Adjustable template used for production of resin tile

An adjustable, resin tile technology, used in applications, household components, household appliances, etc., can solve the problems of increasing mold manufacturing costs and management costs, and achieve the effect of reducing the number of specifications, improving versatility, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

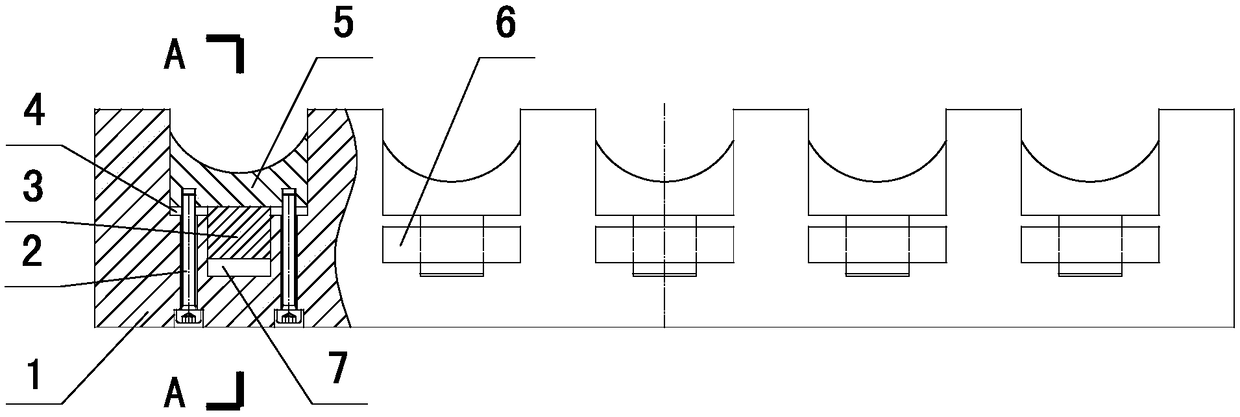

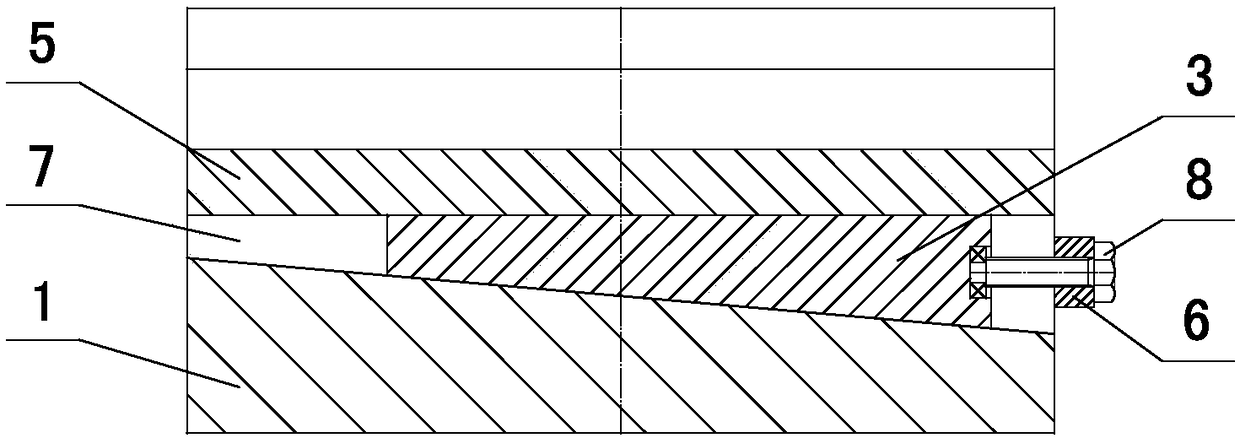

[0016] Such as figure 1 As shown, the adjustable formwork for the production of resin tiles includes a formwork main body 1 arranged horizontally, and several first through grooves 4 are opened on the formwork main body 1, and the first through grooves 4 run through the front and rear sides of the formwork main body 1. , the bottom of each first through groove 4 is provided with a second through groove 7, the second through groove 7 runs through the front and rear sides of the formwork body 1, and the bottom of the second through groove 7 is low at the front and high at the back and slopes upward. A tile mold 5 is arranged in the first through groove 4, and a positioning block 3 is arranged at the bottom of the tile mold 5, and the positioning block 3 is arranged in the second through groove 7. 5 is fixed in the first through groove 4 by several first screws 2 .

[0017] In this embodiment, the front side of the second through groove 7 is horizontally provided with an adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com