Method for laying down at least an elastic element in a process for producing tyres for vehicles, process for producing tyres for vehicles and apparatus for laying down at least one elastic element

A technology of elastic elements and manufacturing methods, applied in tires, applications, home appliances, etc., can solve the problems of not being able to follow elastic elements, laying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

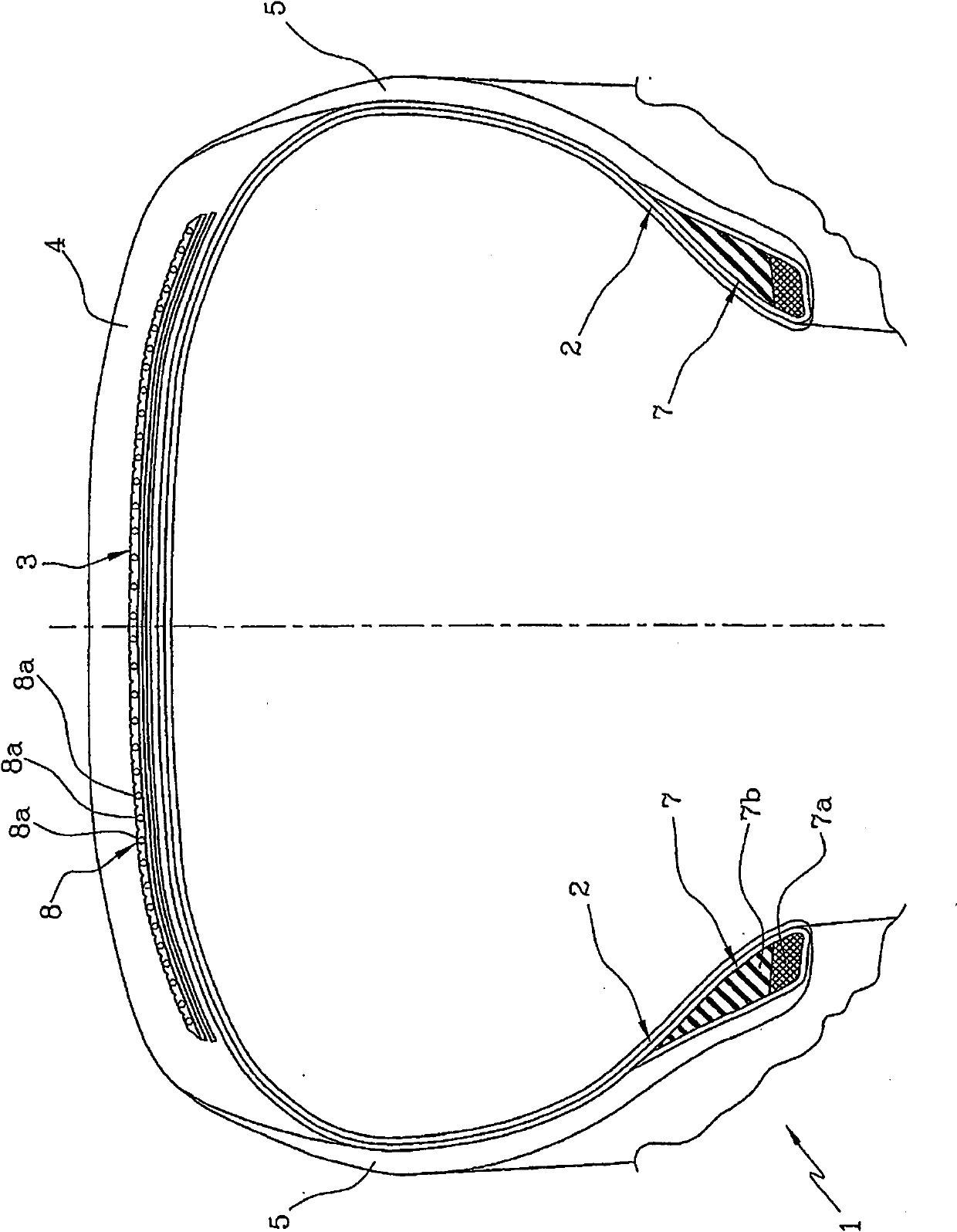

[0073] Referring to the accompanying drawings, a general-purpose tire manufactured using the control method and process of the present invention is generally indicated by 1 .

[0074] For the production of tires 1 ( figure 1 ), providing a carcass structure 2 and a belt structure 3 suitably associated with each other. Furthermore, a tread band 4 is associated outside said belt structure 3 .

[0075] At the radially inner end of the carcass structure 2, a so-called bead 7 may be produced in association with a filler insert 7b, within which at least one "bead core" 7a is provided.

[0076] Applied to the side surfaces of the carcass structure 2 are sidewalls 5 of elastomeric material, each sidewall 5 extending from one side edge of the tread band 4 to a corresponding bead 7 .

[0077] It should be understood that the radially outer end of each sidewall 5 may be interposed between the edge of the tread band 4 and the carcass ply 6 ("underside sidewall" type configuration), or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com