Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reliable equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resistive current tester for great current zinc oxide lightning arrester

ActiveCN101403777AReduce hardware overheadReliable equipmentElectrical testingMeasurement using digital techniquesVoltage sensorZinc

The invention provides a large-current ZnO arrester resistant current testing instrument, comprising a digital signal processor. A voltage channel is formed by the sequential cascading of a voltage sensor, a filter amplification circuit and an AD converter, a voltage signal is led out from a PT secondaly side by a voltage testing wire and is transmitted to the digital signal processor after processing; a current passage is formed by the sequential cascading of a current transmitter, a filter amplification circuit and an AD converter, a current signal is taken out from a discharging counter at the lower end of the arrester and is transmitted the current signal to the digital signal processor after processing. The current testing instrument has the advantages of high testing precision, convenient usage and safety and reliability.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +2

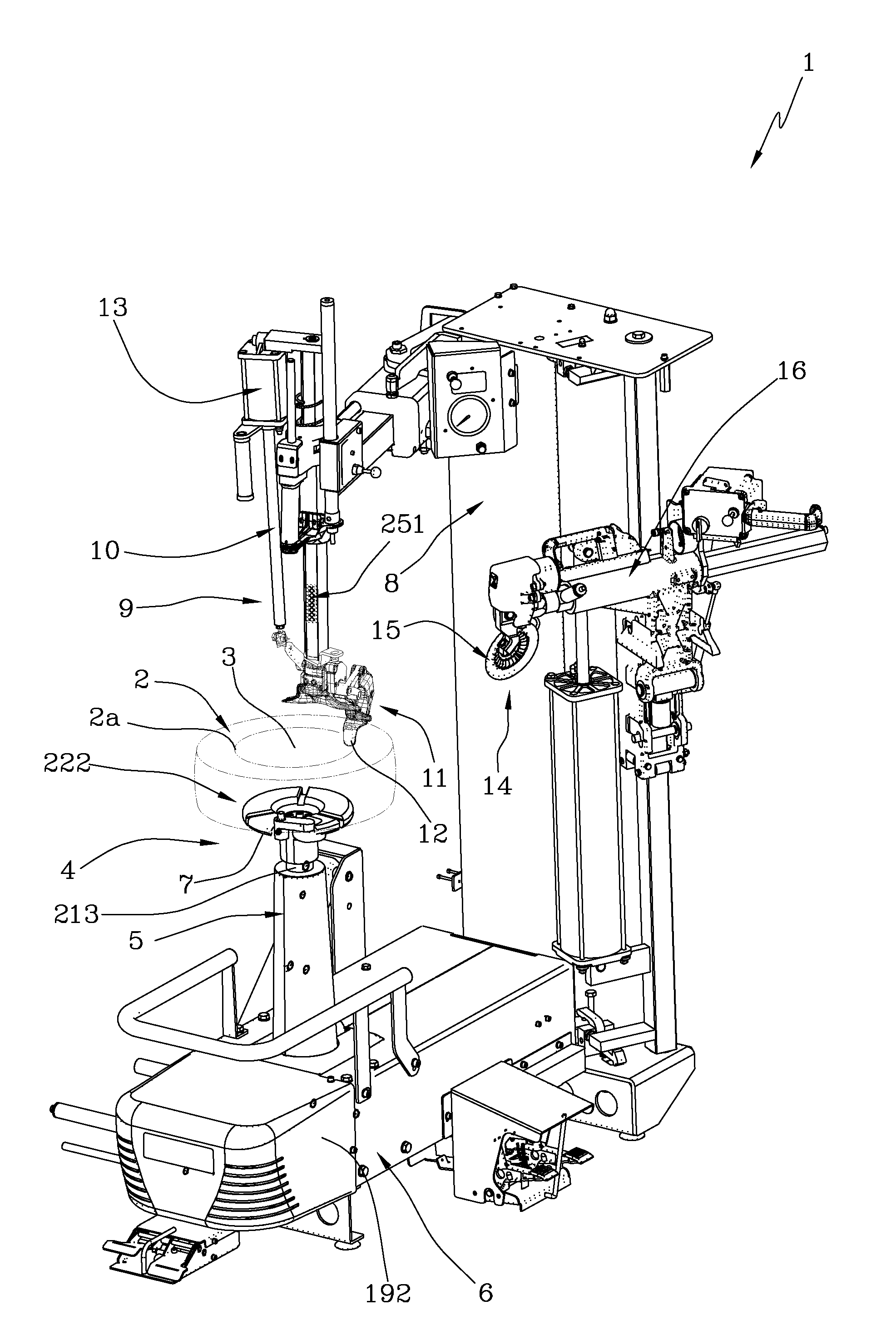

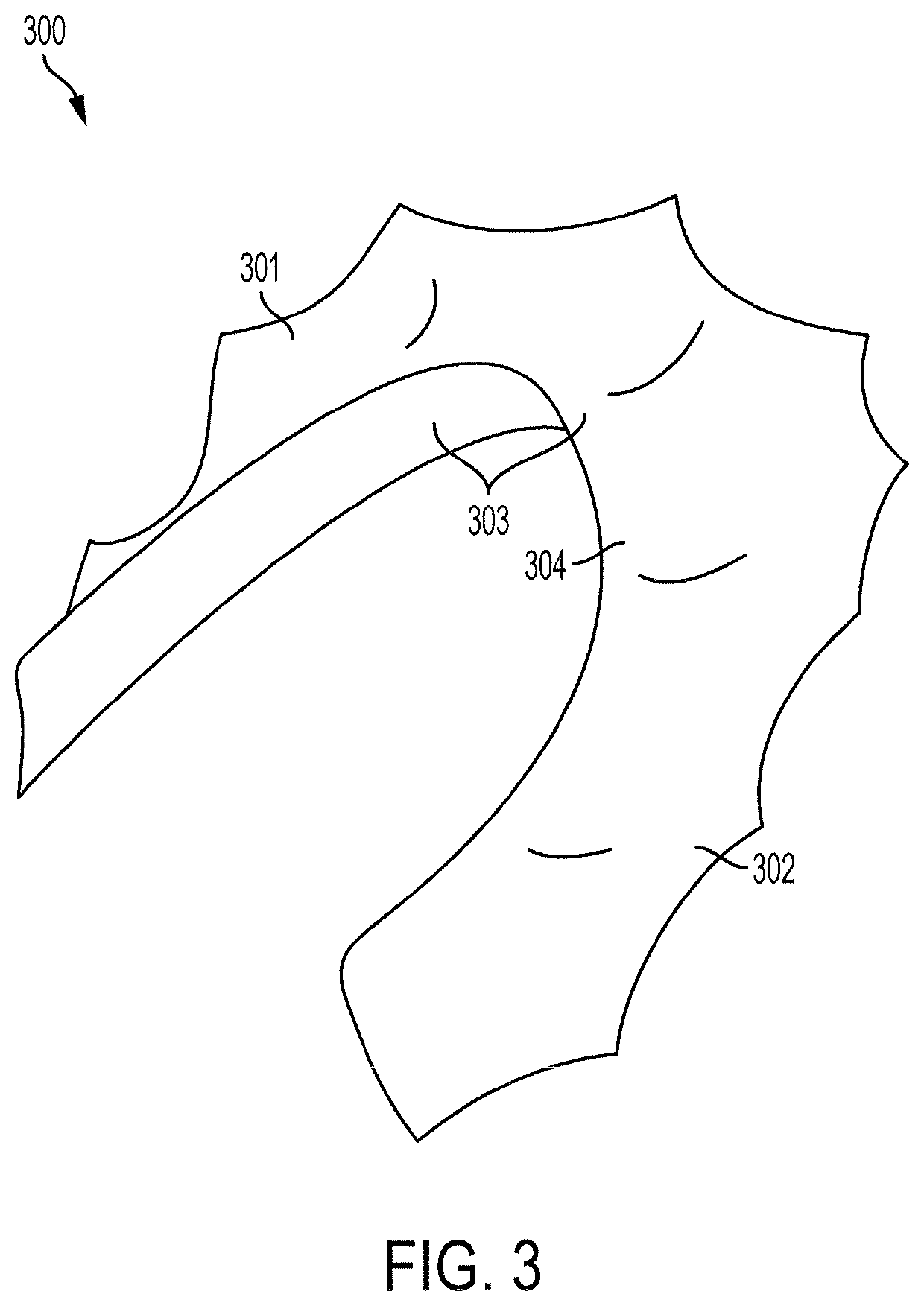

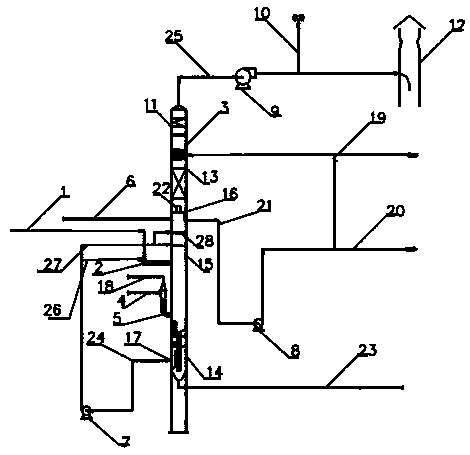

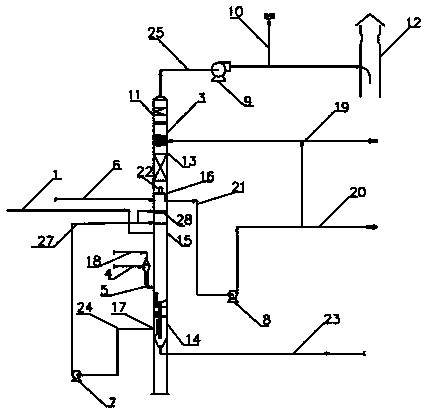

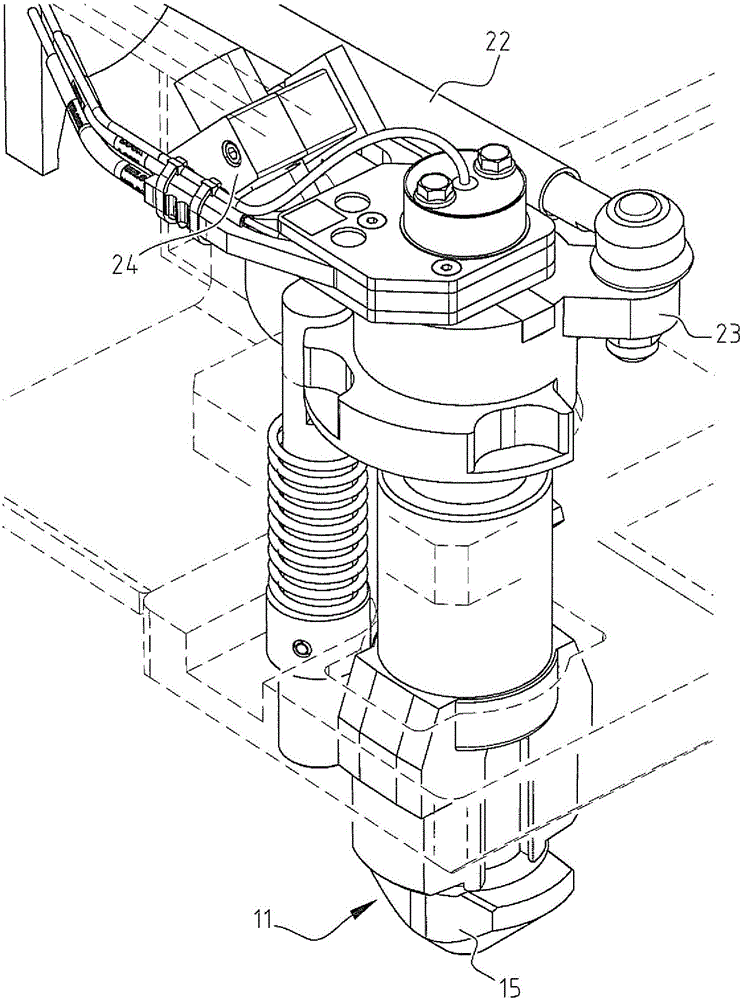

Apparatus and method for mounting and removing tyres on and from respective wheel rims

ActiveUS20110100558A1Reliable and precise mannerFacilitate interruptionTyre repairingMechanical engineering

Owner:NEXION SPA

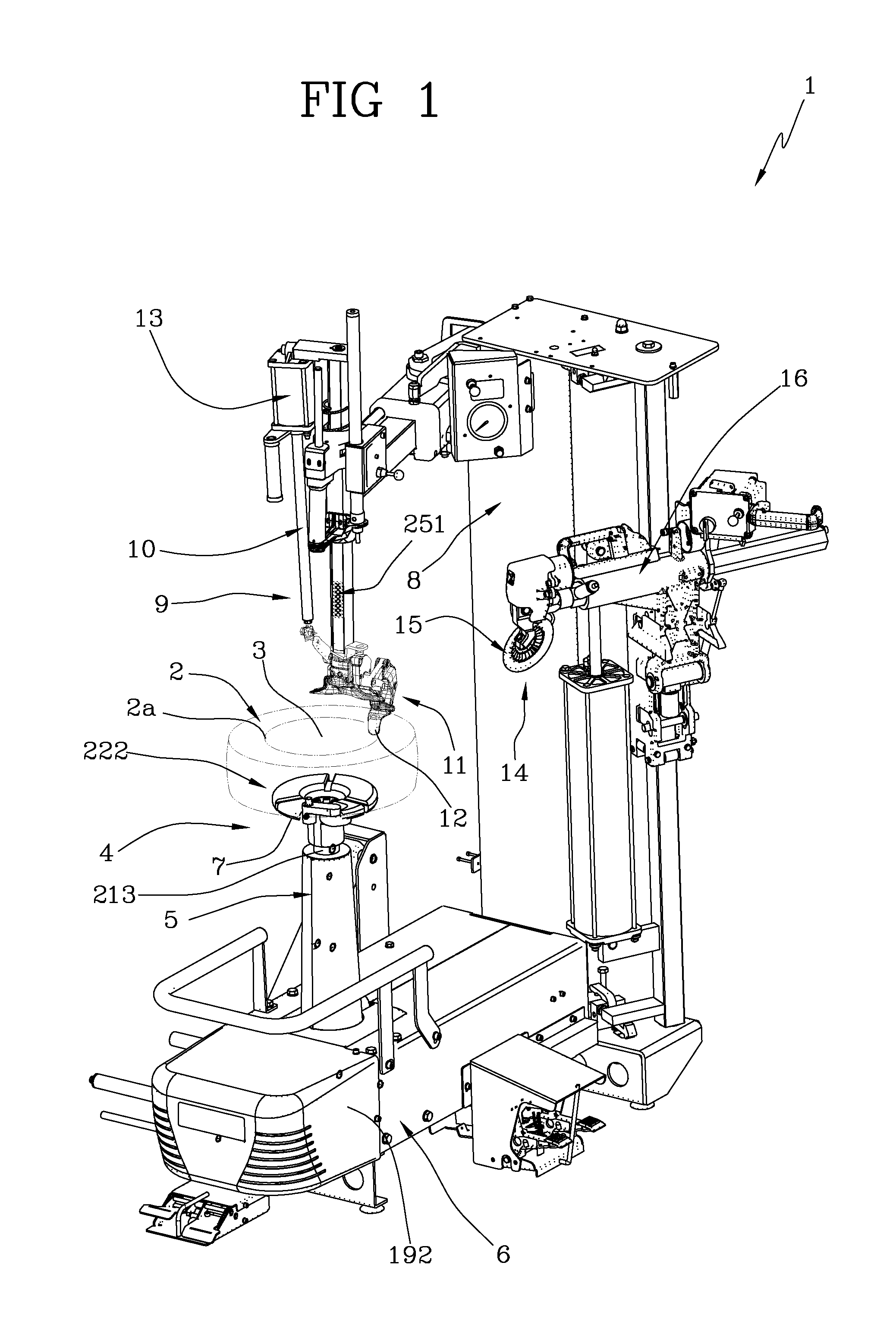

Glass-metal sealing process for vacuum heat collecting tube

The glass-metal sealing process for vacuum heat collecting tube includes the following steps: pre-oxidizing the part of the sealing metal workpiece, pre-vitrifying the part of the sealing metal workpiece, and sealing the glass and the pre-vitrified part of the sealing metal workpiece through heating. The glass-metal sealing process of the present invention has greatly lowered sealing temperature, greatly shortened sealing time, raised sealing quality, simplified sealing equipment and lowered production cost.

Owner:江希年 +2

Electrophoretic particles, electrophoretic dispersion liquid, display sheet, display device, and electronic equipment

ActiveUS9645467B2Dispersibility mainlyImprove charging characteristicsElectrographic processes using photoelectrophoresisTenebresent compositionsElectrophoresisOrganic group

Electrophoretic particle include a core particle; a siloxane-based compound that is bonded to a surface of the core particle and contains a connection structure in which a plurality of siloxane bonds are serially connected to each other; and a polarizing group that is an organic group bonded to the surface of the core particle, contains a main skeleton and a substituent bonded to the main skeleton, and has unevenly distributed electrons on the particle side of the main skeleton or the opposing side thereof.

Owner:E INK CORPORATION

Production method of fine oxide dispersed steel

The invention provides a production method of fine oxide dispersed steel. The production method is characterized by comprising the following steps of: forming a through hole in the lower pipe wall of an RH (Ruhrstahl-Heraeus) downcomer, connecting the through hole with an external gas source or powder feeding equipment through a spray pipe, blowing inert gas into molten steel through the spray pipe in an RH molten steel refining and deoxidizing process or removing an oxygen product by blowing deoxidation powder by taking the inert gas serving as a carrier; and spraying useful alkali soil powder by taking the inert gas as a carrier or spraying useful oxide mass points to generate fine dispersed oxides and keeping clean circulation for less than 10 minutes after bellowing, wherein the inert gas is Ar, N2 or CO2 with the air flow of 10-1,000 L / min and the air pressure of 1.0-15 atm. The production method has a simple process and low production cost. By adopting the production method, a large amount of fine oxide dispersed steel with the oxide particle size being less than 1 mum can be produced stably and quickly.

Owner:ANGANG STEEL CO LTD

High-resolution crystal orientation acquisition method based on scanning electron microscope

InactiveCN106501292ASimple equipmentEasy to operateMaterial analysis by measuring secondary emissionImage resolutionElectron diffraction

The invention provides a high-resolution crystal orientation acquisition method based on a scanning electron microscope. The high-resolution crystal orientation acquisition method comprises the following steps: (1) preparing a metal sample with the thickness of 300-500 mu m in a wire cut electrical discharge machining manner; gradually polishing with gold-phase sandpaper to reduce the thickness to be less than 100 mu m; using an automatic twin-jet electropolisher to perform twin-jet electropolishing thickness-reduction for 30-200 seconds at voltage of 10-25 V in electrolyte; and (2) placing the metal sample in a pre-tilt sample stage for clamp fixing, and acquiring parameters at a tilt angle between the sample and an electron beam of 20-0 degrees, an acceleration voltage of 15-30 kV and a working distance of 5-9 mm. The high-resolution crystal orientation acquisition method provided by the invention realizes spatial resolution and angle resolution significantly superior to a conventional backscattered electron diffraction technology in crystal orientation analysis aspect under a scanning electron microscope platform, and further has advantages of being simple in equipment, convenient to operate, technically reliable, high in data acquisition efficiency, easy in processing and analysis, good in repeatability and the like.

Owner:CHONGQING UNIV OF TECH

Apparatus and method for mounting and removing tyres on and from respective wheel rims

ActiveUS8776858B2Reliable equipmentAvoid damageStatic/dynamic balance measurementTyresMechanical engineering

Owner:NEXION SPA

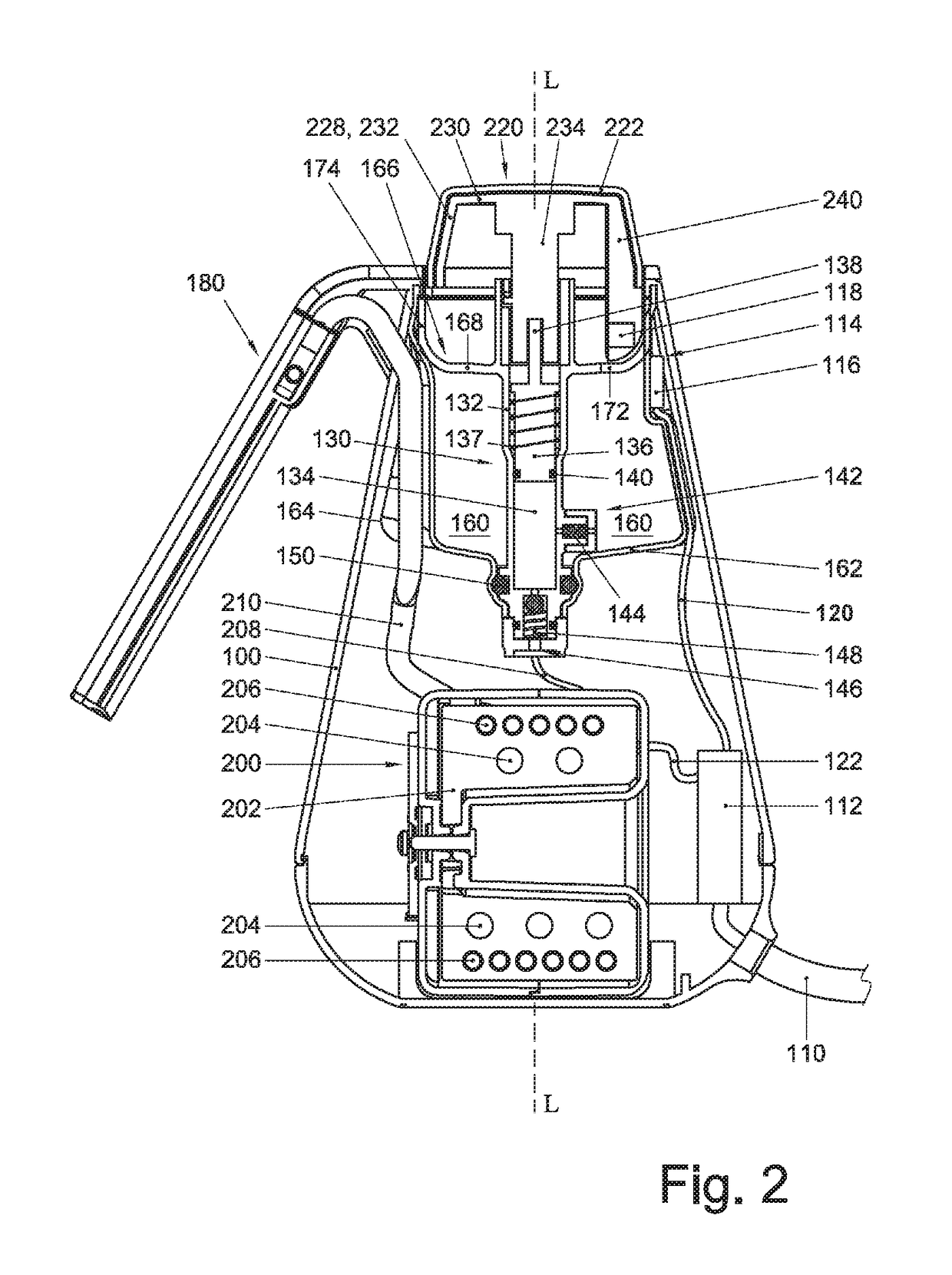

Manually operated in-cup milk frothing appliance

InactiveUS20140373735A1Reduce manufacturing costReliable equipmentMilk preservationBeverage vesselsActuatorControl theory

A milk frothing appliance (1), comprising:—a water reservoir (160);—a steam generator (200);—a milk frothing device (180) that is fluidly connected to the steam generator (200); and—a hand pump (130) that is fluidly connected to both the water reservoir and the steam generator, comprising a manually operable actuator (220) that is moveable between a first actuator position and a second actuator 138 position, and that upon movement from the first actuator position into the second actuator position causes displacement of fluid from the water reservoir to the steam generator (200).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Organic silicon complete variable-pressure thermal coupling rectification device and rectification method

PendingCN113827996AResolve Partial CouplingSolve the defect of not achieving full couplingSilicon organic compoundsEnergy recuperation in distillationThermodynamicsReboiler

The invention discloses an organic silicon complete variable-pressure thermal coupling rectification device and rectification method. The device comprises a high boiler removal tower, a low boiler removal tower, a high-pressure binary tower and a low-pressure binary tower. The low boiler removal tower and the low-pressure binary tower are each provided with a tower kettle coupling reboiler. The top of the high boiler removal tower is connected with the tower kettle coupling reboiler of the low-pressure binary tower, and a gas-phase material flow at the top of the high boiler removal tower provides a heat source for the tower kettle coupling reboiler of the low-pressure binary tower. The tower top of the high-pressure binary tower is connected with the tower kettle coupling reboiler of the low boiler removal tower, and a gas-phase material flow at the top of the high-pressure binary tower provides a heat source for the tower kettle coupling reboiler of the low boiler removal tower. By adjusting the feeding amounts of the high-pressure binary tower and the low-pressure binary tower, complete coupling of heat of the high boiler removal tower, heat of the low boiler removal tower and heat of the high-pressure binary tower and heat of the low-pressure binary tower is achieved, the defect that in the prior art, partial coupling between towers is achieved, and complete coupling is not achieved is overcome, energy consumption is reduced, and meanwhile, equipment investment which has to be additionally increased for stable operation of the system is reduced.

Owner:天津市华瑞奕博化工科技有限公司

Defibrillator with retractable cable

InactiveUS7039460B2Broaden applicationEasy to retractHeart defibrillatorsArrangements using take-up reel/drumEngineeringElectrical and Electronics engineering

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

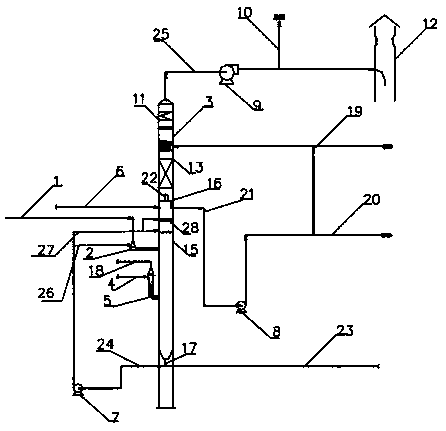

Intelligent bin tray transfer system and method thereof

The invention discloses an intelligent bin tray transfer system. The intelligent bin tray transfer system comprises a control mechanism, a transfer mechanism, a transportation mechanism, an emptying mechanism and a positioning mechanism. A method comprises the following steps: (S1) the transportation mechanism drives the transfer mechanism to enter the positioning mechanism; (S2) the transportation mechanism leaves away; (S3) the transfer mechanism is ascended; (S4) the transfer mechanism is centered and positioned; (S5) materials are emptied; (S6) the transportation mechanism enters the positioning mechanism, and is connected with the transfer mechanism; (S7) the transfer mechanism is descended; (S8) the transportation mechanism drives the transfer mechanism to leave from the positioningmechanism; and (S9) the step (S1) is returned to for renewed actuation. The Intelligent bin tray transfer system and the method thereof achieve full-automatic tray transfer and circulating operation,realize unmanned workshop and precise transportation, increase the tray conveying quantity, prominently improve the production efficiency, reduce the production cost, reduce the labor intensity of operators, meet industrial 4.0 demands, accelerate optimal upgrading of industrial structures, and achieve excellent market popularization value.

Owner:福建宏泰智能工业互联网有限公司

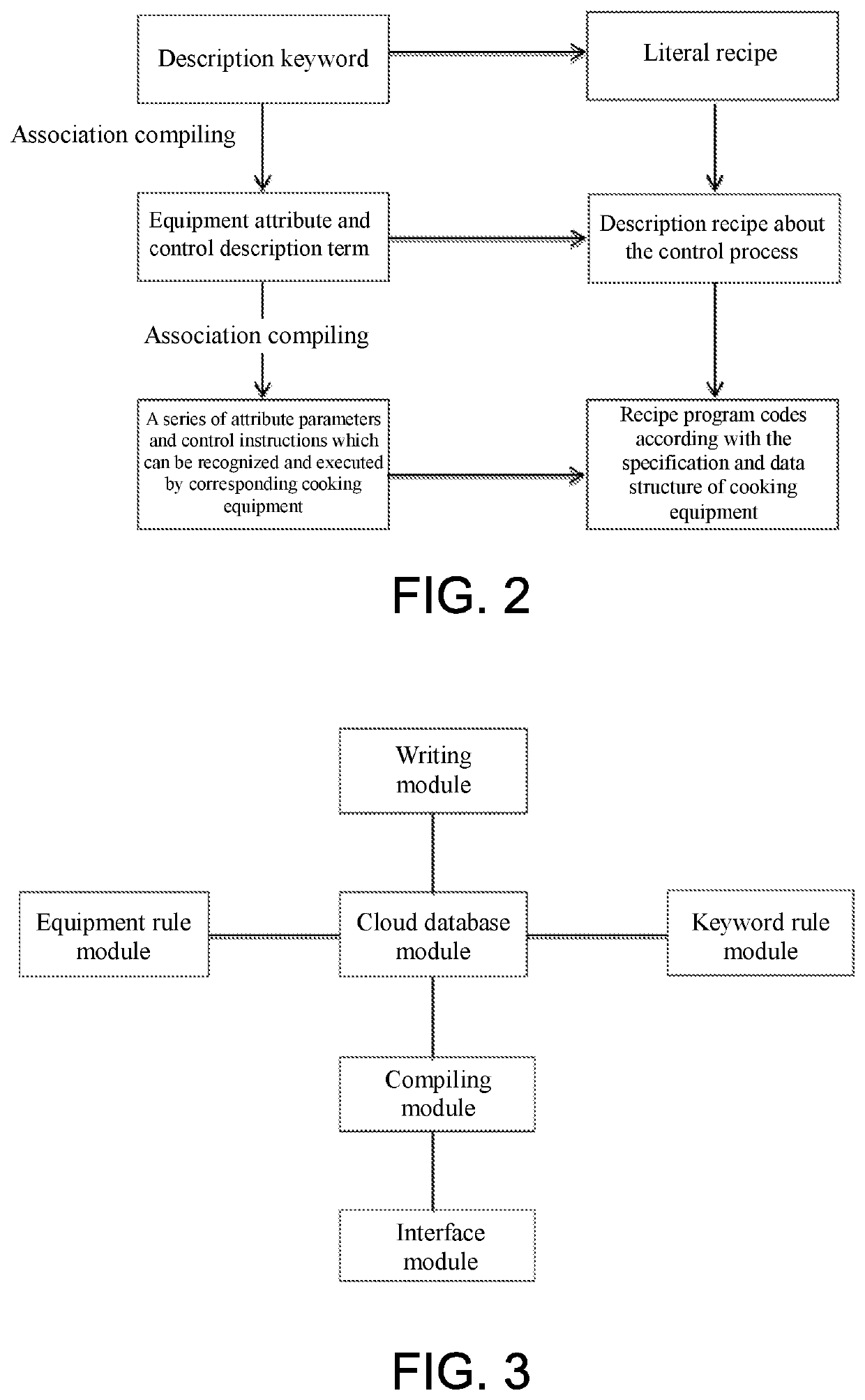

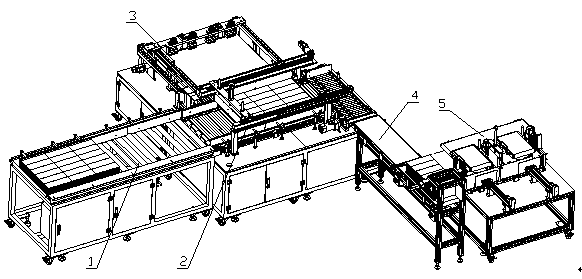

Recipe program code generation method and recipe compiling cloud platform system

ActiveUS20200241847A1Reliable equipmentWeb data indexingCompiler constructionSoftware engineeringComputer programming

The invention relates to the technical field of cooking, in particular to a recipe program code generation method and a recipe compiling cloud platform system. The recipe program code generation method comprises the following steps: firstly, establishing equipment attribute and control description terms which are associated with corresponding attributes or cooking motions of equipment and also associated with a description keyword term bank; then, selecting corresponding cooking equipment and inputting a literal description recipe; finally, analyzing description keywords in the literal recipe by compiling software and associating the description keywords with the equipment attribute and control description terms of the cooking equipment of the corresponding type, so that recipe program codes are generated. According to the recipe compiling method and the cloud platform system of the invention, the recipe program codes can be generated through automatic conversion as long as the corresponding cooking equipment is selected and the literal recipe is input, recipe editors do not need to be familiar with computer programming languages, the technical problems of recipe program code generation in the prior art are solved, the recipe program generation efficiency and effect are improved, and it is ensured that the recipe program codes can be executed on the cooking equipment safely and reliably.

Owner:SHENZHEN YIJUYUN TECH CO LTD

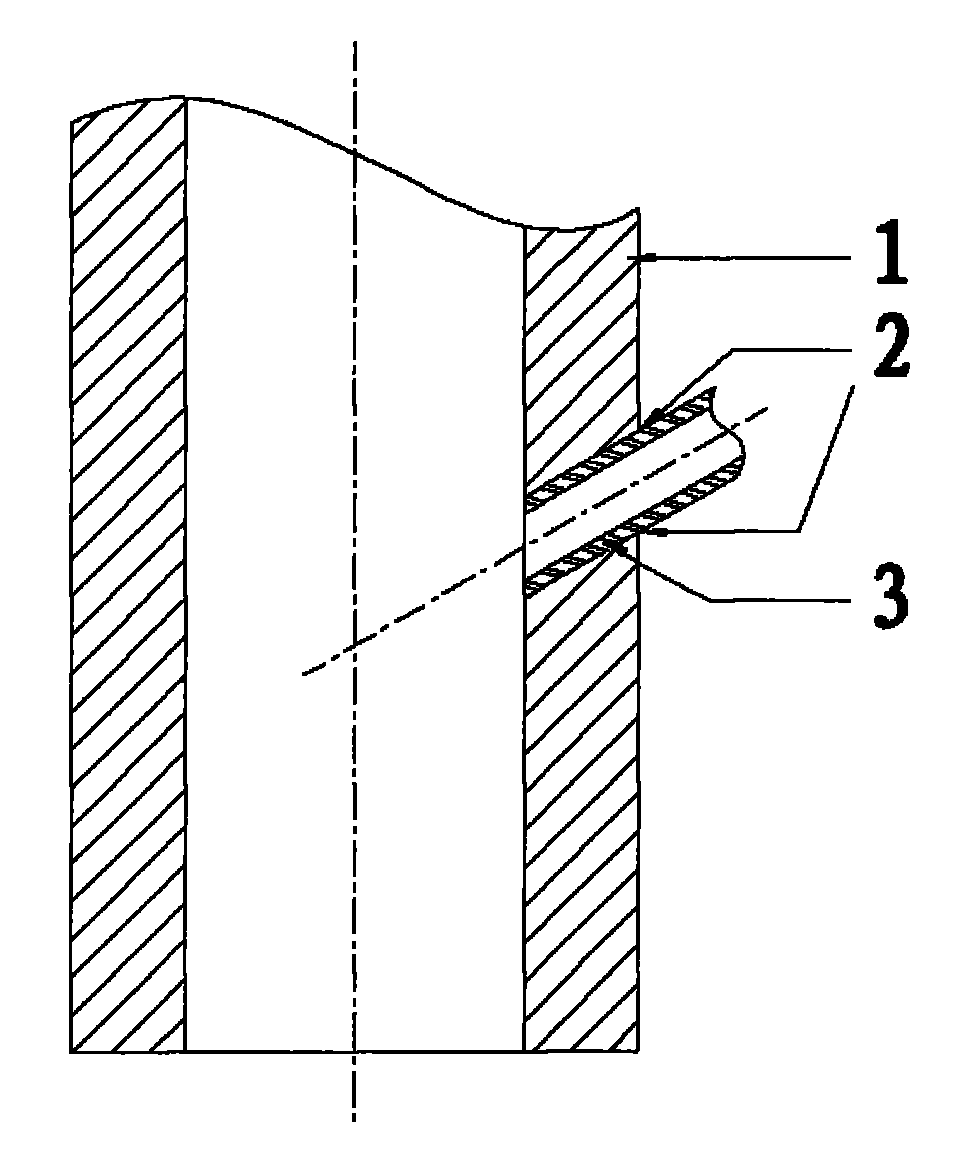

Mobile electronic apparatus and method for controlling read/write rate of data

InactiveUS20030047057A1Reliable methodRead rate is decreasedElectrophonic musical instrumentsStringed musical instrumentsControl dataMobile electronics

Owner:SONY CORP

Oral insert and uses thereof for calculating forces to the head

ActiveUS20200008744A1DurableHigh measurement accuracyInertial sensorsDiagnostic recording/measuringDentistryBiomedical engineering

The present disclosure generally provides oral inserts useful for determining forces experienced by a user, such as a human user, to the head, for example, by measuring one or more of acceleration, velocity, displacement, or rotation. In some aspects, the disclosure provides oral inserts that, when worn properly by a human user, calculate the forces experienced by the user's head with high accuracy. In some aspects, the disclosure provides systems for detecting and calculating forces experienced by the user's head and to determine whether such forces are above a certain threshold indicative of increased concussion risk. In some aspects, the disclosure provides methods for calculating forces experienced by the user's head and determining whether such forces are above a certain threshold indicative of concussion.

Owner:OCELLUS LLC

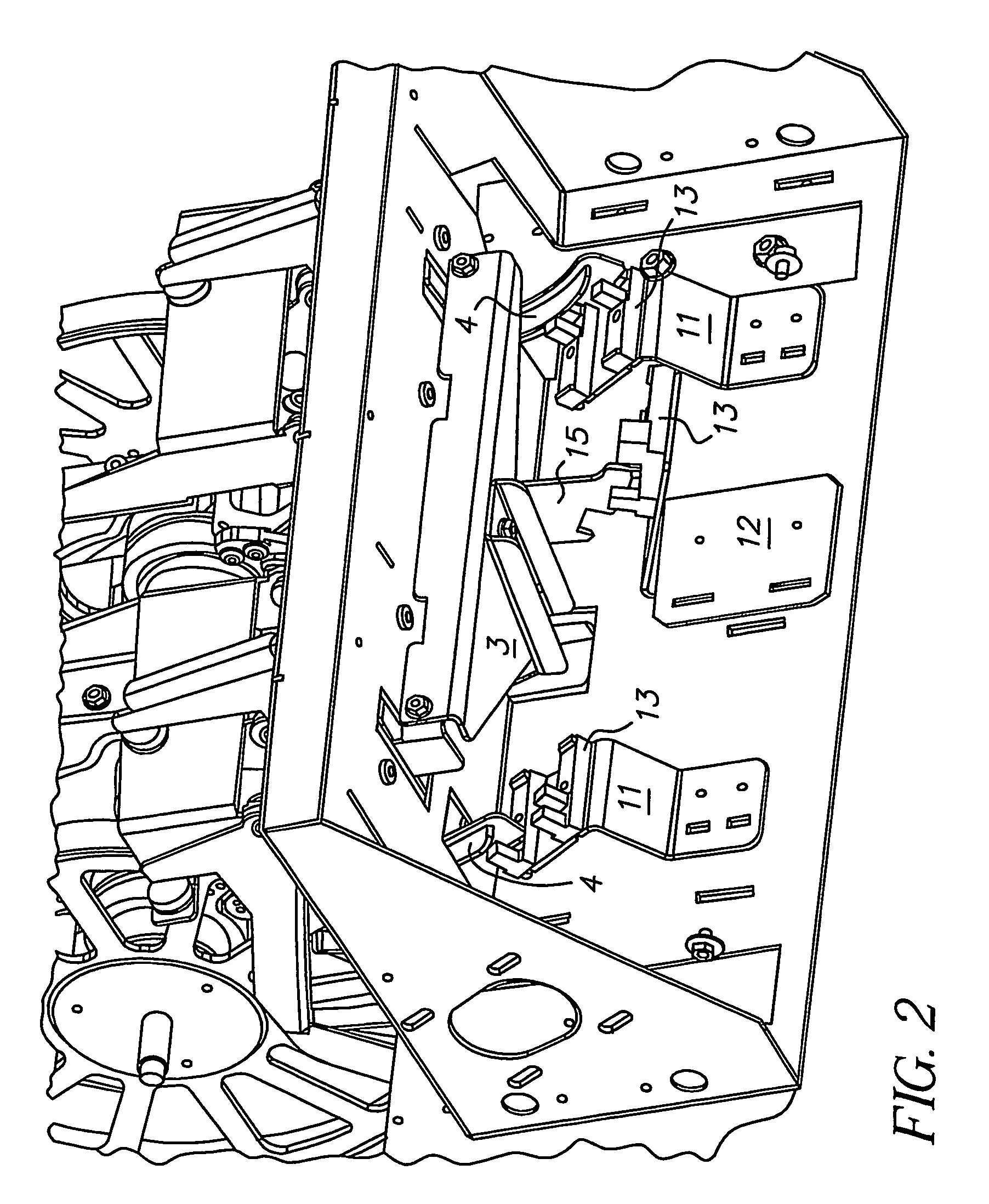

Device for placing sheets for a printer

InactiveUS7635130B2Heavy loadReliable equipmentPile receiversArticle deliveryEngineeringSheet material

Owner:EASTMAN KODAK CO

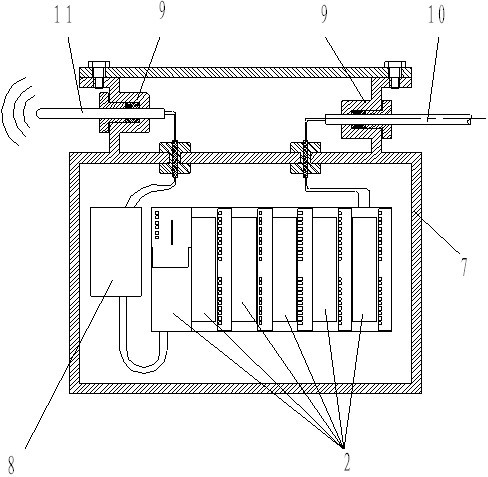

Underground wireless automatic control device for mining

InactiveCN102591309AAdaptableReliable equipmentTotal factory controlProgramme total factory controlAutomatic controlRemote computer

Disclosed is an underground wireless automatic control device for mining, belongs to the technical field of automatic control devices, and is used for wireless automatic control and monitoring of mining underground operating devices. The technical scheme includes that the mining underground wireless automatic control device comprises a plurality of control computers and a plurality of controllers, wherein programmable logic controller (PLC), distributed control system (DCS) and fieldbus control system (FCS) serve as the core of the plurality of controllers, and both the computers and the controllers are placed in an explosion-proof tank which reaches the mining safety level; the control computers and the controllers are connected through wireless signals; and data connections between controllers, between controllers and control computers, between control computers, and between control computers and remote computers are established. According to the underground wireless automatic control device for the mining, wireless connections of underground control can be achieved, controlling staff are enabled to monitor and control automatic operation of various devices in real time; the device can be moved without stop of production during excavation of a roadway and moving forward of a coal cutter, and connection and covering for the whole course of the underground control is achieved. The underground wireless automatic control device for the mining has the advantages of being high in degree of automation, reliable in connection, high in adaptability, comprehensive in control, and the like.

Owner:河北首力科技有限公司

Device For Placing Sheets For A Printer

InactiveUS20080036136A1Reliable and reliableHeavy loadPile receiversArticle deliverySheet materialEngineering

Owner:EASTMAN KODAK CO

Manually operated in-cup milk frothing appliance

A milk frothing appliance including a water reservoir; a steam generator; a milk frothing device that is fluidly connected to the steam generator; and a hand pump that is fluidly connected to both the water reservoir and the steam generator. The hand pump including a manually operable actuator that is moveable between a first actuator position and a second actuator position, and that upon movement from the first actuator position into the second actuator position causes displacement of fluid from the water reservoir to the steam generator. The actuator is further moveable between a third actuator position and a fourth actuator position.

Owner:KONINK PHILIPS ELECTRONICS NV

Recipe program code generation method and recipe compiling cloud platform system

ActiveUS10789049B2Reliable equipmentWeb data indexingOther databases queryingSoftware engineeringComputer programming

The invention relates to the technical field of cooking, in particular to a recipe program code generation method and a recipe compiling cloud platform system. The recipe program code generation method comprises the following steps: firstly, establishing equipment attribute and control description terms which are associated with corresponding attributes or cooking motions of equipment and also associated with a description keyword term bank; then, selecting corresponding cooking equipment and inputting a literal description recipe; finally, analyzing description keywords in the literal recipe by compiling software and associating the description keywords with the equipment attribute and control description terms of the cooking equipment of the corresponding type, so that recipe program codes are generated. According to the recipe compiling method and the cloud platform system of the invention, the recipe program codes can be generated through automatic conversion as long as the corresponding cooking equipment is selected and the literal recipe is input, recipe editors do not need to be familiar with computer programming languages, the technical problems of recipe program code generation in the prior art are solved, the recipe program generation efficiency and effect are improved, and it is ensured that the recipe program codes can be executed on the cooking equipment safely and reliably.

Owner:SHENZHEN YIJUYUN TECH CO LTD

Fly ash curing and stabilizing system for household waste

InactiveCN111112291ASimple processReliable equipmentSolid waste disposalTransportation and packagingProcess engineeringFirming agent

The invention relates to a fly ash curing and stabilizing system for household waste. The system comprises a fly ash curing system, a stabilizing system, a weighing hopper, a stirring treatment systemand an output device. Screw weighing feeders are arranged at the lower ends of the fly ash curing system and the stabilizing system correspondingly, and flow pipelines are arranged at the lower endsof the screw weighing feeders. The lower ends of the flow pipelines are connected with the weighing hopper. A stirrer and a water supply device are arranged on the stirring treatment system. A chelating agent storage tank is arranged in the water supply device. A liquid metering tank is arranged in the stirrer. The lower end of the stirrer is connected with the output device. By means of a curingand stabilizing process adopting a curing agent and an agent, the process is simple, equipment is reliable, the system is completely sealed on a powder side, dust is prevented from being generated, the material ratio is statically metered, the precision is high, the ratio is accurate, batch type stirring is adopted, the mixing uniformity is high, ton bag packaging is adopted, the environment is tidy, and the automation degree is high.

Owner:张家港市长泰机械科技有限公司

Lottery distributing system

A lottery distributing system is mounted at the front end of a lottery automatic packaging production line, includes a roller conveyor, a support dividing line component, a support plate extraction-storage component, a line dividing stack component and a stack dividing book component. After lotteries are cut, the lotteries are placed on a support plate in an n*m manner, wherein n refers to row andm refers to line, and the lottery stacking height can be freely set; the support plate is manually pushed onto the roller conveyor; the support dividing line component includes a wide-width pallet conveyor, a movable push plate, a fixed baffle, a narrow-width pallet conveyor and a rack; the support plate extraction-storage component includes a clamping claw, a plate extraction mechanism, a lifting platform and a rack; the line dividing stack component includes a belt conveyor, a pushing module and a rack; the stack dividing book component includes a feeding belt conveyor, a feeding module A,a scraper blade belt conveyor A, lifting module A, a discharging belt conveyor, a movable baffle, a feeding module B, a scraper blade belt conveyor B, a lifting module B and a rack.

Owner:中轻长泰(长沙)智能科技股份有限公司 +1

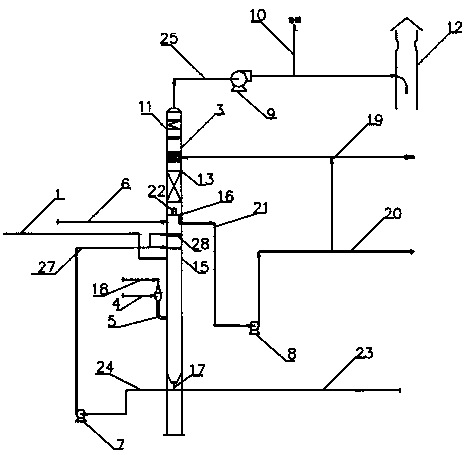

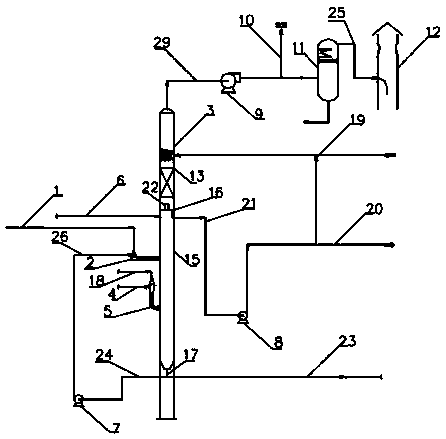

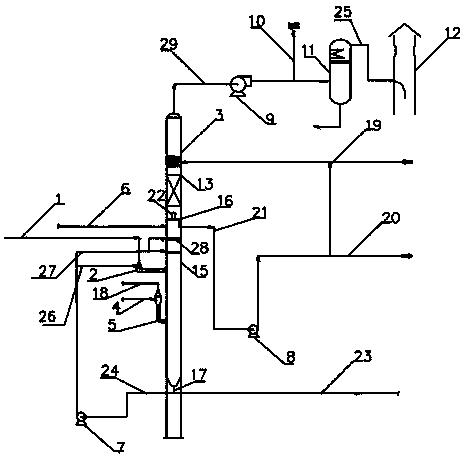

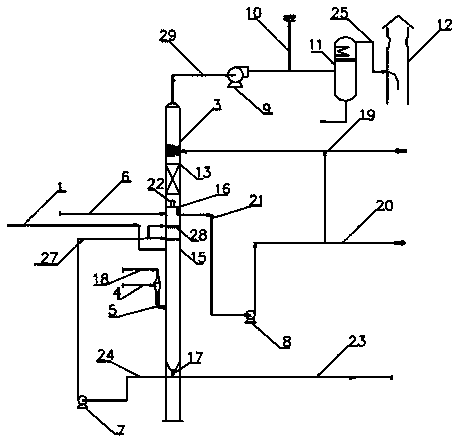

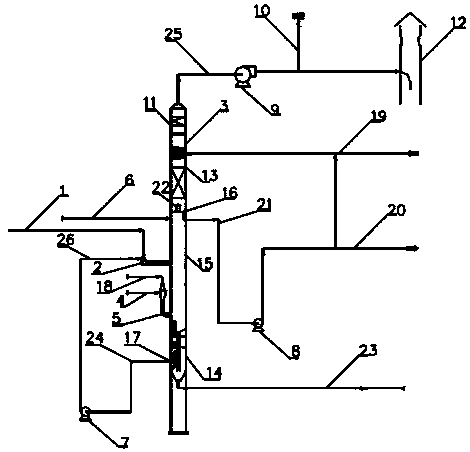

A coking tail gas treatment device

The invention discloses a coking tail gas treatment device to solve the problems of water vapor, malodorous gas pollution, secondary pollution caused by the discharge of tail gas VOC and coke powder along with the tail gas in the existing delayed coking device. The coking tail gas treatment device includes a tail gas treatment tower. The tail gas treatment tower is sequentially composed of a desaturation section, a desulfurization section, a gas-liquid separation section and a settling section from top to bottom. A desulfurization section oil collecting tank is arranged below the desulfurization section in the tail gas treatment tower. Below the gas-liquid separation section, there are coke tower tail gas and other equipment in the coking unit to generate tail gas injection pipeline, coke tank tail gas injection pipeline, coke tower discharge steam injection pipeline, and the bottom of the tail gas treatment tower is provided with washing sewage extraction pipeline The lower part of the settling section is provided with a washing water extraction bucket, the upper part of the desulfurization section is provided with an absorbing liquid injection line, the lower part of the desulfurization section oil collection tank is provided with a desulfurization section oil collection tank extraction outlet, and the top of the tail gas treatment tower is provided with a desaturated coking tail gas pipeline.

Owner:CHINA PETROLEUM & CHEM CORP +2

Device for dispersing nano material in scale via liquid state turbulent flow instant high-pressure cutting method

The invention discloses a device for dispersing nano material in scale via a liquid state turbulent flow instant high-pressure cutting method. The device comprises a feeding opening, a turbulent flow generating chamber, a high-pressure turbulent flow flowing tank and a discharging opening; flow with processed material enters the front end of the feeding opening, and the rear end of the feeding opening is connected to one side of the turbulent flow generating chamber; and the front end of the high-pressure turbulent flow flowing tank is connected to the other side of the turbulent flow generating chamber, and the rear end of the high-pressure turbulent flow flowing tank is connected to the discharging opening. The invention is practical and effective; the device is stable and reliable; and the nanostructure unit suspension of a plurality of materials prepared by the invention is expected to be applied to a plurality of fields such as industry, agriculture and the like.

Owner:三亚百泰生物科技有限公司

Coking tail gas treatment method and coking tail gas treatment device

ActiveCN111068494ASolve secondary pollutionFix the leakCombination devicesGas treatmentCokeSolid particle

The invention discloses a coking tail gas treatment method and a coking tail gas treatment device. A purpose of the invention is to solve the problems of secondary pollution and the like caused by vapor and malodorous gas pollution and tail gas VOC and coke powder discharge along with tail gas of the coke pool and the coke powder of the existing delayed coking device. According to the device, cokepool tail gas, coke tower discharge steam, coke tower tail gas and tail gas generated by other equipment in a coking device enter the gas-liquid separation section of a tail gas treatment tower and are subjected to gas-liquid separation; the gas-phase coking tail gas rises to a desulfurization section and is in countercurrent contact with an absorption liquid entering from the upper portion of the desulfurization section so as to be desulfurized; the desulfurized coking tail gas continuously rises to reach a desaturation section; after desaturation, the tail gas is discharged from the top ofthe tail gas treatment tower, VOC is removed, and then the tail gas is emptied; the rich absorption liquid is pumped out, pressurized and returned to the upper portion of the desulfurization section;after failure, the waste liquid is externally sent to a treatment unit; and the washing water containing solid particles in the tail gas treatment tower enters a settling section downwards, the washing sewage containing solid particles comes out from the bottom of the tail gas treatment tower, and the clarified washing water comes out from a washing water pumping hopper at the lower portion of thetail gas treatment tower and is pressurized so as to be recycled as circulating washing water.comes out from the top of the tail gas treatment tower, VOC is removed, and then the tail gas is emptied;the rich absorption liquid is pumped out, pressurized and returned to the upper portion of the desulfurization section; after failure, the waste liquid is sent to a treatment unit; and the washing water in the tail gas treatment tower flows out downwards from the bottom of the tail gas treatment tower, one part is discharged out of the device, and the other part is pressurized and then recycled as circulating washing water.

Owner:CHINA PETROLEUM & CHEM CORP +2

Coking tail gas treatment process and coking tail gas treatment device

ActiveCN111068493ASolve secondary pollutionFix the leakCombination devicesGas treatmentCokeWater circulation

The invention discloses a coking tail gas treatment process and a coking tail gas treatment device. A purpose of the invention is to solve the problems of secondary pollution and the like caused by vapor and malodorous gas pollution and tail gas VOC and coke powder discharge along with tail gas of the existing delayed coking device. According to the device, coke pool tail gas, coke tower dischargesteam, coke tower tail gas and tail gas generated by other equipment in a coking device enter the gas-liquid separation section of a tail gas treatment tower and are subjected to gas-liquid separation; the gas-phase coking tail gas rises to a desulfurization section and is in countercurrent contact with an absorption liquid entering from the upper portion of the desulfurization section so as to be desulfurized; the desulfurized coking tail gas is discharged from the top of the tail gas treatment tower, enters a desaturator and is desaturated; the desaturated coking tail gas is discharged fromthe desaturator, VOC is removed, and then the tail gas is emptied; the rich absorption liquid is pumped out, pressurized and then returned to the upper portion of the desulfurization section; after failure, the waste liquid is externally sent out to a treatment unit and is treated; and the washing water in the tail gas treatment tower flows out downwards from the bottom of the tail gas treatmenttower, one part is discharged out of the device, and the other part is pressurized and then recycled as circulating washing water.

Owner:CHINA PETROLEUM & CHEM CORP +2

Double-drive no-tillage finger clip type precision fertilization seeder

InactiveCN104094705BDoes not affect normal workThe amount of fertilizer is accurateFertiliser and seeding apparatusFertiliser equipmentsMonitoring systemMechanical engineering

The invention relates to a dual drive no-tillage finger-clamping type precision fertilizing-seeding machine, which comprises a base fertilizer application part assembly, a seeding monomer assembly, a drive mechanism, a monitoring system part assembly, a deep fertilization fertilizer box assembly, a land wheel part assembly, a main beam and traction beam part assembly, and a straw cutting and deep fertilization part assembly. The fertilizing-seeding machine is characterized in that: the drive mechanism adopts a dual drive structure, and comprises a left drive rubber wheel part assembly, a drive part assembly and a right drive rubber wheel part assembly, wherein the left drive rubber wheel part assembly and the right drive rubber wheel part assembly are symmetrically arranged and mounted on the left side and the right side of the drive part assembly respectively. With the characteristics of simple and reasonable structure, safer and more reliable working quality, the fertilizing-seeding machine provided by the invention thoroughly solves the shortcomings of large working resistance, high drive slip rate and the like in original no-tillage seeding machines.

Owner:JILIN KANGDA AGRI MACHINERY

Coking tail gas treatment process and coking tail gas treatment device

The invention discloses a coking tail gas treatment process and a coking tail gas treatment device. A purpose of the invention is to solve the problems of secondary pollution and the like caused by vapor and malodorous gas pollution and tail gas VOC and coke powder discharge along with tail gas of the existing delayed coking device. According to the device, coke pool tail gas, coke tower dischargesteam, coke tower tail gas and tail gas generated by other equipment in a coking device enter the gas-liquid separation section of a tail gas treatment tower and are subjected to gas-liquid separation; the gas-phase coking tail gas rises to a desulfurization section and is in countercurrent contact with an absorption liquid entering from the upper portion of the desulfurization section so as to be desulfurized; the desulfurized coking tail gas continuously rises to reach a desaturation section; after desaturation, the tail gas is discharged from the top of the tail gas treatment tower, VOC isremoved, and then the tail gas is emptied; the rich absorption liquid is pumped out, pressurized and returned to the upper portion of the desulfurization section; after failure, the waste liquid is externally sent to a treatment unit; and the washing water containing solid particles in the tail gas treatment tower enters a settling section downwards, the washing sewage containing solid particlescomes out from the bottom of the tail gas treatment tower, and the clarified washing water comes out from a washing water pumping hopper at the lower portion of the tail gas treatment tower and is pressurized so as to be recycled as circulating washing water.

Owner:CHINA PETROLEUM & CHEM CORP +2

Intelligent detection system of ATP speed sensor

PendingCN113588987AReliable equipmentReliable technical supportTesting/calibration of speed/acceleration/shock measurement devicesGear wheelControl engineering

The invention discloses an intelligent detection system for an ATP speed sensor. The intelligent detection system comprises a computer, a detection platform, a horizontal moving unit, a driving execution unit and a detection unit, the horizontal moving unit is used for adjusting a gap between the driving execution unit and the detection unit; the driving execution unit comprises a servo motor, the servo motor is fixed on the moving plate, and an output shaft of the servo motor is provided with a first gear disc and a brake; the detection unit comprises a mounting vertical plate, the mounting vertical plate is vertically fixed on the detection platform and right faces the first gear disc, a mounting groove is formed in the mounting vertical plate, and a speed sensor is arranged in the mounting groove; and the computer is electrically connected with the driving mechanism, the position sensor, the speed sensor, the servo motor and the brake. The performance of the ATP speed sensor can be accurately detected, and reliable equipment guarantee and technical guarantee are provided for safe application of ATP equipment.

Owner:中国铁路工会太原电务段委员会

Industrial production apparatus for high-power microwave pyrolysis of biomass

PendingCN108587652AImprove utilization efficiencyShorten the timeLiquid hydrocarbon mixture productionSpecial form destructive distillationCollection systemEngineering

The invention relates to an industrial production apparatus for high-power microwave pyrolysis of biomass. The industrial production apparatus comprises a material conveying system, a microwave pyrolysis system, a pyrolysis flue gas separation and collection system, a suction and discharge system and a biomass fuel gas utilization system, wherein a microwave reflection diffusion chamber completelycovers a large-capacity microwave oven cavity, the microwave power density is increased by multiple microwave sources, adjacent and opposite microwave waveguides are arranged in a staggered manner, and the phase angle of input microwave is controlled by PLC, such that the sealing and the heat insulation of the furnace cavity are ensured, the microwave radiation leakage is shielded, and the industrial production and safe operation for continuous and efficient high-power microwave pyrolysis of biomass is achieved. Compared to the existing biomass pyrolysis device, the industrial production apparatus of the present invention has the following characteristics that the time is shortened by 55-90%, the energy consumption is reduced by 50-80%, the solid, liquid and gas products produced by the biomass pyrolysis are completely collected and utilized, no waste is discharged, the clean production is achieved, and the reliable equipment and the control method are provided for the comprehensive industrial application of biomass resources.

Owner:DEHONG SENLANG PYROLYSIS TECH EQUIP

Method and apparatus for detecting crack formation in lifting members and lifting frame

InactiveCN103299170BReliable equipmentCompact equipmentForce measurement by measuring optical property variationTension measurementEngineering

The present invention relates to a method for detecting crack formation in a lifting member, comprising the steps of measuring the stress under load at two points of the lifting member, comparing the measured stresses, and when the measured stresses differ too much from each other A warning signal is generated frequently. The invention also relates to a device for detecting crack formation in a lifting member, comprising: means arranged at two points of the lifting member for measuring the stress under load; connected to the measuring means for comparing the measured means for stress; and means connected to the comparison means for generating a warning signal when the measured stresses differ too much from each other. Finally, the invention relates to a lifting frame comprising: a plurality of lifting members mounted on the lifting frame close to the corners of the lifting frame; and a crack detection device connected to the lifting members.

Owner:STINIS BEHEER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com