Device and method used for detecting flake material infrared image printing quality

A sheet material and image detection technology, applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of unfavorable large banknote printing quality detection, no image processing device disclosed, and high-speed production cannot be satisfied. , to achieve the effect of improving uniformity and clarity, simple structure and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

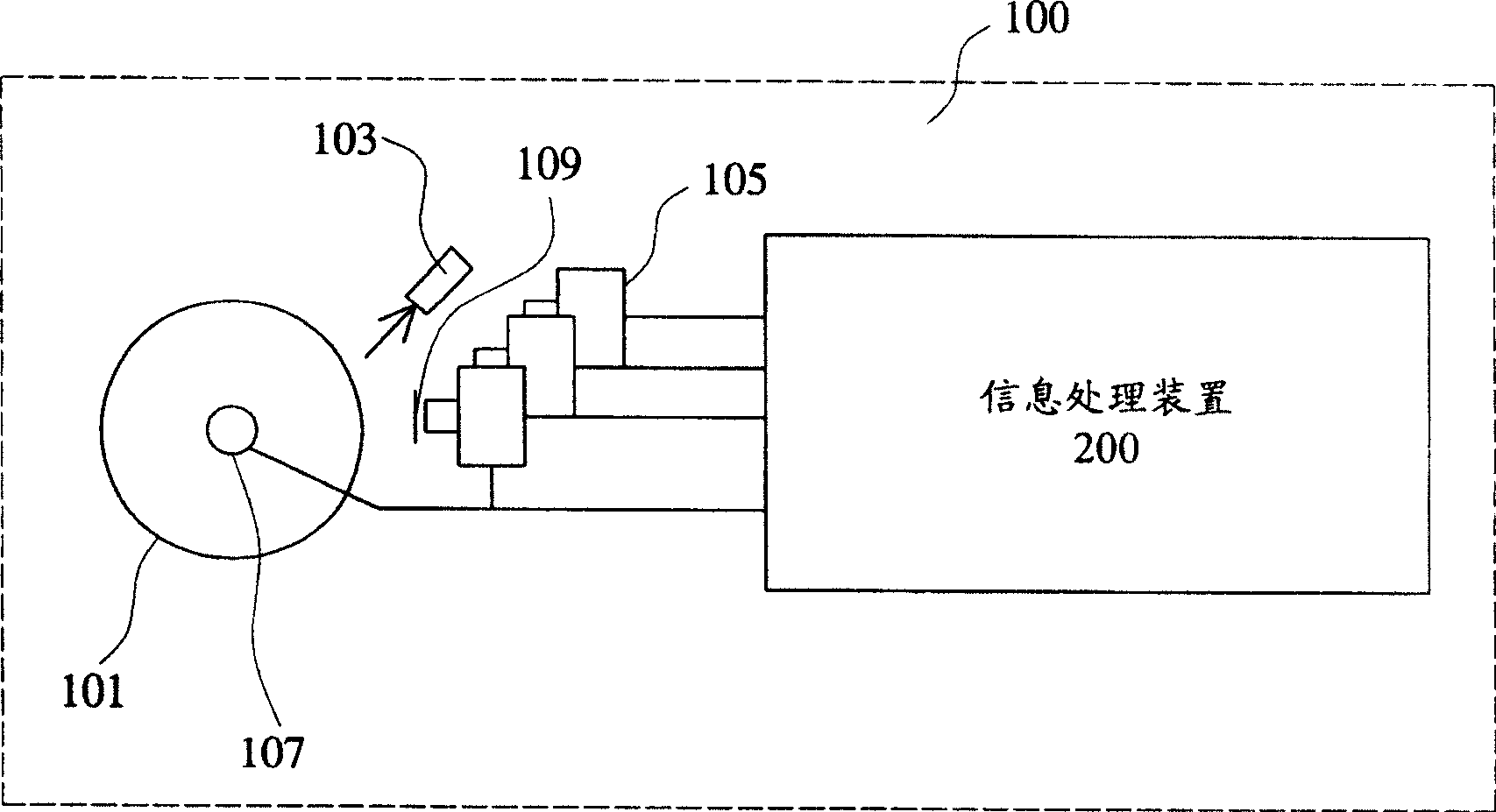

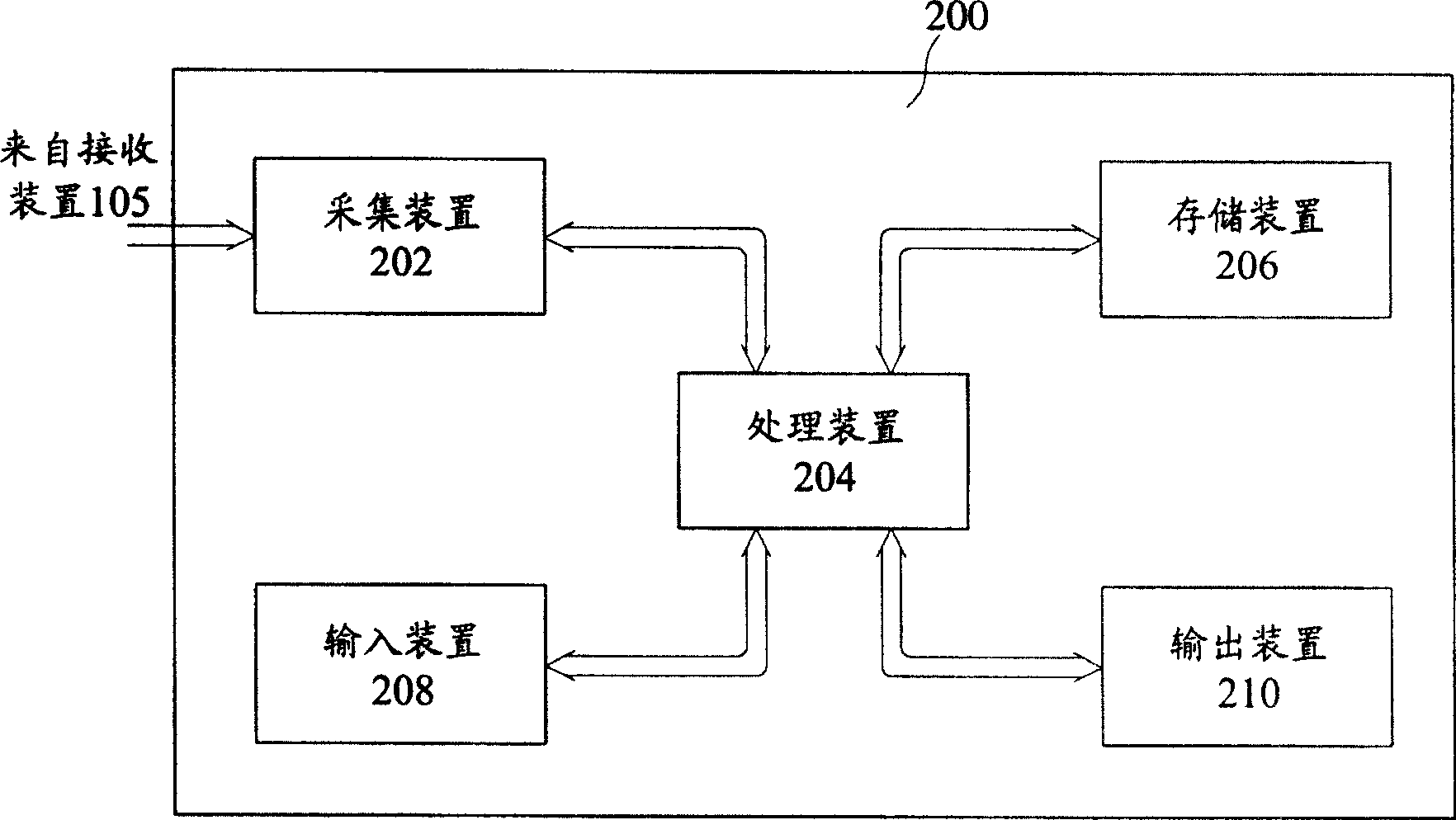

[0042] The invention will now be described with reference to the accompanying drawings, figure 1 It is a schematic diagram of the structure of the detection device disclosed in the present invention. The detection device 100 includes a transmission device 101 , an irradiation device 103 , a receiving device 105 , and an information processing device 200 . The transmission device 101 is provided with an encoder 107 for making the transmission device 101 , the irradiation device 103 and the receiving device 105 work synchronously. The sheet material is placed on the transport device 101 . The receiving device 105 is provided with an infrared filter 109 for transmitting infrared light. The illuminating device 103 irradiates light onto the sheet material located on the conveying device 101, the receiving device 105 receives the infrared light reflected or diffused from the sheet material, and converts it into a detection image, and the information processing device 200 receives ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com