Permanent magnet motor rotor punching with self-starting ability and industrial frequency conversion performance

A technology of rotor punching and permanent magnet motor, applied in the field of electric motor, can solve the problems of cost reduction and efficiency increase, reduction of motor overload capacity, high market promotion price, saving mold material cost and labor cost, improving starting performance, The effect of optimizing the design of the groove size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

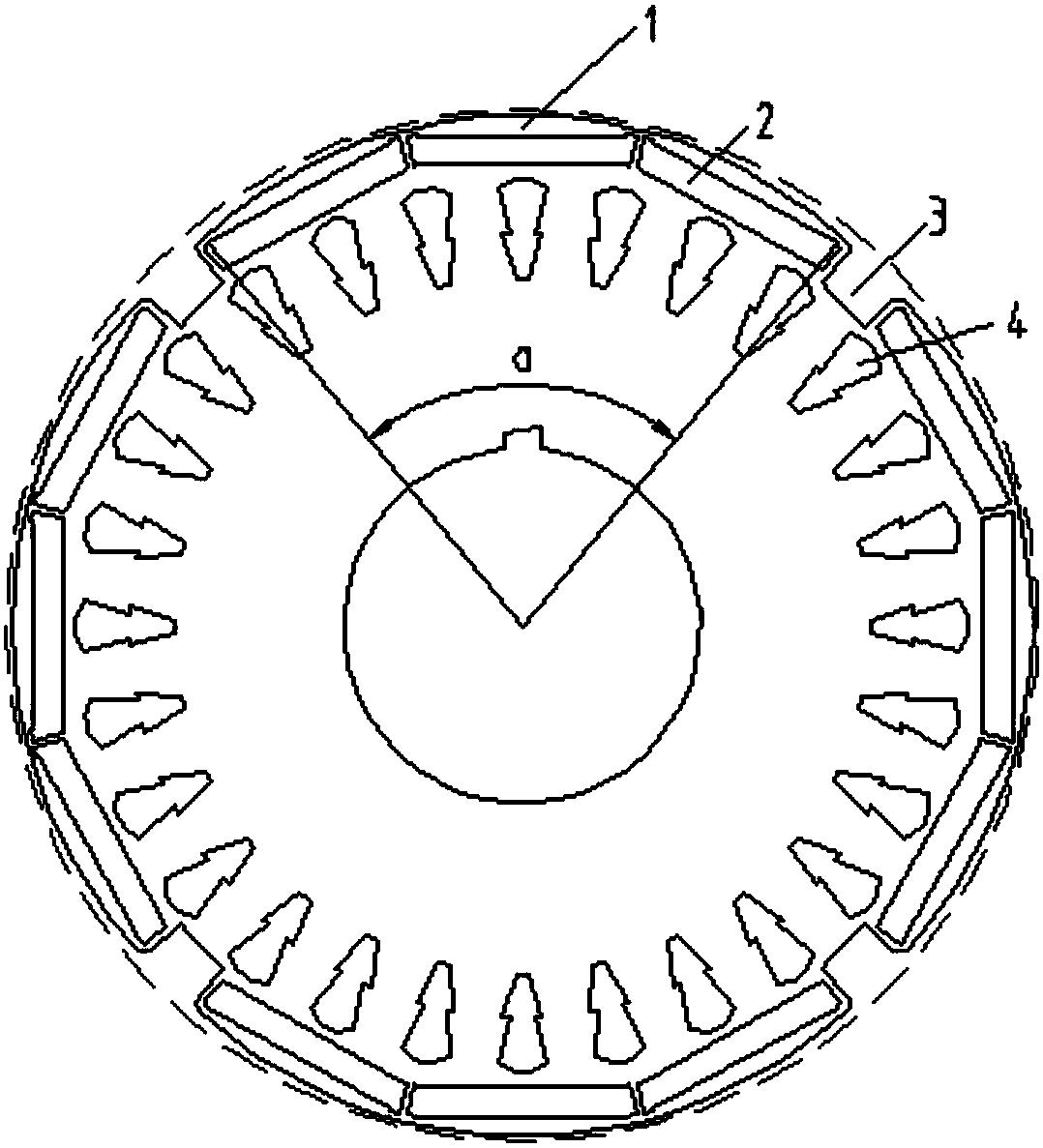

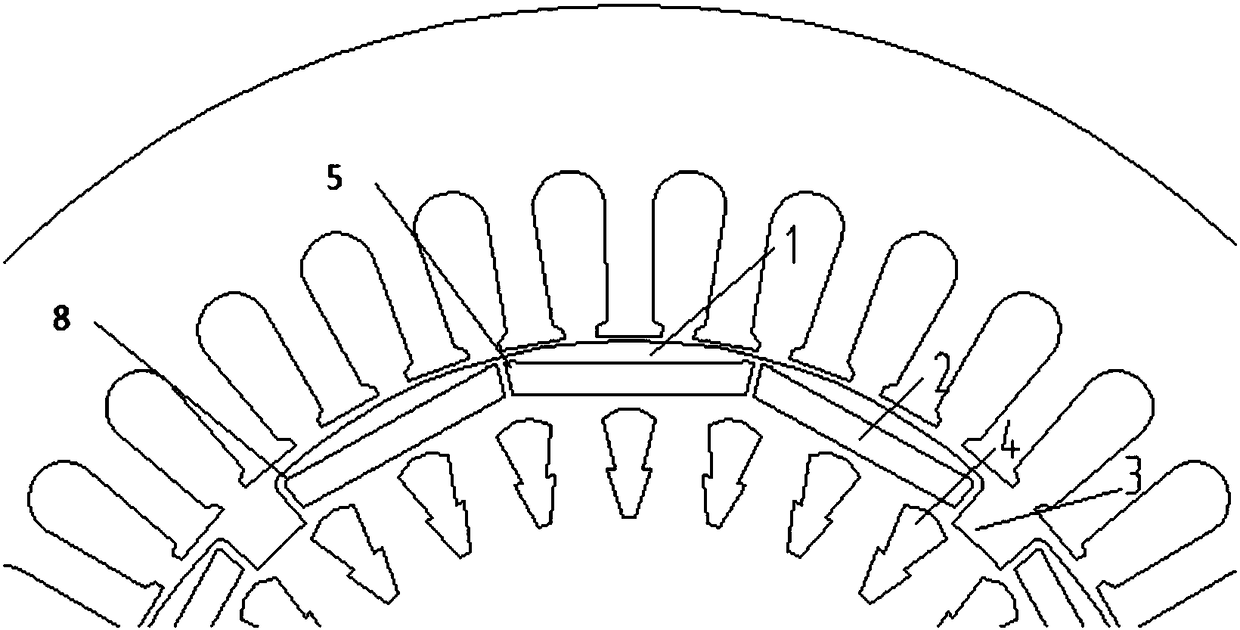

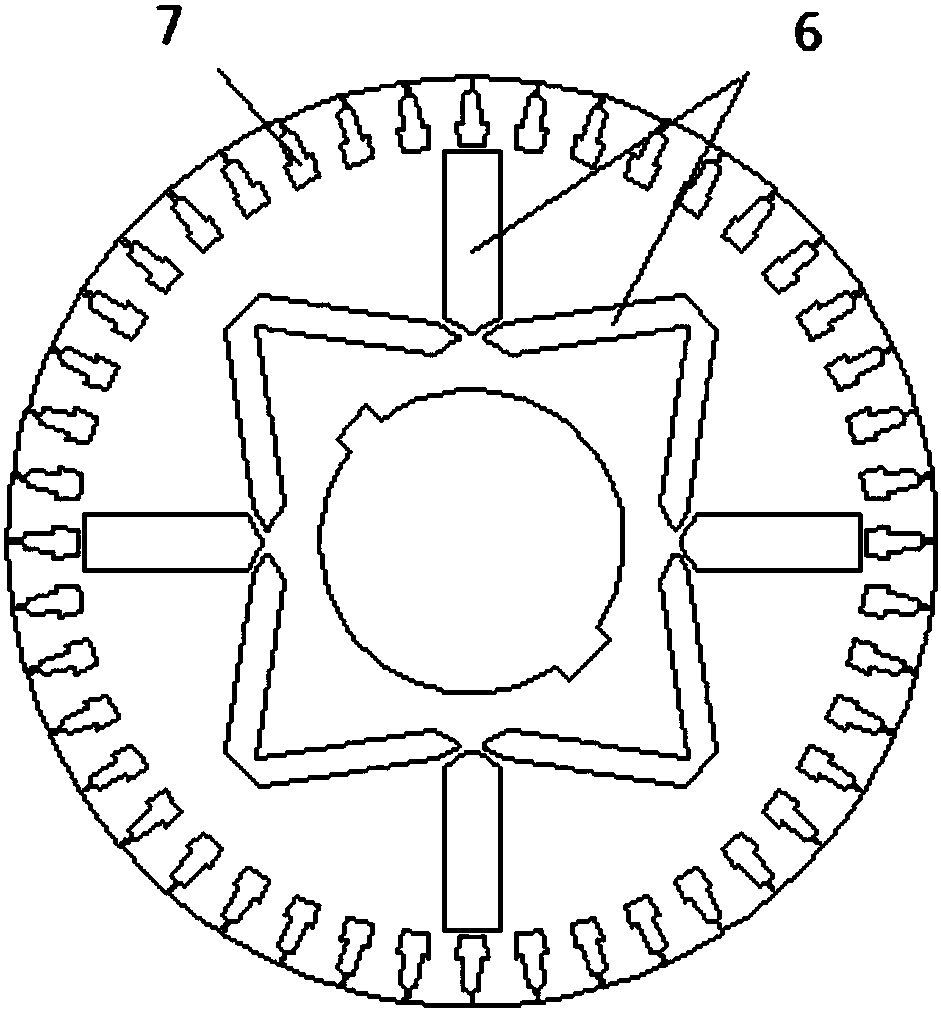

[0035] A permanent magnet motor rotor stamping with self-starting capability and industrial frequency conversion performance, such as figure 1 and figure 2 As shown, the stamping structure includes rotor poles, permanent magnet slots, permanent magnets, slots between poles and evenly distributed slots arranged at the lower part of the permanent magnet slots. The number of punching poles is 4 poles, the number of permanent magnet slots and permanent magnets for each pole is 3 pieces, the magnetic pole angle is 0.75~0.8 times of 360 / 2p, p is the number of pole pairs of the motor, and the outer circle of the magnetic pole is the punching piece with the rotor A circular arc with different concentricity, its radius is (0.89~0.93)×R, R is the radius of the outer circle of the rotor punching piece, and it is set in the evenly distributed slots under the permanent magnet slots.

[0036] Such as figure 1 As shown, in view of the requirements of the load on the starting performance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com