Anti-breakage wire stranding machine

A twisting machine and anti-broken technology, which is applied to conductor/cable supply devices, electrical components, circuits, etc., can solve the problems that it is difficult to ensure the reliability of twisted wire cores for operators, and consumes a lot of manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

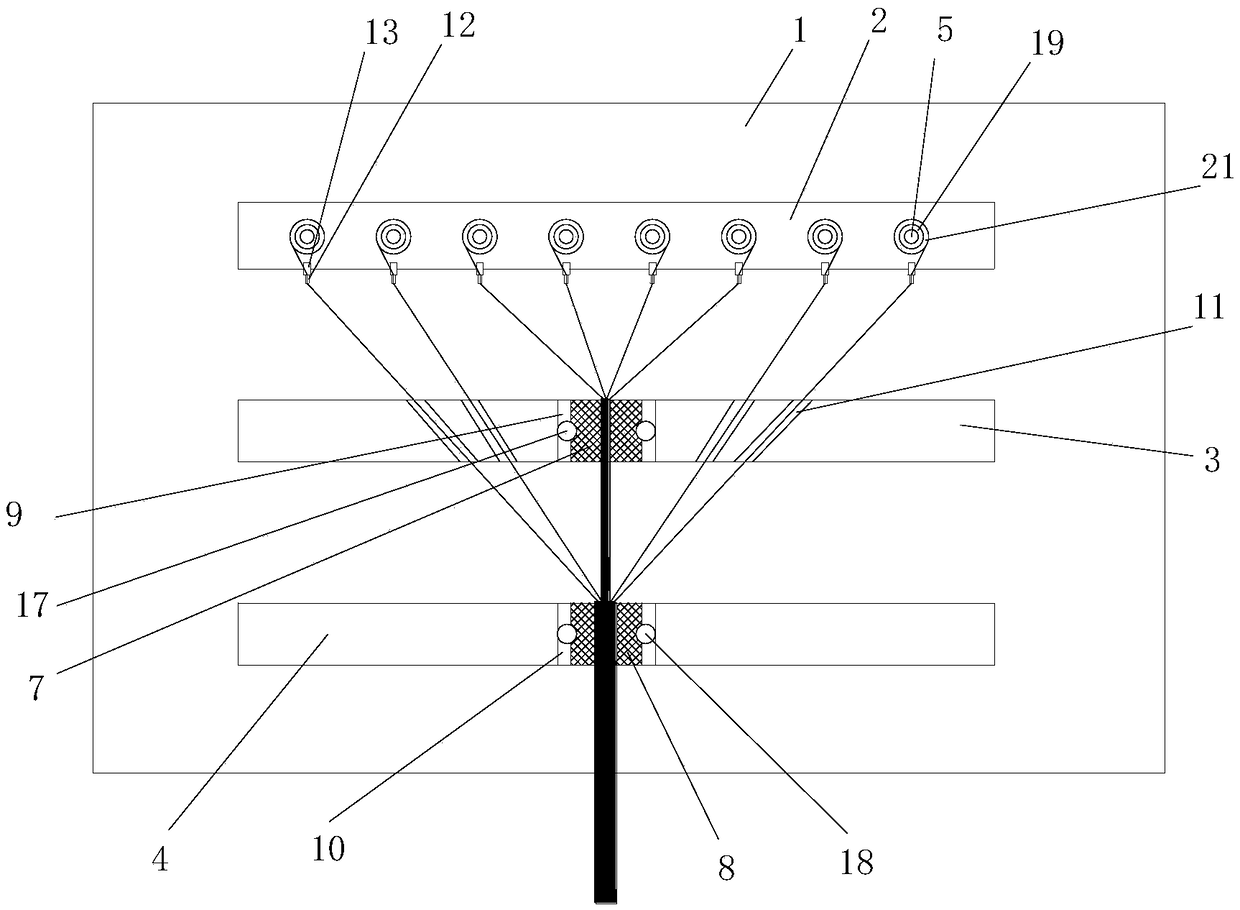

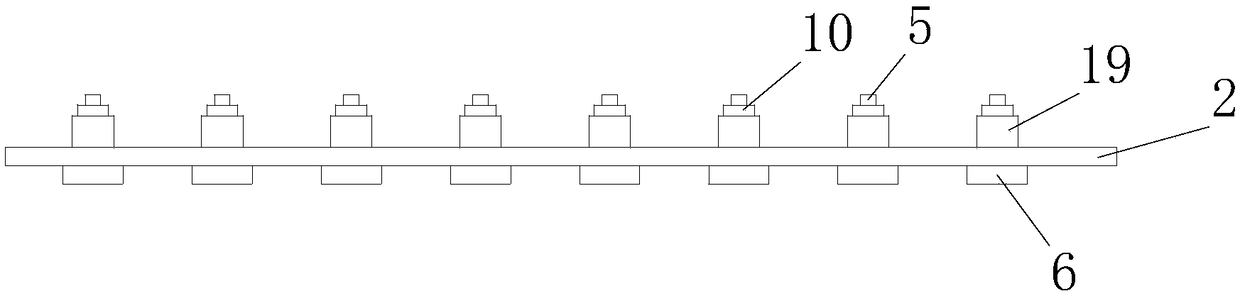

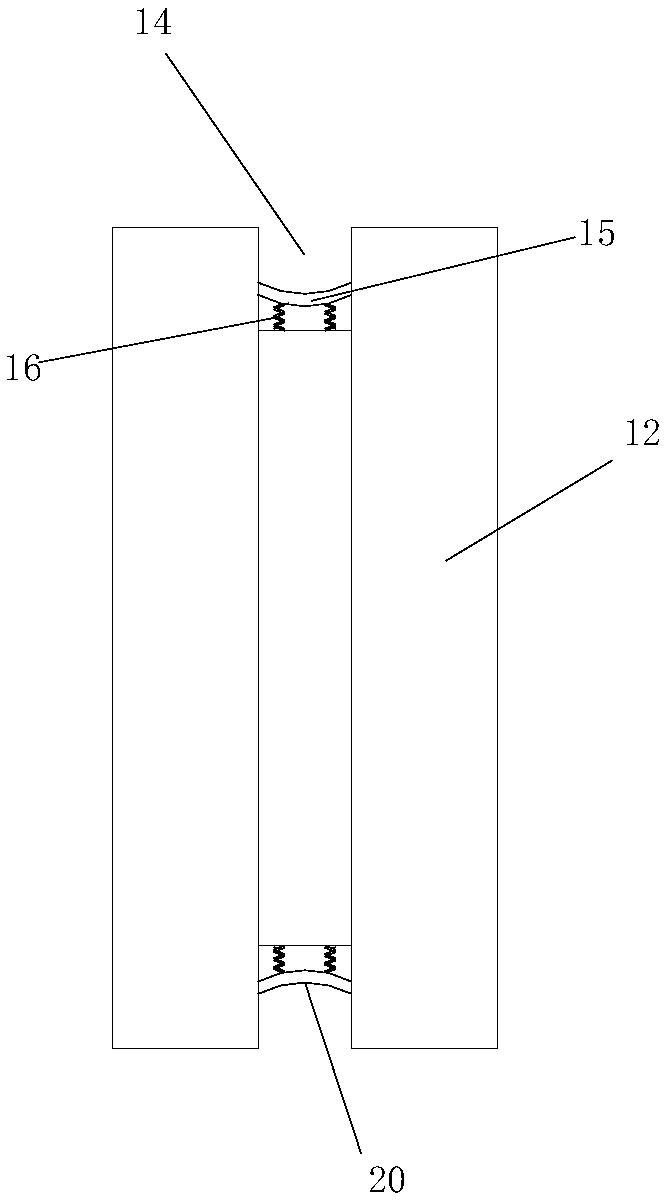

[0020] Such as Figure 1-Figure 3 as shown, figure 1 It is a structural schematic diagram of an anti-breakage stranding machine proposed by the present invention; figure 2 It is a structural schematic diagram of the pay-off reel in a kind of anti-broken wire stranding machine proposed by the present invention; image 3 It is a structural schematic diagram of a guide wheel in a wire breakage prevention stranding machine proposed by the present invention.

[0021] refer to Figure 1-Figure 3 , the present invention proposes an anti-broken wire stranding machine, including a workbench 1, a pay-off frame 2, a first strand frame 3, a second strand frame 4, a plurality of pay-off shafts 5, a plurality of drive mechanisms 6, A plurality of guide assemblies, a first strand die 7 and a second strand die 8, wherein:

[0022] The pay-off frame 2, the first strand frame 3, and the second strand frame 4 are arranged in parallel and sequentially. The pay-off frame 2, the first strand f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com