Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Reduce processing equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic flux-switching generator

ActiveCN102005837AGood direct output sine performanceImprove robustnessMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineAlternating current

The invention discloses a magnetic flux-switching generator, which comprises a stator, a rotor, a magnet exciting coil and an armature coil, wherein the number of the poles of the rotor is equal to the number of the slots of the stator; the two circle edges of the armature coil are positioned in two adjacent slots of two adjacent stator gears; winding coils are connected end to end in series in turn to form single-phase centralized armature windings; and the magnet exciting coil is vertical to the armature coil. In the invention, the single-phase centralized armature windings and a permanent magnet or / and single-phase centralized magnet exciting windings are adopted in the stator part, the rotor has straight or slant slots and the number of the poles of the rotor is equal to that of the slots of the stator; and thus, the generator retains the structural advantages of compactness, simplicity, high robustness and suitability for high-speed rotation of the conventional magnetic flux-switching generator and can be directly used as a single-phase alternating current power supply due to the same phase of the electrodynamic potentials generated by the coils, and the cost of the generator is low.

Owner:SOUTHEAST UNIV

Method and system for controlling the amount of Anti-fouling additive for particulate-induced fouling mitigation in refining operations

InactiveUS20100163461A1Reducing particulate-induced foulingImprove efficiencyThermal non-catalytic crackingRefining with non-metalsParticulatesFouling mitigation

A method and system for controlling fouling in a hydrocarbon refining process that includes measuring a level of a particulate in a process stream of the hydrocarbon refining process in communication with a hydrocarbon refinery component, identifying an effective amount of additive capable of reducing particulate-induced fouling based at least in part on the measured level of the particulate in the process stream, and introducing the effective amount of additive to the hydrocarbon refining process.

Owner:WRIGHT CHRIS A +5

Manufacture process of high performance ductile iron roll

The present invention discloses manufacture process of high performance ductile iron roll, belongs to the field of crane roll making technology, and solves the problem of once casting formation. By means of the research on high performance cast ductile iron and the research on casting mold material, paint and casting process, the present invention has simplified roll manufacturing process, raised material utilization, low power consumption, obviously raised mechanical performance and use performance of the roll and obviously lowered production cost.

Owner:SHANDONG HUIFENG CASTING TECH

3D glass coloring method

InactiveCN108275887AReduce processing equipmentReduce manufacturing costGlass reforming apparatusGlass tempering apparatusGeneration processNumerical control

The invention provides a 3D glass coloring method. The method comprises the following steps: 1, cutting: cutting a large glass plate into a plurality of glass plates with a preset size; 2, carrying out computerized numerical control (CNC), placing the glass plates into a CNC engraving and milling machine for edging; 3, screen printing ink: performing screen printing on non-visible areas of the edged glass plates with ink of preset color; 4, carrying out hot bending molding: putting the glass plates, printed with the ink by means of screen printing, into a hot bending machine for hot-bending molding so as to form 3D glass; 5, carrying out light sweeping: treating the 3D glass, subjected to the hot-bending molding, by means of light sweeping; 6, hardening: hardening the 3D glass subjected tothe light sweeping so as to enhance the strength of the 3D glass. According to the method, the coloring process is completed at the early stage of the 3D glass generation process, so that the processing devices required for the later stage coloring can be reduced, and the production cost is greatly reduced; in addition, the screen printing technology is lower in difficulty and higher in yield.

Owner:JIANGXI LIANCHUANG ELECTRONICS CO LTD

Natural rubber processing technique

The invention discloses a natural rubber processing technique which comprises the following procedures: crushing, creping, pelleting, drying, weighing and packaging. The natural rubber processing technique is suitable for mixing and processing rubber materials of different grades, a screening procedure is additionally set after the crushing procedure, and a hammer-crushing procedure is additionally set after the creping procedure. The invention aims to provide the natural rubber processing technique which is capable of enabling the processed rubber to be relatively high in consistency, stability and cleanness.

Owner:景谷民森橡胶有限责任公司

Manufacturing method of blind-hole compressor impeller

The invention discloses a manufacturing method of a blind-hole compressor impeller. The manufacturing method comprises the following steps: step 1, installing an impeller blank on a numerical-control vertical lathe, turning the bottom end surface, a bottom end outer circle, a back arc and a large outer circle, and machining a blind hole by utilizing a reamer; step 2, clamping the large outer circle by utilizing three claws, leveling the bottom end surface, and turning a meridian plane and a top end surface; step 3, locating by utilizing the bottom end surface, connecting a bolt with the blind hole by threads, straining the bolt, clamping the back arc and the bottom end outer circle by utilizing a clamp, machining a threaded hole, and milling an inner hexagonal hole, blades and runner. By adopting the manufacturing method, the machining precision can be guaranteed, the production efficiency is improved, and the manufacturing cost is reduced.

Owner:重庆ABB江津涡轮增压系统有限公司

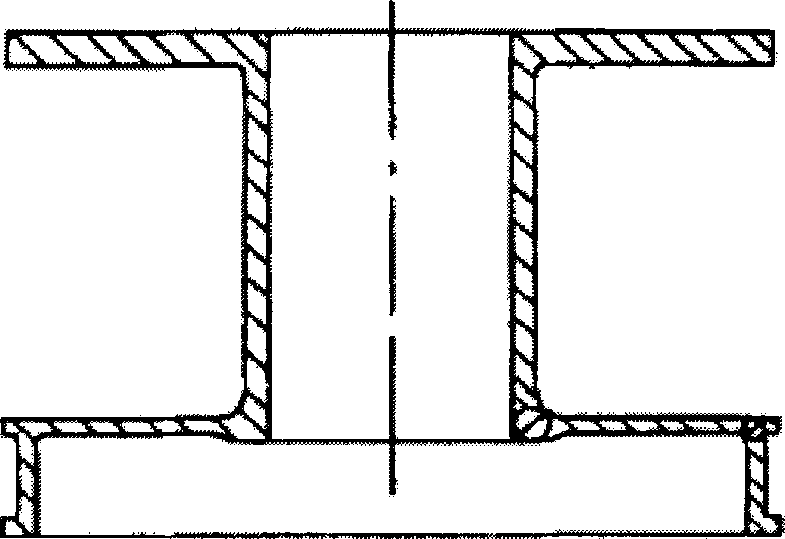

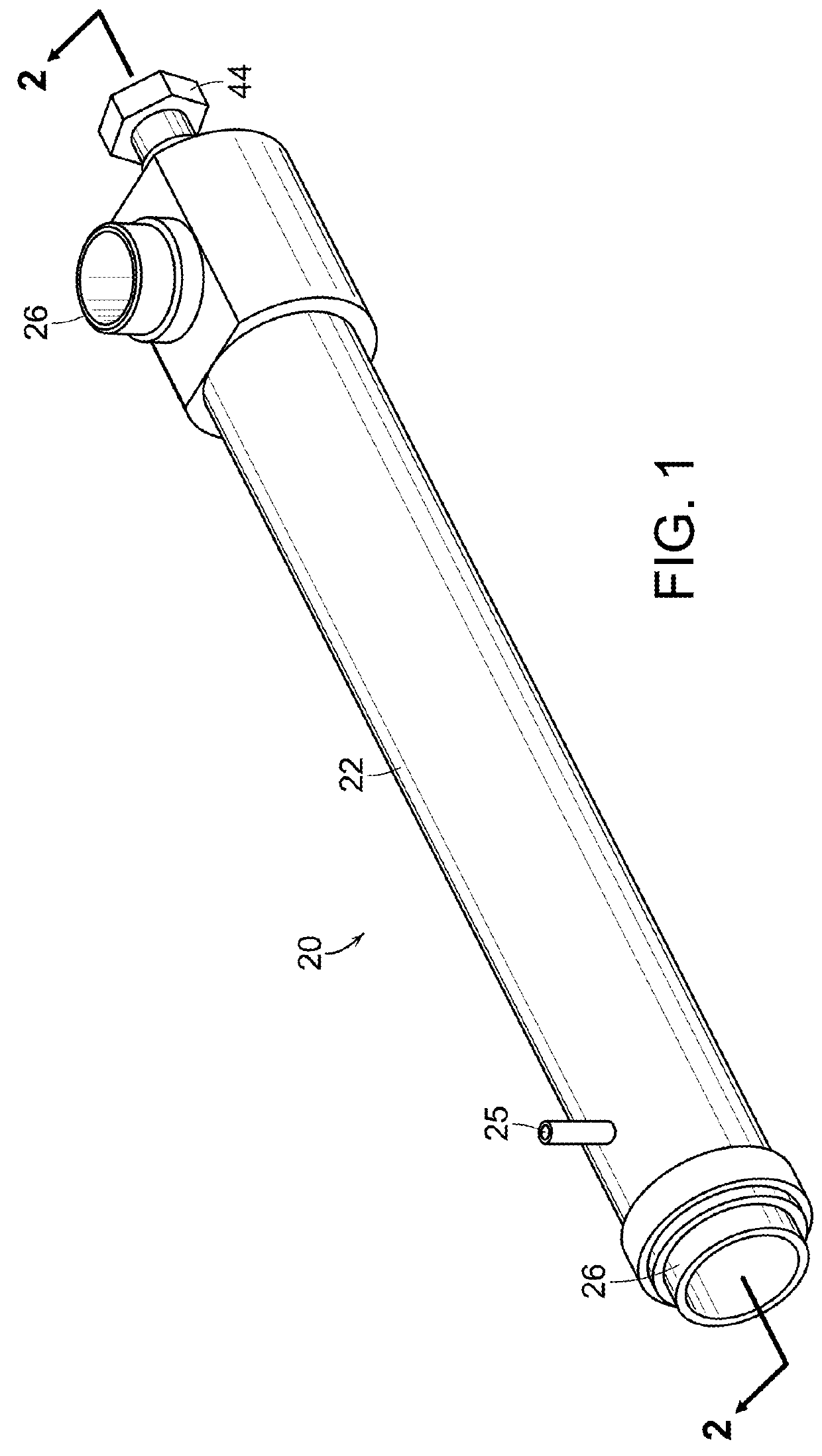

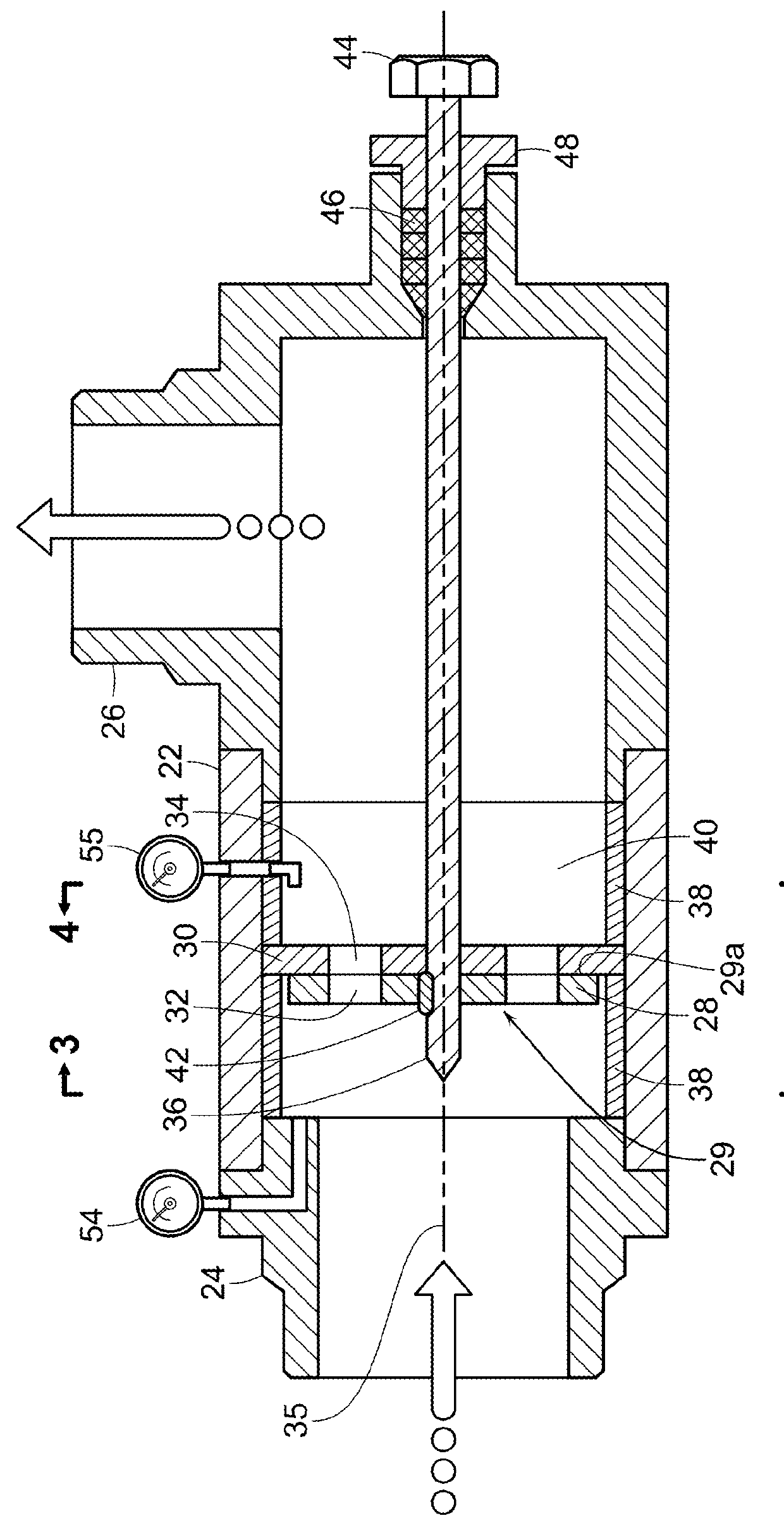

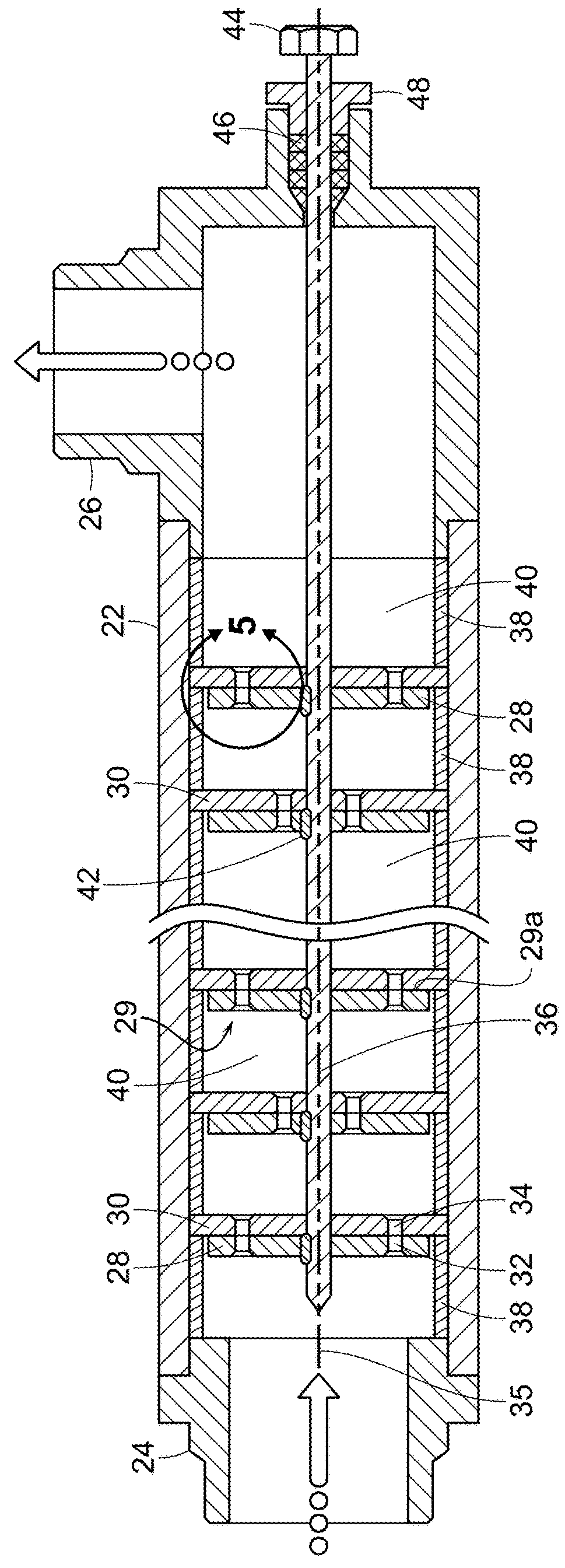

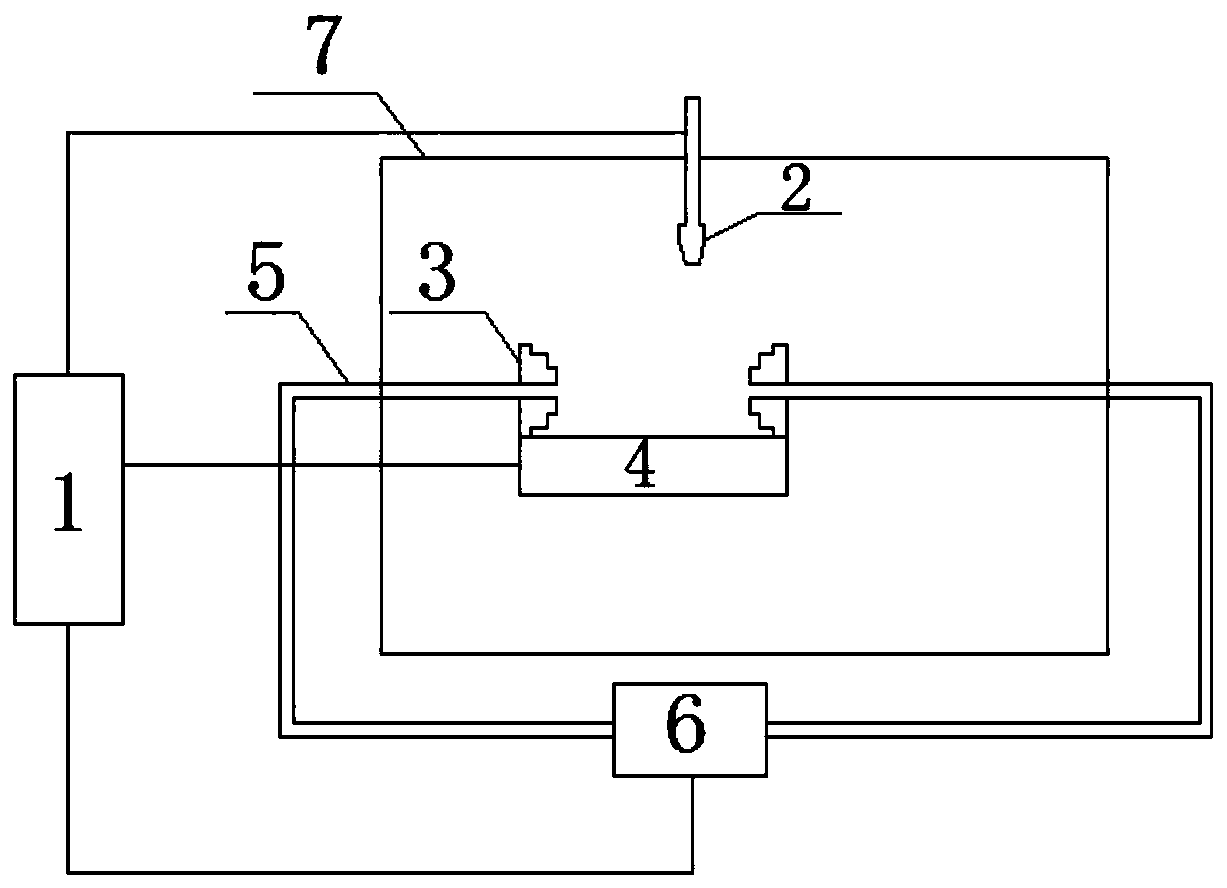

Variable flow-through cavitation device

ActiveUS20180161740A1Fast mass transferImprove treatment efficiencyShaking/oscillating/vibrating mixersFlow mixersCavitationEngineering

A flow-through cavitation device having an elongated housing with an inlet and an outlet. One or more variable multi-jet nozzles are disposed throughout the elongated housing with a working chamber following each variable multi-jet nozzle. Each variable multi-jet nozzle consists of a movable disk fixedly mounted on a central shaft and a stationary disk fixedly mounted on the housing and in contact with the rotating disk. The movable and stationary disks of each variable multi-jet nozzle have through channels. The flow cross-sectional area of the through channels is variable by rotating the movable disk relative to the stationary disk.

Owner:CAVITATION TECH

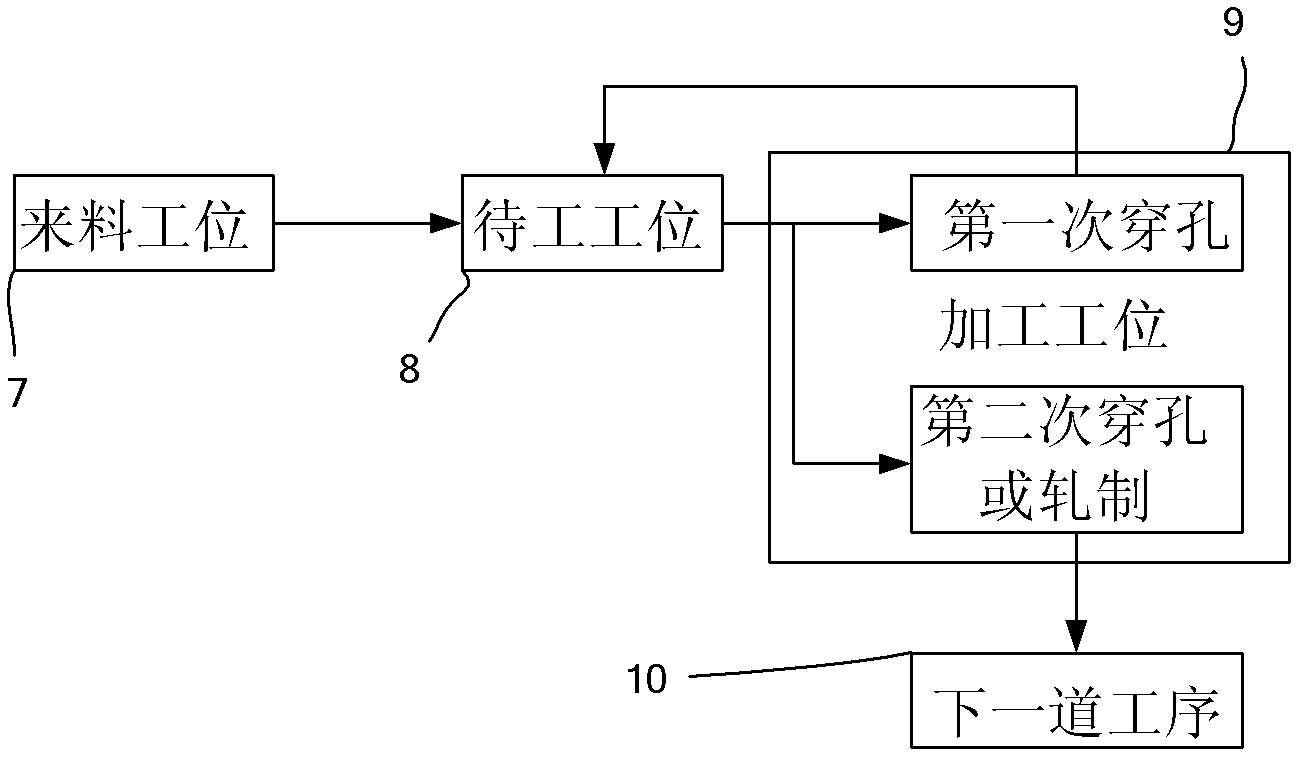

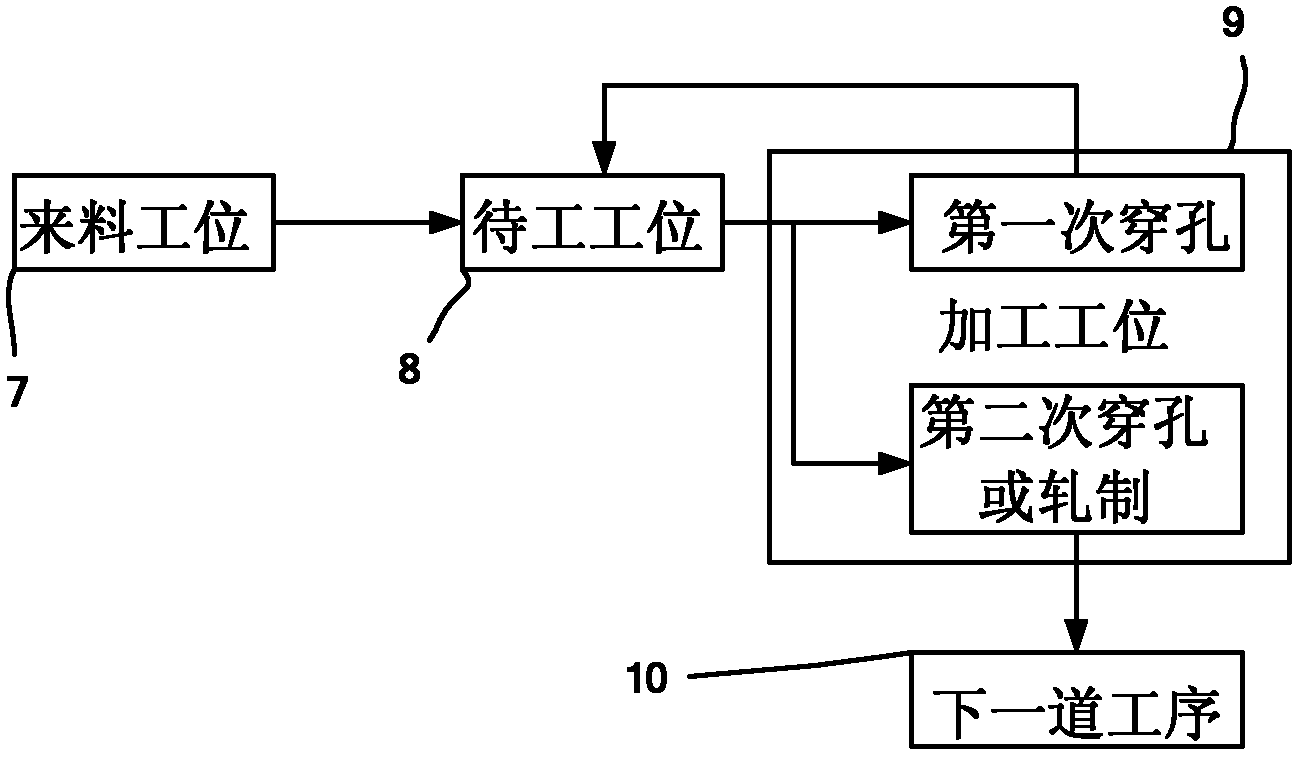

Continuous piercing method for seamless steel tube

InactiveCN102303048AReduce processReduce processing equipmentMetal rolling arrangementsSteel tubeEngineering

The invention discloses a continuous piercing method for a seamless steel tube, comprising the following steps of: (1) obtaining a heated blank from a feeding work station, conveying the blank to a waiting work station; (2) conveying the blank from the waiting work station to a processing work station for the first piercing so as to form a hollow billet; (3) conveying back the hollow billet to the waiting work station; (4) conveying the hollow billet from the waiting work station into the processing work station for performing secondary piercing on the hollow billet or rolling the hollow billet into a pierced billet; (5) conveying the hollow billet processed with the secondary piercing or the rolled pierced billet into next work procedure. The method has the benefit that, in comparison with the prior art, the method can cycle the hollow billet back to the waiting work station and the processing work station, and can roll or perfume the secondary piercing on the hollow billet without independently setting equipments and work procedures, so that work procedures are reduced, processing equipments are reduced, work cost is decreased, work efficiency is improved, energy wastage in secondary heating is avoided, burning loss is reduced, and yield is improved.

Owner:TAIYUAN HEAVY IND

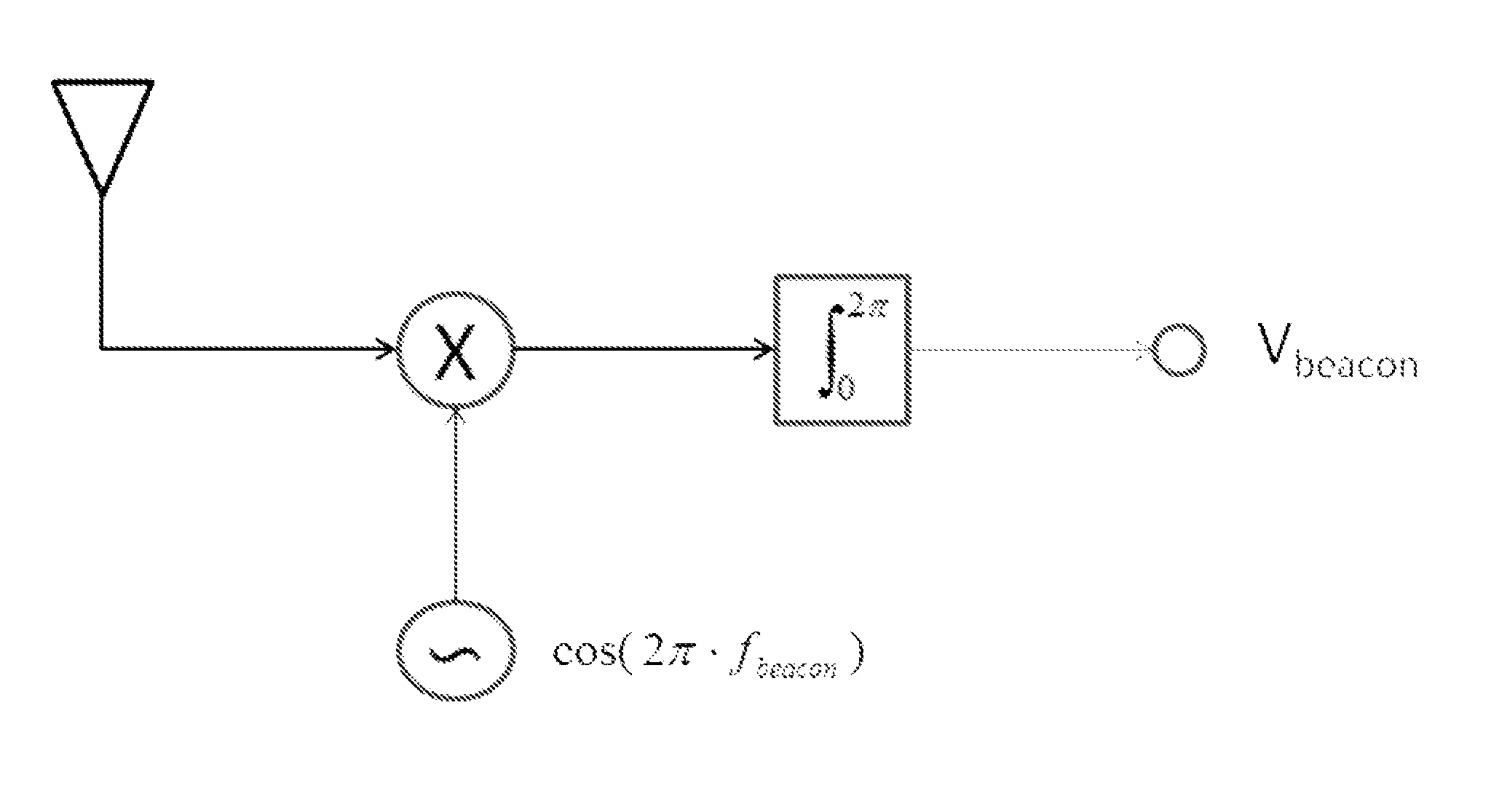

Method for Satellite Beacon Signal Detection and Antenna Alignment

InactiveUS20140266871A1Improve system reliabilityReduce processing equipmentRadio transmissionAntenna detailsSatelliteBackground noise

A method for detecting a beacon signal, by receiving a beacon signal and processing the beacon signal with respect to a local copy of the beacon signal. The processing including multiplying the beacon signal with a local copy of the beacon signal and integrating the result to generate a background noise filtered beacon signal output. The beacon signal output may be utilized to align an antenna with the beacon signal by adjusting alignment until the beacon signal output is either maximized or minimized, depending upon the function applied.

Owner:ASC SIGNAL CORP

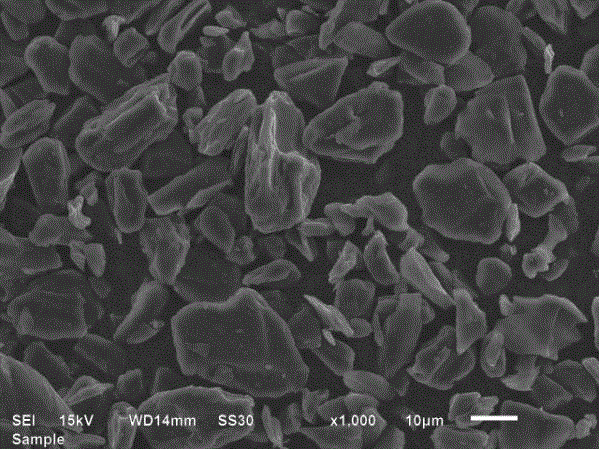

Anode material of lithium ion battery and preparation method of anode material

The invention relates to an anode material of a lithium ion battery and a preparation method of the anode material, belonging to the field of an anode material of the lithium ion battery. The anode material of the lithium ion battery, provided by the invention, comprises graphite particles, wherein the surfaces of the graphite particles are coated with nano-copper particles, and the surfaces of the nano-copper particles are provided with a layer of copper oxide. The anode material has the advantages of high conductivity, high capacity, high compaction and favorable cycle performance, and the bounce rate of a pole piece is low.

Owner:湖南海容新材料有限责任公司

Oxidation of aromatic hydrocarbons using brominated anthracene promoters

InactiveUS20050192459A1Reduce formationReduce processing equipmentOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAnthraceneProcess equipment

Brominated anthracene is effectively used in a catalyst system as promoter for the catalytic oxidation of aromatic hydrocarbons in the production of aromatic carboxylic acids and results in reduced corrosion of process equipment and reduced formation of alkyl bromides while providing yield and quality comparable to that of conventional bromine promoters.

Owner:BP CORP NORTH AMERICA INC

Novel continuous skew rolling process for seamless steel pipe

InactiveCN104138905AReduce distanceReduce heat exchange lossSpecial data processing applicationsMetal rolling arrangementsMaterial PerforationMetal

The invention belongs to the technical field of seamless steel pipe hot rolling processes and relates to a novel continuous skew rolling process for a seamless steel pipe. A plurality of groups of rollers are arranged on a rack, certain parameters are set according to a calculation formula, multiple processes such as perforation, pipe rolling, flattening and rounding during seamless steel pipe production are integrated together, perforation, rolling and the like of a pipe blank are completed in one step, and a finished product pipe is obtained by adopting a continuous skew rolling method. The novel continuous skew rolling process for the seamless steel pipe has the advantages that the machining equipment is reduced, the working cost is decreased, the working efficiency is improved, an intermediate reheating furnace can be omitted, metals with small temperature zones or being difficult to deform can be rolled, and hot finished product pipes with high quality can be directly obtained.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Solar flat plate collector

InactiveCN103644662AIncrease contact areaCombined thermal resistance is smallSolar heating energySolar heat devicesProcess equipmentHeat resistance

The invention discloses a solar flat plate collector which comprises a shell. A heat insulation board, a heat absorption board core and a high transmittance board are sequentially stacked in the shell, the heat absorption board core comprises a heat collection water inlet pipe, a heat collection water outlet pipe and a plurality of heat collection rack pipe components, the heat collection water inlet pipe and the heat collection water outlet pipe are arranged at two ends of the heat absorption board core, the heat collection rack pipe components are mounted between the heat collection water inlet pipe and the heat collection water outlet pipe, each heat collection rack pipe component comprises a heat collection rack pipe and heat collection fins, two ends of each heat collection rack pipe are communicated, an arc structure is arranged on each heat collection fin and sleeved on the outer wall of each heat collection rack pipe, and the outer diameter of each arc structure is as same as that of each heat collection rack pipe. The arc structures wrap external circles of the heat collection rack pipes, the contact area of the heat collection fins and the heat collection rack pipes is large, combined heat resistance is low, and the solar flat plate collector has the advantages of inexpensiveness of processing equipment and simplicity in assembly.

Owner:郭强

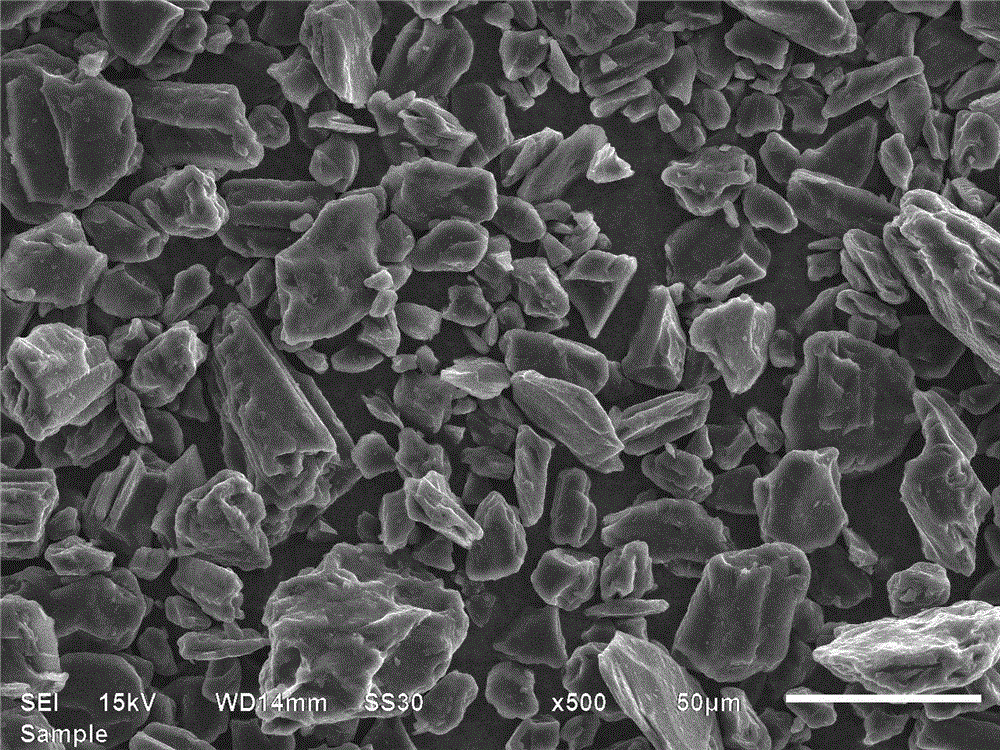

Preparation method of isotropic graphite material

ActiveCN105280918ASimple processReduce processing equipmentCell electrodesNickel saltProcessing cost

The invention relates to a preparation method of a graphite material, in particular to a preparation method of an isotropic graphite material. The method comprises the following steps: (a) adding water-soluble organic polymers, coke and a soluble iron salt and / or nickel salt; (b) dropwise adding an alkali liquor, so that iron or nickel ions are deposited on the graphite surface; (c) filtering and drying sediments; and (d) heating the sediments to 2600-3,000 DEG C in an inert gas protection, carrying out a thermal treatment and then cooling the sediments. The preparation method is simple in process and low in processing cost.

Owner:湖南海容新材料有限责任公司

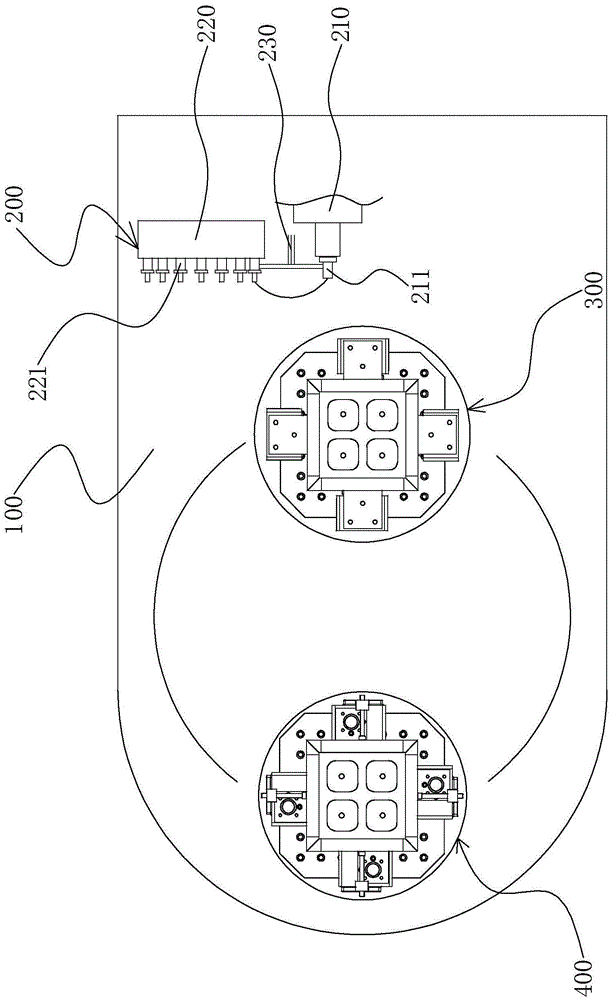

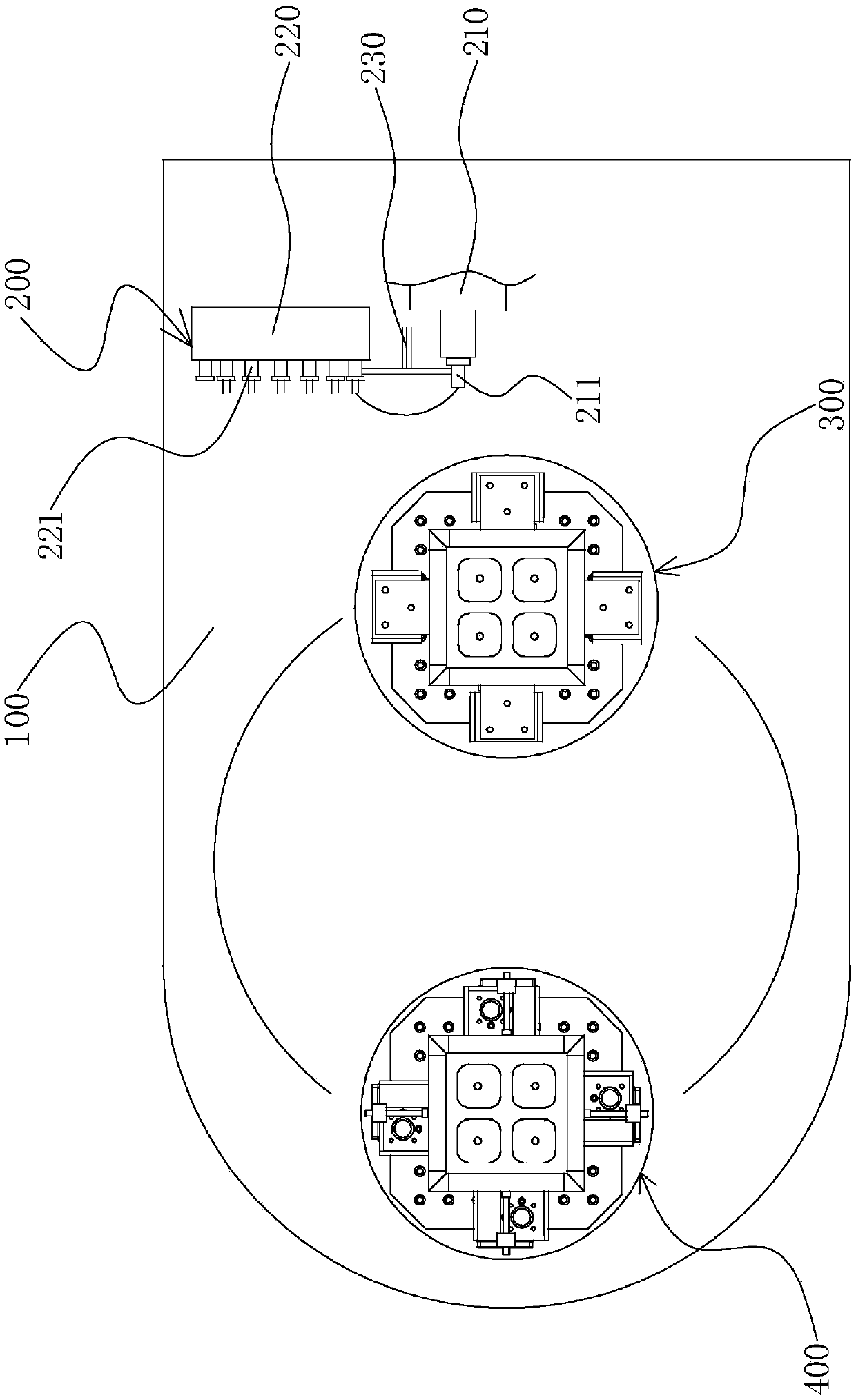

Processing production line of gas meter housing

PendingCN110052844AEasy to processReduce processing equipmentLiquid spraying plantsOther manufacturing equipments/toolsProduction lineGas meter

The invention provides a processing production line of a gas meter housing. The processing production line solves the problems that different processing equipments are required in different proceduresin the existing processing course, more processing equipment is required in the whole processing course, the production efficiency is low, the labor intensity is high, the cost is high and the product quality is difficult to control. The original multiple processing procedures are simplified, the processing equipment is reduced, processing of the multiple procedures can be carried out by the single equipment, the equipment corresponding to each step only requires one-time working stroke, so that the processing can be completed, the unnecessary processing steps are reduced, the processing timeis shortened, and the processing efficiency of products is improved substantially.

Owner:浙江巨宏仪表有限公司

Split-type detonation fracture splitting machining technology of laser initiation of connecting rod tip

ActiveCN104668926AImprove cracking efficiencyHigh energy and high cracking efficiencyShock waveDetonation

Disclosed is a split-type detonation fracture splitting machining technology of laser initiation of a connecting rod tip. The technology includes: before fracture splitting, machining two fracture splitting grooves in the inner side of the big end hole of each connecting rod through a broach or laser; loading more than two connecting rods into a bottom plate box in an overlapping manner, placing a detonation subject and an expanding medium in the big end hole of the connecting rods and pressing through a pressing cover plate; trigging a high-pressure ball gap switch through the laser to be switched on during fracture splitting, 30-100KA pulsed heavy current is exerted to a copper wire penetrating the detonation subject which is detonated to generate transient high-energy high-pressure shock waves to exert dynamic load to the inner wall of the big end hole of the connecting rods, and fracture tips of the fracture splitting grooves are enabled to loss stability to be expanded to form entire fracture shearing surfaces. By the arrangement, fracture splitting for more than two connecting rods can be realized at one step, fracture splitting efficiency is high, the combined fracture surfaces are interlocked and high in resistance to shear bearing capacity, machining equipment is effectively saved, and machining cost is lowered.

Owner:XI AN JIAOTONG UNIV

Preparation method of high-temperature alloy material for locomotive motor retaining ring

InactiveCN112575198AEasy to prepareReduce processing equipmentElectric machineryAutomotive engineering

The invention provides a preparation method of a high-temperature alloy material for a locomotive motor retaining ring. The preparation method comprises the steps of raw material preparation, vacuum smelting and electroslag remelting. According to the preparation method, the process of an existing high-temperature alloy material for the retaining ring is optimally designed, the feeding sequence isreasonably arranged, the preparation process is simplified, the processing equipment is reduced, the preparation cost is reduced, and the market competitiveness of enterprises is improved.

Owner:江苏新核合金科技有限公司

Variable flow-through cavitation device

ActiveUS10507442B2Fast mass transferImprove treatment efficiencyFlow mixersMixing methodsCavitationEngineering

A flow-through cavitation device having an elongated housing with an inlet and an outlet. One or more variable multi-jet nozzles are disposed throughout the elongated housing with a working chamber following each variable multi-jet nozzle. Each variable multi-jet nozzle consists of a movable disk fixedly mounted on a central shaft and a stationary disk fixedly mounted on the housing and in contact with the rotating disk. The movable and stationary disks of each variable multi-jet nozzle have through channels. The flow cross-sectional area of the through channels is variable by rotating the movable disk relative to the stationary disk.

Owner:CAVITATION TECH

Glass supporting method and structure of glass curtain wall

InactiveCN1316128CResolve defects not subject to shear stressDoes not affect glue injectionWallsAdhesiveStructural engineering

A structure for supporting the glasses of glass curtain wall is composed of transverse beams, glasses, secondary frames and the structural adhesive between glass and secondary frame. It has also the glass supporting plates consisting of horizontal and oblique supporting plates.

Owner:杜军桦

Method of preparing game intercrystalline regular polystyrene directly from monomer polymerization

A process for preparing the syndiotactic gamma-polystyrene directly from monomers copolymerizing includes such steps as loading the pure styrene in anhydrous non-oxygen reactor, adding C12-C30 hydrocarbon solvent, stirring while heating, adding main catalyst and cocatalyst, polymerizing in high-purity N2, washing with alcohol, filter and drying.

Owner:ZHEJIANG UNIV

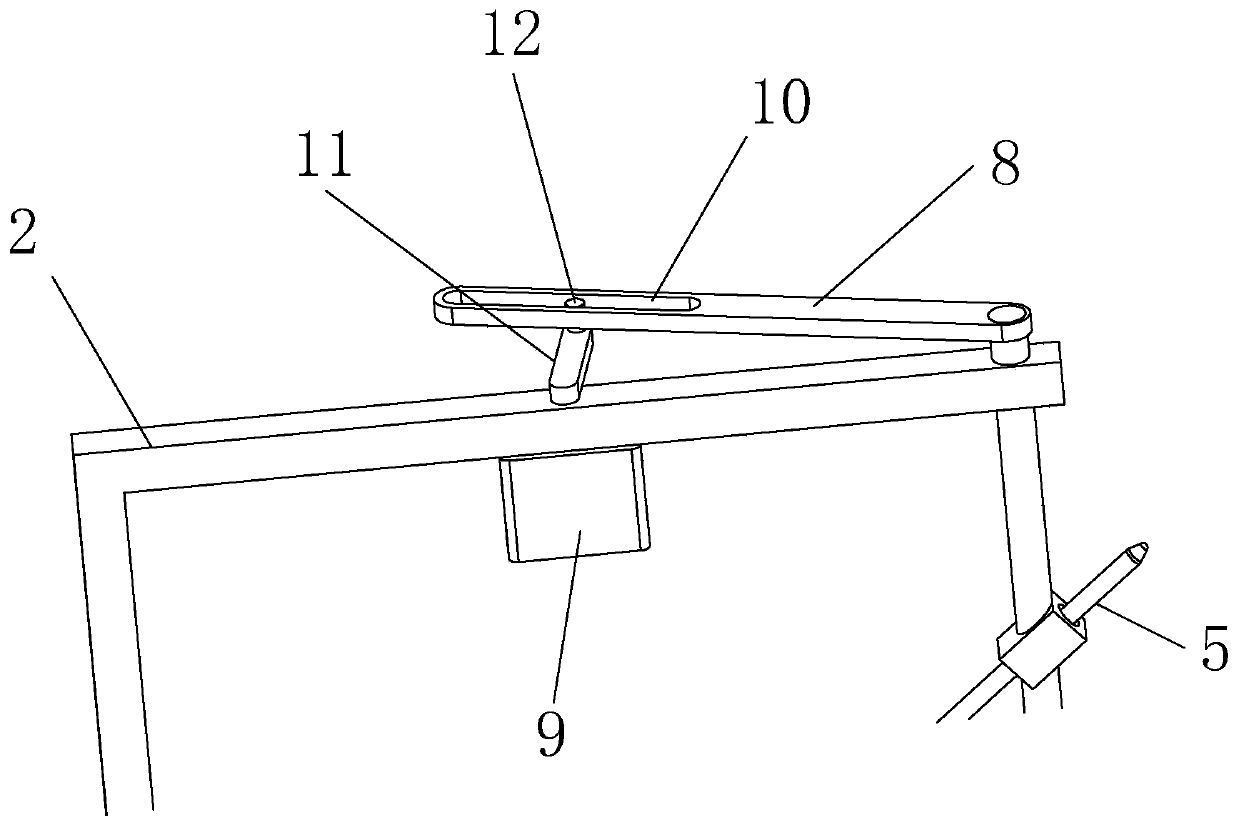

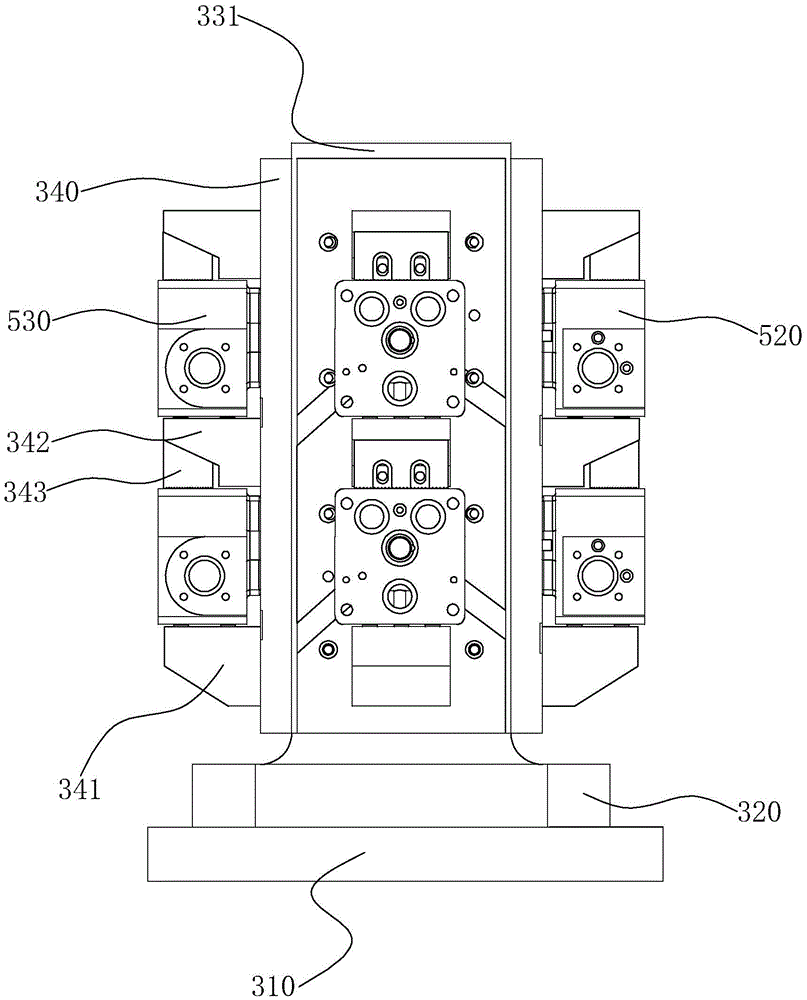

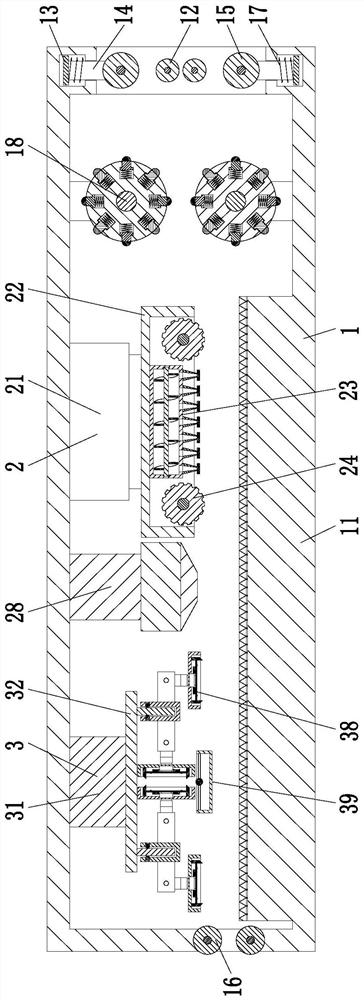

A special proportional pressure control valve processing device for injection machine

ActiveCN103706810BHigh positioning accuracyGood consistency of precisionTurning machinesMachine controlEngineering

The invention provides a machining device for a proportional pressure control valve special for an injection machine, and belongs to the technical field of lathe machining. The machining device solves the technical problems that an existing control valve is complex in machining technology, low in production efficiency and poor in accuracy. The machining device for the proportional pressure control valve special for the injection machine comprises a fixed platform, an annular guide rail and a machining unit are arranged on the fixed platform, and a first installing unit and a second installing unit are arranged on the annular guide rail and respectively provided with a plurality of control valves; each control valve is provided with six faces, wherein three adjacent faces form a first set of machining faces, the other three faces form a second set of machining faces, the first installing unit and the second installing unit respectively revolve on the annular guide rail, and the first set of machining faces of the control valves in the first installing unit and the second set of machining faces of the control valves in the second installing unit are respectively machined through the machining unit. The machining device is high in production efficiency, simple in technology and accurate in positioning, and the machined control valves are good in uniformity of overall accuracy.

Owner:NINGBO HOYEA MACHINERY MFG

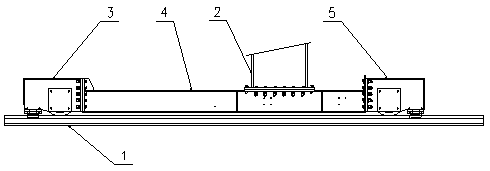

Traveling mechanism based on module structure and assembling method

InactiveCN108249360AReduce processing difficultyReduce processing costsLifting devicesStorage devicesReference lineMachining

The invention discloses a traveling mechanism based on a module structure and an assembling method. The traveling mechanism comprises a front traveling wheel box, a bottom supporting beam and a rear traveling wheel box. The front traveling wheel box and the rear traveling wheel box which are assembled and adjusted respectively are each connected with the bottom supporting beam through bolts to form a whole, and the front traveling wheel box, the bottom supporting beam and the rear traveling wheel box are on the same reference line. A split structure way is adopted, the size and weight of the front traveling wheel box and the rear traveling wheel box are relatively small, the machining difficulty and cost are reduced, installation is more convenient, assembling precision and installation efficiency are improved, and maintenance and replacing efficiency for bearings in the traveling wheel boxes is high.

Owner:CHANGCHUN BEIFANG INSTR EQUIP +2

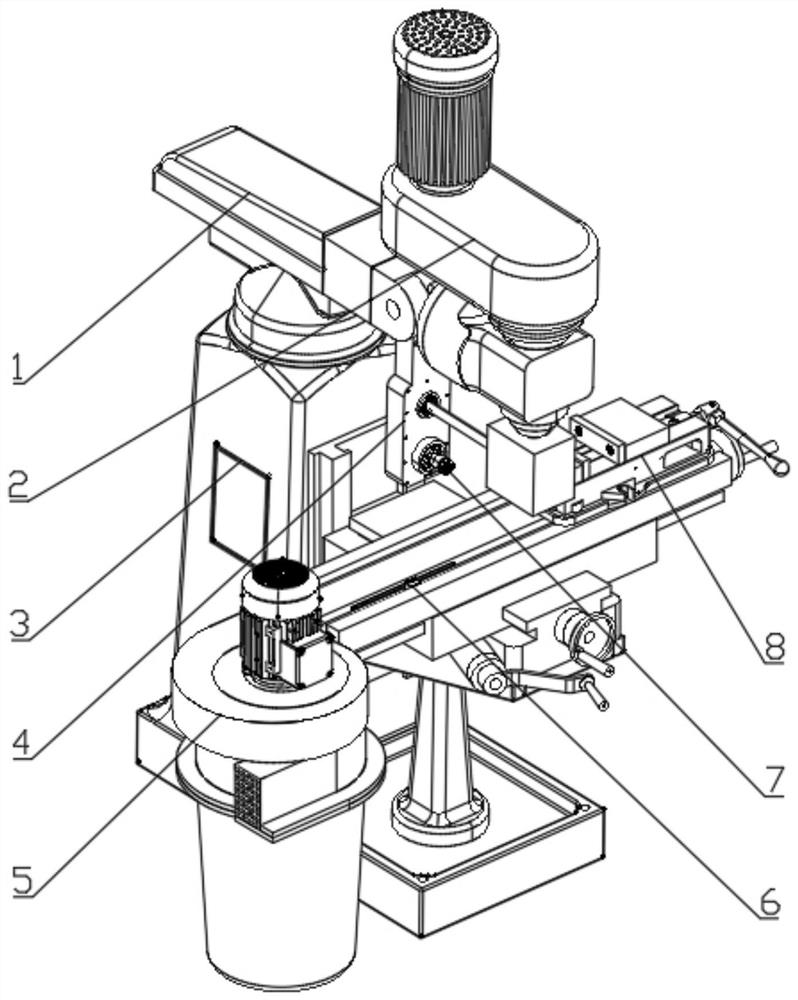

Axial stable machining milling machine and machining method thereof

PendingCN113020669AImprove machining accuracyLarge processing spaceMilling machinesMaintainance and safety accessoriesMachiningWind power

The invention relates to the technical field of milling machines, in particular to an axial stable machining milling machine which comprises a fixing base, a transmission conversion mechanism, a transmission device, a workbench and a scrap removing mechanism. The transmission device is arranged at the upper end of the fixing base and rotationally connected with the fixing base, the upper end of the transmission conversion mechanism is arranged inside the lower end of the transmission device and connected with the transmission device in a transmission mode, the workbench is arranged at the front end of the fixing base, and the scrap removing mechanism is arranged on one side of the workbench. Due to the fact that the conversion mechanism is arranged, vertical machining of the milling machine is changed into axial machining, and the machining space and the machining range of machining of the milling machine are enlarged; and due to the fact that the scrap removing mechanism is arranged, a wind power scrap removing mode is adopted, residual scraps on the workbench are sucked away, most of the scraps can be effectively removed, and the corrosion damage of the scraps to the workbench is reduced. The invention further provides a machining method of the axial stable machining milling machine.

Owner:勤利自动化设备(韶关)有限公司

A rotating metal target and its preparation method and device

ActiveCN110257785BHigh purityRefine the grain sizeVacuum evaporation coatingSputtering coatingHigh energy electron beamElectron bunches

The invention provides a rotary metal target material and a preparation method and device thereof, and belongs to the field of target material preparation. The preparation method comprises the following steps: under the vacuum condition, carrying out regional remelting treatment on a metal pipe through a high-energy electron beam, and then cooling to obtain the rotary metal target material. According to the rotary metal target material and the preparation method and device thereof, the high-energy electron beam is used for carrying out regional remelting on the metal pipe, and meanwhile cooling treatment is combined, so that the rotary metal target material has high purity and no impurities existing in the target material, and the grain size of the rotary metal target material is refined; and the preparation method is simple in process, the process is easy to control, the cost of processing equipment is low.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

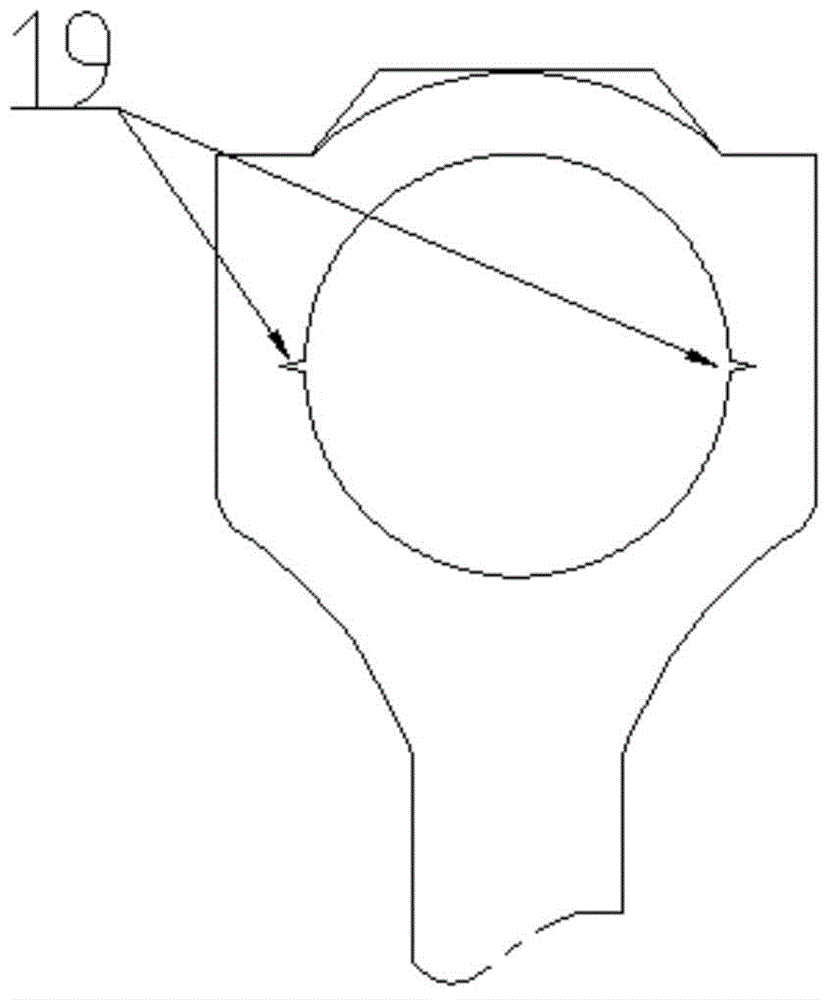

Pressure valve

InactiveCN109955085AHigh positioning accuracyGood consistency of precisionMetal working apparatusPositioning apparatusMachine controlEngineering

The invention provides a pressure valve and belongs to the technical field of lathe machining. The technical problems that an existing control valve machining process is complex, the production efficiency is low, and the locating precision is poor are solved. The pressure valve comprises a fixed platform, an annular guide rail and a machining unit are arranged on the fixed platform, and a first mounting unit and a second mounting unit are arranged on the annular guide rail. The first mounting unit and the second mounting unit are provided with a plurality of control valves correspondingly, andeach control valve is provided with six faces, wherein three adjacent faces form a first set of machining faces, and the other three faces form a second set of machining faces. The first mounting unit and the second mounting unit revolute on the annular guide rail, and the first sets of machining faces of the control valves in the first mounting unit and the second sets of machining faces of thecontrol valves in the second mounting unit are machined by the machining unit. The pressure valve is high in production efficiency, simple in process, accurate in positioning and good overall precision consistency of the machined control valves.

Owner:郑霄

A compound machine for chamfering and rolling cutting of ring parts

ActiveCN105436898BAct as a power sourceEasy to operateOther manufacturing equipments/toolsHydraulic cylinderHobbing

The invention discloses a chamfering and rolling-cutting compound machine for annular elements. The chamfering and rolling-cutting compound machine comprises a workbench, a control panel as well as an edge-rolling mechanism, a main power mechanism and an edge-cutting mechanism which are sequentially installed on the workbench from left to right, and electrically connected with the control panel, wherein the main power mechanism comprises a power source, an installation platform connected with the power source and installed on the workbench, and a pressing assembly located above the installation platform; the edge-cutting mechanism comprises a cutter assembly, a first slide assembly and a first hydraulic cylinder; the cutter assembly is installed on the first slide assembly, and the first hydraulic cylinder is installed at one side of the first slide assembly; the edge-rolling mechanism comprises a rolling assembly, a second slide assembly and a first cylinder; the rolling assembly is installed on the second slide assembly, and the first cylinder is installed at one side of the second slide assembly. The chamfering and rolling-cutting compound machine disclosed by the invention is capable of completing the procedures of chamfering and trimming during an edge-rolling process, thus increasing production efficiency, and simplifying machining equipment.

Owner:嘉兴市标速汽车零部件股份有限公司

Method and rolling cutter for manufacturing LED multi-chip package substrate

ActiveCN103904202AReduce manufacturing costReduce processing equipmentSolid-state devicesSemiconductor/solid-state device manufacturingSquare pyramidMicrometer

The invention discloses a method and rolling cutter for manufacturing an LED multi-chip package substrate. The rolling cutter is fixed to a main shaft of a vertical milling machine, moving states of three shafts of the milling machine are respectively controlled, the pressing amount of the main shaft and the rolling speed of the rolling cutter are controlled, and accordingly the LED multi-chip integrated package substrate provided with an inverted right-square pyramid structure is obtained. The rolling cutter is manufactured in a precise cutting mode, the surface of the outer circle of the rolling cutter is provided with five columns of right-square pyramid structures, and the angle of each right-square pyramid ranges from 60 degrees to 100 degrees. The heights of conical teeth of the cutter range from 300 micrometers to 500 micrometers, the outer diameter of the cutter ranges from 30 mm to 50 mm, and the inner diameter of the cutter ranges from 10 mm to 15 mm. The method and rolling cutter can meet the manufacturing requirements of the LED multi-chip integrated package substrate provided with the inverted right-square pyramid light obtaining structure, substrate machining efficiency can be greatly improved, and compared with a traditional machining method, cost is lower and speed is higher.

Owner:SOUTH CHINA UNIV OF TECH

Method of directly preparing beta intercrystalline polystyrene directly from monomer polymerization

A process for preparing the syndiotactic beta-polystyrene directly from monomers polymerizing includes such steps as loading pure styrene in anhydrous non-oxygen reactor, adding C10-C30 hydrocarbon solvent, stirring while heating, adding main catalyst and cocatalyst, polymerizing in high-purity N2, washing with alcohol, filtering and drying.

Owner:ZHEJIANG UNIV

Method of directly preparing beta intercrystalline polystyrene directly from monomer polymerization

A process for preparing the syndiotactic beta-polystyrene directly from monomers polymerizing includes such steps as loading pure styrene in anhydrous non-oxygen reactor, adding C10-C30 hydrocarbon solvent, stirring while heating, adding main catalyst and cocatalyst, polymerizing in high-purity N2, washing with alcohol, filtering and drying.

Owner:ZHEJIANG UNIV

A three-in-one composite paper bag manufacturing process

ActiveCN111169098BQuality improvementAchieve reductionBag making operationsPaper-makingProcess engineeringNonwoven fabric

The invention relates to a manufacturing process of a three-in-one composite paper bag. The manufacturing process of the three-in-one composite paper bag adopts the following composite paper bag manufacturing equipment. The composite paper bag manufacturing equipment includes a conveying and pressing device, a coating drying device and a cutting and bonding device; The conveying and laminating device described above has a hollow structure, a coating drying device is installed on the right side of the conveying and laminating device, and a cutting and bonding device is installed on the left side of the conveying and laminating device. The present invention can solve the problem that in the production process of the three-in-one composite paper bag of the existing equipment, kraft paper and non-woven fabric are usually combined and then directly coated with a film. There are gaps and air bubbles between the kraft paper and the non-woven fabric, resulting in gaps in the film coating process. It cannot be glued to the air bubbles, which reduces the quality of the composite bag, and the existing equipment usually cuts the composite paper and then glues it once to make a composite bag during the production process of the three-in-one composite paper bag , The two steps of separate processing lead to problems such as more equipment required for processing, long processing time, and low efficiency.

Owner:义乌市金婚包装科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com