Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reduce the number of specifications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

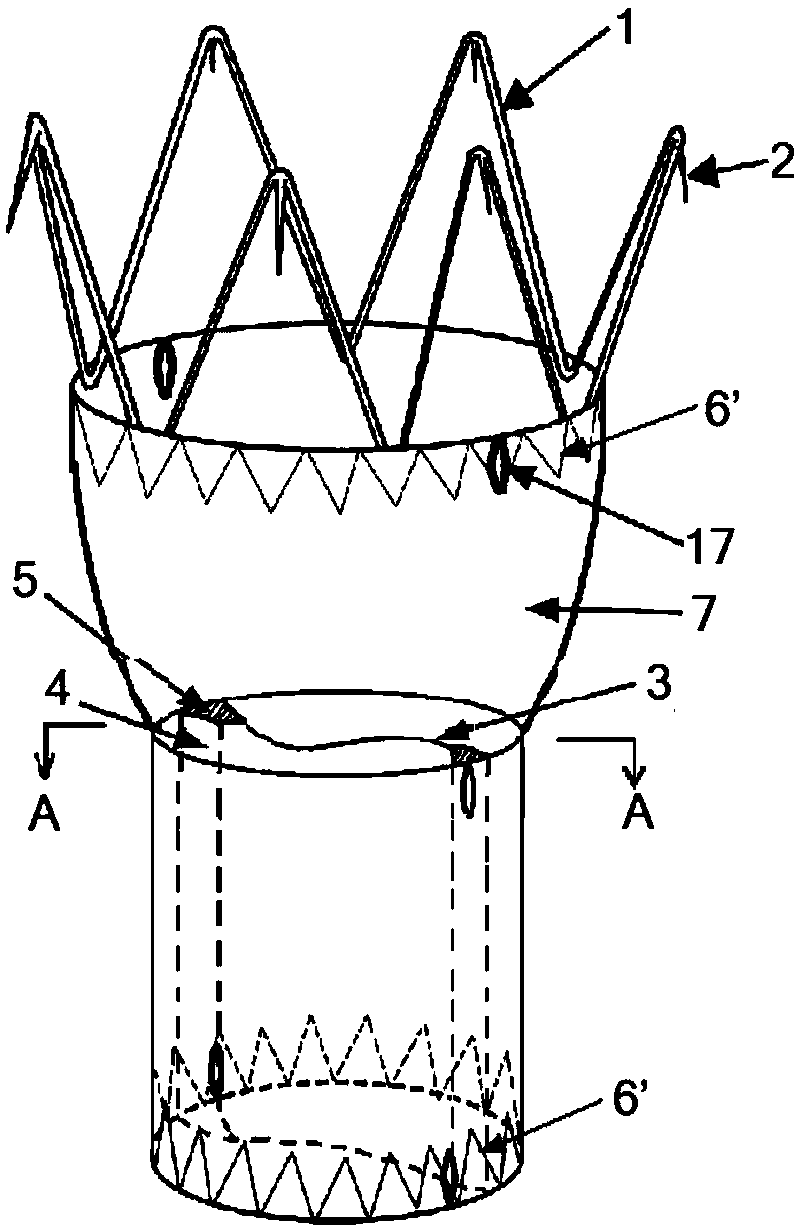

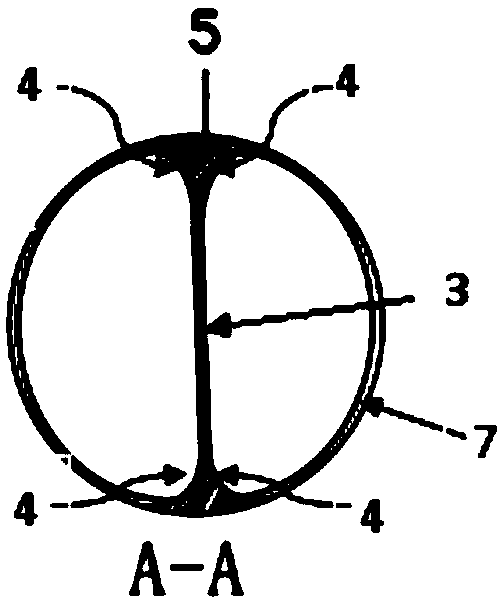

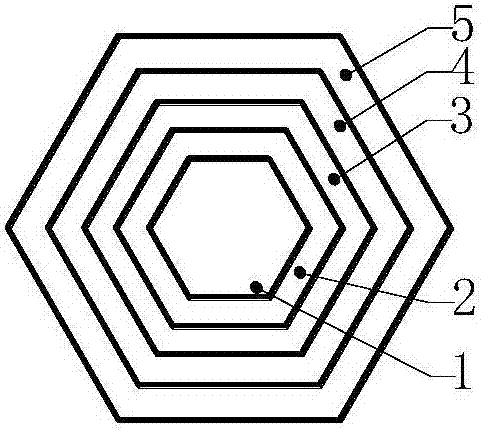

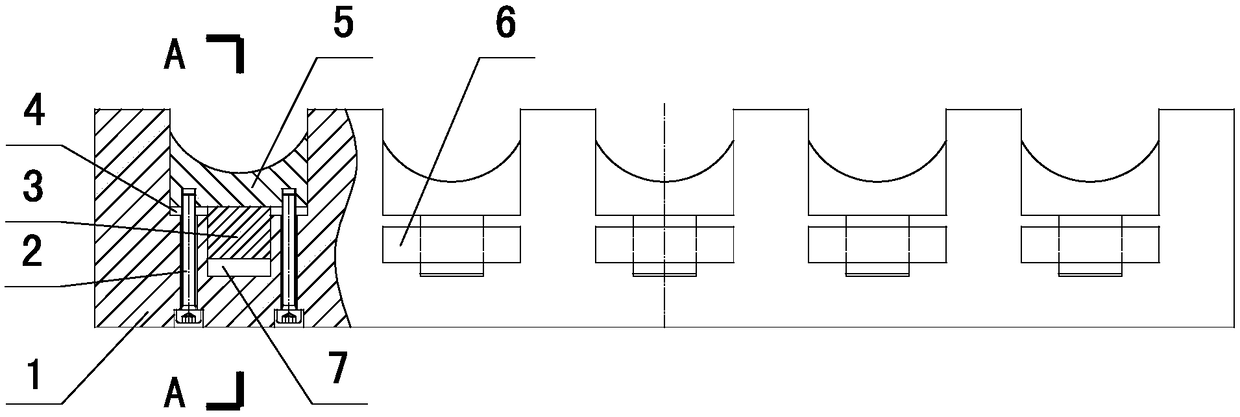

Combined abdominal aorta covered stent system and utilization method thereof

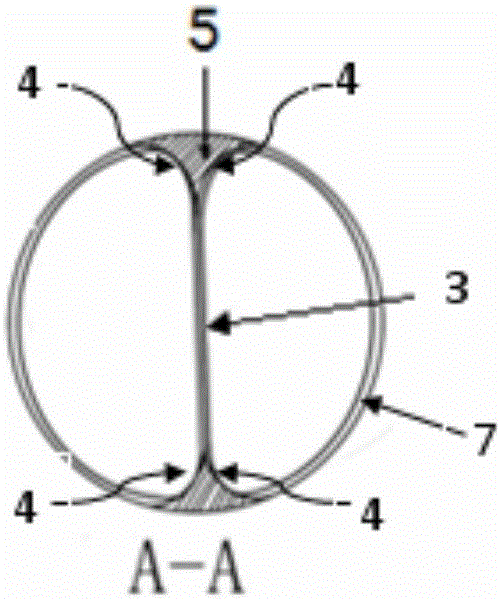

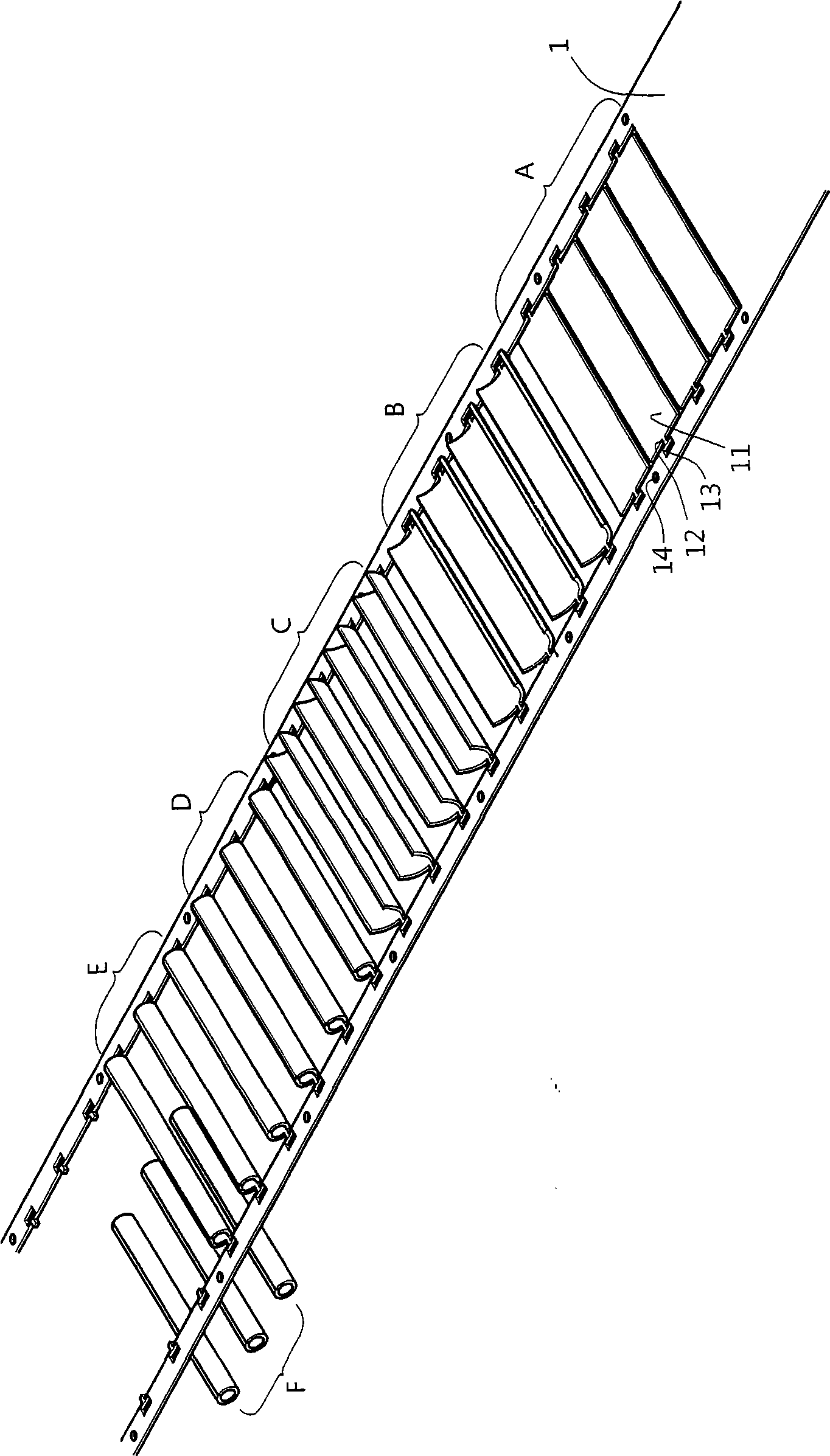

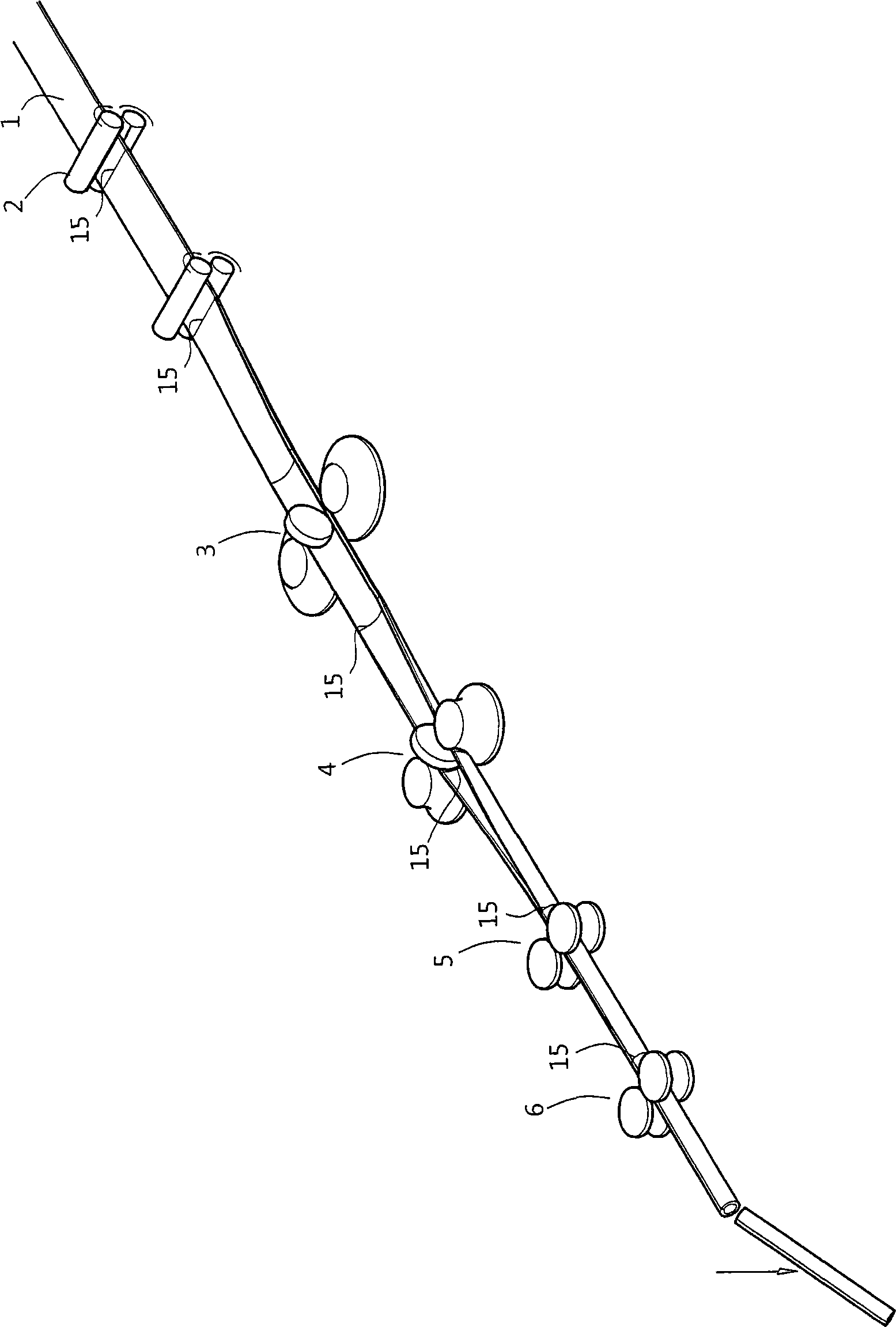

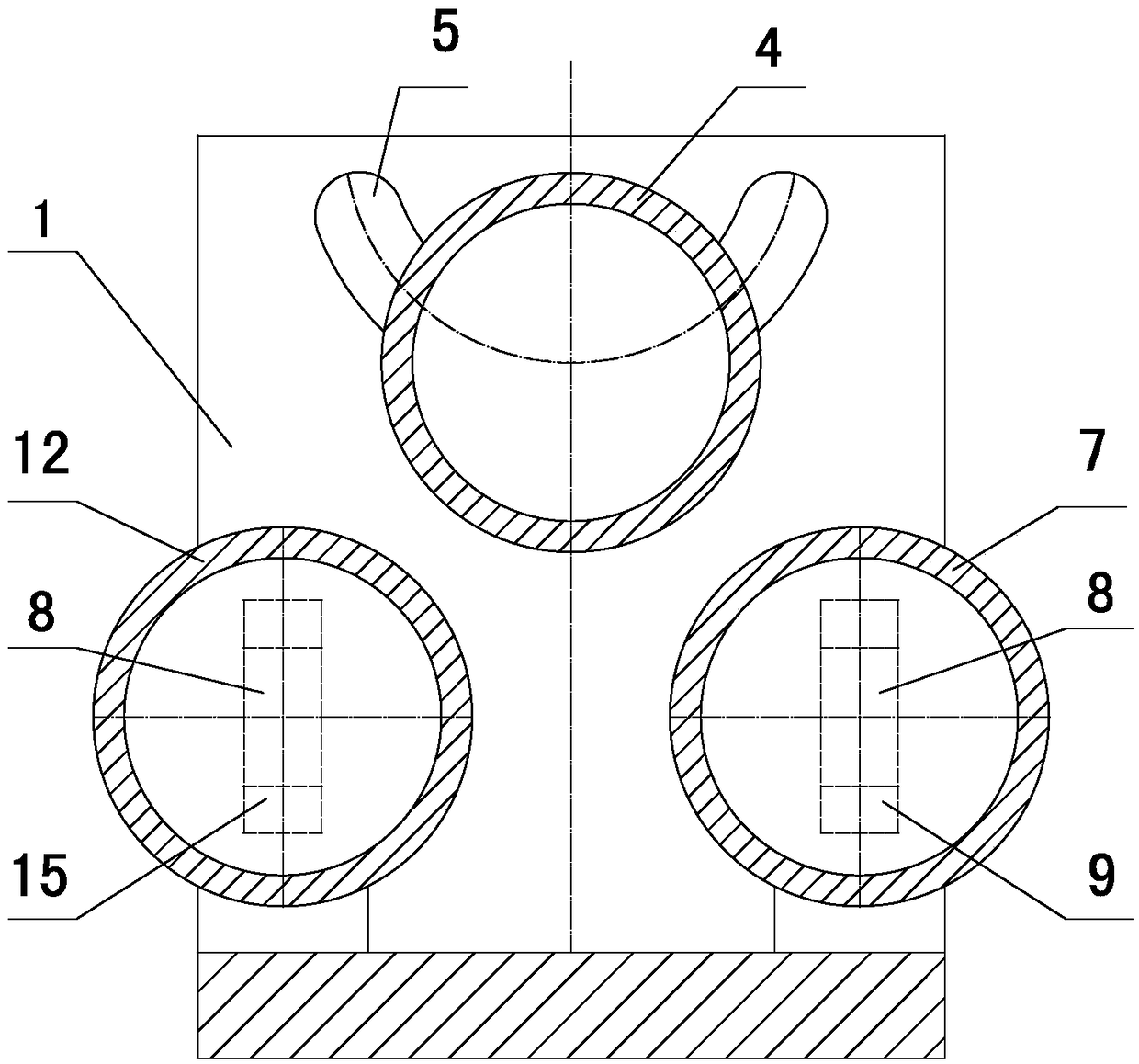

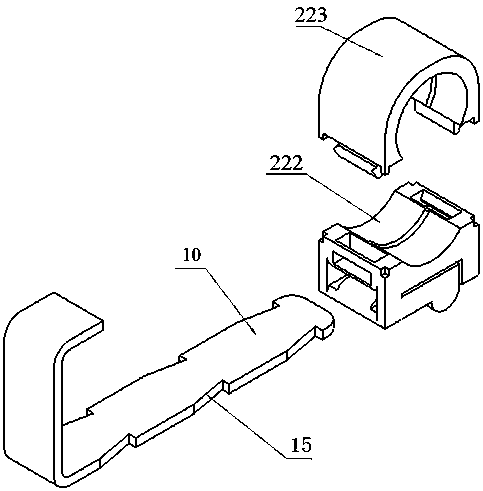

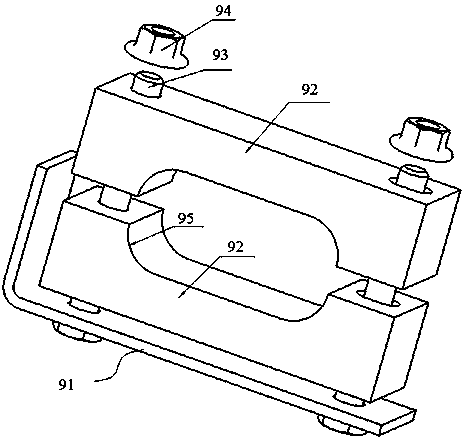

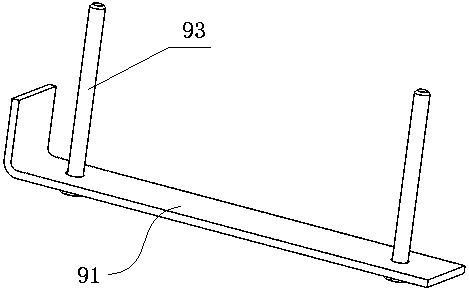

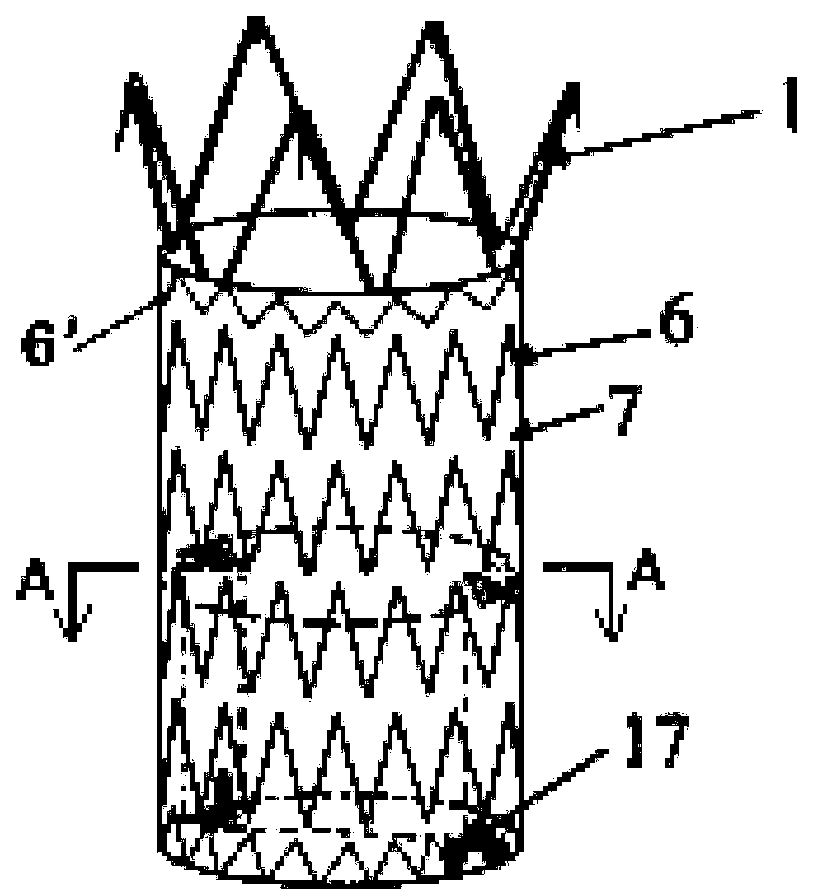

A combined abdominal aorta covered stent system and a utilization method thereof are applied to surgeries for endovascular interventional treatment of abdominal aortic aneurysm. The system comprises a body covered stent and a pair of branch covered stents, and each of the stent is cylindrical and provided with a delivery system. The near end of the body covered stent is a bare stent with barbs, a covered section comprises an upper half portion in a single-cavity cylinder shape and a lower half portion with a fixed outer diameter, and the lower half portion is averagely partitioned into two cavities by a longitudinal partition. Small-waveband stent rings are designed at near and far ends of the covered section of the body covered stent, and other covered parts can be either provided with stent rings or not. The upper half portion of the covered section is implanted at a neck position of infrarenal aortic aneurysm, and the lower half portion is suspended in an aneurysm cavity. The branch covered stents parallelly and internally sleeve the two cavities of the body covered stent, near ends of the branch covered stents are flush with the near end of the lower half portion of the body covered stent and fill the cavities of the body covered stent in a self-adoption manner, and far ends of the branch covered stents are implanted into iliac artery branches to better adapt to arterial aneurysms excessive in aneurysm neck torsion.

Owner:北京有卓正联医疗科技有限公司

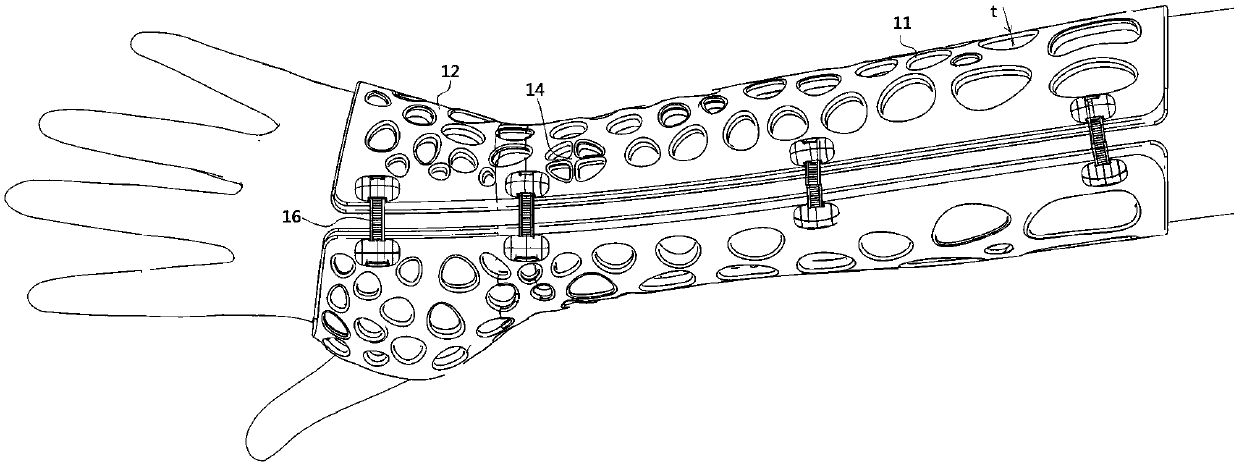

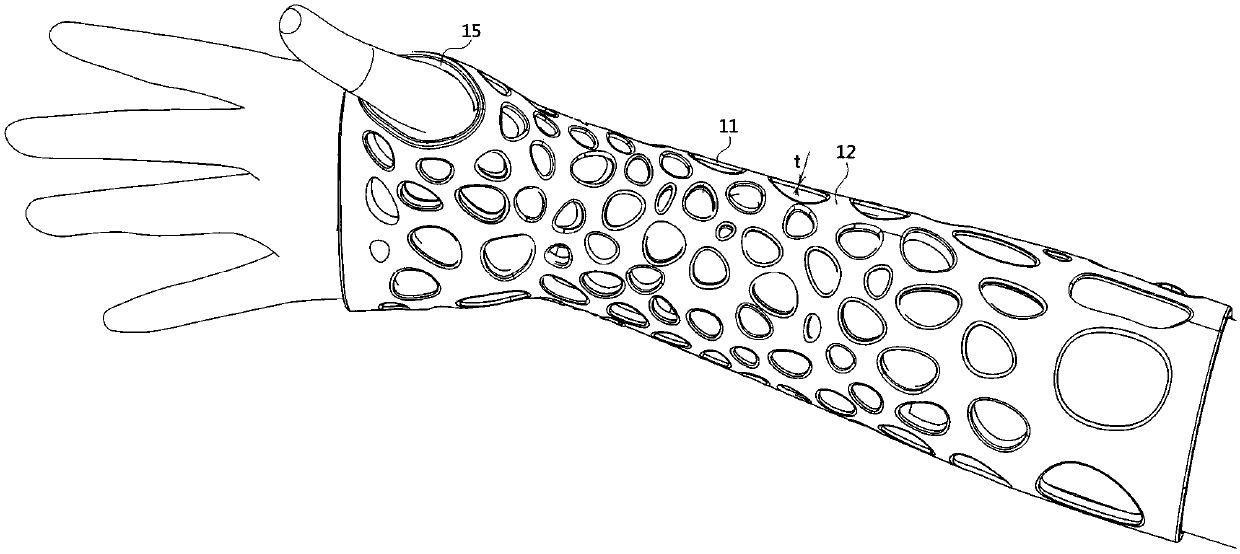

Adjustable outer fixing support and its material formula, preparation method and use method

Owner:WUHAN XUNSHU TECH CO LTD

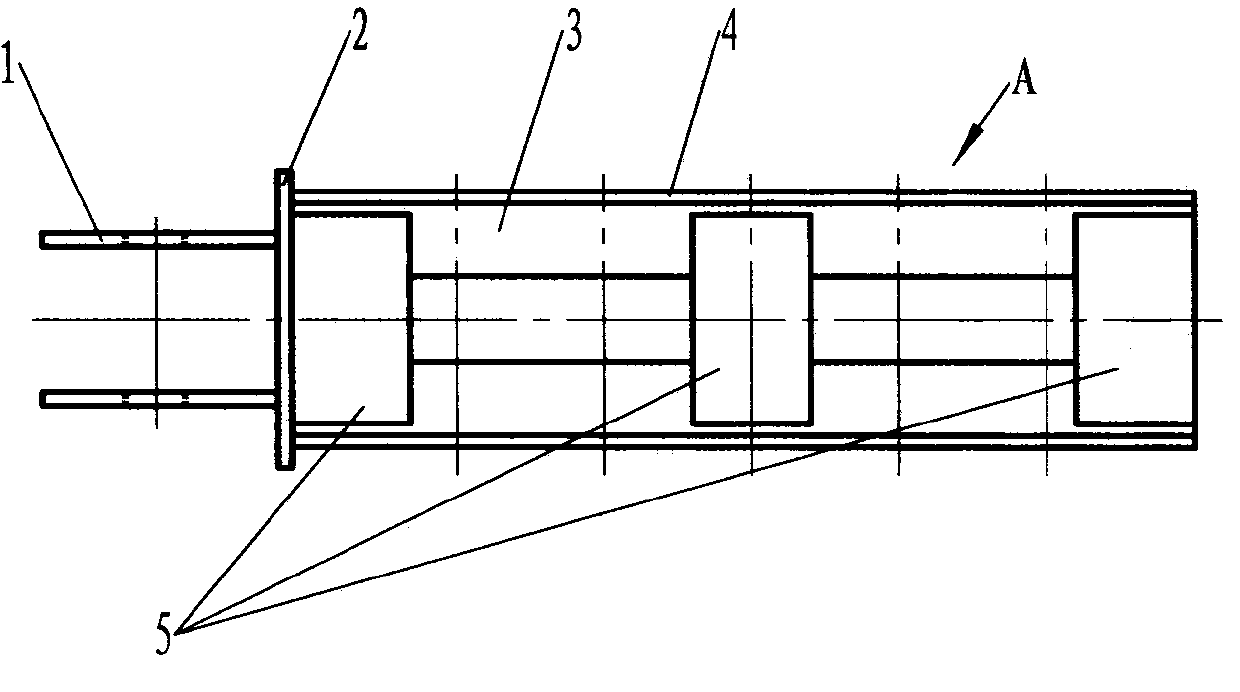

Production method of shoe heel steel pipe

InactiveCN101530871AReduce the number of specificationsIncrease production capacityMetallurgyContinuous rolling

The invention provides a production method of a shoe heel steel pipe, more particularly relates to the fixed pipe which is embedded in the shoe heel and used for being knocked in by a pinned top-piece, and the invention uses a continuous rolling method for forming to replace the punch forming of a progressive die. The method is characterized in that a band material is firstly subjected to compression-sheering forming at breaking mark in accordance with predetermined length of the steel pipe, and then the band material is rolled continuously by a plurality of groups of rolling wheels with different curvatures so that the flat-shaped band material are rolled into the expected shape of a round pipe, and finally the shaped pipe material is broken off at the previous breaking mark. Therefore the heel steel pipe with required length and outside diameter is formed. Through the above method of continuous rolling, uninterrupted continuous production of steel pipes can be carried out, which enhances the production efficiency. All the steel pipes with the same diameter but different lengths can be manufactured by the same group of rolling wheel, thus being capable of reducing expenses and costs of the mold substantially.

Owner:晏扬工业股份有限公司

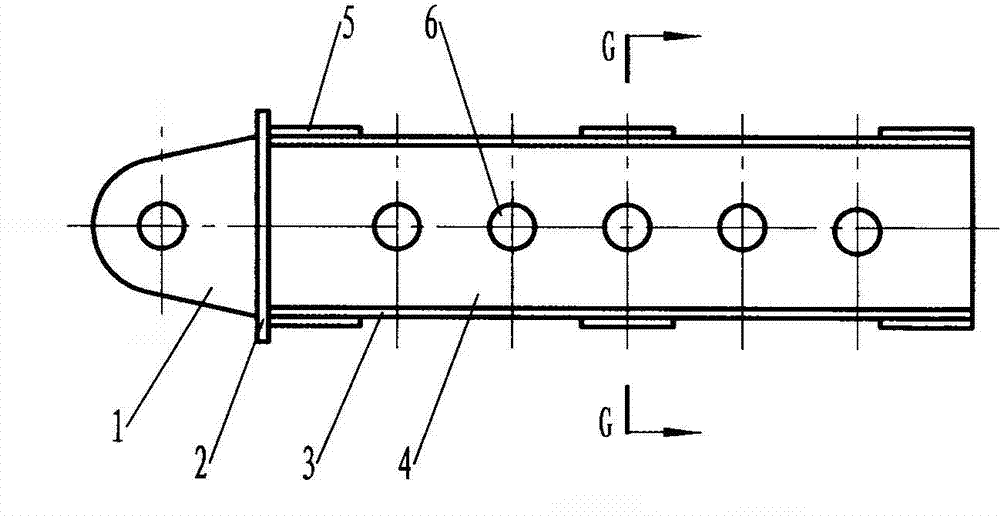

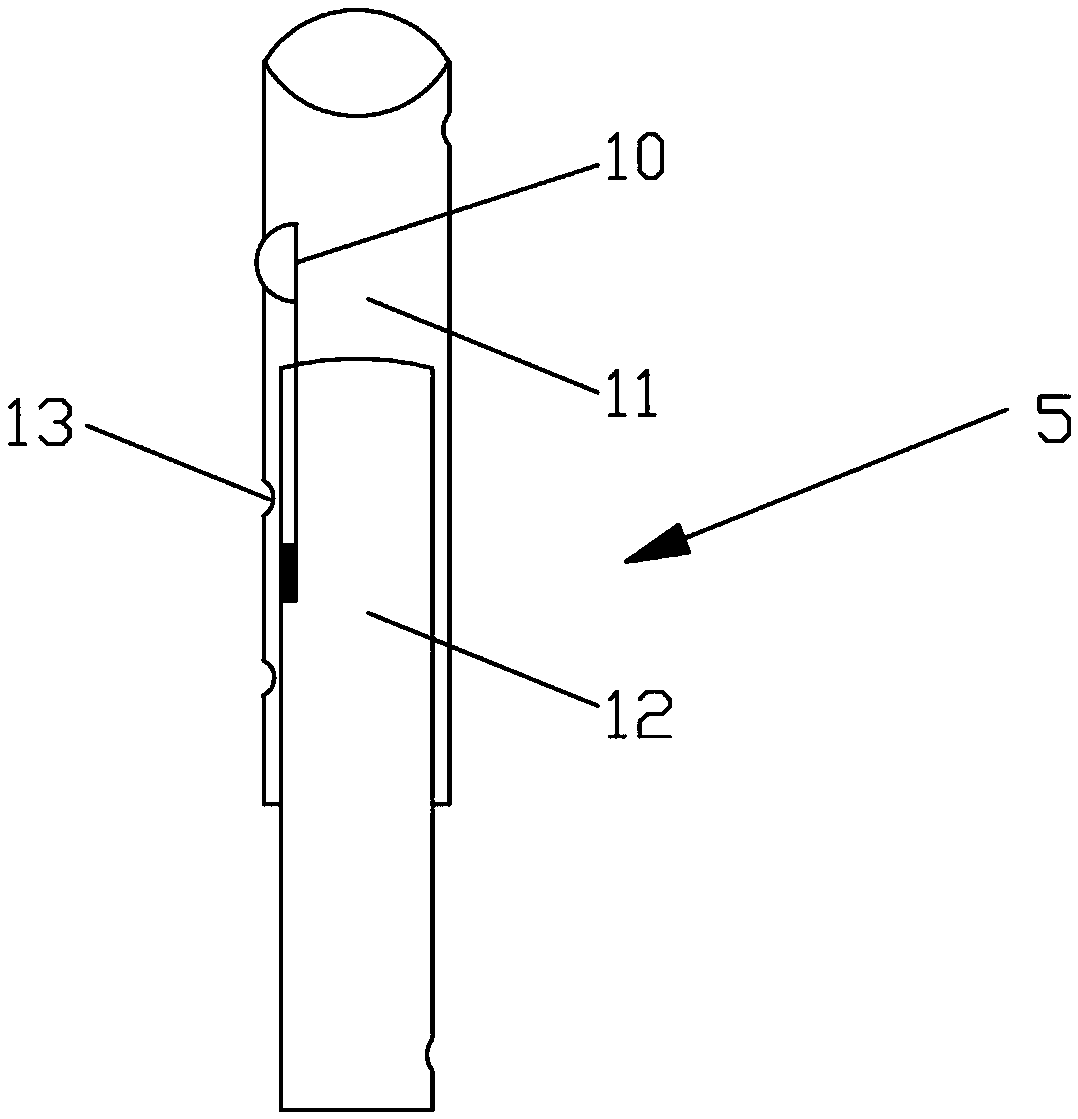

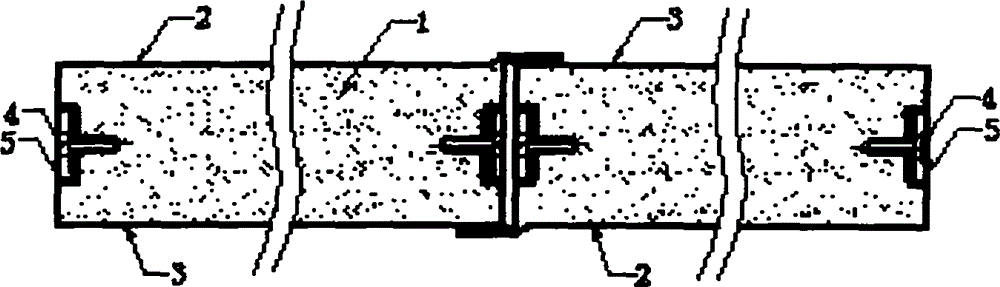

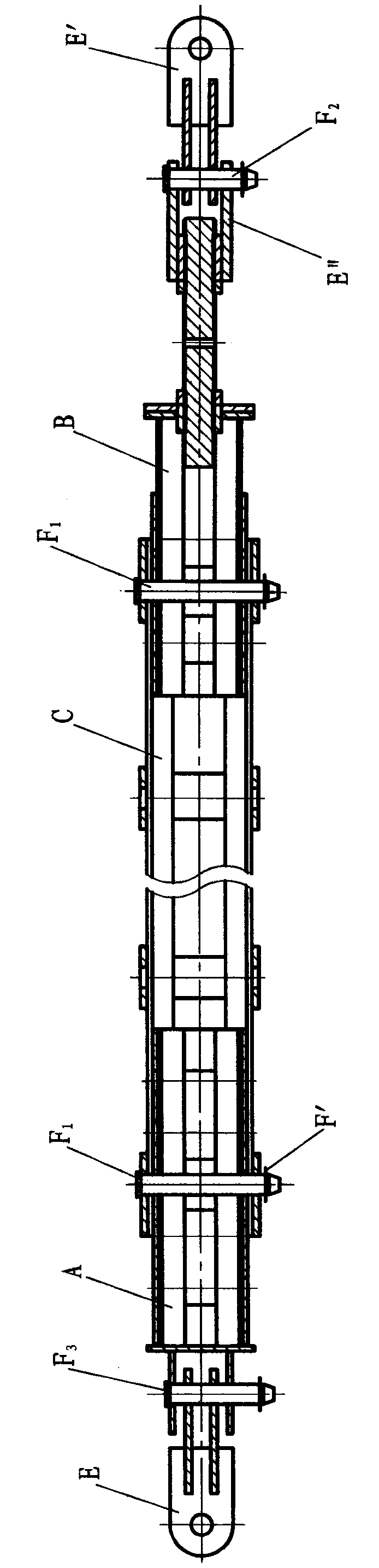

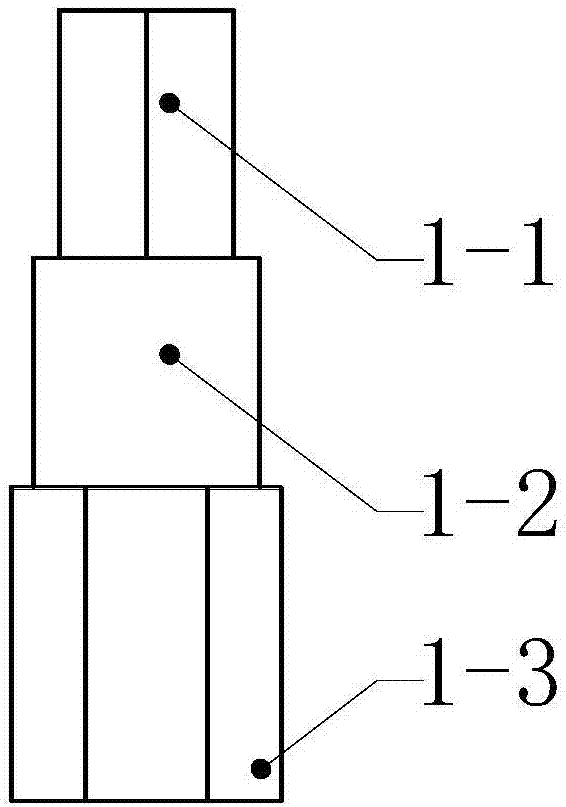

Modular combined-type tower crane attached bar with extensive stepless adjustment-type length

InactiveCN103086287ARealize stepless adjustmentStepless adjustable lengthCranesTower craneMechanical engineering

The invention discloses a modular combined-type tower crane attached bar with extensive stepless adjustment-type length. The modular combined-type tower crane attached bar with extensive stepless adjustment-type length comprises an upper connecting element, a lower connecting element, a screw rod adjustment device, a bar head, a bar tail, first bar bodies and second bar bodies; a first bar body or the combination of two first bar bodies and a second bar body is arranged between the bear head and the bar tail; when a bar body is arranged between the bar head and the bar tail, the bar head and the bar tail are respectively inserted into mounting holes at two ends of the first bar body, and are connected together respectively through a first pin shaft; when the combination of two first bar bodies and the second bar body is arranged between the bar head and the bar tail, two ends of the second bar body are respectively inserted into mounting holes at one ends of the two first bar bodies, and are connected together respectively through two fourth pin shafts; the bar head and the bar tail are respectively inserted into mounting holes at the other ends of the two first bar bodies, and are connected together respectively through a first pin shaft. The modular combined-type tower crane attached bar with extensive stepless adjustment-type length is simple to connect, can be used for improving the stress situations of the attached bar and a tower body at the attached point and the attached part, and is much safe and reliable in operation.

Owner:TANGSHAN CONSTR GRP

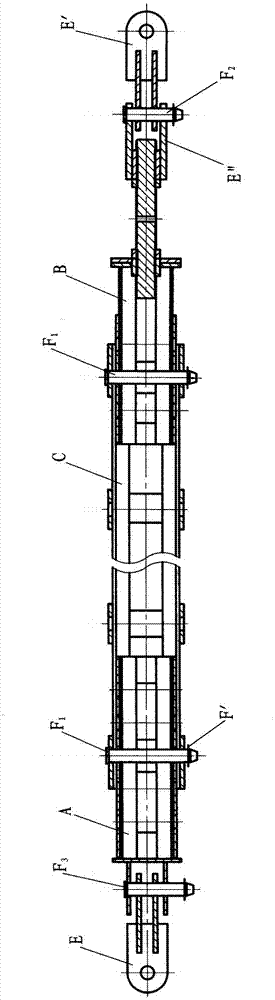

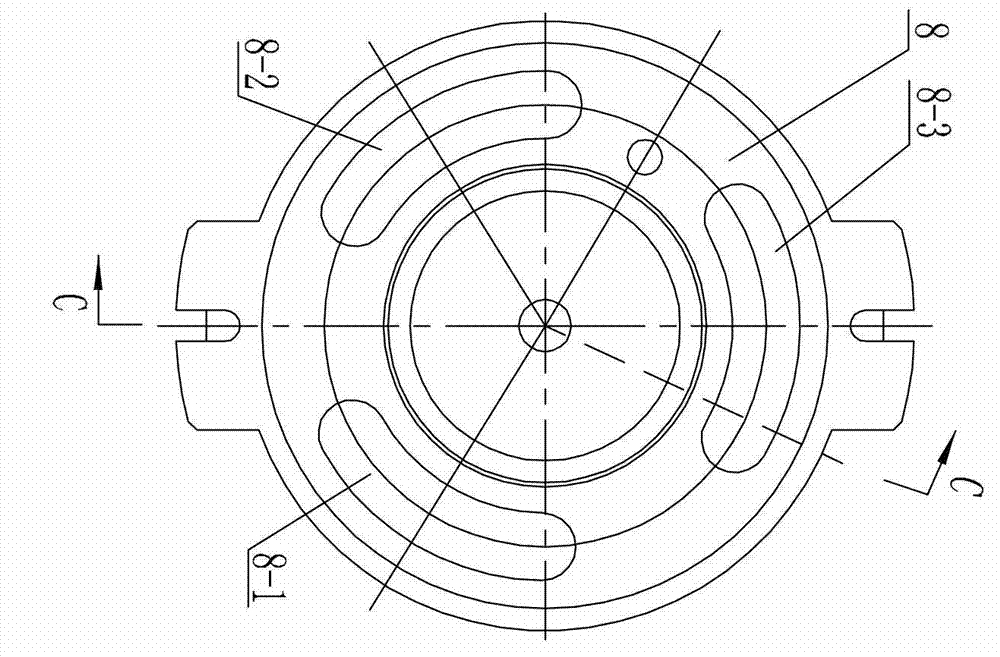

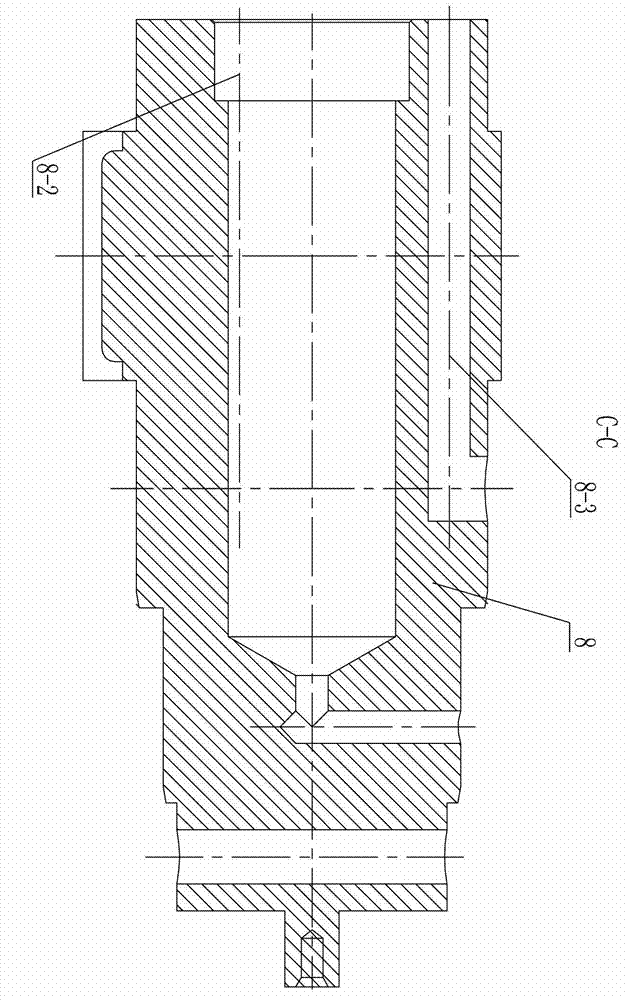

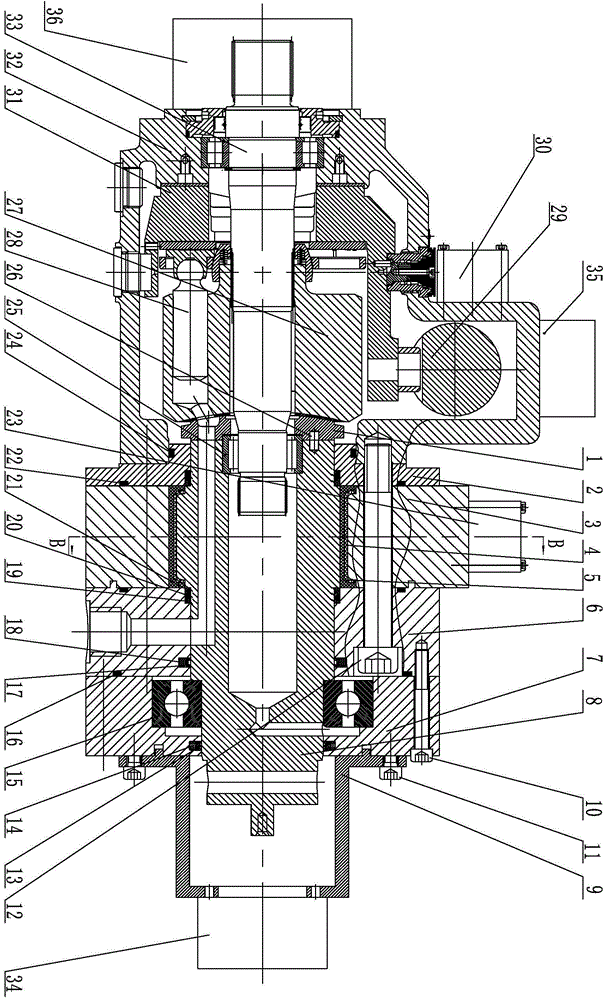

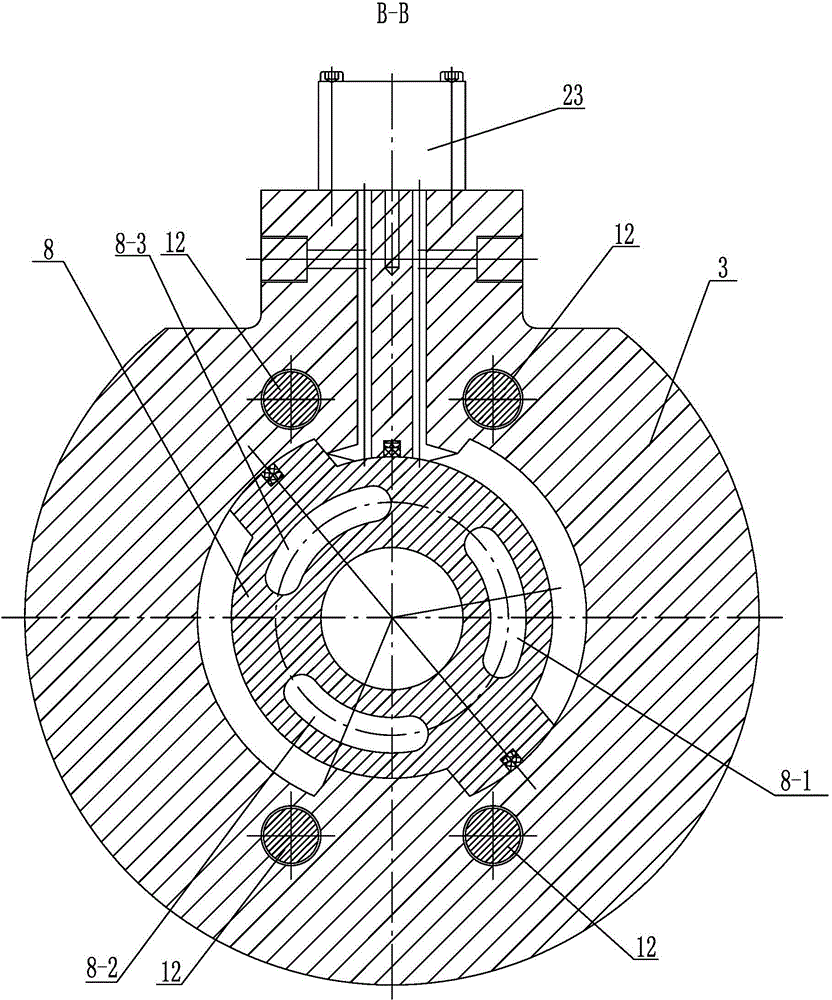

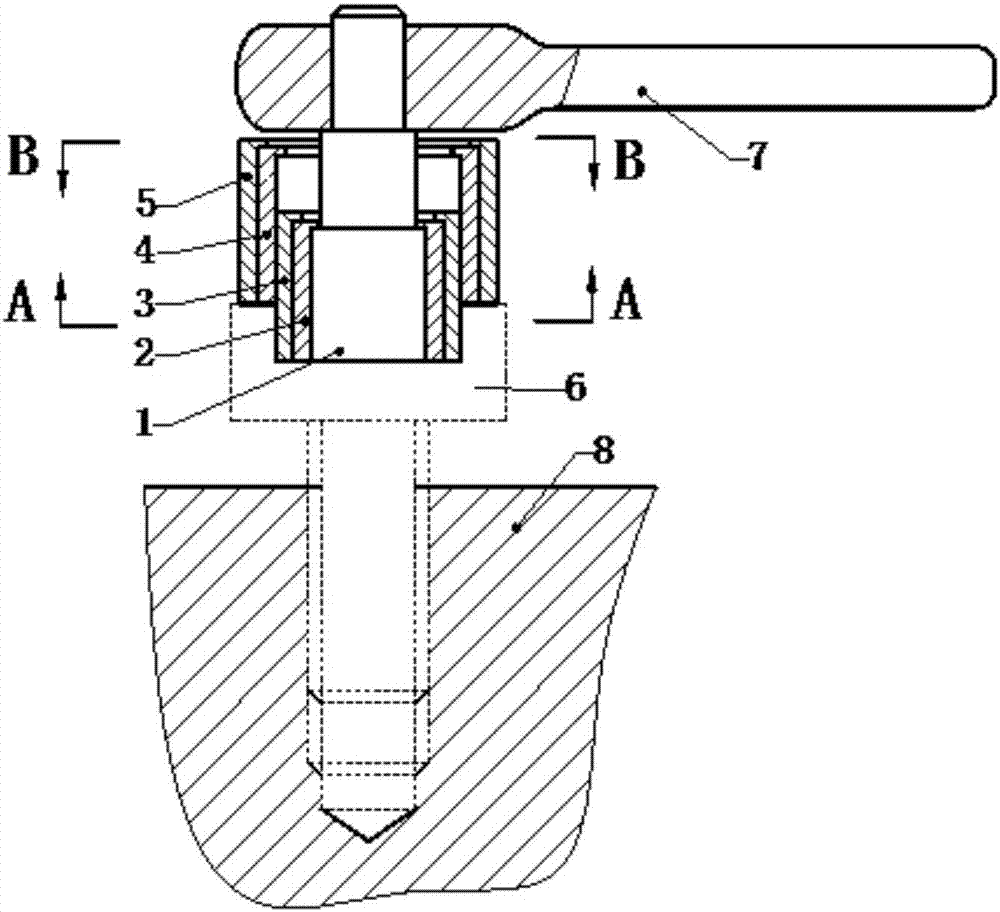

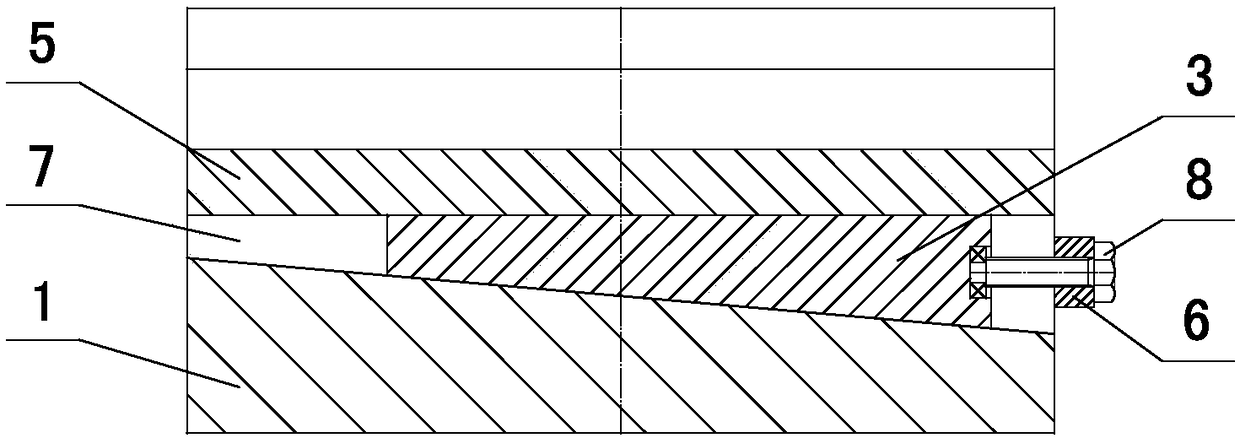

Variable electro-hydraulic servo hydraulic transformer

ActiveCN103174689ASolve out of controlRecoverable load energyFluid-pressure convertersFluid-pressure actuator componentsHydraulic cylinderDrive shaft

The invention provides a variable electro-hydraulic servo hydraulic transformer, and relates to an electro-hydraulic servo hydraulic transformer which resolves the problems that an existing hydraulic transformer is controllable in loading pressure and uncontrollable in loading flow, alternatively, the loading pressure and the loading flow are coupled, hydraulic transformers of different standards need to be applied to different areas, and universalization is not achieved. The variable electro-hydraulic servo hydraulic transformer comprises a thrust plate servo mechanism and a swash plate servo mechanism, the valve plate servo mechanism comprises a thrust plate, an end cover, a thrust shell, a bearing cover, a bearing, a first hydraulic control valve and a swing motor, the thrust plate is in detachable connection with a blade shaft, a motor shell is arranged between the end cover and the thrust shell and in detachable connection with the end cover and the thrust shell, and the first hydraulic control valve is arranged on the motor shell. The swash plate servo mechanism comprises a cylinder, a hydraulic cylinder, a second hydraulic control valve, a swash plate, a shell, a transmission shaft and a plurality of plungers, wherein the shell is in detachable connection with the end cover. The variable electro-hydraulic servo hydraulic transformer is used for a system control valve of the hydraulic field.

Owner:HARBIN INST OF TECH

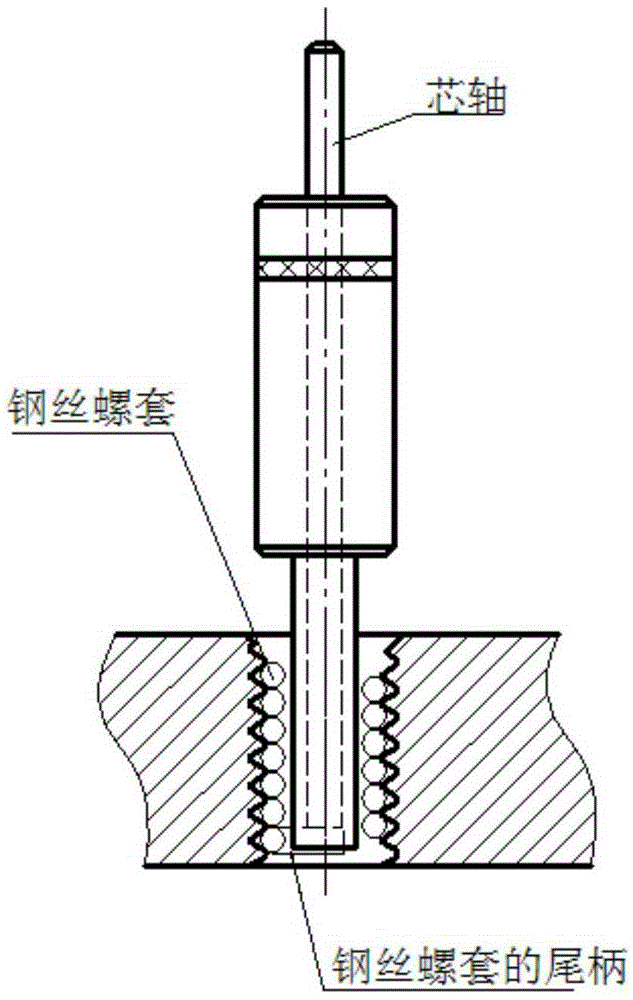

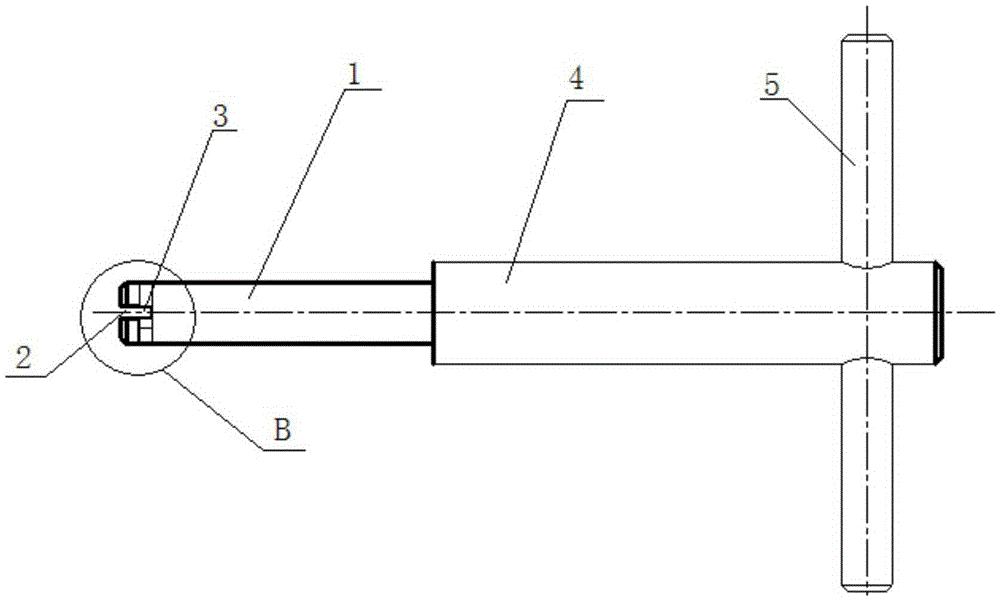

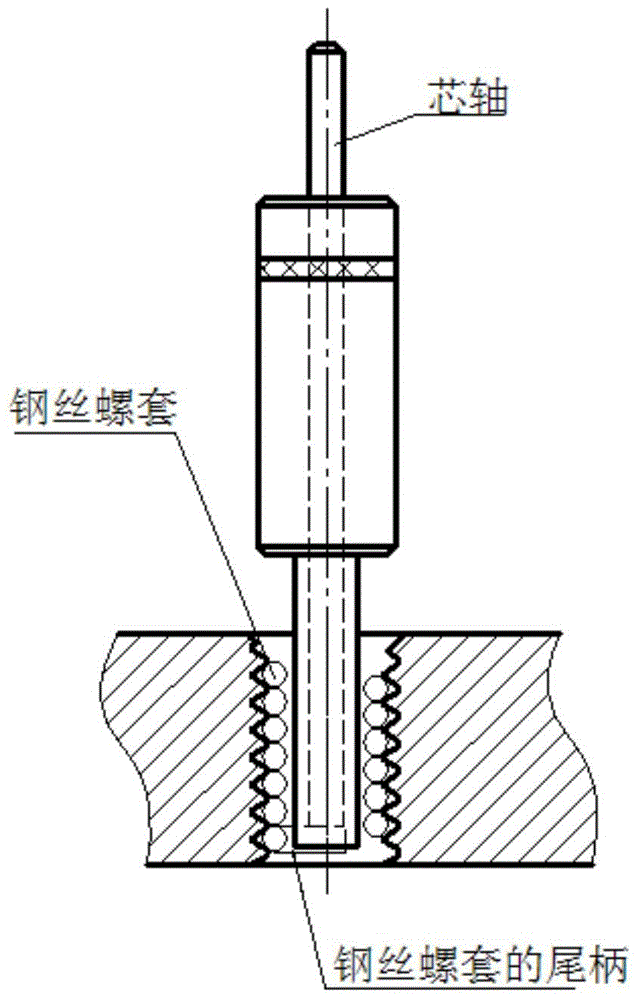

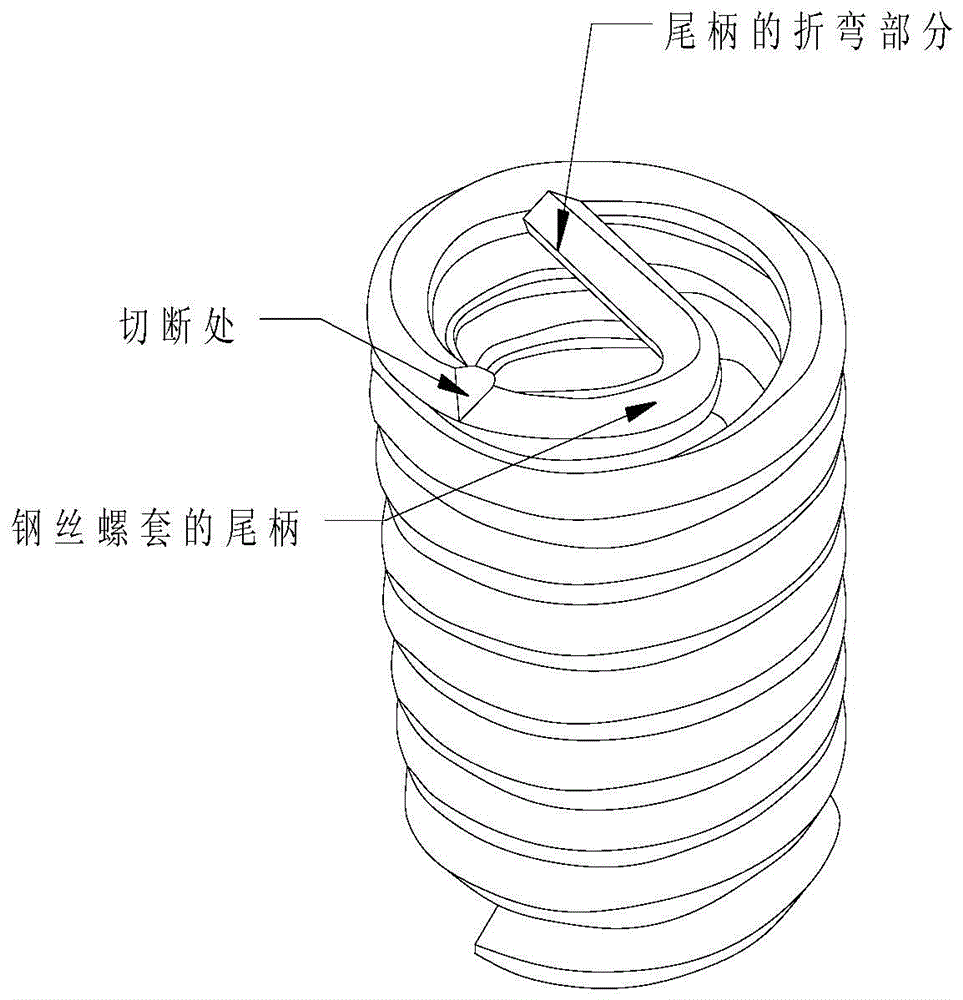

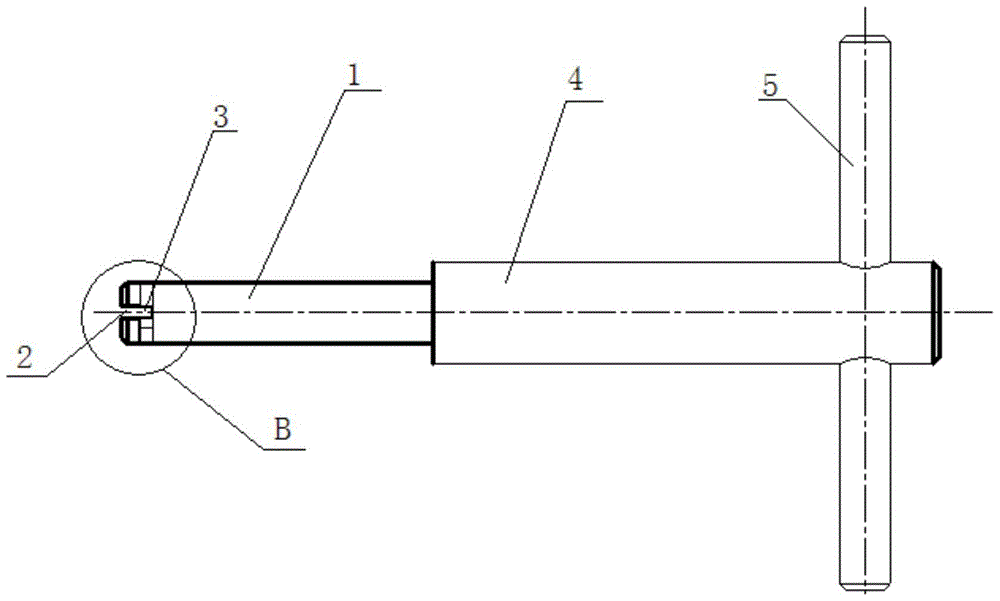

Device and method for cutting off and collecting steel wire thread sleeve tail shank of casing with complex blind cavity

The invention belongs to the technical field of new manufacturing and maintaining of a casing part with a steel wire thread sleeve needing to be mounted in a space flight and aviation gas turbine engine, and particularly relates to a device and method for cutting off and collecting the steel wire thread sleeve mounted on a casing with a complex blind cavity. The device comprises a connecting rod, a hand shank rod and a guide core bar. A groove A is formed in the portion of one end of the lead core bar. After a tail shank is inserted along an inner hole of the steel wire thread sleeve, the bent part of the tail shank can enter along an opening of the groove A, a groove B is formed in the circumferential direction of the groove A, a certain included angle is formed by the groove B and the groove A, and after the bent part of the tail shank enters the groove A, the lead core bar is rotated so that the bent part can enter the groove B. The other end of the lead core bar is connected with one end of the connecting rod, and the other end of the connecting rod is connected with the hand shank rod used for enabling the guide core bar and the connecting rod to rotate. Two process steps of cutting off the tail shank and taking out the waste tail shank of a previous steel wire thread sleeve assembling technology are combined into one process step of cutting off and taking out, the tail shank is taken out while being cut off, and broken tail shanks do not need to be found any more.

Owner:AECC AVIATION POWER CO LTD

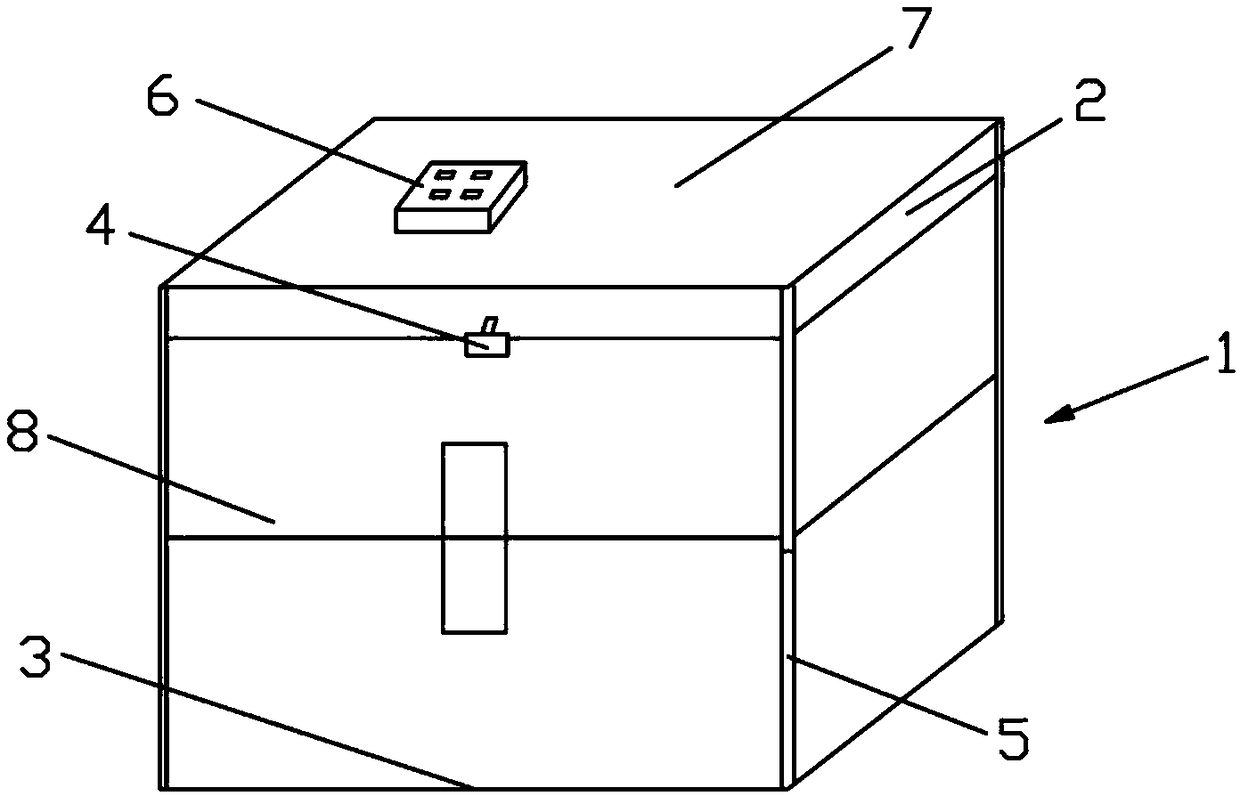

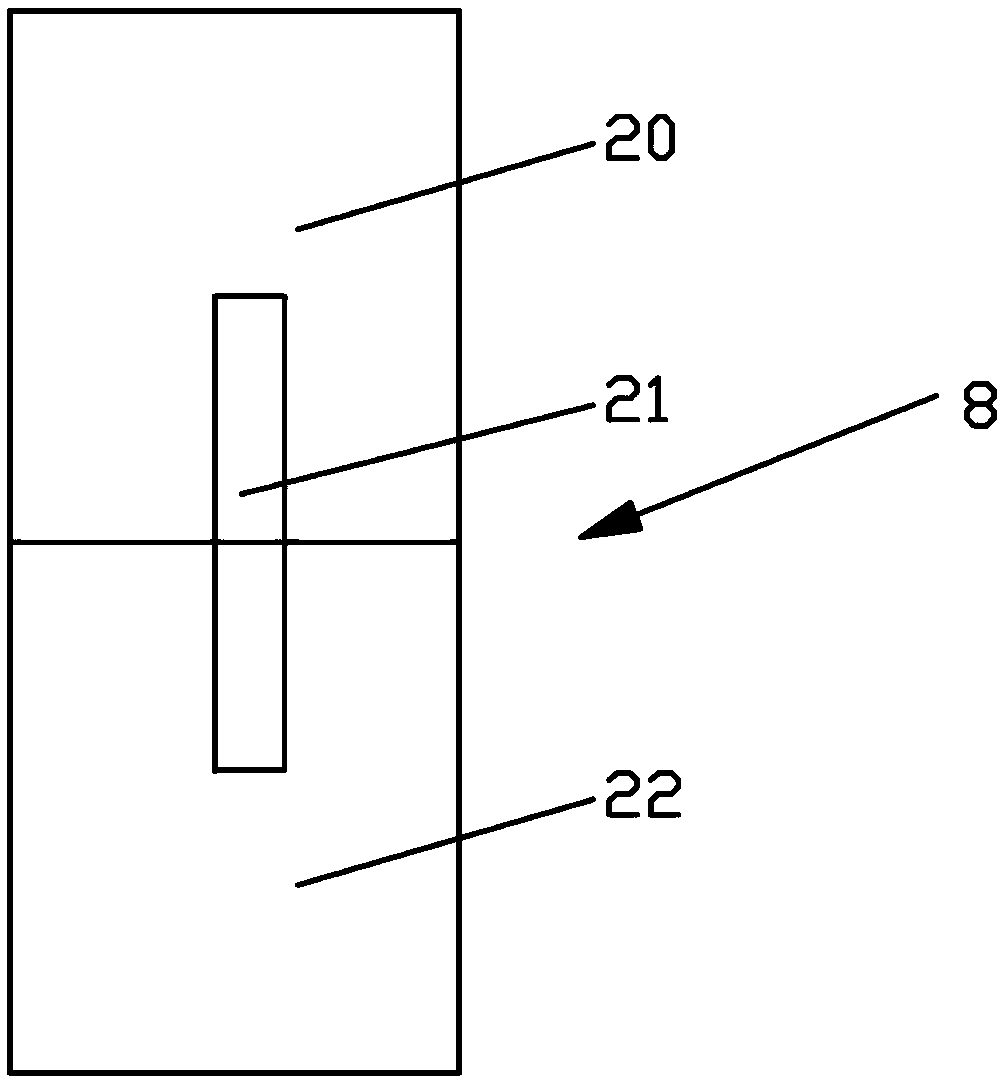

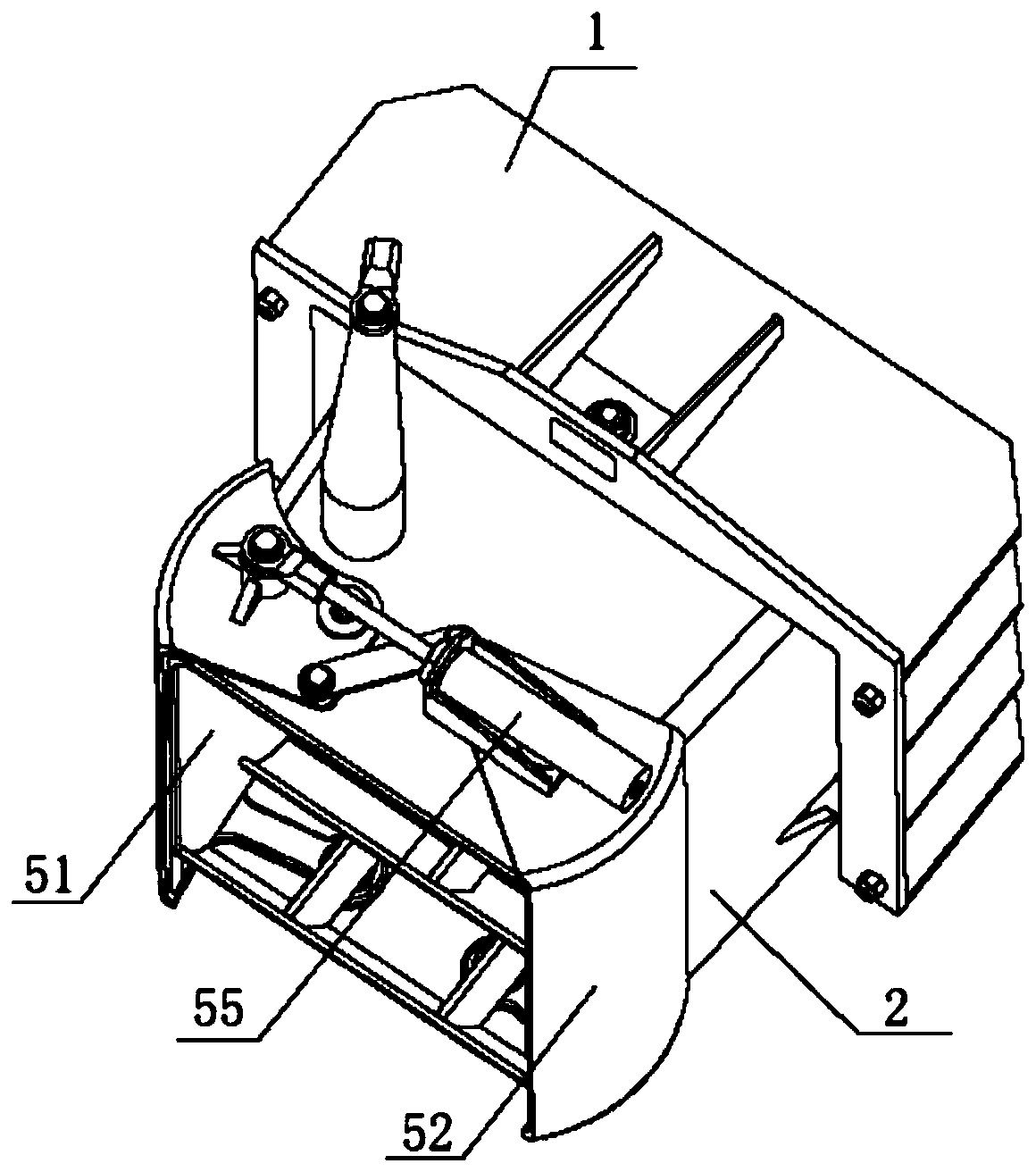

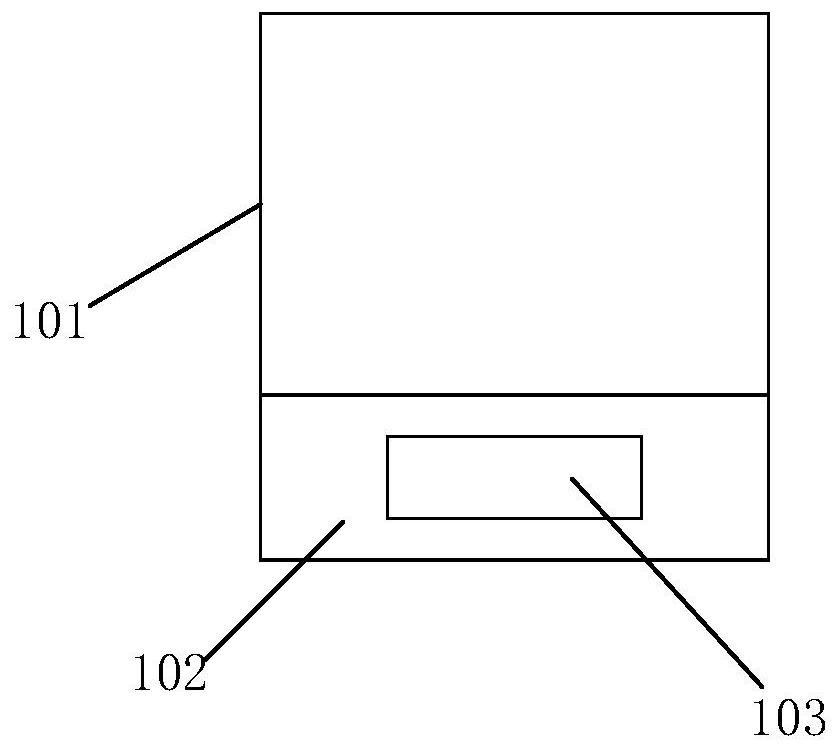

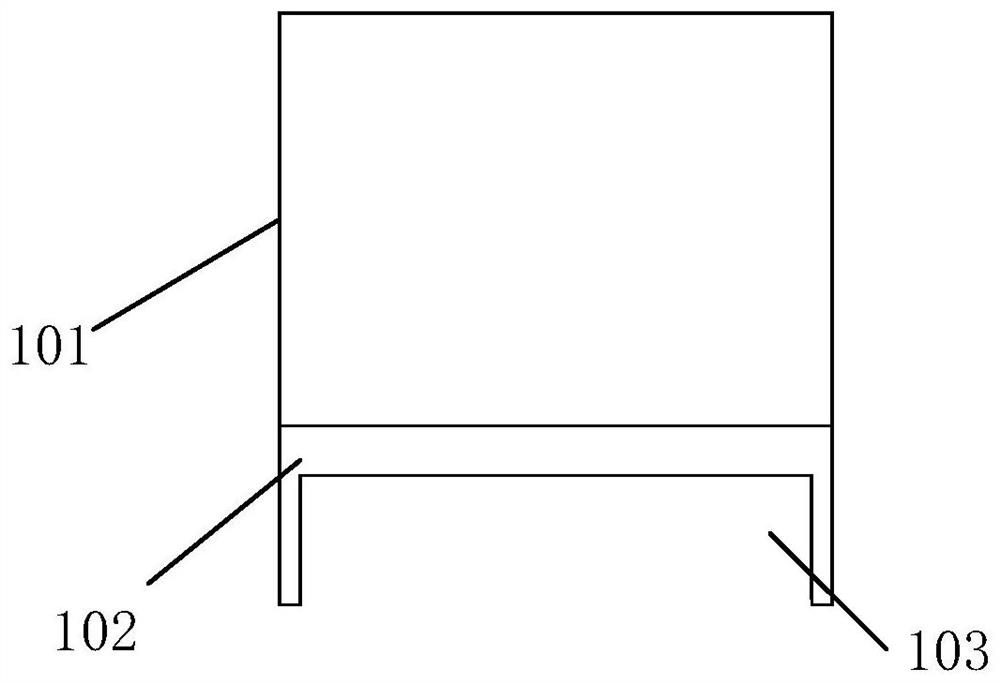

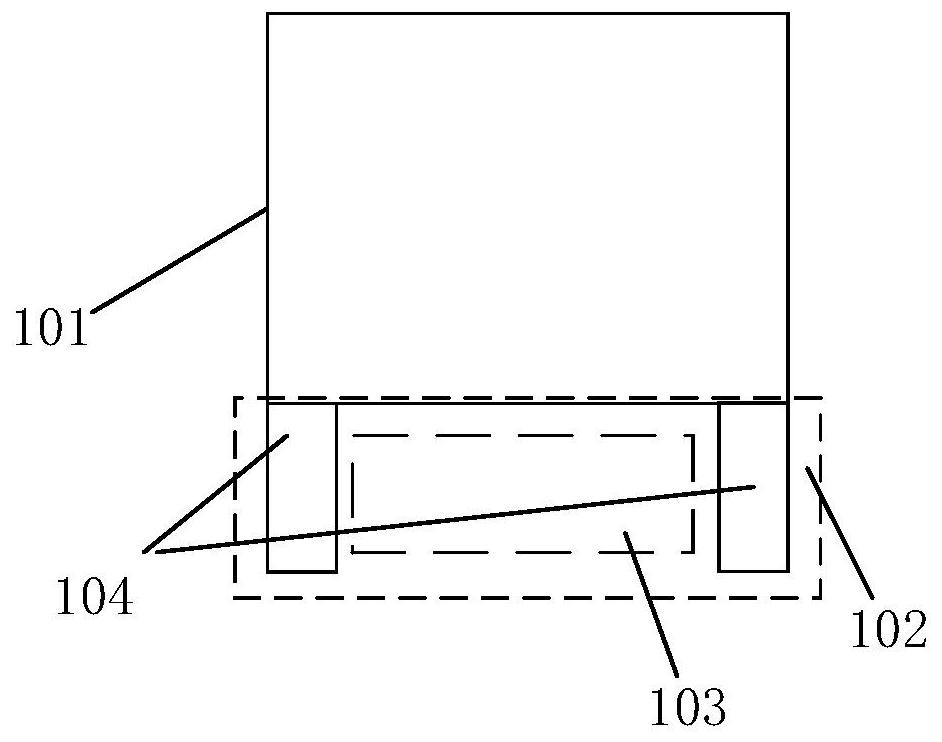

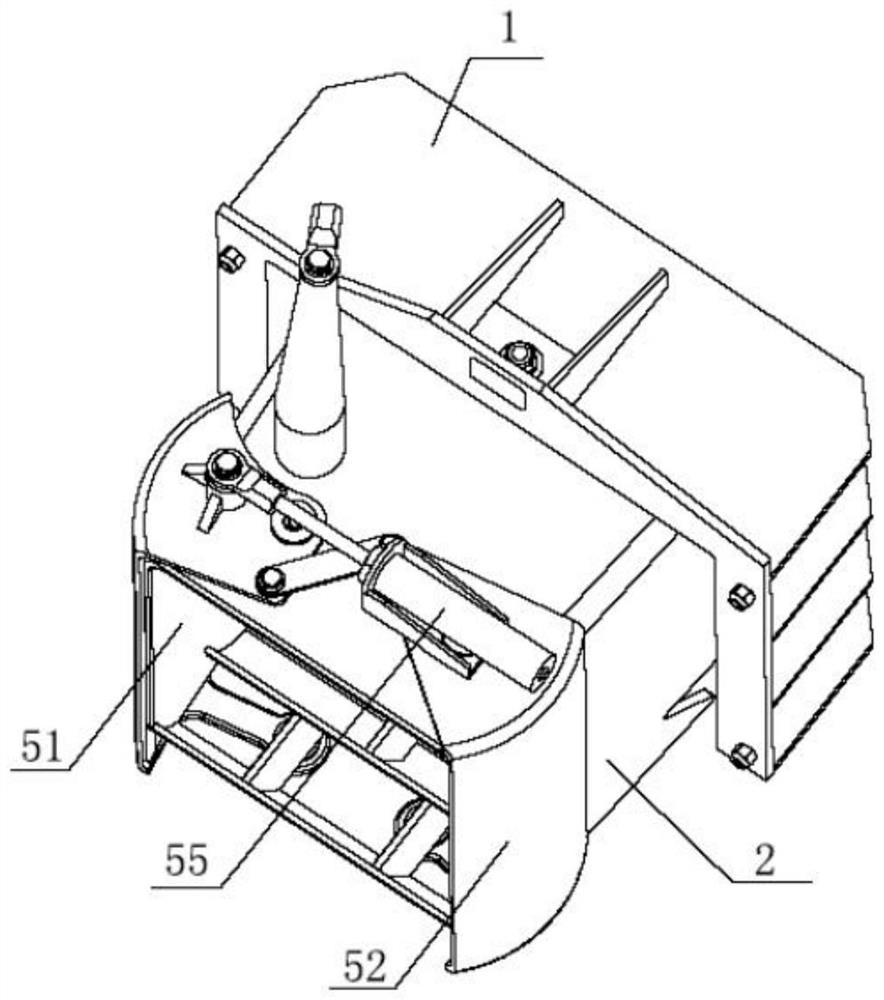

Express delivery box recyclable and adjustable in size

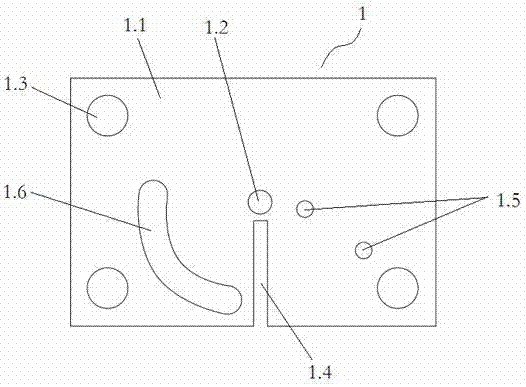

InactiveCN108657598AReduce the number of specificationsImprove efficiencyPackage recyclingClosure with auxillary devicesElectromagnetic lockEngineering

The invention relates to the technical field of express delivery boxes, in particular to an express delivery box recyclable and adjustable in size. The express delivery box recyclable and adjustable in size comprises a box body, a box cover and a box bottom; the box body (1) is fixedly connected with the box bottom; one sides of the box body and the box cover are hinged; the other sides of the boxbody and the box cover are correspondingly connected through an electromagnetic lock; the box cover is provided with an electronic assembly and an express receipt placement area; the electronic assembly controls unlocking and locking of the electromagnetic lock; and the box body is provided with a telescopic mechanism for adjusting the size of the box body. By the adoption of the structural arrangement, the size of the express delivery box can be adjusted by the telescopic mechanism, the specification and number of express delivery boxes are reduced, the use efficiency and space of the box are improved, unlocking and locking of the express delivery box are achieved through the electronic assembly, goods tracking and positioning can be achieved through a GPS chip, and goods are prevented from being lost.

Owner:WUHAN UNIV OF TECH

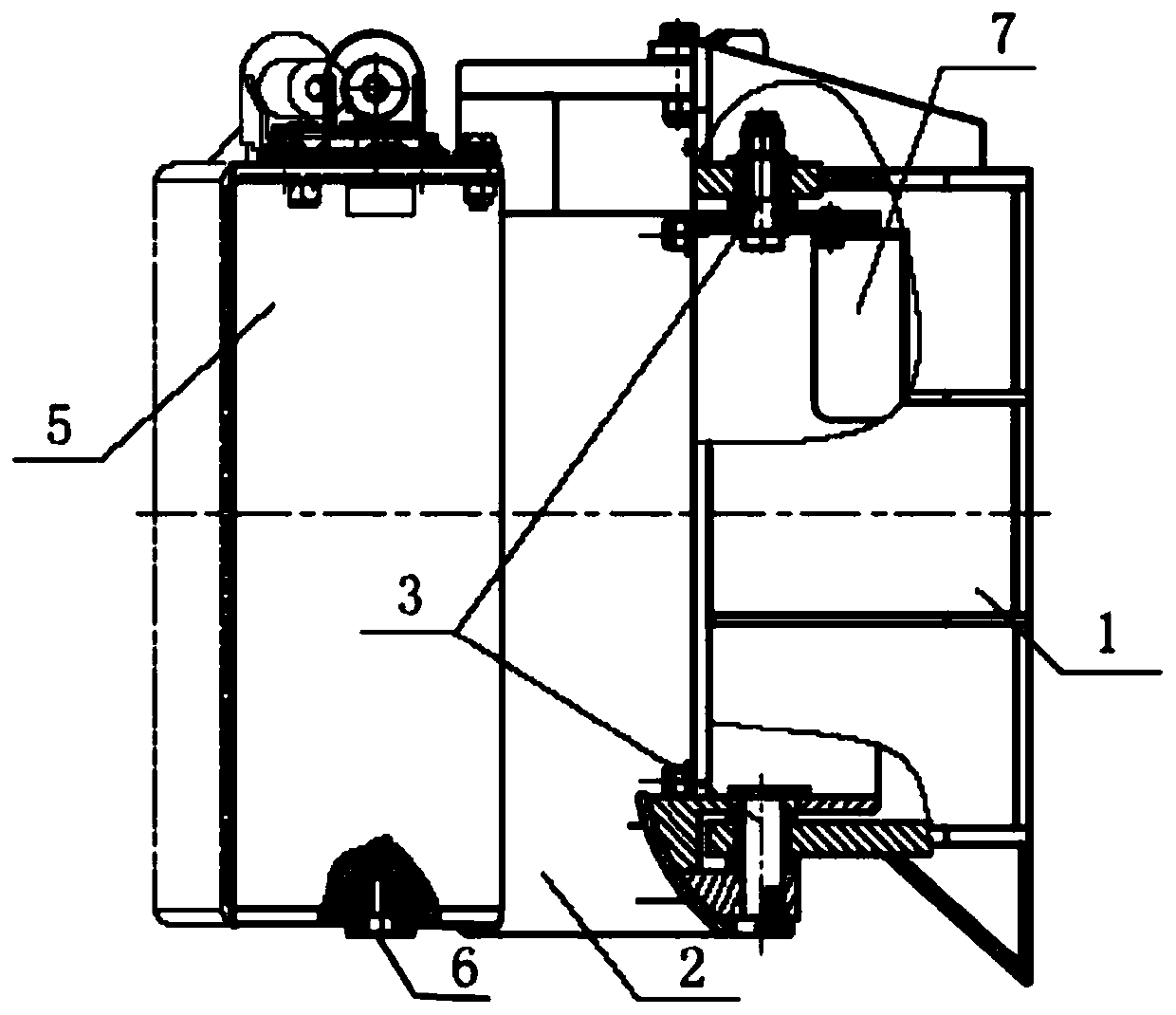

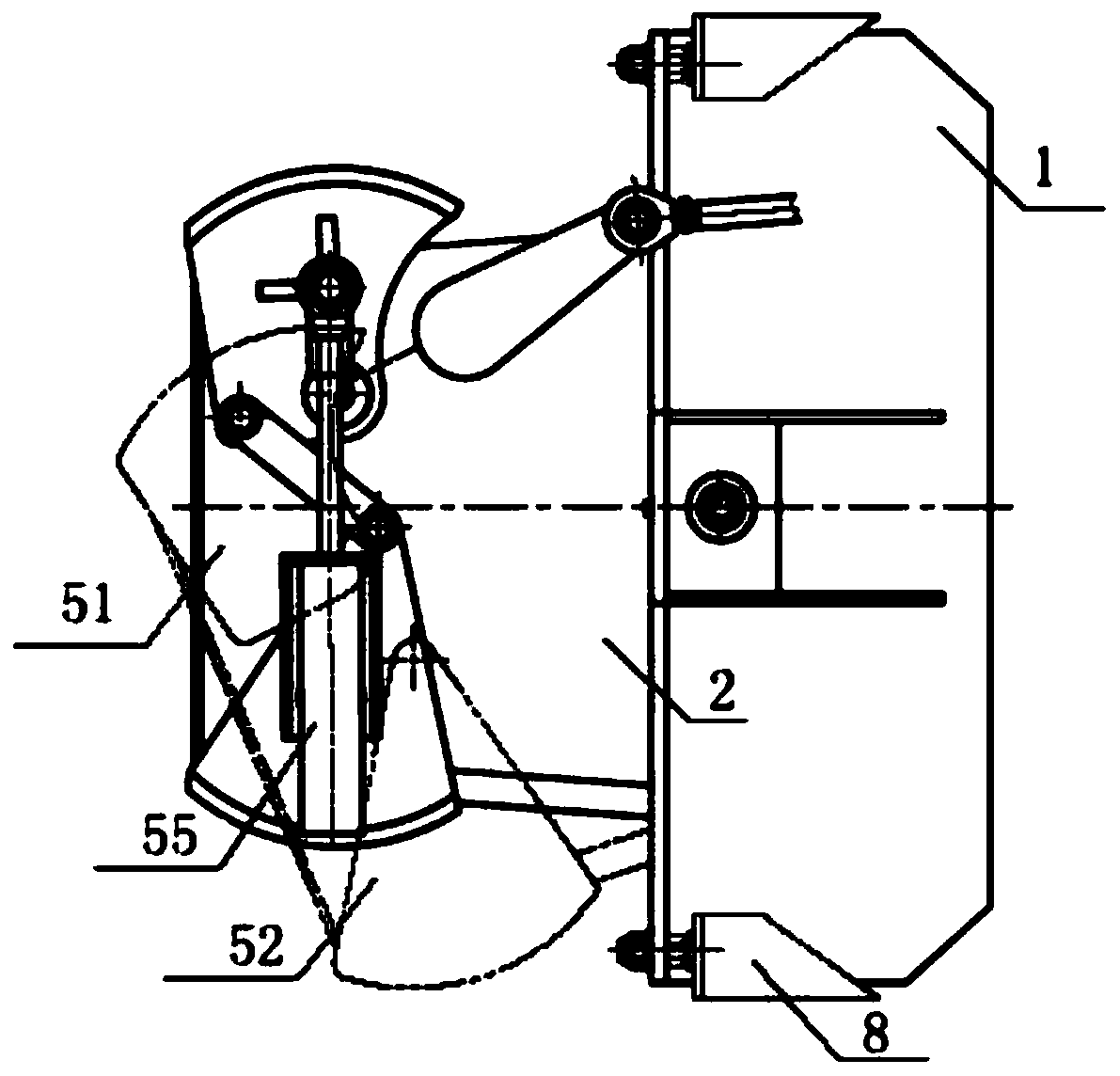

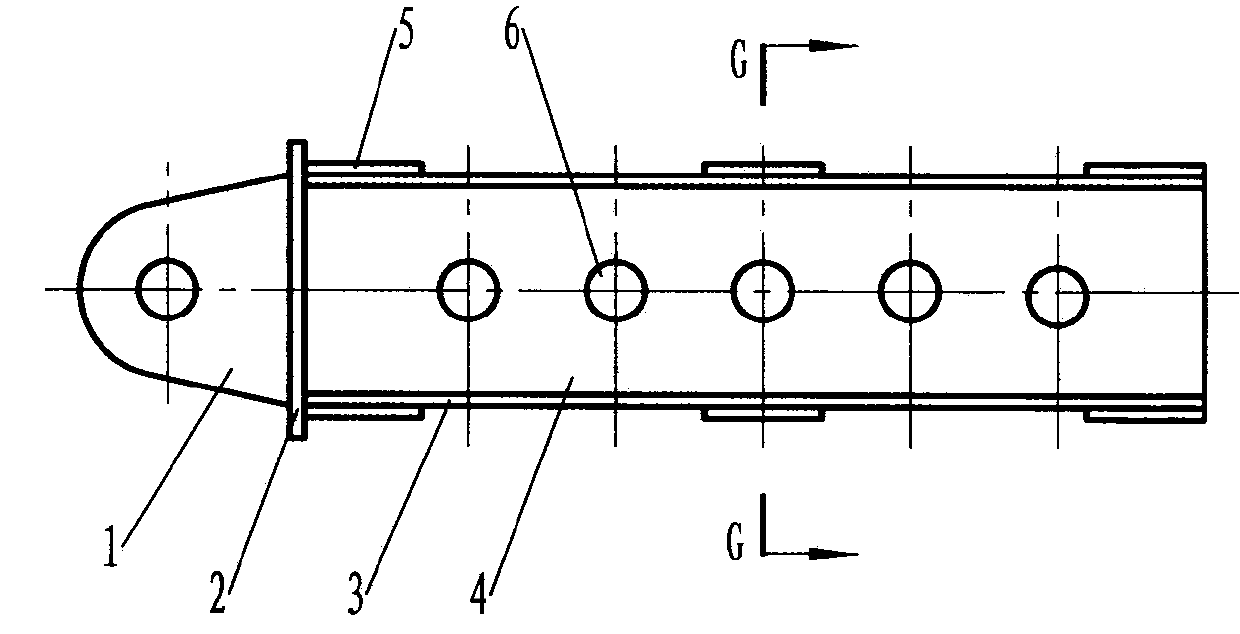

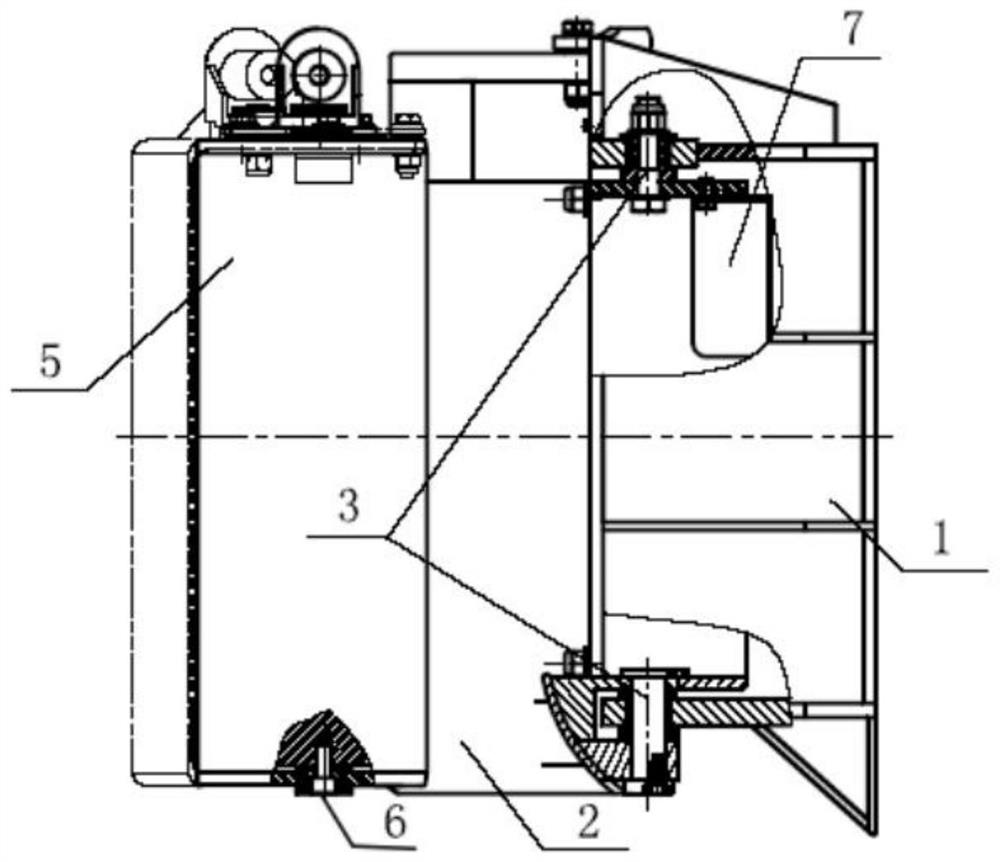

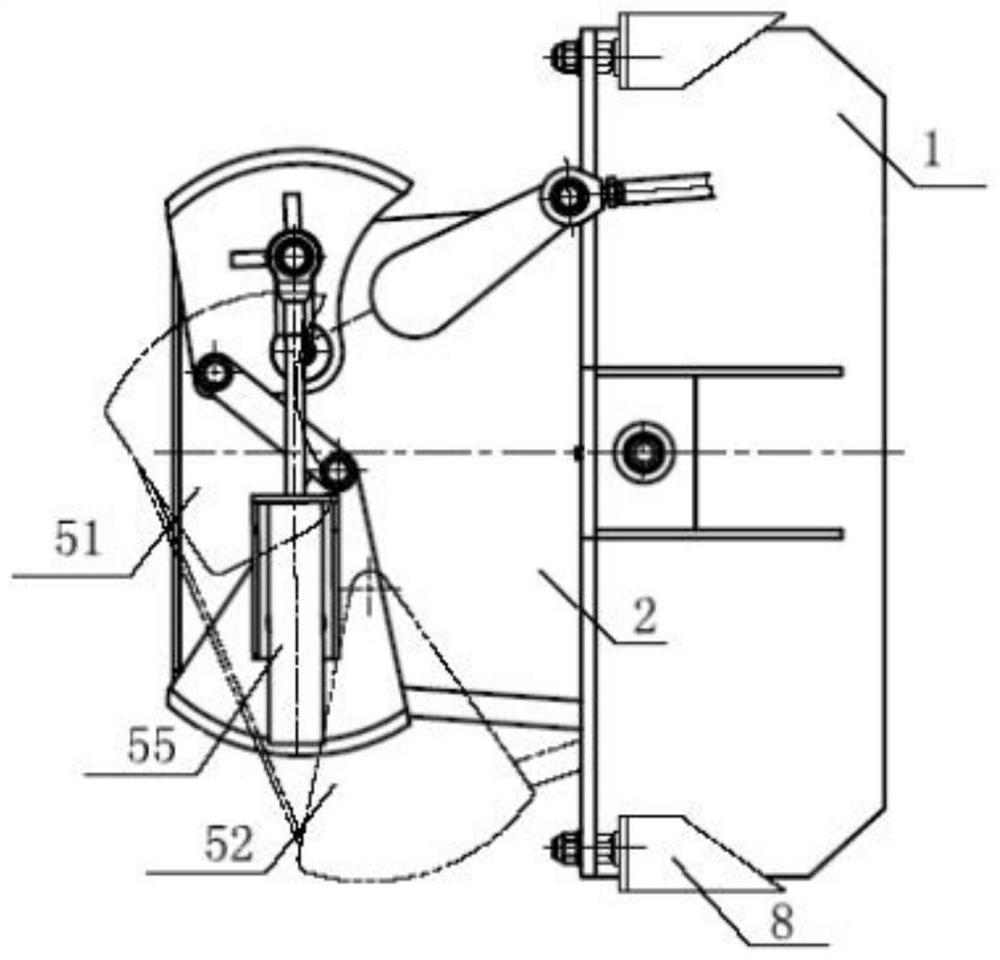

Modular water-jet propulsion steering and backward navigation mechanism

ActiveCN110481751AReduce the number of specificationsRealize connectionlessSteering by jetsModularityWater flow

The invention provides a modular water-jet propulsion steering and backward navigation mechanism, and relates to the technical field of ship propulsion. The mechanism comprises a steering and backwardnavigation mechanism bracket for fixing a water-jet propulsion steering and backward navigation mechanism; a rudder which is connected with the steering and backward navigation mechanism bracket through a first pin shaft and is used for moving left and right around the first pin shaft under the driving of a steering oil cylinder arranged in the rudder, so that the jet water flow is reversely folded towards the side to realize steering; a reversing vehicle door which is connected with the rudder through a second pin shaft and used for achieving the ahead function in the open state and enablingthe jet water flow to be reversely folded towards the ship bottom in the closed state so as to achieve backward navigation; and an auxiliary rudder plate which is installed on the rudder through a fastener and used for rotating along with the rudder so as to improve the rudder effect. Through modularization of the water jet propulsion steering and backward navigation mechanism, the specificationnumber of the mechanism is reduced, the design and machining cost is reduced, and the machining period is shortened; the assembling and disassembling difficulty is effectively reduced; the processingdifficulty and the rejection rate of the guide vane body are reduced; and product reliability is improved.

Owner:708TH RES INST OF CSSC

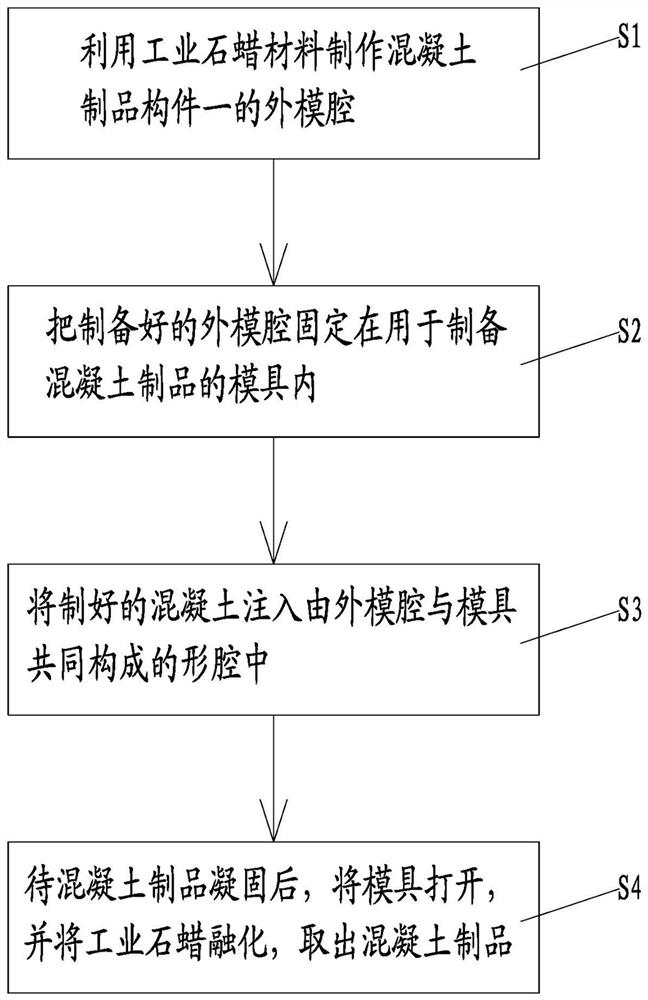

Concrete product forming process

InactiveCN113561294AImprove pass rateSolve the difficulty of demouldingCeramic shaping mandrelsCeramic shaping coresParaffin waxStructural engineering

The invention discloses a concrete product forming process. The concrete product forming process comprises the following steps: firstly, manufacturing an outer mold cavity or an inner mold core of a concrete product by utilizing an industrial paraffin material; fixing the prepared outer mold cavity or inner mold core in a mold for preparing the concrete product; then injecting prepared concrete into a cavity formed by the outer mold cavity or the inner mold core and the mold; and finally, after the concrete product is solidified, opening the mold, melting the paraffin, and the taking out the concrete product. According to the concrete product forming process, the processing problem of concrete products with special structures and difficult demolding can be solved, the mold structure is simple, the manufacturing time is short, the universality is high, and the mold investment cost is greatly reduced.

Owner:付庆文

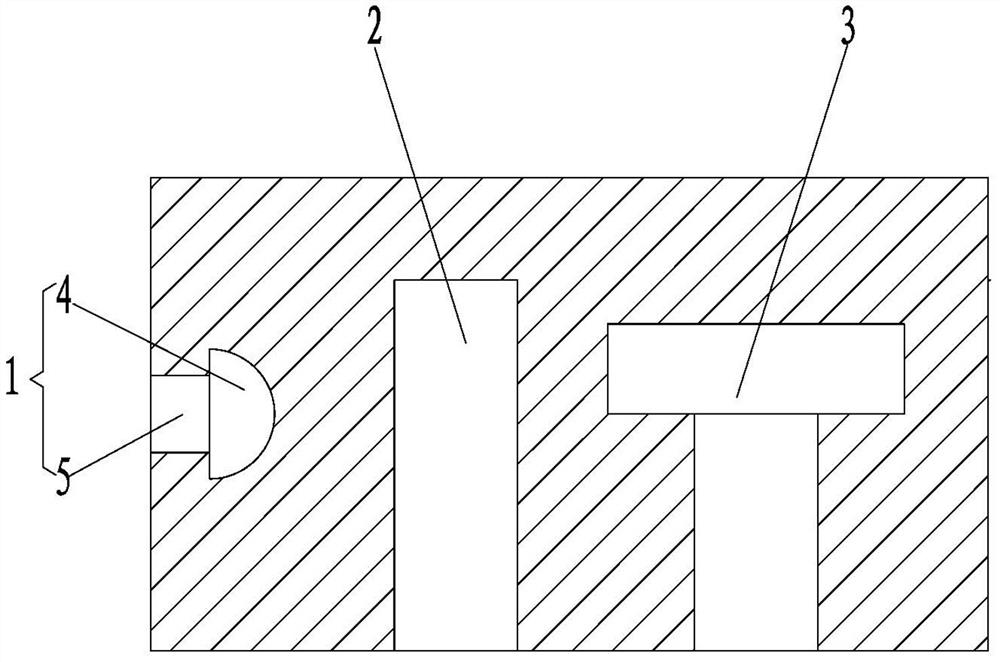

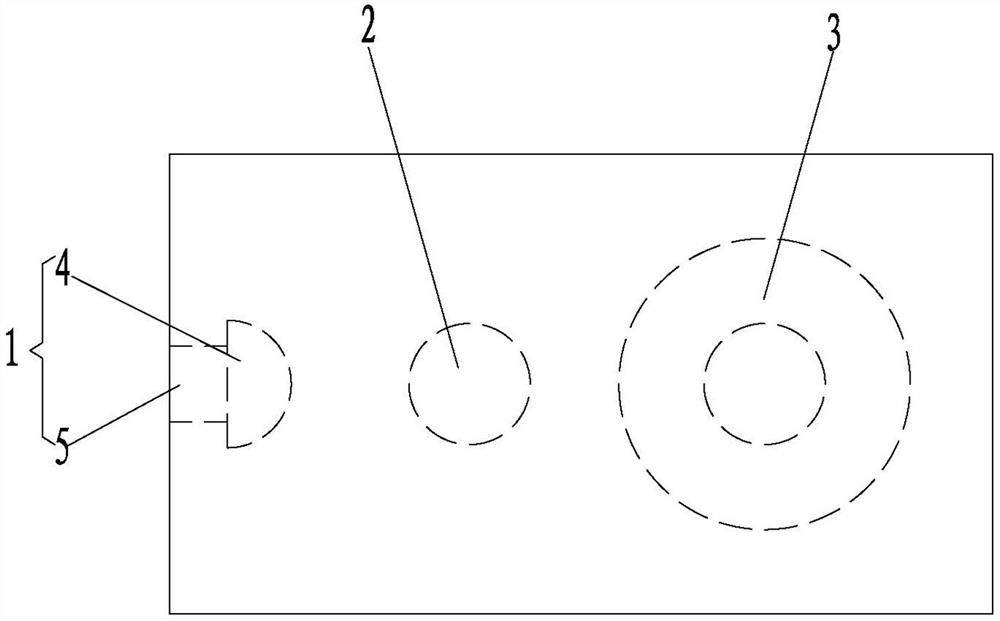

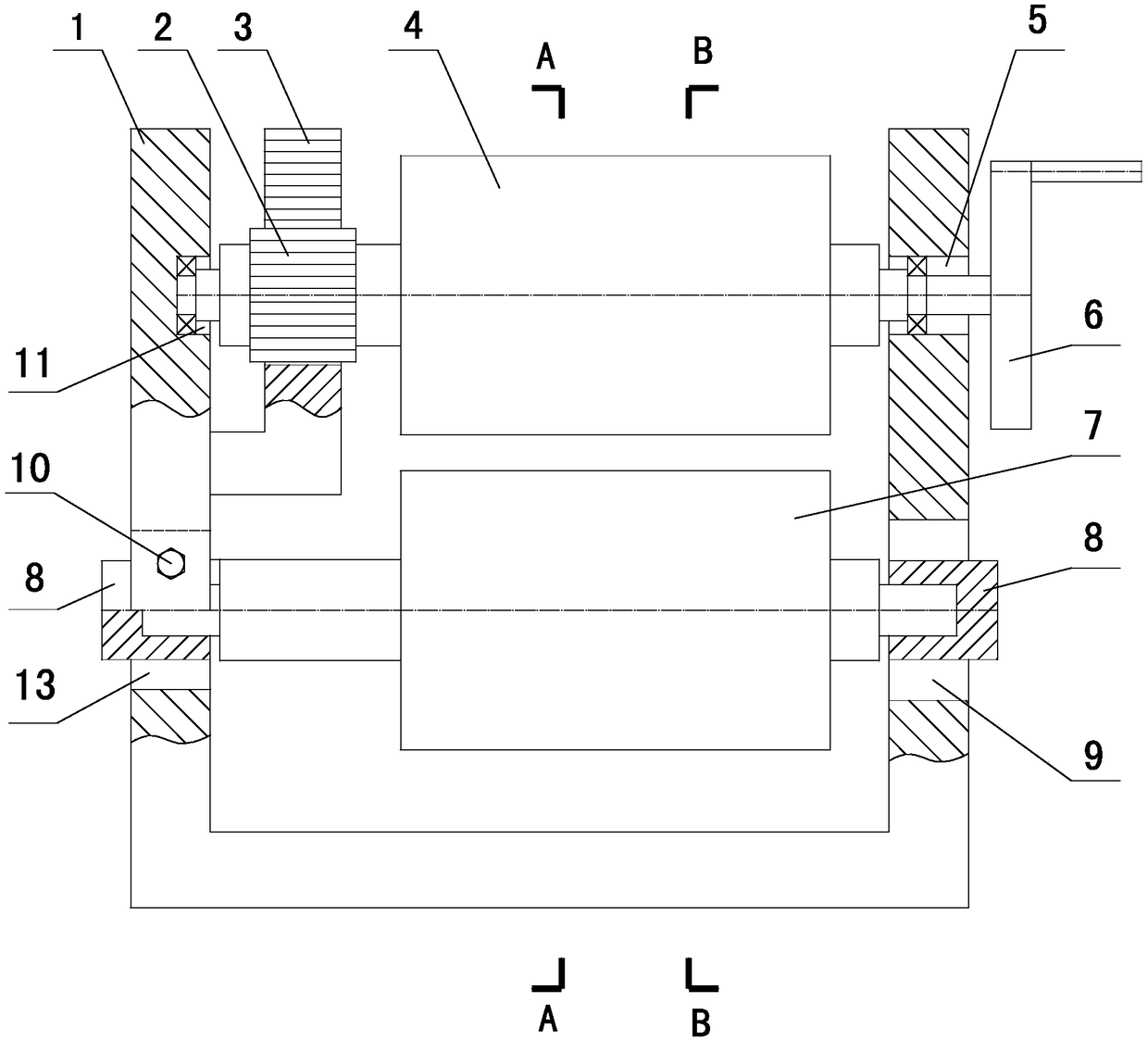

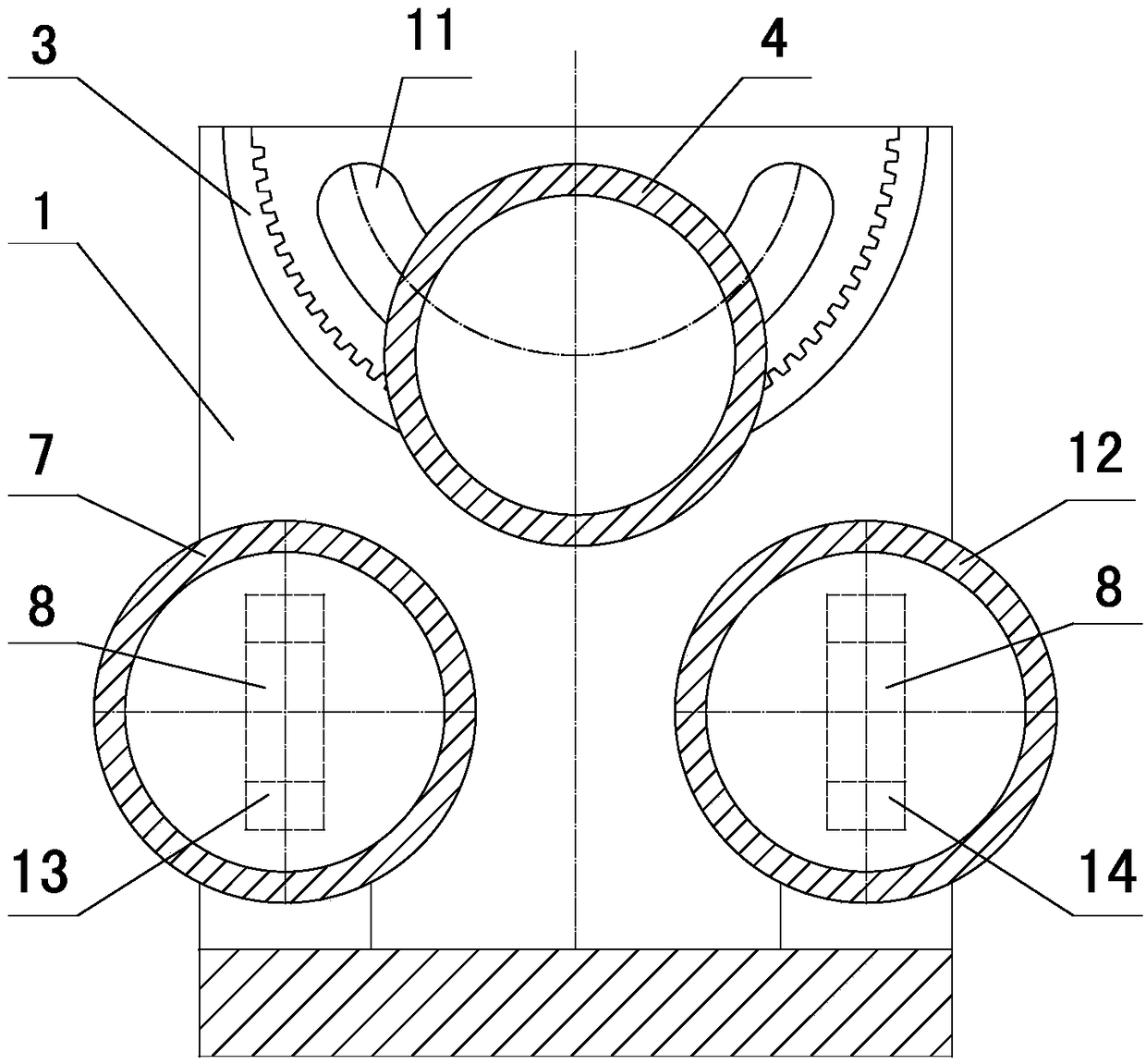

Manual plate rolling equipment

InactiveCN109261759AAchieve bendingReduce the number of specificationsArchitectural engineeringEngineering

Owner:重庆宏冠重型机械制造有限公司

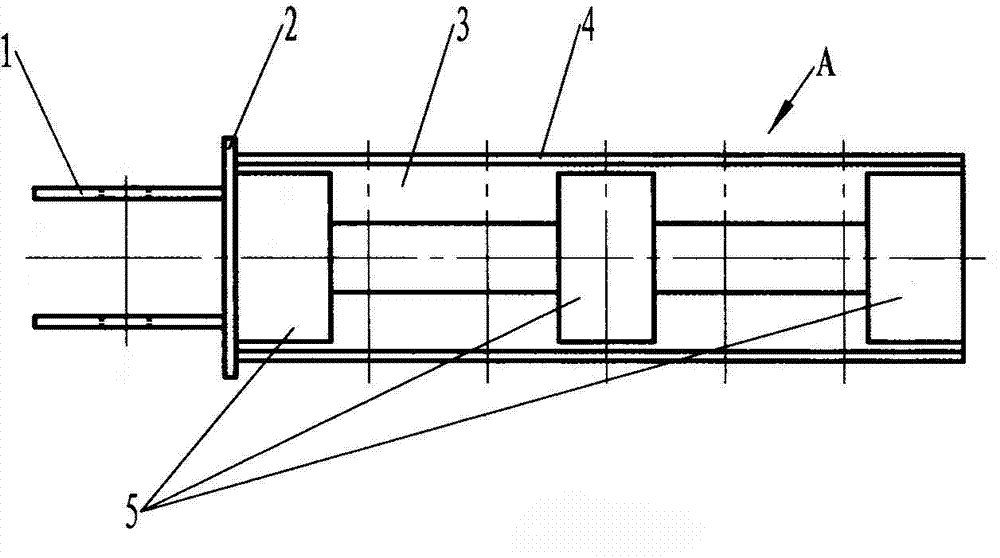

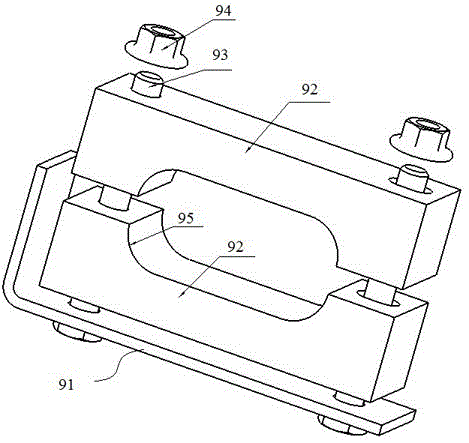

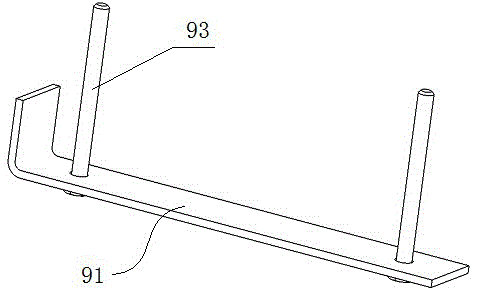

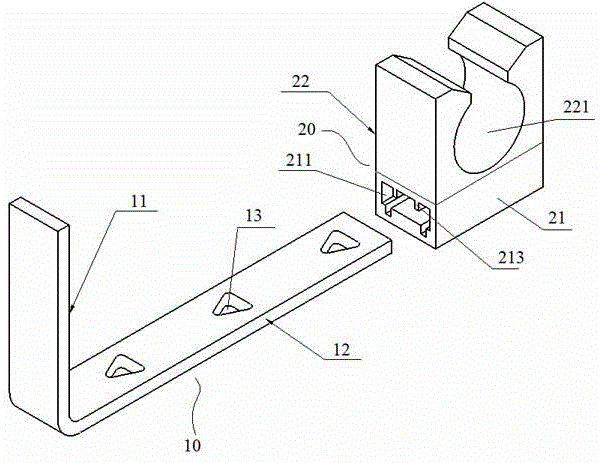

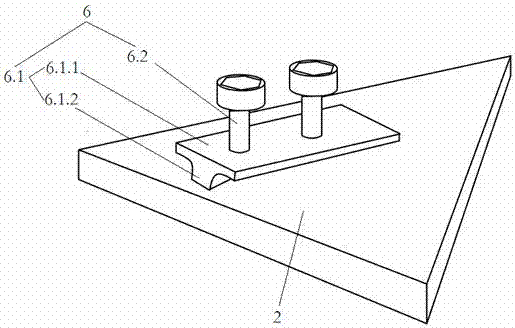

A line card and its line code bracket, an insulated line code and a vehicle using the line card

ActiveCN105416201BMeet fixed needsReduce the number of specificationsElectric/fluid circuitLine cardEngineering

The invention relates to a wire clamp as well as a wire pressing plate support, insulation wire pressing plates and a vehicle using the wire clamp. The wire clamp comprises the wire pressing plate support and the insulation wire pressing plates, wherein the wire pressing plate support comprises a plug-in mounting part for sequential sleeving by the insulation wire pressing plates; two or more wire pressing plate mounting positions are arranged on the plug-in mounting part; each insulation wire pressing plate comprises a plug-in mounting hole used for sleeeving the plug-in mounting part, a wire pressing plate structure used for being detachably fixed with the wire pressing plate support when the mounting is in position, and a wire fixing structure used for fixing a wire. When the wire clamp is used, the insulation wire pressing plates of which the quantity correspond to the quantity of to-be-fixed wires are sequentially fixed onto the wire pressing plate support through the plug-in mounting hole, and the to-be-fixed wires are fixed by the wire fixing structure, so as to meet the wire fixing demand; all that is needed is to produce insulation wire pressing plates of different specifications according to wires of different diameter specifications, so that the specification quantity of fixing devices can be greatly reduced, the selection and the use are convenient, the error rate can be lowered, and the operation efficiency can be improved.

Owner:ZHENGZHOU YUTONG BUS CO LTD

Power distribution device and vehicle using the same

InactiveCN111619349ASmall footprintAvoid occupyingElectric devicesSubstation/switching arrangement casingsMechanical engineeringElectrical and Electronics engineering

Owner:ZHENGZHOU YUTONG BUS CO LTD

Wire clamp as well as wire pressing plate support, insulation wire pressing plates and vehicle using wire clamp

ActiveCN105416201AMeet fixed needsReduce the number of specificationsElectric/fluid circuitMechanical engineeringEngineering

The invention relates to a wire clamp as well as a wire pressing plate support, insulation wire pressing plates and a vehicle using the wire clamp. The wire clamp comprises the wire pressing plate support and the insulation wire pressing plates, wherein the wire pressing plate support comprises a plug-in mounting part for sequential sleeving by the insulation wire pressing plates; two or more wire pressing plate mounting positions are arranged on the plug-in mounting part; each insulation wire pressing plate comprises a plug-in mounting hole used for sleeeving the plug-in mounting part, a wire pressing plate structure used for being detachably fixed with the wire pressing plate support when the mounting is in position, and a wire fixing structure used for fixing a wire. When the wire clamp is used, the insulation wire pressing plates of which the quantity correspond to the quantity of to-be-fixed wires are sequentially fixed onto the wire pressing plate support through the plug-in mounting hole, and the to-be-fixed wires are fixed by the wire fixing structure, so as to meet the wire fixing demand; all that is needed is to produce insulation wire pressing plates of different specifications according to wires of different diameter specifications, so that the specification quantity of fixing devices can be greatly reduced, the selection and the use are convenient, the error rate can be lowered, and the operation efficiency can be improved.

Owner:ZHENGZHOU YUTONG BUS CO LTD

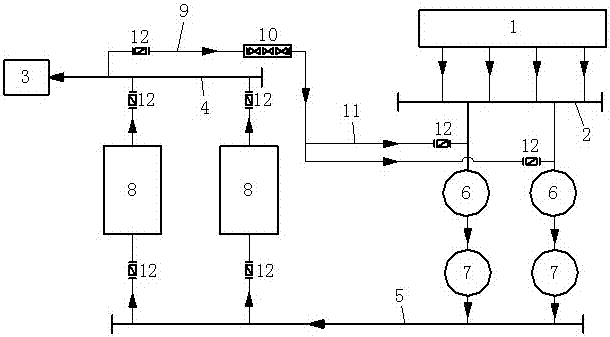

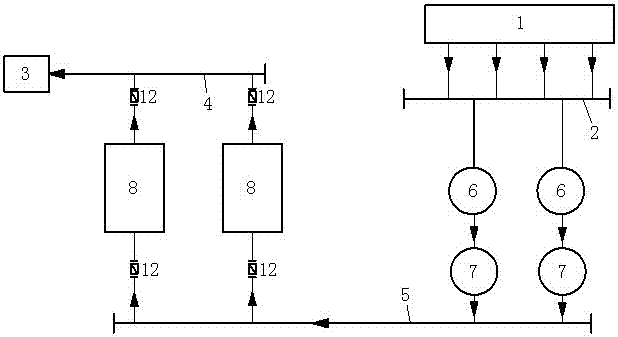

Method and device for ensuring low-load and stable operation of gas discharger

The invention discloses a method and device for ensuring the stable operation of a gas discharger with low load. The method is to use a group of gas dischargers to supply gas to users. When the gas delivery capacity is the lowest, the excess gas is returned to the intake main pipe or the scrubber inlet through the recirculation pipe connected to the user main pipe to ensure the normal operation of the gas discharge machine. In the present invention, by adding a recirculation pipeline between the user main pipe and the intake main pipe, the excess gas is returned to the intake main pipe or the inlet of the scrubber to reduce the pressure of the user main pipe and ensure that the gas pressure at the user end is maintained within a safe range. Since the present invention adopts the same specifications of the gas discharge machine, it can avoid the frequent start and stop of the gas discharge machines of different specifications, reduce the workload of the production and operation personnel, and also greatly reduce the specification and quantity of the spare parts of the equipment, which is beneficial to the production management, greatly reducing production costs.

Owner:GUIYANG AL-MG DESIGN & RES INST

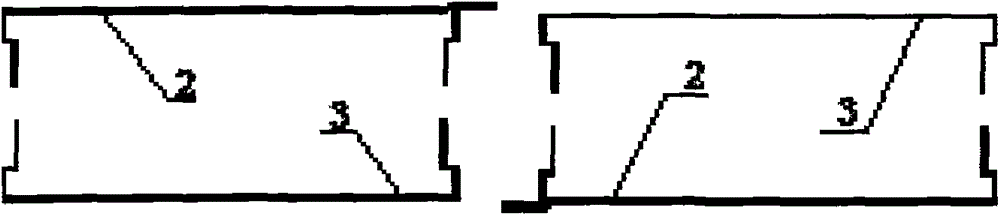

Novel door leaf of fire-proof door

InactiveCN105134038AReduce the number of blockagesReduce the number of specificationsFireproof doorsEconomic benefitsEngineering

The invention belongs to the field of doors and windows, and specifically relates to a novel door leaf of a fire-proof door. The novel door leaf is suitable for two-piece fire-proof doors and single-piece fire-proof doors. The novel door leaf comprises a door core plate, a door leaf panel, rivets and insertion bars, wherein the door core plate is wrapped up by the door leaf panel, the door leaf panel is formed by two paint-free steel plate, different in specification, vertically jointed, and the joint portions are fixed through rivets, the bottom portion of the door leaf panel is in a topless U shape, the top portion of the door leaf panel is in a topless T shape, and a lateral bar is arranged on the side surface of the topless T shape. The types of specifications of the door leaf panels are reduced, and a paint-free steel plate is employed. The manufacture process is simplified, the production efficiency is improved, and the economic benefit of a manufacturing company is improved.

Owner:宋伟滨

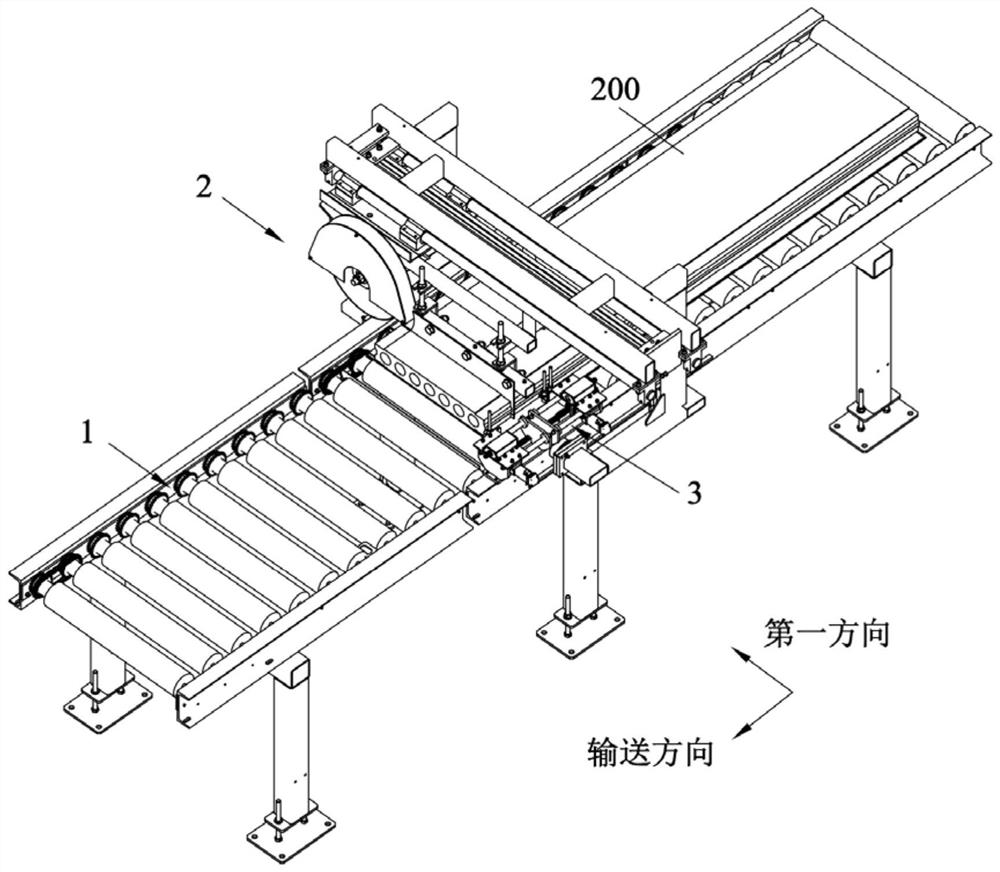

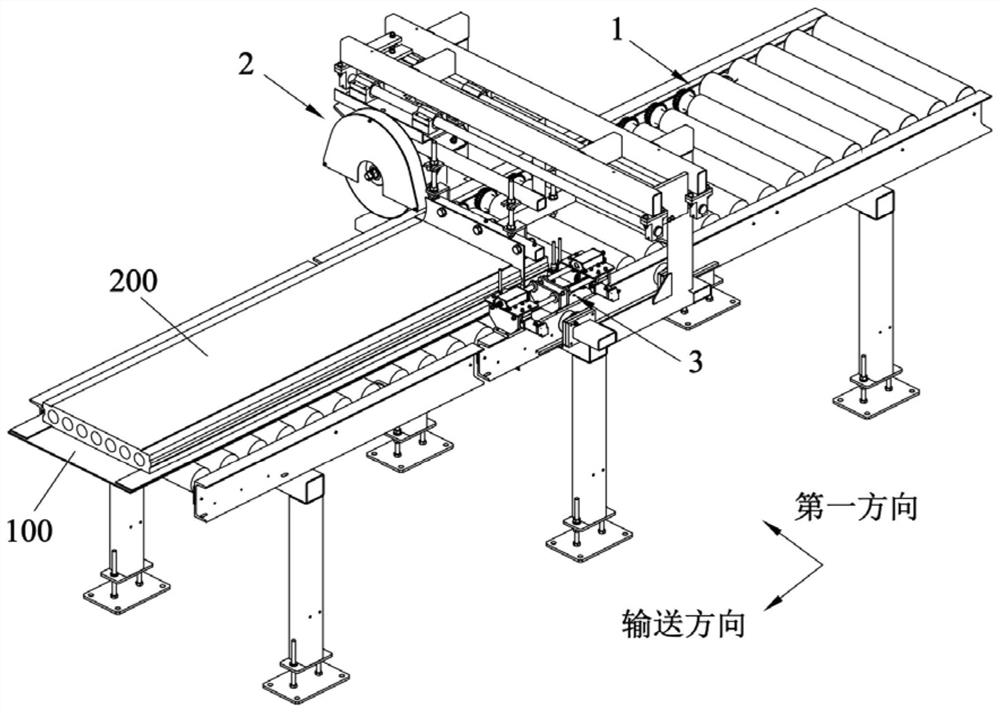

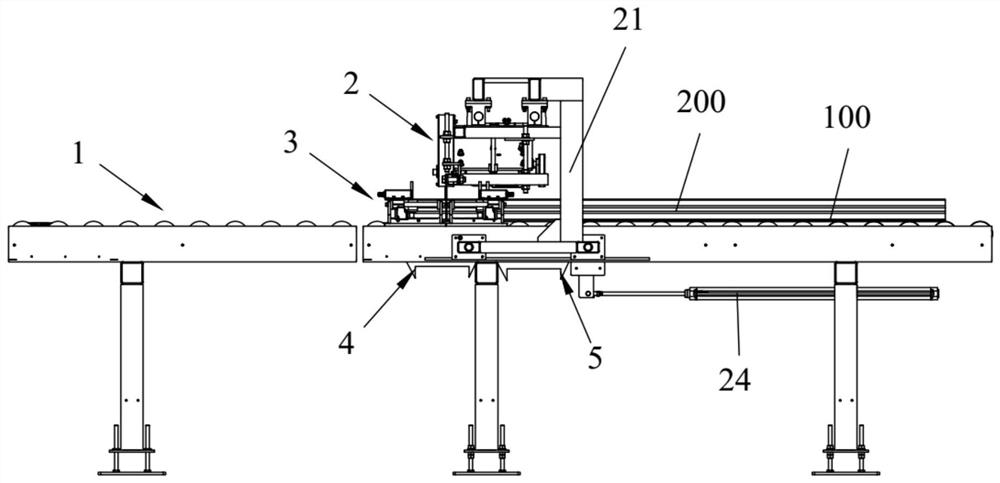

Workpiece cutting method and wallboard cutting device

PendingCN114311331AReduce the number of specificationsLow costWorking accessoriesStone-like material working toolsWall plateMechanical engineering

The invention relates to the technical field of building machinery, in particular to a workpiece cutting method and a wallboard cutting device. The workpiece cutting method comprises the following steps that a control system sets the maximum cutting length L0 of each end of a workpiece; the control system calculates the total cutting length L of the workpiece; when L is smaller than or equal to L0, one end of the workpiece in the length direction is cut, and the cutting length is the total cutting length; when L0 < L < = 2L0, the two ends of the workpiece in the length direction are cut respectively, and the sum of the cutting lengths of the two ends is equal to the total cutting length. According to the workpiece cutting method, one end or two ends of the workpiece can be cut according to the relation between the cutting length L and the preset value L0, it is guaranteed that the distance between the end of the formwork and the end of the finished product is smaller than or equal to the preset value L0, and therefore the situation that the exceeding part of the formwork deforms due to gravity in the hoisting or maintaining process is avoided; finished products with more specifications can be produced by the template with one specification, so that the specification number of the template is reduced.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Modular combined-type tower crane attached bar with extensive stepless adjustment-type length

InactiveCN103086287BRealize equidistant adjustmentStepless adjustable lengthCranesEngineeringTower crane

A modularized combined tower crane attachment rod with a large length and stepless adjustment, which has an upper connector, a lower connector, a screw adjustment device, a rod head, a rod tail, a first rod body, and a second rod body. A first shaft or a combination of two first shafts and one second shaft is provided between the club head and the club tail. When a first shaft is provided between the club head and the club tail, the club head and the club tail are respectively inserted into the installation holes at both ends of the first shaft, and are connected together by a first pin shaft. When there is a combination of two first shafts and one second shaft between the club head and the club tail, the two ends of the second shafts are respectively inserted into the mounting holes at one ends of the two first shafts, each through The two fourth pin shafts are connected together, and a rod head and a rod tail are respectively inserted into the mounting holes at the other ends of the two first shafts, and each is connected together by a first pin shaft. It is simple to connect, improves the force condition of the attachment rod itself, the attachment point and the attachment tower body, and makes the work safer and more reliable.

Owner:TANGSHAN CONSTR GRP

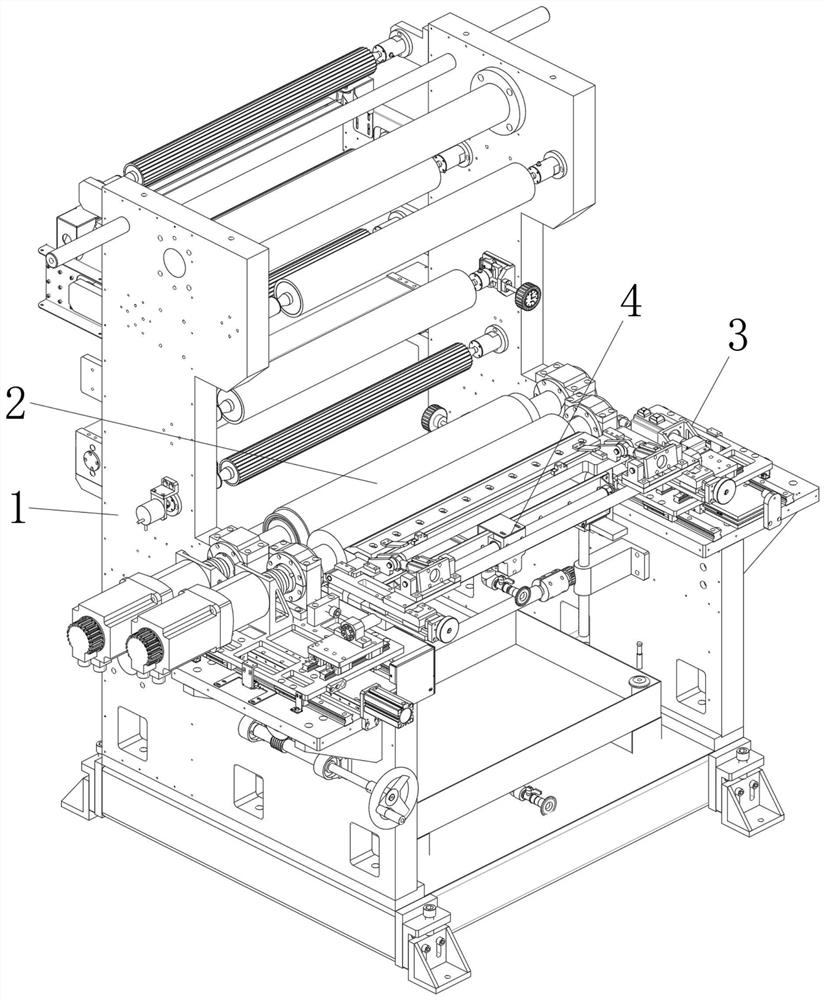

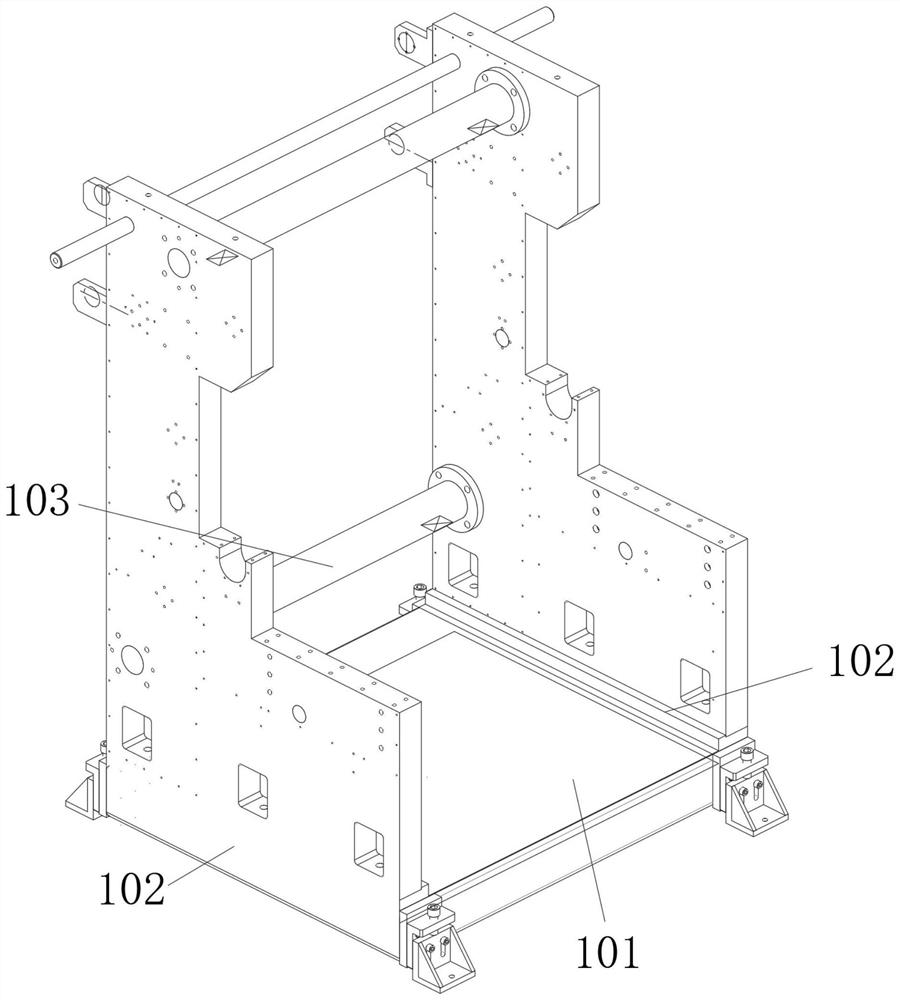

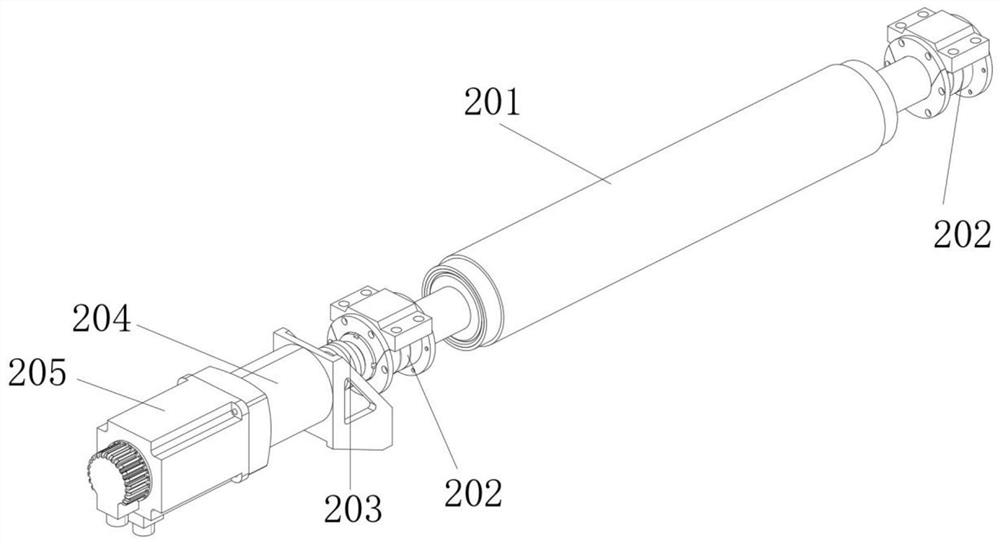

Gap coating module

PendingCN113103735AReduce the number of specificationsSave time for roll changeoverRotary intaglio printing pressPrinting press partsPhysicsWall plate

The invention discloses a cap coating module. The cap coating module comprises a rack, wherein an impressing roller mechanism, a gravure roller mechanism and a coating box mechanism are arranged on the rack; the rack comprises a bottom frame, two symmetrical wallboards are fixedly arranged on the two sides of the bottom frame, and transverse supports distributed longitudinally are arranged between the two wallboards; the impressing roller mechanism is arranged between the two wallboards, the impressing roller mechanism comprises an impressing rubber roller arranged between the two wallboards, an impressing servo motor fixed on the wallboards is arranged at one end of the impressing rubber roller, and a transmission shaft of the impressing servo motor is fixedly connected with one end of the impressing rubber roller through an impressing coupler; and the gravure roller mechanism comprises a gravure roller erected between the two wallboards, a gravure servo motor is arranged at one end of the gravure roller, a scraper mechanism is arranged behind the gravure roller, a scraper transverse movement driver is arranged on one side of the scraper mechanism, a roller reciprocating driver is arranged at the top of each wallboard, and the coating box mechanism is arranged under the gravure roller.

Owner:广东捷盟智能装备有限公司

Variable electro-hydraulic servo hydraulic transformer

ActiveCN103174689BSolve out of controlRecoverable load energyFluid-pressure convertersFluid-pressure actuator componentsHydraulic cylinderDrive shaft

The invention provides a variable electro-hydraulic servo hydraulic transformer, and relates to an electro-hydraulic servo hydraulic transformer which resolves the problems that an existing hydraulic transformer is controllable in loading pressure and uncontrollable in loading flow, alternatively, the loading pressure and the loading flow are coupled, hydraulic transformers of different standards need to be applied to different areas, and universalization is not achieved. The variable electro-hydraulic servo hydraulic transformer comprises a thrust plate servo mechanism and a swash plate servo mechanism, the valve plate servo mechanism comprises a thrust plate, an end cover, a thrust shell, a bearing cover, a bearing, a first hydraulic control valve and a swing motor, the thrust plate is in detachable connection with a blade shaft, a motor shell is arranged between the end cover and the thrust shell and in detachable connection with the end cover and the thrust shell, and the first hydraulic control valve is arranged on the motor shell. The swash plate servo mechanism comprises a cylinder, a hydraulic cylinder, a second hydraulic control valve, a swash plate, a shell, a transmission shaft and a plurality of plungers, wherein the shell is in detachable connection with the end cover. The variable electro-hydraulic servo hydraulic transformer is used for a system control valve of the hydraulic field.

Owner:HARBIN INST OF TECH

A combined abdominal aortic stent graft system and its application method

A combined abdominal aorta covered stent system and a utilization method thereof are applied to surgeries for endovascular interventional treatment of abdominal aortic aneurysm. The system comprises a body covered stent and a pair of branch covered stents, and each of the stent is cylindrical and provided with a delivery system. The near end of the body covered stent is a bare stent with barbs, a covered section comprises an upper half portion in a single-cavity cylinder shape and a lower half portion with a fixed outer diameter, and the lower half portion is averagely partitioned into two cavities by a longitudinal partition. Small-waveband stent rings are designed at near and far ends of the covered section of the body covered stent, and other covered parts can be either provided with stent rings or not. The upper half portion of the covered section is implanted at a neck position of infrarenal aortic aneurysm, and the lower half portion is suspended in an aneurysm cavity. The branch covered stents parallelly and internally sleeve the two cavities of the body covered stent, near ends of the branch covered stents are flush with the near end of the lower half portion of the body covered stent and fill the cavities of the body covered stent in a self-adoption manner, and far ends of the branch covered stents are implanted into iliac artery branches to better adapt to arterial aneurysms excessive in aneurysm neck torsion.

Owner:北京有卓正联医疗科技有限公司

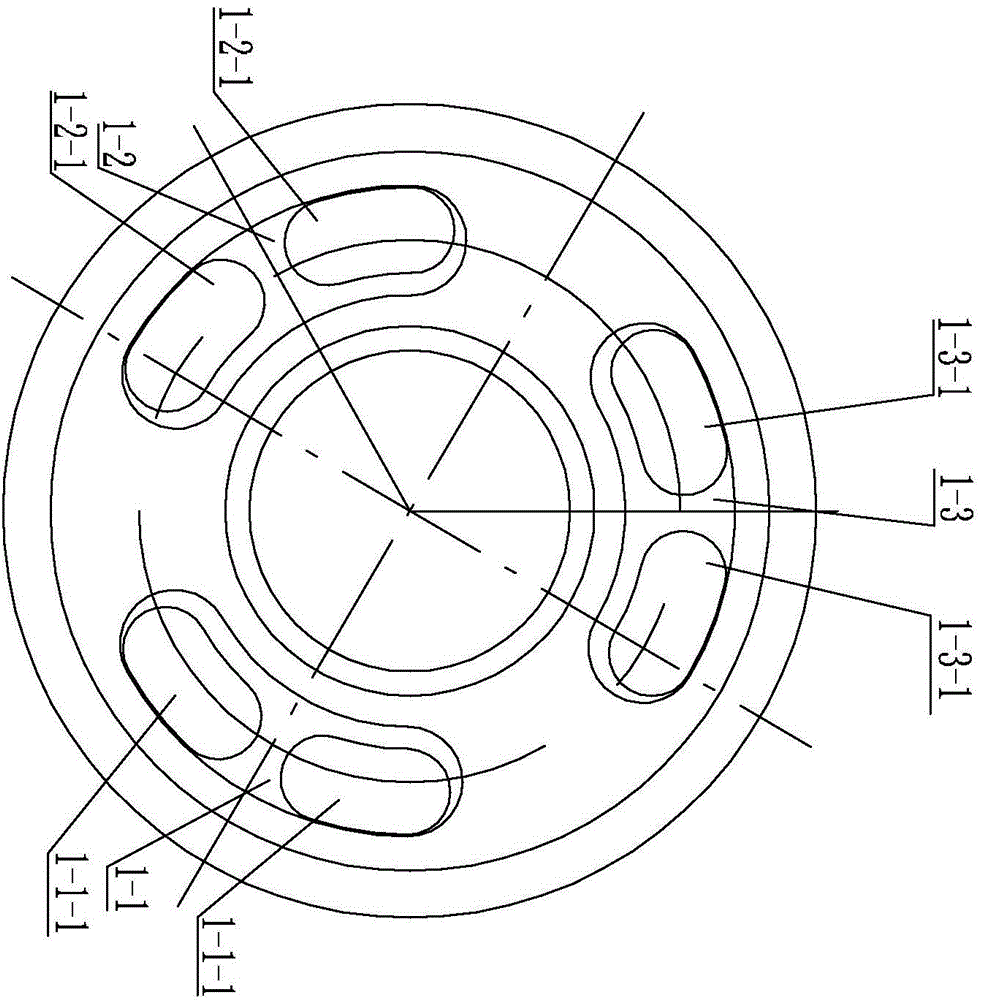

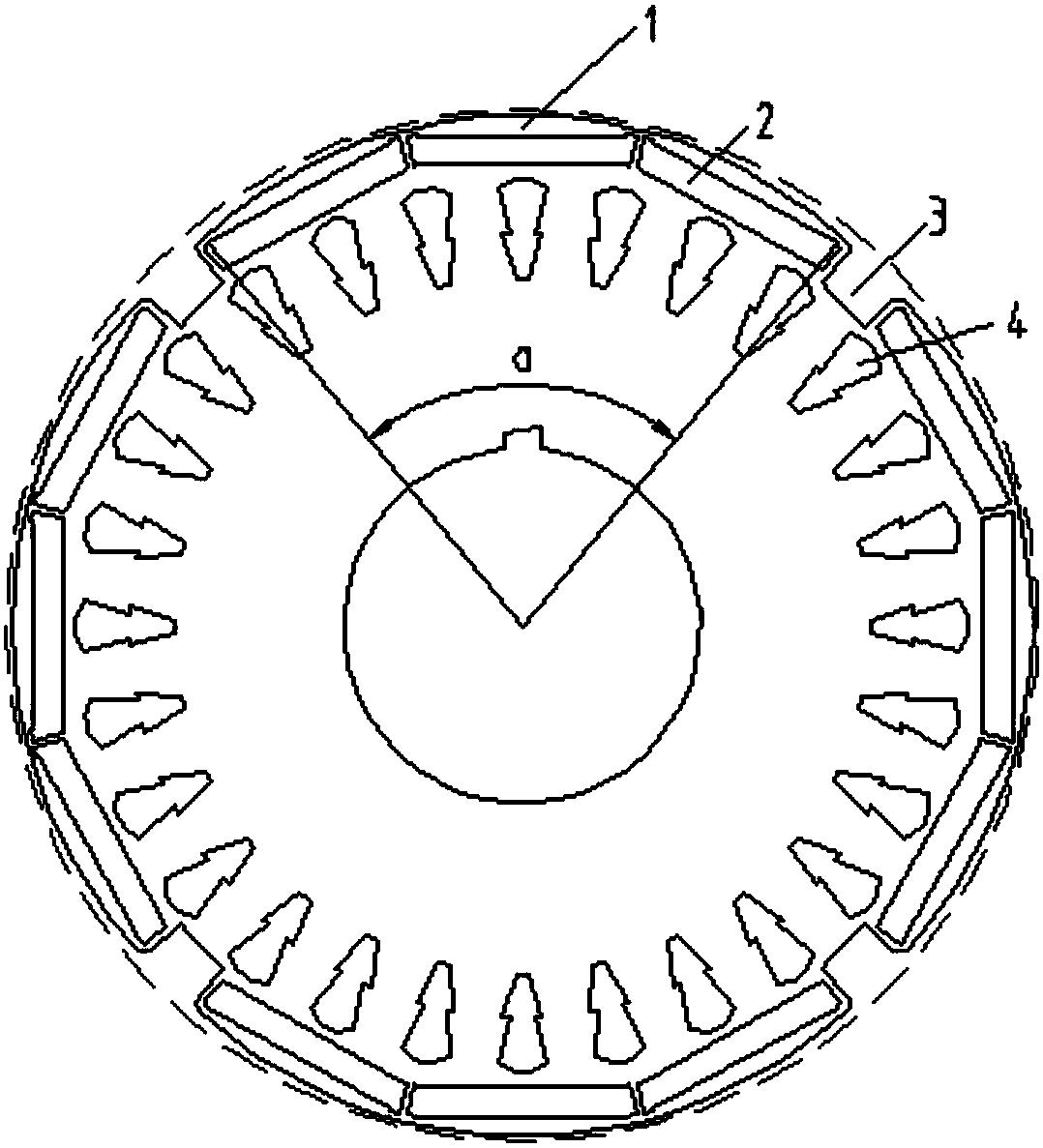

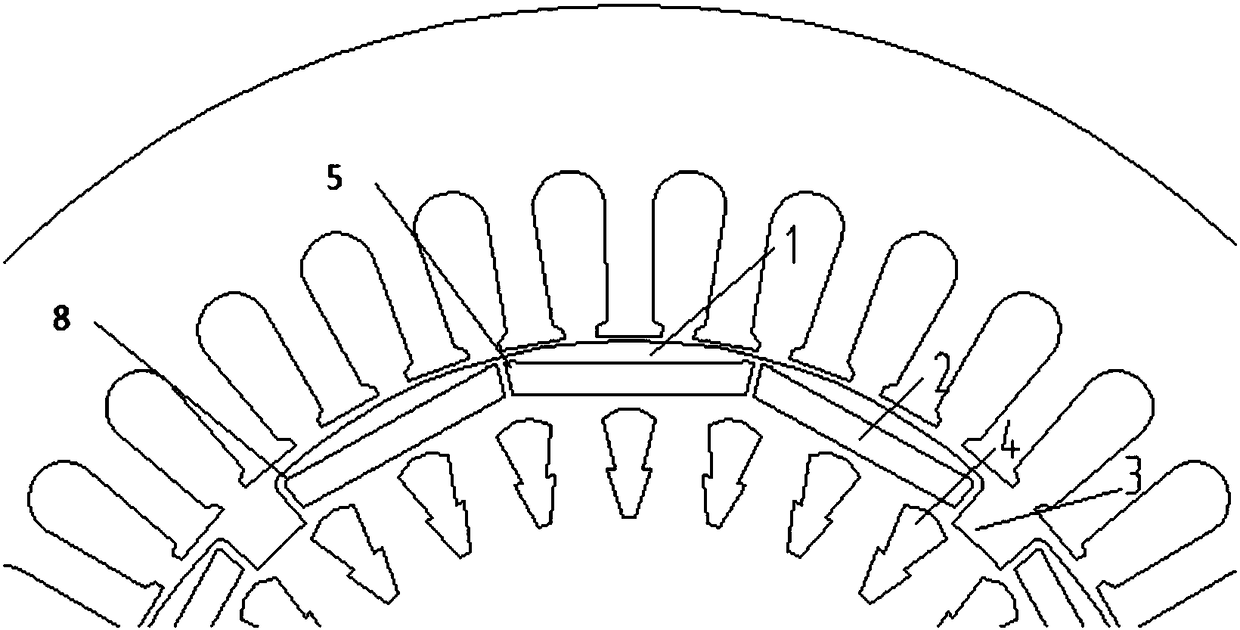

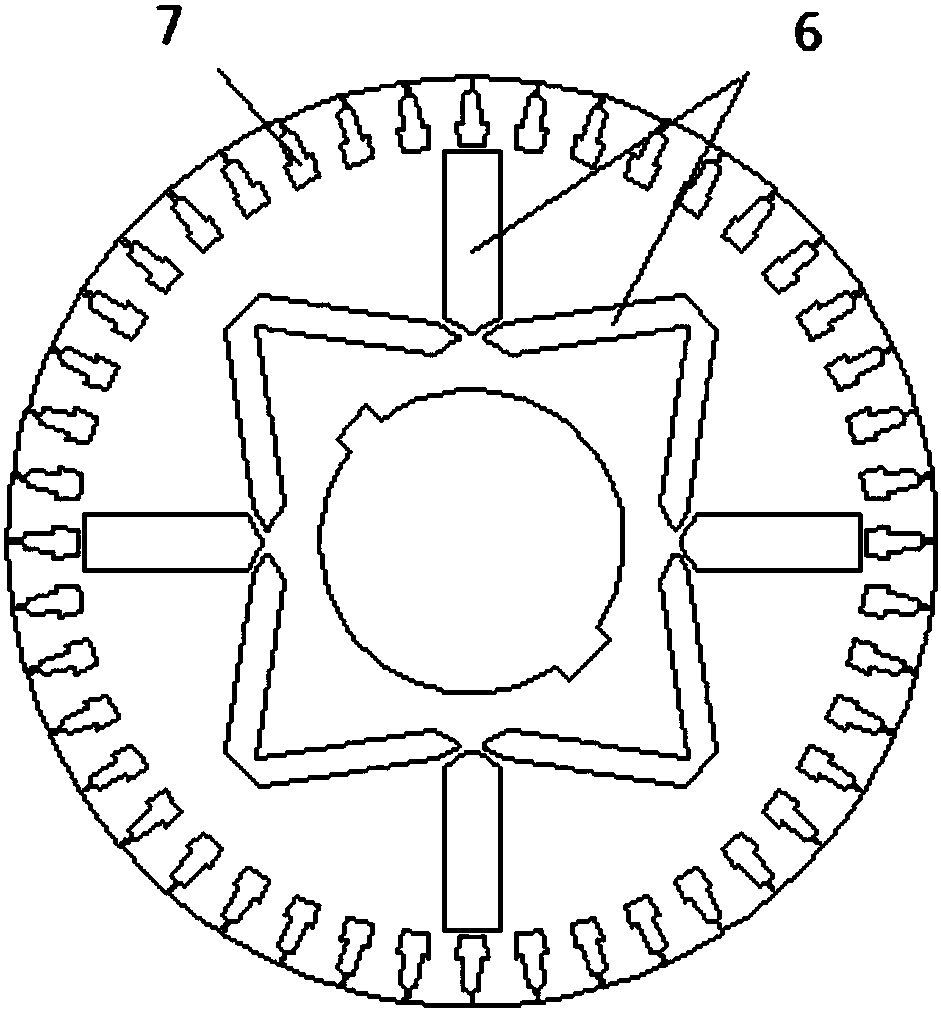

Permanent magnet motor rotor punching with self-starting ability and industrial frequency conversion performance

ActiveCN106411005BReduce the number of specificationsLow costMagnetic circuit rotating partsPunchingFrequency conversion

The invention discloses a permanent magnet motor rotor stamping with self-starting capability and industrial frequency conversion performance. The stamping structure includes rotor magnetic poles, permanent magnet slots, permanent magnets, slots between poles and a uniform Distributed slots; the number of punching poles is greater than or equal to 2, and the number of permanent magnet slots and permanent magnets per magnetic pole is greater than or equal to 1; the magnetic pole angle is 0.75~0.8 times of 360 / 2p, and p is the number of pole pairs of the motor; the outer circle of the rotor pole It is a circular arc that is not concentric with the rotor punch, and its radius is (0.89~0.93)×R, R is the outer circle radius of the rotor punch; permanent magnets are embedded in permanent magnet slots, and there is an inter-pole gap between adjacent rotor poles. groove.

Owner:SHENYANG POLYTECHNIC UNIV

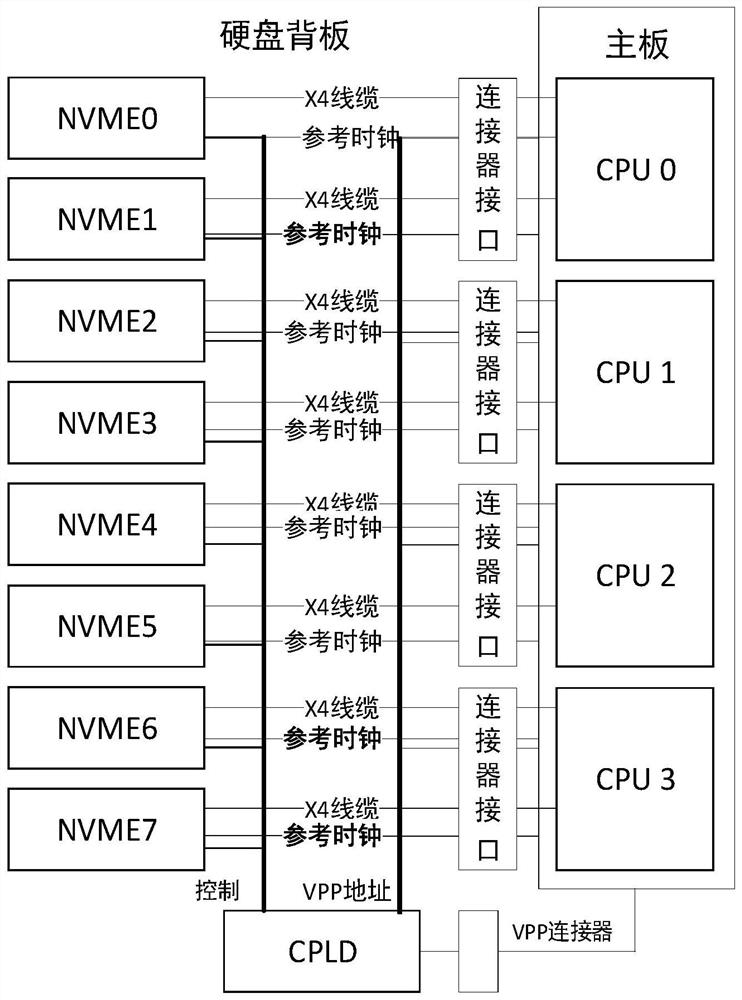

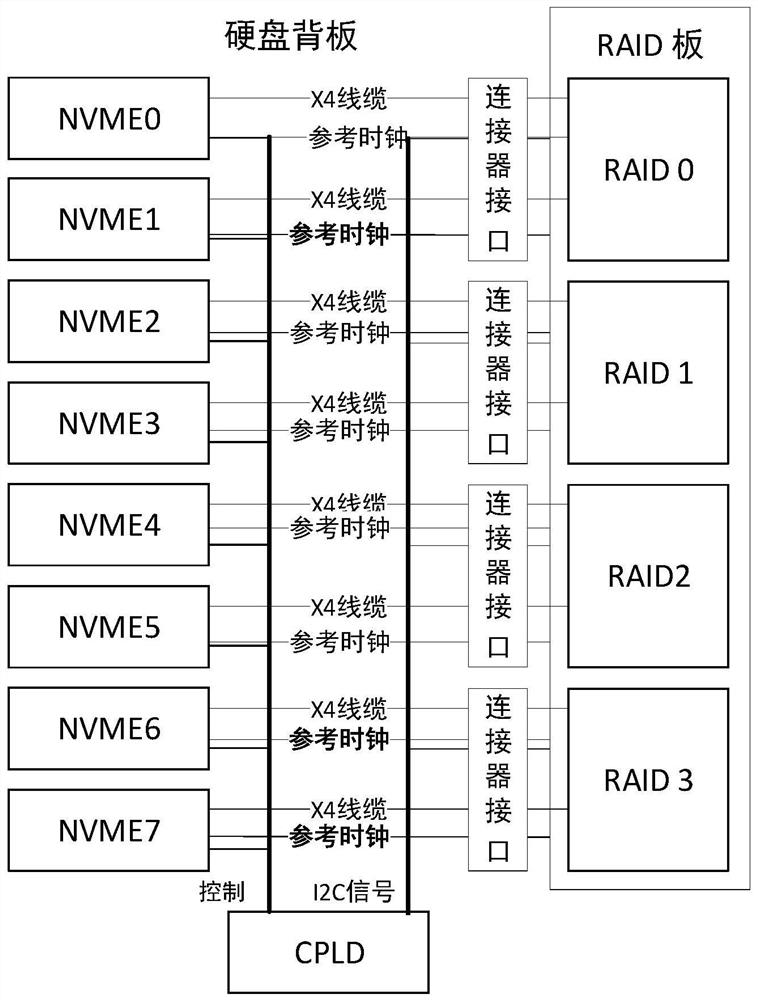

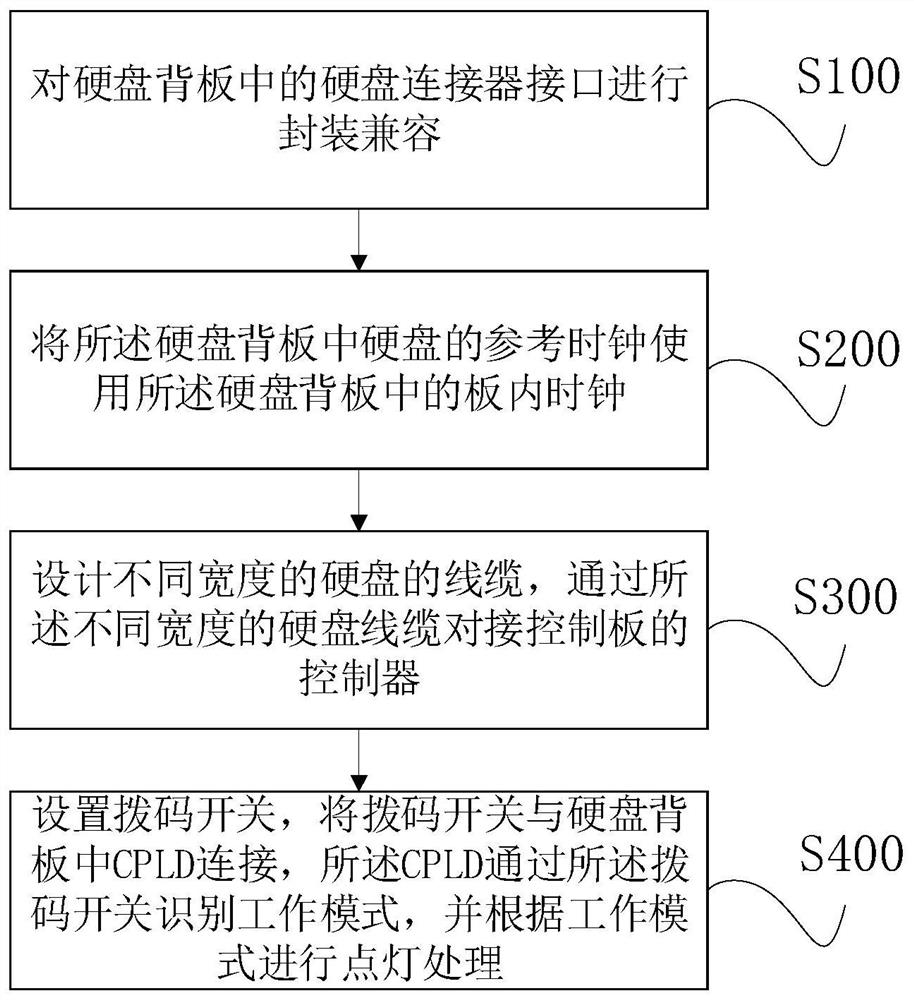

Hard disk backboard connection method and device supporting hard disks with various bit widths

PendingCN113190084AReduce the number of specificationsTroubleshoot Reference Clock Source IssuesDigital processing power distributionEnergy efficient computingBackplaneEngineering

The invention discloses a hard disk backplane connection method supporting hard disks with various bit widths. The method comprises the following steps: carrying out packaging compatibility on a cable connector interface of a hard disk backplane; setting a reference clock of the NVME hard disk as an in-board clock in the hard disk backboard; designing cables of the NVME hard disks with different widths, and butting a controller through the cables; setting a dial switch, connecting the dial switch with a CPLD, identifying a working mode by the CPLD through the dial switch, and lighting according to the working mode. By means of the mode, the problem that a current multi-mode hard disk backboard only supports an NVME hard disk with the x4 width and does not support an NVME hard disk with the x2 width and an NVME hard disk with the x1 width can be solved, the specification number of the hard disk backboard is reduced, and the competitiveness of the whole system is improved.

Owner:SHANDONG YINGXIN COMP TECH CO LTD

Collar pressing mold

ActiveCN105177960BImprove versatilityLow costIroning apparatusTextiles and paperEngineeringMechanical engineering

Owner:HEILAN HOME

An integrated wrench for hexagon socket bolts

The invention discloses an integrated wrench for hexagon socket screws. The integrated wrench comprises a core shaft. One end of the core shaft is inserted into a handle, the core shaft is sleeved with a hexagonal cylinder set, and the hexagonal cylinder set can slide in the axial direction of the core shaft. According to the integrated wrench for the hexagon socket screws, the mode that the hexagonal cylinder set and the core shaft are combined is adopted, it is achieved that the hexagon socket screws in various specifications can be disassembled and assembled through one wrench, and other tools are avoided in the adjusting process. The integrated wrench for the hexagon socket screws is rapid in operation, convenient to carry and practical, the number of different-specification wrenches for disassembling and assembling the hexagon socket screws can be decreased, the wrench does not need to be replaced in one process of operating the hexagon socket screws in multiple specifications, and therefore working efficiency is greatly improved.

Owner:SHAANXI UNIV OF TECH

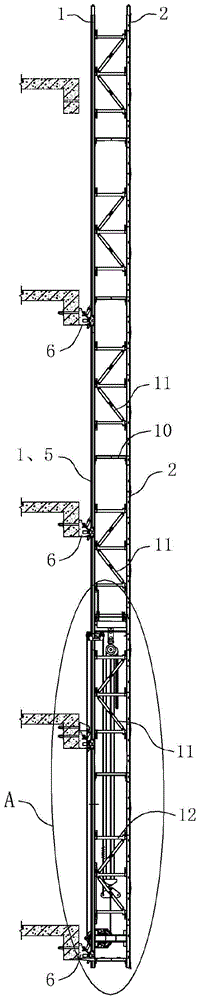

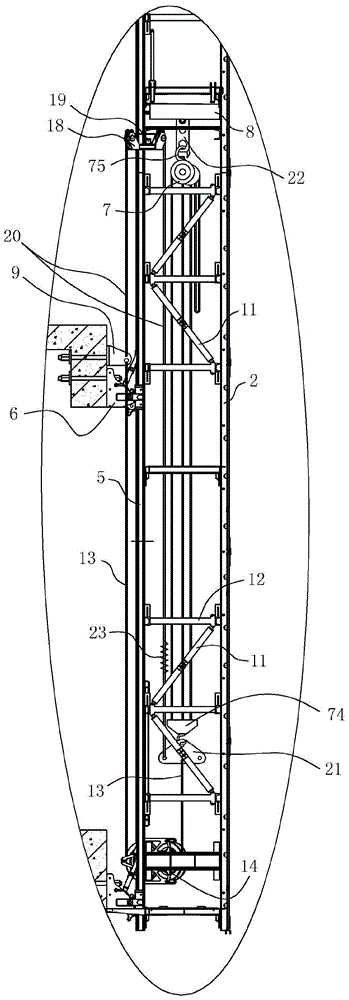

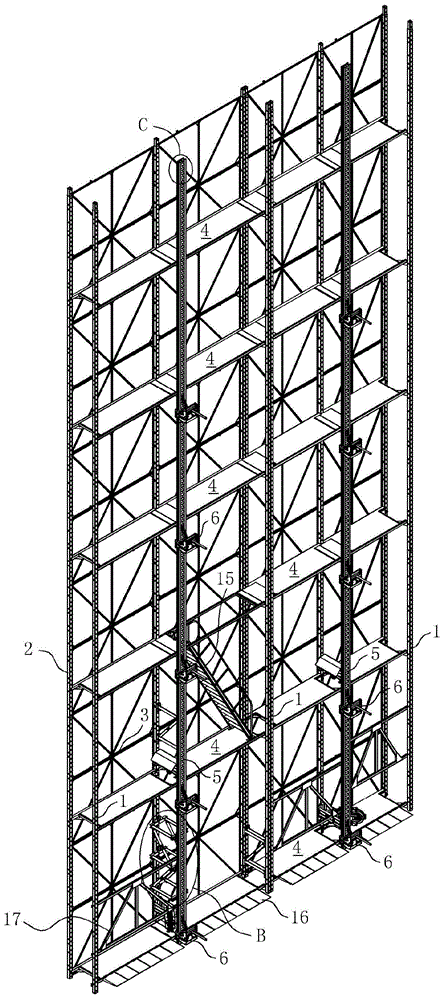

Attached automatic lifting multi-storey construction platform

ActiveCN103821341BSimplify the disassembly procedureReduce the number of specificationsBuilding support scaffoldsFalseworkArchitectural engineering

The invention discloses an attached automatic lifting multilayer construction platform, and belongs to a building scaffold. The attached automatic lifting multilayer construction platform comprises a plurality of side-by-side inner-row upright posts and outer-row upright posts; a protective net board is arranged among the outer-row upright posts; a multilayer platform bottom plate is arranged between the inner-row upright posts and the outer-row upright posts; guide rails are arranged among the inner-row upright posts; the construction platform further comprises a central crane lifting system; the central crane lifting system at least comprises an electric hoist, a fixed hanger and a movable hanger; the mutually independent outer-row upright posts, inner-row upright posts and guide rails are adopted, and are connected into a whole by virtue of supporting rods and the platform bottom plate, the assembly and disassembly procedure of the construction platform is effectively simplified, and artificial uncertain factors in the installation process are reduced. Under the mutual cooperation of a horizontal supporting frame and a double-column offset steering device, the central crane lifting system can be directly arranged between any one outer-row upright post on the construction platform and the corresponding guide rail, and the supporting structure for the installation of the lifting system is simplified.

Owner:JUSTREACH SCI & TECH CO LTD CHENGDU

A modular water jet propulsion steering and reversing mechanism

ActiveCN110481751BReduce the number of specificationsRealize connectionlessSteering by jetsWater flowControl theory

The invention provides a modularized water-jet propulsion steering reversing mechanism, which relates to the technical field of ship propulsion, and includes a steering reversing mechanism bracket for fixing the water-jet propulsion steering reversing mechanism; It is connected to the support of the navigation mechanism, and is used to move left and right around the first pin shaft under the drive of a steering cylinder built in the rudder, so that the jet water flow is reversed to the side to realize steering; the reversing door is connected to the rudder through a second pin shaft, It is used to realize the forward steering function when it is in the open state, and to make the jet water flow reverse to the bottom of the ship to achieve reverse sailing when it is in the closed state; the auxiliary rudder plate is installed on the rudder through fasteners, and is used to rotate together with the rudder to lift the rudder effect. The invention reduces the number of specifications of the steering and reversing mechanism through water jet propulsion, reduces design and processing costs, and shortens the processing cycle; effectively reduces the difficulty of assembly and disassembly; reduces the processing difficulty and scrap rate of guide vanes ; Improved product reliability.

Owner:708TH RES INST OF CSSC

A device and method for cutting and collecting the tail shank of the steel wire screw sleeve of the complex blind cavity receiver

The invention belongs to the technical field of new manufacturing and maintaining of a casing part with a steel wire thread sleeve needing to be mounted in a space flight and aviation gas turbine engine, and particularly relates to a device and method for cutting off and collecting the steel wire thread sleeve mounted on a casing with a complex blind cavity. The device comprises a connecting rod, a hand shank rod and a guide core bar. A groove A is formed in the portion of one end of the lead core bar. After a tail shank is inserted along an inner hole of the steel wire thread sleeve, the bent part of the tail shank can enter along an opening of the groove A, a groove B is formed in the circumferential direction of the groove A, a certain included angle is formed by the groove B and the groove A, and after the bent part of the tail shank enters the groove A, the lead core bar is rotated so that the bent part can enter the groove B. The other end of the lead core bar is connected with one end of the connecting rod, and the other end of the connecting rod is connected with the hand shank rod used for enabling the guide core bar and the connecting rod to rotate. Two process steps of cutting off the tail shank and taking out the waste tail shank of a previous steel wire thread sleeve assembling technology are combined into one process step of cutting off and taking out, the tail shank is taken out while being cut off, and broken tail shanks do not need to be found any more.

Owner:AECC AVIATION POWER CO LTD

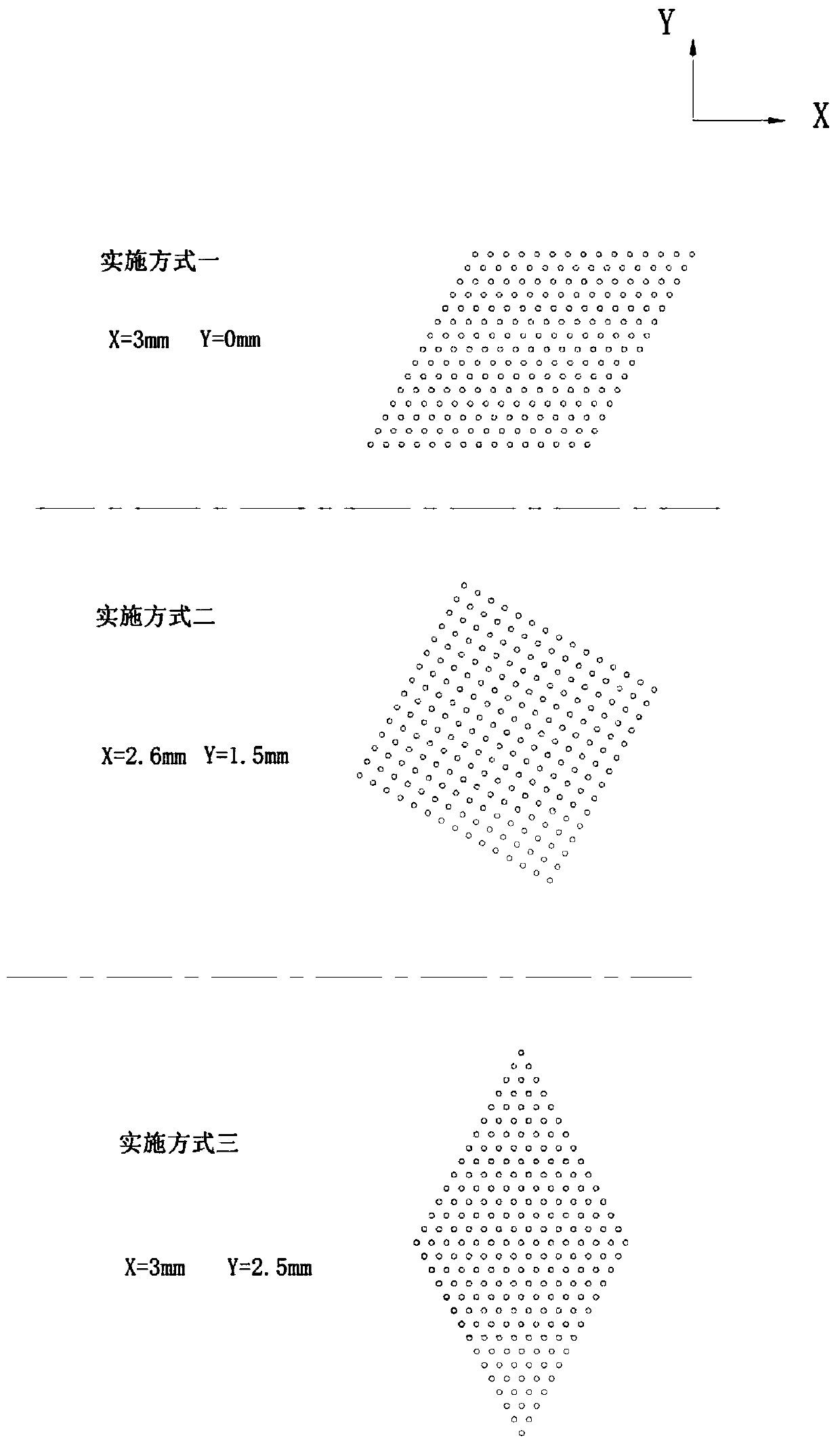

Method and device for punching to manufacture two-dimensional pattern

PendingCN111349725AReduce the number of specificationsReduce the labor intensity of mold changeLeather clicking/perforating/clickingManufacturing cost reductionPunching

The invention relates to a method and device for punching to manufacture a two-dimensional pattern. The method comprises the steps that a punch pin moving mechanism drives a punch pin die to move transversely for X displacement so as to change the transverse relative position of the punch pin die and a leather material; a leather material moving mechanism drives the leather material to be punchedto move longitudinally for Y displacement so as to change the longitudinal relative position of the punch pin die and the leather material; and a punch pin lifting mechanism drives the punch pin die to rise and fall, and then the leather material is punched by the punch pin die. The two-dimensional coordinate position of the punch pin die relative to the leather material can be changed by changingvalues of the X displacement and the Y displacement, therefore, a plurality of different types of patterns can be manufactured through punching by just one set of die without exchanging the punch pindie frequently, the specifications and the number of dies are greatly reduced, and die change work intensity of workers is greatly reduced; and moreover, since the punch pie die can be moved transversely for the X displacement, the number of the punch pins of the die can be greatly reduced so that the pressure required for punching the leather material can be reduced, the rigid of machines does not need to be too high, and the manufacturing cost is beneficially reduced.

Owner:DONGGUAN ANZE AUTOMATION EQUIP

Adjustable template used for production of resin tile

InactiveCN109016447AChange heightImprove versatilityDomestic articlesAgricultural engineeringMetal mold

The invention relates to an adjustable template used for the production of resin tile, and belongs to the technical field of metal molds. The adjustable template includes a horizontal-arranged template main body, a plurality of first through grooves are formed in the template main body and penetrate through the front and rear side faces of the template main body, and a second through groove is formed in the groove bottom of each first through groove; and the second through grooves penetrate through the front and rear side faces of the template main body, the groove bottom of each second through groove is low at the front part and high in the back part and tilts upwards, a tile mold is arranged in each first through groove, a positioning block is arranged at the bottom of each tile mold, each positioning block is arranged in the corresponding second through groove, the bottom face of each positioning block is low at the front part and high at the back part and tilts upwards, and the tile molds are fixed in the first through grooves through a plurality of first screws. The adjustable template improves the universality of a model, the specification quantity of the molds is reduced, and the cost is reduced.

Owner:重庆雅克塑料制品有限公司

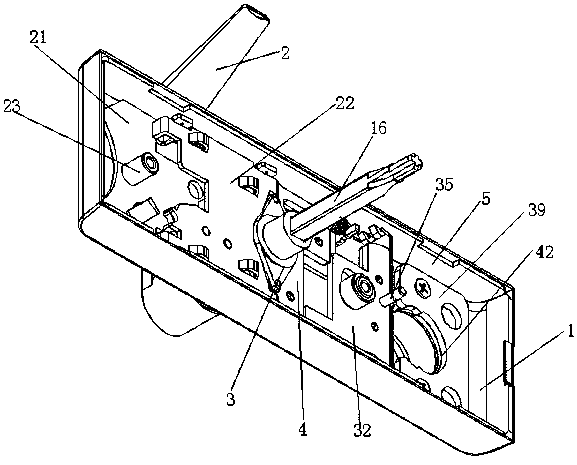

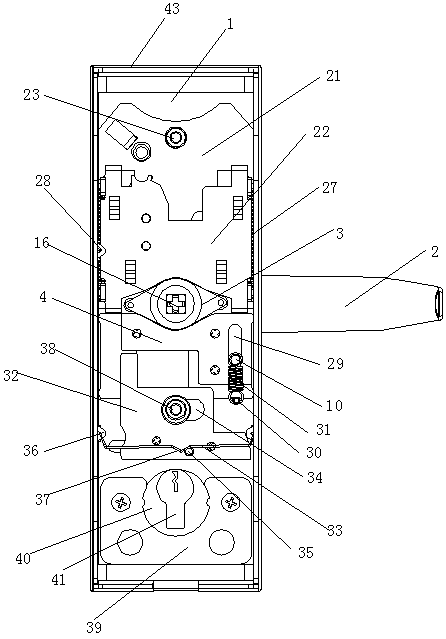

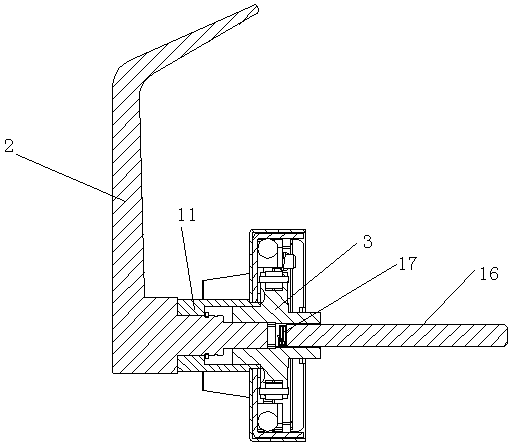

Novel door lock panel handle

PendingCN110894761AExtended service lifeReduce wearKeyhole guardsLock casingsTorsional angleStructural engineering

The invention discloses a novel door lock panel handle. The novel door lock panel handle comprises a panel, a handle installed on the panel, a rhombic torsional angle, shifting mechanisms installed inthe panel, a safety mobile piece, a rotary limiting mechanism and an adjustment mechanism. The shifting mechanisms are located above the rhombic torsional angle. The safety mobile piece is located below the rhombic torsional angle. The rhombic torsional angle is driven by the handle to turn, the handle resets through the shifting mechanisms above and below, and the safety mobile piece, and at thesame time, the safety mobile piece is limited in movement by the rotary limiting mechanism below, and the rotary limiting mechanism is adjusted by the adjustment mechanism below in the limiting state.

Owner:江苏东冠智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com