Apparatus for homogenization and separation of samples

A technology of homogenization and equipment, applied in chemical instruments and methods, centrifuges, transportation and packaging, etc., can solve problems such as leakage of lubricants, leaks in seals, damage to gear units, etc., to achieve long operating time, high centrifugal force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

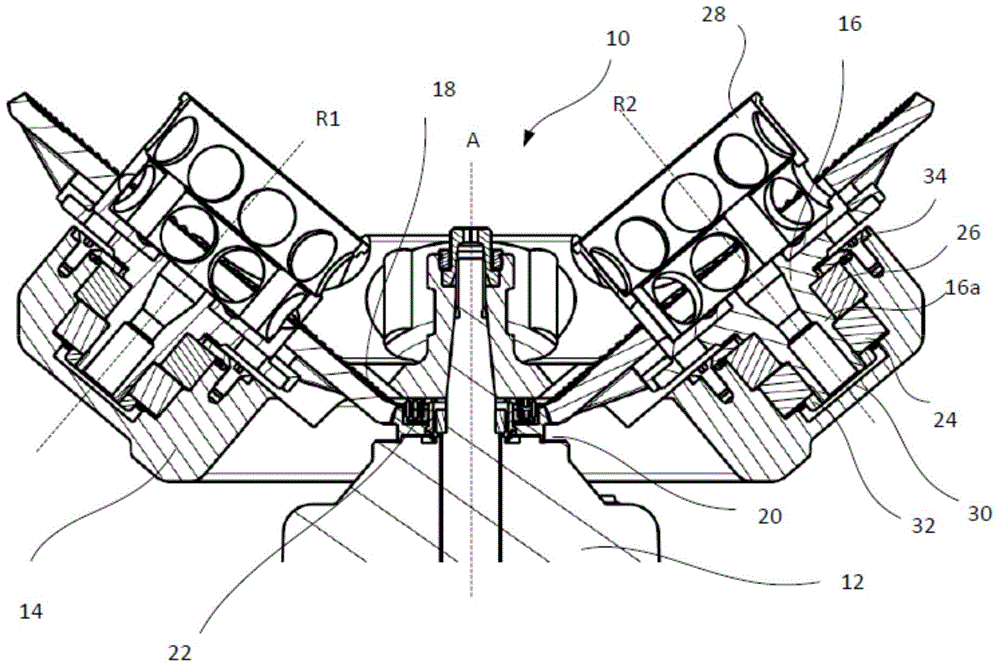

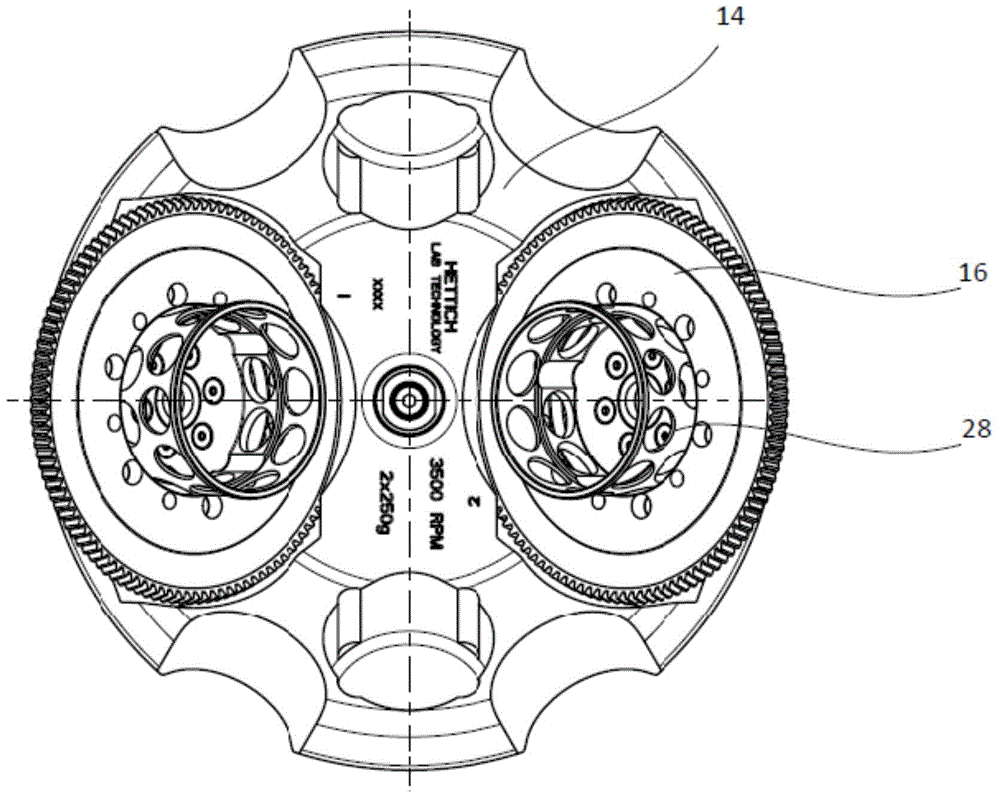

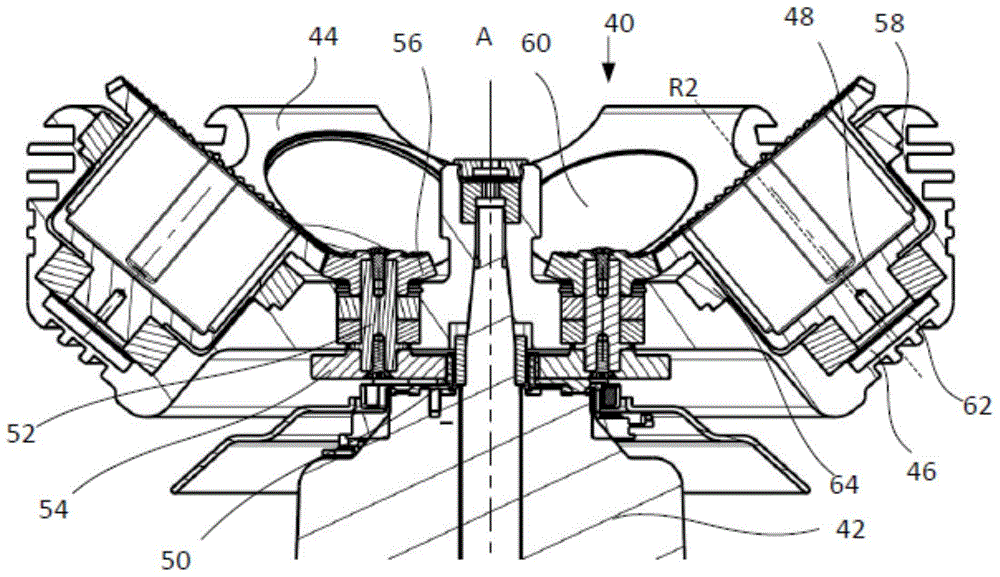

[0101] figure 1 The view in FIG. 2 shows a double centrifuge 10 for homogenization and separation of media, which comprises a centrifuge motor 12 and a centrifuge rotor 14 . The centrifuge rotor 14 rotates about an axis A corresponding to the drive shaft of the centrifuge motor 12 . The centrifuge rotor 14 is connected to a rotation unit 16 mounted rotatably about rotation axes R1 , R2 of the rotation unit. The rotary units 16 have on their peripheral parts gear teeth 18 which mesh with a gear 22 which is non-rotatably mounted on the centrifuge motor housing 20 . Rotation of the centrifuge rotor 14 relative to the motor 12 about the motor axis A will cause the rotation units 16 to rotate about their rotation unit axes R. FIG. Each rotating unit 16 is mounted in a recess 30 in the centrifuge rotor 14 which is provided in the centrifuge rotor 14 specifically for the purpose of mounting the rotating unit, each rotating unit 16 being inserted into two bearings 24 , 26 (the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com