotating shaft is arranged in the U-shaped plate, a pinion is arranged at the end part of the rotating shaft, a first spline cylinder is fixed on one side, far away from the table tennis balls, of each big gear, rectangular boxes are arranged on front and rear sides of the U-shaped plate, first bevel gears are arranged in the rectangular boxes, and second bevel gears are arranged on left side plates; a first spline shaft capable of sliding in the axial direction of the first spline cylinder is inserted into the first spline cylinder, clamping plates are fixed to the end, close to the table tennis ball, of the first spline shaft, a pressure spring is installed between each clamping plate and the large gear, and the two clamping plates can clamp the table tennis balls under the action of the pressure springs; a hole is formed in a right side plate of the shell, and the table tennis balls can penetrate through the hole.

Owner:郑州大学体育学院

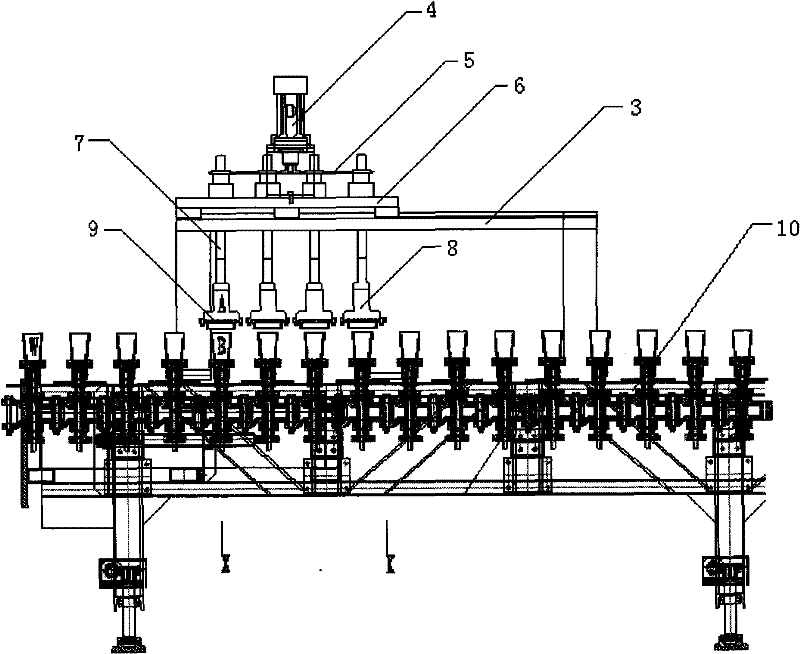

Spot welding needle grinding device

PendingCN108274347AGrind properlyRotation speed adjustmentEdge grinding machinesGrinding carriagesEngineeringSpot welding

The invention relates to a spot welding needle grinding device. The spot welding needle grinding device comprises a moving mechanism, a rotating mechanism, clamping mouths, welding needle bodies, a connection rack and lower fixtures. According to the spot welding needle grinding device, the welding needle bodies are fixed to the lower portion of the rotating mechanism through the clamping mouths,after the spot welding needle grinding device is powered on, the rotating mechanism starts rotating, then by means of stretching and contracting of the output end of the moving mechanism, ascent and descent of the rotating mechanism are realized, the corresponding welding needle bodies perform ascent and descent along the clamping mouths together, because the center portions of the lower fixturesare provided with grooves, the grooves are internally provided with grinding coatings, the welding needle bodies correspond to the grooves in the center portions of the lower fixtures, when the outputend of the moving mechanism extends downward to a certain limit, the welding needle bodies start making contact with the grooves in the center portions of the lower fixtures, thus grinding of the welding needle bodies is realized, the rotating speed of the rotating mechanism can be adjusted according to requirements, therefore the spot welding needle grinding device can perform suitable grindingon the welding needle bodies according to the actual condition.

Owner:苏州速安行新能源科技有限公司

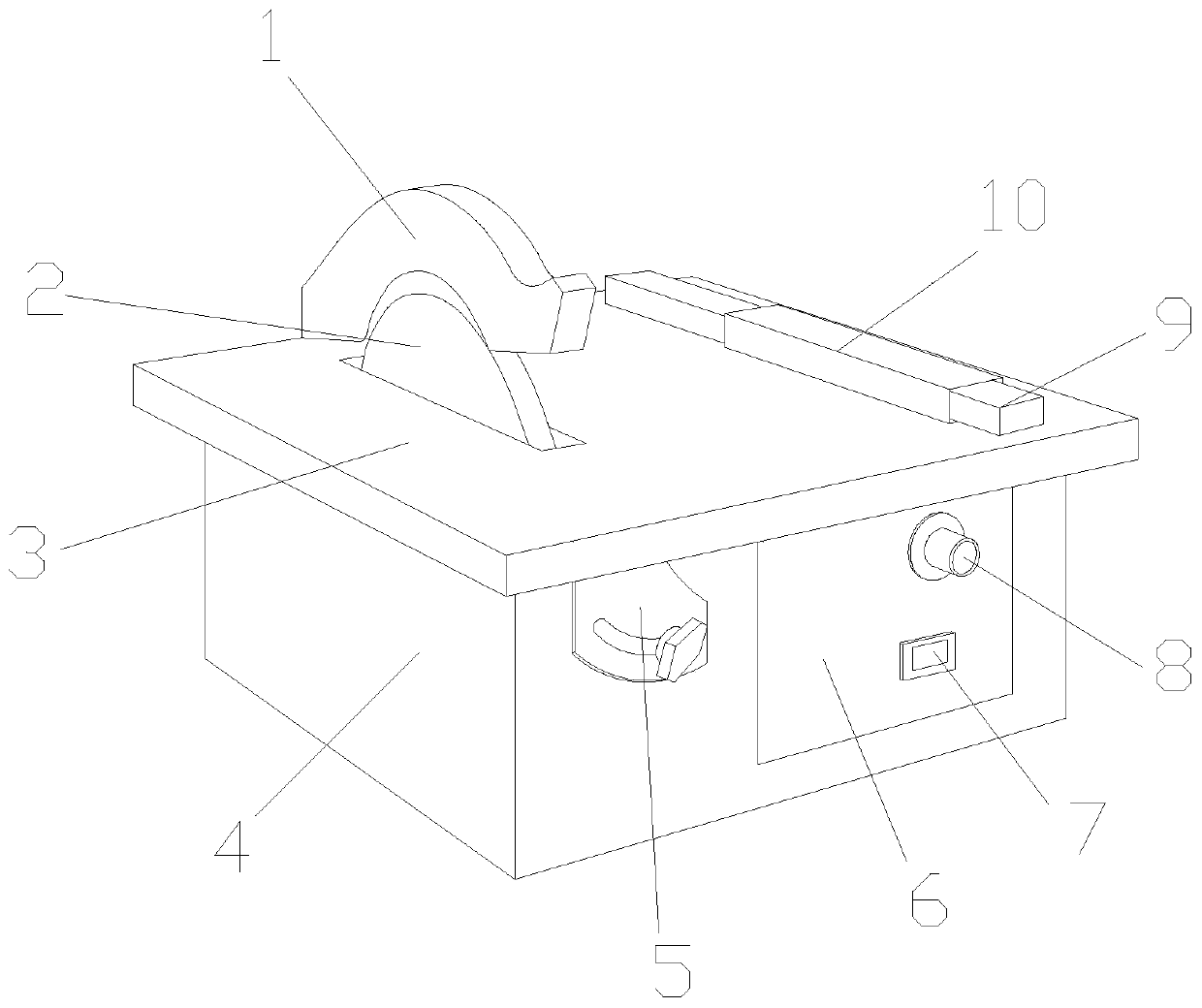

Waste paper cutting device capable of preventing cutter from accidentally injuring people after completion of cutting

InactiveCN112553934AReduce the chance of accidentally injuring people with cutting knivesAvoid accidental injuryPaper recyclingRaw material divisionElectric machineryDrive motor

The invention relates to the technical field of pulpers, and discloses a waste paper cutting device capable of preventing a cutter from accidentally injuring people after completion of cutting; the waste paper cutting device comprises a workbench; the right side of the workbench is movably connected with a rotary knob, the left side of the rotary knob is fixedly connected with a threaded rod, andthe side, away from the rotary knob, of the threaded rod is movably connected with a rotary disc. According to the waste paper cutting device capable of preventing the cutter from accidentally injuring people after completion of cutting, the rotary knob is rotated, the threaded rod drives the rotary disc to move left and right at the moment, the rotation ratio between a driven disc and a driving disc is further changed, and the rotation speed of a cutting blade is changed at the moment; therefore, the effect that the cutting speed can be adjusted according to different materials is achieved. After cutting is completed, a third spring drives a second trapezoidal block to move leftwards, at the moment, the second trapezoidal block impacts a metal ball to trigger a stop button, a driving motor of the device stops working, and thus the effect of reducing the probability that a cutting knife accidentally hurts people during cutting is achieved.

Owner:温州复弘机械设备有限公司

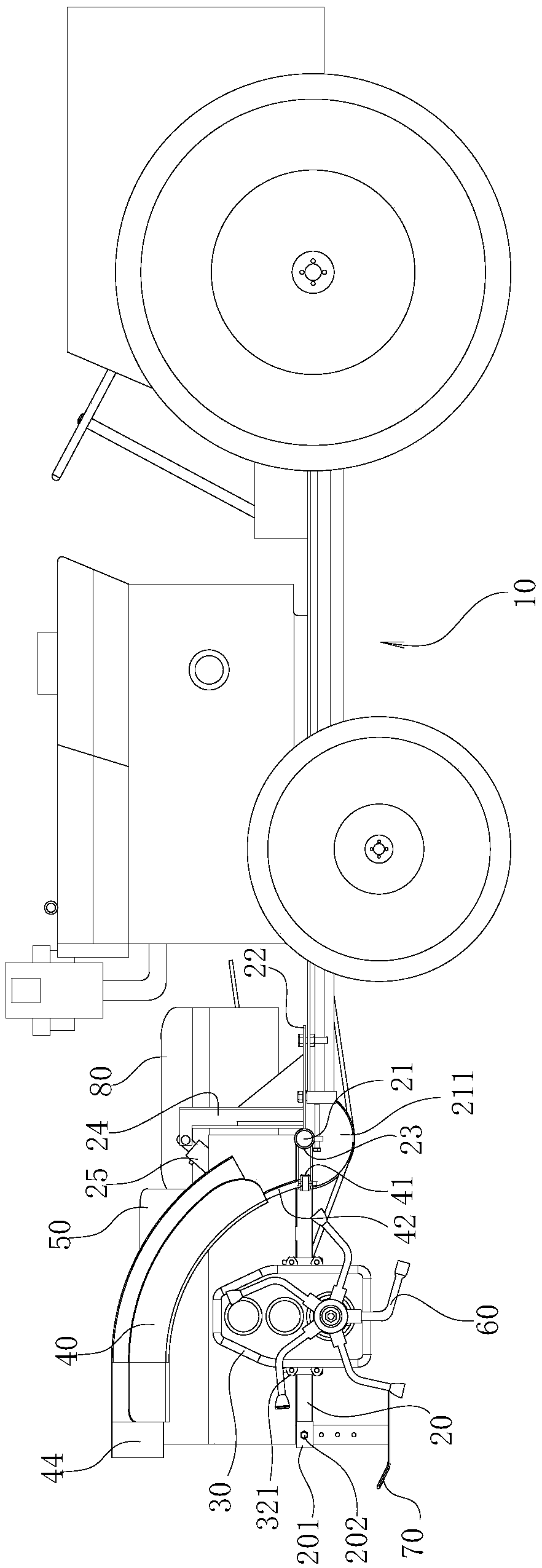

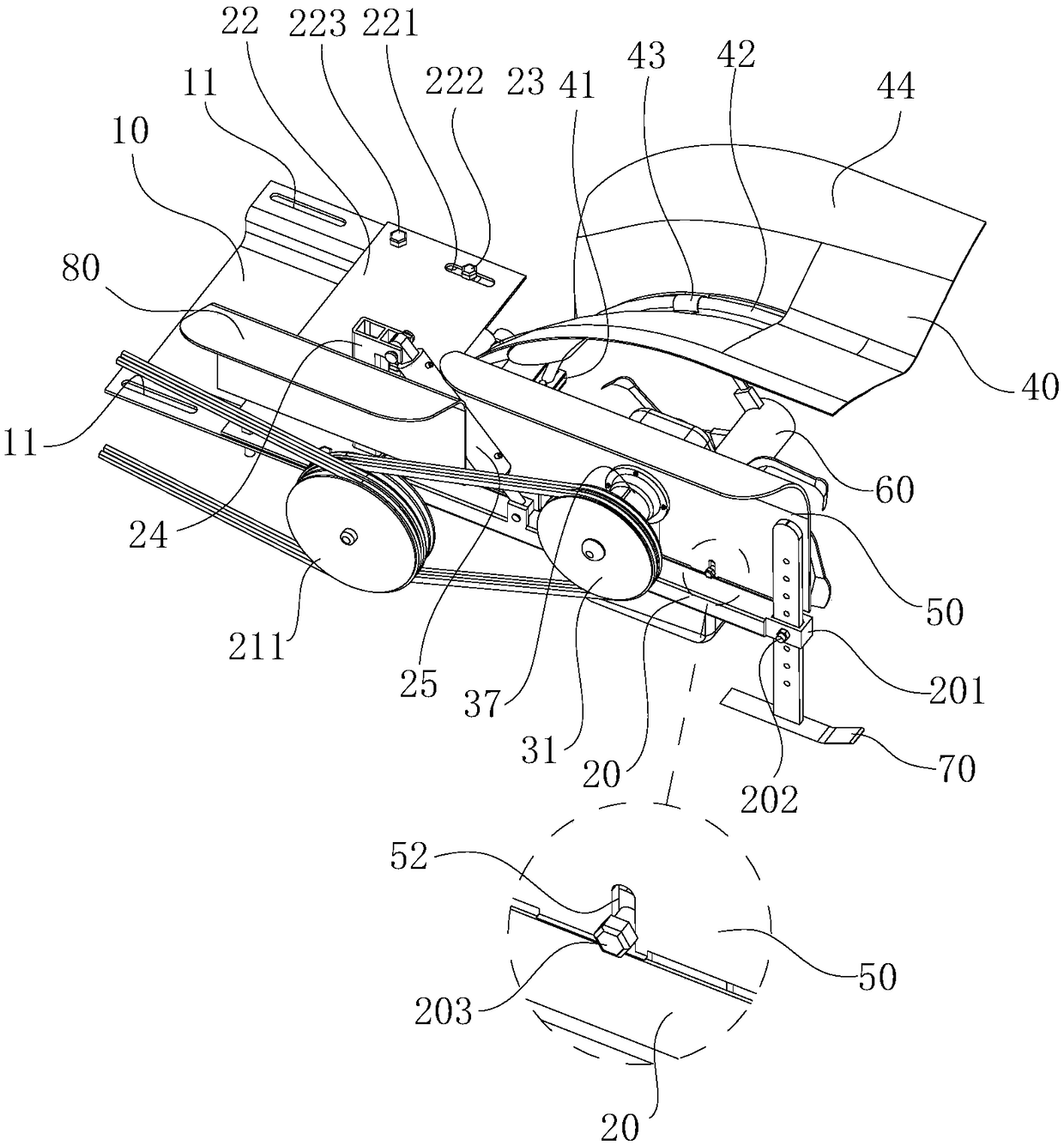

Rotating direction conversion mechanism of cutter assembly of front mounted ditching machine

The invention relates to a rotating direction conversion mechanism of cutter assembly of a front mounted ditching machine, which comprises a gearbox, wherein the gearbox comprises a box body. An inputgear, a transition gear and an output gear are rotatably arranged in the box body. The input gear meshes with the transition gear, and the transition gear meshes with the output gear. An input shaftis arranged at the input gear, and an output shaft is arranged at the output gear. A ditching cutter assembly is arranged at the output shaft. The gearbox comprises three gears, which can not only adjust rotating speed of the ditching cutter assembly, but also change the rotating direction of the ditching cutter assembly, so that the tangential direction of the ditching cutter assembly and the ground is oriented toward the front end of the long side of the four-wheel tractor, so as to achieve ditching operation, prevent soil residue, weeds and branches from falling out behind the four-wheel tractor, and avoid the occurrence of blockage or flame out caused by excessive load of the ditching cutter assembly.

Owner:田开林

A device used to homogenize and separate samples

ActiveCN104619405BRotation speed adjustmentRotating receptacle mixersTransportation and packagingCentrifuge rotorSeparate sample

Owner:ANDREAS HETTICH GMBH & CO KG +1

Apparatus and method for detecting sheet-like material

InactiveCN1670513BImprove detection accuracySimple structurePaper-money testing devicesColor/spectral properties measurementsEngineeringIrradiation

This invention provides a device and method to test slice materials, wherein, the device comprises transmission device, irradiation device, and receiving device and information process device. The transmission device is to transmit the slice materials; the irradiation device is located on one side of the slice material to irradiate the slice materials; the receiving device is located on the otherside of the slice materials, comparing to the irradiation device, to receive transmission light from slice material and to convert the received light into relative test images; the information processdevice is to collect and process image measurement and compare the tested image and the mode board to test the transmission image quality.

Owner:CHINA BANKNOTE PRINTING & MINTING

Device and method used for detecting flake material fluorescent image printing quality

InactiveCN100476413CImprove claritySimple structurePaper-money testing devicesOptically investigating flaws/contaminationInformation processingFluorescence

The present invention relates to an equipment for detecting printed quality of fluorescence image of sheet material. Said equipment includes transmission device, lighting device, receiving device and information processing device. Said invention also provides the action of the above-mentioned every device and detection method by using said equipment.

Owner:CHINA BANKNOTE PRINTING & MINTING

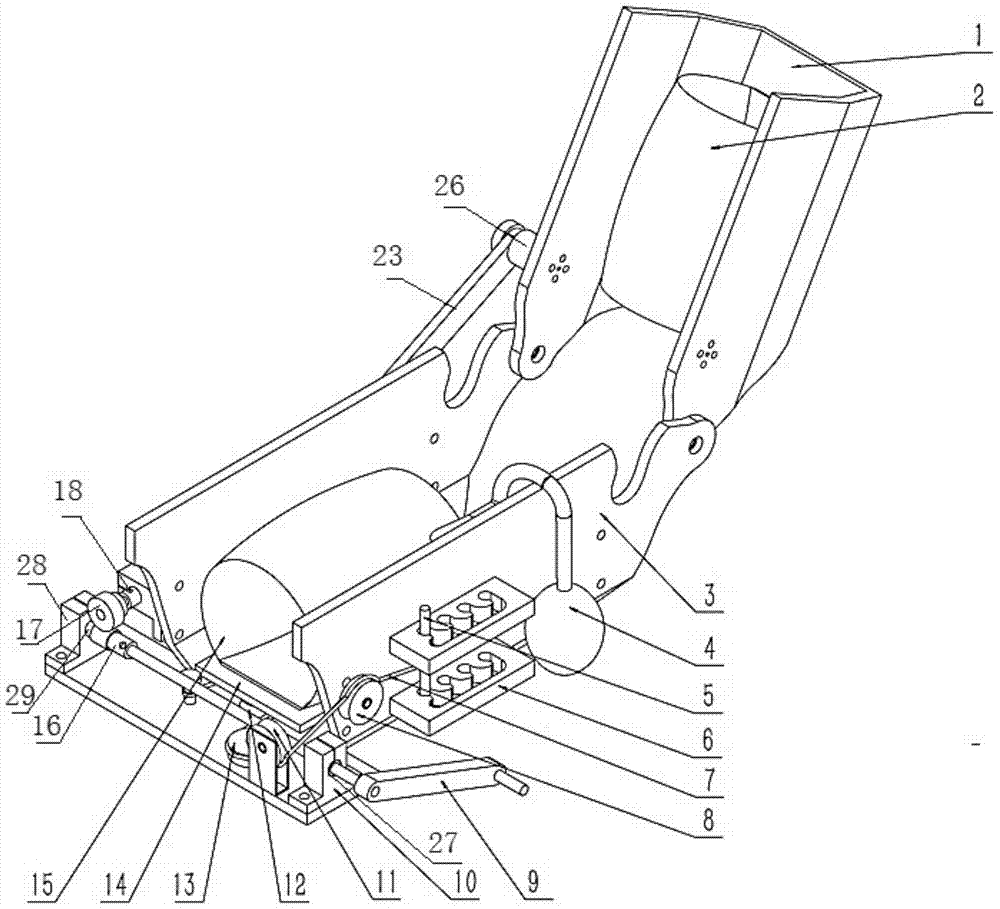

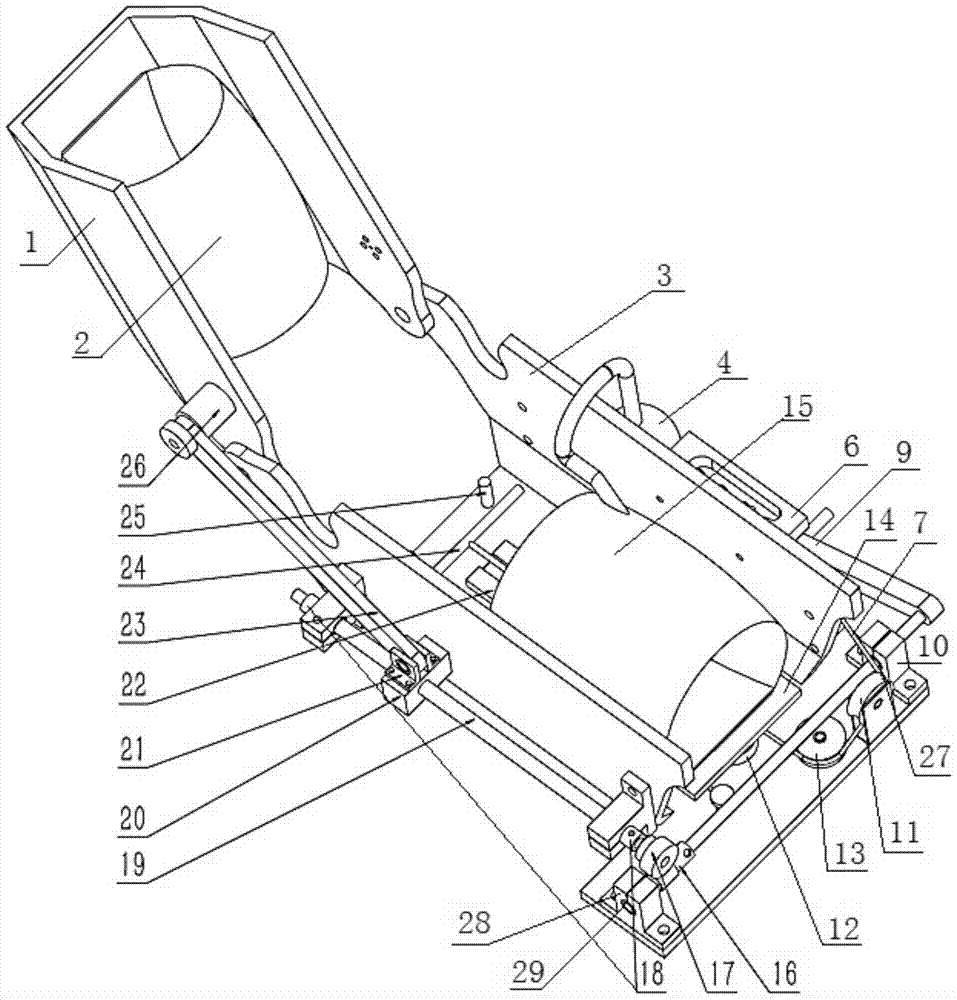

Fire head servo tracking device for edge-melting polishing machine

The invention discloses a fire head servo tracking device for an edge-melting polishing machine, which comprises a machine body, a fire ring moving servo drive motor, a frame, a fire ring rotating motor, a chain, a movable frame, a fire-jet head, a fire-jet ring, a fire tray and a horizontal edge-melting polishing machine, wherein the fire ring moving servo drive motor is fixed on the machine body; one end of the fire ring moving servo drive motor is connected with the movable frame; the fire ring rotating motor is fixed on the movable frame; one end of the fire ring rotating motor is connected with the fire-jet head through the chain; the fire-jet head is fixed on the movable frame; the fire-jet ring is arranged at the tail end of the fire-jet head; the inside of the fire-jet ring is provided with the fire tray; and the horizontal edge-melting polishing machine encircles the machine body. The fire head servo tracking device for the edge-melting polishing machine adopts frequency conversion control to contribute to regulating rotating speed, and adopts servo drive floating tracking to enable a fire ring to move synchronously along products; and the whole device has convenient operation, high operating efficiency and high energy utilization.

Owner:TAICANG HUANG FA JI MACHINERIES & MOLDS

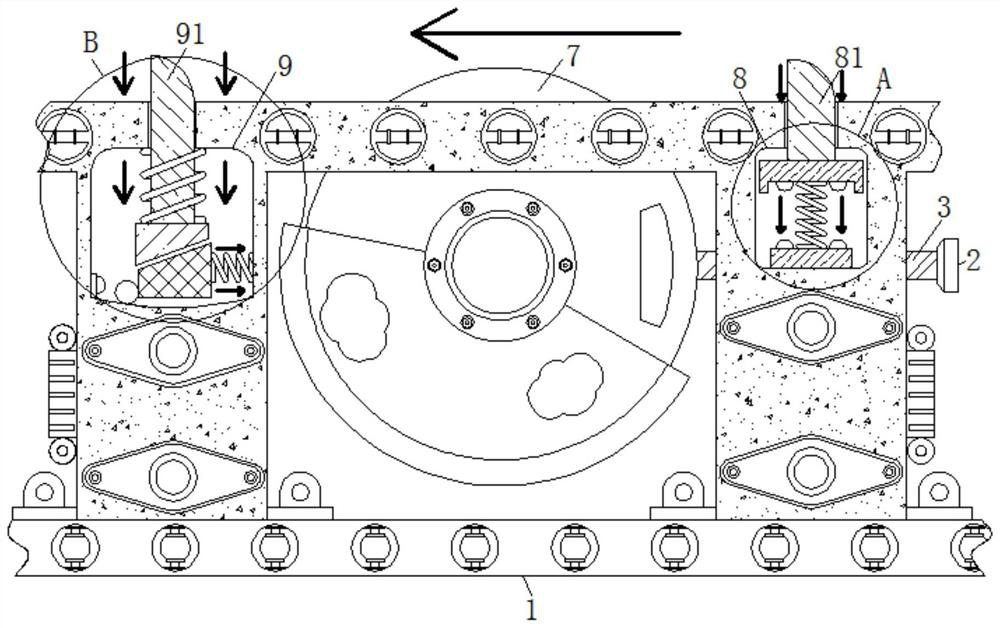

A Coal Mine Scraper Conveyor Chain Drive Speed Limiting Positioning Device

ActiveCN112027509BWork lessNo abnormal phenomenonConveyorsControl devices for conveyorsRotational axisGear wheel

The invention discloses a speed-limiting positioning device for chain drive of scraper conveyor for coal mines, comprising a motor, a fixing seat, a chain main body and a fixing cylinder. A reserved groove is arranged through the middle of the fixing seat, and the middle of the reserved groove A fixed cylinder is installed in a snap fit, and there are two fixed cylinders. The top of the fixed cylinder on the left is connected with a motor, and the top of the motor is connected with the rotating shaft. The baffle is on the left and right sides of the rotating gear. There is provided, and the outer part of the rotating gear and the chain main body are meshed and connected with each other, and the chain main body is arranged on the outer surface of the fixed seat. When the scraper conveyor chain drive speed-limiting positioning device for coal mine is in use, it can well control the moving speed of the chain, so as to ensure that the entire chain can be well controlled when the whole chain moves at overspeed. Therefore, the phenomenon of breakage caused by the overspeed movement of the chain will not occur.

Owner:山东能源集团鲁西矿业有限公司

a ball-serving device

The invention provides a ball-serving device, which effectively solves the problem that the existing ball-serving machine cannot spin the ball at high speed, and the track speed of the table tennis ball is difficult to control; A U-shaped plate is fixed on the right side of the vertical plate, and table tennis balls are placed in the U-shaped plate. There are large gears on the front and rear side plates of the U-shaped plate, and there is a rotating shaft in the U-shaped plate. The pinion gear is fixed on the side of the big gear far away from the table tennis ball with a coaxial spline cylinder, and the end of the spline cylinder away from the table tennis ball is fixed with a worm gear. There is a horizontal worm screw corresponding to the worm gear in the housing cavity. Active rotation; the spline barrel is inserted with a spline shaft that can slide along its axial direction, a splint is fixed on the end of the spline shaft close to the table tennis ball, and a compression spring is installed between the splint and the big gear. The splint can clamp the table tennis ball under the action of the compression spring; a hole is provided on the right side plate of the casing, and the table tennis ball can pass through the hole.

Owner:郑州大学体育学院

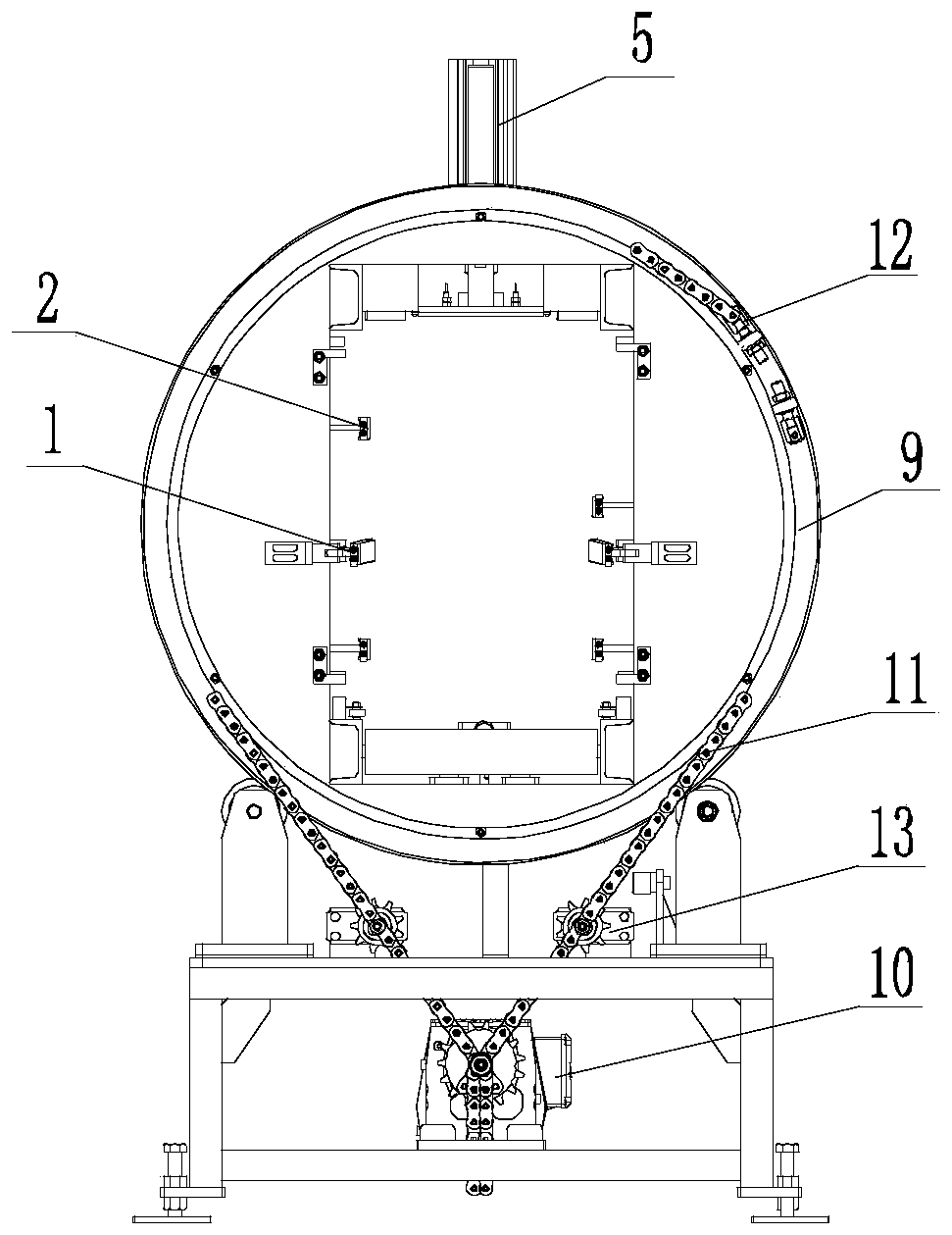

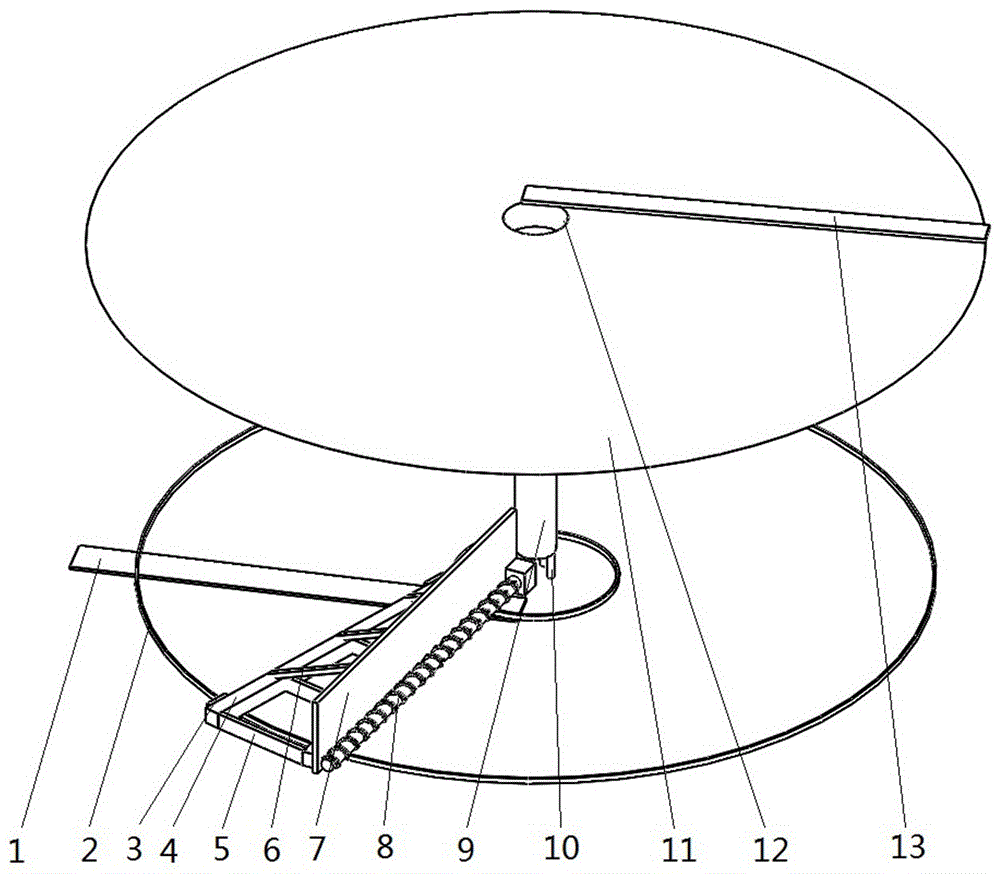

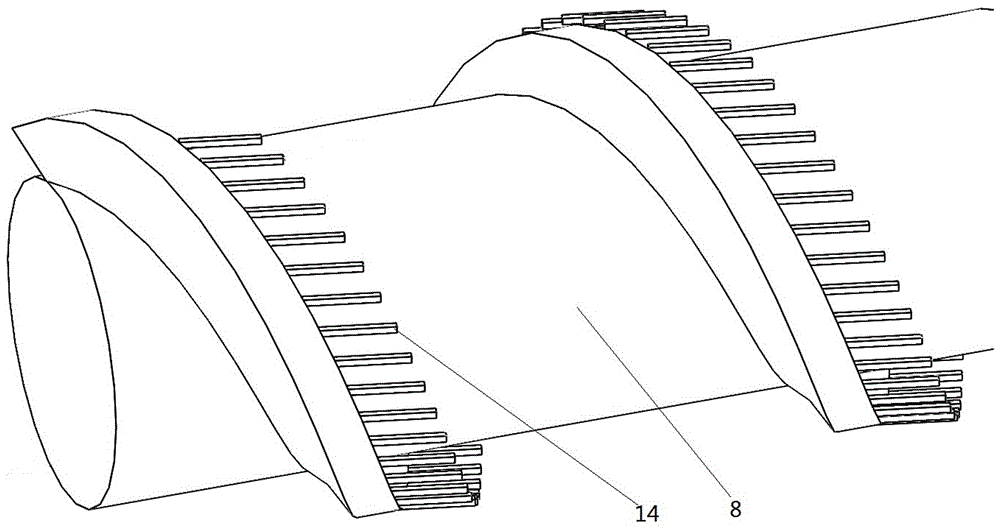

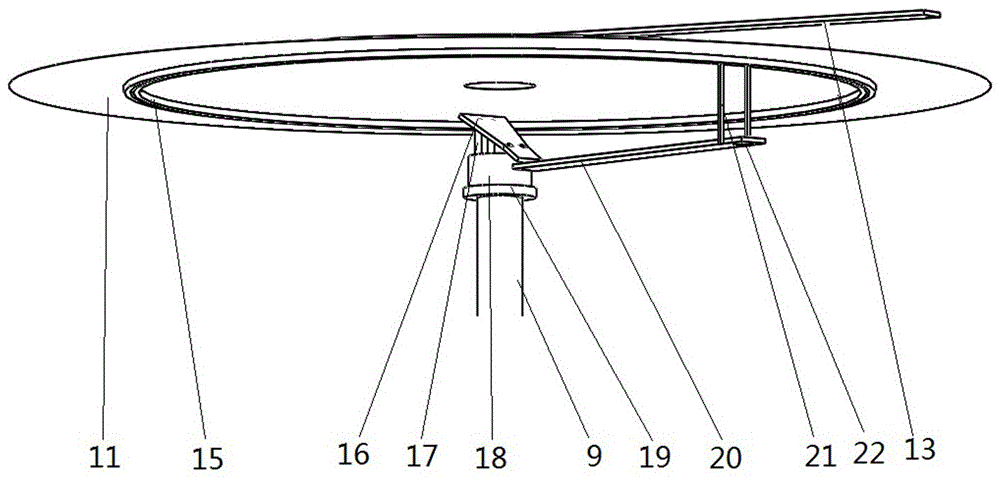

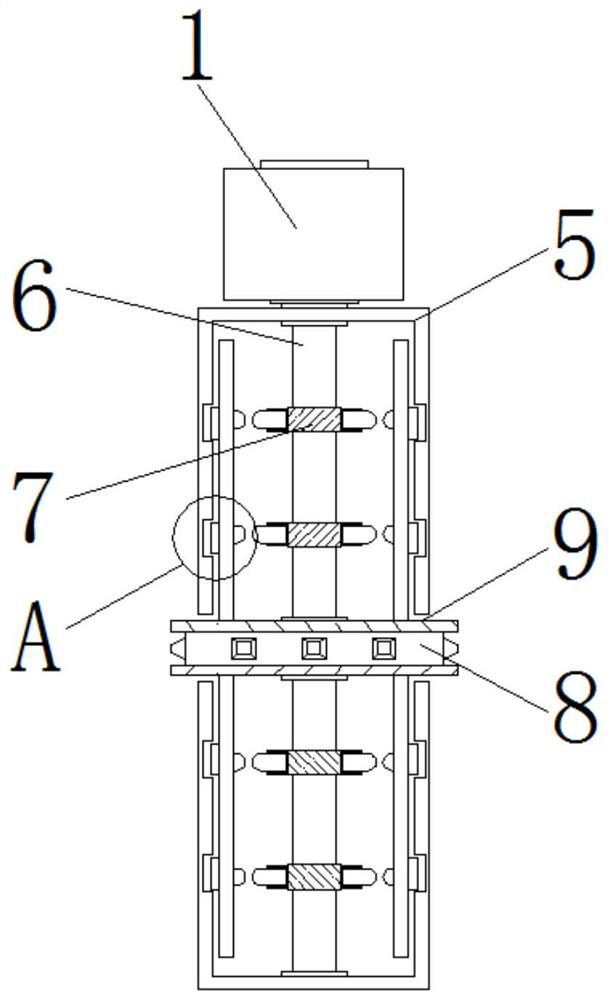

Rotary welding device

InactiveCN102357765BFlexible and balancedBlocking inertiaWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRotating disc

The invention discloses a rotary welding device, comprising a frame as well as a drive component and a rotary component which are fixed on the frame. The rotary welding device is characterized in that the rotary component comprises a fixed disk fixed on the frame and a rotary disk rotationally installed on the fixed disk; the fixed disk is also equipped with a support rolling device which comprises a riding wheel rotationally installed on the fixed disk; and the riding wheel is positioned between the fixed disk and the rotary disk and is matched with the rotary disk. The rotary disk is provided with a soft steel wire clamping slot on which a soft steel wire rope is sleeved, and two ends of the soft steel wire rope are respectively connected with the drive component. The rotary welding device disclosed by the invention is reasonable in design and reliable in performance, ensures that the rotary disk can rotate more flexibly in a more balanceable mode when loading the rotation of a large-sized workpiece, can obtain good welding quality, has high work efficiency, lightens labor intensity of workers, and is convenient and safe in operation and maintenance.

Owner:TONGLU TIANYUAN MECHANICAL & ELECTRICAL

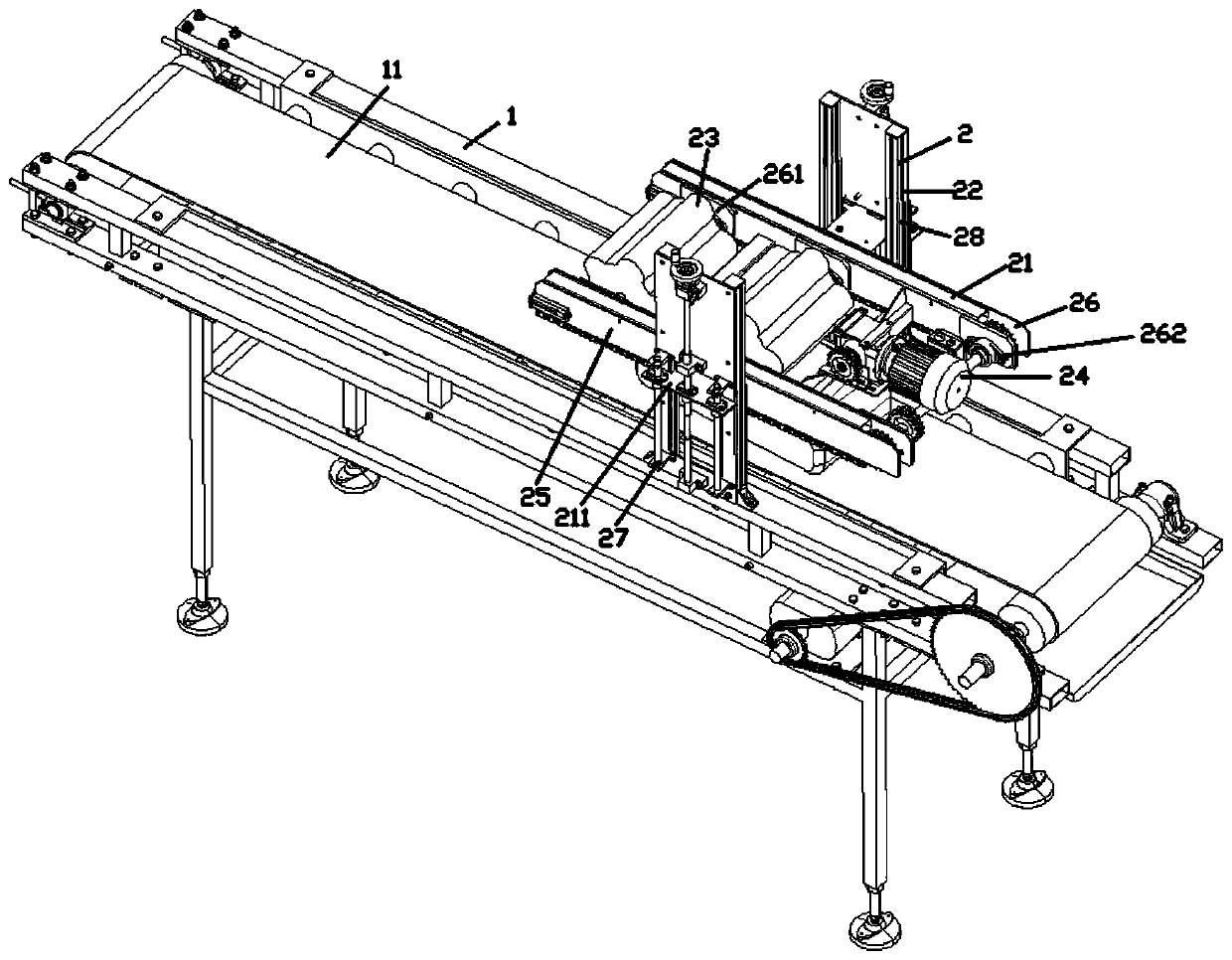

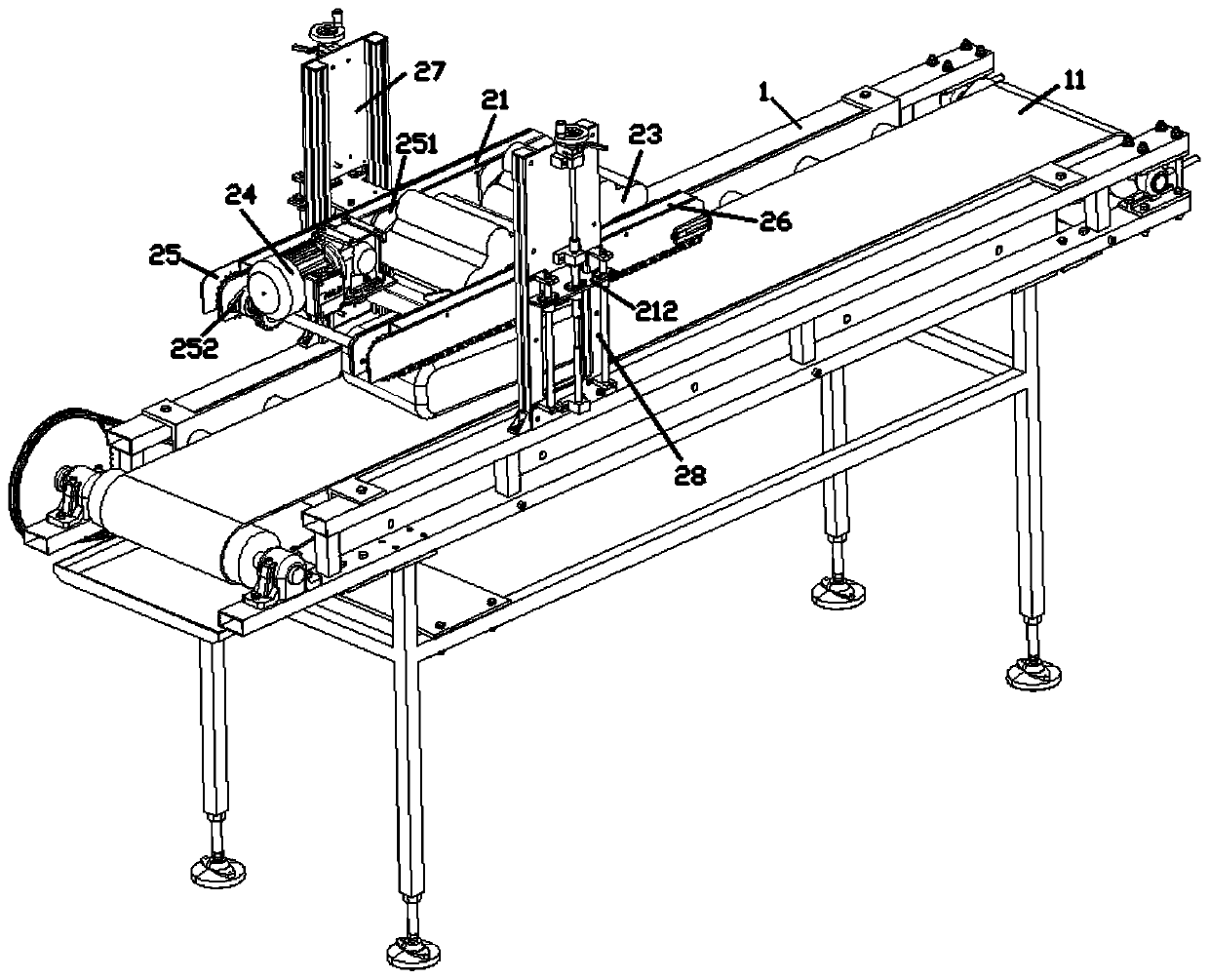

Packaging shaping machine

InactiveCN111071572ARotation speed adjustmentSolve difficultyPackaging machinesControl engineeringEngineering

The invention discloses a packaging shaping machine. The packaging shaping machine comprises a belt conveyor and a shaping mechanism arranged on the belt conveyor. The belt conveyor comprises a conveying belt. The shaping mechanism comprises a shaping support and a sliding mechanism. The shaping support is located above the conveying belt, the shaping support is connected with the sliding mechanism, and the shaping support is driven based on the sliding mechanism to move in the direction vertical to the conveying belt. At least one shaping part and a shaping part drive assembly are arranged inthe shaping support, shaping part connecting shafts of the shaping parts are hinged into the shaping support, the shaping part connecting shafts are connected with the shaping part drive assembly, and the shaping part connecting shafts are driven by the shaping part drive assembly to rotate in order to drive the shaping parts to rotate. According to the packaging shaping machine, the shaping heights of the shaping parts and the rotating speeds of the shaping parts can be adaptively adjusted, so that different shaping requirements are met, and high applicability is achieved.

Owner:华南智能机器人创新研究院 +1

Method for laying down at least an elastic element in a process for producing tyres for vehicles, process for producing tyres for vehicles and apparatus for laying down at least one elastic element

A method of laying down at least one elastic element in a process for producing tyres for vehicles includes the following steps: determining a first parameter representative of a laying speed at which at least one elastic element is laid down around a tyre forming drum; determining a second parameter representative of a percent elongation to be applied to the elastic element; adjusting, as a function of the first and second parameters, a rotation speed of a control roller positioned upstream of the forming drum and having a radially external surface at least partly in engagement with the elastic element for controlling the laying profile of the at least one elastic element. A process for producing tyres for vehicles and an apparatus for carrying out the laying method are also described.

Owner:PIRELLI TYRE SPA

Roller drive system of textile machinery

InactiveCN103103644ARotation speed adjustmentIncrease productivityDrafting machinesMotor driveGrating

The invention discloses a roller drive system of textile machinery. The roller drive system comprises a motor drive module and a roller, wherein the roller comprises an upper roller and a lower roller which are both in a cylindrical shape. The upper roller and the motor drive module are fixed on a support, and the motor drive module drives the lower roller to rotate. A grating ruler displacement sensor is arranged on the roller, and comprises a scale grating and a grating read head. The scale grating is fixed on the circular face of one end of the lower roller, and the grating read head is fixed on the support. According to rotation speed of the lower roller, power of the motor drive module is adjusted, and production efficiency is improved.

Owner:SUZHOU ZUNYUAN TEXTILE

Plastic pipe cutting equipment for household water feeding and drainage

InactiveCN109940676ARotation speed adjustmentQuick cutMetal working apparatusInterference fitWater leakage

Owner:杨勇武

Device and method used for detecting flake material infrared image printing quality

InactiveCN100498306CImprove claritySimple structurePaper-money testing devicesOptically investigating flaws/contaminationInformation processingEngineering

The present invention provides an equipment for detecting printed quality of infrared image of sheet material. Said equipment includes transmission device, lighting device, receiving device and information processing device. Said invention also provides the action of every device, and its method for detecting printed quality by using said equipment.

Owner:CHINA BANKNOTE PRINTING & MINTING

Active Elbow Joint Rehabilitation Machine

ActiveCN105148460BNo secondary damageSpeed up recoveryGymnastic exercisingHuman–machine interfaceEngineering

The invention relates to an active elbow joint rehabilitation machine, which includes a rotary pulling mechanism, a linear pulling mechanism and a human-machine interface mechanism; the linear pulling mechanism includes a sliding platform, a platform slide rail, a pull wire, a movable pulley, a fixed pulley, and a pull rod and a draw bar slot; the human-machine interface mechanism includes a forearm cuff and a forearm support; the platform slide rail is arranged on the bottom surface of the forearm support, and is matched and connected with the sliding platform, and the sliding platform can be placed on the The upper and lower surfaces of the sliding platform are respectively provided with the forearm cuff and the movable pulley; one end of the pull wire is fixed on the front part of the bottom surface of the forearm support, and the other end is bypassed The movable pulley then goes around the fixed pulley located on the bottom surface of the forearm support and is connected with the pull rod; the pull rod is arranged in the pull rod slot. The present invention does not cause secondary injury in the whole process of manual operation, and the manufacturing cost is low.

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com