Axial stable machining milling machine and machining method thereof

A stable and milling machine technology, applied in the field of milling machines, can solve problems such as low machining accuracy, corrosion of the workbench, and increased surface damage of parts, so as to save processing time, expand the processing range, and reduce processing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

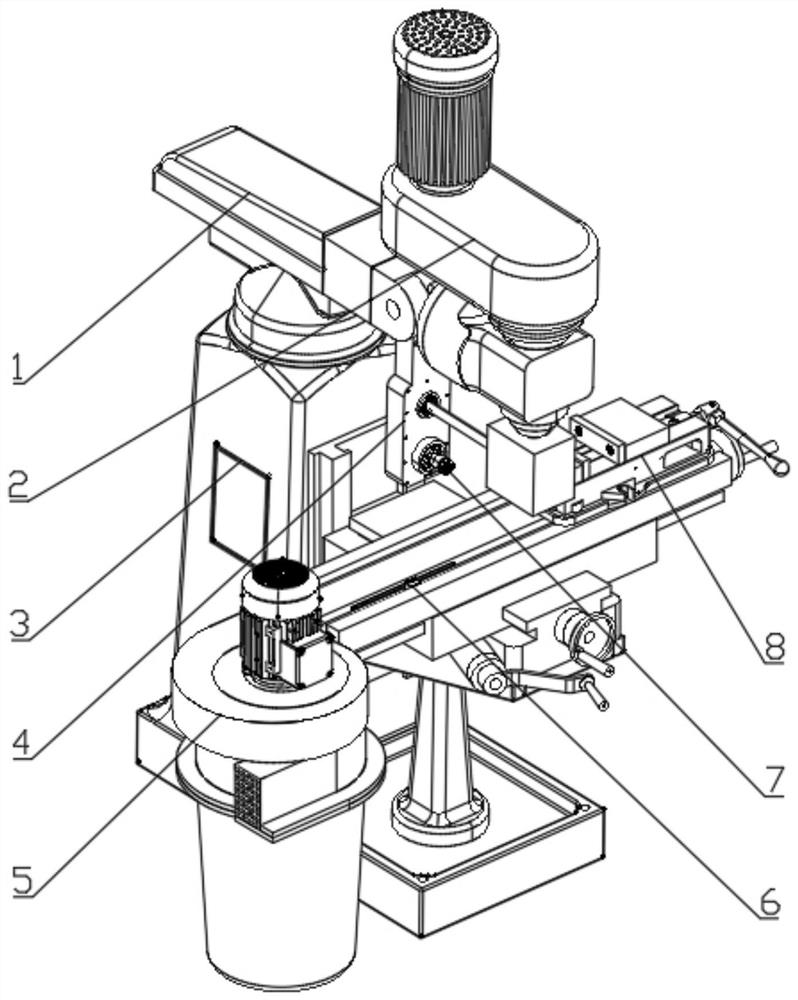

[0045] Such as Figure 1-7 As shown, an axially stable milling machine includes a fixed seat 3, a main connecting arm 1, a secondary connecting arm 11, a transmission conversion mechanism 4, a transmission 2, a workbench 10, a chip removal mechanism, a lateral movement mechanism 15, a longitudinal movement Mechanism 12 and vertical movement mechanism 13, the lower side of the middle end of the main connecting arm 1 is rotationally connected with the upper end of the fixed seat 3, the rear end of the auxiliary connecting arm 11 is rotationally connected with the front end of the main connecting arm 1, and the actuator 2 is arranged at the front end of the auxiliary connecting arm 11 The upper side, and the lower end of the driver 2 passes through the front end of the auxiliary connecting arm 11, the upper end of the transmission conversion mechanism 4 is arranged inside the lower end of the driver 2 and is connected to the driver 2, and the front side of the lower end of the fix...

Embodiment 2

[0052] Such as Figure 1-7 As shown, an axially stable milling machine includes a fixed seat 3, a main connecting arm 1, a secondary connecting arm 11, a transmission conversion mechanism 4, a transmission 2, a workbench 10, a chip removal mechanism, a lateral movement mechanism 15, a longitudinal movement Mechanism 12 and vertical movement mechanism 13, the lower side of the middle end of the main connecting arm 1 is rotationally connected with the upper end of the fixed seat 3, the rear end of the auxiliary connecting arm 11 is rotationally connected with the front end of the main connecting arm 1, and the actuator 2 is arranged at the front end of the auxiliary connecting arm 11 The upper side, and the lower end of the driver 2 passes through the front end of the auxiliary connecting arm 11, the upper end of the transmission conversion mechanism 4 is arranged inside the lower end of the driver 2 and is connected to the driver 2, and the front side of the lower end of the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com