Large pulling resistance slidable ball and socket bearing

A technology of spherical hinge bearing and pullout resistance, which is applied to bridge parts, bridges, protective buildings/shelters, etc., can solve the problems of difficult positioning of pullout baffles, position deviation, stress concentration, etc., and achieve good Sliding effect, small frictional moment, and large pullout contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

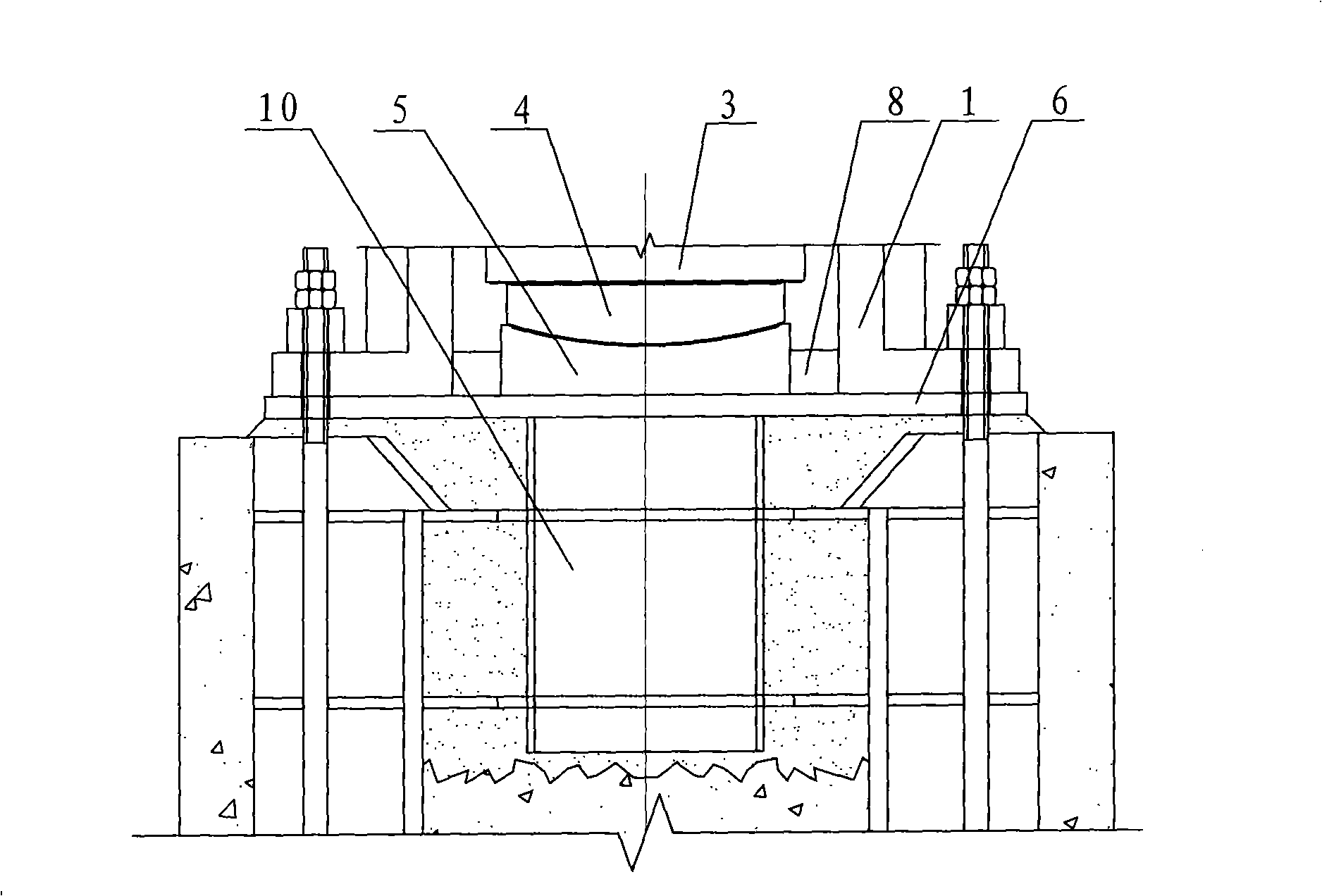

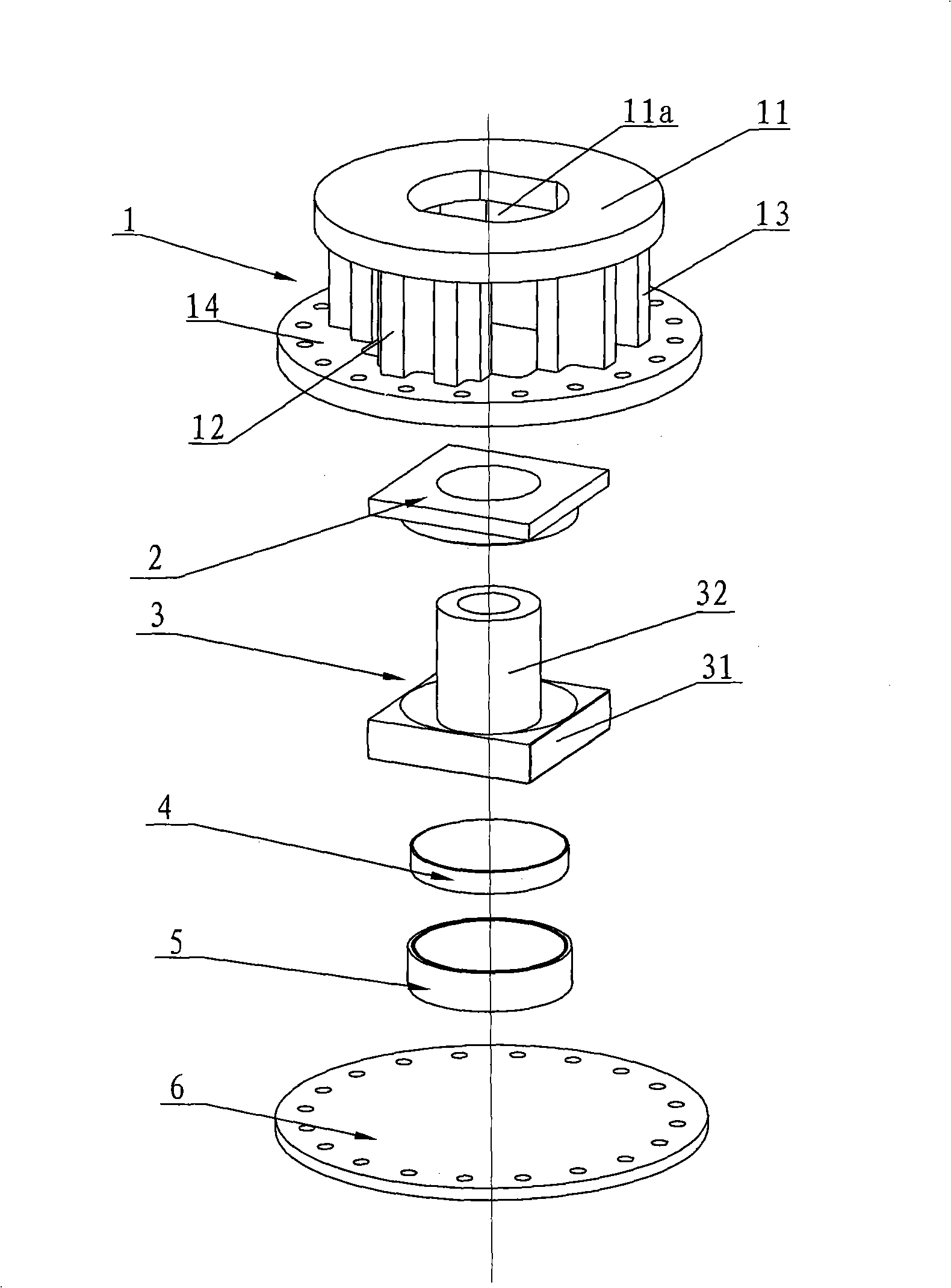

[0050] Such as Figure 1 to Figure 2 The slidable spherical hinge support with large pull-out force shown in 1 includes a support shell 1, a support bottom plate 6, a spherical hinge support structure, a force transmission part 3 and a pull-out resistance part 2, and the support shell 1, The centerlines of the support base plate 6, the spherical hinge support structure, the force transmission member 3 and the pull-out member 2 are all coincident, the support base plate 6 is located under the support shell 1 and is fixedly connected with it, and the support base plate 6 is used for connecting with The shear members 10 pre-embedded in the reinforced concrete are connected.

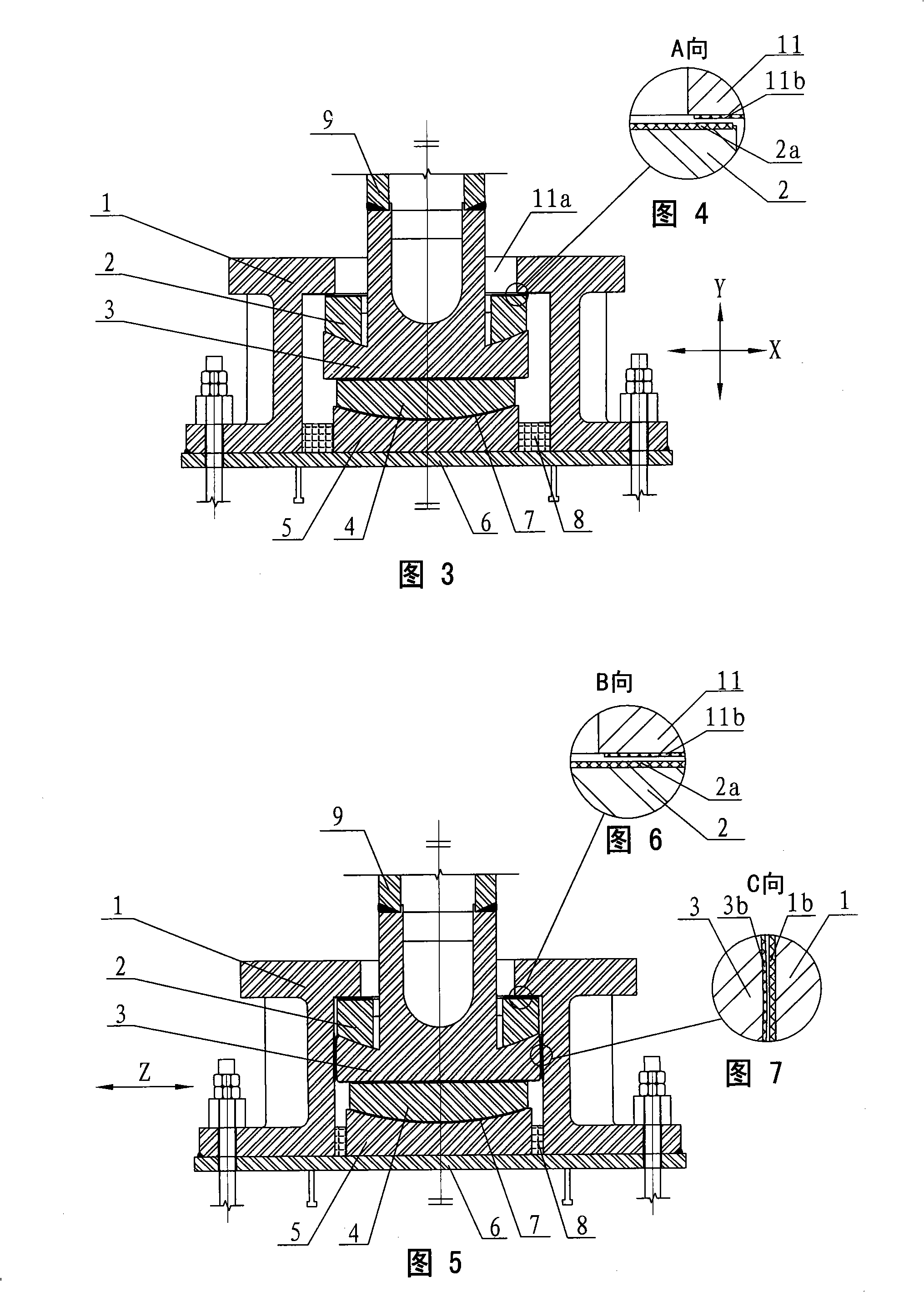

[0051] The support housing 1 is a structural unit formed by integral casting of the base and the housing top plate 11, which is reliable under force. The base is a cylindrical base, which is composed of a hollow cylinder and an annular base plate 14 located on the bottom of the cylinder. The shell top plate...

Embodiment 2

[0058] Such as Figure 22 , Figure 23 The large pull-out force slidable spherical hinge bearing shown is different from the first embodiment in that the outer edge contour surface of the force transmission member base 31 of this embodiment and the inner wall surface of the bearing housing 1 are on the left and right sides. There is a sliding gap for the movement of the force transmission member 3 in the direction (X direction) and the front and rear direction (Z direction). force needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com