Rotating direction conversion mechanism of cutter assembly of front mounted ditching machine

A technology of rotating direction and switching mechanism, which is applied in the direction of tillage implements, agricultural machinery and implements, etc. It can solve problems such as easy blockage, heavy ditching machine load, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

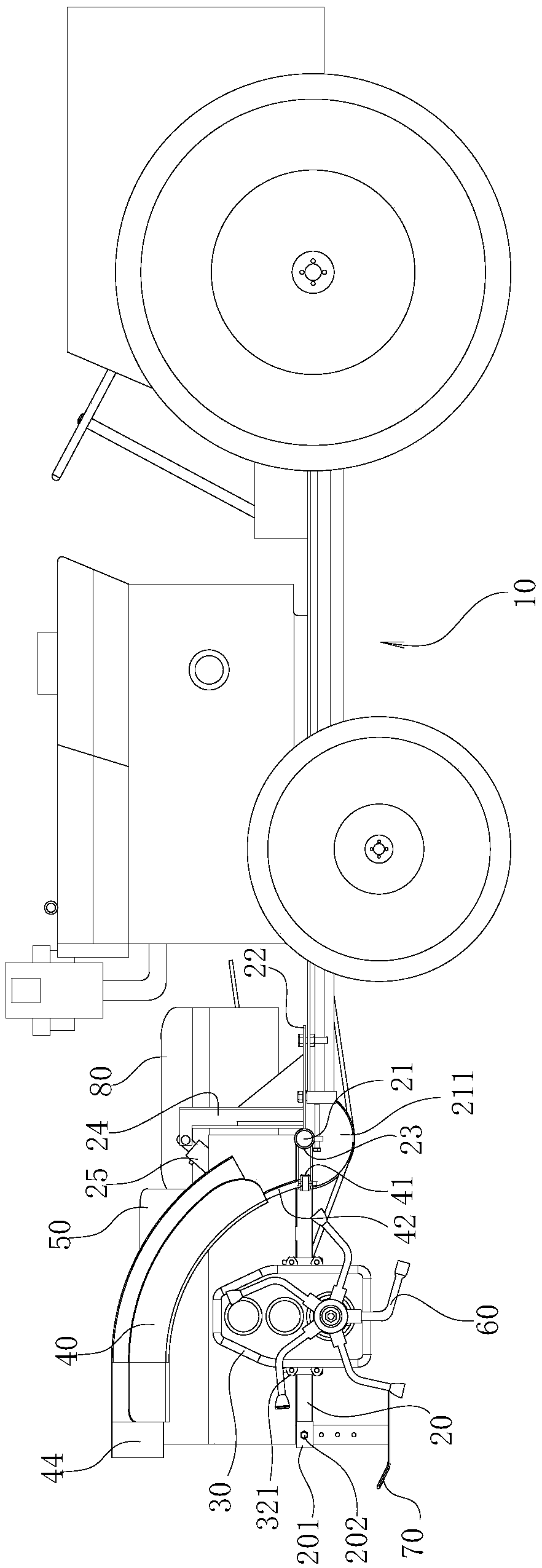

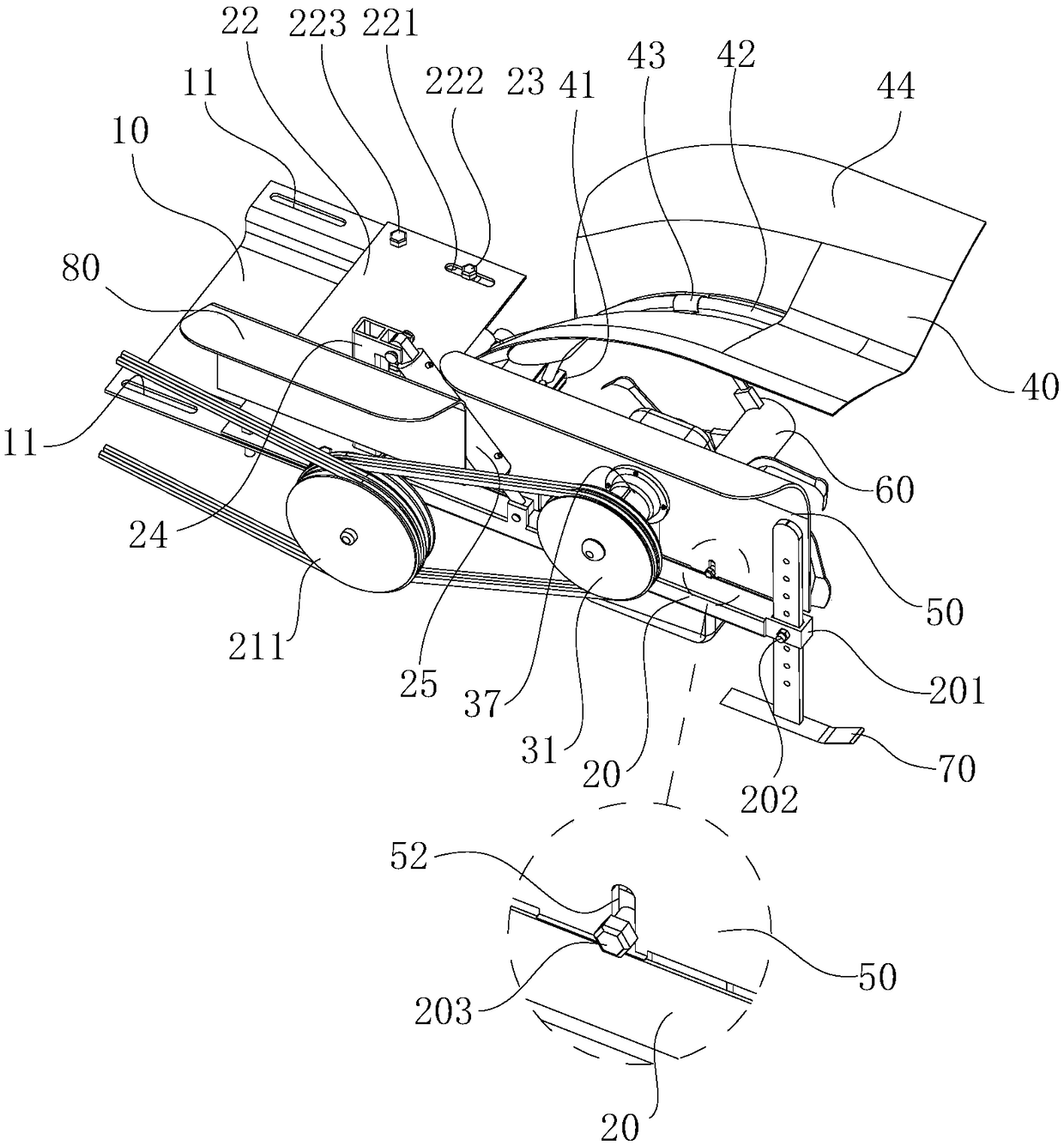

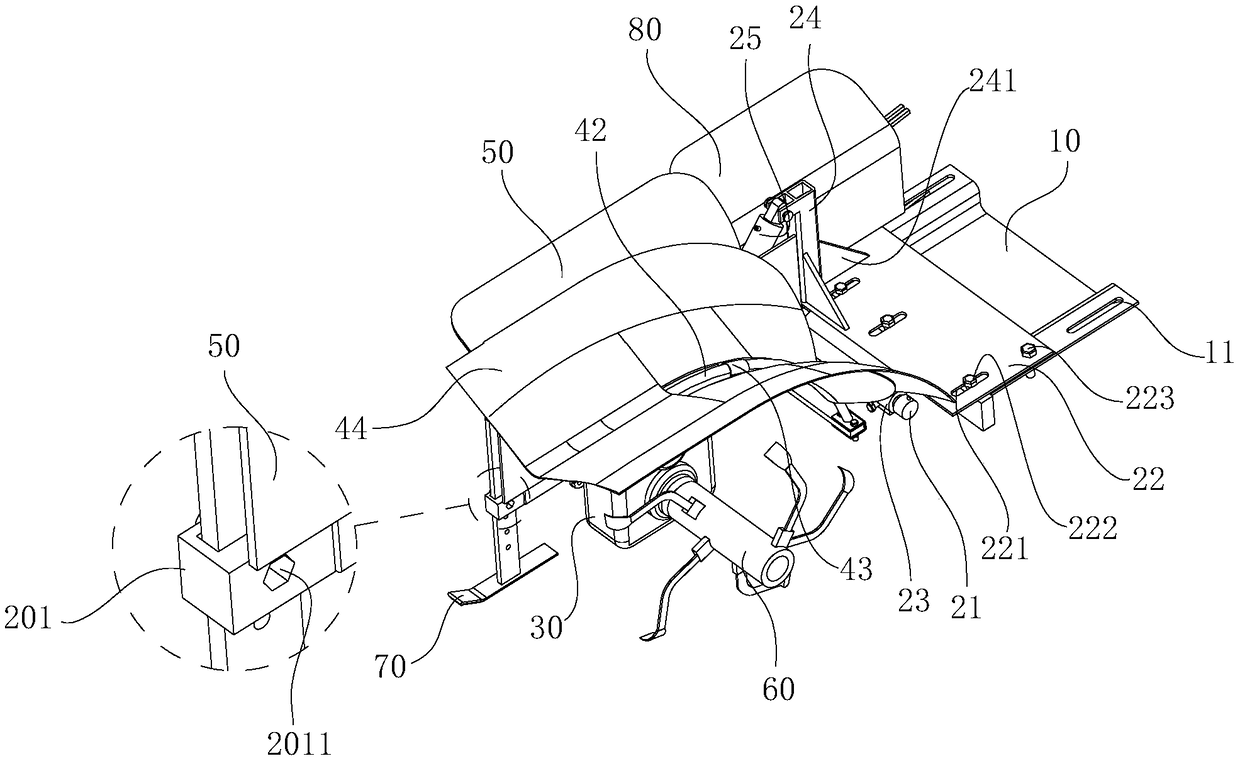

[0021] refer to Figure 1 to Figure 7 , the characteristics of the tool assembly rotation direction conversion mechanism of this front-mounted ditching machine are described in detail as follows:

[0022] The following is a detailed description of the tool assembly rotation direction conversion mechanism of the front-mounted ditcher of the present invention in conjunction with the entire front-mounted ditcher:

[0023] The front-mounted ditching machine includes a frame 20 hingedly connected to the front end of the four-wheel tractor 10, the hinge axis of the frame 20 is horizontal and the length direction is perpendicular to the vehicle length direction of the four-wheel tractor 10, and the frame 20 is provided with There is a gearbox 30, the input shaft of the gearbox 30 is connected with the driving wheel of the four-wheel tractor 10 through a transmission mechanism, the output shaft of the gearbox 30 is provided with a ditching tool assembly 60, and the four-wheel tractor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com