Production method of fine oxide dispersed steel

An oxide and fine technology, applied in the field of metallurgy, can solve the problems of difficult to control particle dispersion, high equipment requirements, powder spraying and oxygen can not be carried out at the same time, etc., to achieve the effect of low production cost, simple process and reliable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

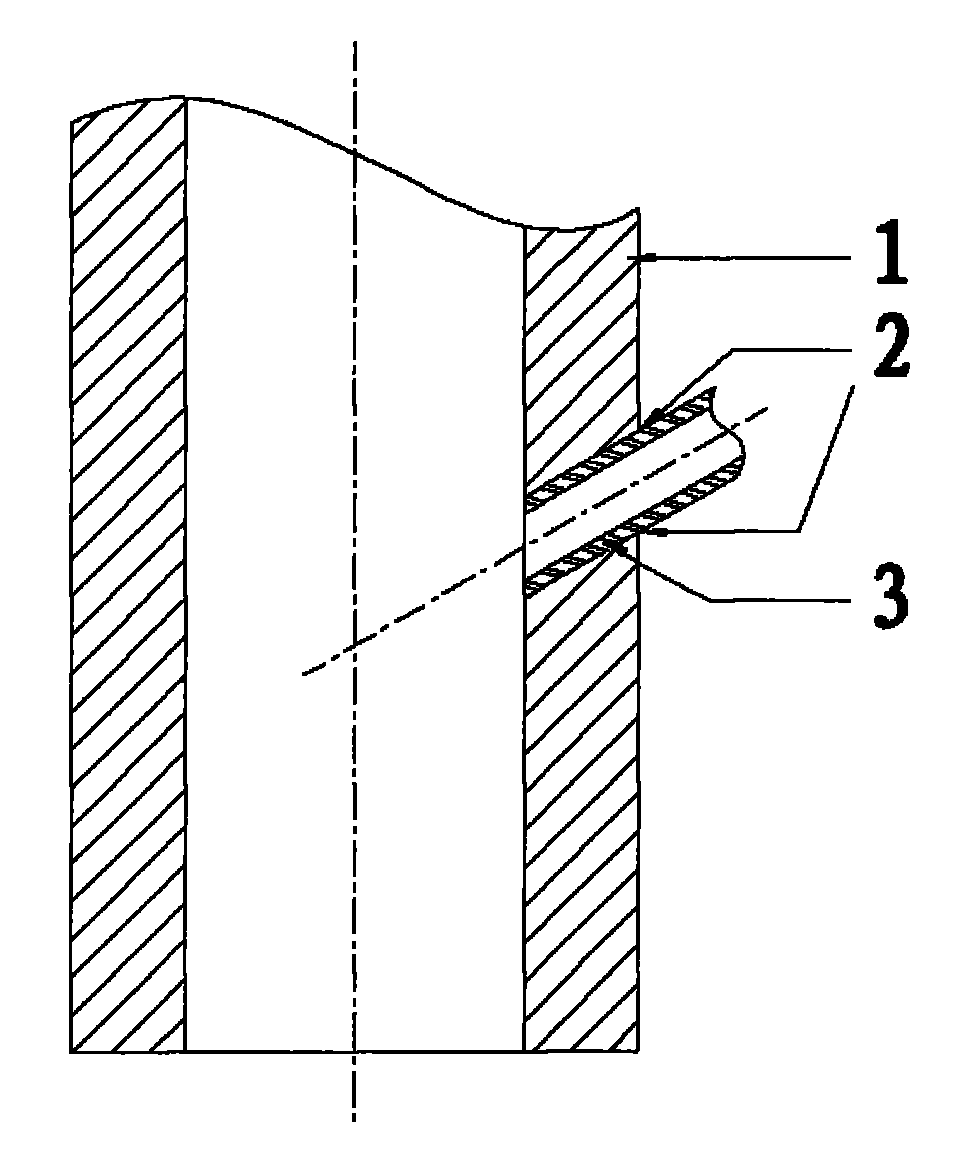

[0019] Drill holes on the tube wall 1 at the lower part of the RH downcomer, and there is one through hole 2, and the axial direction of the through hole 2 forms an included angle of 30° with the RH downcomer axis. The position of the through hole 2 is 300mm away from the lower edge of the RH downcomer. The through hole 2 leads into the nozzle 3, which extends outward and is fixed on the outer shell of the vacuum chamber. The powder equipment is connected, and the inner diameter of the spray pipe 3 is 5mm.

[0020] The production method of fine oxide dispersion steel is as follows:

[0021] [1] During the RH refining and deoxidation process of molten steel, use the above-mentioned powder feeding equipment to blow argon gas, and use the bubbles to float, collide, grow and capture to remove the deoxidized products with larger particles in the molten steel, thereby removing the deoxidized products produced in the refining process Deoxidation products, reducing the total oxygen c...

Embodiment 2

[0024] Drill holes on the tube wall 1 at the lower part of the RH downcomer. There are two through holes 2 arranged in a longitudinal arrangement. The axial direction of the through holes 2 forms an included angle of 45° with the RH downcomer axis. The position of the through hole 2 is 300mm and 350mm from the lower edge of the RH descending pipe respectively. The through hole 2 is introduced into the nozzle 3, which extends outward and is fixed on the outer shell of the vacuum chamber. Or connect with purchased powder feeding equipment, the inner diameter of the nozzle 3 is 6mm.

[0025] The production method of fine oxide dispersion steel is as follows:

[0026][1] During the RH refining and deoxidation process of molten steel, use the above-mentioned powder feeding equipment to spray low melting point pre-slag powder (pre-slag powder composition weight percentage is CaO: 50%, Al 2 o 3 : 20%, SiO 2 : 10%, MgO: 10%, CaF 2 : 10%), the particle size of the powder is <100 μm...

Embodiment 3

[0029] Drill holes on the tube wall 1 of the lower part of the RH downcomer. The number of through holes 2 is two and distributed horizontally and symmetrically. The axial direction of the through holes 2 forms an included angle of 60° with the RH downcomer axis. The position of the through hole 2 is 400mm away from the lower edge of the RH downcomer. The through hole 2 leads into the nozzle 3, which extends outward and is fixed on the outer shell of the vacuum chamber. The powder equipment is connected, and the inner diameter of the spray pipe 3 is 6mm.

[0030] The production method of fine oxide dispersion steel is as follows:

[0031] [1] During the RH refining and deoxidation process of molten steel, the above-mentioned powder feeding equipment is used to inject CaCO 3 Powder, the particle size of the powder is less than 100μm, the injection powder dose is 100kg, and the powder delivery rate is 5-20kg / min. It mainly uses the decomposition of carbonate to produce a large...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com