Apparatus and method for detecting sheet-like material

A sheet material and image detection technology, applied in the direction of measuring devices, material analysis, and material analysis through optical means, can solve problems such as inability to inspect, inability to detect the quality of laser coding holes, and reduce the accuracy of paper defect detection, etc., to achieve Improve detection accuracy, reduce accuracy requirements, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

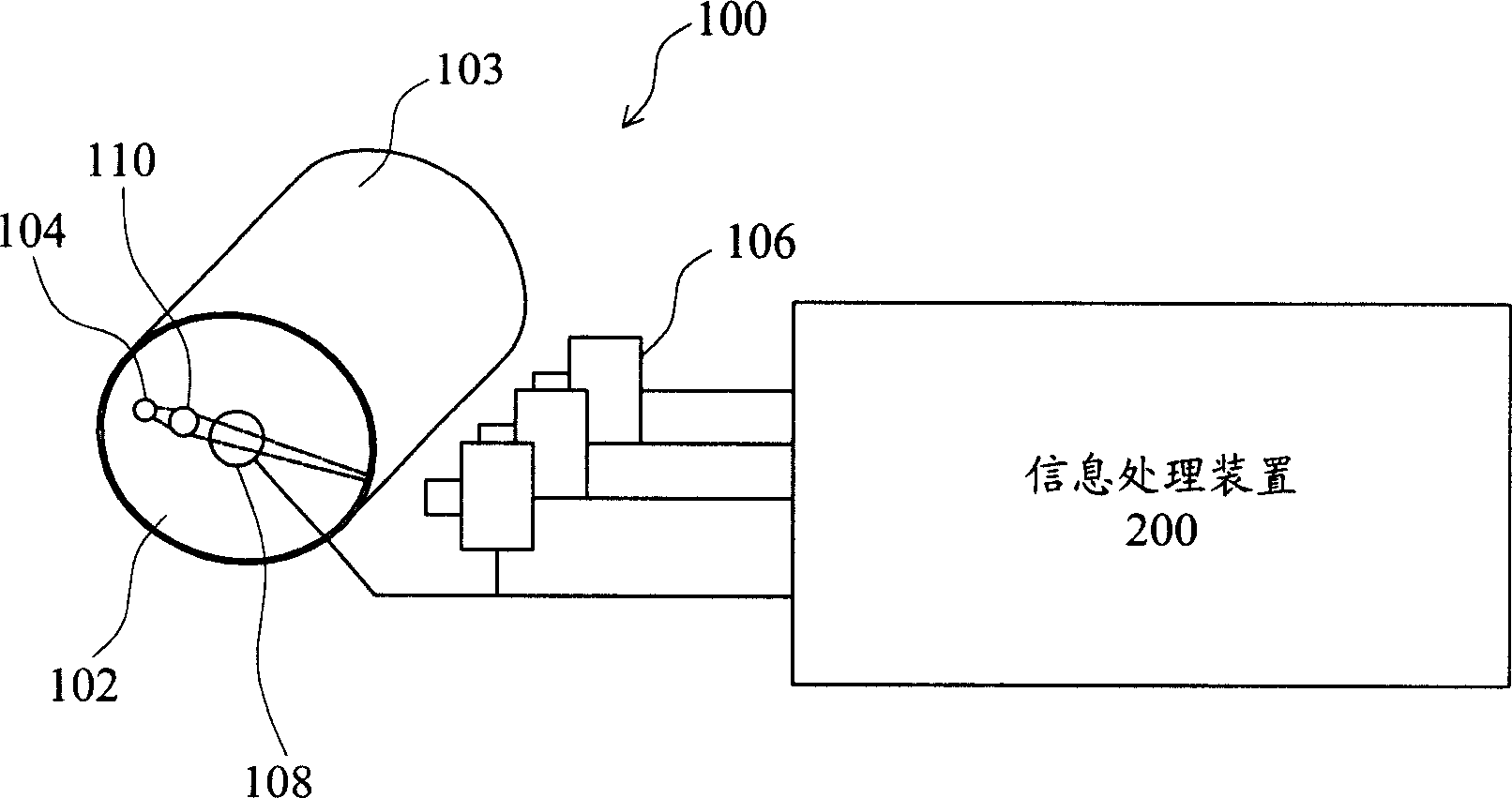

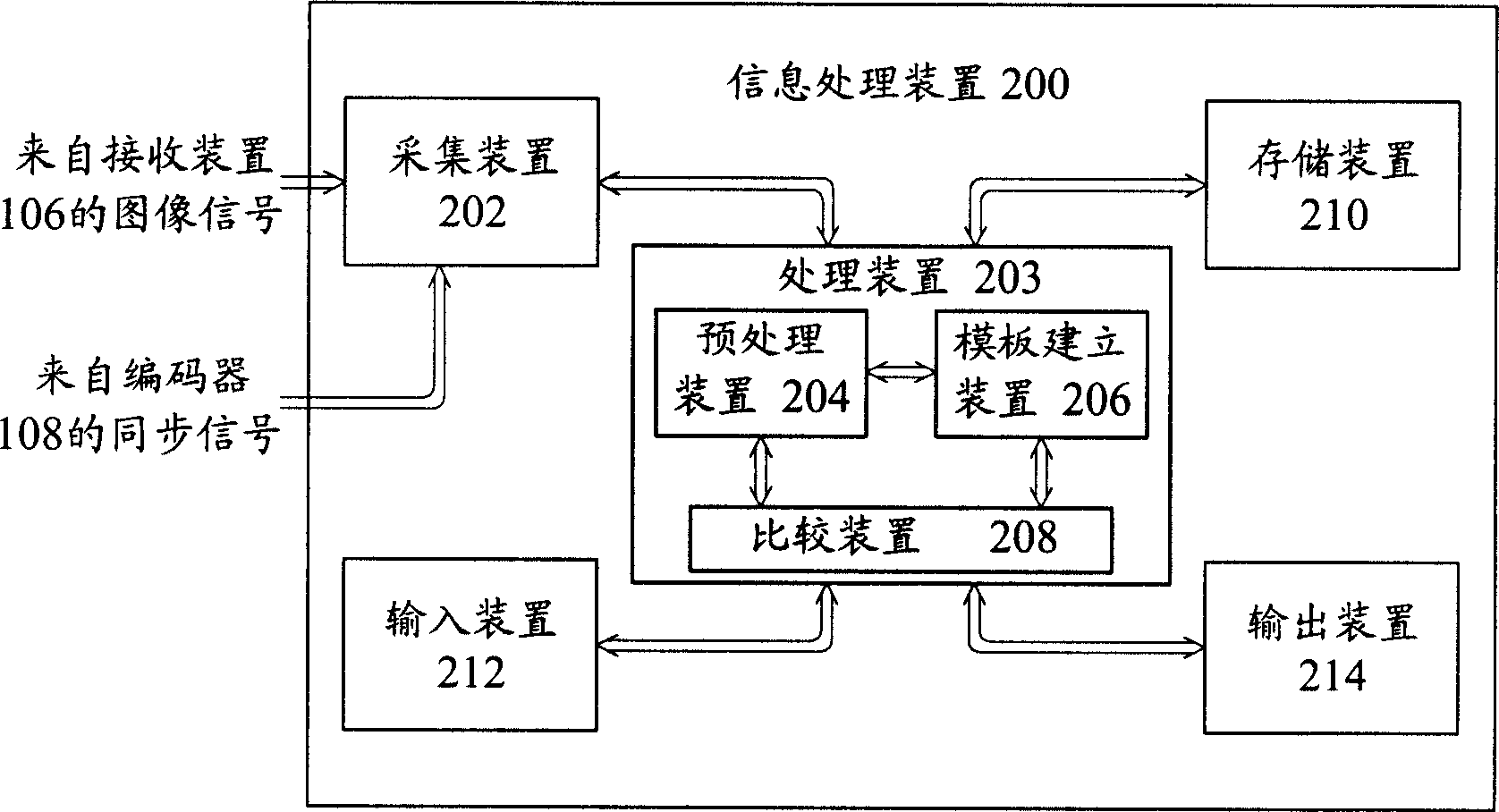

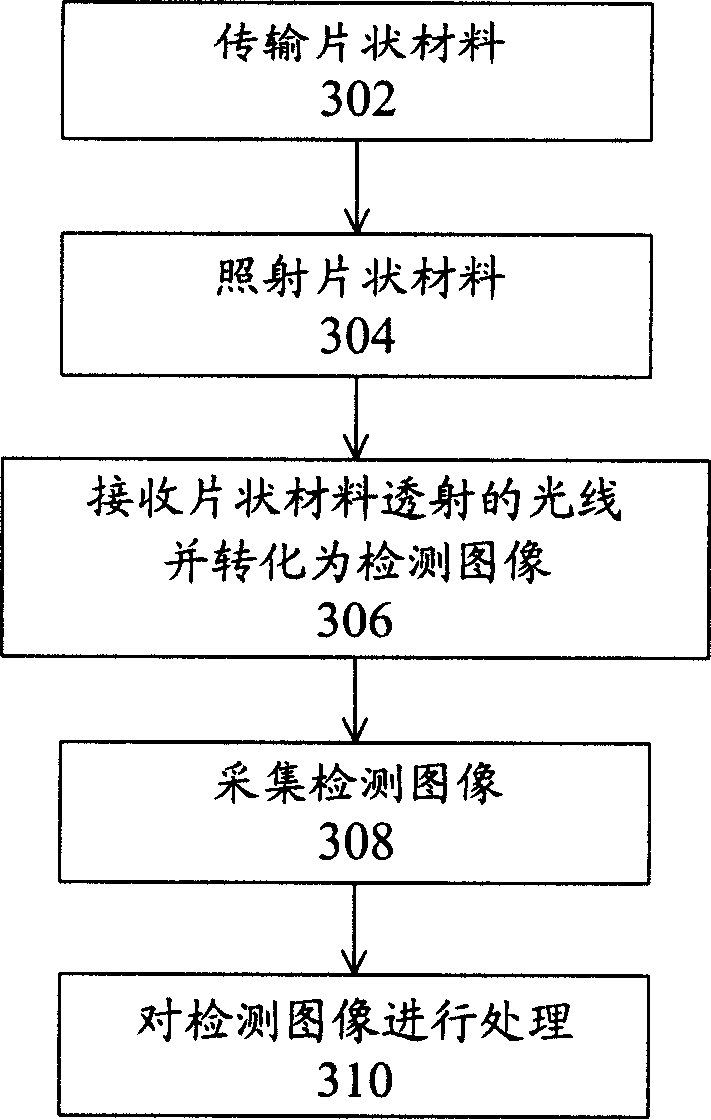

[0037] The invention will now be described with reference to the accompanying drawings. figure 1 is a schematic structural diagram of the detection device 100 according to the present invention. The detection device 100 includes: a transport device 102, used to carry and transport a sheet material 103; an irradiation device 104, arranged on one side of the sheet material, for irradiating light onto the sheet material; a receiving device 106, arranged on The other side of the sheet material 103, opposite to the transmission device 102, is used to receive the light transmitted from the sheet material, and convert the received light into a corresponding detection image; the information processing device 200 is used to collect and The inspection image is processed and compared to the template to inspect the quality of the transmission image of the sheet material. The template establishment process is as follows. Before the detection, a template needs to be established. Through vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com