Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

347results about How to "Reduce frictional torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

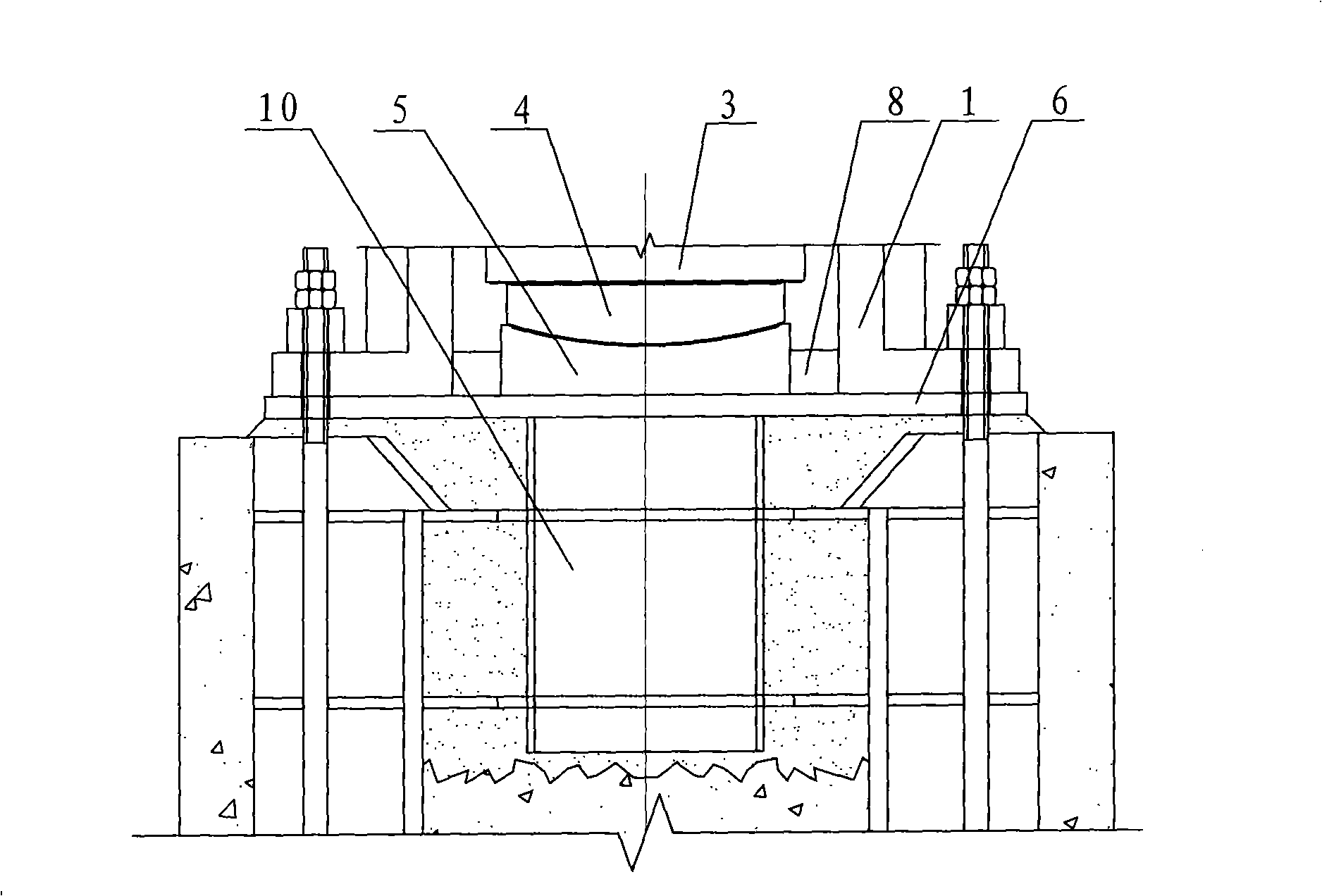

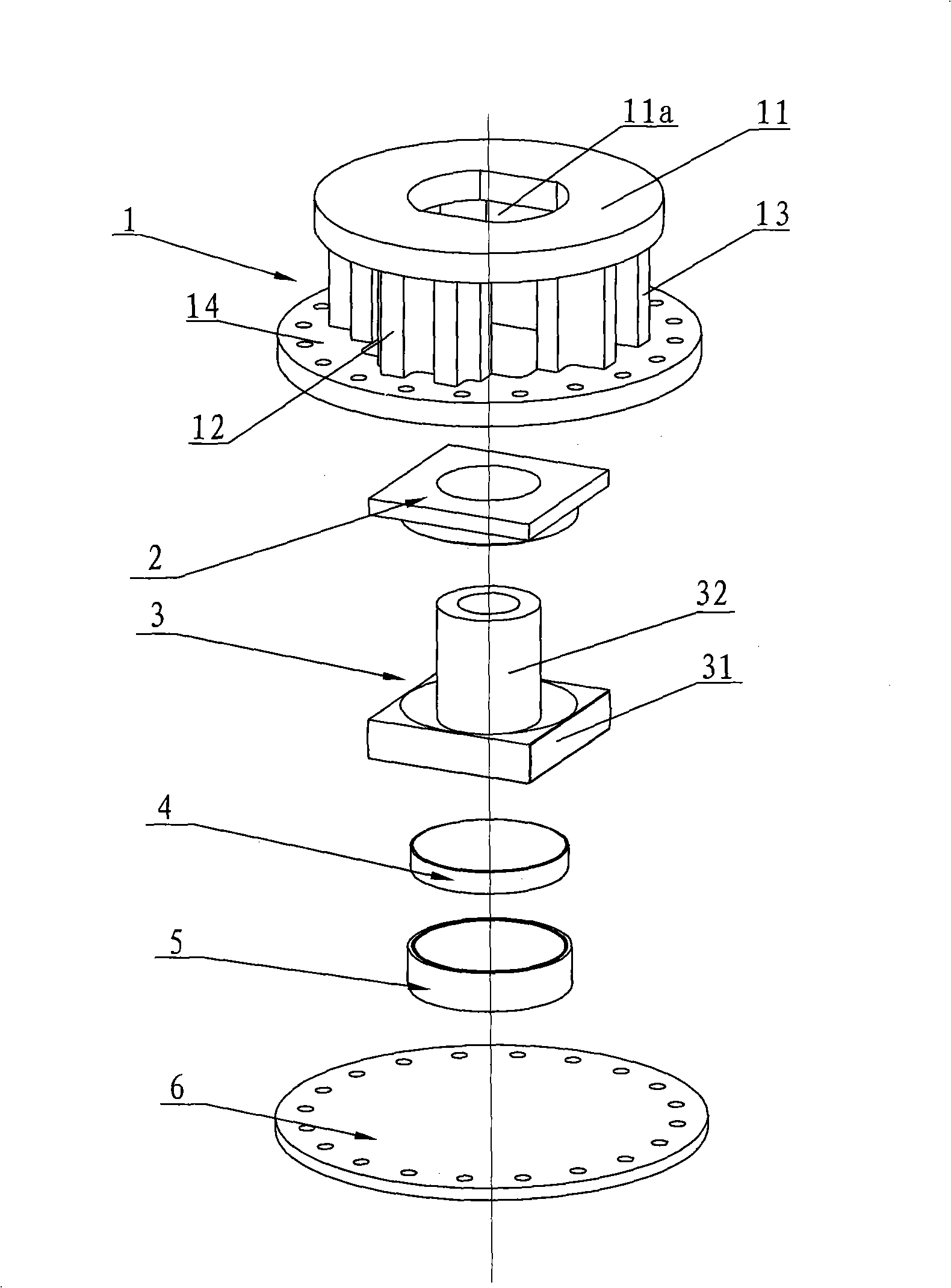

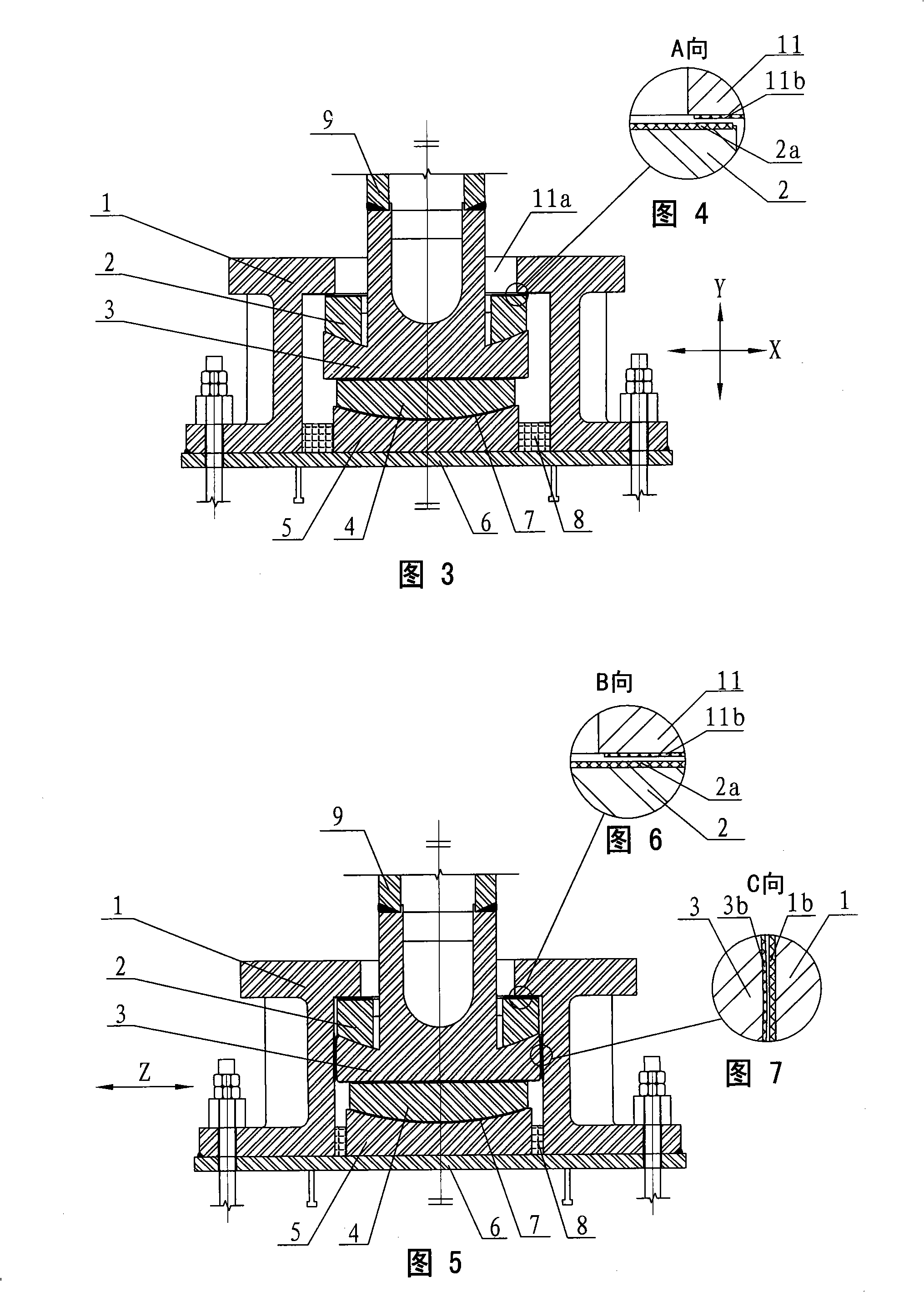

Large pulling resistance slidable ball and socket bearing

ActiveCN101289833AHigh pullout resistanceImprove stress resistanceBridge structural detailsBuilding constructionsPull forceEngineering

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

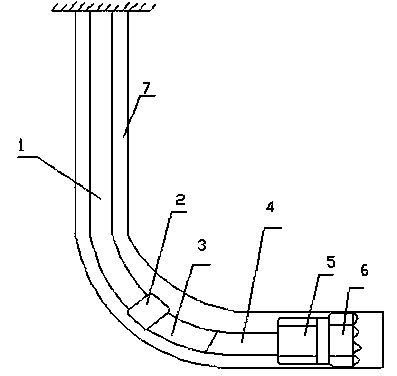

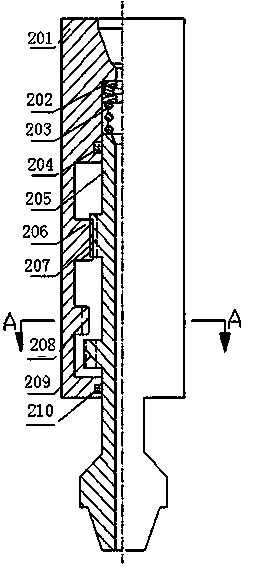

Complex structural well drag-reduction wrenching-reduction compound drilling method

ActiveCN103510871AReduce frictional torqueReduce drilling riskDrilling rodsDirectional drillingPetroleum engineeringDrill bit

The invention discloses a complex structural well drag-reduction wrenching-reduction compound drilling method. An underground drag-reduction wrenching-reduction device is arranged between an upper-portion drilling rig and a measurement-while-drilling drilling assembly combination, and therefore the upper-portion drilling rig can rotate independently relative to the measurement-while-drilling drilling rig; a reaction torque balancing device is arranged between a power drilling rig and a drill bit, and the disturbance of the reaction torque generated by a power drilling rig to a tool face is eliminated. The complex structural well drag-reduction wrenching-reduction compound drilling method has the advantages that the drag-reduction wrenching-reduction device can change the drill string sliding drilling into rotary drilling during the guiding drilling process, the friction resistance and the torque loss are reduced, and the occurrence rate of complex situations that the drill string is stuck and clamped is reduced; the reaction torque balancing device can effectively eliminate the influence of the reaction torque generated by a power drilling rig on the tool face, the tool face is controlled to be stable, the well track control accuracy is improved, the well body quality is improved, and complex structure well efficient drilling is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

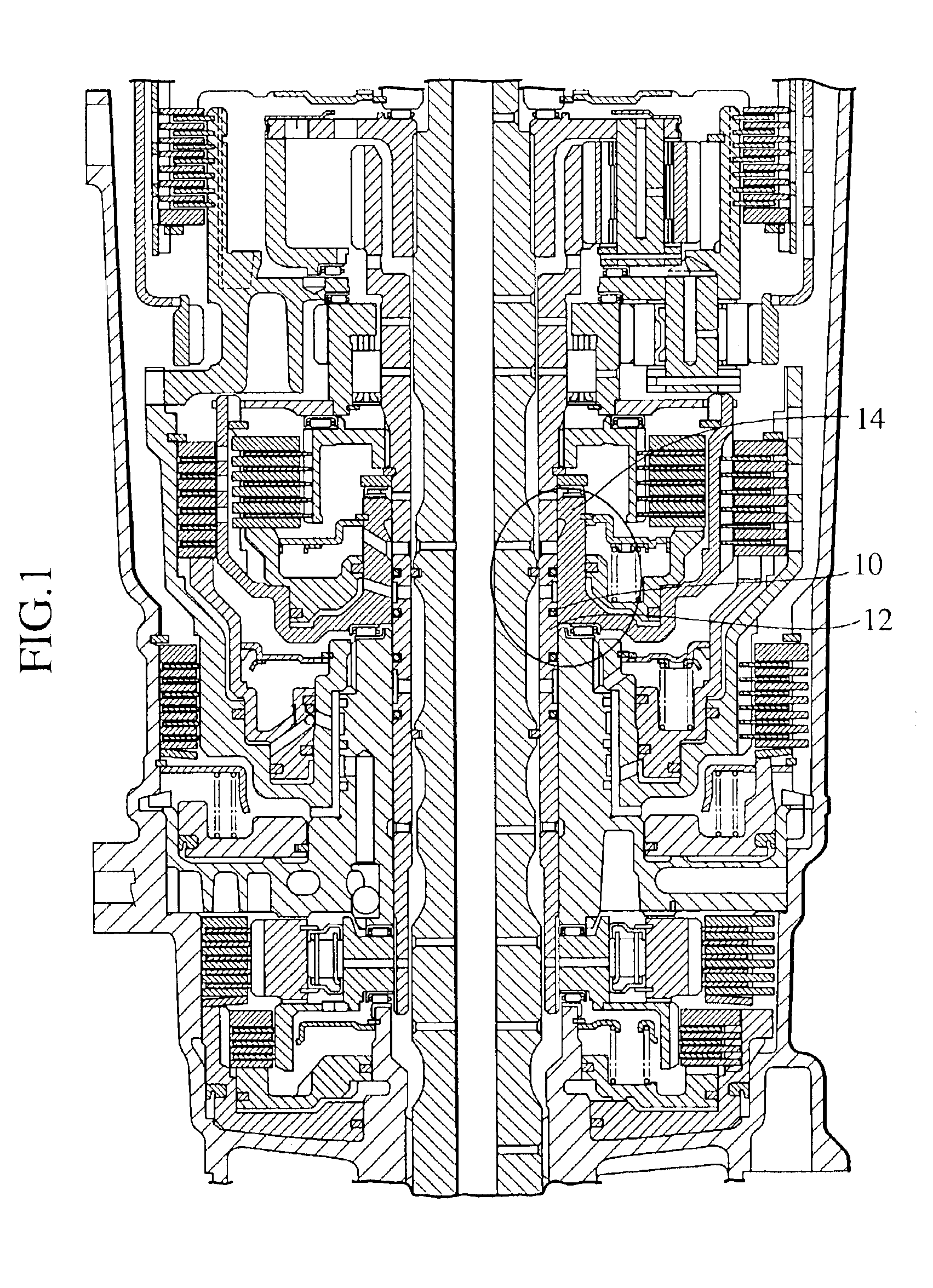

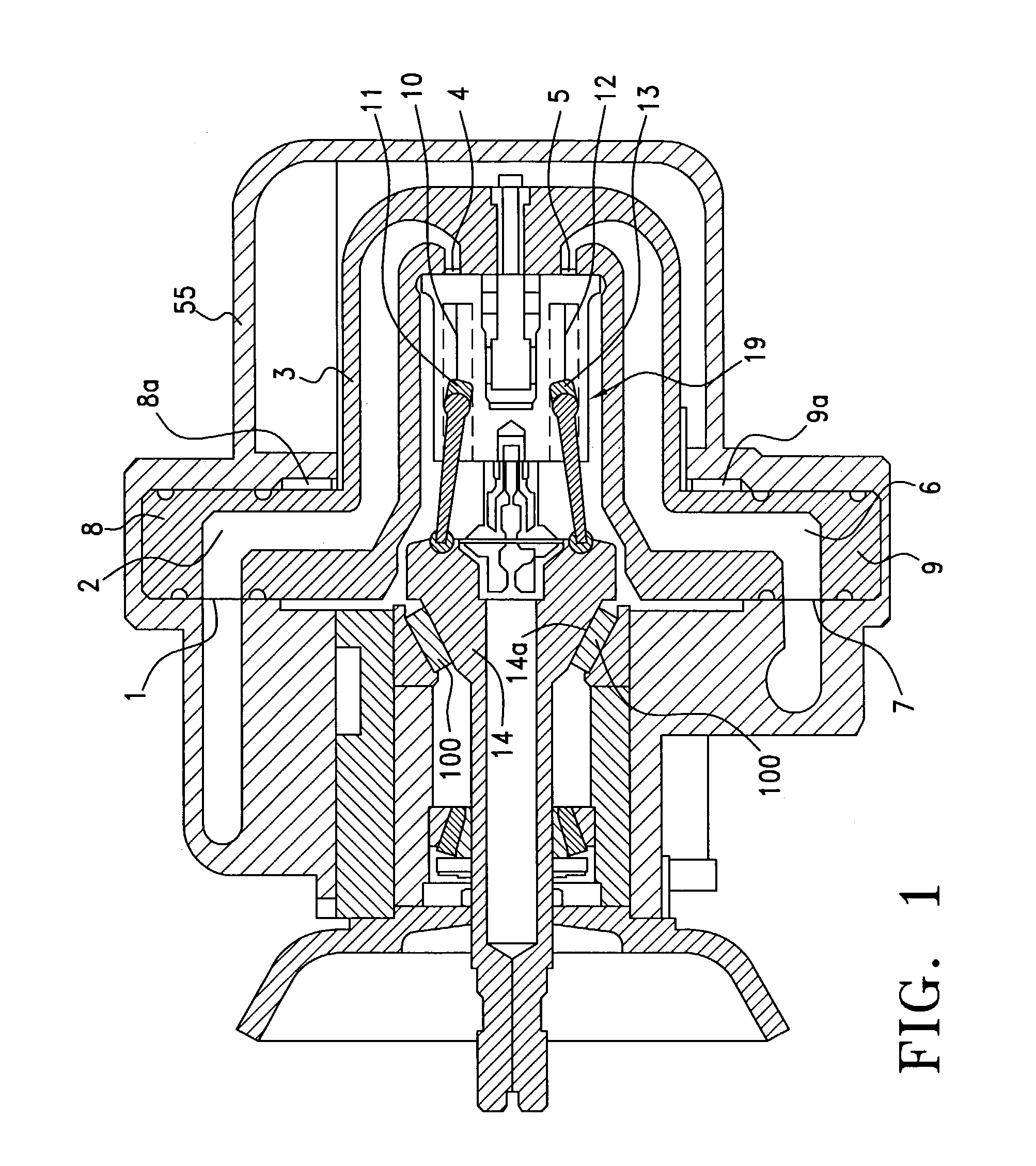

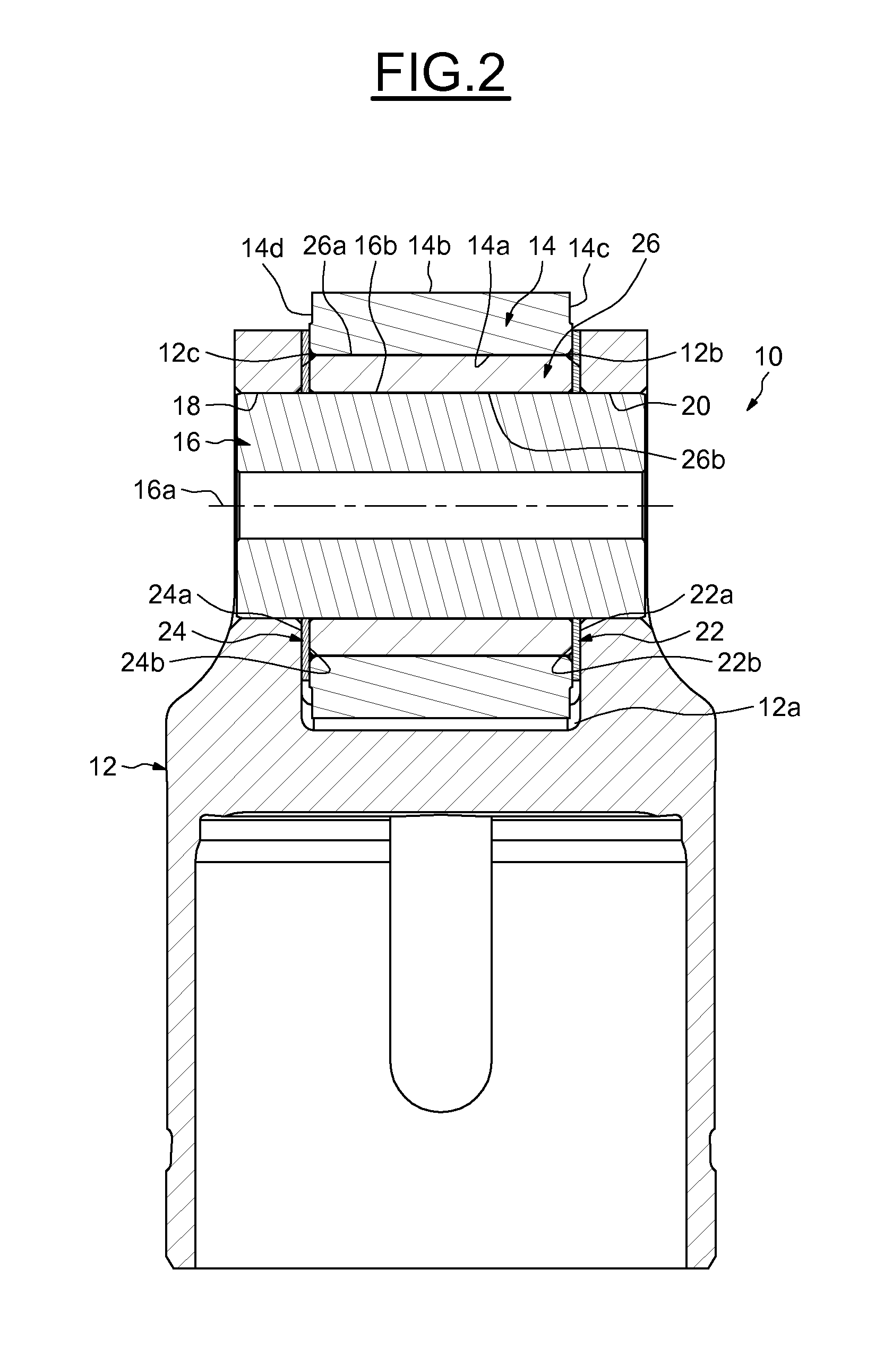

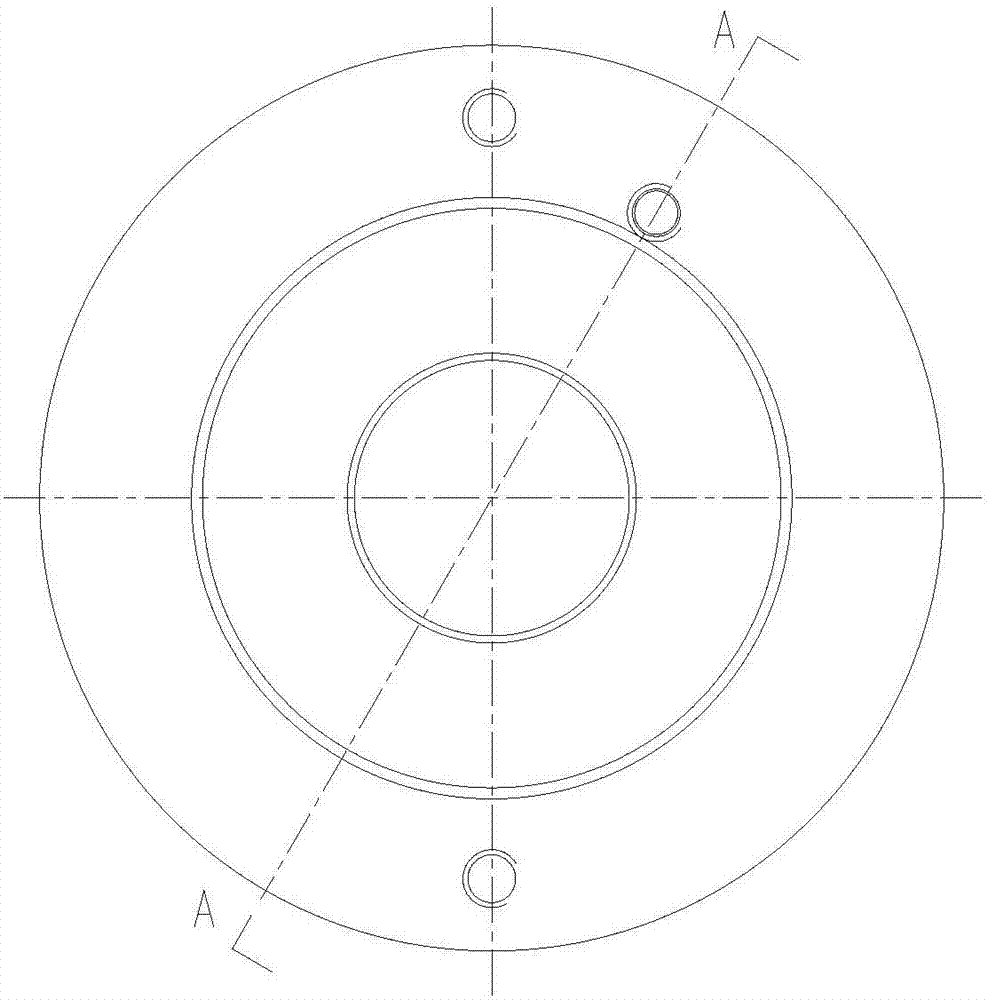

Seal ring and seal device

InactiveUS6884827B2Increase fuel consumptionReduce frictional torqueEngine sealsOther chemical processesHardnessEngineering

A seal ring seals operating oil hermetically and is attached to an annular seal ring groove provided on an outer circumference of a shaft member. The seal ring comprises fluororesin, metal powder having a hardness equal to or more than that of any of a side surface of the seal ring groove serving as a sliding partner and an inner circumferential surface of a housing engaged relatively rotatable with the outer circumference of the shaft member, and modified fluororesin formed by irradiating an ionizing radiation in a range from 1 kGy to 10 MGy inclusive in a state of being heated up to a melting point thereof or higher under an inert gas atmosphere with an oxygen partial pressure of 1.33 kPa or less.

Owner:NISSAN MOTOR CO LTD +1

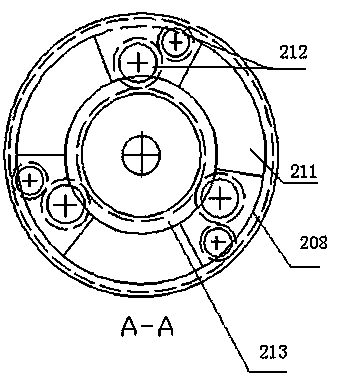

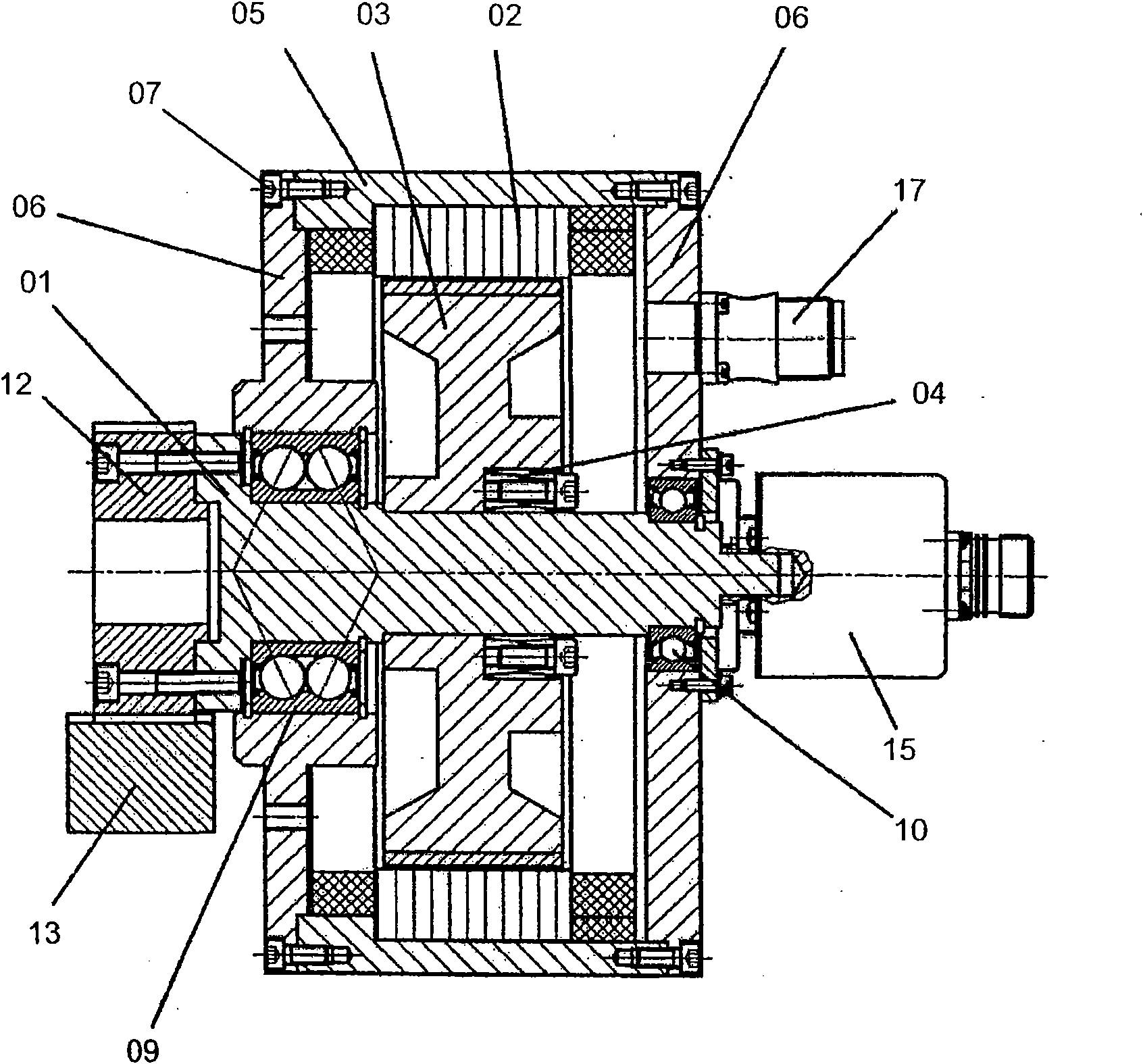

High-efficiency, large angle, variable displacement hydraulic pump/motor

InactiveUS7014429B2Improve efficiencyIncrease speedFluid gearingsMulti-stage pumpsHydraulic pumpEngineering

A variable displacement hydraulic / pump motor has a yoke with a pair of shafts aligned to define a yoke pivot axis and connected to a valve plate therebetween having intake and discharge apertures. A rotatable cylinder barrel has piston cylinders open at one end to receive a piston head and opening through fluid ports at another end, flush against the valve plate surface. A drive block is mounted on an input / output shaft for rotation about a central axis of rotation inclined at an angle relative to the longitudinal axis of the cylinder barrel which may be changed by a drive engaging the yoke at a point near its pivot axis. Loads on bushings supporting the yoke shafts are reduced by providing radially extending fluid ports in the shafts and in communication with the intake and discharge apertures of the valve plate.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

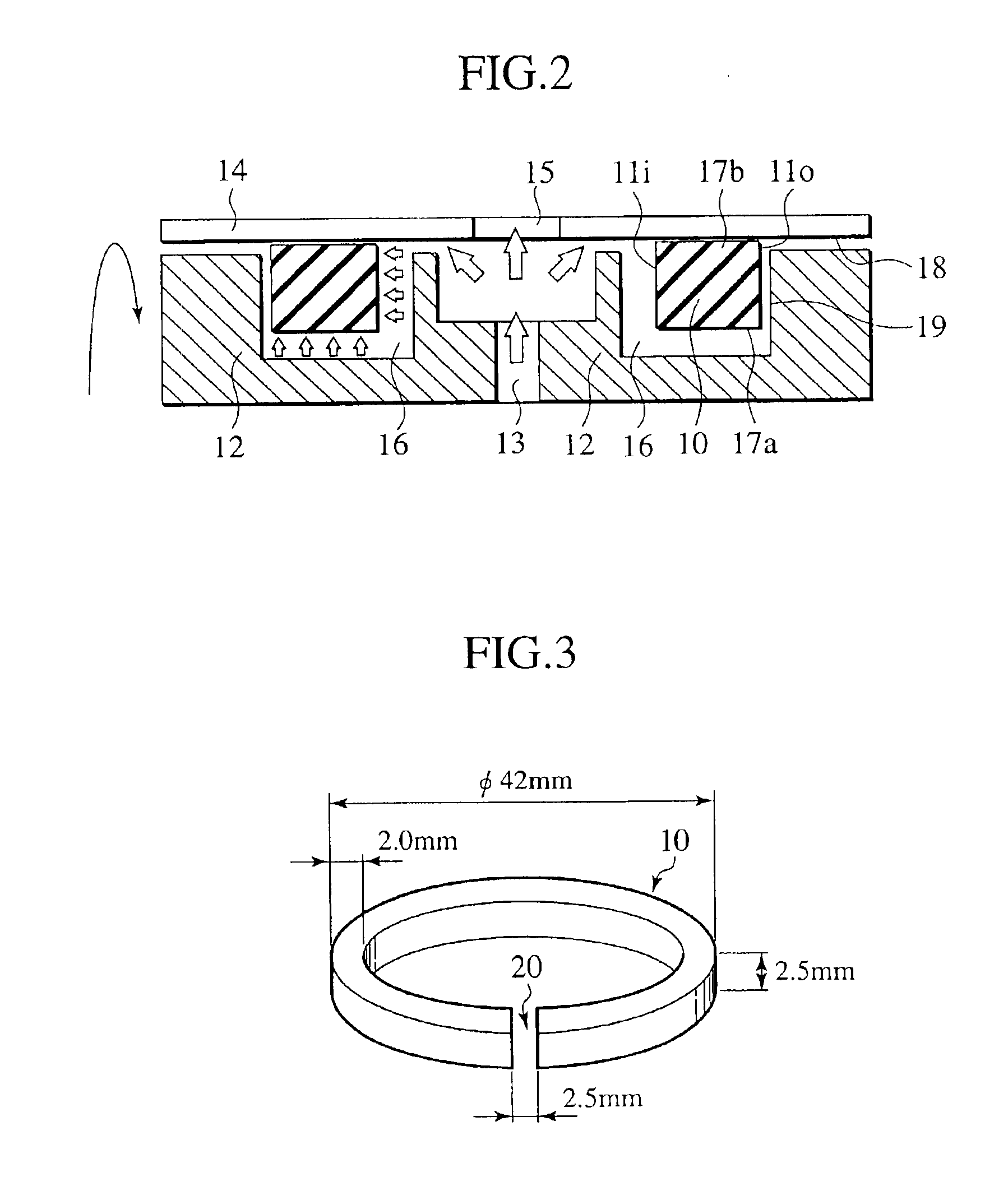

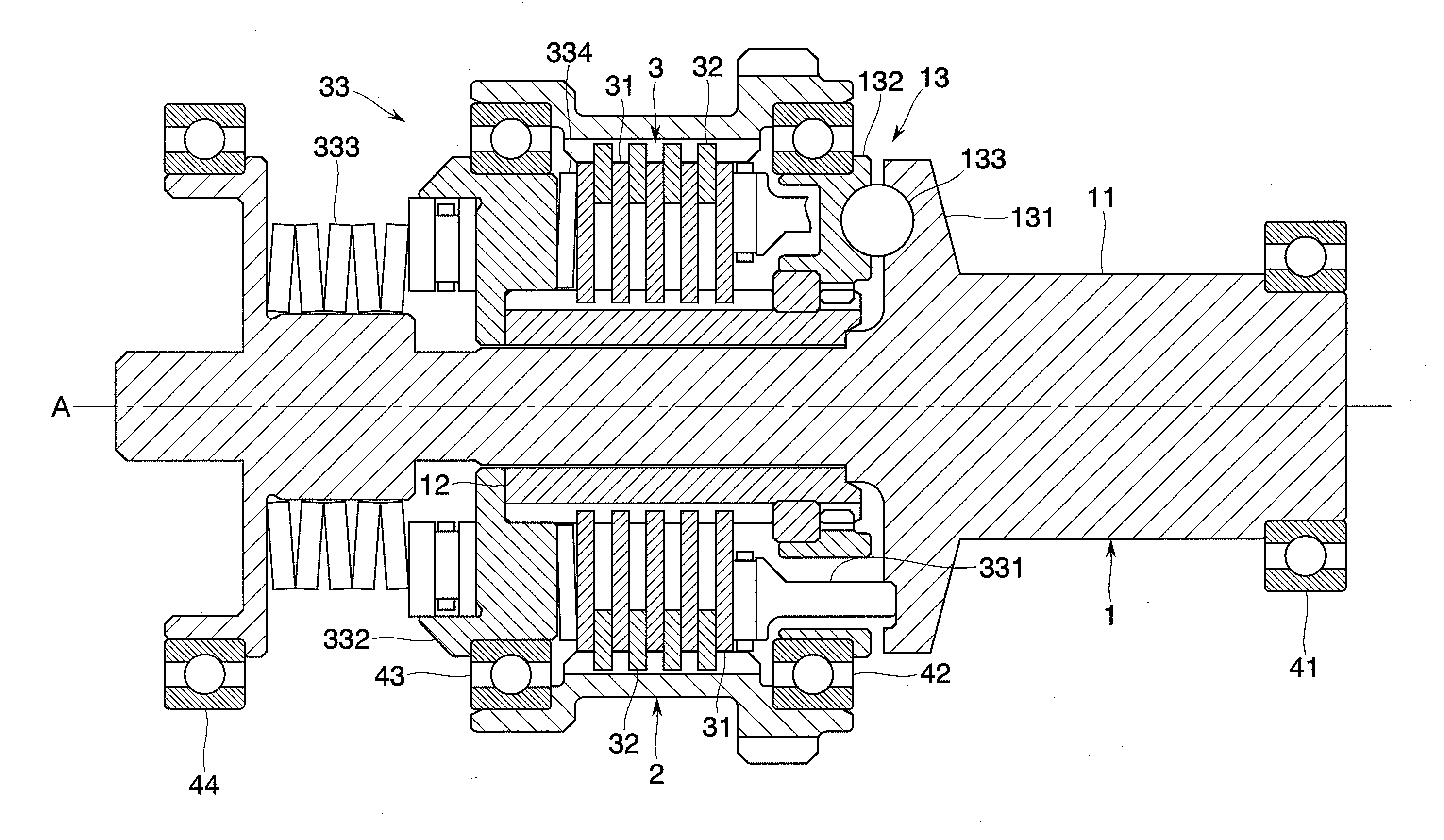

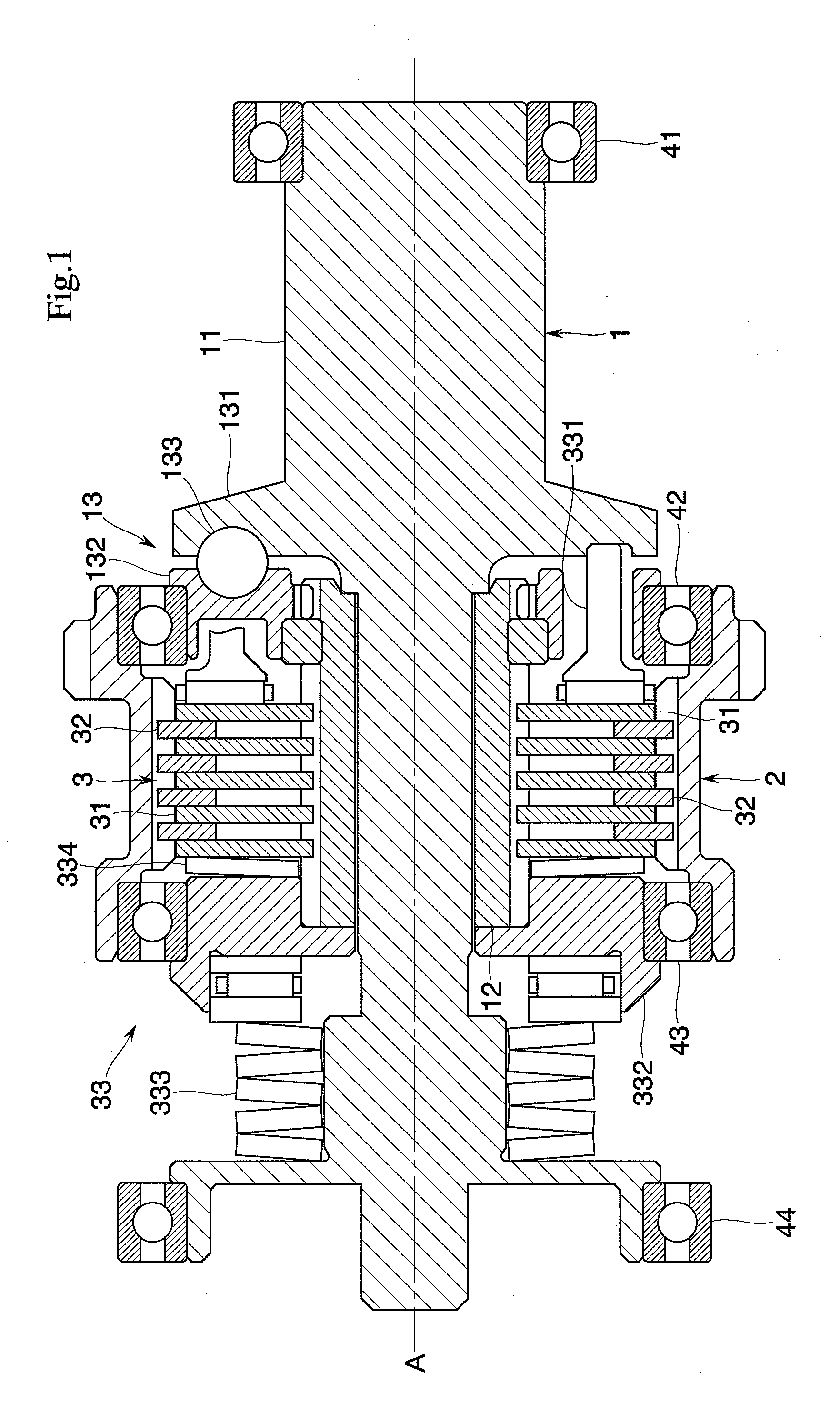

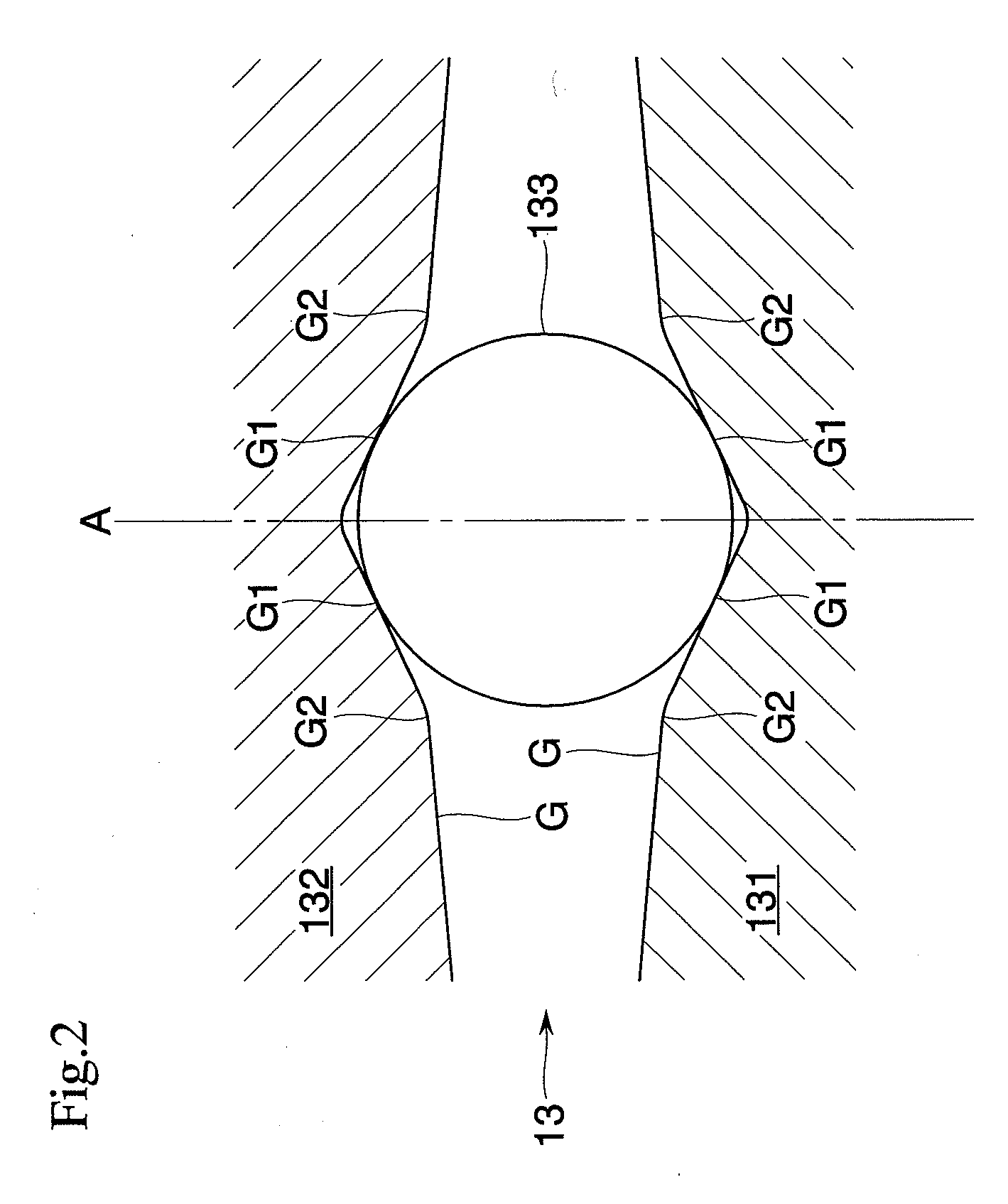

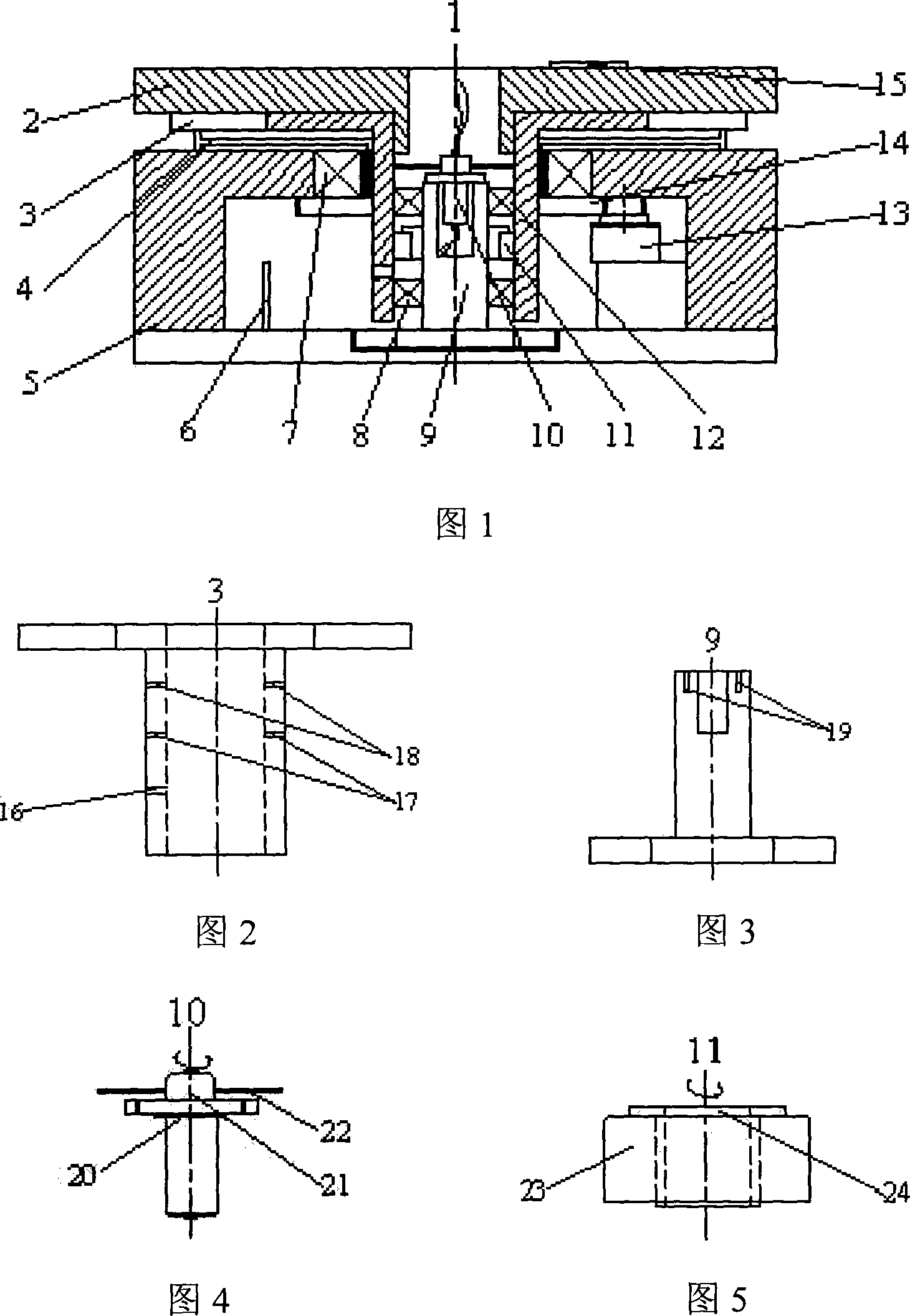

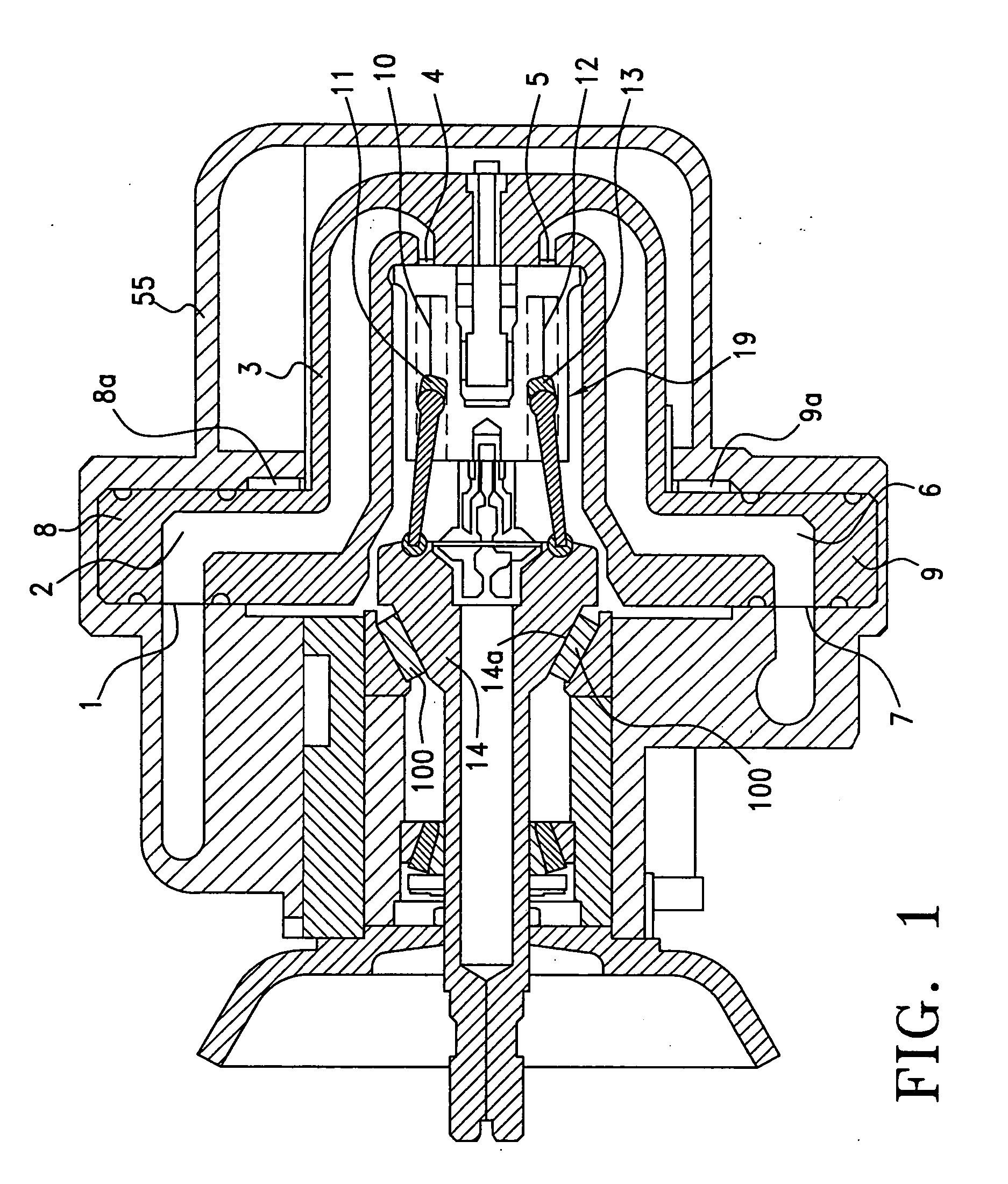

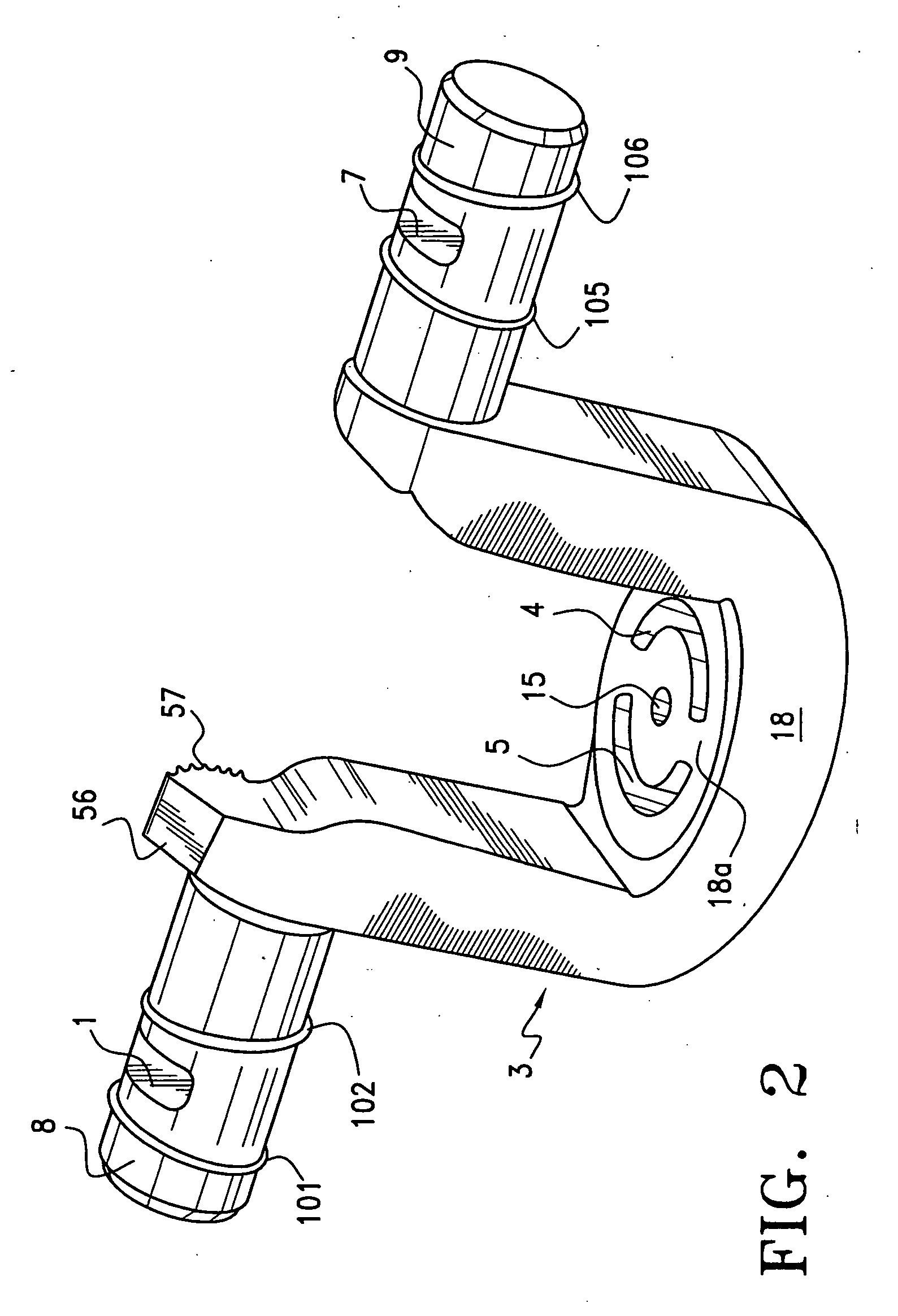

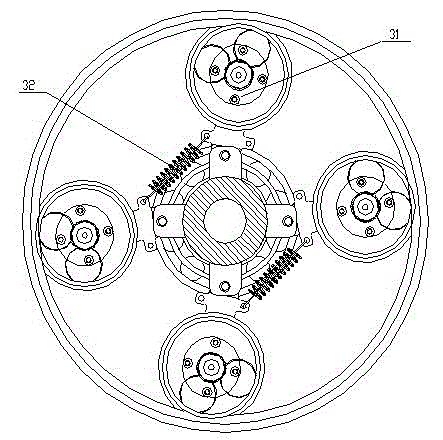

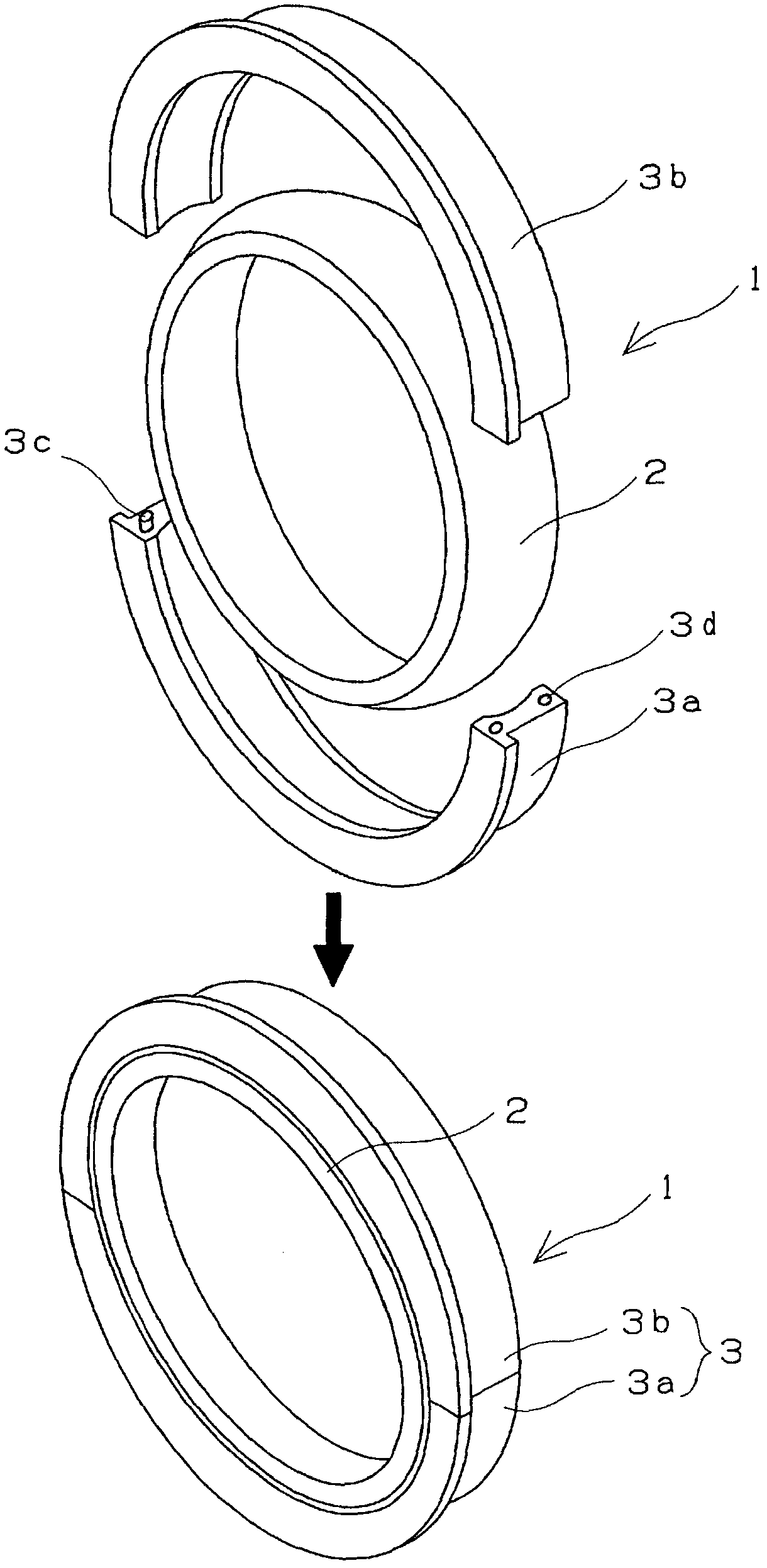

Torque limiting mechanism

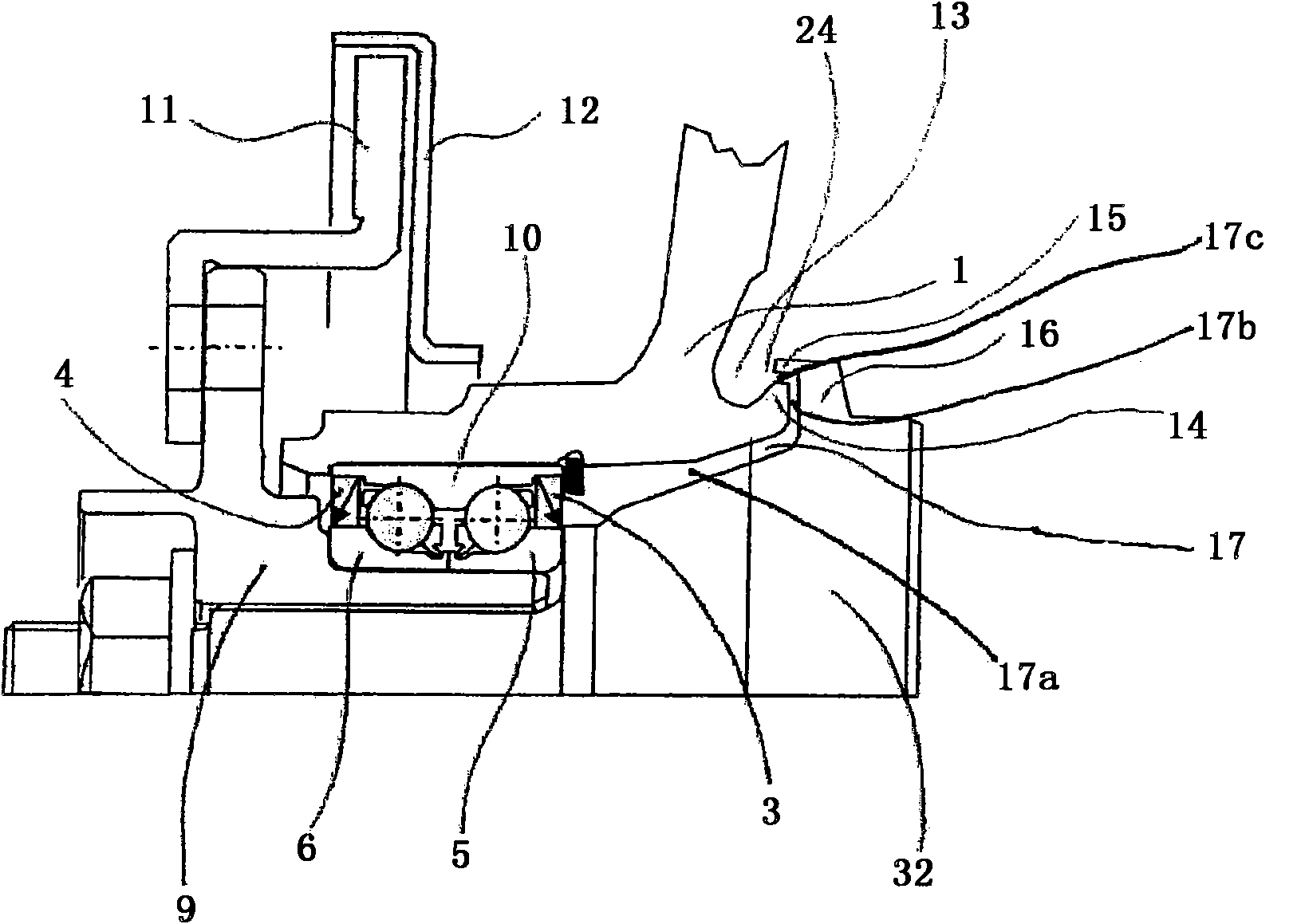

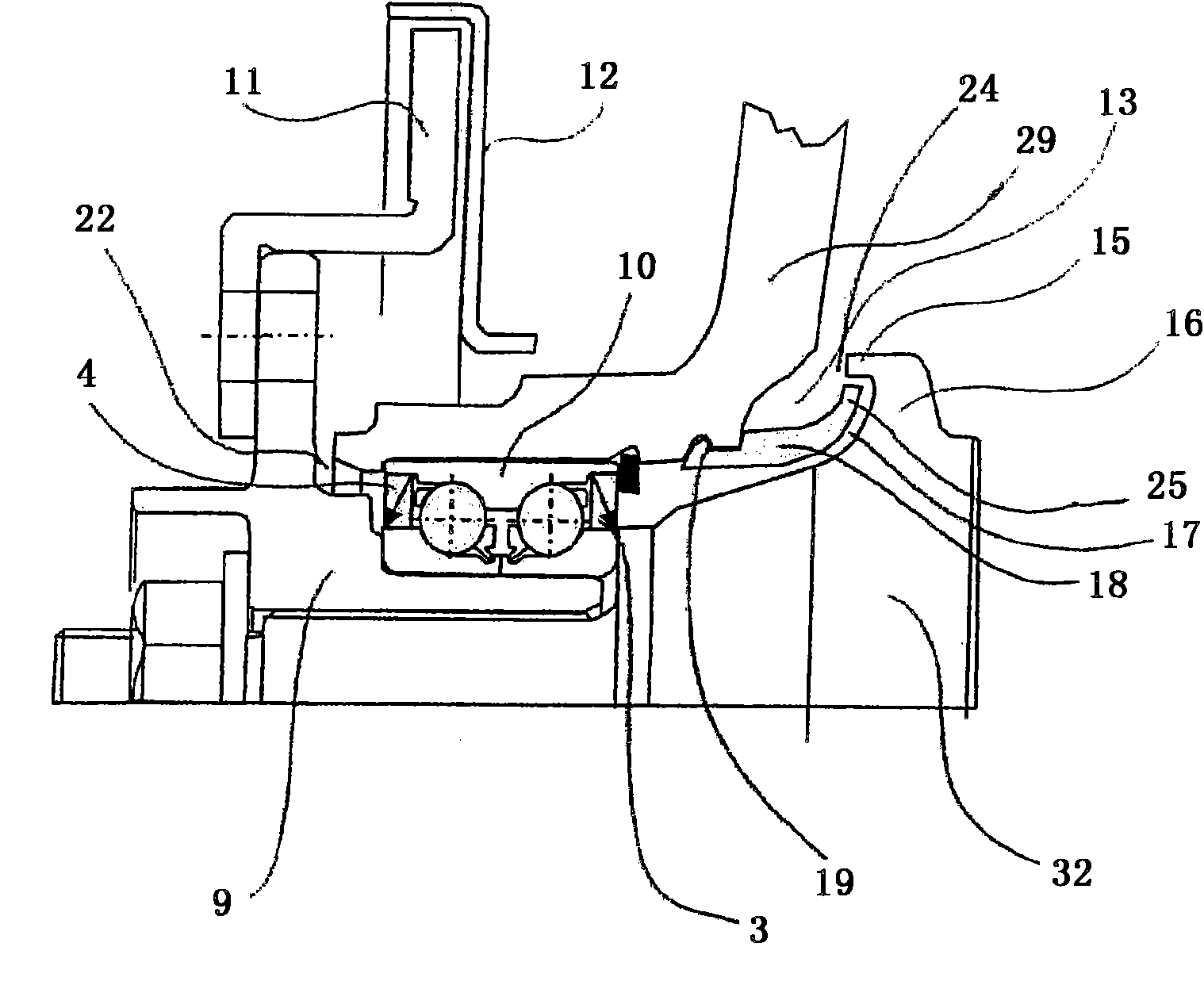

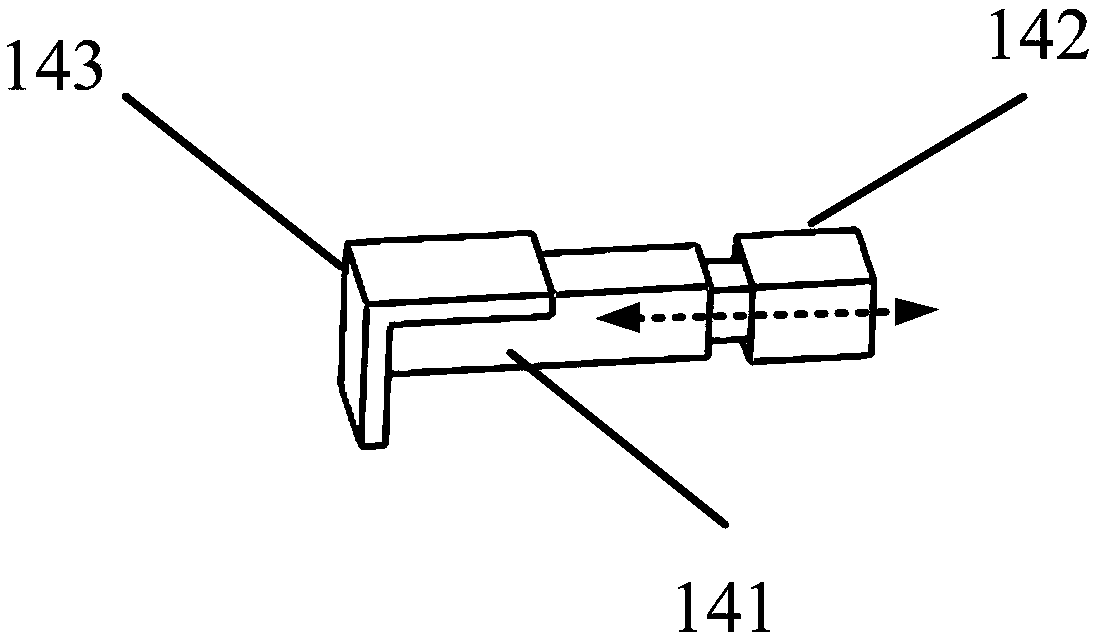

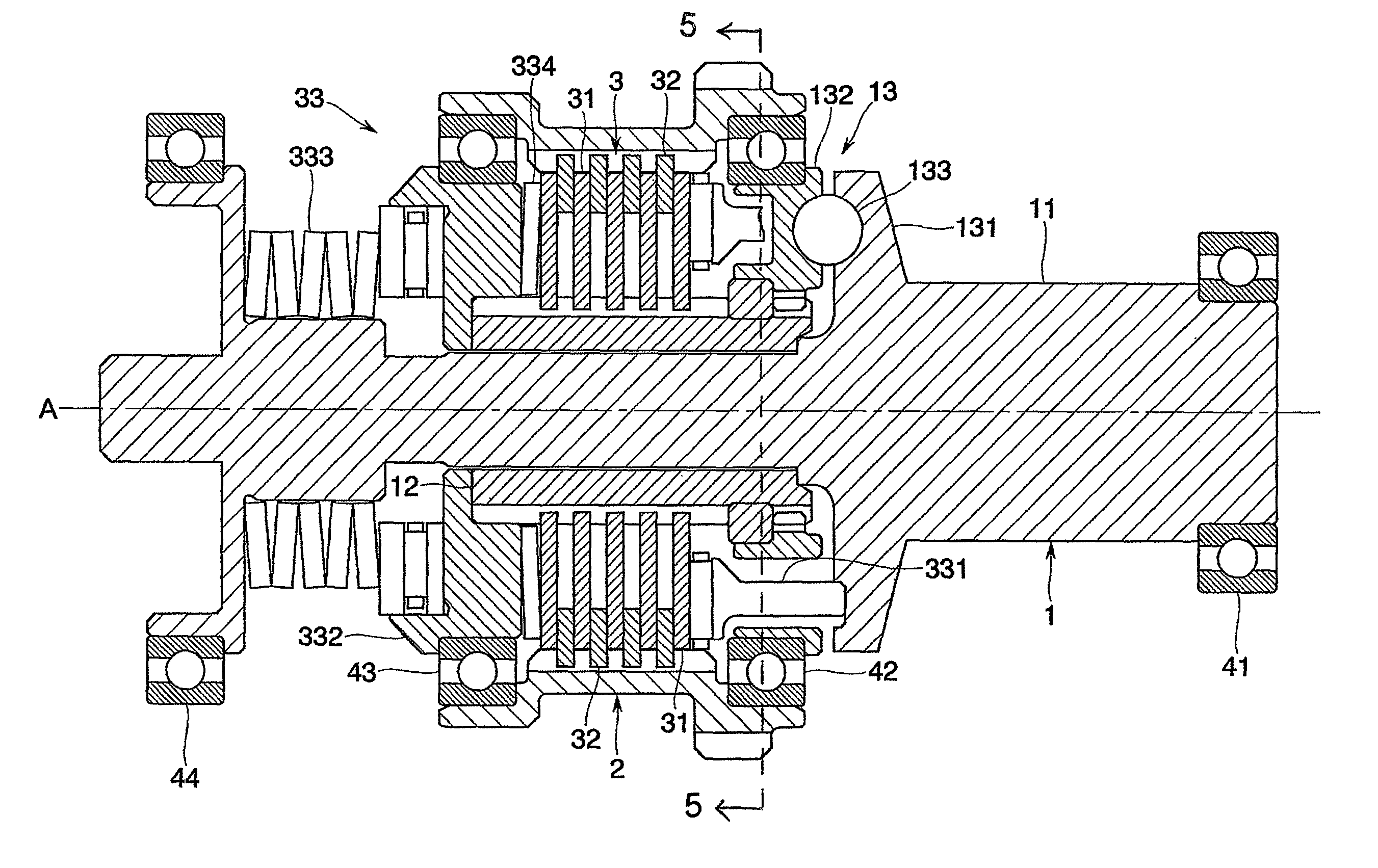

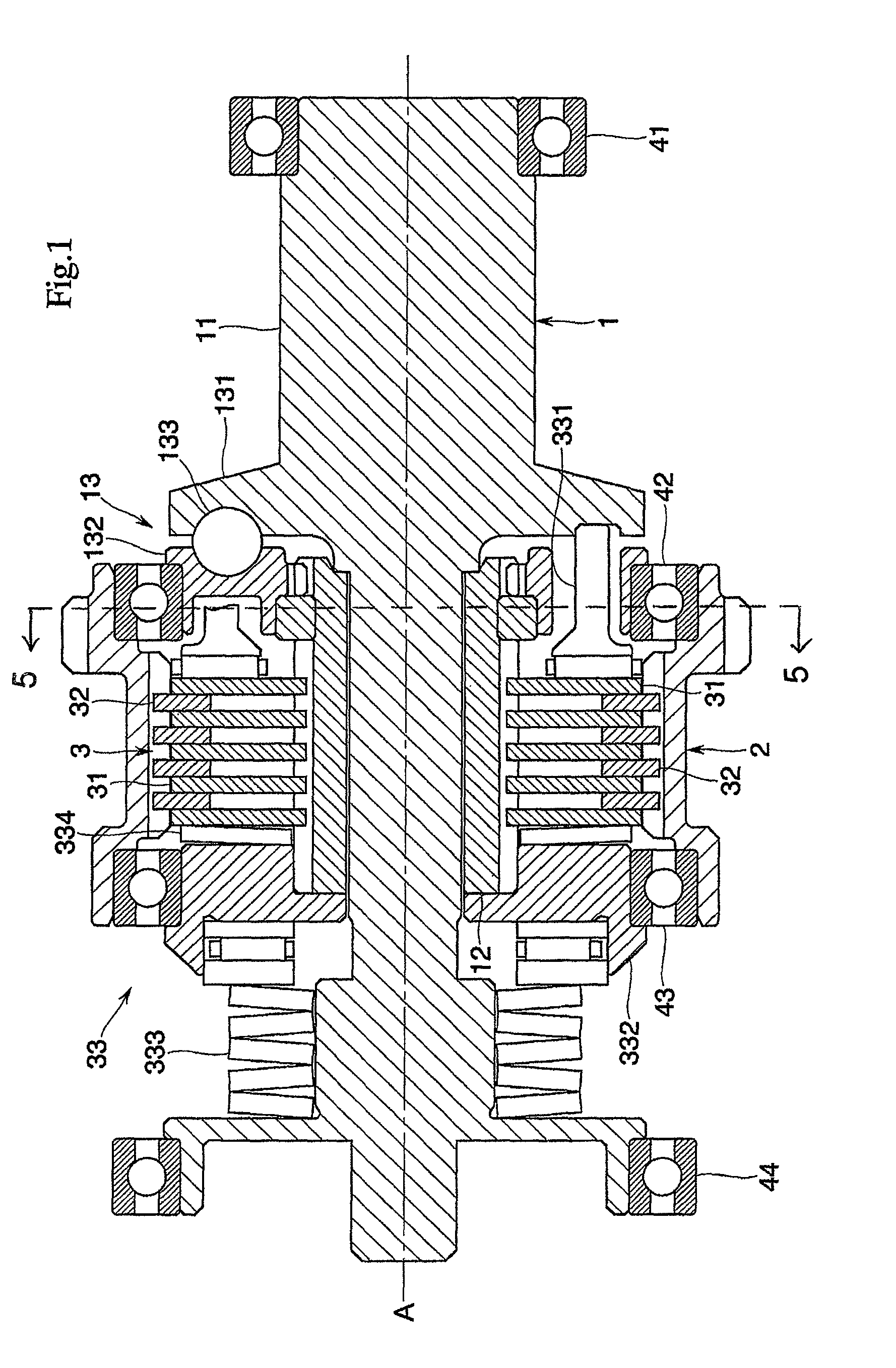

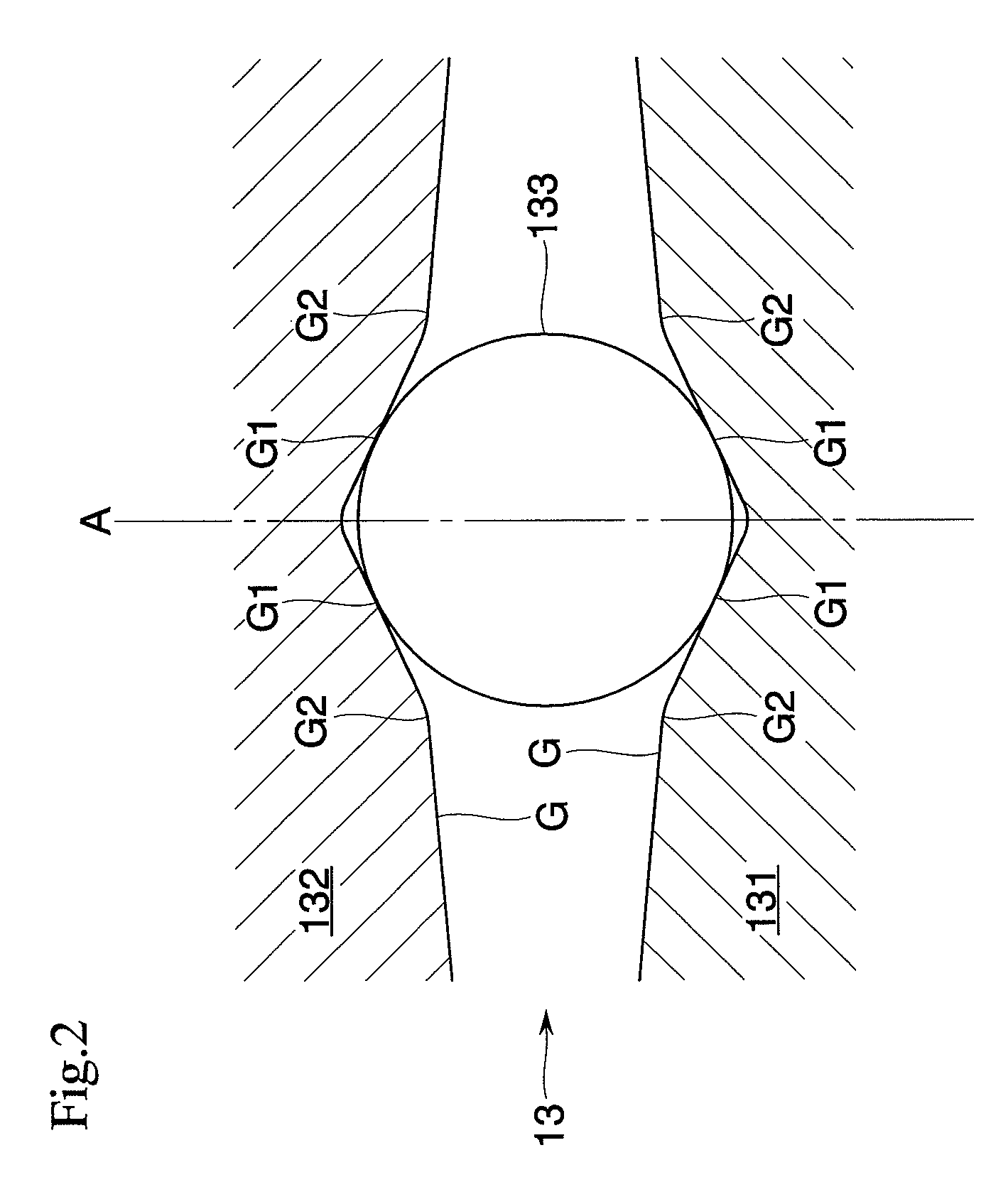

ActiveUS20090301836A1Reduce frictionReduce frictional torqueMechanical actuated clutchesSlip couplingAxial thrustCam

An intended object of the present invention is to realize a high-precision torque limiting mechanism capable of limiting an output torque to a magnitude of not more than a prescribed value, as well as to reduce a frictional torque produced upon occurrence of a slip. To accomplish this object, a ball ramp section 13 is attached to a slip clutch section 3 for reducing friction between friction plates 31 and 32 forming the slip clutch section 3 and limiting a torque to be transmitted by utilizing an axial thrust produced at the ball ramp section 13 in accordance with the magnitude of an input torque. The precision with which the torque to be transmitted is limited is enhanced by making improvements to the shape of an internal side surface of a recess G formed in each of cam elements 131 and 132 of the ball ramp section 13.

Owner:SHIMADZU CORP

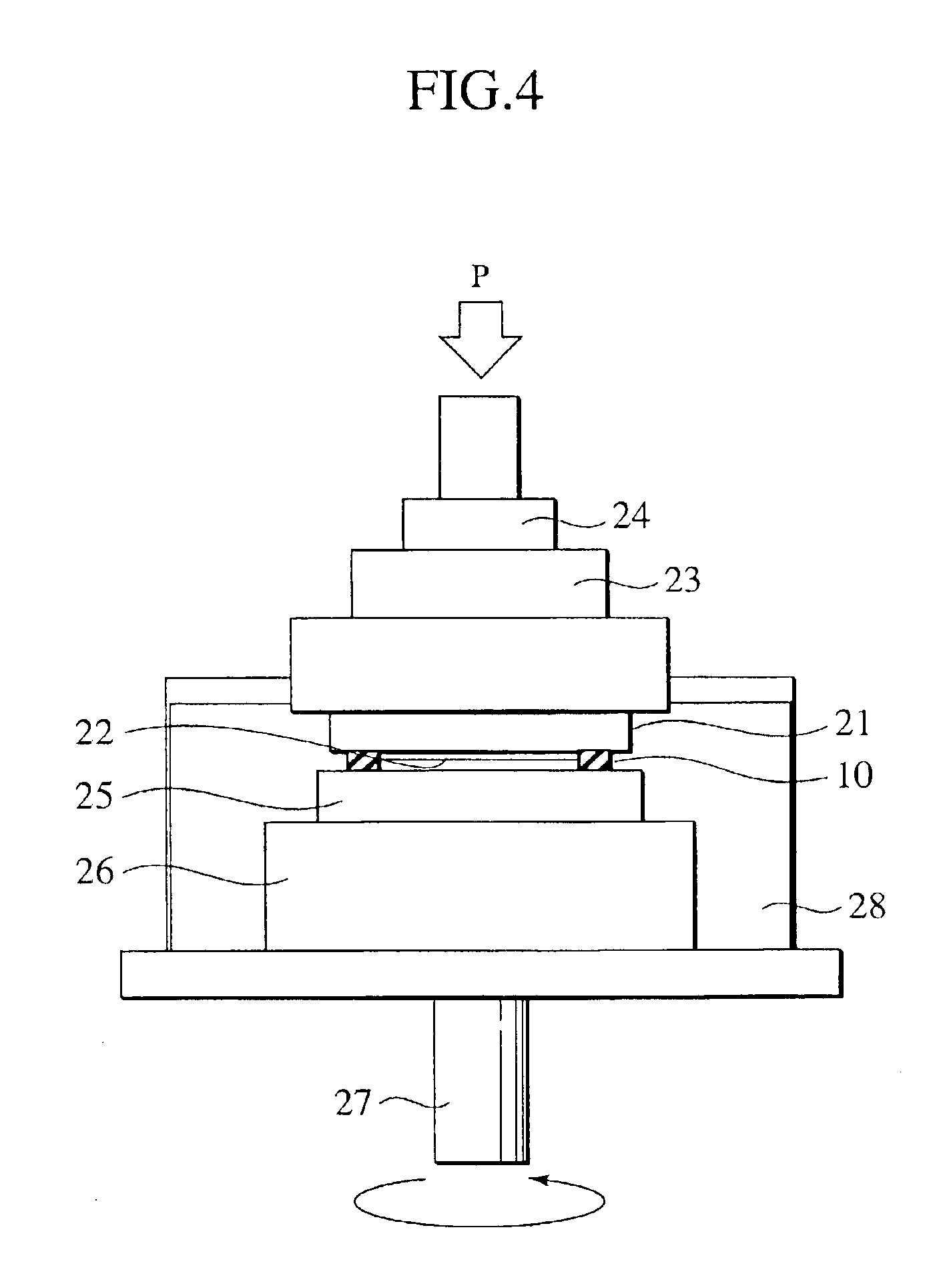

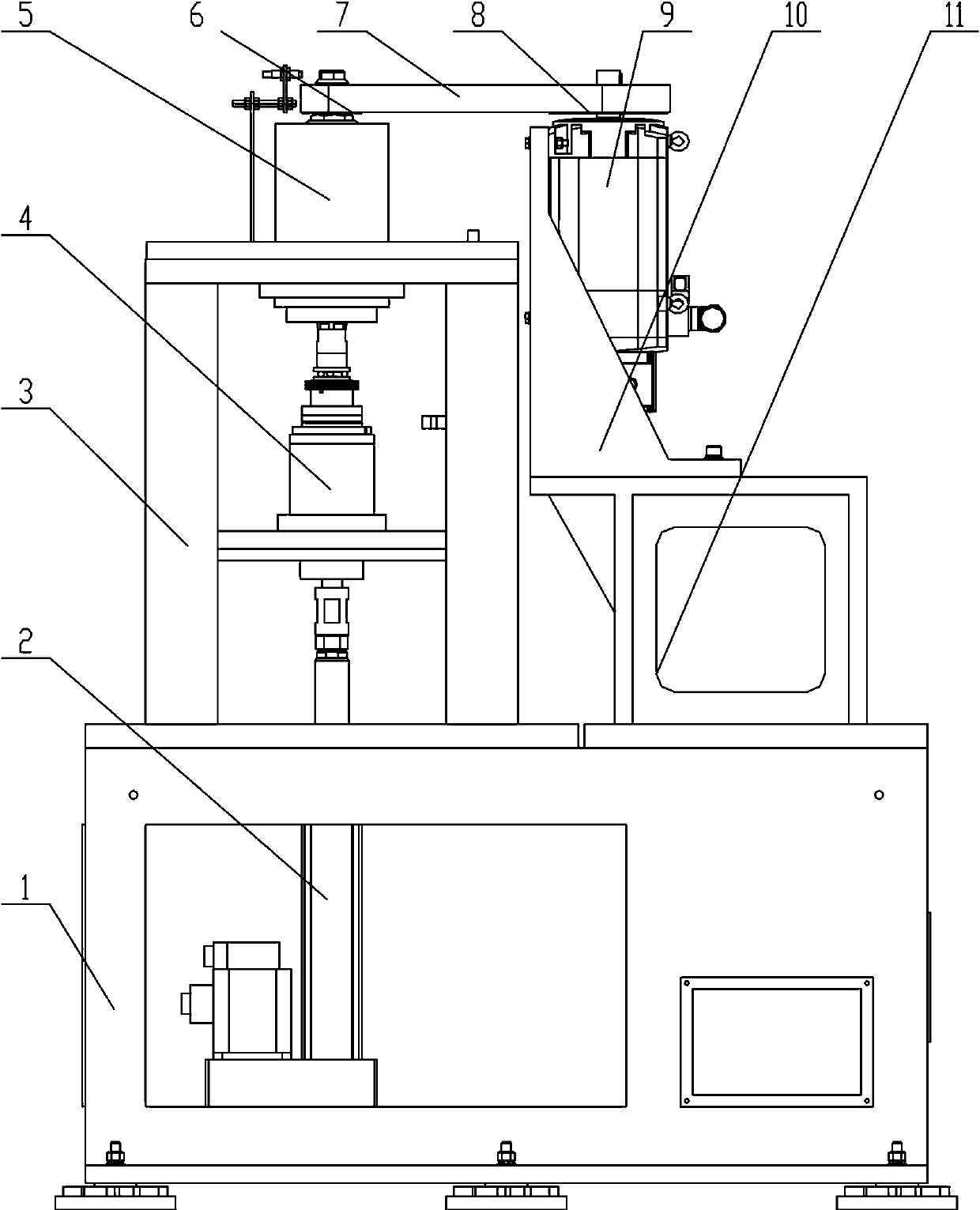

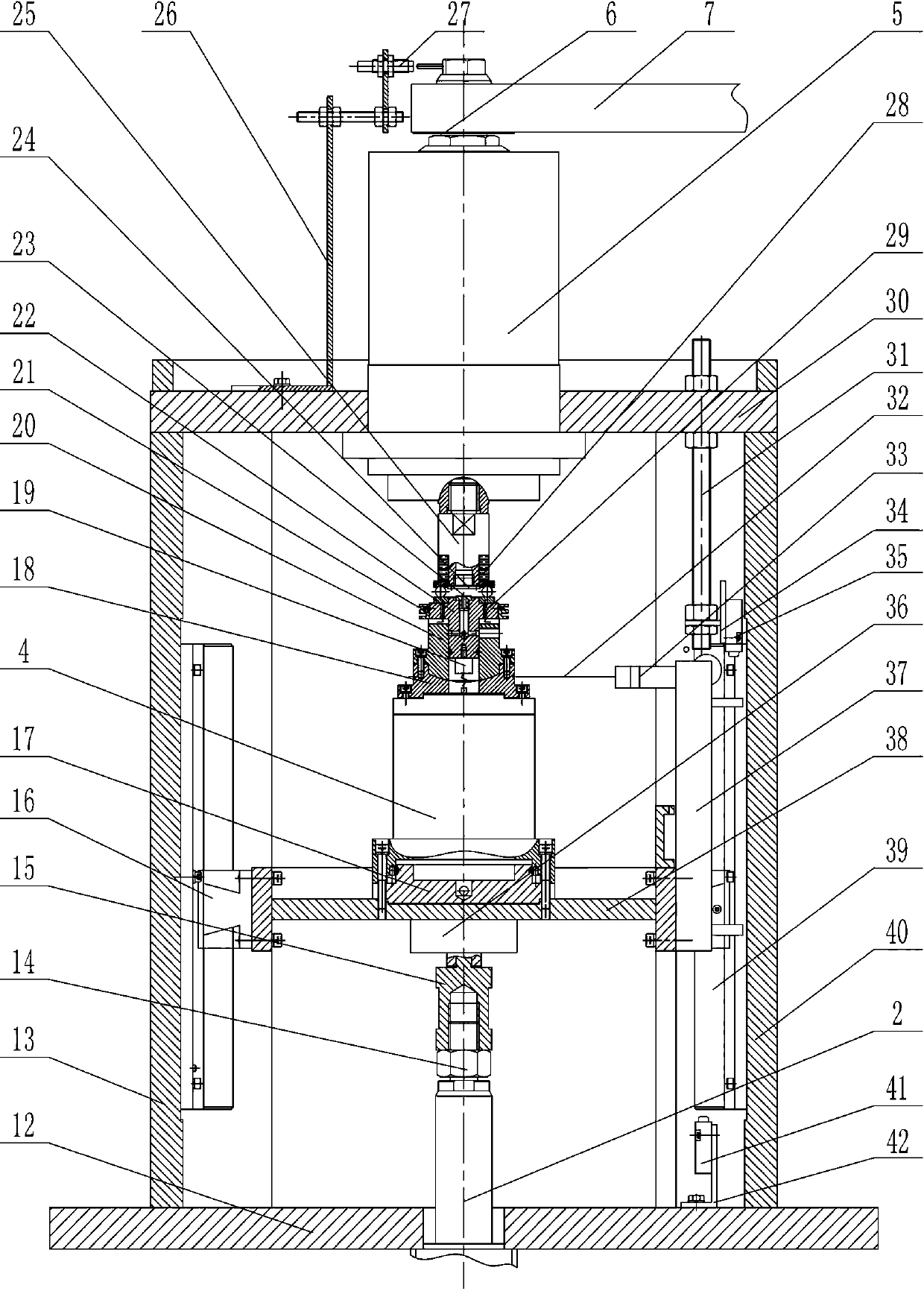

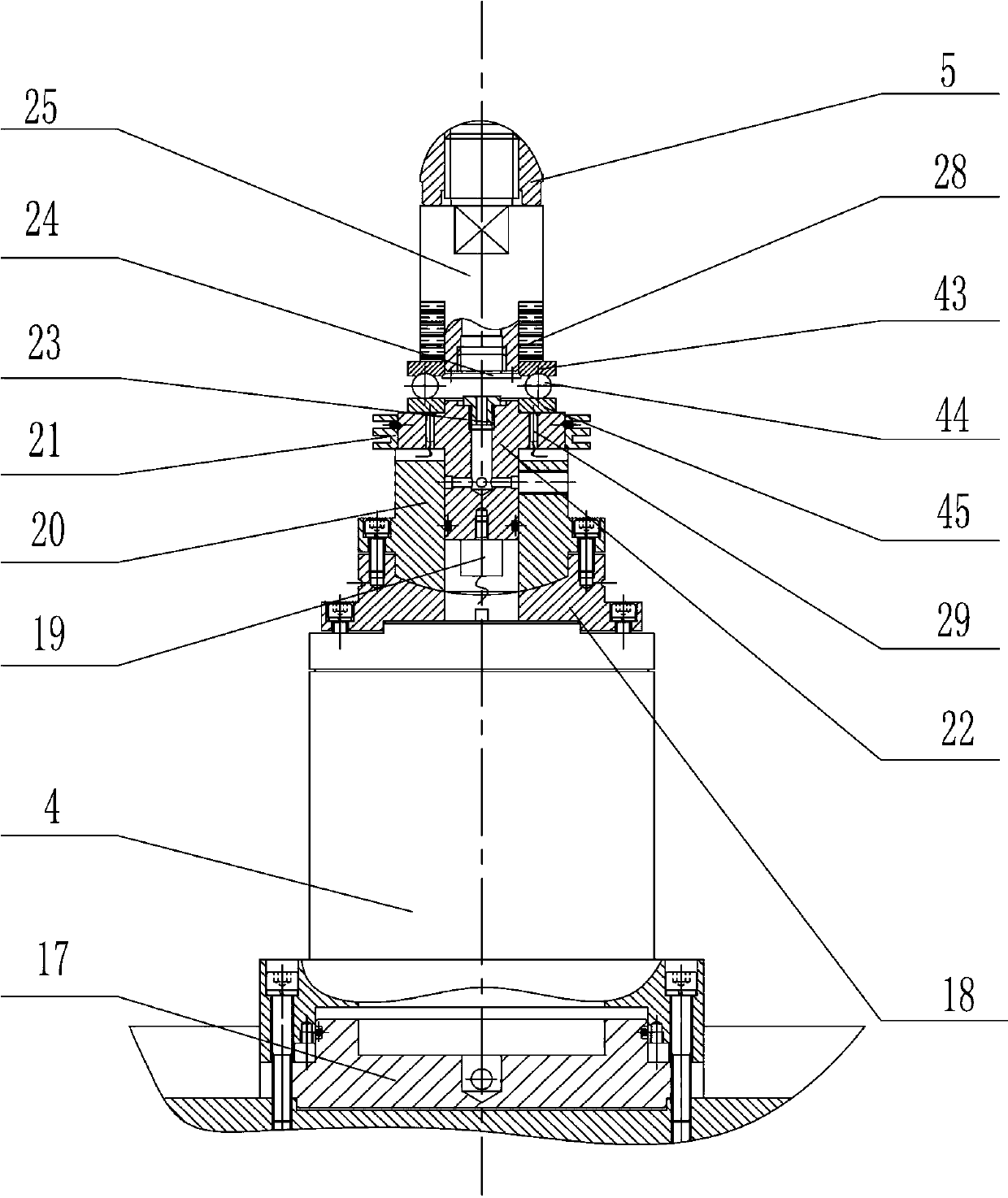

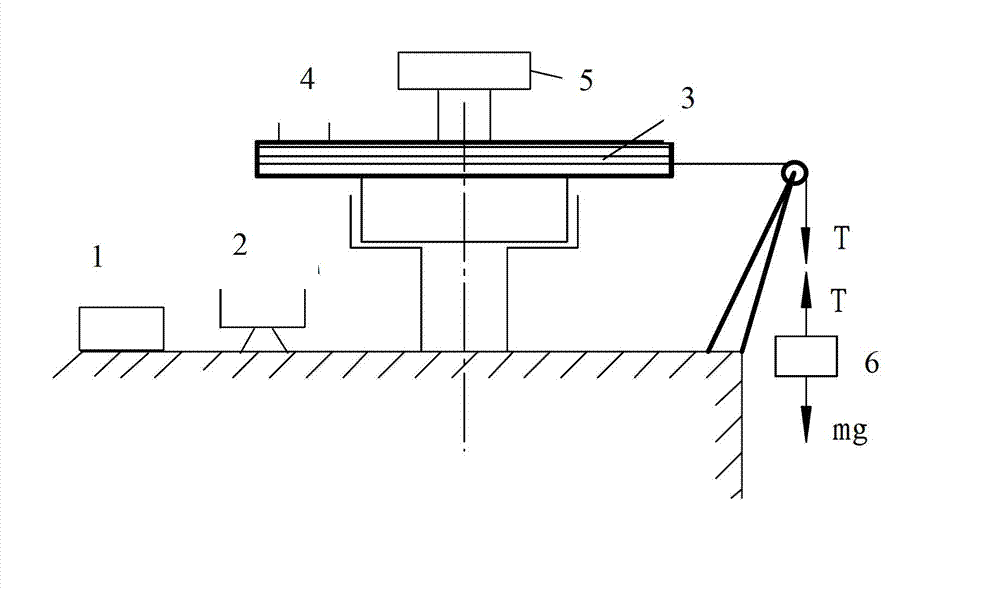

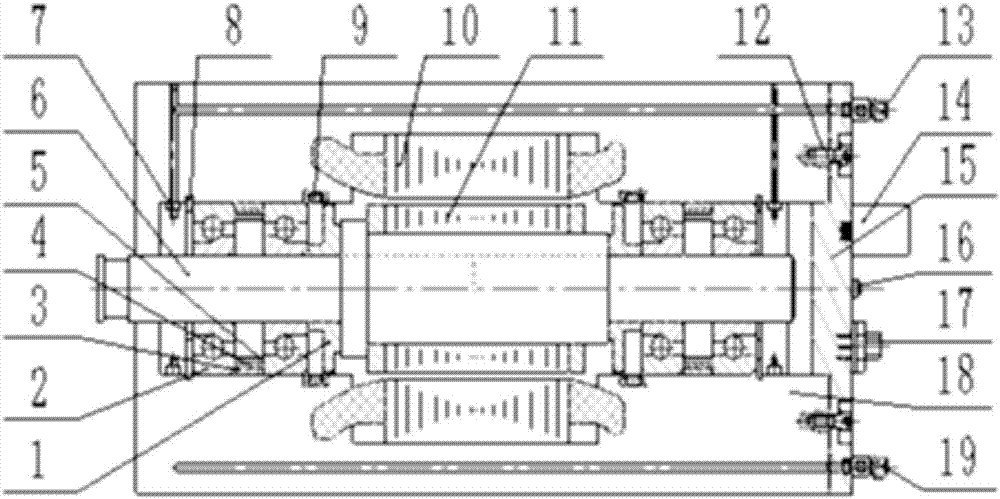

High-speed rolling contact fatigue testing machine

InactiveCN103344553AUse cleanEasy to controlUsing mechanical meansMaterial analysisRolling contact fatigueEngineering

The invention discloses a high-speed rolling contact fatigue testing machine. The high-speed rolling contact fatigue testing machine is characterized in that a driving pulley (6) arranged on the upper end of the output shaft of a servo motor (9) is in transmission connection with a driven pulley (8) arranged on the upper end of a static pressure main shaft (5), and the static pressure main shaft (5) is fixed on an upper beam (30) arranged on a rack (3); a servo electric cylinder (2) is connected with a pressure sensor (36) fixed on the lower surface of a moving beam through a connecting piece (15) of the pressure sensor; the upper end of a hydraulic supporting platform (4) is fixed on a sphere base lower part (18), a lower test specimen base (21) is connected with a sphere base upper part (20), and the lower test specimen base (21) is connected with a test specimen base ring (45) in a clearance fit mode. The high-speed rolling contact fatigue testing machine provided by the invention has the advantages that the rolling contact of a bearing material under a high speed and heavy load working condition is simulated, the key parameter of rolling contact fatigue of a testing material can realize accurate detection, and finally, the data support is provided for evaluating the rolling contact fatigue property of the bearing material.

Owner:YANSHAN UNIV

Novel high speed rotating platform based on optical fiber rotating connector

InactiveCN101221269AHigh stability and precisionHigh bandwidthCoupling light guidesEngineeringOpto electronic

The invention discloses a high speed rotary platform device based on a fiber rotation connecting device. The device is provided with a base which is sequentially provided with a round inductosyn, a T-shaped fine hollow main shaft and a rotary working platform. The T-shaped fine hollow main shaft is internally provided with a connecting shaft and the lower end of the connecting shaft is provided with a regular hexagon skirt. A third bearing, an electric slide ring and a second bearing are arranged between the outer side of the connecting shaft and the inner side of the T-shaped fine hollow main shaft. The upper end of the connecting shaft is provided with a connecting shaft fixing hole and a connecting shaft groove. The connecting shaft groove is internally provided with the fiber rotation connecting device. A first bearing is arranged between the outer side of the T-shaped fine hollow main shaft and the base. The base is provided with a servo motor which is connected with the T-shaped fine hollow main shaft by a gear set. The base and the rotary working platform are provided with a base photoelectric-electrolight switch module and a rotary platform photoelectric-electrolight switch module. The invention ensures the stability and precision of the system under a situation that the rotary platform rotates at high speed and has the advantages of simple system structure, small yawp inference on a signal access, large bandwidth and small signal attenuation.

Owner:ZHEJIANG UNIV

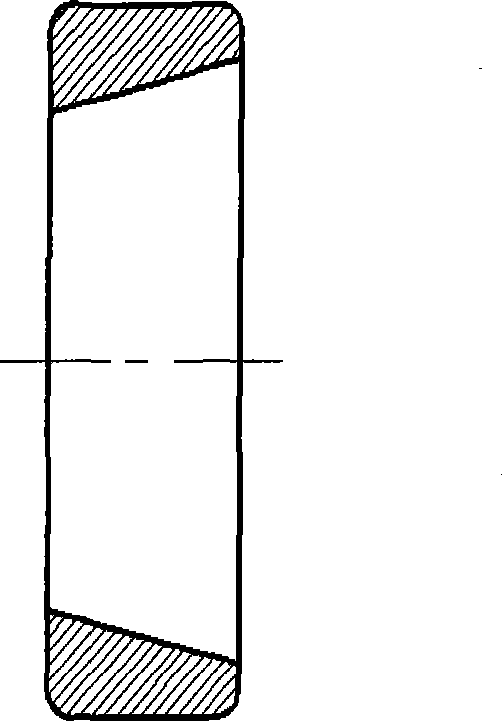

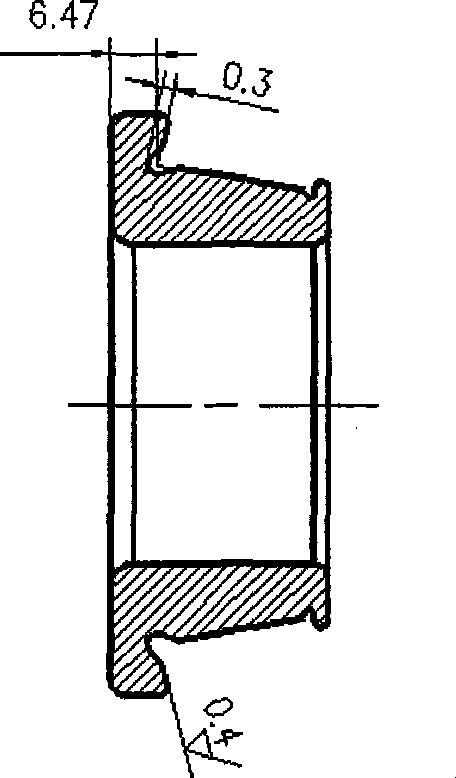

Tapered roller bearing with high strength and low friction torque

The invention relates to a tapered roller bearing with high strength and low friction torque, comprising an outer ring, an inner ring, a plurality of rollers and a cage, wherein the rollers are clamped between the outer ring and the inner ring and used for supporting and realizing relatively rotating; and the cage is used for guiding the rollers to move; a big rib of the inner ring is a convex curved rib; the root part width of the big rib of the inner ring is larger than 6.47 mm, and the axial depth of an oil groove is smaller than 0.5 mm; the raceway buses and the roller buses of the inner ring and the outer ring are in a logarithm curve convexity shape; the number of the rollers is less than 16, the length of the rollers is smaller than 24 mm, and the convex diameter of a raceway is small; the sphere base surface diameter of the rollers is smaller than 136 mm, and the diameter of the rollers is larger than 21.671 mm. The invention has long service life, saves the energy and reduces the energy consumption.

Owner:FUJIAN YONGAN BEARING

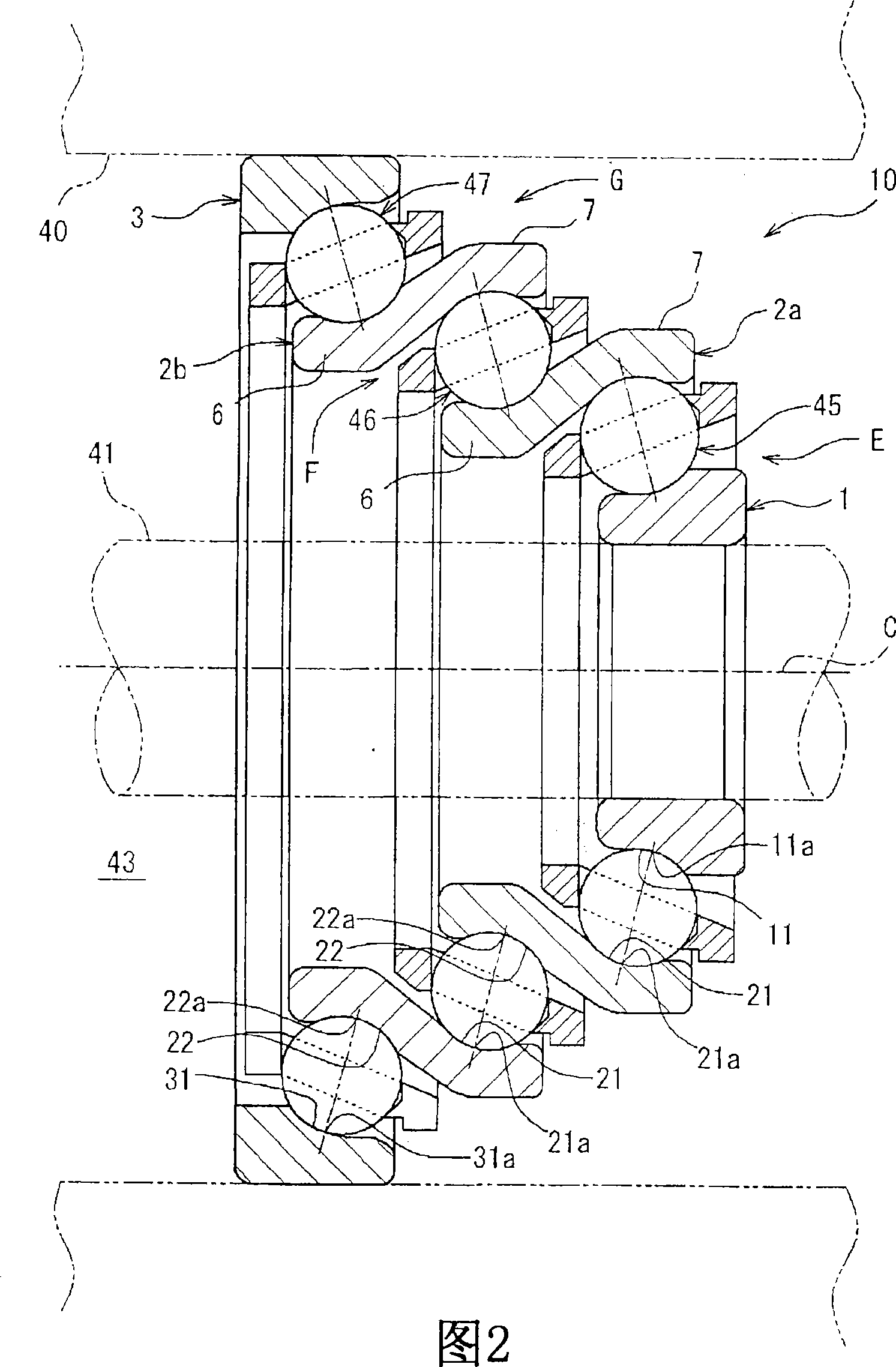

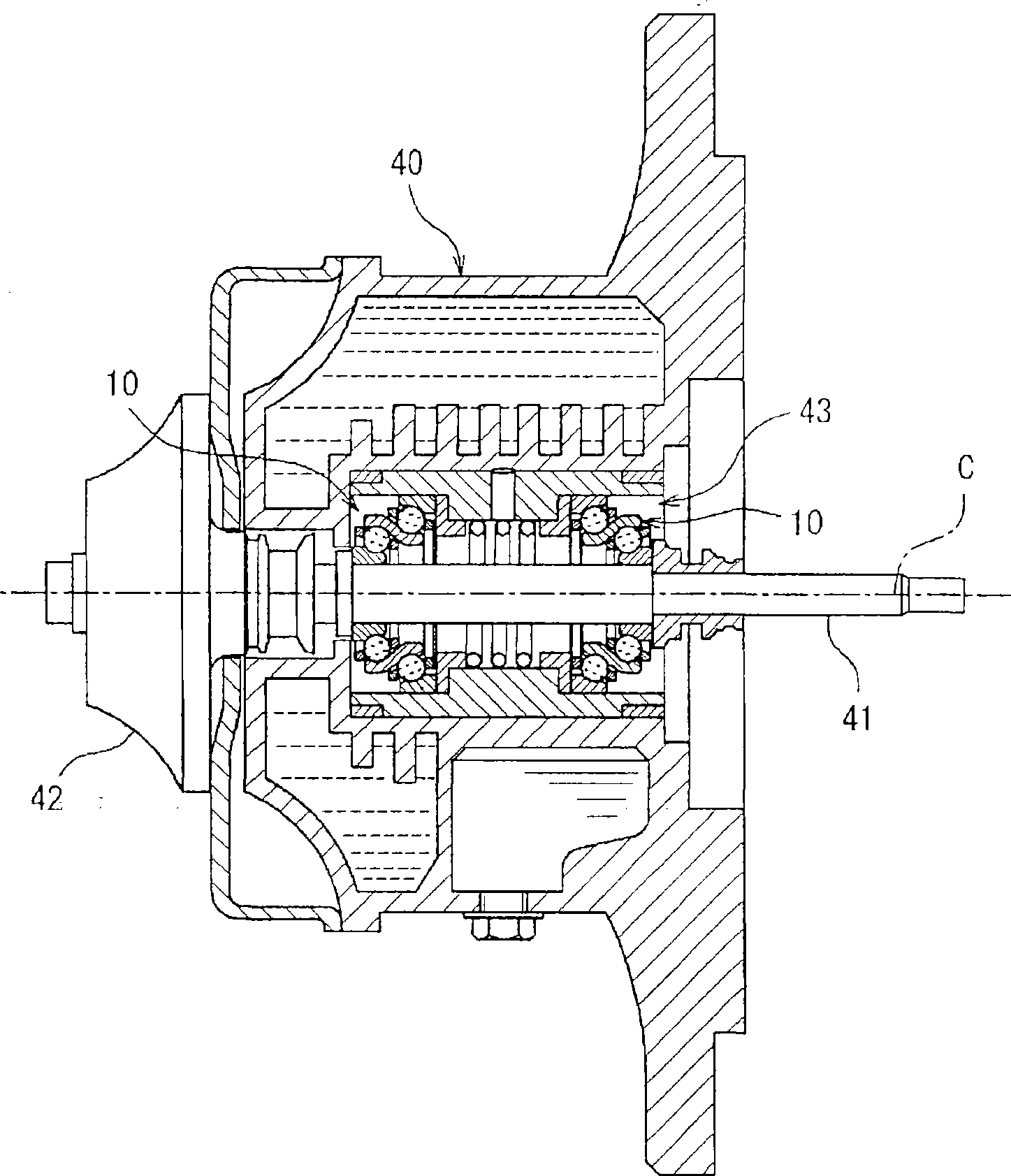

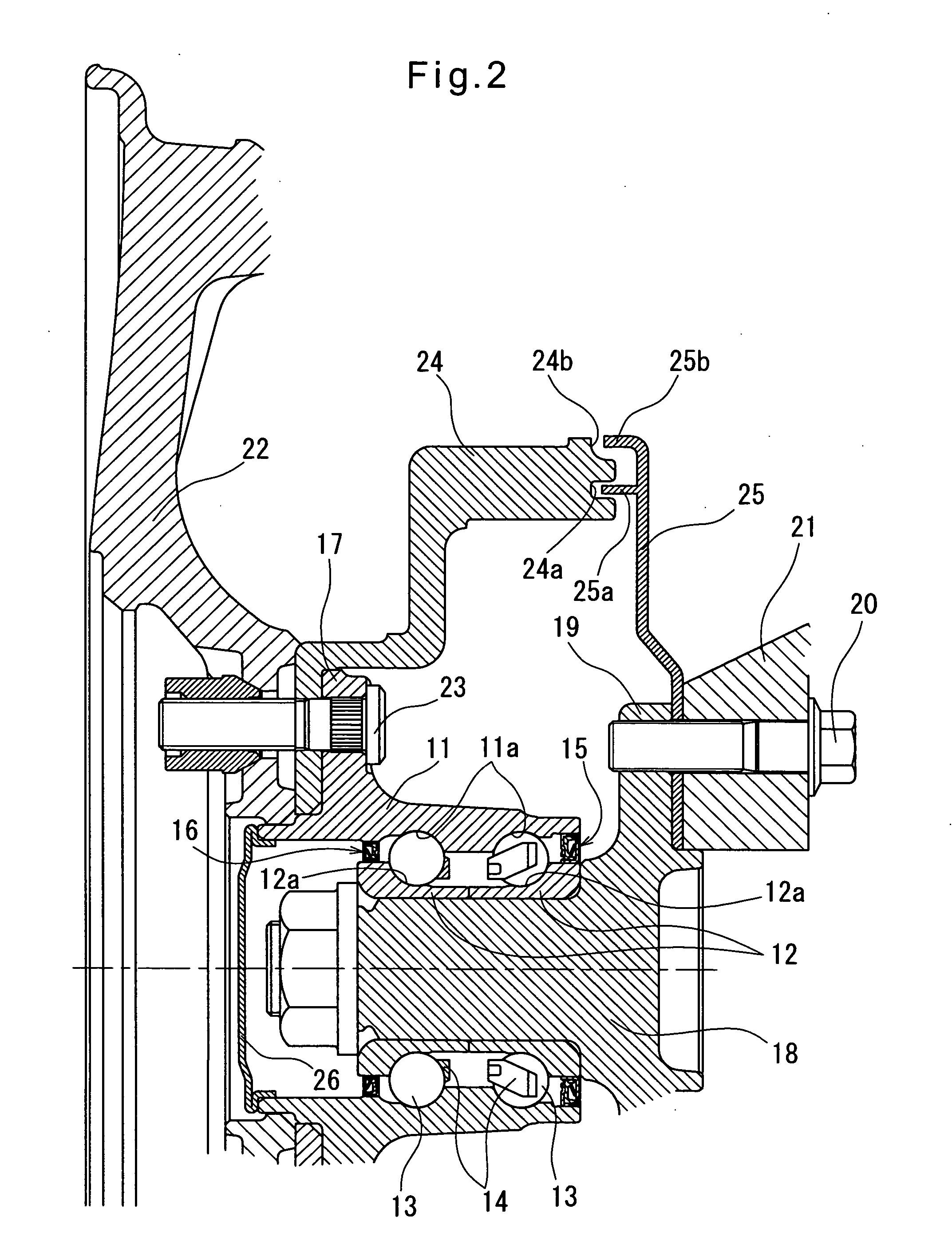

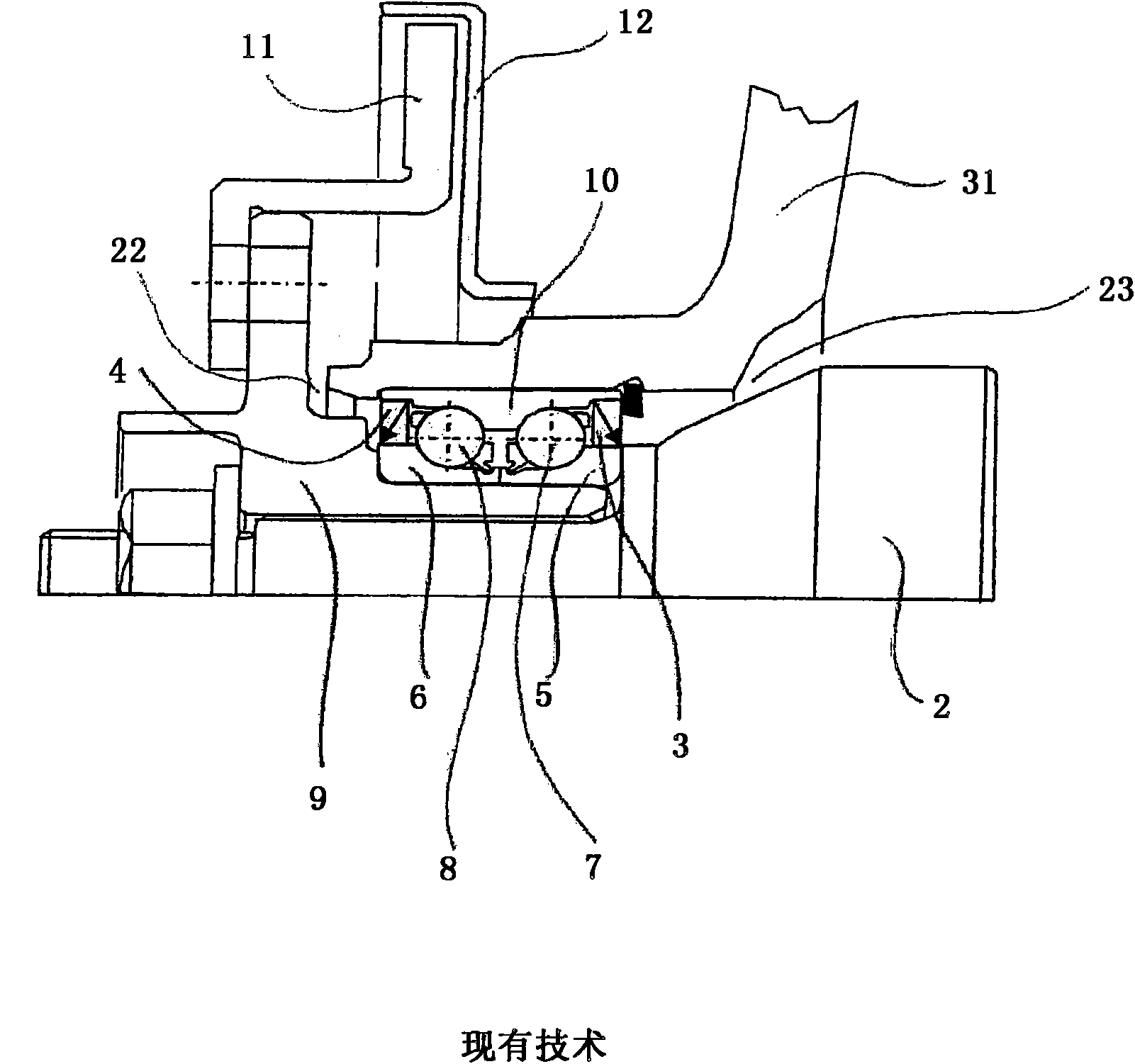

Composite type automobile hub bearing unit

ActiveCN102141080AReduce frictional torqueImprove reliabilityBearing assemblyHubsBall bearingNeck parts

The invention discloses a composite type automobile hub bearing unit which comprises a flange large inner ring, a small inner ring and an outer ring, wherein the end part of the flange large inner ring is provided with a turned edge; the neck part of the flange large inner ring is provided with a step; the small inner ring is fixed on a shaft neck between the turned edge and the step by the turned edge; the step on the neck part of the flange large inner ring is provided with a conical outer roller path; the small inner ring is provided with a spherical outer channel; the inner side of the outer ring is provided with a conical inner roller path and a spherical inner channel; a tapered roller is arranged between the conical outer roller path and the conical inner roller path; and a ball roller is arranged between the spherical outer channel and the spherical inner channel. In the technical scheme of the invention, a bearing with greater stress at the inner side is designed into a tapered roller type, a bearing with smaller stress at the outer side is designed into an angular-contact ball bearing structure, so that the hub bearing unit hardly has early failure, simultaneously the quality risk brought about by the complex manufacturing can be reduced, and the reliability of a unit assembly can be improved better.

Owner:ZHEJIANG ZHAOFENG MECHANICAL & ELECTRONICS CO LTD

High-efficiency, large angle, variable displacement hydraulic pump/motor

InactiveUS20060051216A1Improve efficiencyHigh displacement angleYielding couplingFluid gearingsHydraulic pumpControl theory

A variable displacement hydraulic / pump motor has a yoke with a pair of shafts aligned to define a yoke pivot axis and connected to a valve plate therebetween having intake and discharge apertures. A rotatable cylinder barrel has piston cylinders open at one end to receive a piston head and opening through fluid ports at another end, flush against the valve plate surface. A drive block is mounted on an input / output shaft for rotation about a central axis of rotation inclined at an angle relative to the longitudinal axis of the cylinder barrel which may be changed by a drive engaging the yoke at a point near its pivot axis. Loads on bushings supporting the yoke shafts are reduced by providing radially extending fluid ports in the shafts and in communication with the intake and discharge apertures of the valve plate.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

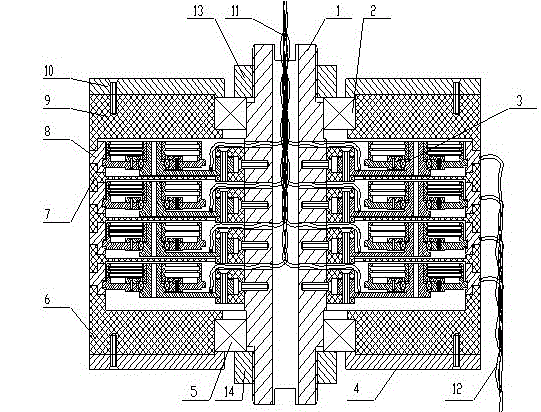

Rolling confluence ring device suitable for transmission with large power

ActiveCN103151670AIncrease conductive powerReduce frictional torqueRotary current collectorInternal cavityPower circuits

The invention discloses a rolling confluence ring device suitable for transmission with large power. The device comprises an inner conductive wire, an outer conductive wire, an inner shaft, a plurality of layers of confluence assemblies and a mounting assembly, wherein the inner shaft is provided with a cavity; the layers of confluence assemblies are respectively connected with the outer conductive wire and the inner conductive wire, the inner conductive wire is arranged in the cavity of the inner shaft in a penetrating way, the layers of confluence assemblies are connected with the outer conductive wire, the layers of confluence assemblies are mutually insulated, and the inner conductive wire, the outer conductive wire, the inner shaft and the layers of confluence assemblies fixedly form an integral structure through the mounting assembly; and the layers of confluence assemblies are respectively connected with an external power circuit through the outer conductive wire so as to carry out confluence to the inner conductive wire for the external power circuit. By the adoption of the device, the confluence assemblies can be flexibly configured according to a specific use environment to improve conductive power; and meanwhile a friction torque is small, the service life is long, and the device further has the characteristics of high reliability, compact structure, adaptability to transmission with large power and the like.

Owner:SHANGHAI SPACEFLIGHT INST OF TT&C & TELECOMM

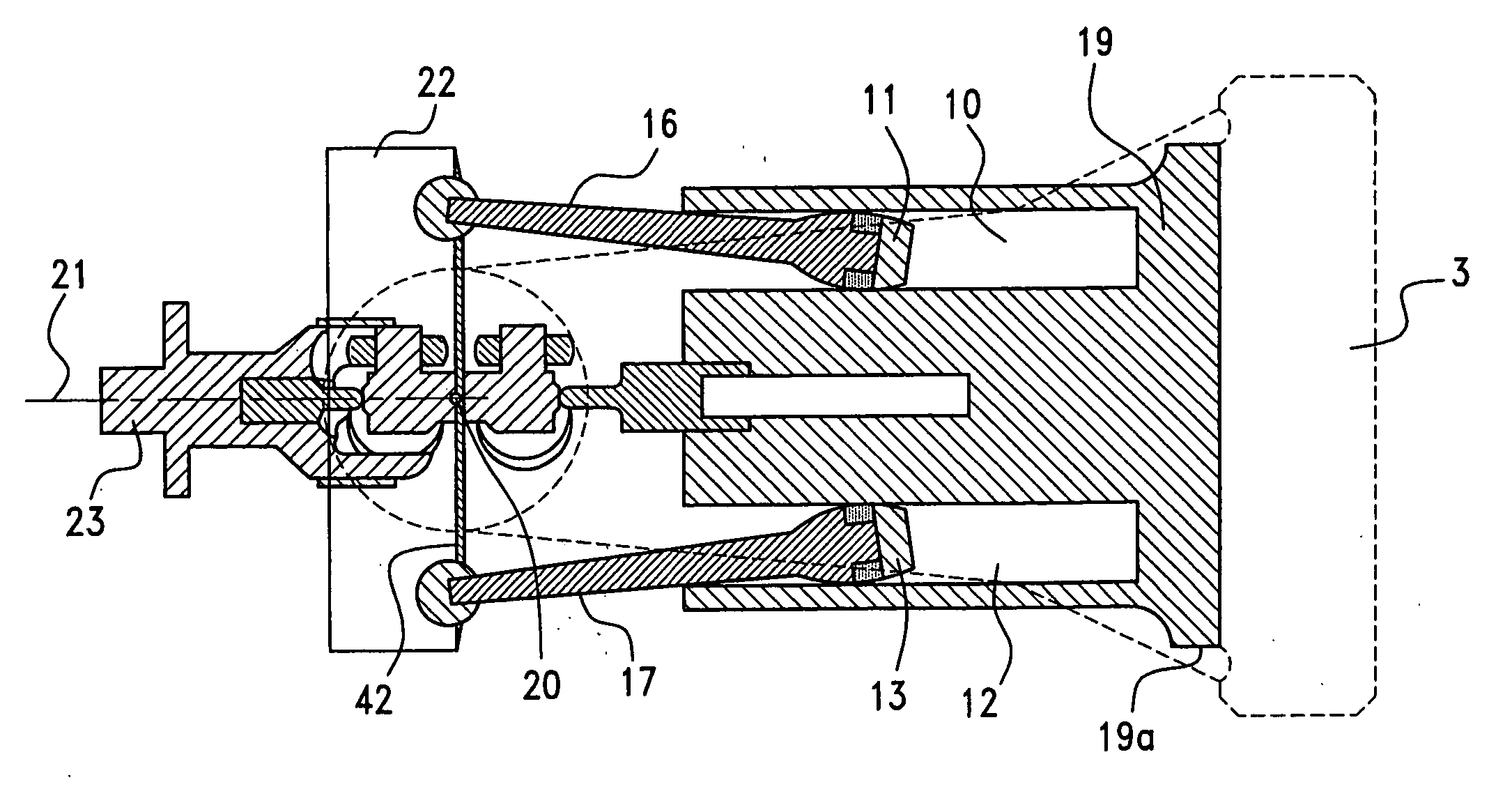

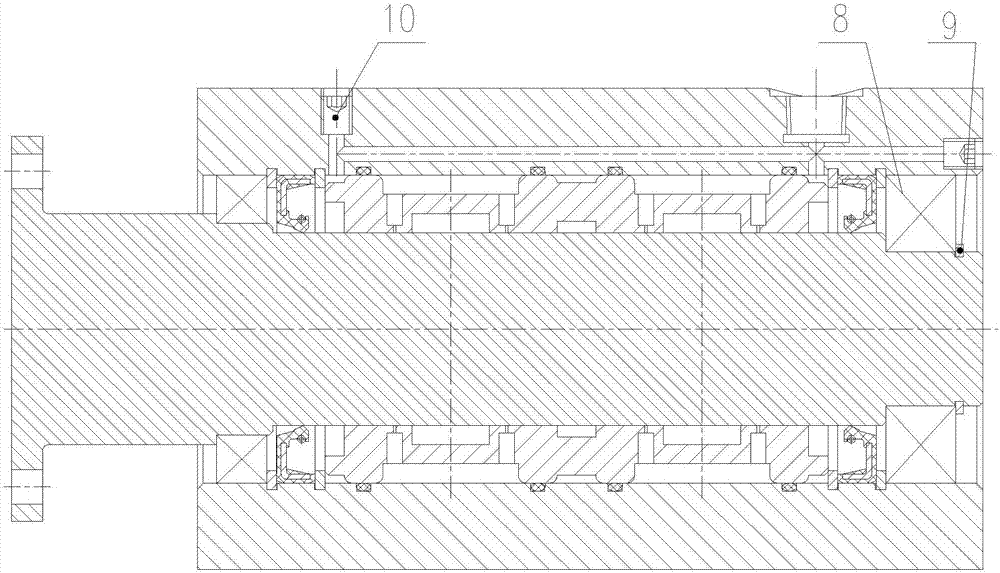

Driving device for controlled displaceable carriages

InactiveCN101585151ADoes not affect prestressReduce frictional torqueRolling contact bearingsShaftsFixed bearingPinion

The invention relates to a driving device for controlled displaceable carriages of machine base frame in machine tool; the driving device is provided with a controllable electric motor mounted on a shaft(1); the controllable electric motor comprising a stator (2) and a rotor (03), a pinion (12) positioned on the shaft (1) and driven by the electric motor and a gear rod (13) joggled with the pinion (12); wherein the gear rod (13) is arranged at a machine base frame; and at least two movable bearings (09, 10) for supporting the shaft (01); wherein the movable bearings (09, 10) are mounted in the void of the housing plate (06). The driving device according to the invention is characterized in that: a movable bearing is configured into a fixed bearing (09) and a bearing is configured into a floating bearing (10); the rotor (03) and the shaft (01) are connected through the fixing element of the machine.

Owner:SCHAEFFLER TECH AG & CO KG

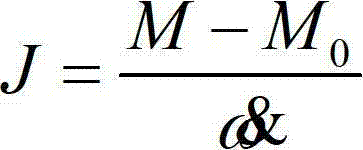

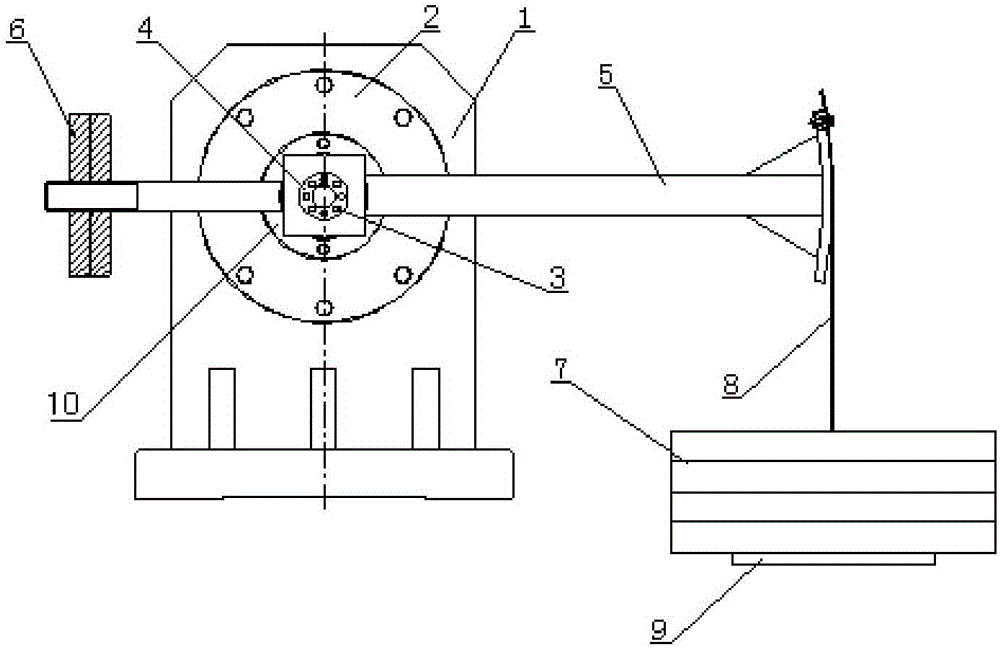

Device and method for testing wire-wound moment of rotary table

InactiveCN102879139ASimple structureReduce frictional torqueWork measurementTorque measurementEngineeringRate gyro

The invention relates to a device and a method for testing the wire-wound moment of a rotary table. The device for testing the wire-wound moment of the rotary table comprises a rotating platform, a rate gyroscope, a B code, a rotating platform driving unit and a data processing computer, wherein the rotating platform and the B code are electrically connected with the data processing computer respectively; the rotating platform driving unit drives the rotating platform to rotate; and a rotating component to be tested and the rate gyroscope are arranged on the rotating platform, and the rotating component to be tested, the rate gyroscope and the rotating platform rotate synchronously. The device for testing the wire-round moment of the rotary table is simple in structure, and the device and the method for testing the wire-round moment of the rotary table are high in testing accuracy and convenient to operate.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Rolling bearing and supercharger using the same

InactiveCN101415961AReduce frictional torqueRolling contact bearingsBearing componentsRolling-element bearingEngineering

Provided is an inner ring having a first raceway at an outer periphery thereof, an outer ring having a second raceway at an inner periphery thereof, an intermediate ring which is interposed between these, and has a third raceway at an inner periphery thereof and also has a fourth raceway at an outer periphery thereof, first rolling elements interposed between the first raceway and the third raceway, and second rolling elements interposed between the fourth raceway and the second raceway. The intermediate ring includes a larger-diameter ring portion, and a smaller-diameter ring portion formed on the larger-diameter ring portion through an inclined ring portion. The third raceway is formed at a boundary portion between the larger-diameter ring portion and the inclined ring portion, and the fourth raceway is formed at a boundary portion between the smaller-diameter ring portion and the inclined ring portion.

Owner:JTEKT CORP

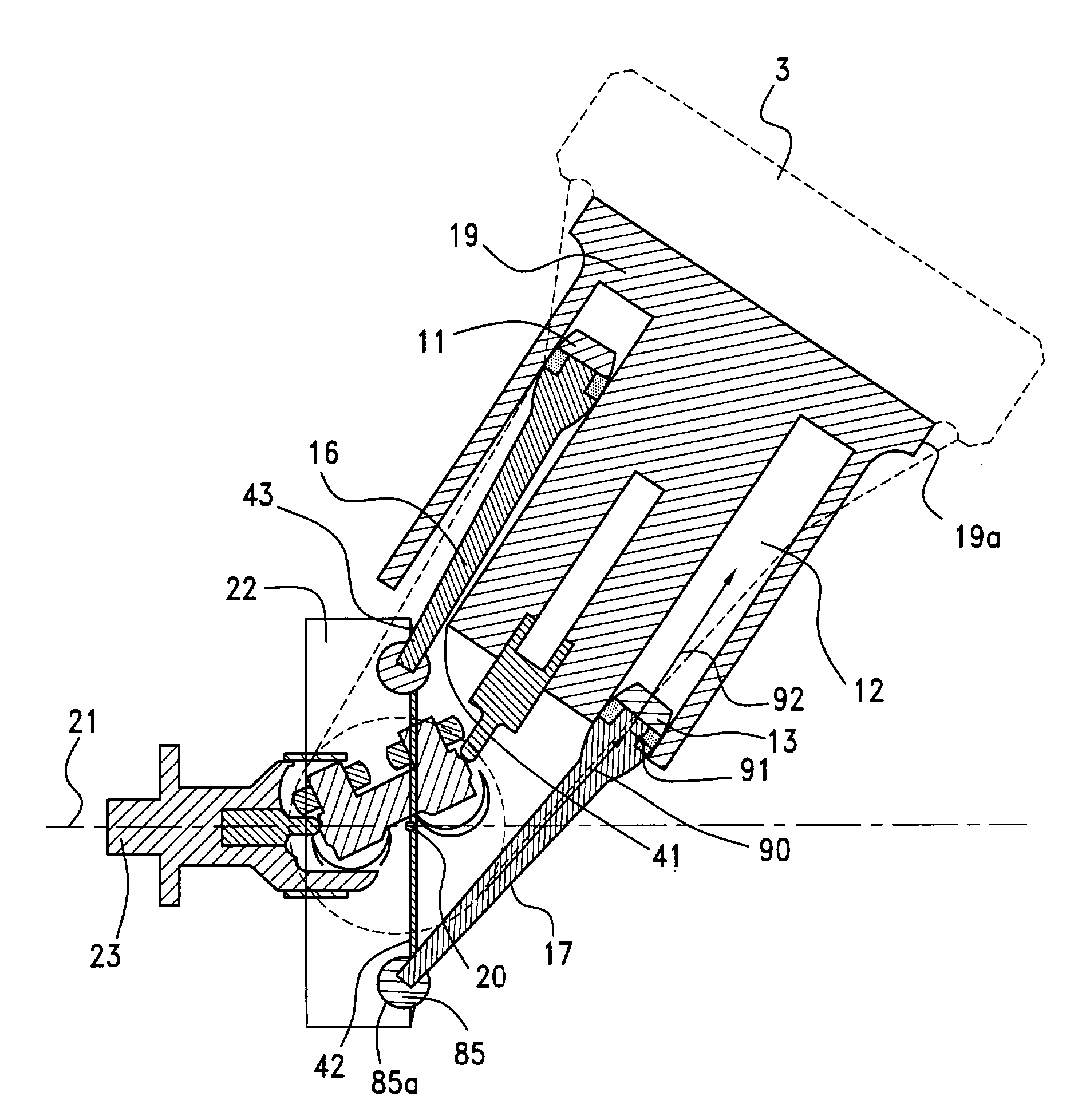

Cam follower roller device

ActiveUS20150176691A1Reduce frictional torqueEasy to assembleValve arrangementsCam-followersEngineeringCam follower

The cam follower roller device including a body, a shaft mounted on the body, a roller mounted on the shaft in a rotationally movable manner, and at least one friction element mounted on the shaft axially between the roller and the body. The friction element is separate from the body and from the roller.

Owner:AB SKF

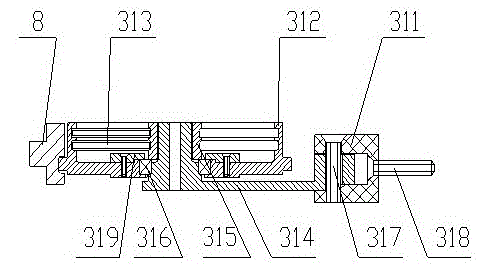

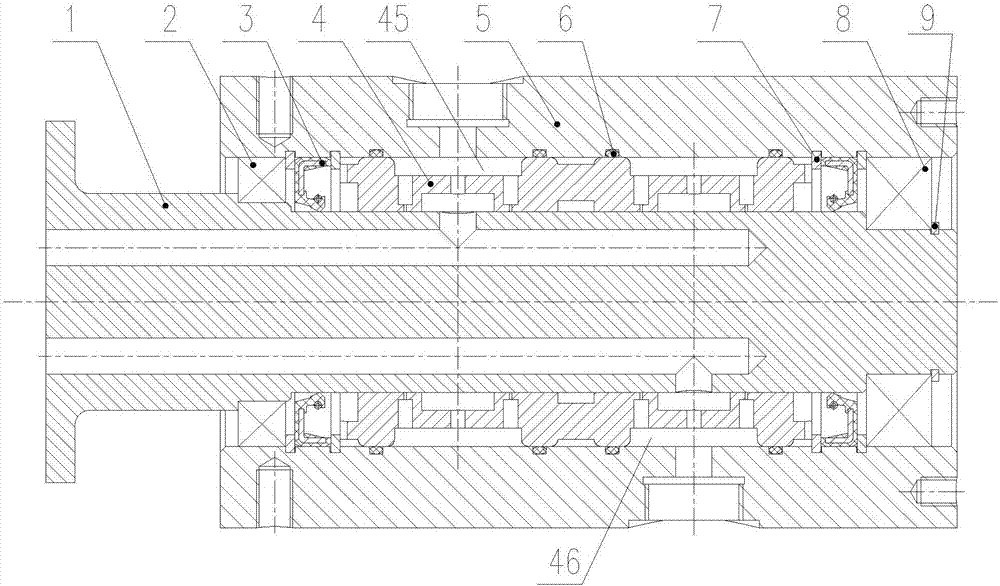

Electric spindle angular contact ball bearing pre-tightening force regulating mechanism

ActiveCN107344245AImprove support accuracyHigh rotation accuracyLarge fixed membersBall bearingInjector nozzle

The invention exposes an electric spindle angular contact ball bearing pre-tightening force regulating mechanism. An elastic check ring for a hole, angular contact ball bearings and an oil stopping ring are sequentially arranged on a spindle in a sleeving manner; three layers of sleeves are installed between the bearings installed in pairs; a non-contact type temperature sensor is installed between the bearings and the oil stopping ring; an angular acceleration vibration sensor is installed at the tail end of the electric spindle; and an oil spraying nozzle is installed on the face of the outer side of the bearings. A piezoelectric ceramic driving power source, a connector assembly, an oil receiving nozzle and a water receiving nozzle are installed on an end cover on the tail portion of the electric spindle. The piezoelectric ceramic driving power source is connected with two annularly stacked piezoelectric ceramic sleeves through a circuit. According to the technical scheme, by means of a good automatic pre-tightening force regulating technology, the pre-tightening force of the electric spindle bearings is effectively regulated, the electric spindle temperature rise is regulated and controlled, noise is lowed, the supporting precision and the rotating precision of the bearings are improved, the service life of the bearings is prolonged, and therefore the dynamic performance of the electric spindle is improved, and the machining precision and the work efficiency of a machine tool adopting an electric spindle unit are improved.

Owner:SHENYANG JIANZHU UNIVERSITY

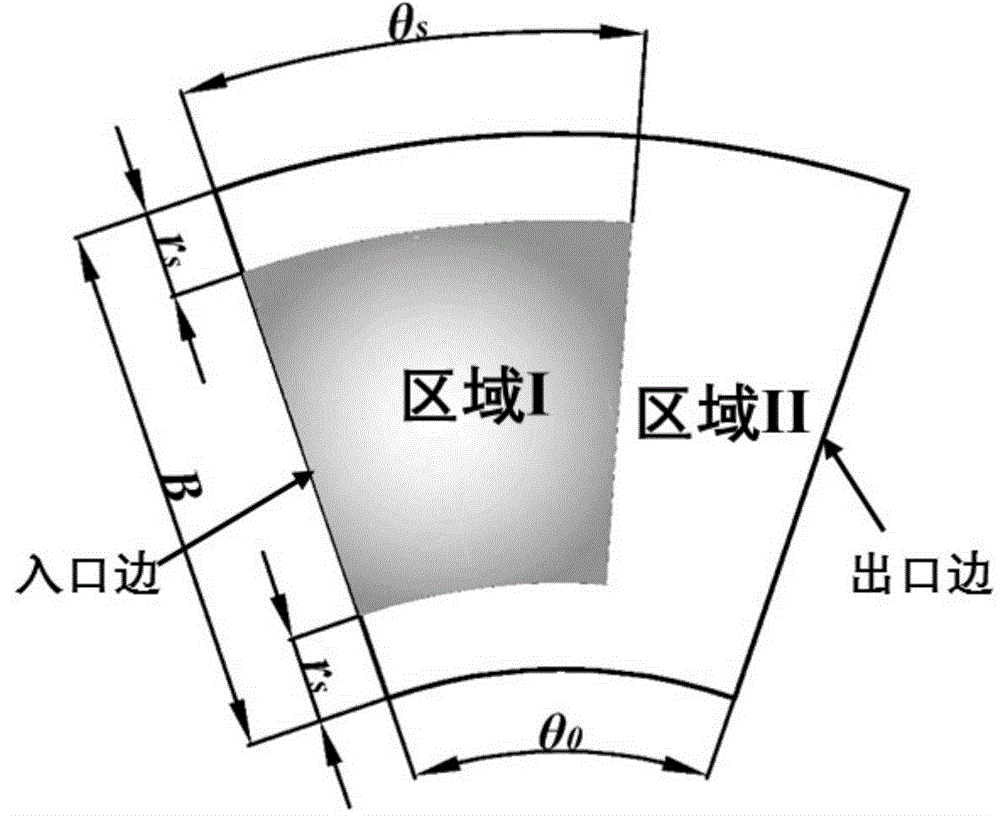

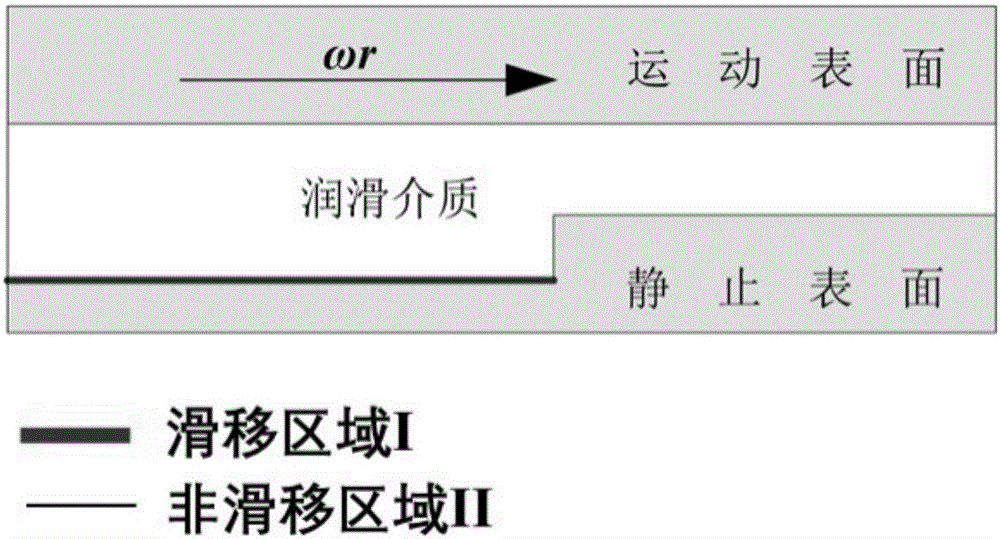

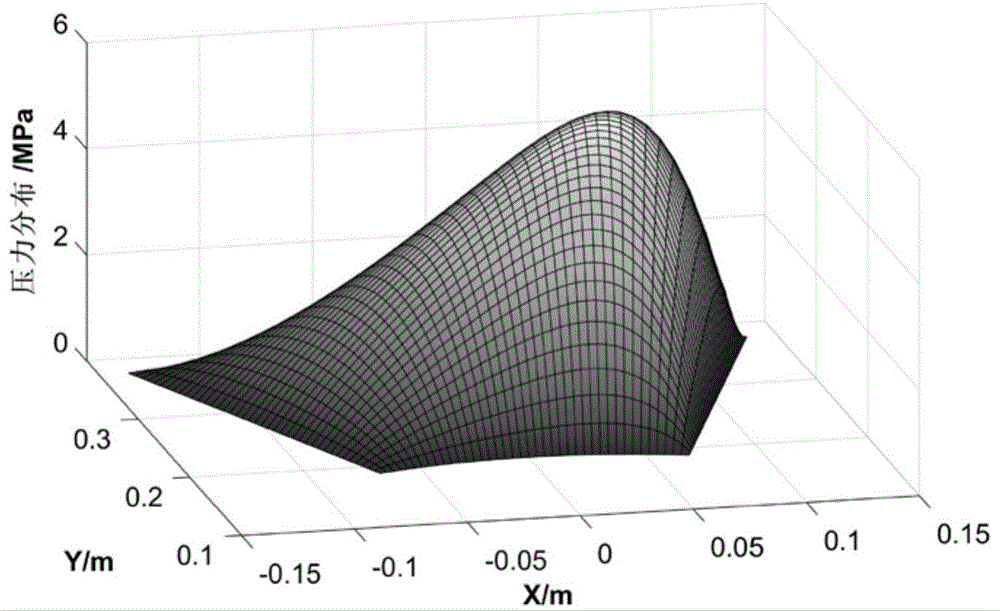

Tilting bush thrust bearing with complex slip surface

ActiveCN106763198AImprove carrying capacityReduce frictional torqueBearing componentsSurface finishingLower limit

The invention provides a tilting bush thrust bearing with a complex slip surface. The tilting bush thrust bearing comprises multiple bushes; the upper surface of each bush is divided into two areas: an area I near an inlet area and a rest area II, wherein the surface treatment is performed for the area I to form a hydrophobic surface so as to achieve lower limit shearing stress and to be liable to generate the interface slip; the surface treatment is performed for the area II to form a hydrophilic surface so as to achieve higher limit shearing stress and to be not liable to generate the interface slip; after the pressure center change caused by the interface effect and the tilting characteristics of the bushes are considered, the radial and peripheral distribution ranges of the area I are optimally obtained; after a lubricating medium flows from the area I to the area II, as the medium flowing continuity can generate additional pressure peak, the bearing capacity of the tilting bush thrust bearing is improved; as the fluid shearing viscosity in the area I is reduced, the friction torque of the tilting bush thrust bearing is reduced; and the step design in different areas solves the problem of no wear resistance of hydrophobic components in the area I.

Owner:TSINGHUA UNIV

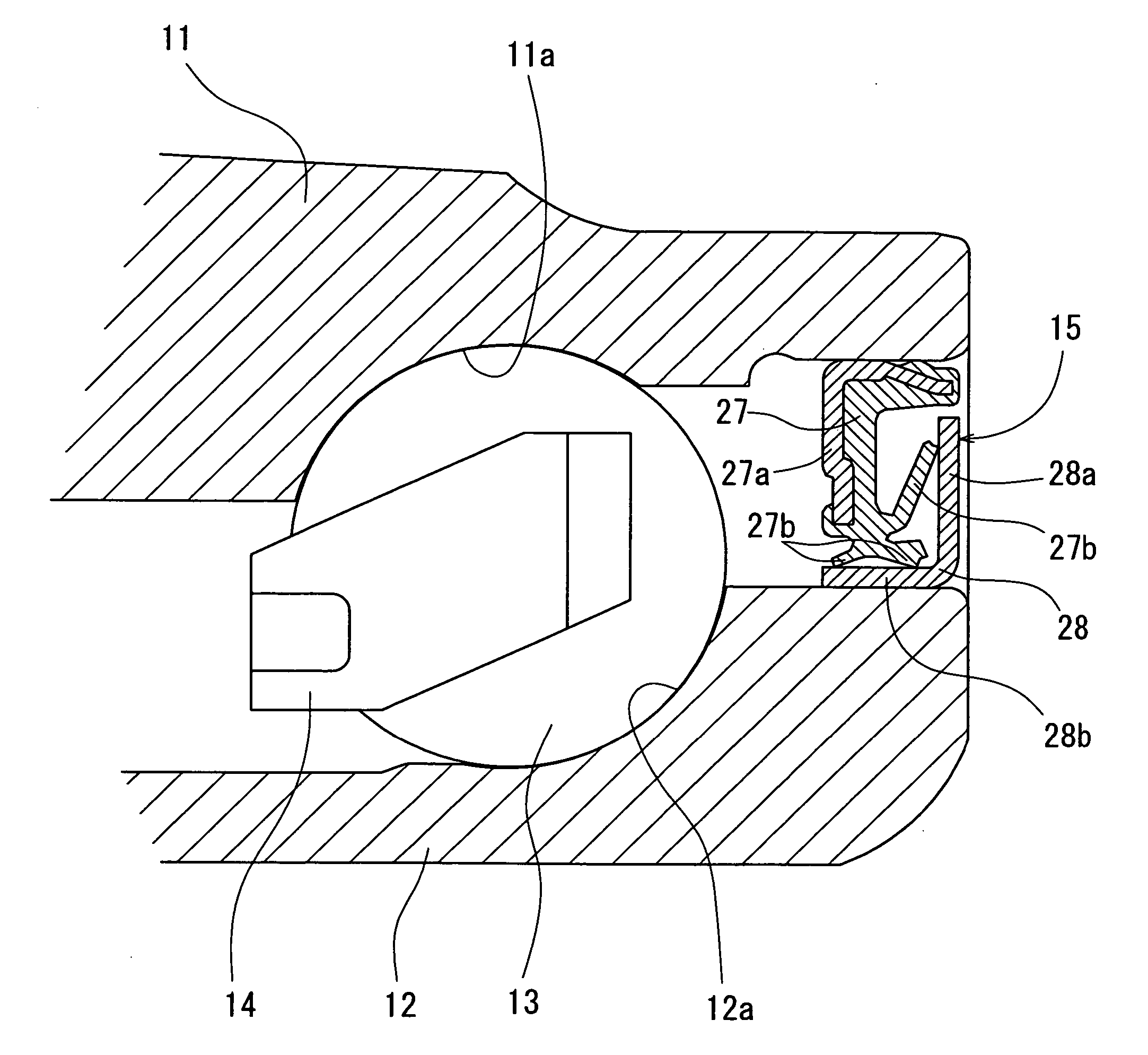

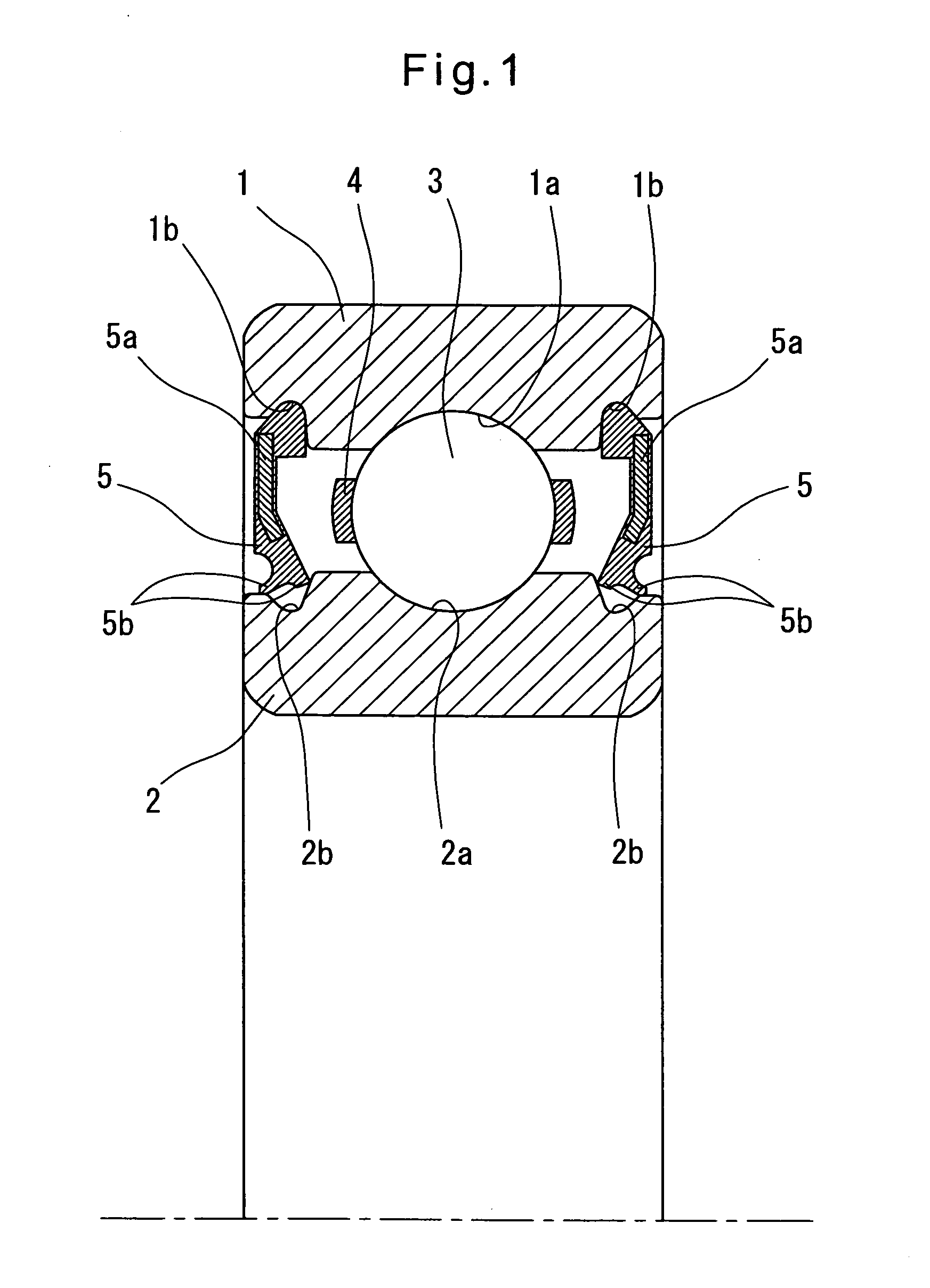

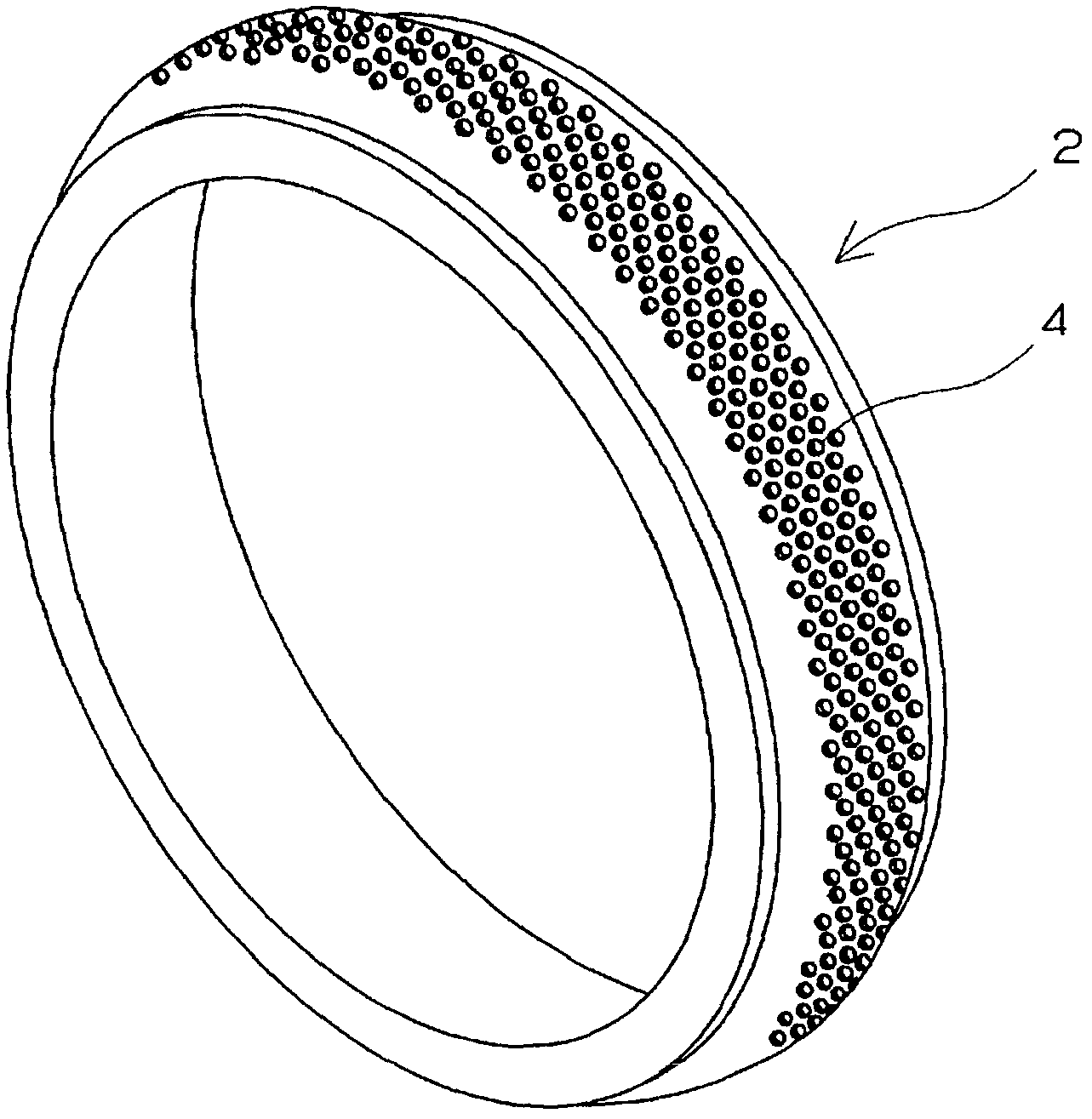

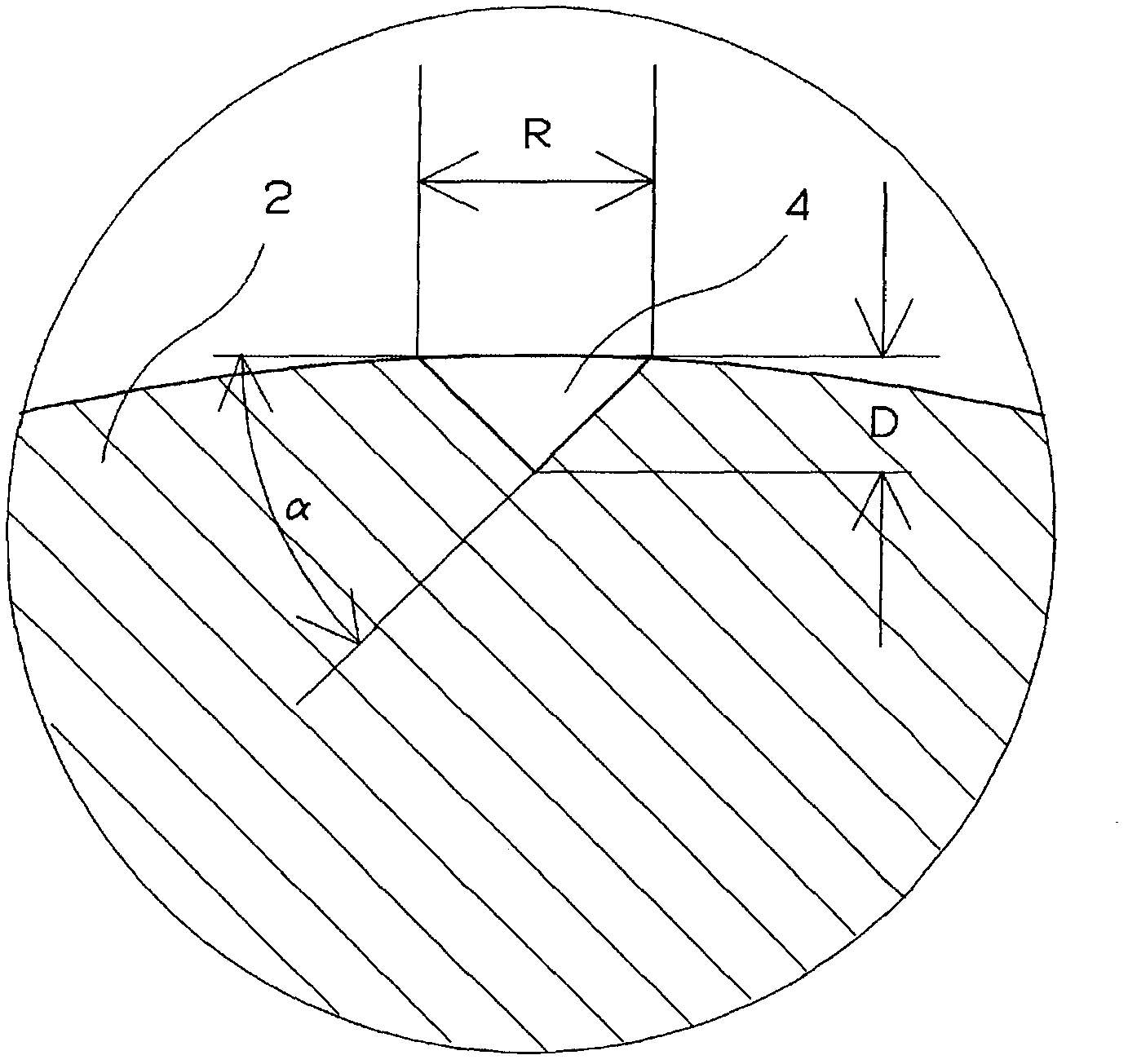

Sealed rolling bearing

InactiveUS20060018579A1Improve surface qualityIncrease speedBall bearingsCastorsContact pressureFriction torque

A sealed rolling bearing is proposed which makes it possible to reduce the torque loss while ensuring high sealing performance. Seal lips of seal members secured to the outer ring of the bearing at both ends thereof are in sliding contact with both ends of the outer periphery of the inner ring of the bearing. These portions of the inner ring that are in sliding contact with the seal lips are subjected to minute shot peening in which minute shots of molybdenum disulfide having a particle diameter of 20 to 200 micrometers are struck against these portions at a high speed of 50 meters per second. This decreases the friction torque attendant to sliding contact of the seal lips and makes it possible to decrease the torque loss of the bearing even if the contact pressure of the seal lips is increased sufficiently to ensure high sealing performance.

Owner:NTN CORP

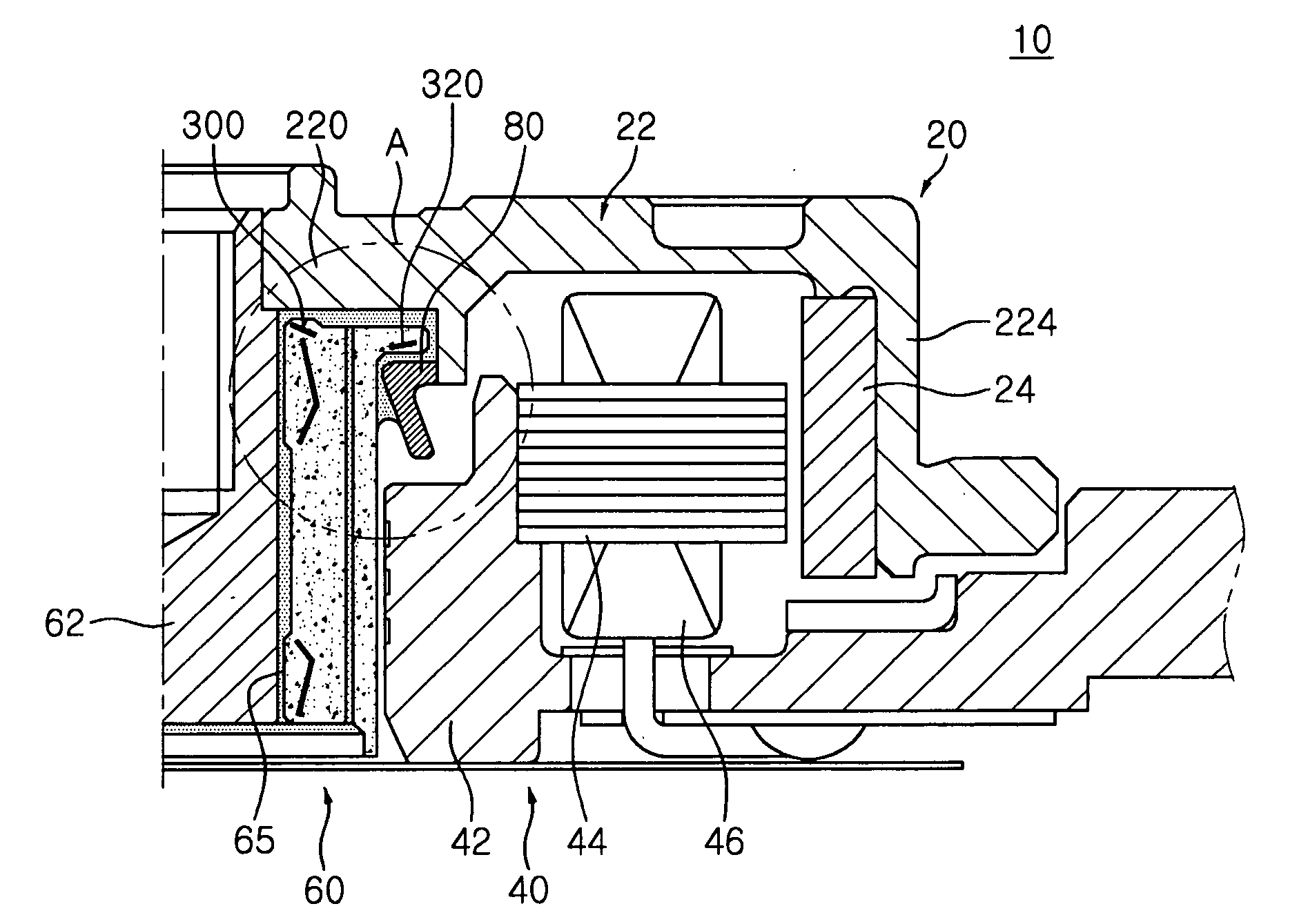

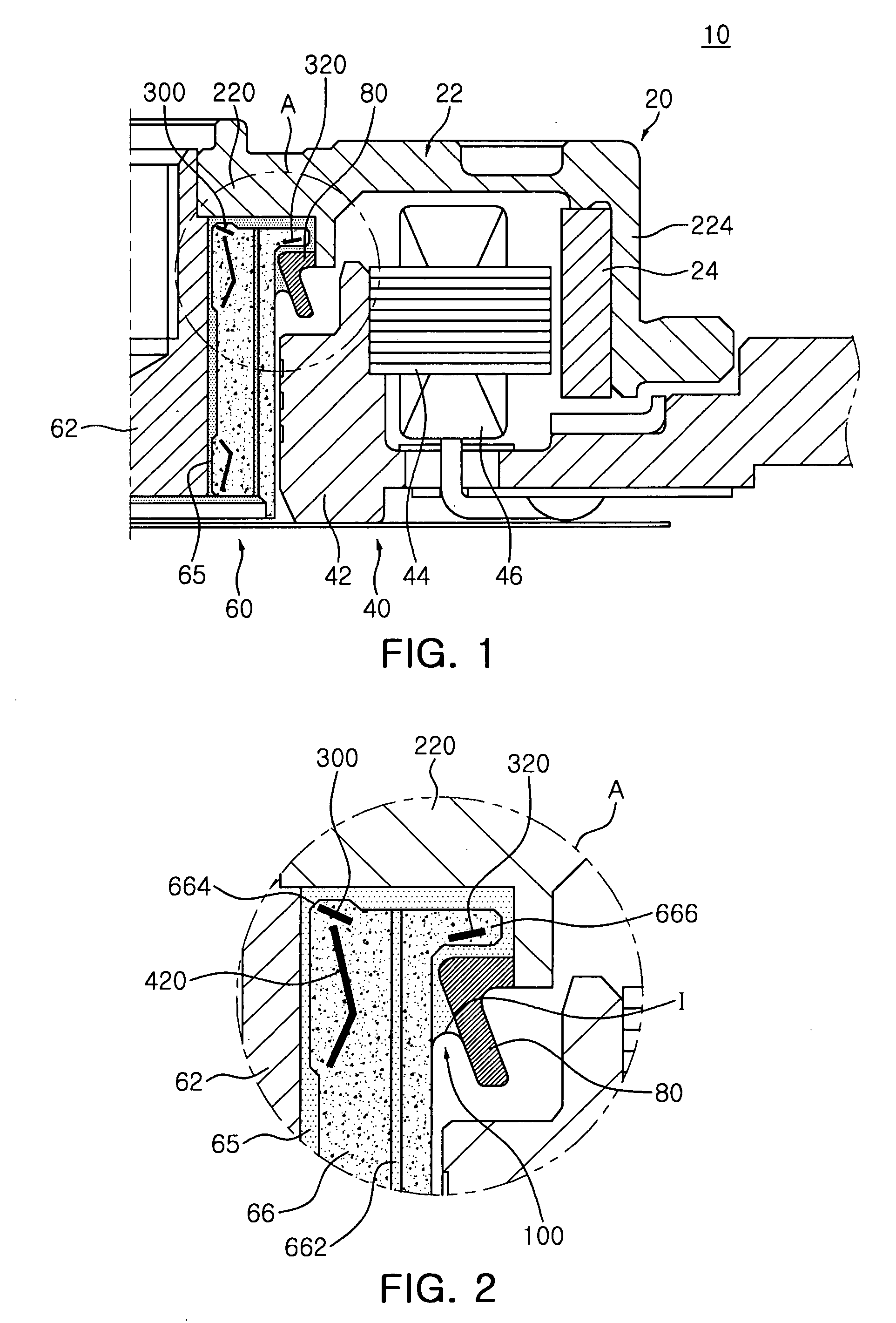

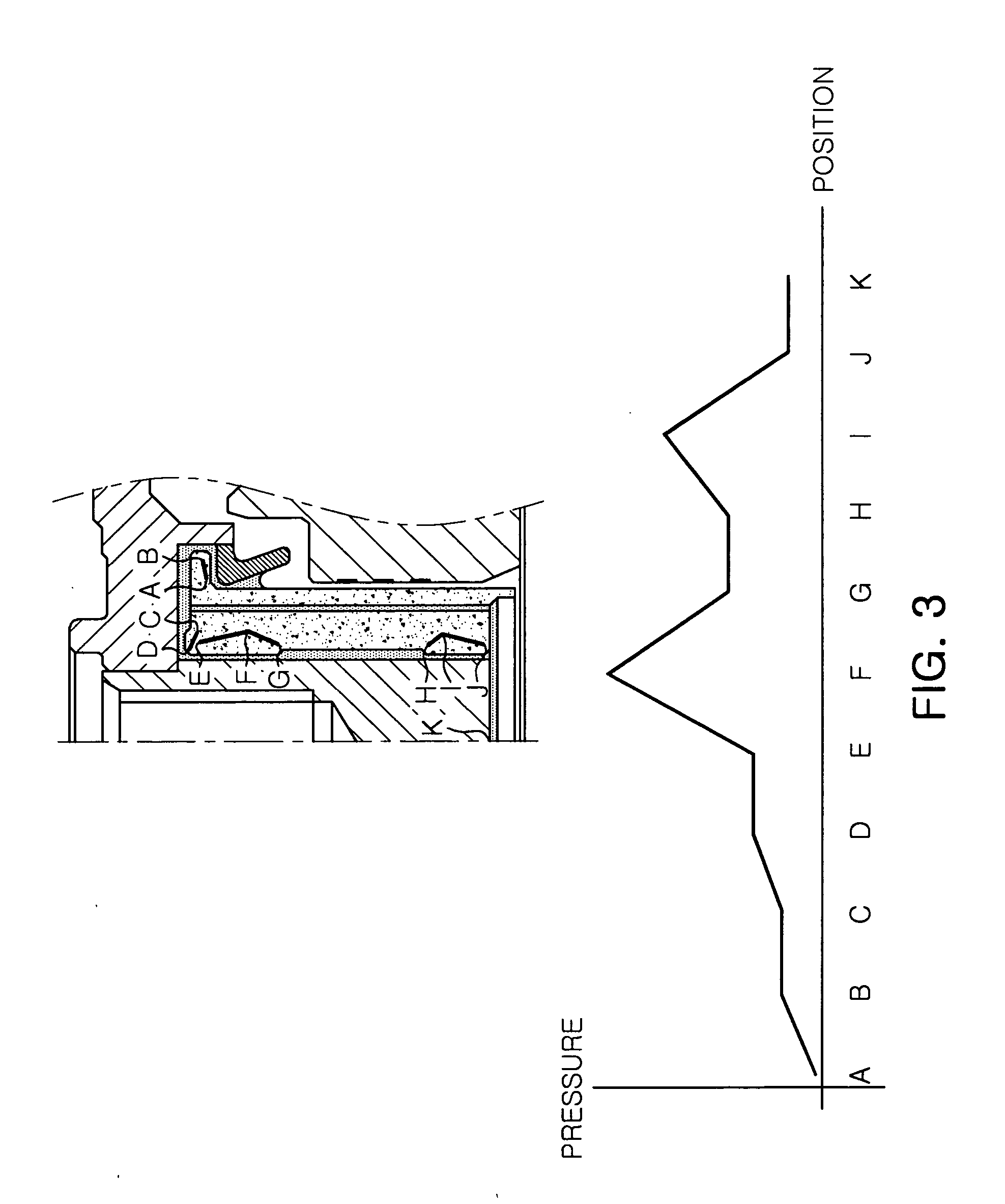

Hydrodynamic bearing assembly and motor having the same

InactiveUS20110115323A1Reduce frictional torqueSliding contact bearingsMechanical energy handlingEngineeringDynamic pressure

There is provided a hydrodynamic bearing assembly including: a sleeve against which a shaft is supported so that an upper end of the shaft, being compressed and inserted into a hub base of a rotor case, protrudes upwardly in an axial direction; a first thrust dynamic pressure generating part formed in at least one of a protrusion and the hub base corresponding to the protrusion, the protrusion being formed at an end of the sleeve along an inner diameter direction; and a second thrust dynamic pressure generating part formed around a protruding end portion of the sleeve, the protruding end portion facing an upper portion of a stopper part in the axial direction and the stopper part rotating together with the rotor case. Also, an oil sealing part has an oil interface between an outer circumferential surface of the sleeve along an outer diameter direction and an inner surface of the stopper part.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Steering knuckle with pre-sealing

InactiveCN101965268AReduce loadSave materialYielding couplingRolling contact bearingsFriction torqueEngineering

The invention relates to a steering knuckle, which is provided for receiving an outer ring of a wheel bearing, and to a wheel bearing arrangement with such a steering knuckle. The object of the invention is to relieve the sealing arrangements of the wheel bearing by a pre-seal, which is designed as a labyrinth seal and to realize an advantageous sealing effect due to an appropriate gap geometry. To this end, the steering knuckle has a collecting channel, which is provided to capture liquids and dirt particles and to discharge them at the periphery. The bearing seal can be changed by this measure, so that savings are possible with a minimum of sealing action of the conventional sealing arrangement and with greatly reduced friction torque. Overall, the sealing action, which is now achieved by the bearing seal and the pre-seal together, is increased or remains at least at the same level while manufacturing costs are reduced.

Owner:SCHAEFFLER TECH AG & CO KG

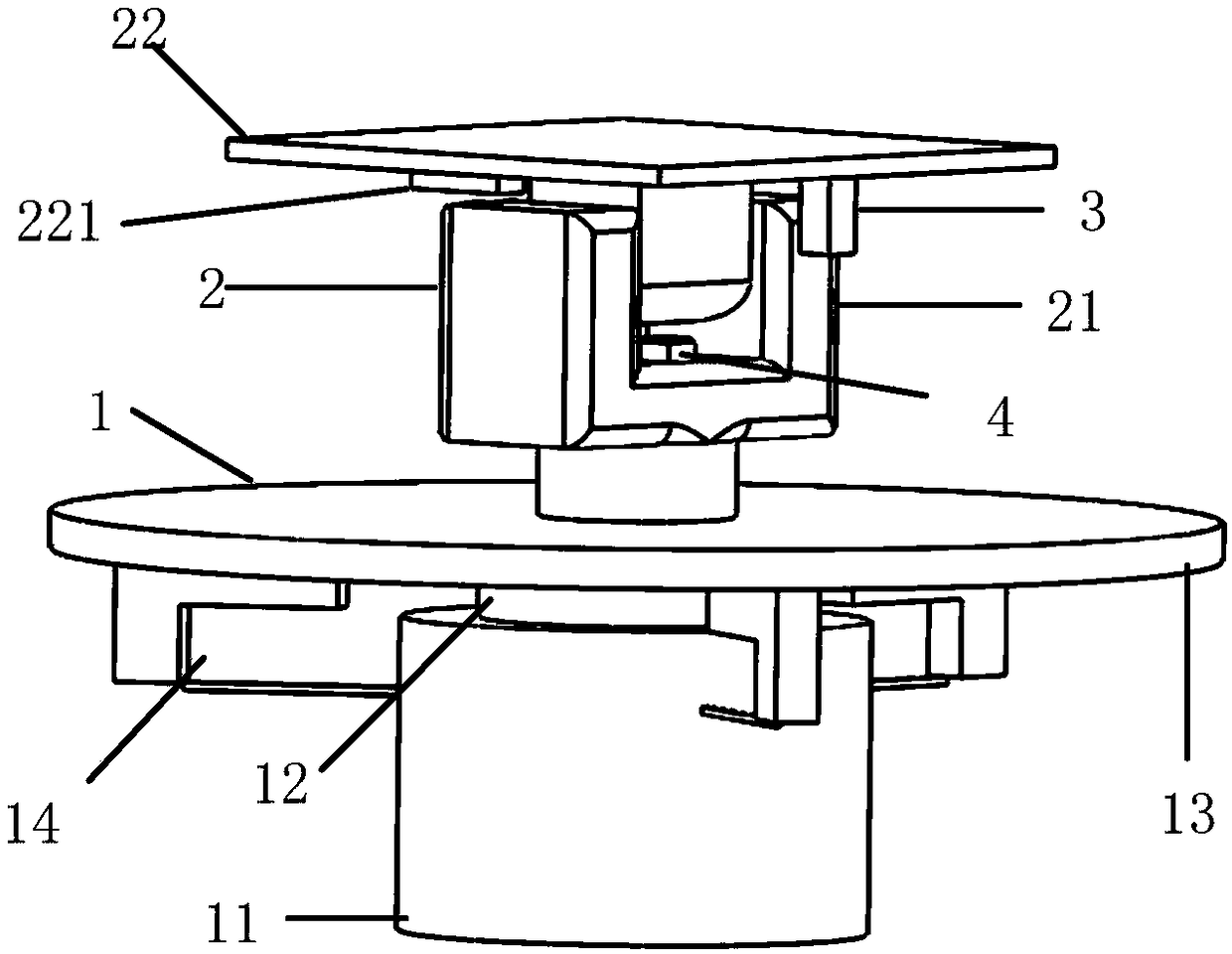

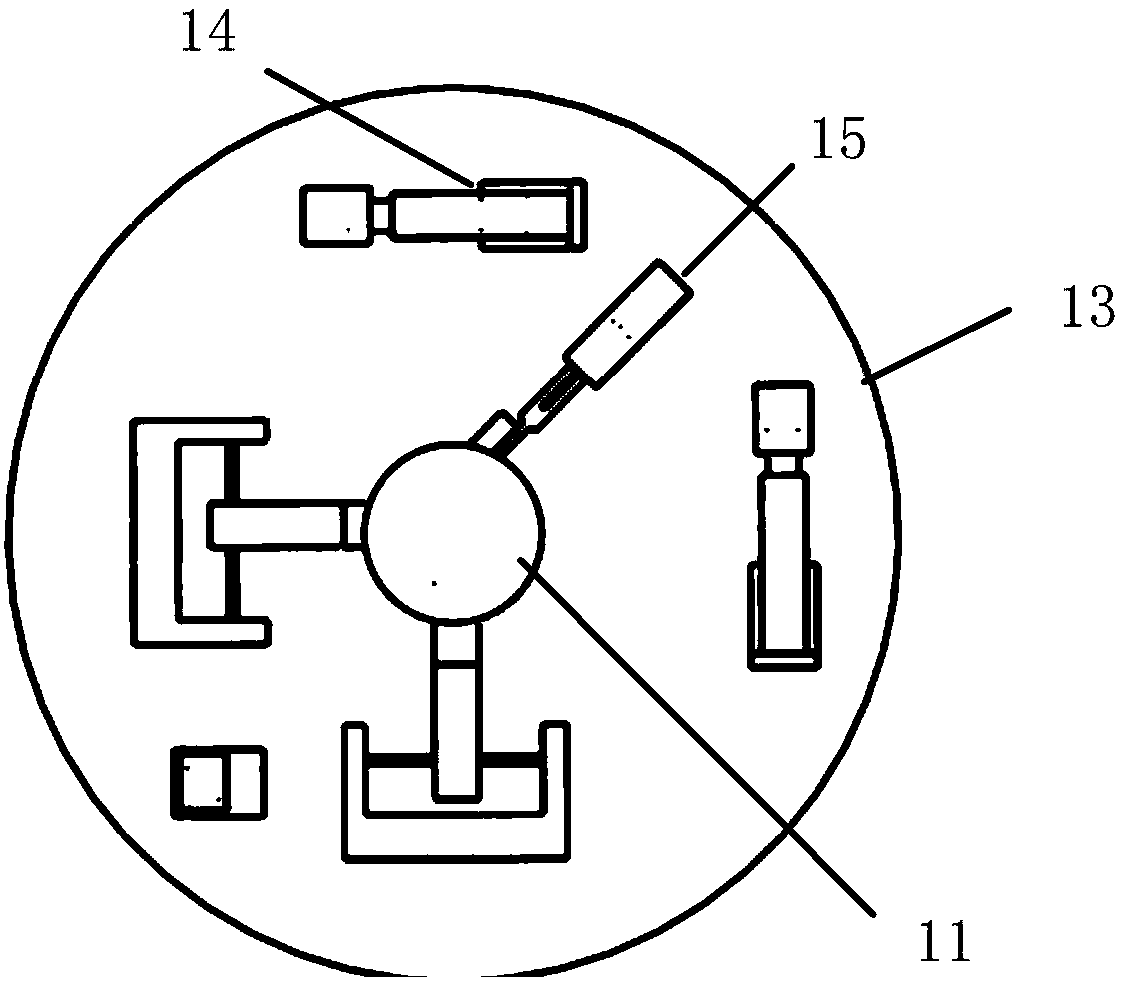

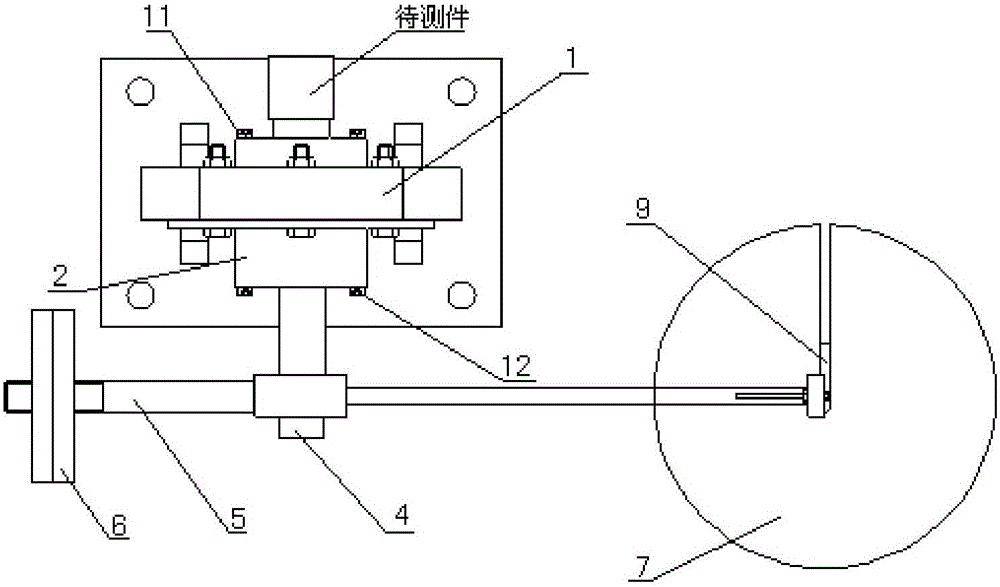

Measuring system and measuring method for centroid

PendingCN109406049ASafe and reliable structureGood precisionStatic/dynamic balance measurementSustainable transportationSurface mountingEngineering

The invention relates to a measuring system and a measuring method for a centroid. The system is compact and reliable in structure, and can test a centroid of a tested piece in any state. The method has a simple calculation process and high calculation precision. The system mainly comprises a three-axis air floating moment test bench, a two-dimensional rotating mechanism, a first centroid adjusting mechanism and a second centroid adjusting mechanism. The three-axis air floating moment test bench comprises a support, an air floating bearing, an air floating platform table, a gravity balance adjusting mechanism, and a force sensor assembly. The lower surface of the air floating platform table is provided with the gravity balance adjusting mechanism for adjusting three directions of X, Y, andZ, and a force sensor assembly for measuring force conditions in the X, Y, and Z directions. The two-dimensional rotating mechanism is mounted on the upper surface of the air floating platform table.The first centroid adjusting mechanism is mounted on the lower surface of a loading plate of a pitching portion in the two-dimensional rotating mechanism, and the tested piece is placed on the uppersurface. An azimuth portion of the two-dimensional rotating mechanism is provided with the second centroid adjusting mechanism.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Environment-friendly composite multisoap base self-repairing bearing grease and preparation method thereof

ActiveCN102604724AImprove performanceOvercoming the lack of extreme pressure wear resistanceLubricant compositionMaximum levelWear resistant

The invention relates to environment-friendly composite multisoap base self-repairing bearing grease and a preparation method of the bearing grease. The bearing grease is prepared from composite base liquid, a composite calcium soap thickening agent, an oxidation and corrosion resistant additive, a tungsten disulfide extreme pressure additive, a metal deactivator, a polarization graphite wear resistant additive, a self-repairing additive and a structure improving agent. According to the bearing grease provided by the invention, an additive containing non-heavy metal elements is used to replace the originally used additive containing heavy metal elements. Because base liquid, a thickening agent and an additive are all optimized, the bearing grease provided by the invention is more excellent in combination property and highlighted in abrasion resistance, maintains an excellent level in extreme pressure property, can fully meet the requirements of the bit bearing extreme pressure, the high temperature, a deep well with high temperature, the high-impact load and the abrasion resistance, meanwhile, can effectively supplement the defect that silver coating is not sufficiently brushed onthe bearing axial diameter plane, and acts a function of repairing an abrasion resistant layer on a metal seal and a rubber seal of a bit bearing, so that the service life of the bearing is prolongedat a maximum level.

Owner:KINGDREAM PLC CO +2

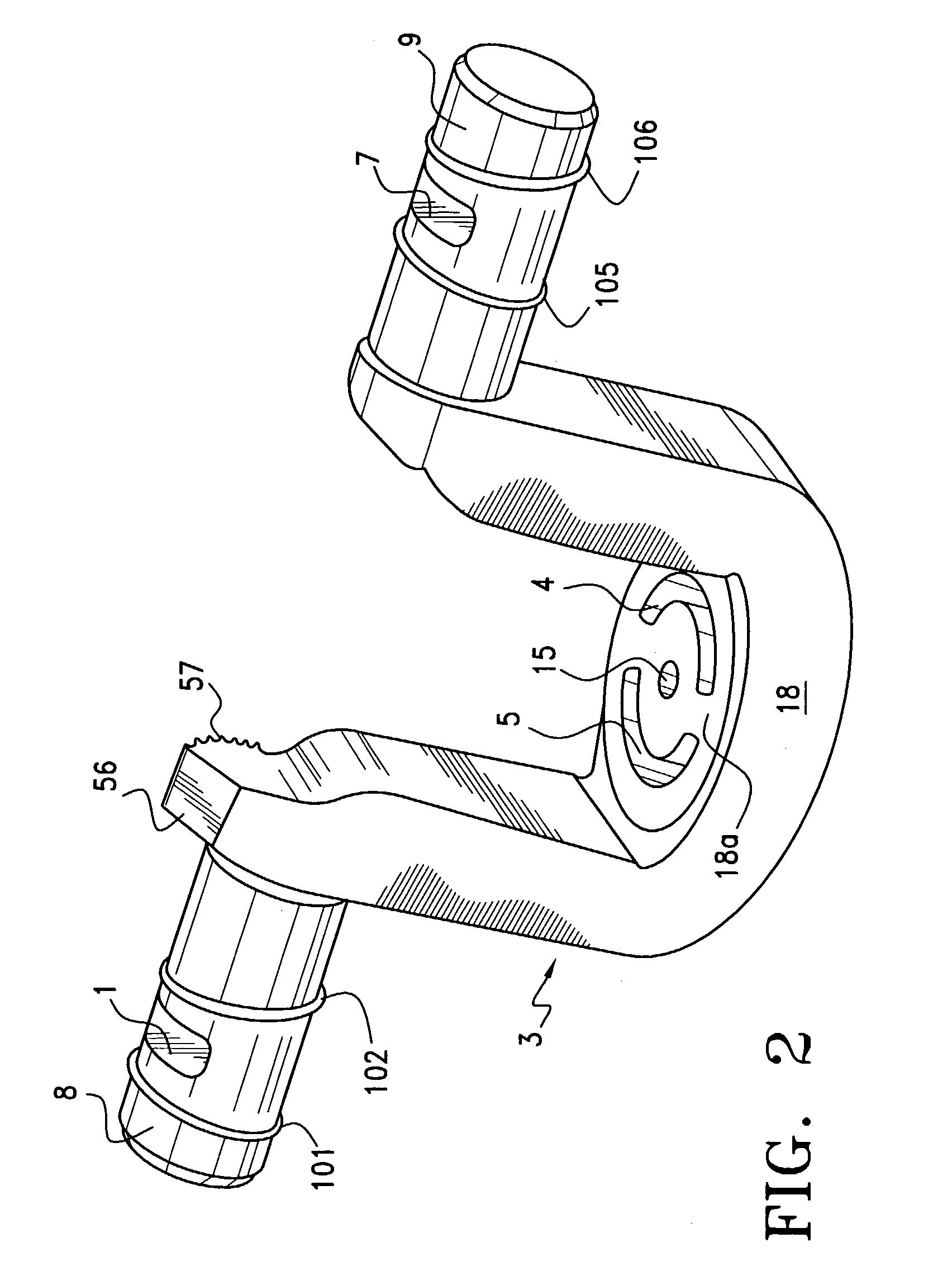

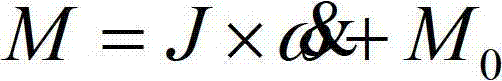

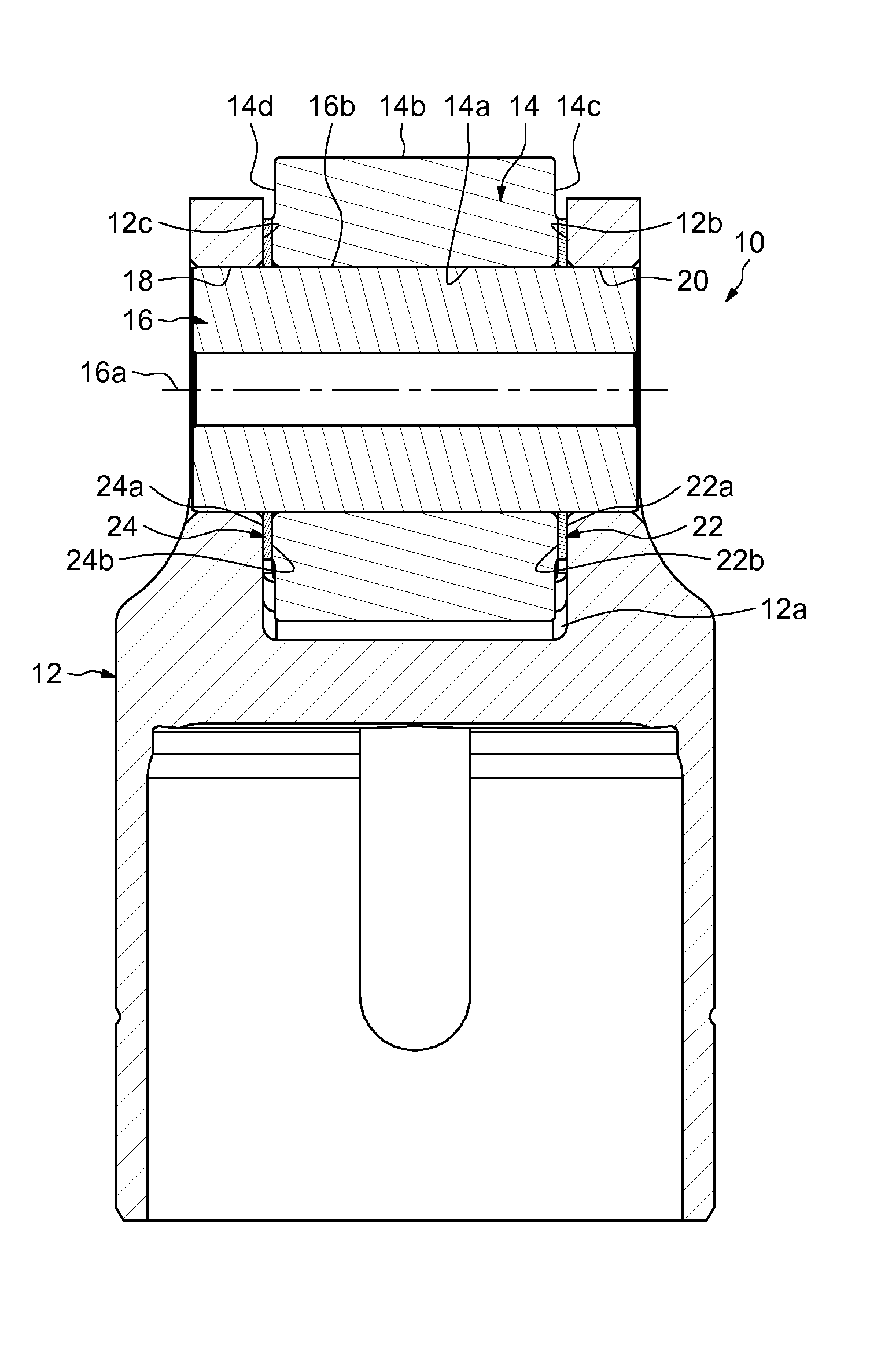

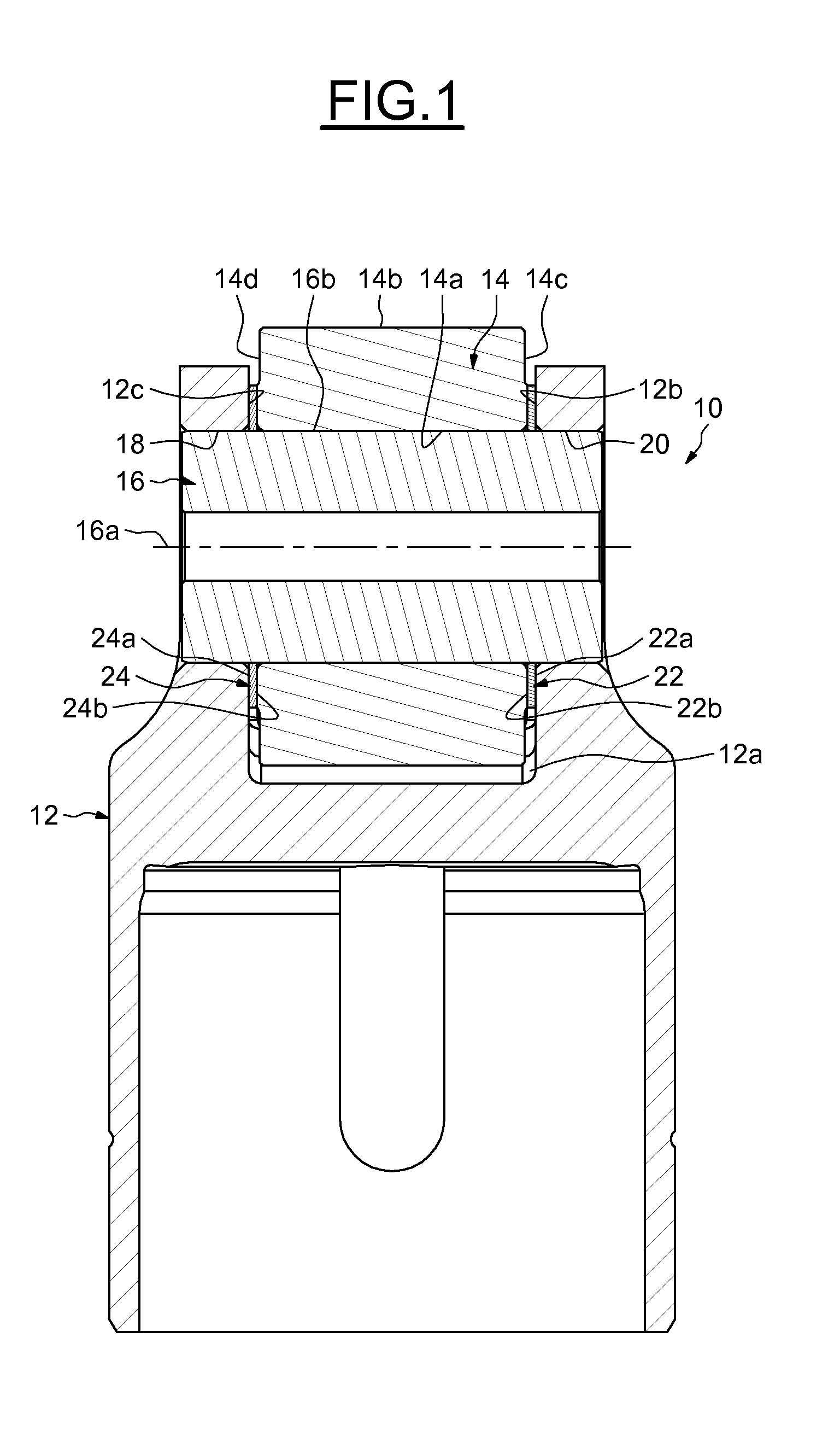

Torque limiting mechanism

ActiveUS8105171B2Reduce frictionReduce frictional torqueMechanical actuated clutchesSlip couplingAxial thrustCam

A high-precision torque limiting mechanism capable of limiting an output torque to a magnitude of not more than a prescribed value, as well as to reduce a frictional torque produced upon occurrence of a slip. To accomplish this object, a ball ramp section (13) is attached to a slip clutch section (3) for reducing friction between friction plates (31) and (32) forming the slip clutch section (3) and limiting a torque to be transmitted by utilizing an axial thrust produced at the ball ramp section (13) in accordance with the magnitude of an input torque. The precision with which the torque to be transmitted is limited is enhanced by making improvements to the shape of an internal side surface of a recess (G) formed in each of cam elements (131) and (132) of the ball ramp section (13).

Owner:SHIMADZU CORP

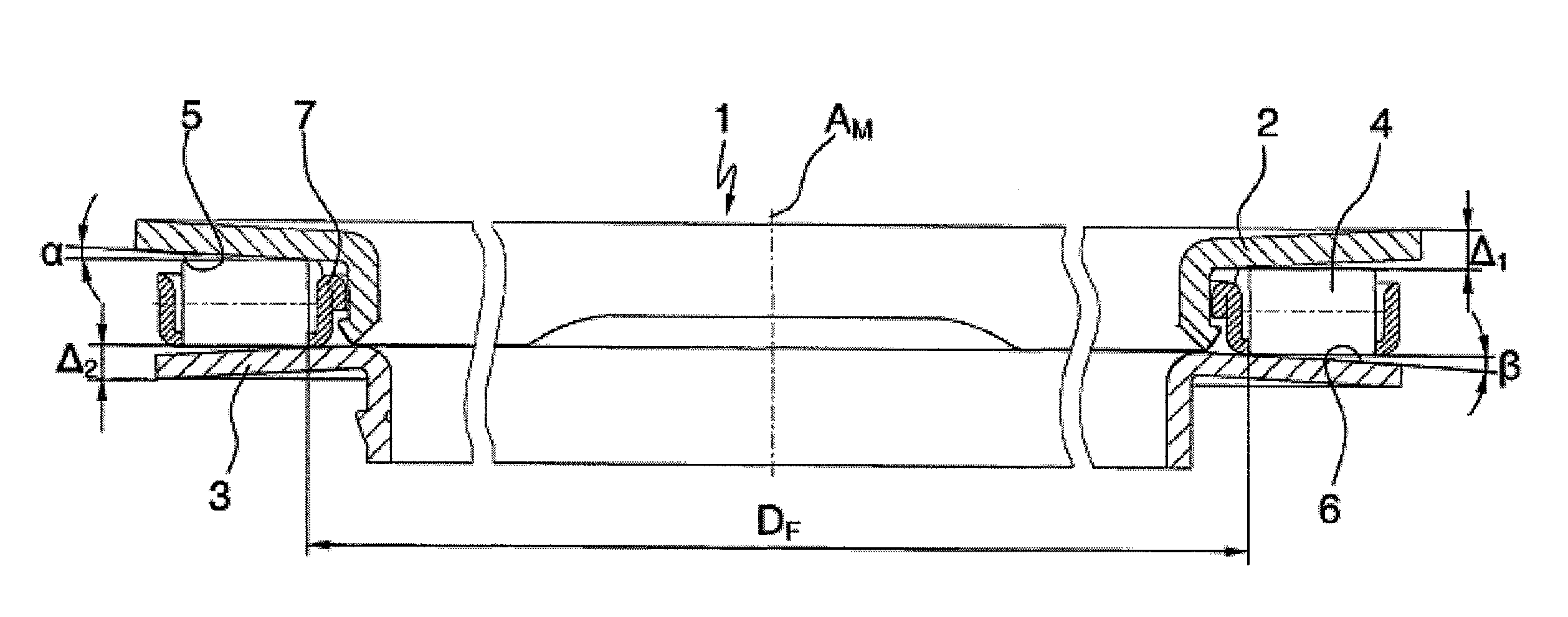

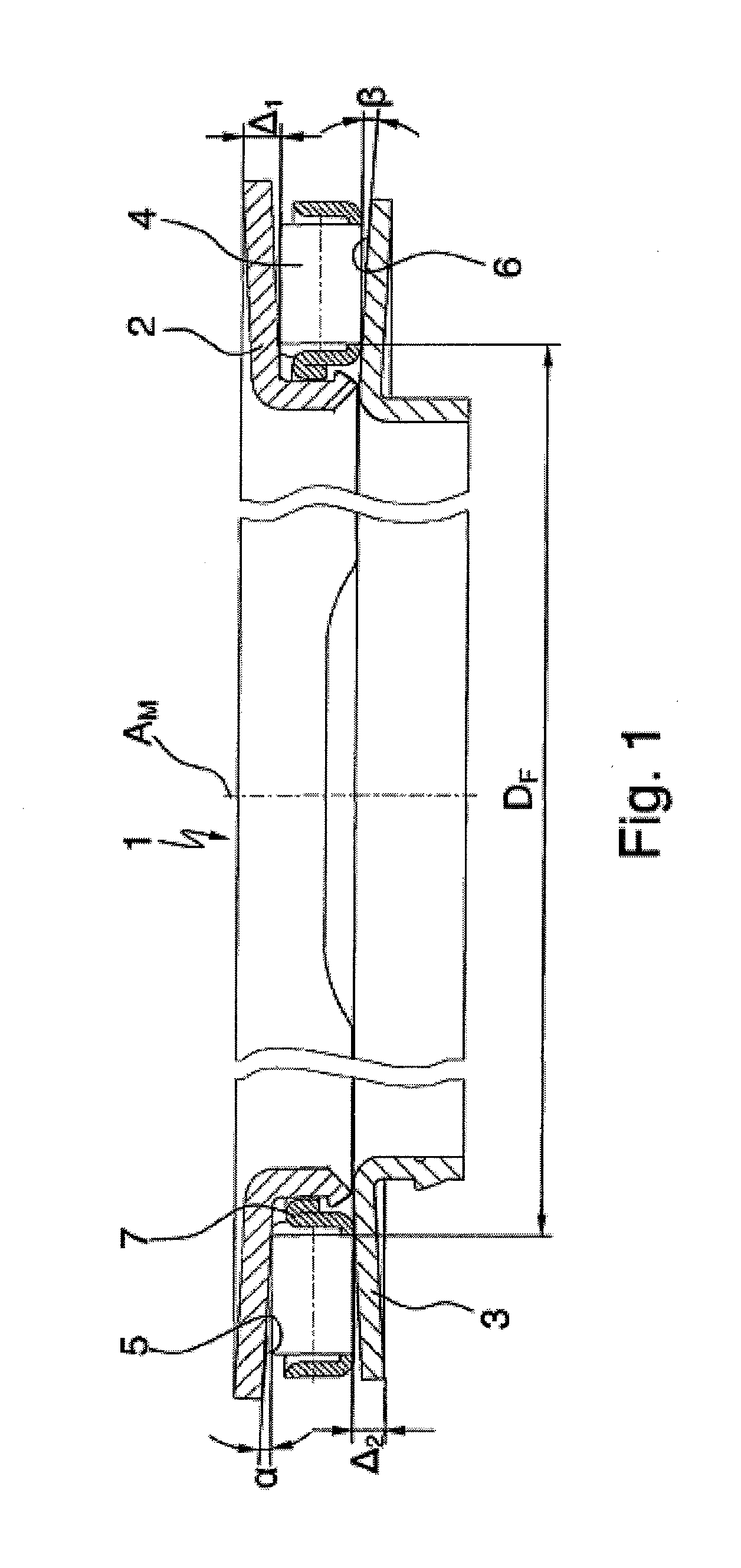

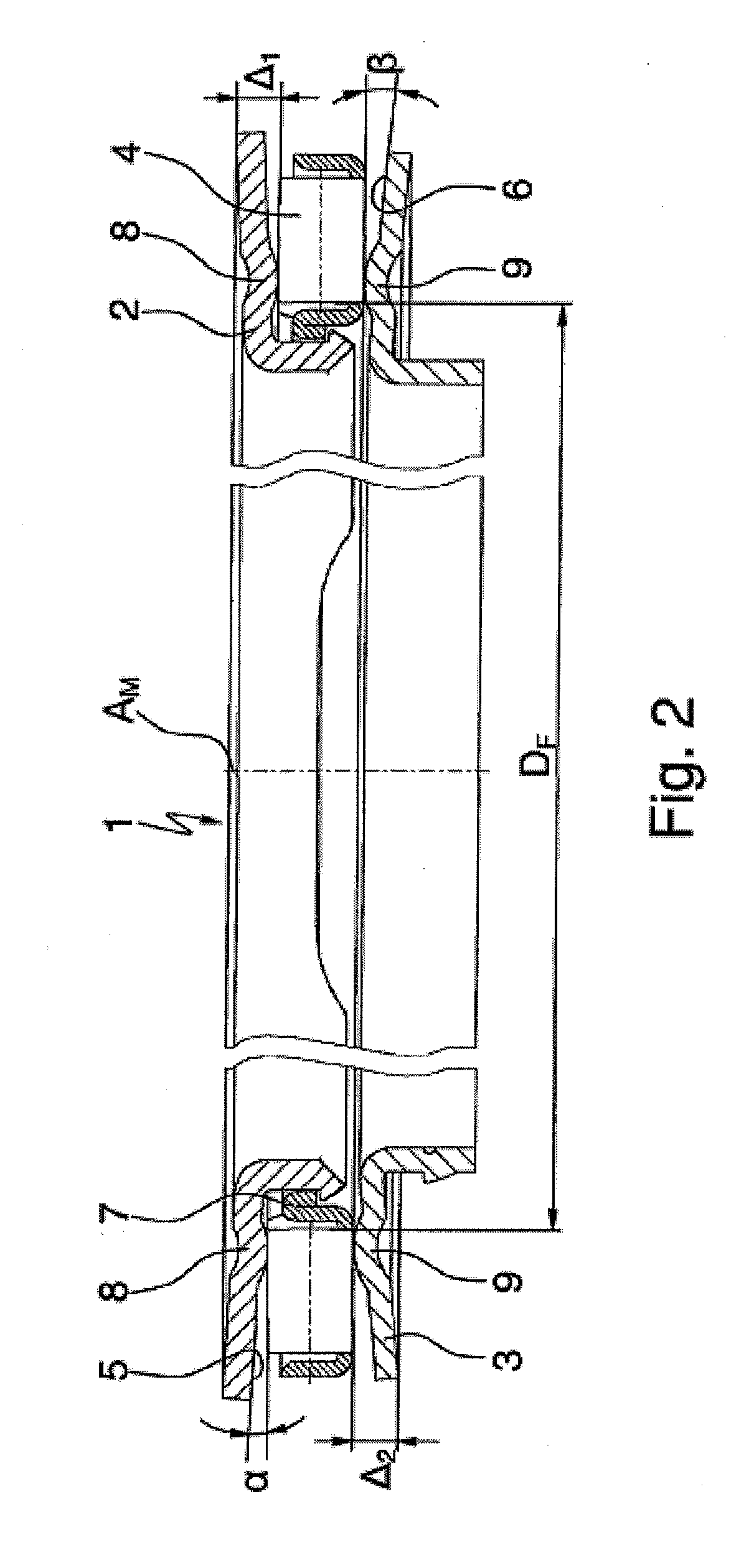

Axial Anti-friction bearing, in particular axial needle bearing

The invention concerns an axial roller bearing (1), in particular an axial needle bearing, consisting essentially of a first annular bearing disk (2) and a second annular bearing disk (3) that are each made of a thin-walled sheet steel and are arranged at a distance from one another on a common center axis (AM), and of a plurality of rolling elements (4) arranged next to one another that roll between the axial inner sides—implemented as races (5, 6)—of the two bearing disks (2, 3) and that are held at uniform distances from one another by a bearing cage (7). According to the invention, the bearing disks (2, 3) of the axial roller bearing (1) are implemented as disk springs that deflect as a function of load and have races (5, 6) positioned at an angle, and are arranged relative to one another such that the rolling elements (4) have low-friction point contact in the unloaded state of the axial roller bearing (1) and only have load-bearing line contact with the races (5, 6) in the fully loaded state of the axial roller bearing (1).

Owner:SCHAEFFLER TECH AG & CO KG

High-performance multi-channel rotary joint for water

The invention discloses a high-performance multi-channel rotary joint for water. A two-stage non-contact sealing mode is adopted by the joint, the first stage of sealing is clearance sealing, and the second stage of sealing is lip sealing. The clearance of the first stage of clearance sealing refers to the clearance between a floating ring and a rotary shaft, part of a water medium enters the micro clearance between the rotary shaft and the floating ring via a throttling hole and forms a fluid film, the fluid film has the hydrostatic effect and the hydrodynamic effect at the same time, the fluid hydrostatic effect plays a leading role under a low speed, and the fluid hydrodynamic effect plays the leading role under a high speed. Lip sealing, as the second stage of sealing, is used for sealing a small quantity of water medium leaked at the first stage of sealing, as for a sealing mechanism of lip sealing, a continuous fluid lubricating film is formed on an interface between a sealing lip and the rotary shaft from the micro perspective, the sealing lip and the rotary shaft are separated from each other by the fluid film, and medium leakage is restrained through a dynamic pressure pumping effect. The high-performance multi-channel rotary joint for water can effectively seal high-pressure media, adapt to an extremely high operation rotation speed and reduces the probability of a wear-out failure.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

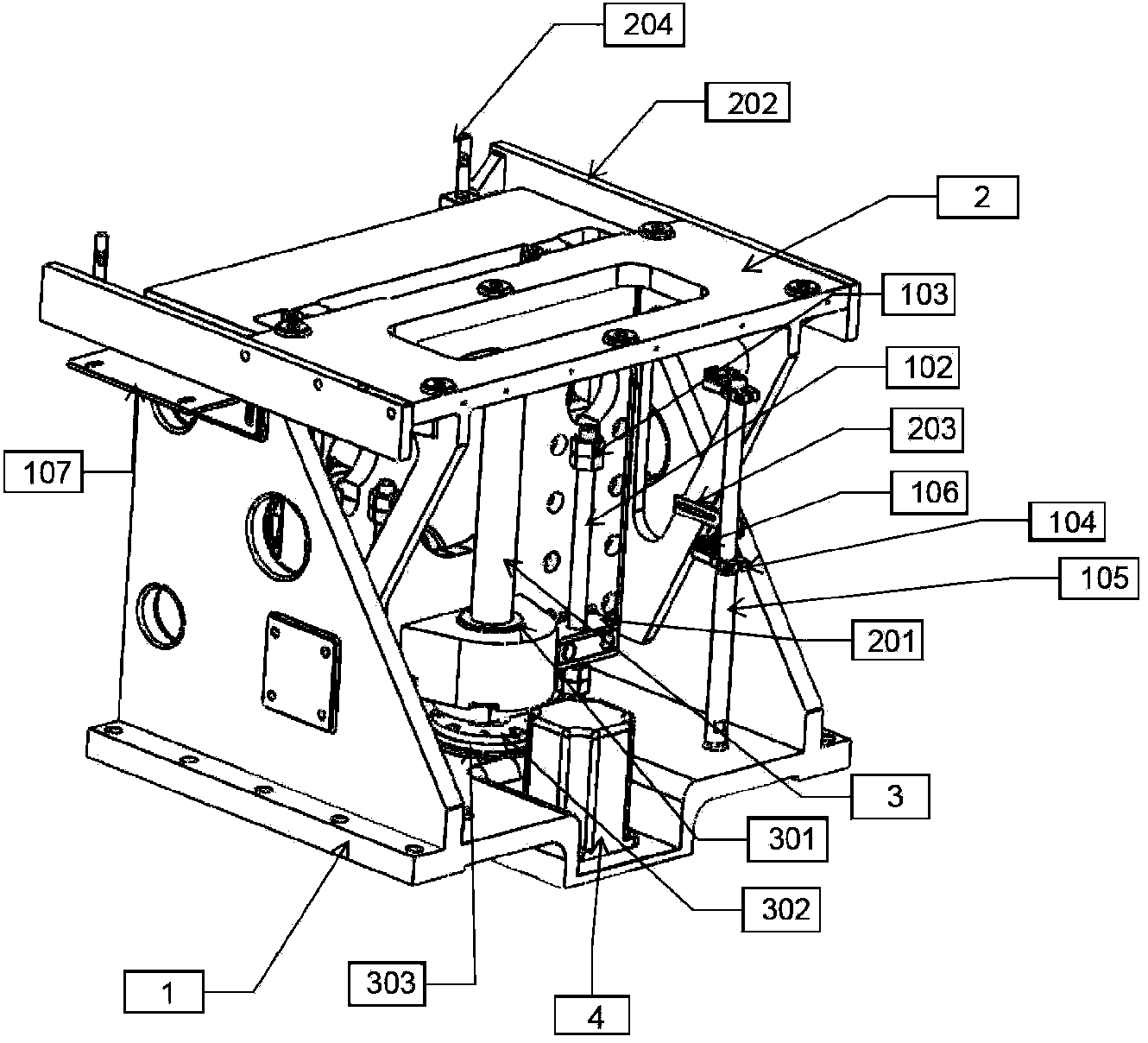

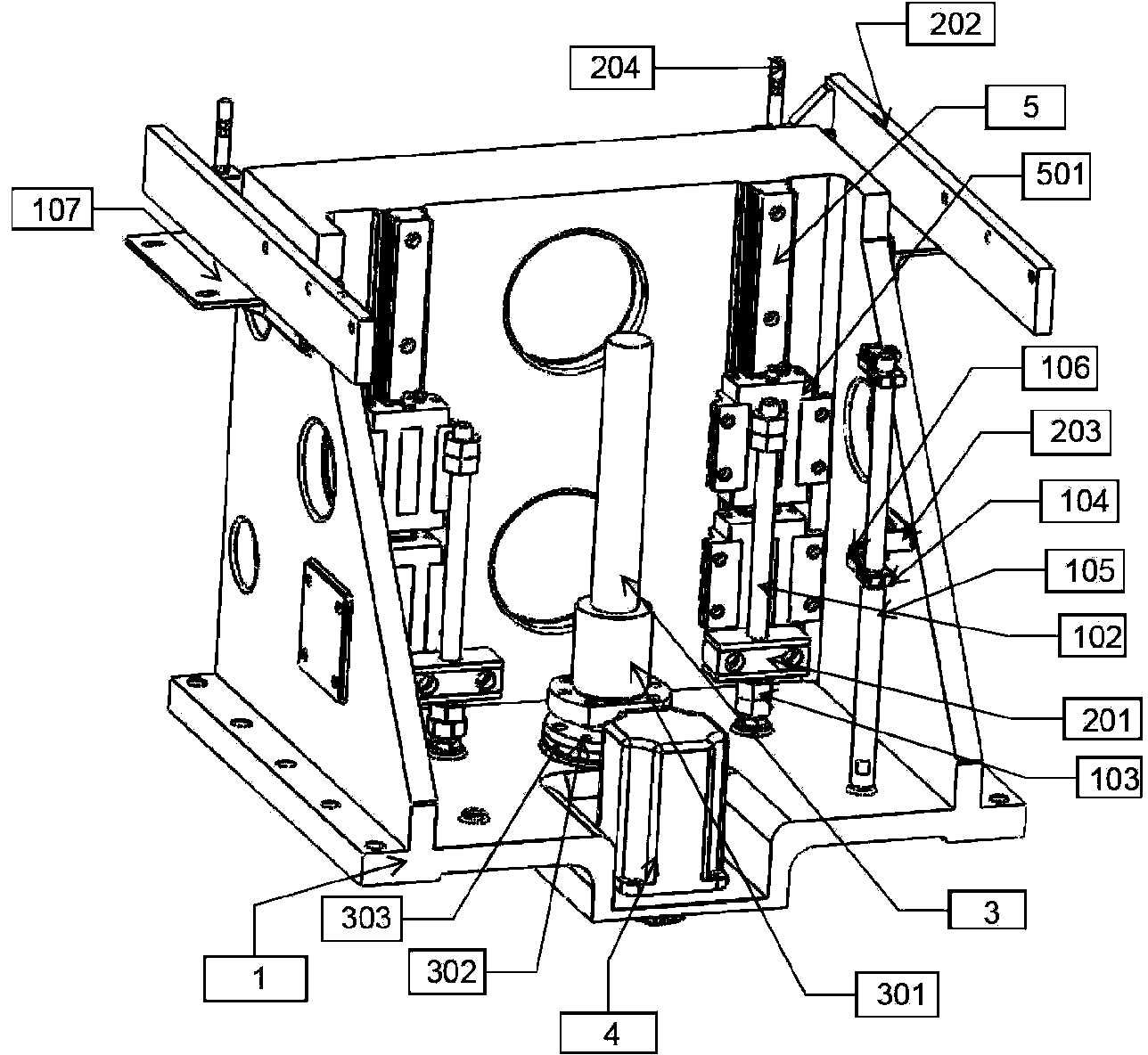

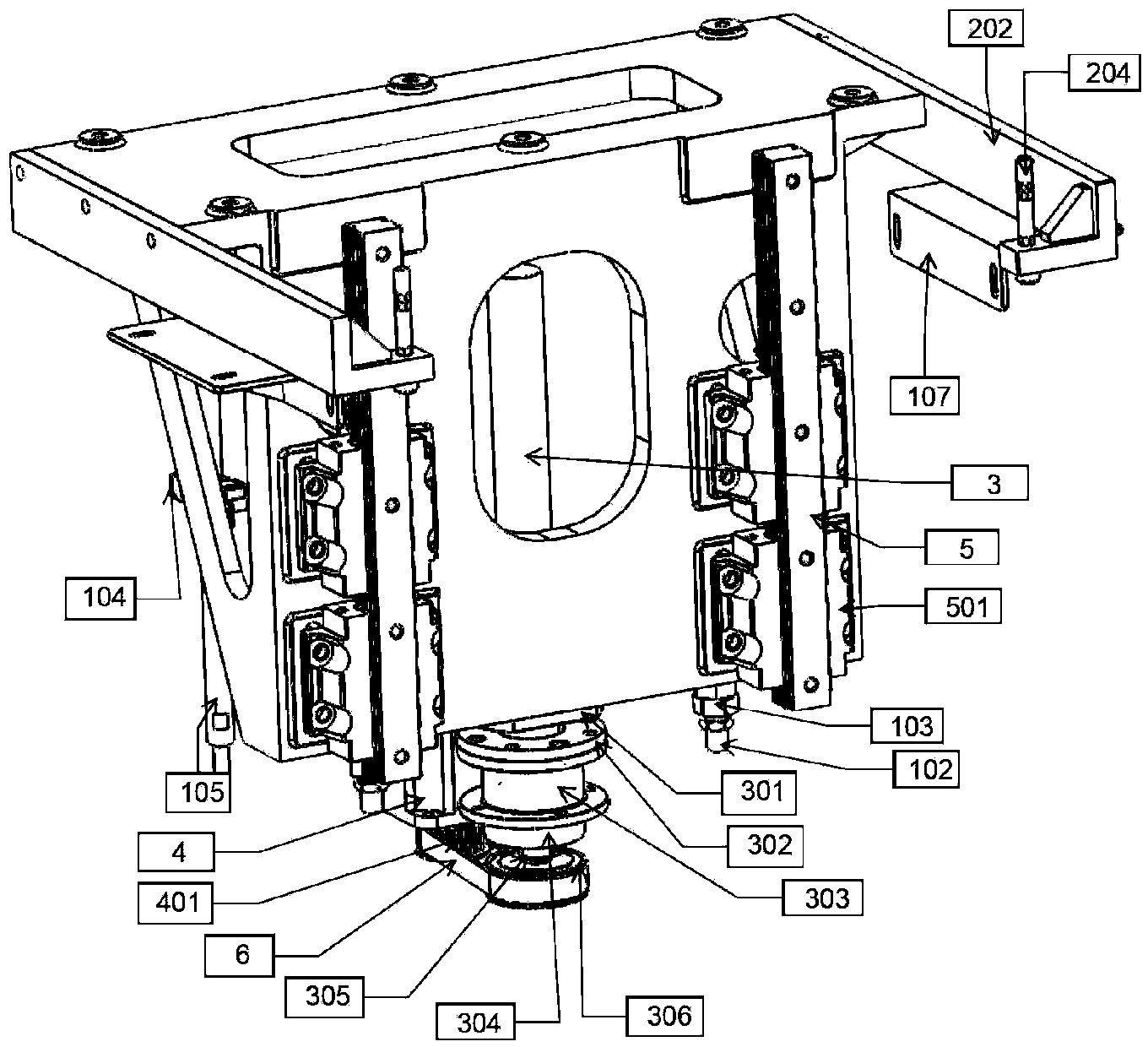

Closed-loop control high-precision positioning lifting system of full-automatic solder paste printer

ActiveCN103862843AImprove stabilityReduce frictional torqueScreen printersFriction torqueClosed loop

The invention discloses a closed-loop control high-precision positioning lifting system of a full-automatic solder paste printer. The closed-loop control high-precision positioning lifting system comprises a support with a power drive device, and a driving synchronous pulley is arranged on the power drive device. A guide device is arranged on the support, and a lifting rack is arranged on the guide device. A power transmission device is arranged on the support, and a driven synchronous pulley is arranged on the power transmission device. An electronic induction device and a stroke buffer device are assembled on the support. According to the scheme, precision lead screws are driven by a precision servo motor to rotate, and then the lifting rack can precisely move and can be precisely positioned along a linear guide rail; the problems that a lifting rack with large inertia is low in control and positioning precision and response speed, poor in stability and the like are solved. According to the scheme, due to the adoption of a ball nut lead screw pair, the transmission friction torque moment is small, efficiency is high, motion is smooth, and precision is high; the structural strength of the lifting rack and the support is greatly improved; a linear guide rail sliding block is adopted in the guide device, smoothness is high, and errors are small.

Owner:SHENZHEN GRANDSEED TECH DEV

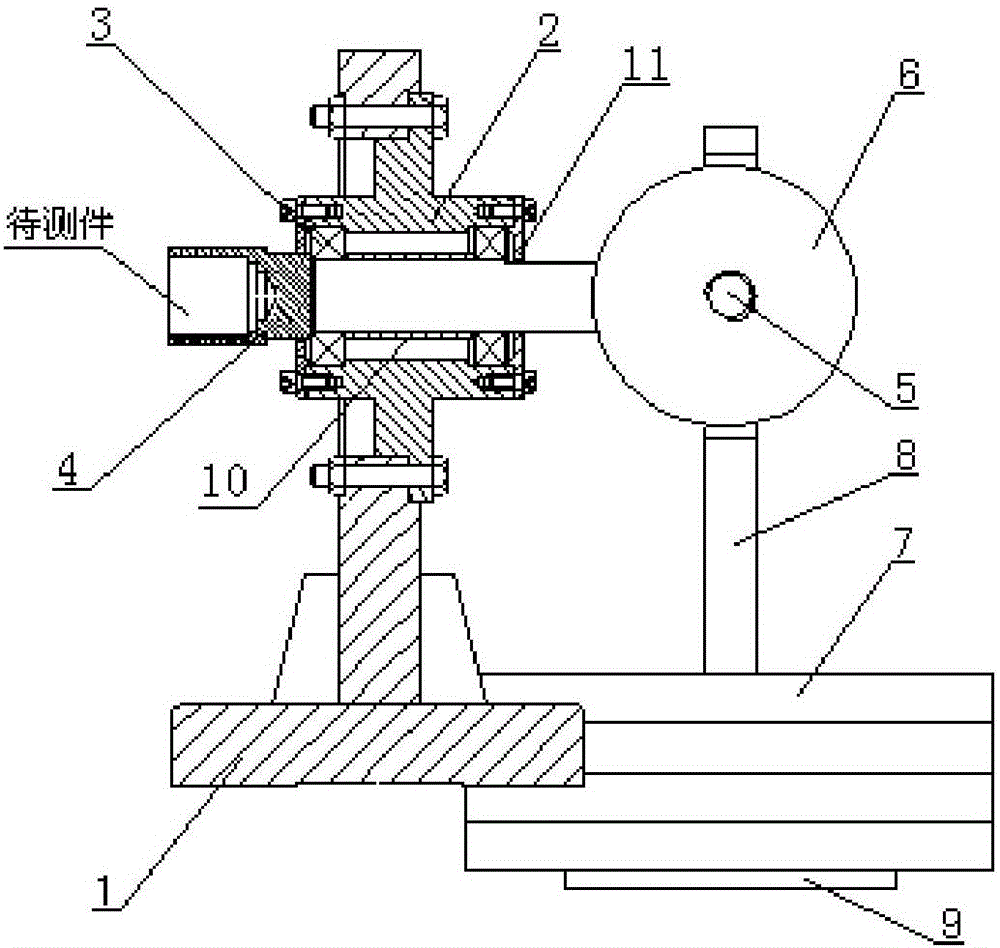

Field torque calibration device

InactiveCN106197843AReduce frictional torqueOvercoming the Difficulties of Pure Torque LoadingForce/torque/work measurement apparatus calibration/testingFriction torqueControl theory

The invention discloses a field torque calibration device. The field torque calibration device comprises a support, a supporting sleeve, bearings, a positioning shaft, a static correction beam, a balance disc and weights. The supporting sleeve used for installing the positioning shaft is arranged on the support, the positioning shaft and the bearings are installed in the supporting sleeve in a matched mode, one end of the positioning shaft is connected with a part to be measured, and the other end of the positioning shaft is fixedly connected with the static correction beam; the weights are hung at one end of the static correction beam, and the balance disc is installed at the other end of the static correction beam. According to the field torque calibration device, the two rows of rolling bearings are adopted as supporting of the positioning shaft, bending moment caused by self-weight of the weights is eliminated, friction moment of the supporting part is reduced, and the problem that pure torque loading can not be carried out on a large torque sensor is solved; the balance disc is installed at one end of the static correction beam, a circular arc structure is arranged at the other end of the static correction beam, and the problem that when the static correction beam is inclined, the length of a force arm is changed is solved; by adopting a thin steel strip to hang the weights, it is ensured that the action force arm of the gravity of the weights is located on the horizontal line all the time, system errors of the device are reduced, and the sensitivity of the device is improved.

Owner:BEIJING AEROSPACE PROPULSION INST

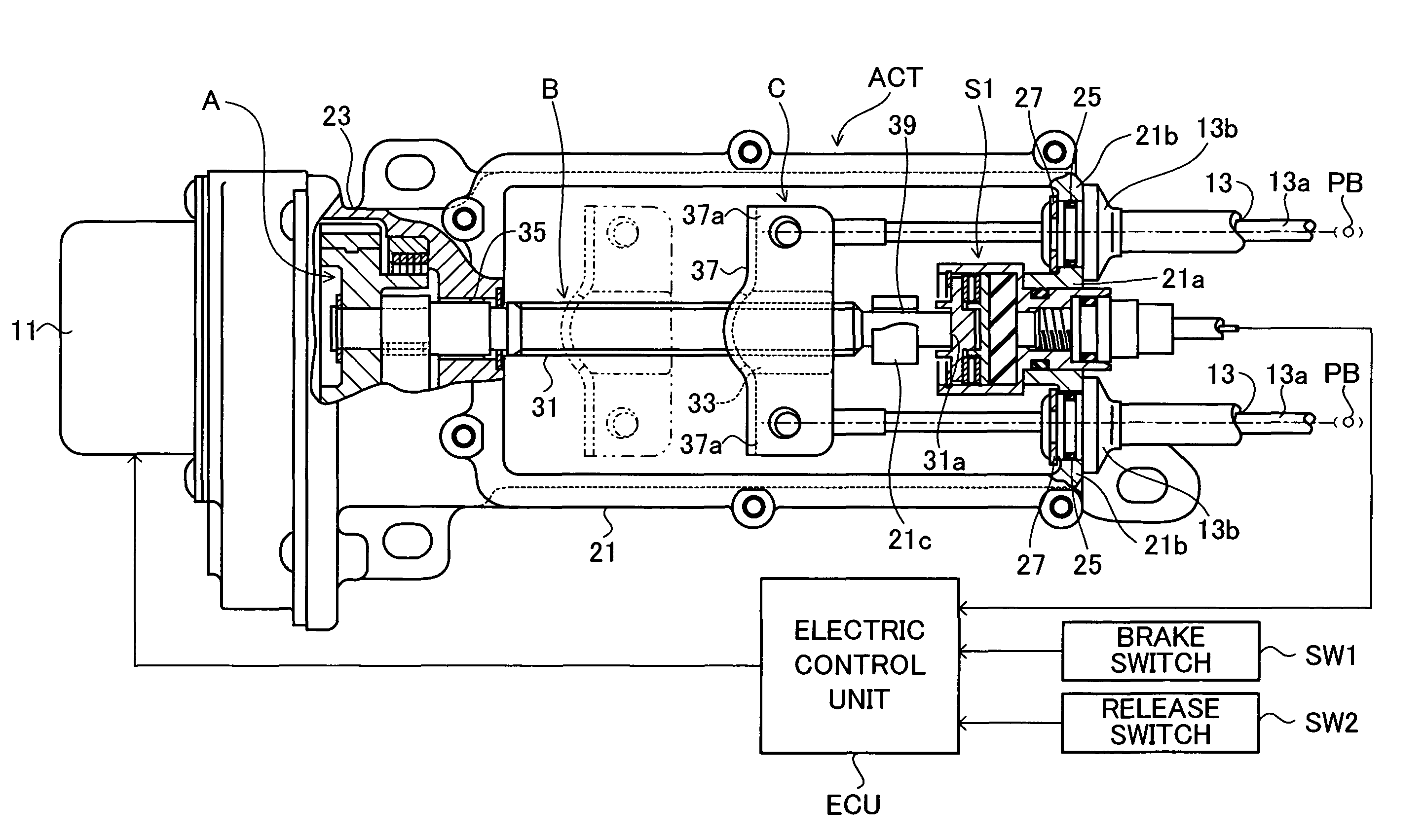

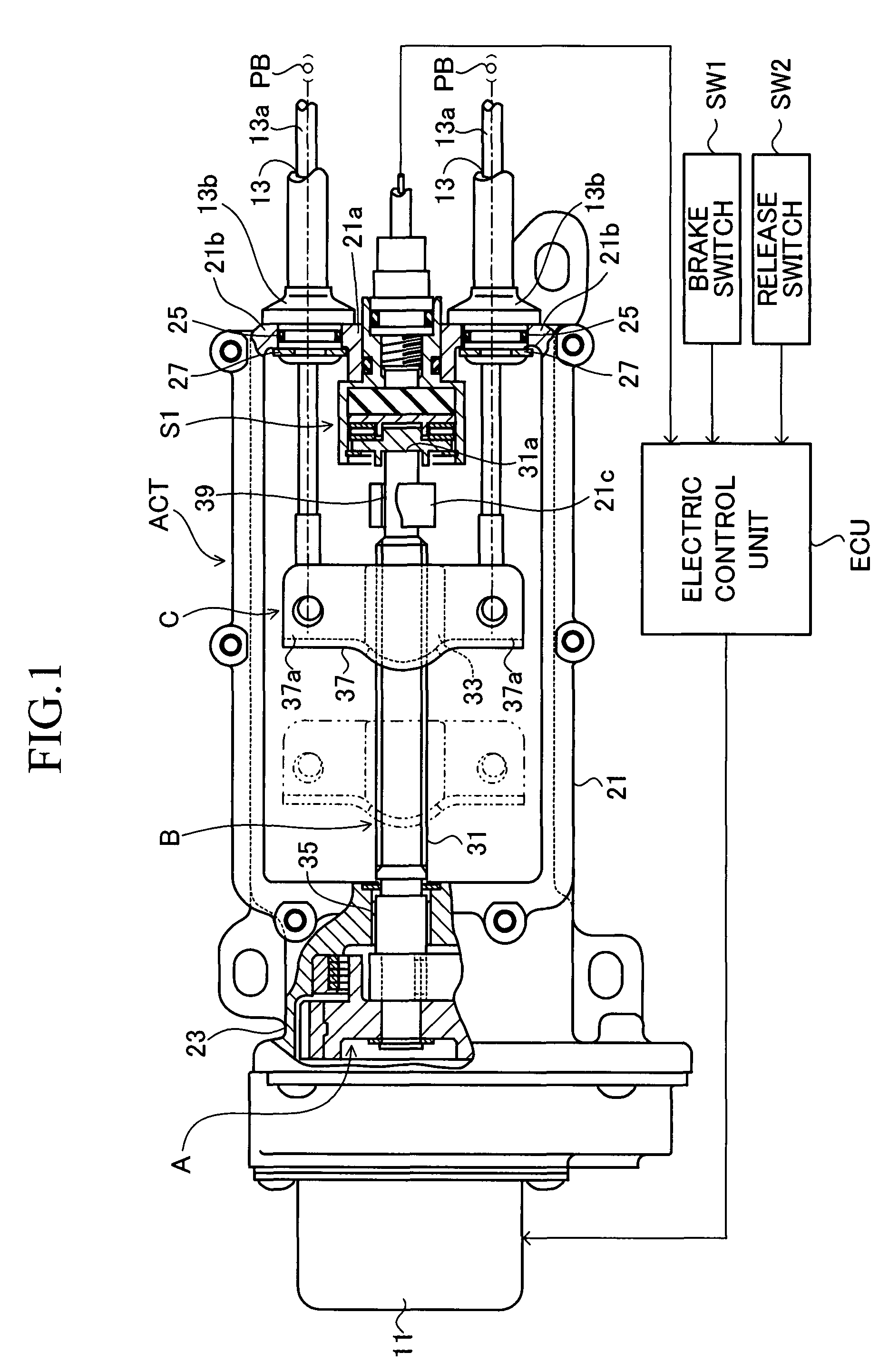

Motor-driven parking brake apparatus

InactiveUS7891468B2Small sizeReduce frictional torqueBraking action transmissionMechanically actuated brakesMotor driveParking brake

Owner:ADVICS CO LTD

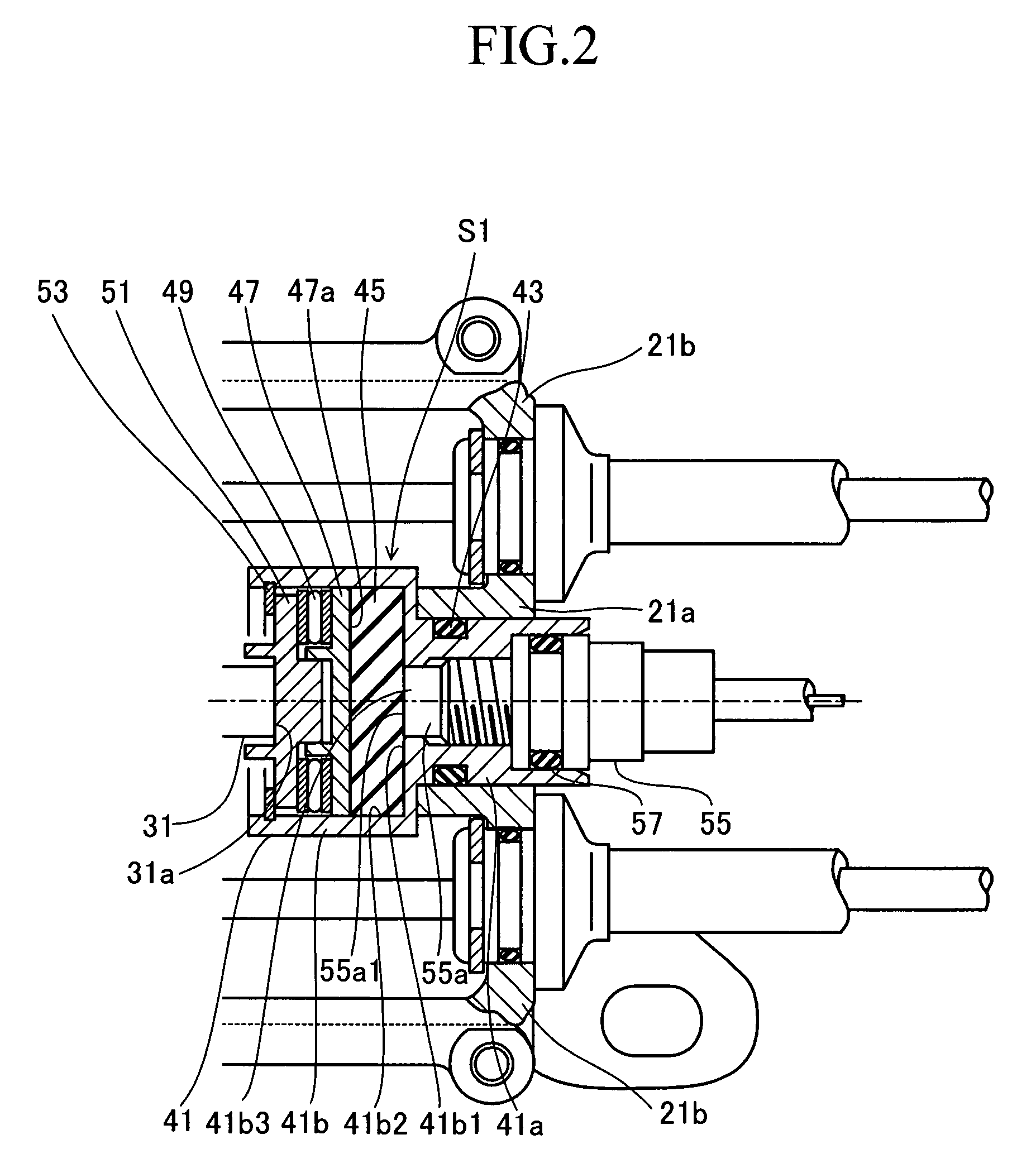

Slide bearing

InactiveCN102549281ASolution to short lifeLow thermal efficiencyShaftsBearing componentsEngineeringSliding contact

A slide bearing having a simple configuration and low friction torque. A slide bearing (1) for supporting heat rollers, such as a fixing roller and a pressing roller which are used for an image forming device, the slide bearing (1) comprising an outer ring (3) and an inner ring (2). Either the outer ring (3) or the inner ring (2) consists of resin, and the other consists of a sintered metal. The outer peripheral surface of the inner ring (2) is a convex surface, and the inner peripheral surface of the outer ring (3) is a concave surface corresponding to the convex surface. The outer ring (3) is bisected in the radial direction, and the inner ring (2) is sandwiched between the bisected halves of the outer ring (3). The inner peripheral surface of the outer ring (3) and the outer peripheral surface of the inner ring (2) are in sliding contact with each other.

Owner:NTN CORP

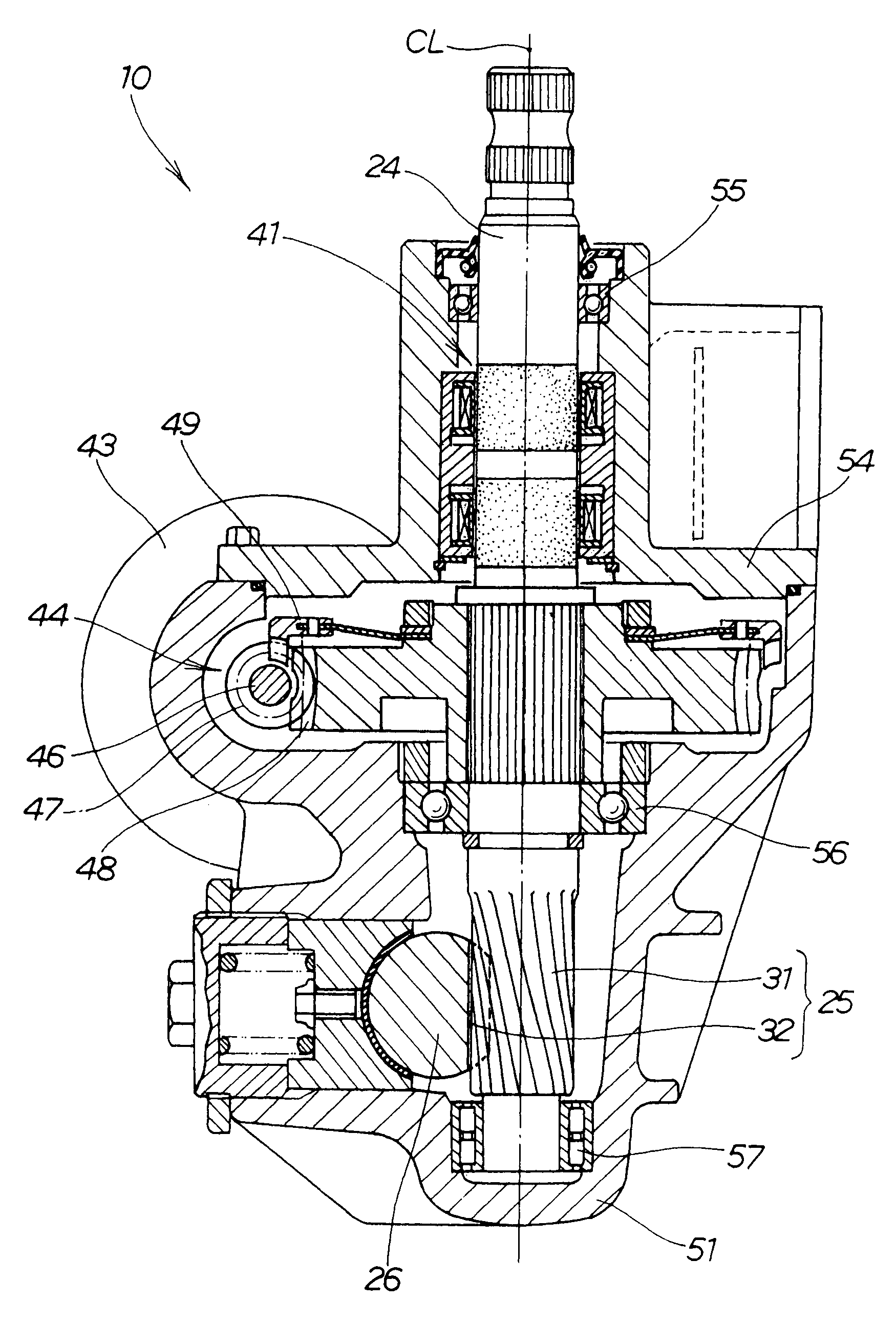

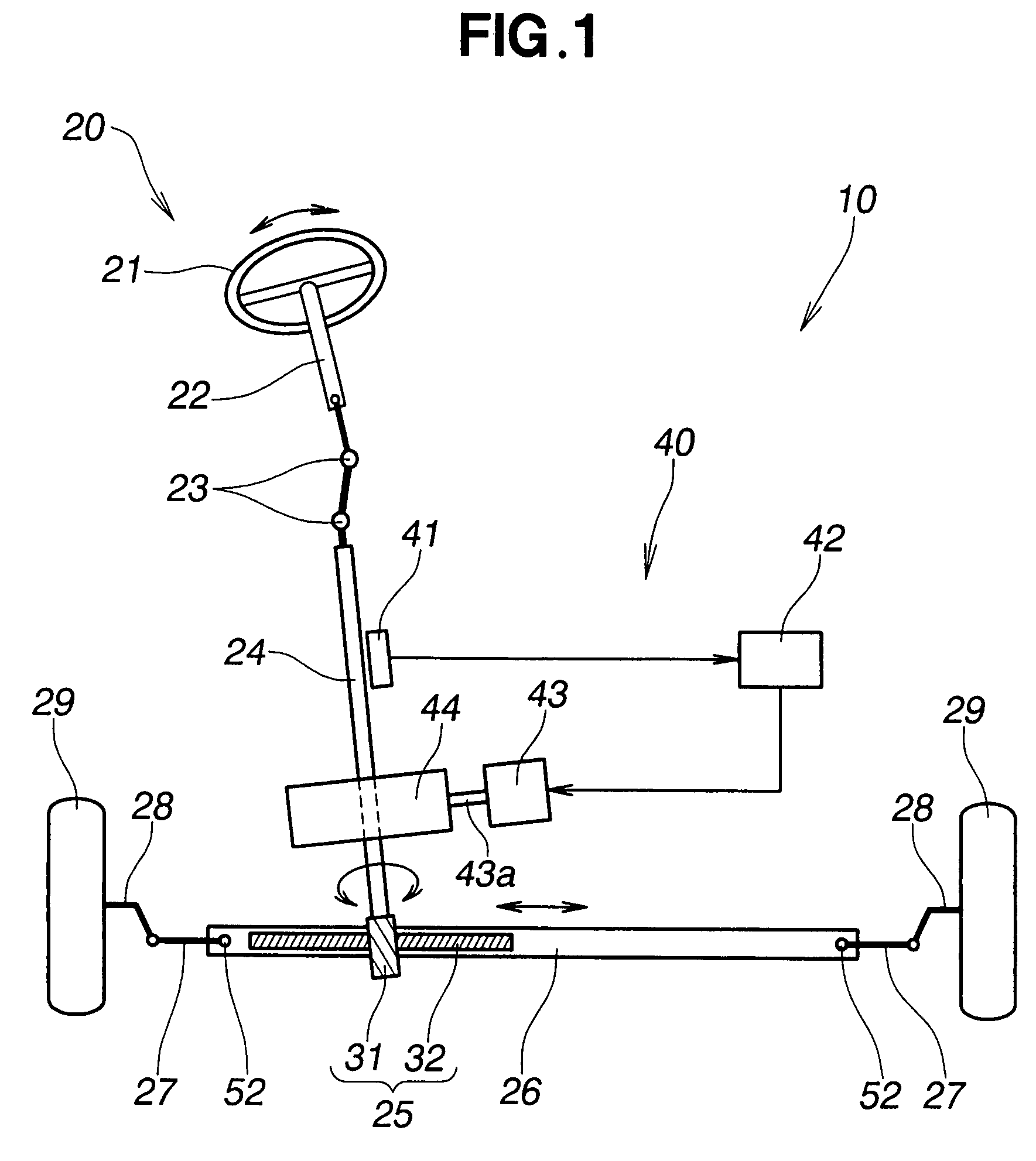

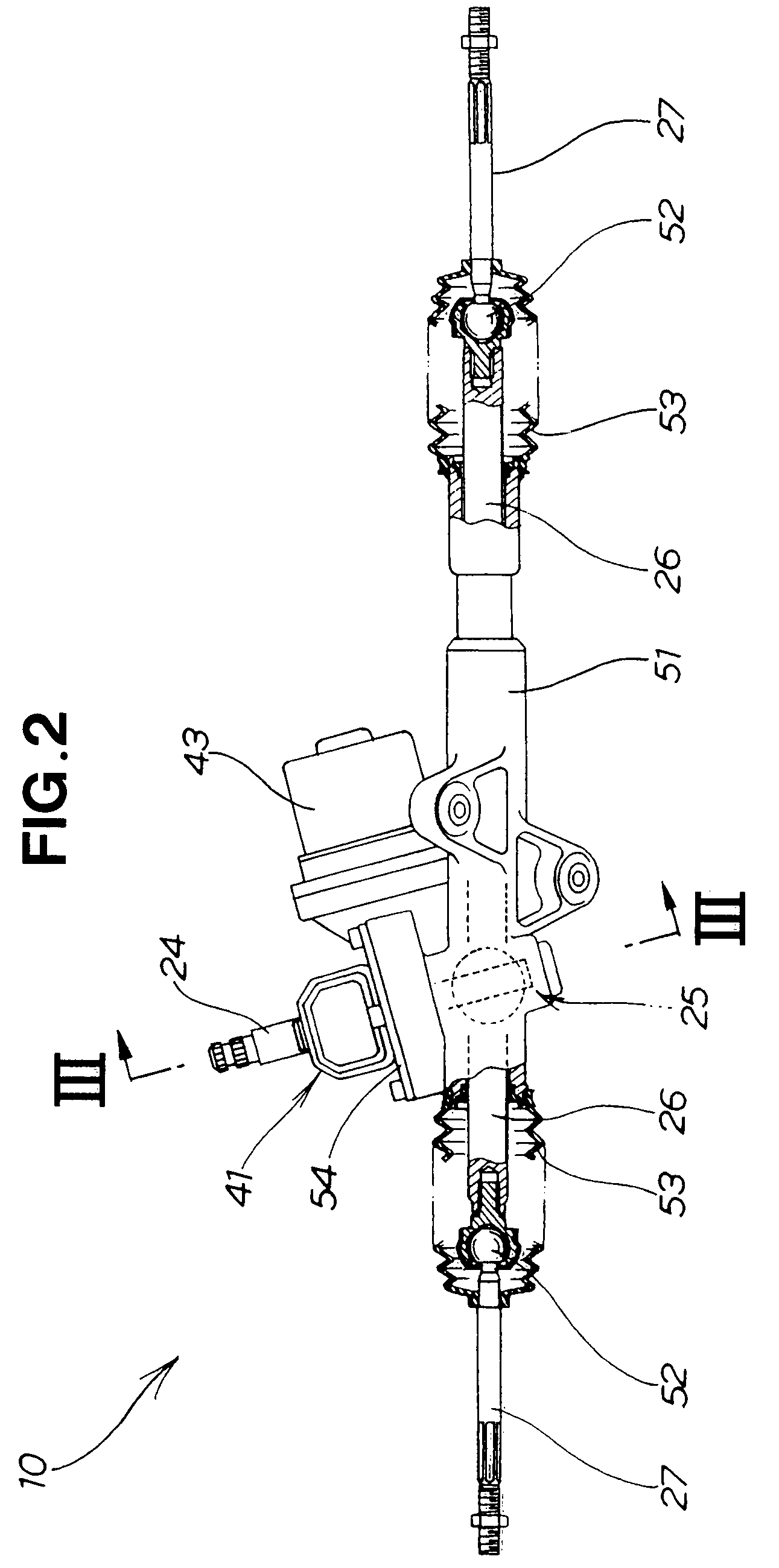

Electric power steering apparatus equipped with worm gear mechanism

InactiveUS7654167B2Reduce loadIncreased durabilityToothed gearingsPortable liftingElectric power steeringLine of action

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com