Circular aging bunker

A circular and cloth belt technology, applied in the field of circular aging warehouse, can solve the problems of inability to flexibly adjust the cloth and materials, affect the quality of the produced bricks, and can not be handled well, so as to reduce site selection requirements and reclaim materials. Convenience and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

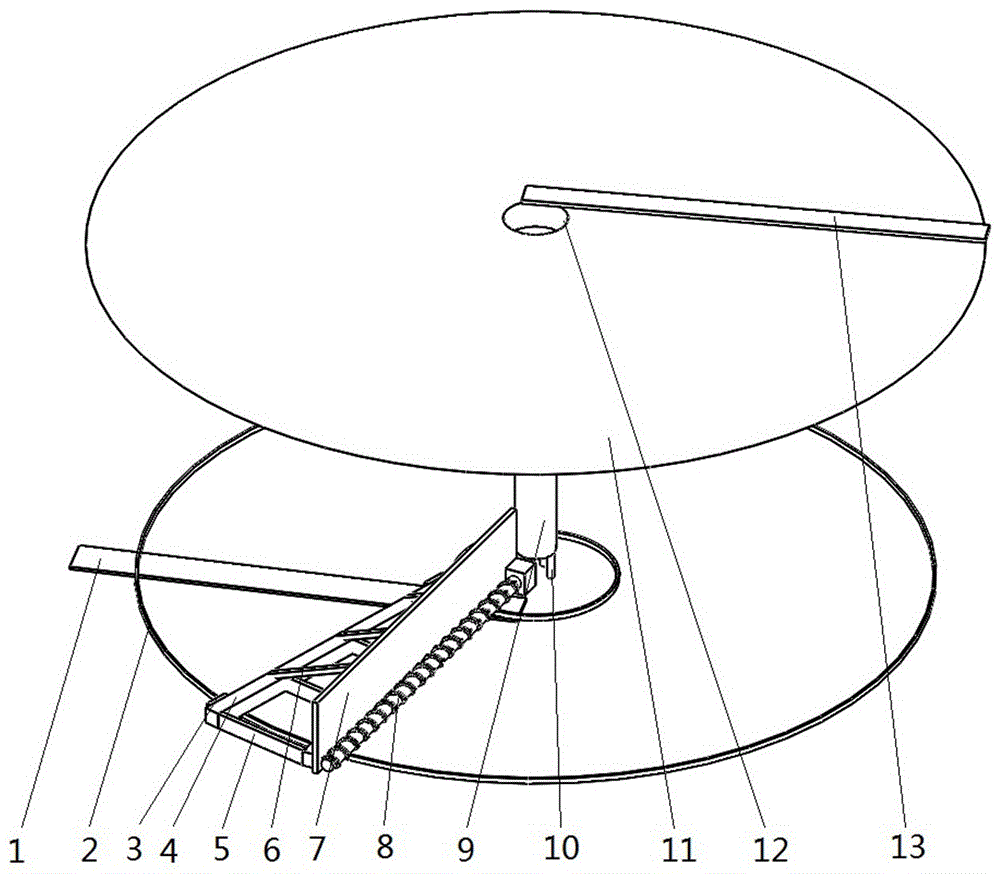

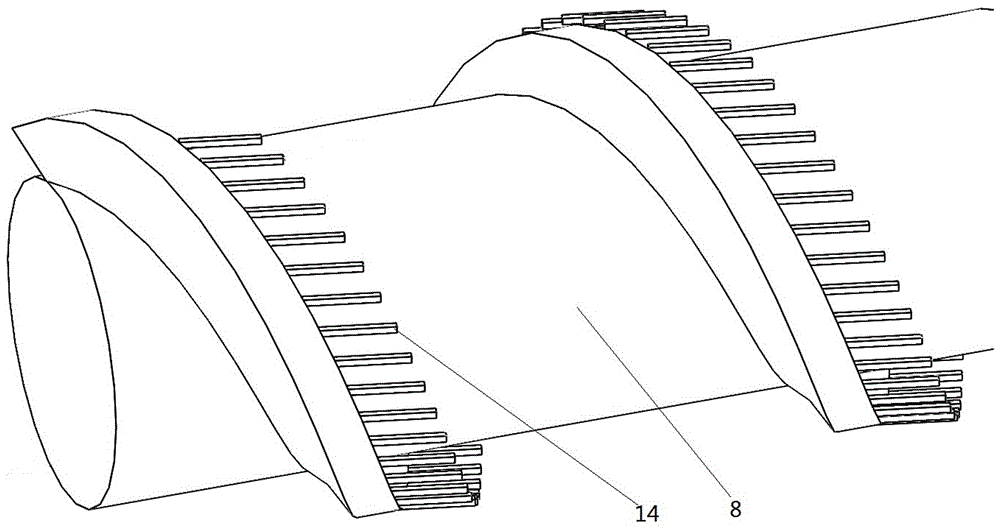

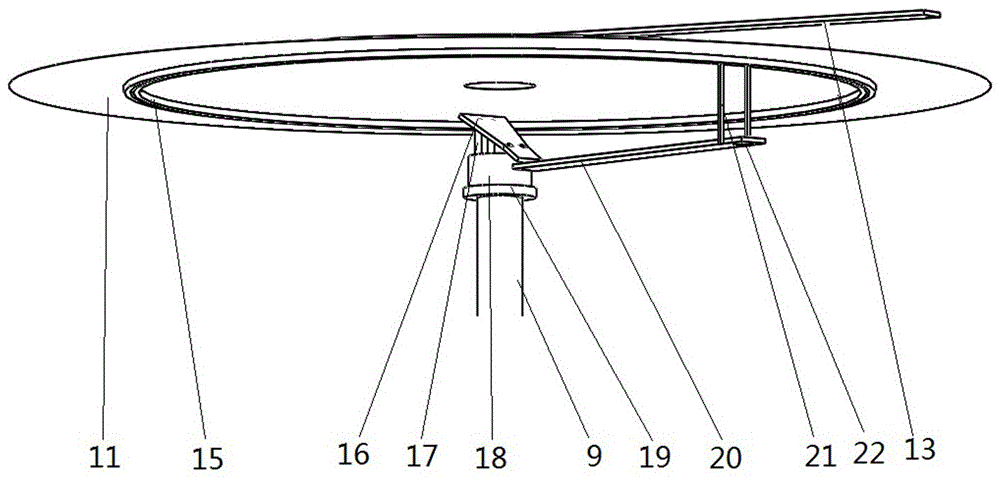

[0020] Example 1, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a circular aging bin includes a ceiling 11, a feeding belt 13, a cloth belt 20, a feeding belt 1 and a column 9, and is characterized in that: the feeding belt 13 is arranged above the ceiling 11, and the center of the ceiling 11 A hole 12 is provided at the center, the outlet of the feed belt 13 is directly above the hole 12, and a blanking plate 16 is arranged directly below the hole 12, the entrance of the cloth belt 20 is directly below the blanking plate 16, and the outlet of the cloth belt 20 A hanging rod 21 is arranged at the top of the hanging rod 21, and a track 15 is arranged on the ceiling 11 directly above the hanging rod 21; a distance measuring sensor 22 is arranged on the bottom of the outlet of the cloth belt 20; A support 17 is provided between the plate 16 and the rotating frame 18; a supporting frame 19 is provided on the top of the column 9, and the supporting frame 19 sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com