Field torque calibration device

A calibration device and on-site technology, applied in the direction of measuring devices, force/torque/power measuring instrument calibration/testing, instruments, etc., can solve problems that affect the accuracy of calibration results, cannot achieve pure torque loading, and sensor output shaft bending , to achieve the effect of easy maintenance and replacement, wide application range and reduction of system errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

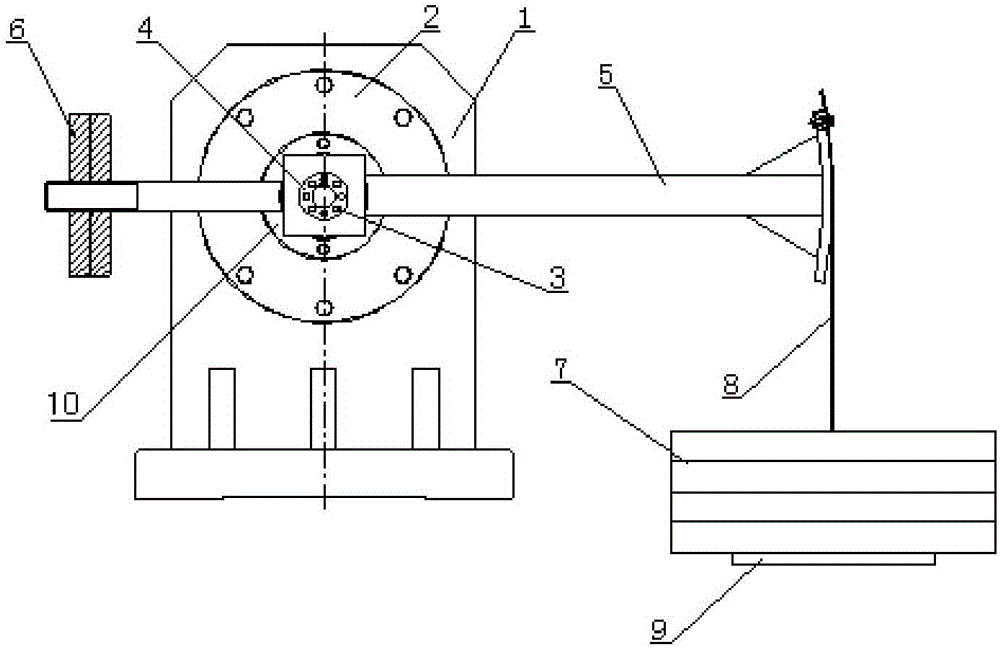

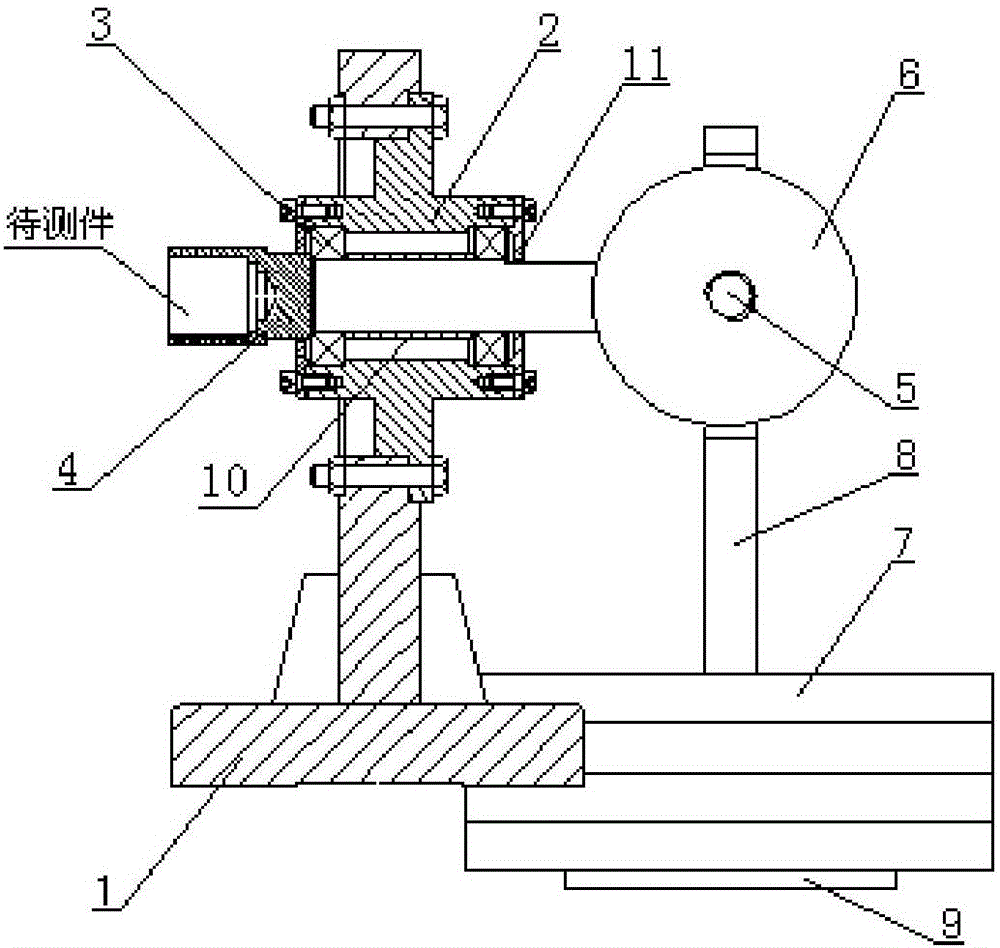

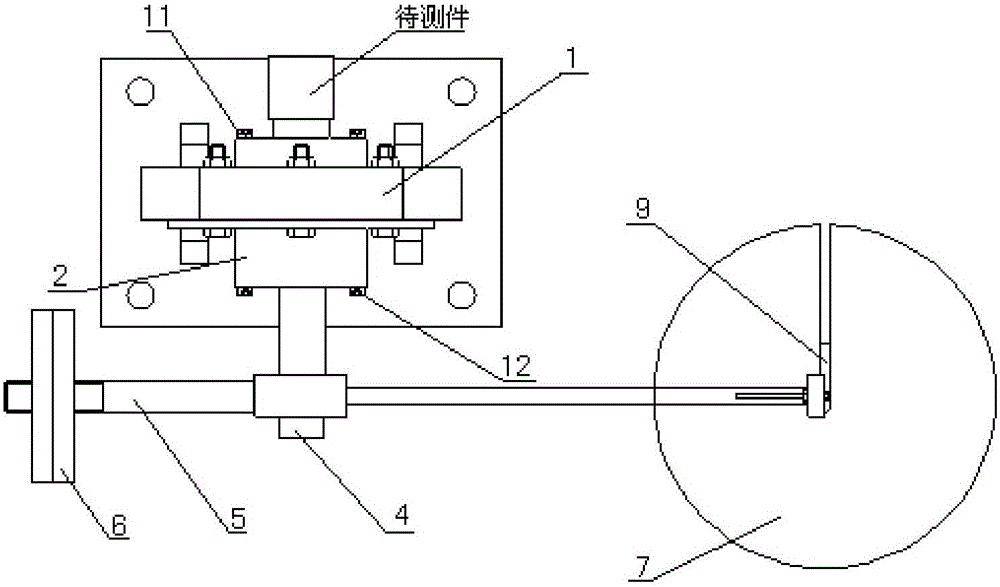

[0028] like Figure 1-3 As shown, an on-site torque calibration device includes a support 1, a support sleeve 2, a bearing 3, a positioning shaft 4, a static calibration beam 5, a balance plate 6 and a weight 7; 4, the supporting sleeve 2, the positioning shaft 4 is matched with the bearing 3 and installed in the supporting sleeve 2, one end of the positioning shaft 4 is connected with the workpiece to be tested, and the other end of the positioning shaft 4 is fixedly connected with the static calibration beam 5, and the static calibration beam 5 A weight 7 is suspended at one end, and a balance plate 6 for adjusting balance is installed at the other end of the static calibration beam 5 .

[0029] The support 1 adopts a cubic structure, and the middle part of the support 1 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com