Method and device for ensuring low-load and stable operation of gas discharger

A stable operation, low-load technology, applied in mechanical equipment, gas/liquid distribution and storage, pipeline systems, etc., can solve problems such as unfavorable production management, low user gas load, and increased equipment spare parts, etc. Management, reduction of production costs, and the effect of reducing the number of specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

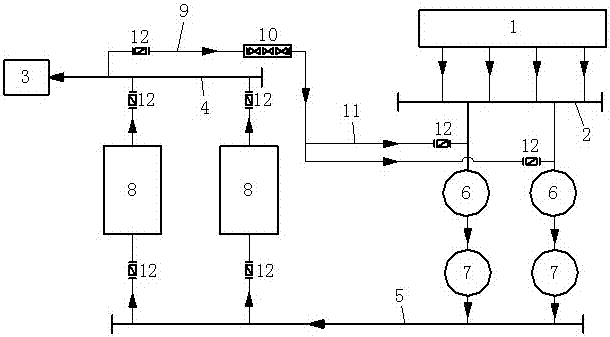

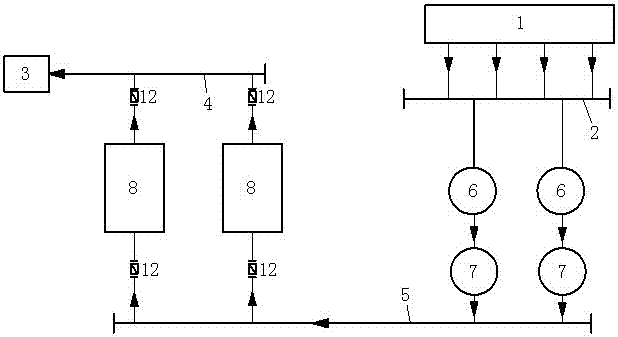

[0020] The method to ensure the stable operation of the gas discharge machine at low load, such as figure 1 shown. The method is to use a group of most commonly used gas dischargers with the same displacement to supply gas to users; to improve the interchangeability of equipment spare parts, reduce the specifications and quantities of equipment spare parts; and reduce the cost of equipment spare parts. When the gas load of the gas user is lower than the minimum gas discharge capacity of a group of gas dischargers, the excess gas is sent back to the intake main pipe or the inlet of the scrubber through the recirculation pipeline connected to the user main pipe, and the recirculation pipeline There is a pressure reducing valve; through the pressure reducing valve, the pressure in the main pipe of the user can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com