Wire clamp as well as wire pressing plate support, insulation wire pressing plates and vehicle using wire clamp

A technology of insulated wires and wire code cards, which is applied to vehicle parts, transportation and packaging, circuits or fluid pipelines, etc. It can solve the problems of various specifications of fixing devices, high error rate, and complicated selection, so as to achieve convenient selection and reduce errors. rate, the effect of reducing the number of specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

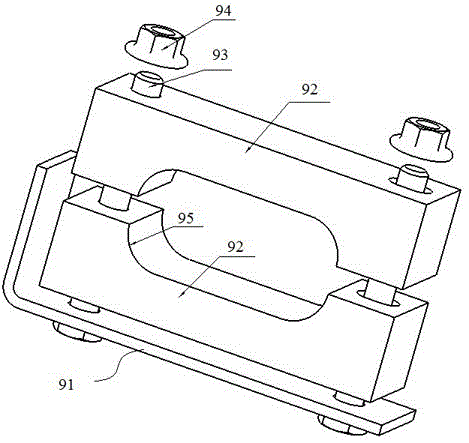

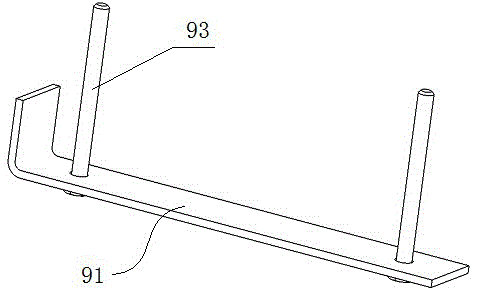

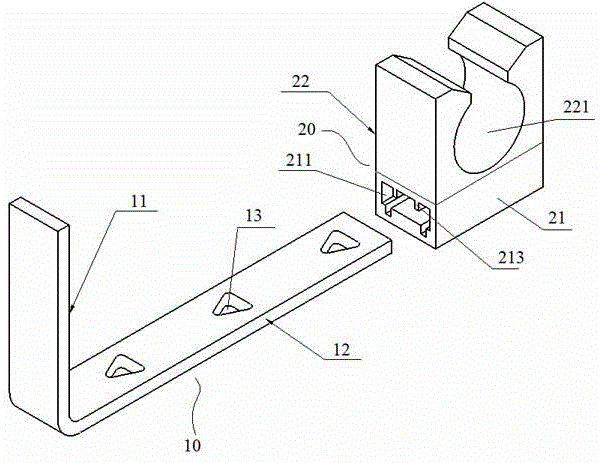

[0046] An embodiment of a line card in the present invention is as Figure 3~Figure 6 As shown, it is a tandem cable clamp, which is used for fixing high-voltage wires of vehicles, and includes a wire code bracket 10 and an insulated wire code 20 for sequentially detachable sleeve on the wire code bracket 10 .

[0047] The line code bracket 10 is a slat structure, which is made by bending a strip steel plate after punching holes. It has a simple structure, less material and light weight. Solder the fixed welding area 11 and the installation area 12 for installing the insulating wire code 20 . Among them, the installation area 12 constitutes an insertion part for the insulated wire codes to be sleeved sequentially, and a plurality of triangular board surface slots 13 are arranged on it, which are used to fit with the elastic clips 212 on the insulated wire code 20 to form a buckle structure, and then Realize the detachable fixation of insulation wire code 20. Each card slot 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com