Special N-phthalate reinforced soft polyethylene plastics for circulation loop and preparation method thereof

A soft polyvinyl chloride, recycling loop technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

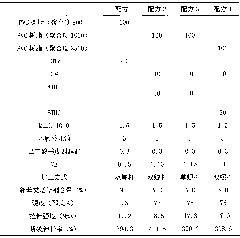

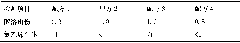

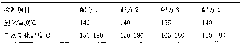

Examples

Embodiment 1

[0026] A special non-phthalic plasticized soft polyvinyl chloride plastic for circulation circuit, which includes the following components in parts by weight:

[0027] PVC resin powder 100 parts by weight ATBC 20 parts by weight

[0028] Epoxidized soybean oil 5 parts by weight Calcium-zinc compound salt 0.5 parts by weight

[0029] 0.1 parts by weight of phenylmethyl silicone oil, 0.1 parts by weight of butyl hyperglycinol (BHA)

[0030] A kind of preparation method of non-orthophthalic plasticized soft polyvinyl chloride plastics special for circulation circuit, the specific steps of the method are as follows:

[0031] 1) With 100 parts by weight of PVC resin powder, 20 parts by weight of ATBC, 5 parts by weight of epoxy soybean oil, 0.5 parts by weight of calcium-zinc compound salt, 0.1 part by weight of benzyl silicone oil, butyl hysteryl fungal ether (BHA) 0.1 parts by weight, mix at a low speed of 100r / min for 6 minutes, then mix at a high speed of 500r / min for 6 minut...

Embodiment 2

[0035] A special non-phthalic plasticized soft polyvinyl chloride plastic for circulation circuit, which includes the following components in parts by weight:

[0036] PVC resin powder 100 parts by weight DOA 35 parts by weight

[0037] Epoxy tall oil 20 parts by weight Tin-zinc 3 parts by weight

[0038] Stearyl alcohol 1 weight part Propyl gallate (PG) 0.6 weight part

[0039] A kind of preparation method of non-orthophthalic plasticized soft polyvinyl chloride plastics special for circulation circuit, the specific steps of the method are as follows:

[0040] 1) 100 parts by weight of PVC resin powder, 35 parts by weight of DOA, 20 parts by weight of epoxy tallow oil, 3 parts by weight of tin-zinc, 1 part by weight of stearyl alcohol, 0.6 parts by weight of propyl gallate (PG) , first mix at low speed 100r / min for 6 minutes, then mix at high speed 500r / min for 6 minutes, discharge and cool;

[0041] 2) Cool the raw materials to 80°C, add them into the hopper of a twin-scr...

Embodiment 3

[0044] The invention provides a special non-orthophthalic plasticized soft polyvinyl chloride plastic for a circulation loop, which comprises the following components in parts by weight:

[0045] PVC resin powder 100 parts by weight DOTP 50 parts by weight

[0046] Epoxy monoglyceride 35 parts by weight Tin-calcium 5.0 parts by weight

[0047] Ethylene glycol distearate 2.0 parts by weight Vitamin E (VE) 1.0 parts by weight

[0048] A kind of preparation method of non-orthophthalic plasticized soft polyvinyl chloride plastics special for circulation circuit, the specific steps of the method are as follows:

[0049] 1) 100 parts by weight of PVC resin powder, 50 parts by weight of DOTP, 35 parts by weight of epoxy monoglyceride, 5.0 parts by weight of tin-calcium, 2.0 parts by weight of ethylene glycol distearate, 1.0 parts by weight of vitamin E (VE) For each part, first mix at a low speed of 100r / min for 6 minutes, then mix at a high speed of 500r / min for 6 minutes, discharge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com