Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

111results about How to "Reasonable use of resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

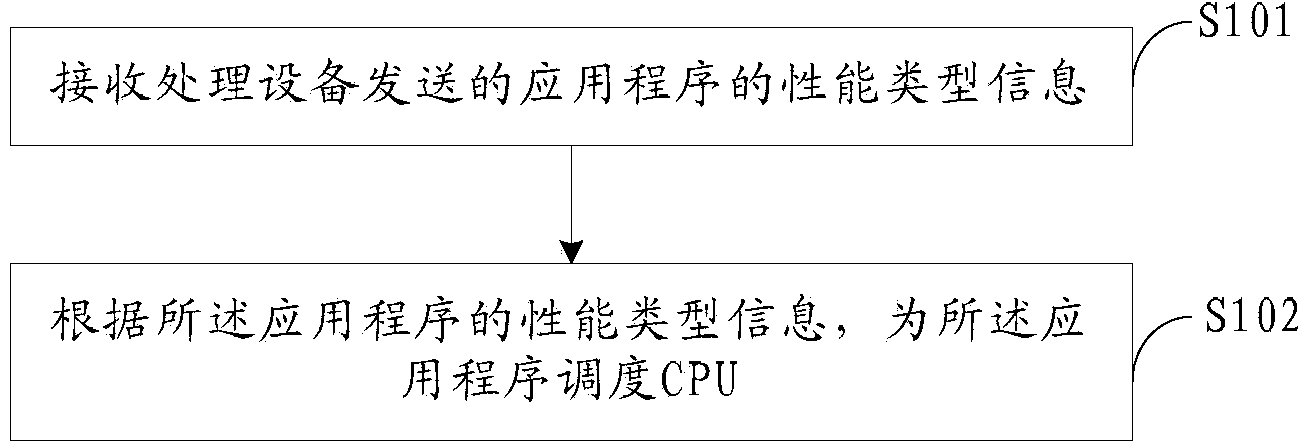

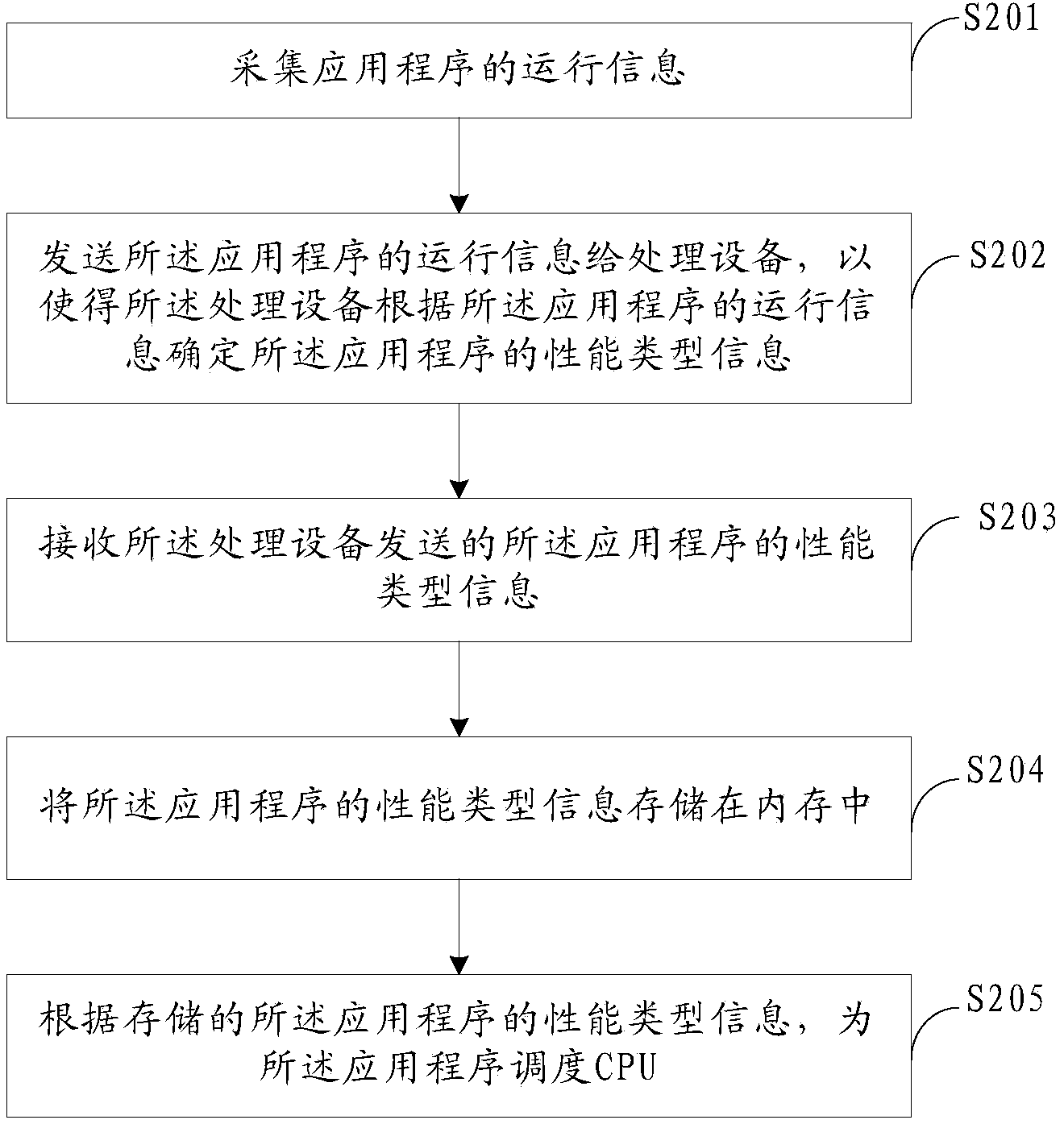

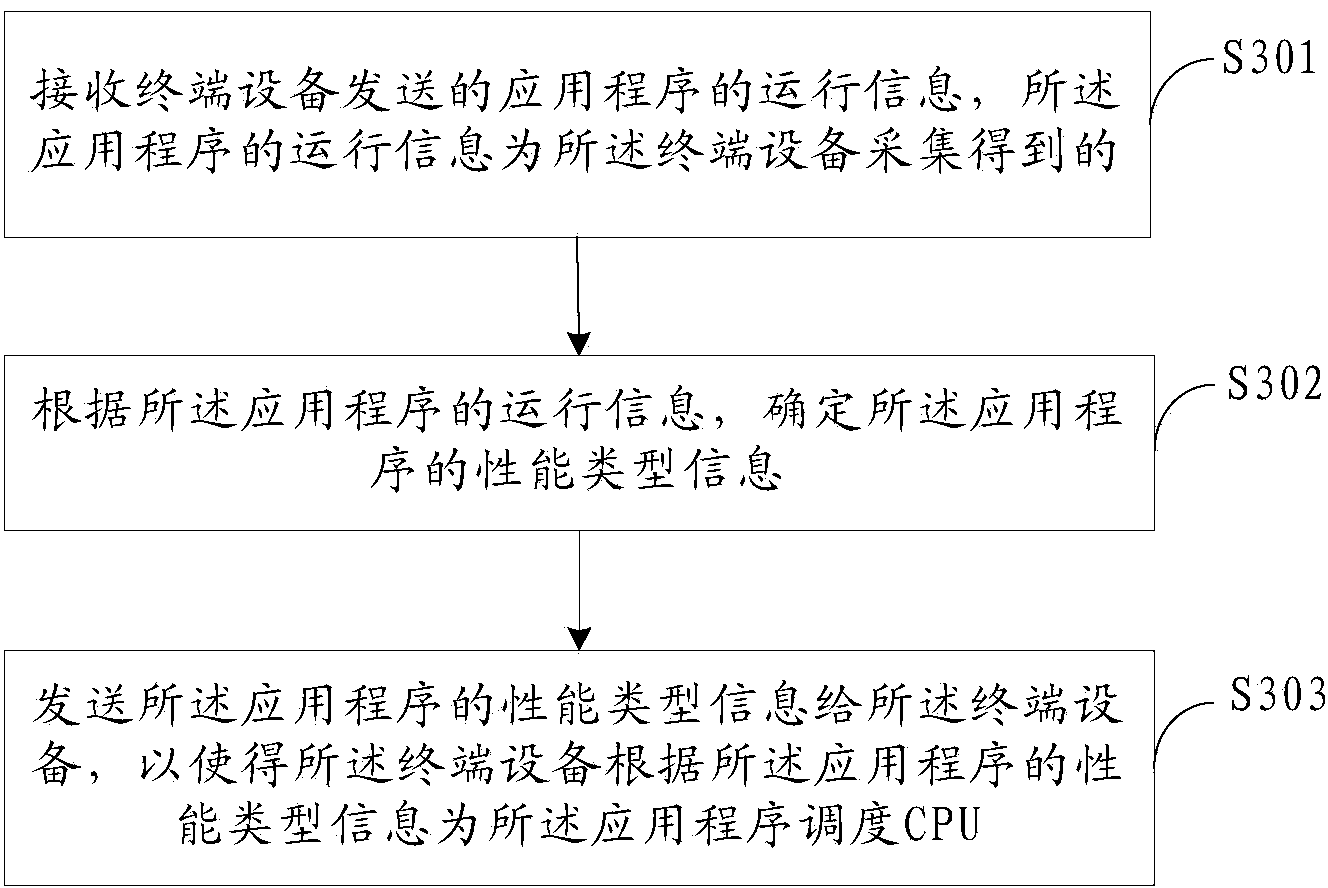

CPU scheduling method, device and system based on heterogeneous multi-core system

ActiveCN103645954AGive full play to the advantagesReasonable use of resourcesResource allocationRational useApplication software

The invention discloses a CPU scheduling method, device and system based on a heterogeneous multi-core system, and relates to the technical field of CPU scheduling on a computer system. The CPU scheduling method, device and system are used for achieving CPU scheduling on the heterogeneous multi-core system, reasonably using resources, improving the system performance and sufficiently giving play to the advantages of the heterogeneous multi-core system. The CPU scheduling method based on the heterogeneous multi-core system includes the steps of receiving application program performance type information sent by a processing device, and scheduling CPUs for application programs according to the application program performance type information.

Owner:HUAWEI TECH CO LTD

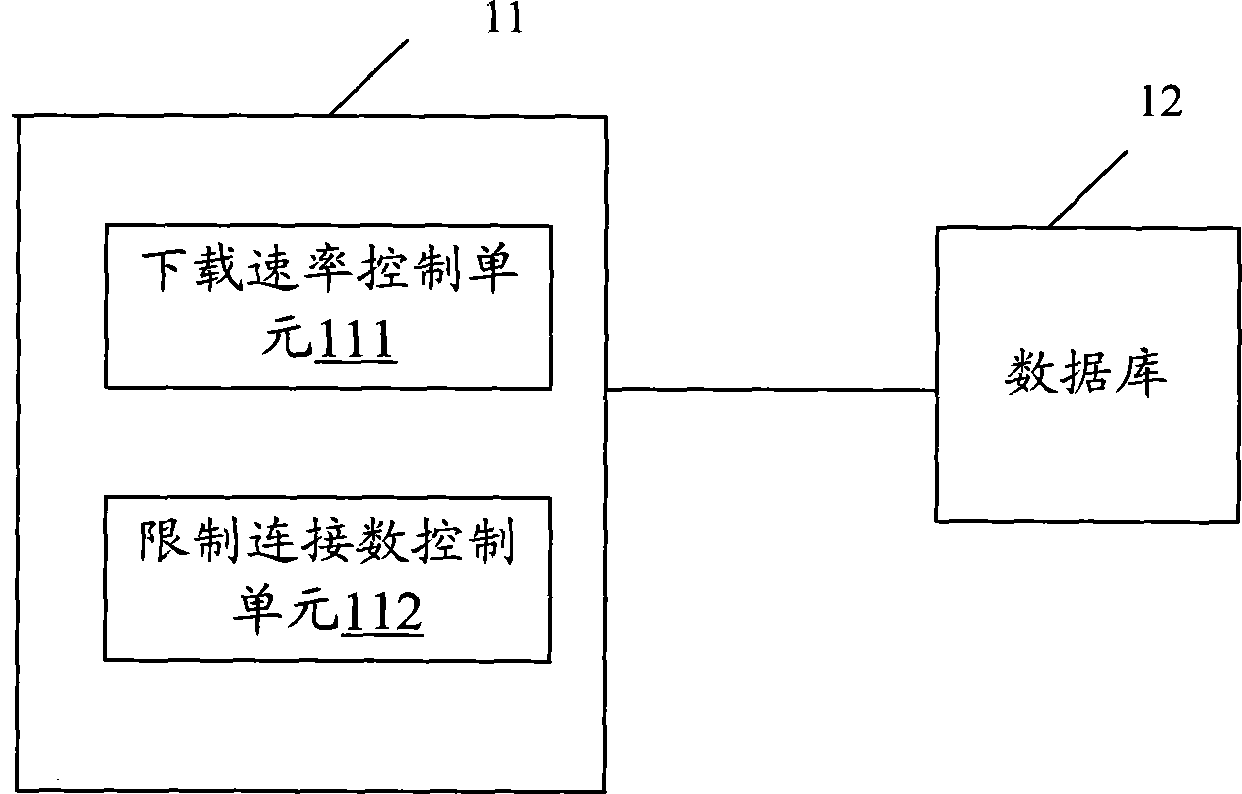

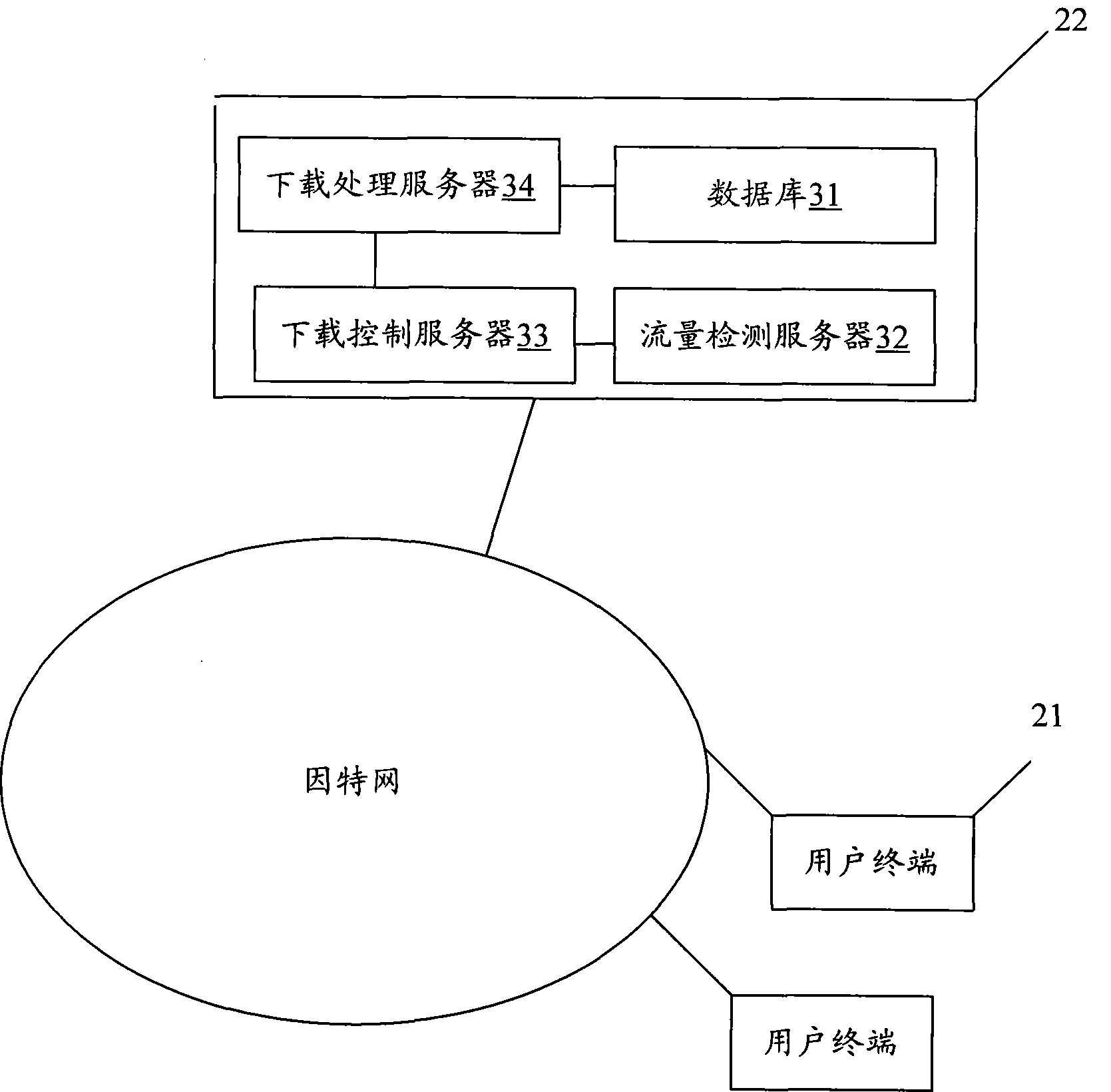

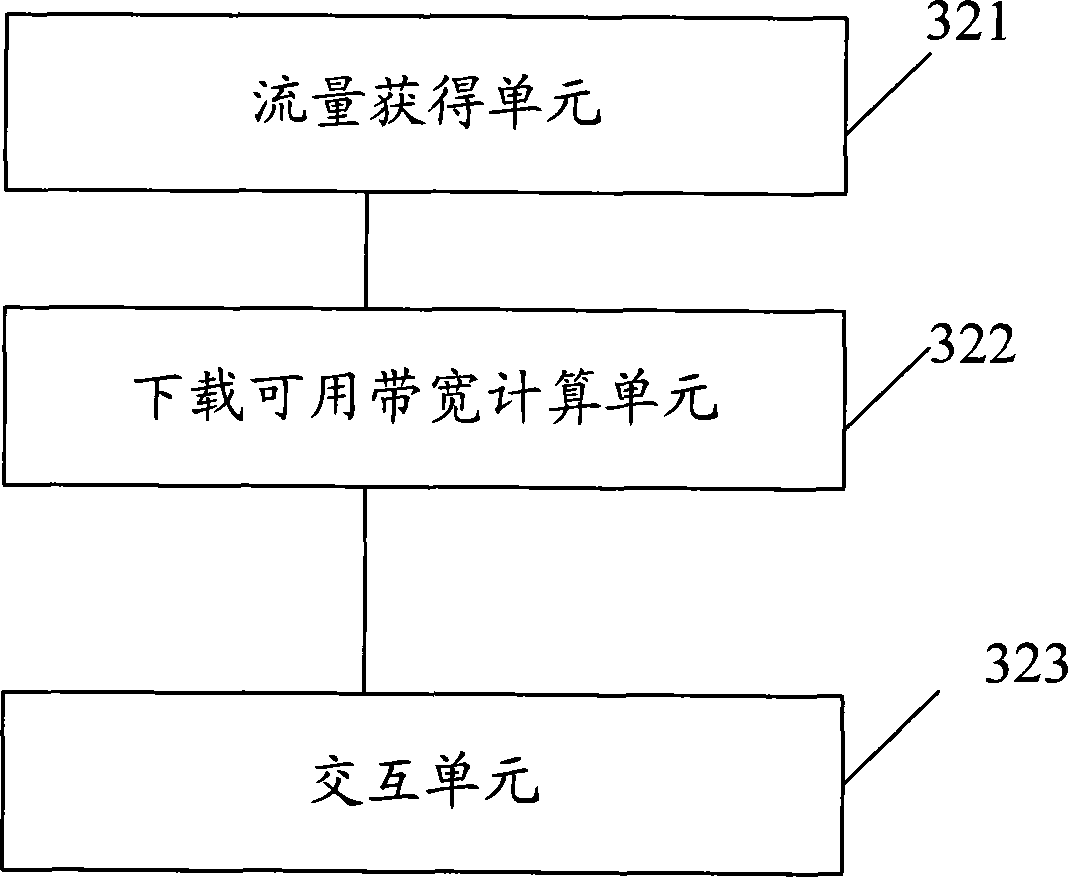

Flow control method and system for software downloading

InactiveCN102045321AOvercome wasteEasy to controlData switching networksTraffic capacityDownload rate

The invention discloses a control method for software downloading, which is used for controlling software downloading by using a software downloading platform. The method comprises the following steps of: (1) receiving a software downloading request of a user; (2) querying the current real-time flow information of the software downloading platform to acquire currently available downloading bandwidth information; (3) judging whether the currently available downloading bandwidth can bear the current downloading or not, refusing the current software downloading request if the currently available downloading bandwidth cannot bear the current downloading, and performing a step (4) if the currently available downloading bandwidth can bear the current downloading; and (4) determining priority of the current software downloading request, and distributing a corresponding bandwidth according to the priority. In the invention, whether the current downloading is allowed is directly determined according to the currently available downloading bandwidth, connections and the downloading rate of the user are not required to be considered, and the control is easy and effective; and the corresponding bandwidth can be distributed according to the priority to realize rational utilization of the entire resources.

Owner:ALIBABA GRP HLDG LTD

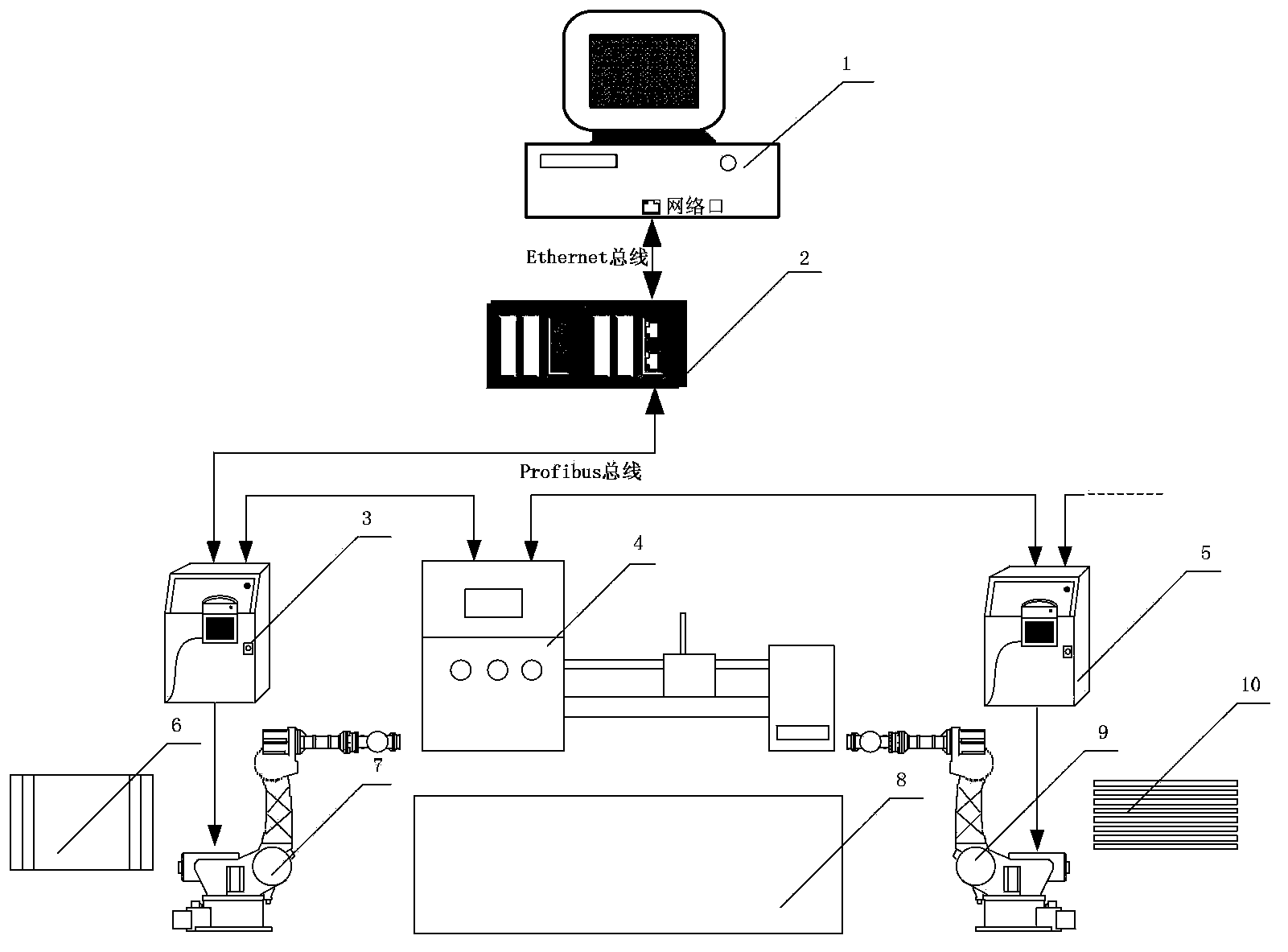

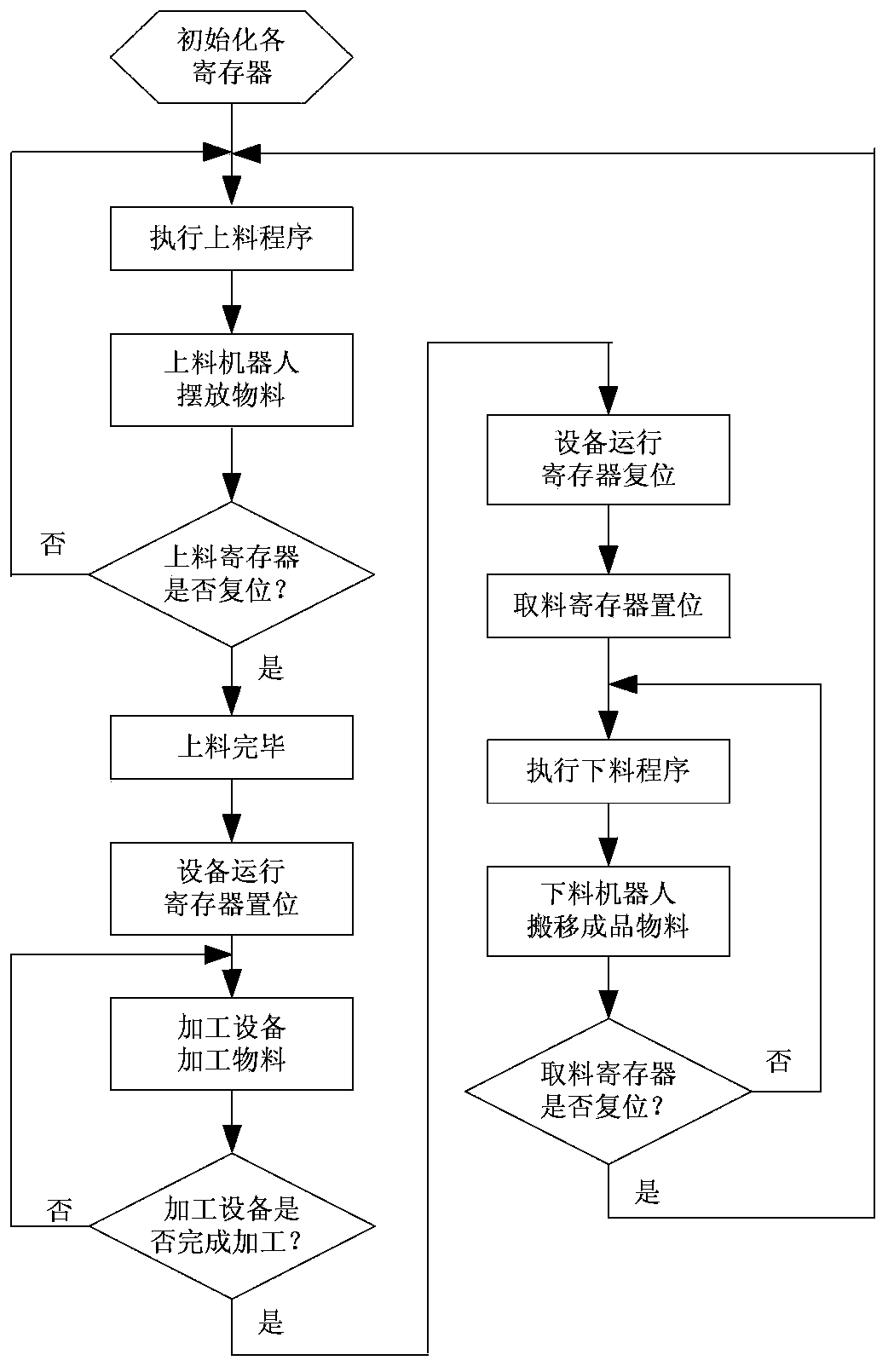

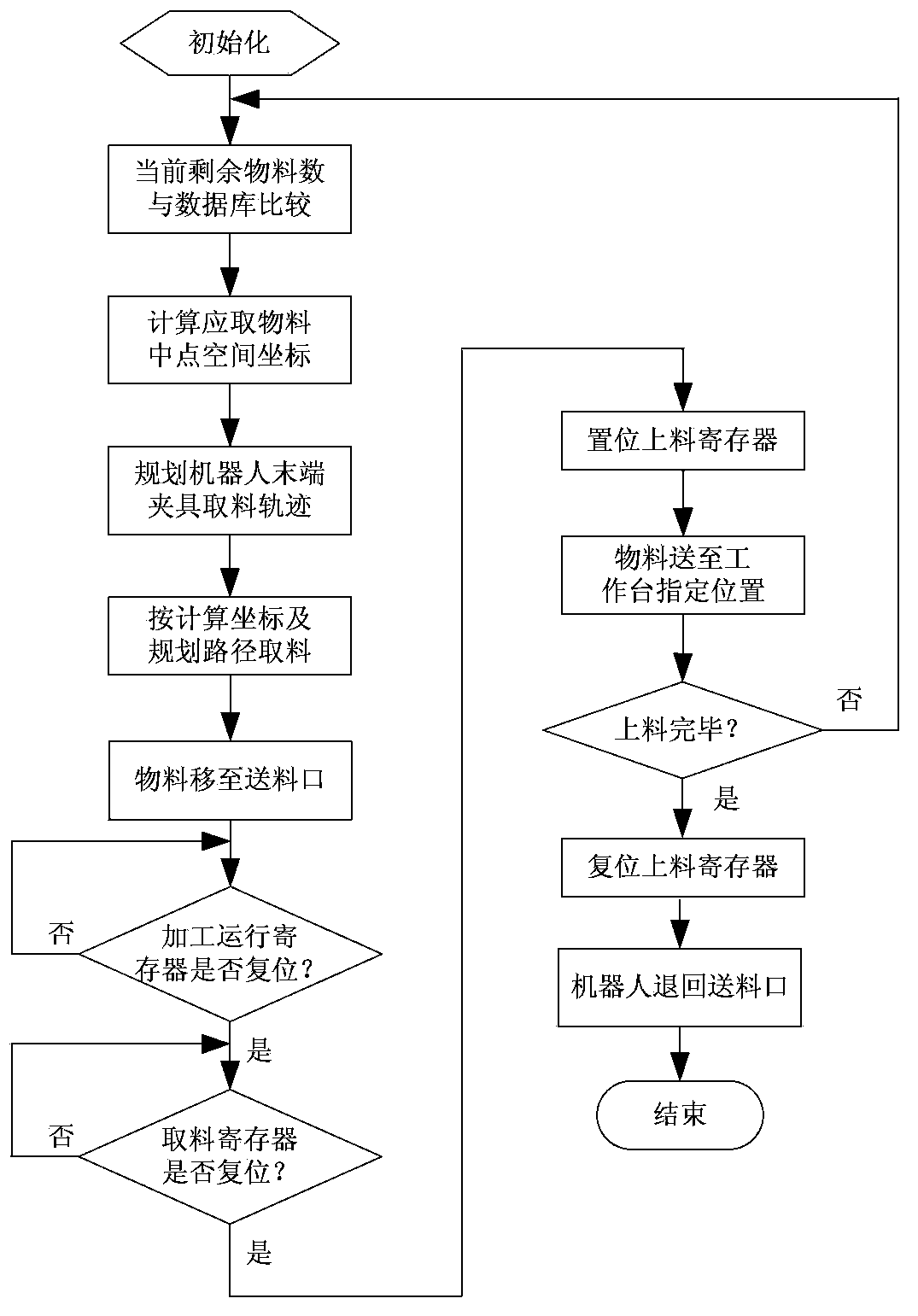

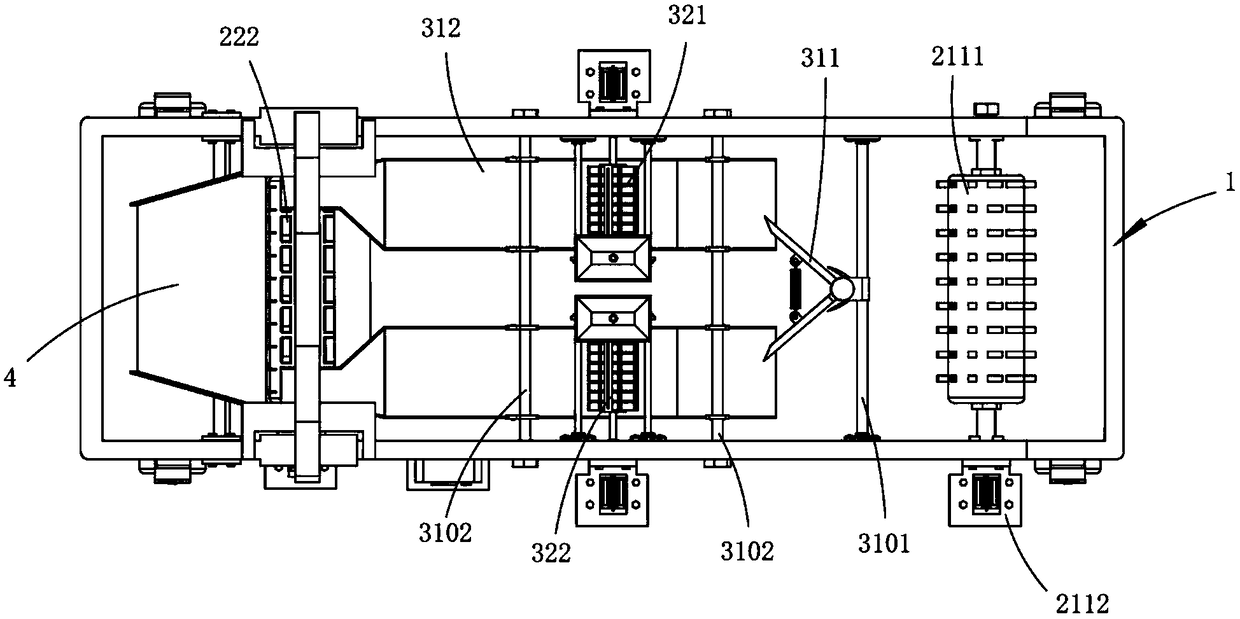

Multi-robot coordination control device and method

ActiveCN103433926AEfficient allocationLow costProgramme-controlled manipulatorProcessor registerPersonal computer

The invention discloses a multi-robot coordination control device and a multi-robot coordination control method. The device comprises an industrial personal computer, a motion controller, a loading robot controller, board processing equipment, an unloading robot controller, a loading robot and an unloading robot, wherein the industrial personal computer is connected with the motion controller, the motion controller is connected with the loading robot controller, the board processing equipment is connected with the loading robot controller and the unloading robot controller respectively, the loading robot controller is connected with the loading robot, and the unloading robot controller is connected with the unloading robot. Through reading values stored in a process register in the motion controller for judging whether the processing equipment processes materials or not, if not, the loading robot is used for executing a loading task, and the unloading robot is in a wait state, and after the loading is finished, the values in the process register are negated, then the unloading robot is used for executing an unloading task. The multi-robot processing course has better consistency, so that the production efficiency is greatly improved.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP

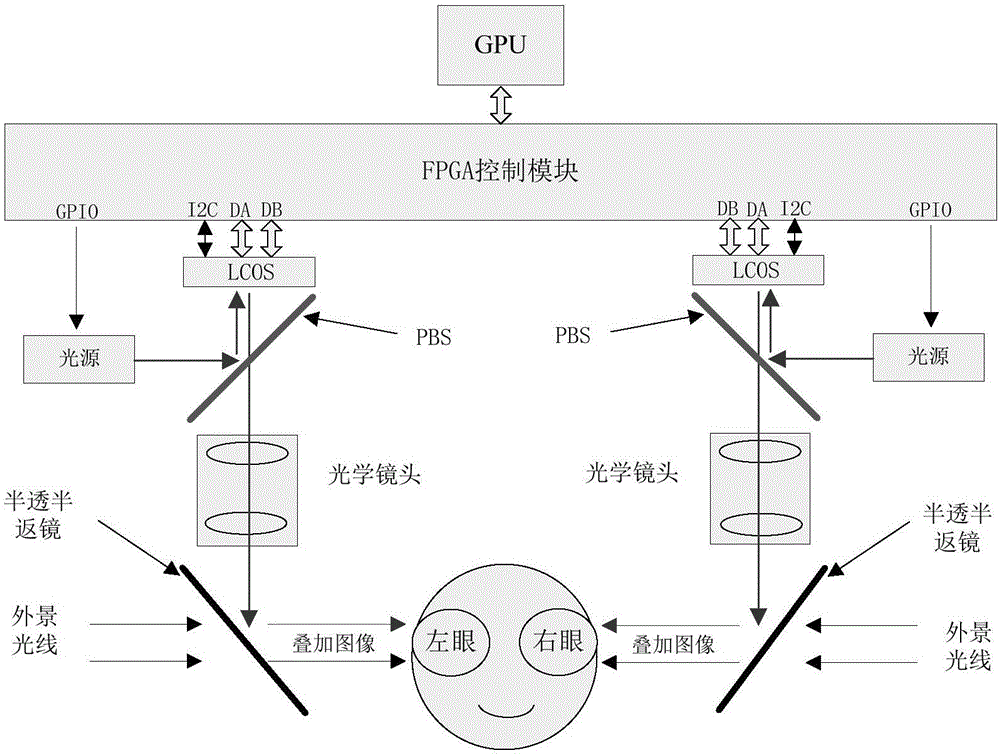

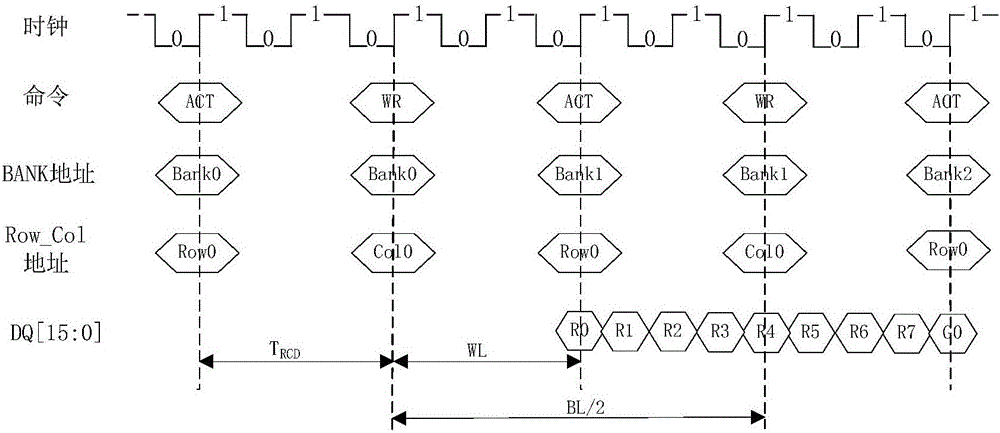

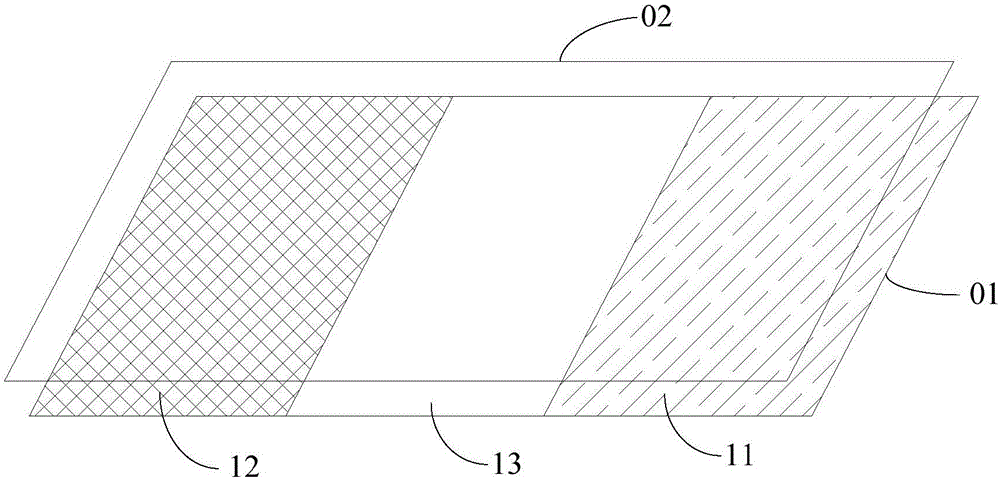

Intelligent helmet binocular display system for electric power inspection and realization method of intelligent helmet binocular display system

PendingCN106154553AStrengthen information exchangeImprove perceptionPicture reproducers using projection devicesOptical elementsSingle chipField-programmable gate array

The invention provides an intelligent helmet binocular display system for electric power inspection and a realization method thereof, which are used for assisting power grid power transformation, power distribution and power transmission inspection. According to the method, a binocular imaging optical subsystem and a sequential logical circuit based on an FPGA (Field Programmable Gate Array) are designed; an invented intelligent helmet binocular enhanced reality display system comprises image acquisition, data conversion, caching, storage, protocol conversion and an interface; intelligent helmet binocular imaging enhanced reality display for the electric power inspection is realized. The intelligent helmet binocular display system is high in hardware integration degree, good in system flexibility, low in power consumption and stable in display stability, and the reliability of the whole system is improved. According to an imaging system provided by the invention, the utilization rate of light source light in an imaging process can reach about one time of that of a single chip type imaging system. An image projected into eyes has more saturated and full colors, and a rainbow picture problem, which disturbs a single chip DLP imaging system, does not occur.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

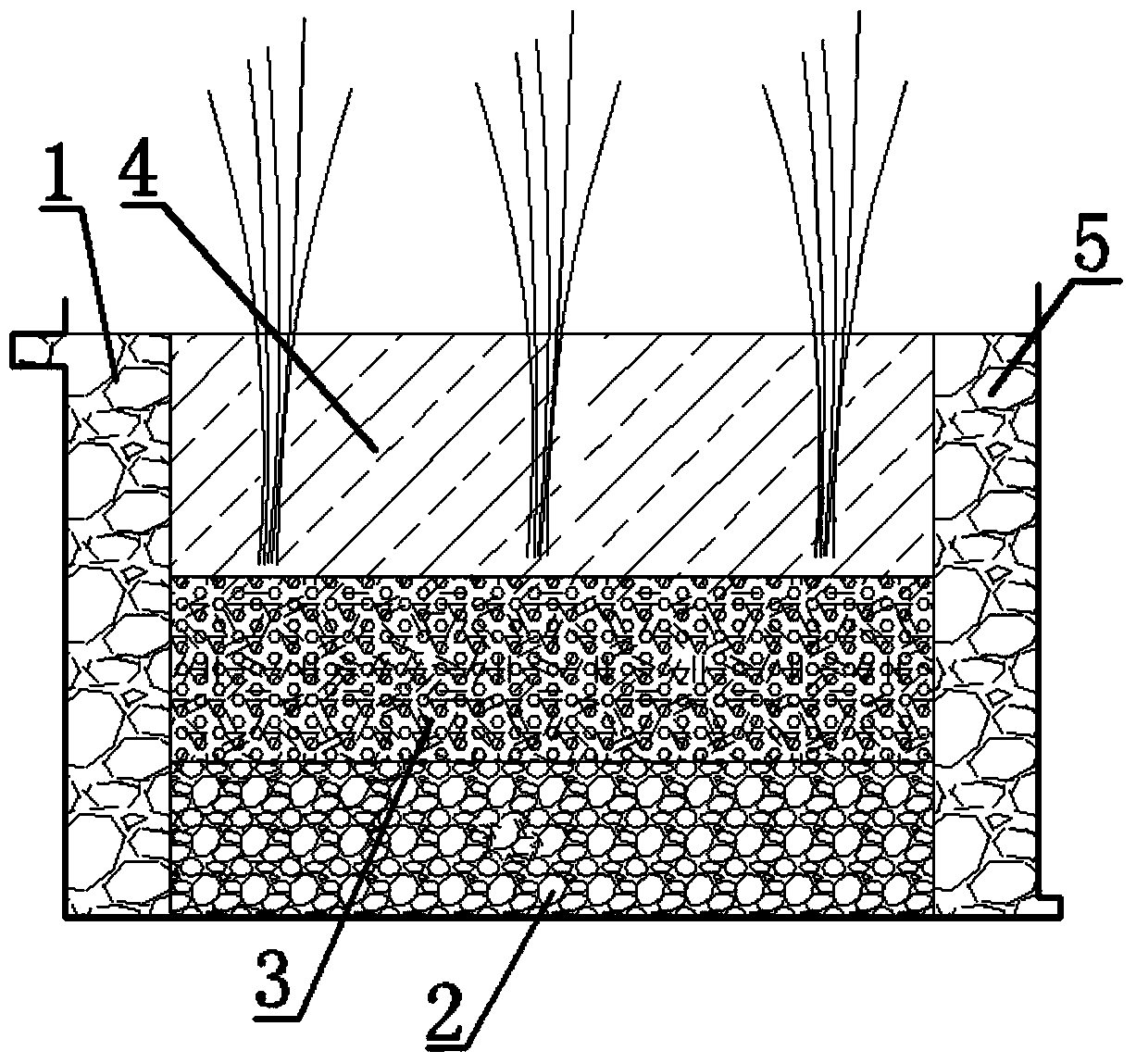

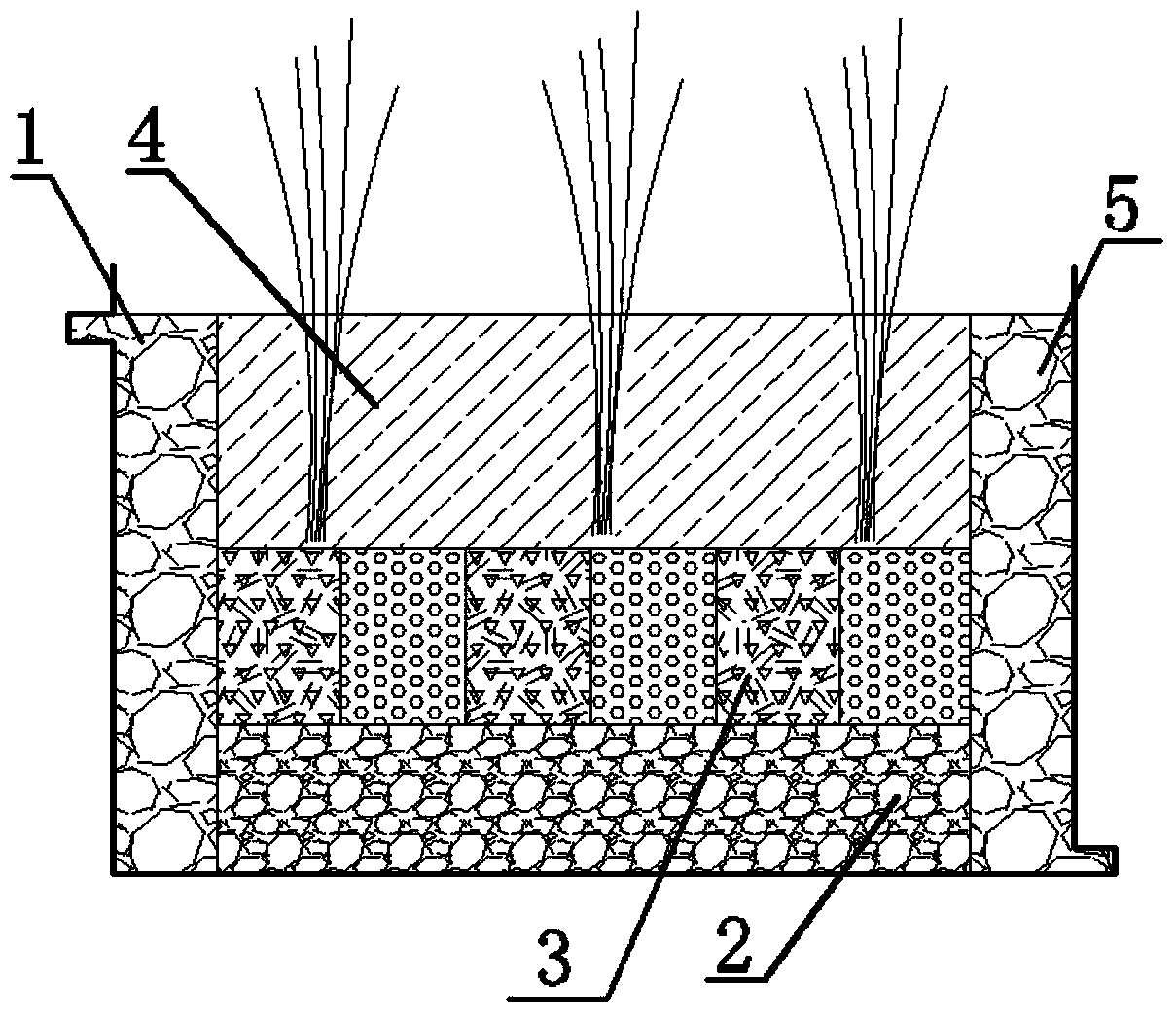

Denitrified sewage treatment device and treatment method for artificial wetland

ActiveCN104291445ASolve the problem that the release cannot be effectively controlledReasonable use of resourcesWater contaminantsTreatment with anaerobic digestion processesConstructed wetlandMedicine

The invention discloses a denitrified sewage treatment device for an artificial wetland. The device comprises a sewage treatment pond. The sewage treatment pond comprises a denitrification layer (3) and a soil layer (4), wherein the soil layer (4) is arranged above or below the denitrification layer (3); the length of the sewage treatment pond is greater than or equal to 1m and the length-width ratio is greater than or equal to 3; the sewage treatment pond is provided with a water inlet and a water outlet; plants are planted on the soil layer (4); and the denitrification layer (3) consists of sulfur particles, plant stem and leaf fragments and gravels. The invention further discloses a denitrified sewage treatment method. The denitrified sewage treatment device disclosed by the invention has the advantages of low cost and good denitrification effect of sewage.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Method for producing alcohol using sweet kaoliang straw

InactiveCN101024848AWide adaptabilityCultivation is simpleBiofuelsMicroorganism based processesHigh energyNew energy

The invention is a method for making alcohol with sugar grass stalks, comprising the steps of: (1) taking sugar grass stalks and removing fringes and roots and cutting into 10-20 mm long sections; (2) placing these sections into fermenting cylinder and adding in water, regulating sugar content, temperature and pH value and obtaining liquid material; (3) adding distillery yeast in the liquid material, uniformly blending and obtaining inoculating liquid material; (4) fermenting the inoculating liquid material at 28deg.C-32deg.C for 52-72 h, and obtaining fermented mash; and (5) distilling the fermented mash in distilling tower and obtaining alcohol with a volume concentration of 95% above. And the sugar grass is a high energy crop, easy to plant, and is a new energy source raw material, according with the requirements for circulating economy and sustainable development.

Owner:刘明全

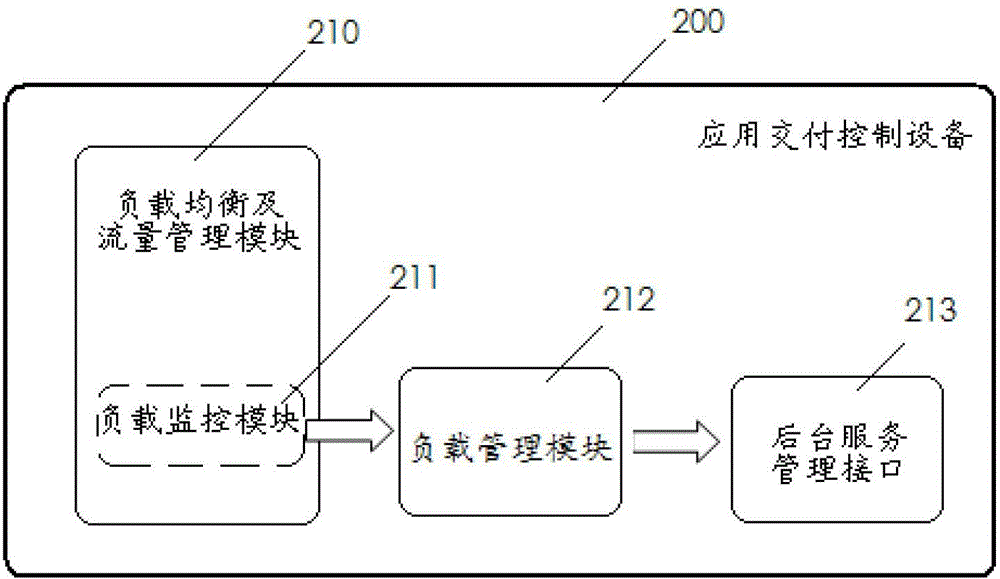

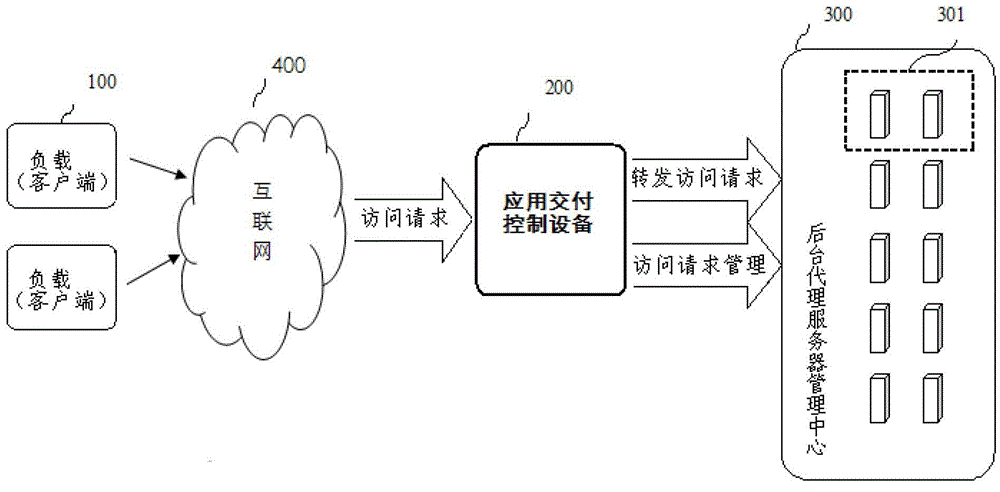

Equipment and method for dynamically configuring proxy server

The invention relates to equipment and a method for dynamically configuring a proxy server. The equipment in the invention at least includes load balancing and flow management module and a load monitoring module therein, a load management module and a background proxy server management interface. The method in the invention performs reasonable deployment on a background proxy server mainly according to load conditions such as client-side access requests of equipment and the condition of the background proxy server management interface. According to the current load conditions, and in cooperation with the proxy server management interface, the equipment in the invention dynamically schedules resources of the background proxy server, thereby enabling limited resources to be reasonably used, and reducing usage cost; when background service is closed, current businesses are guaranteed not to be affected; and the whole process is intelligent, and no manual intervention is needed.

Owner:ARRAY NETWORKS BEIJING

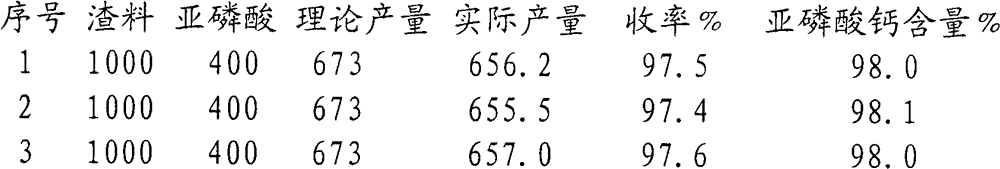

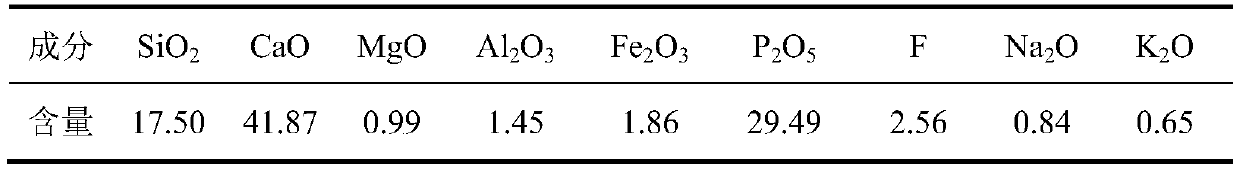

Method for preparing calcium phosphate by utilizing slag charge discharged during sodium hypophosphite preparation

ActiveCN103058156ANo pollution in the processAvoid pollutionSolid waste disposalPhosphorous acidPhosphorous acidCalcium hydroxide

The invention relates to a method for preparing calcium phosphate by utilizing slag charge discharged during sodium hypophosphite preparation. Calcium hydroxide and calcium carbonate in the slag charge react with phosphorous acid to generate calcium phosphate monohydrate, phosphorous acid is prepared according to the condition that the content of calcium hydroxide in the slag discharge is 35.48wt% and the content of calcium carbonate in the slag discharge is 10.91%, calcium phosphate is generated at a certain temperature under a stirring condition, and washing, filtering, drying and smashing are performed after the PH value is regulated, so that pure calcium phosphate is obtained. The method provided by the invention has the following prominent advantages: 1, resource utilization is reasonable, the low-end resource is extended to a high-end product; 2, the equipment investment is small, the process is simple, production is easy to control and the method is environmentally-friendly; and 3, the method provided by the invention can be used for solving the pollution of slag charge discharged by enterprise sodium hypophosphite to environment, and reducing the production cost.

Owner:王军民

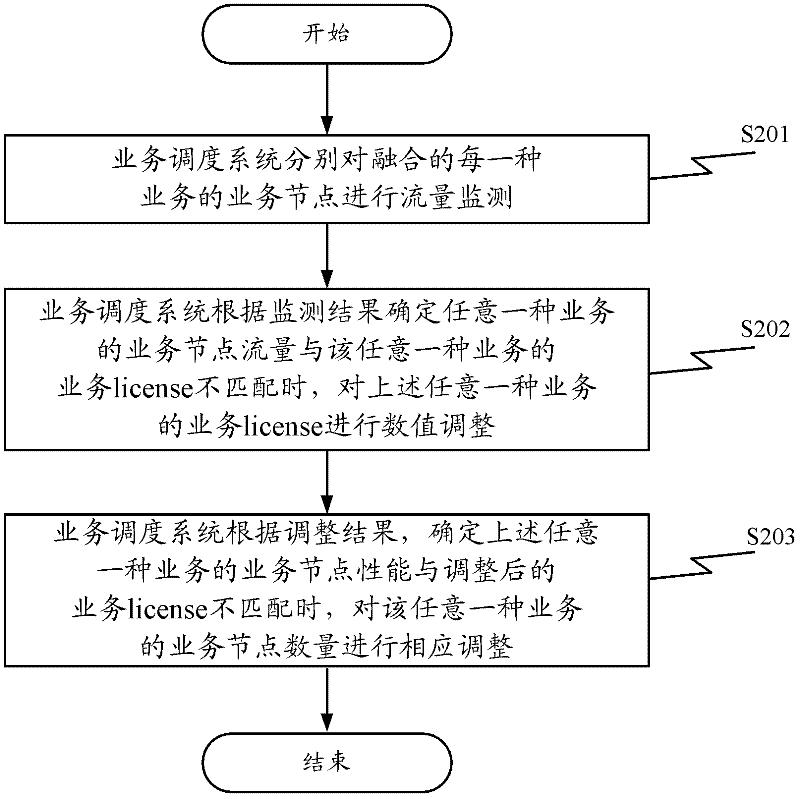

Method, device and system for service scheduling based on service traffic permission

The invention relates to the field of communications, and disclosed are a service-flow-license-based service scheduling method, device and system, which are used for making a service flow license used by a service node match with the performance of the service node, thereby optimizing system resources. In the method, for the current common phenomena of various service platform and unbalanced service development of different operators and different regions, the system can flexibly adjust the number of the service nodes required to be used by any one service in real time according to the service license use conditions of each service node; therefore, the service licenses used by the service nodes can be matched with the performance of the service nodes, and the invention effectively solves the problem of resources wasting caused by the development unbalance of each service in multi-service convergence, reduces running cost to a great extent, maximally rationally allocates software / hardware resources at the same time of improving management efficiency and system usability, and further optimally and most rationally utilizes the resources.

Owner:ZTE CORP

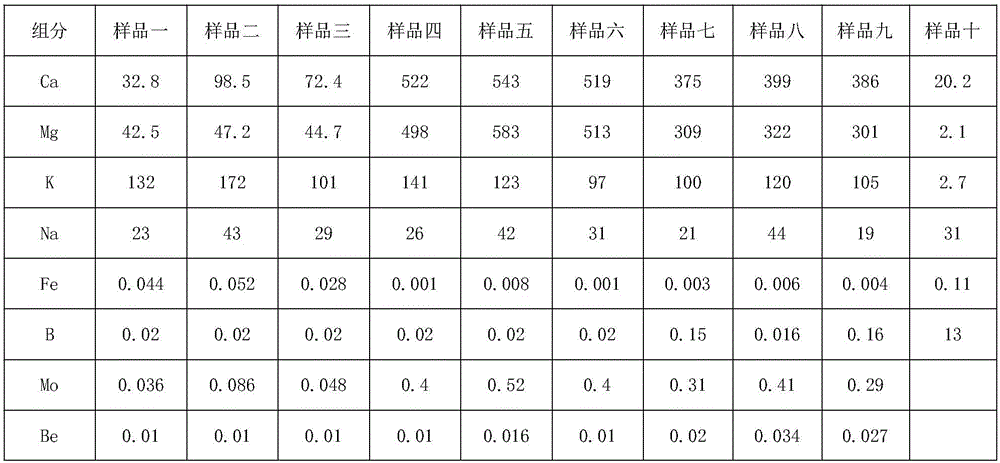

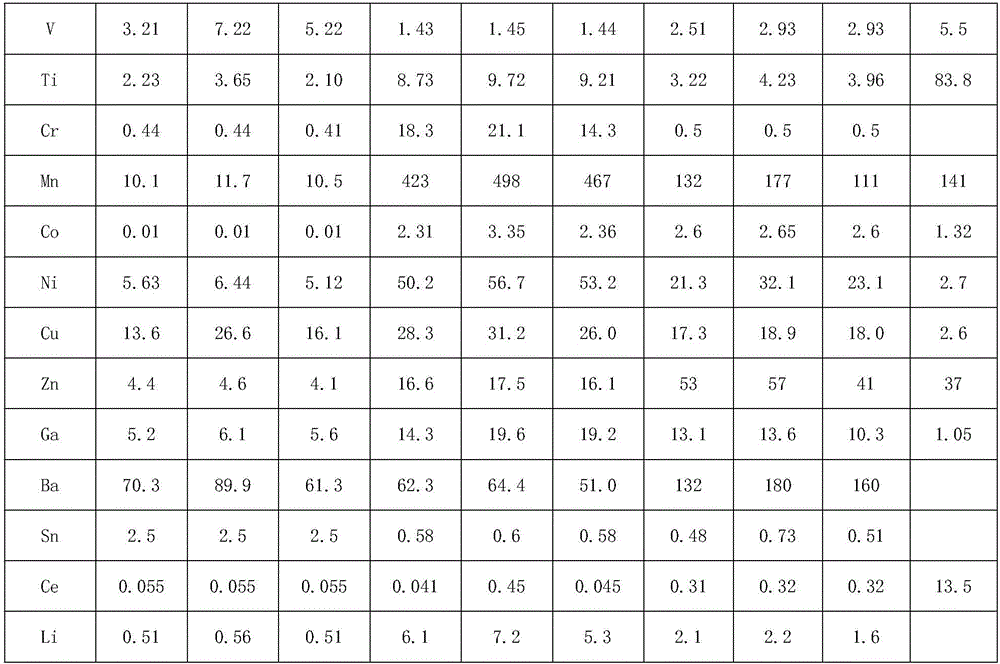

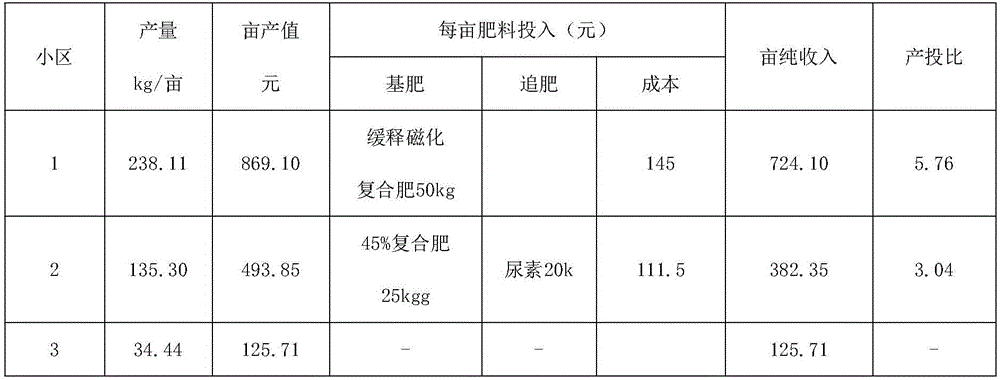

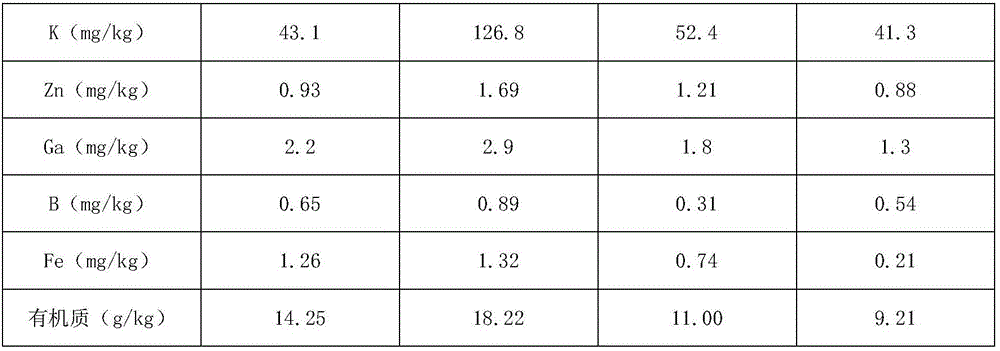

Slow-release magnetized composite fertilizer for planting rapeseed and its preparation method

InactiveCN106187587AIncrease or decrease usageEarly administrationCalcareous fertilisersMagnesium fertilisersPhosphateRapeseed

The invention relates to slow-release magnetized composite fertilizer for planting rapeseed and its preparation method. The slow-release magnetized compound fertilizer for planting rape includes the following raw materials in parts by weight: 24-28 parts of urea, 18-22 parts of potassium dihydrogen phosphate, 3 to 5 parts of calcium powder, 10 to 16 parts of potassium chloride, 2 to 2.5 parts of humic fertilizer, 0.2 to 0.5 part of selenium-rich fertilizer, 0.5 to 1 part of magnesium sulfate heptahydrate, 1 to 2 parts of starch ether, 4 to 8 parts of fertilizer additives, and 34 to 40 parts of magnetic carrier. The slow-release magnetized composite fertilizer for planting rapeseed is characterized in that the iron mineralized tailing sand compound fertilizer is magnetized, the soil environment is improved, the fertilization period of the fertilizer is enhanced, the nutrition absorption of the crop is enhanced, the lodging resistance and disease resistance of the rape are enhanced, yield and earnings are increased, and the environment is protected.

Owner:ANHUI JINLU COMPOSITE MAGNETIC FERTILIZER

Uniform-fertilizing automatic earthing equipment

The invention relates to uniform-fertilizing automatic earthing equipment which comprises a traveling carrier, a soil loosening portion and a soil transferring portion. The soil loosening portion andthe soil transferring portion are mounted on the traveling carrier, the soil loosening portion comprises a shallow-layer soil loosening device and a deep-layer soil loosening device, the soil transferring portion is arranged between the shallow-layer soil loosening device and the deep-layer soil loosening device and comprise a conveying device for transferring upper-surface-layer loose soil generated by the shallow-layer soil loosening device during soil loosening and a soil-moving fertilizing device arranged above the conveying device and used for pushing and fertilizing soil. The soil transferring portion transfers the fertilized loose upper-surface-layer soil onto the deep-layer soil after going through deep-layer soil loosening, and the deep-layer soil loosening device transfers the deep-layer soil as covering soil onto the upper-surface-layer soil at the same time to enable fertilizer to be completely integrated into the soil, so that loss and waste are avoided, land resources areutilized reasonably, and vegetation growth is facilitated.

Owner:台州市智诚工业设计有限公司

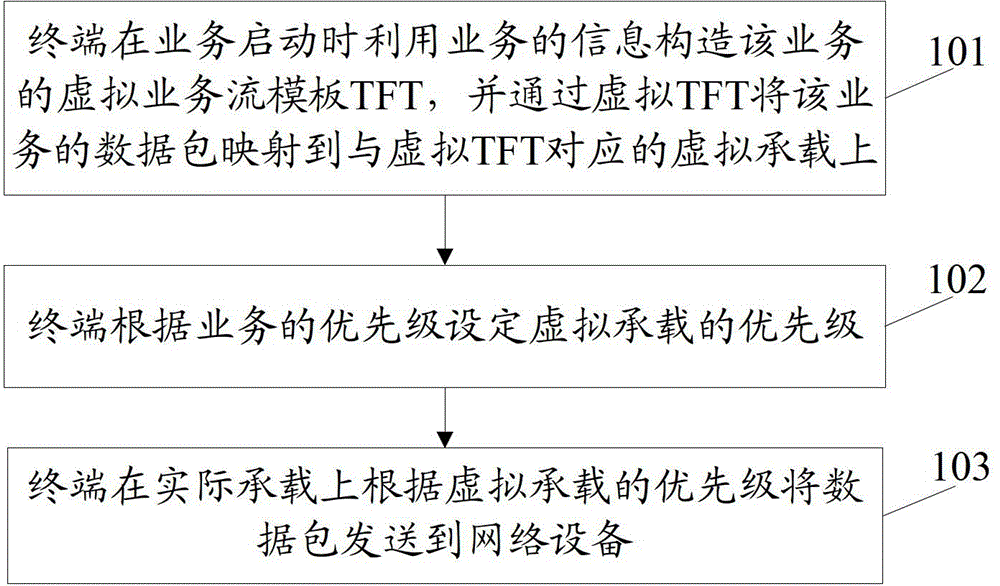

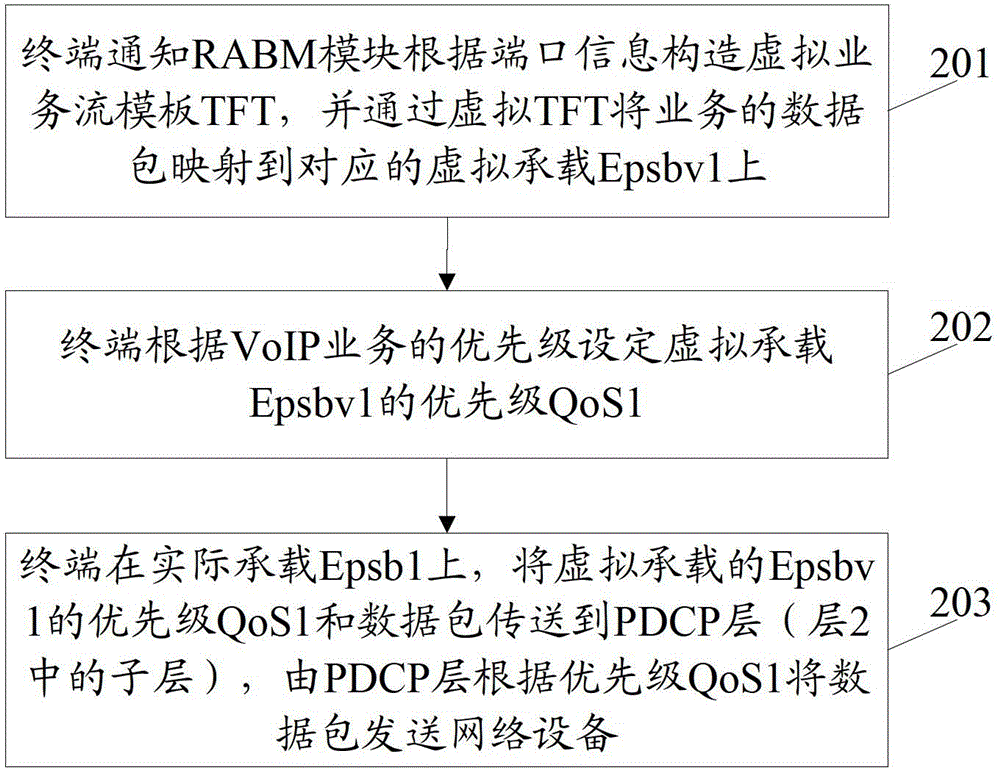

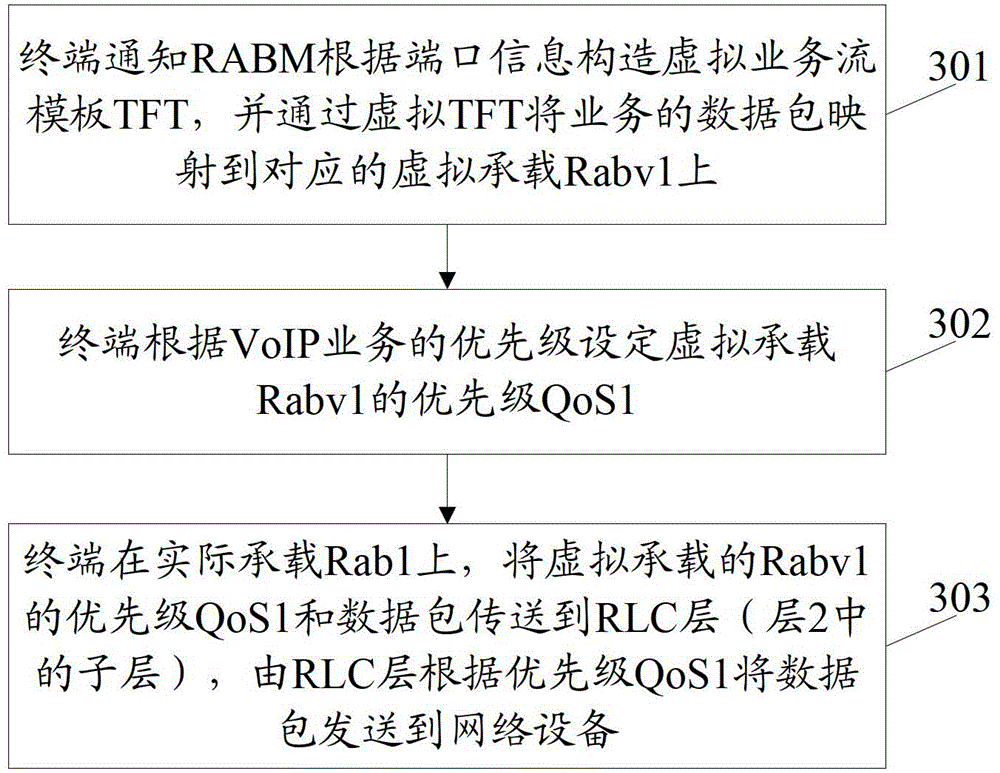

Method and equipment of data transmission

ActiveCN103067982AReasonable use of resourcesNetwork traffic/resource managementData switching networksQuality of serviceResource utilization

Owner:HUAWEI TECH CO LTD

Cloud-computing-based large scale curved surface reconstruction system

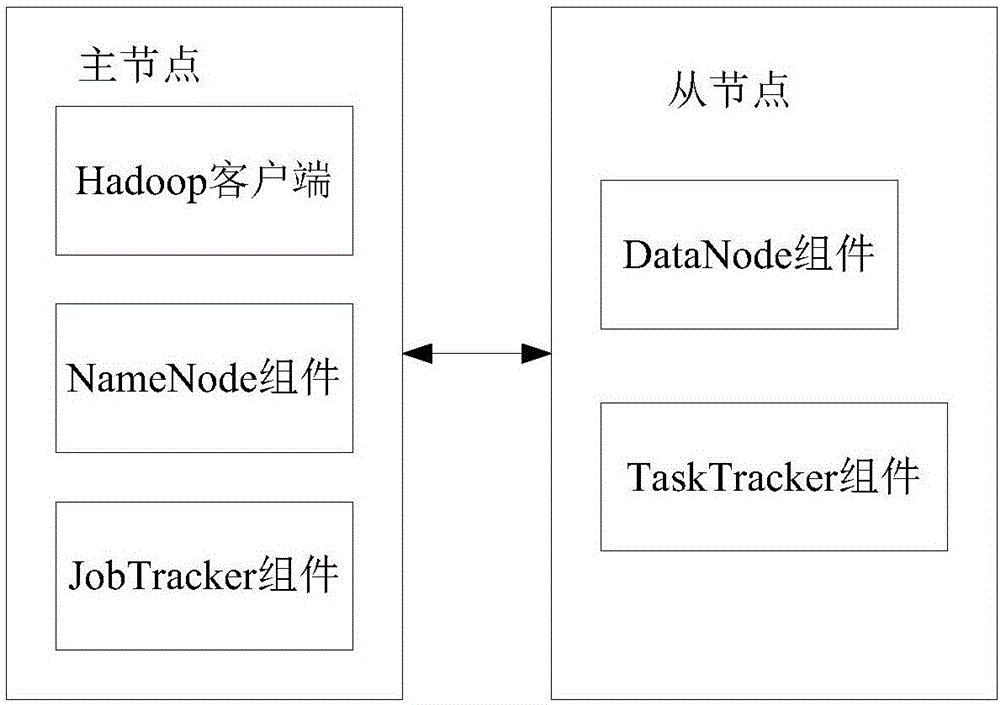

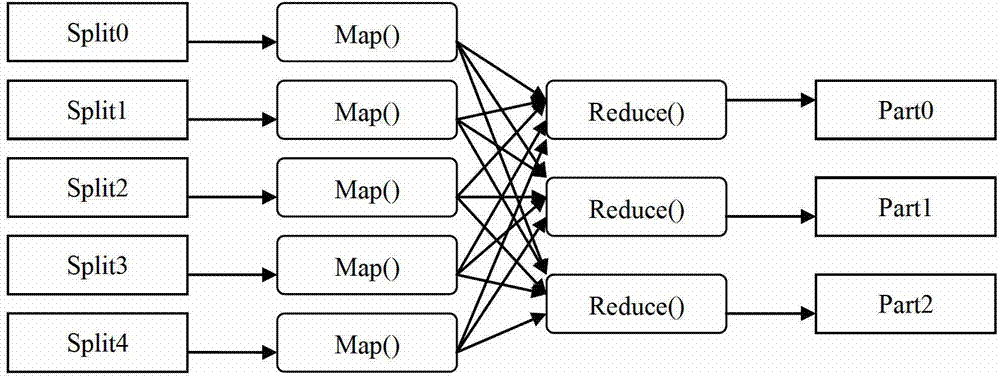

InactiveCN106447775AImproved Surface Reconstruction CapabilitiesStrong computing power3D modellingCouplingSurface reconstruction

The invention discloses a cloud-computing-based large scale curved surface reconstruction system. The system comprises a cloud computing platform deployed with a Hadoop framework. The cloud computing platform includes a main node and a sub-node. The main node is provided with a Hadoop user terminal, a NameNode element, and a JobTracker element. The sub-node is provided with a DataNode element and a TaskTracker element. According to the invention, through the introduction of cloud computing into a curved surface reconstruction system and through the use of the advantages of cloud computing such as high calculation capability and high system parallelism, the curved surface reconstruction capability of a curved surface reconstruction system is increased greatly. The reconstruction system has high expandability, utilizes resources properly and achieves low coupling. With the system, the problems with the insufficiency in single machine's memory and computing ability and the topological merging of the curved surfaces are solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

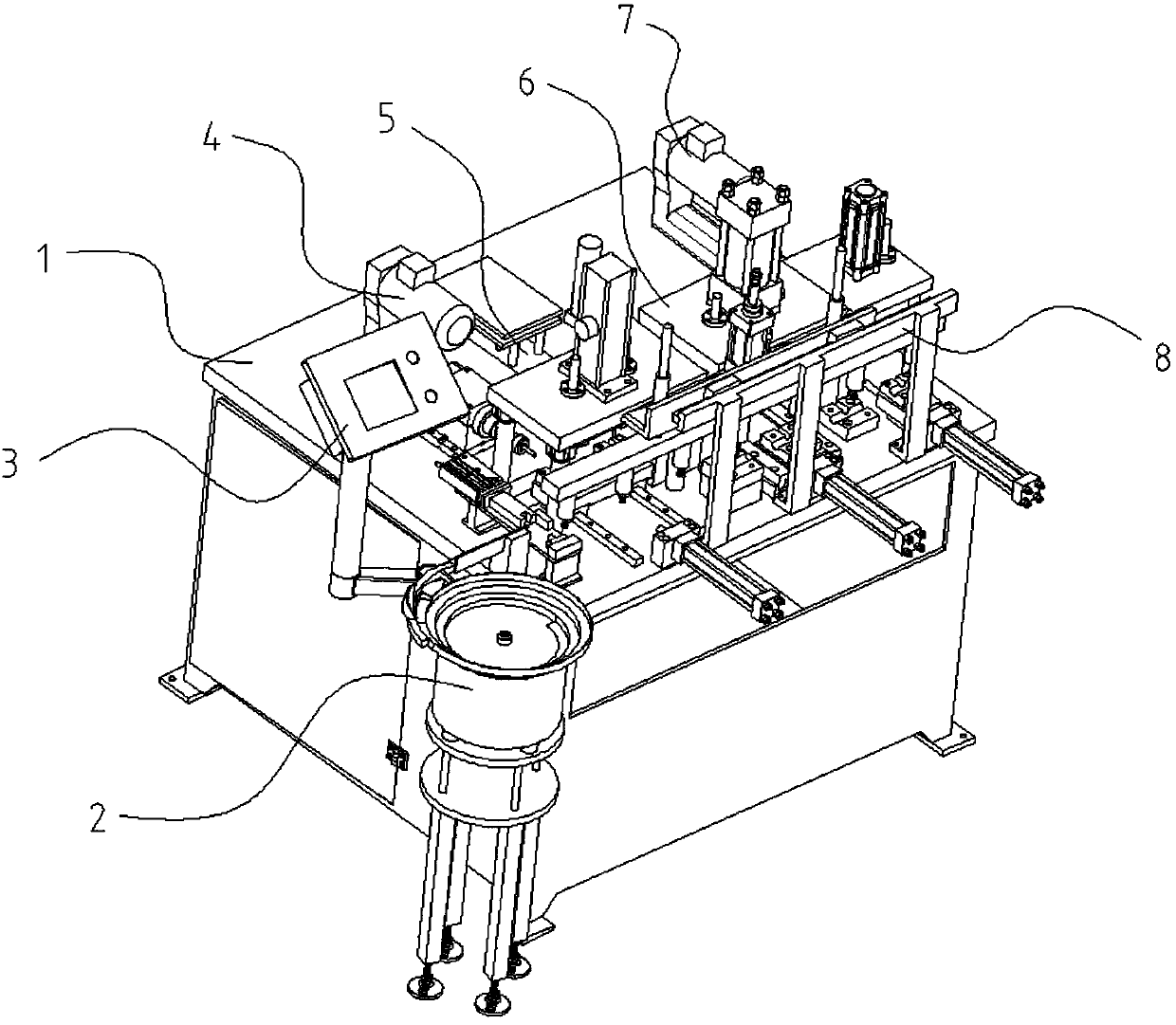

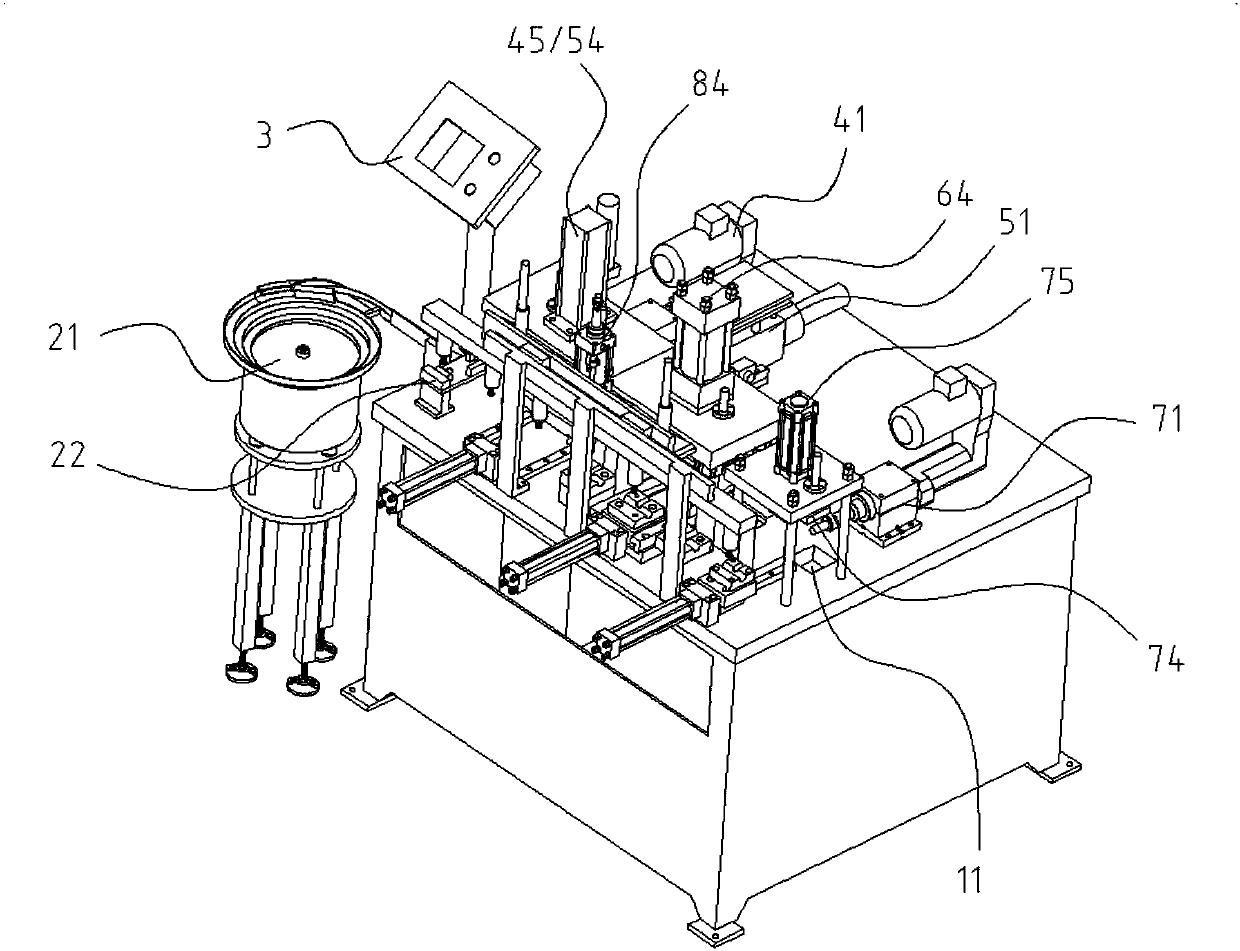

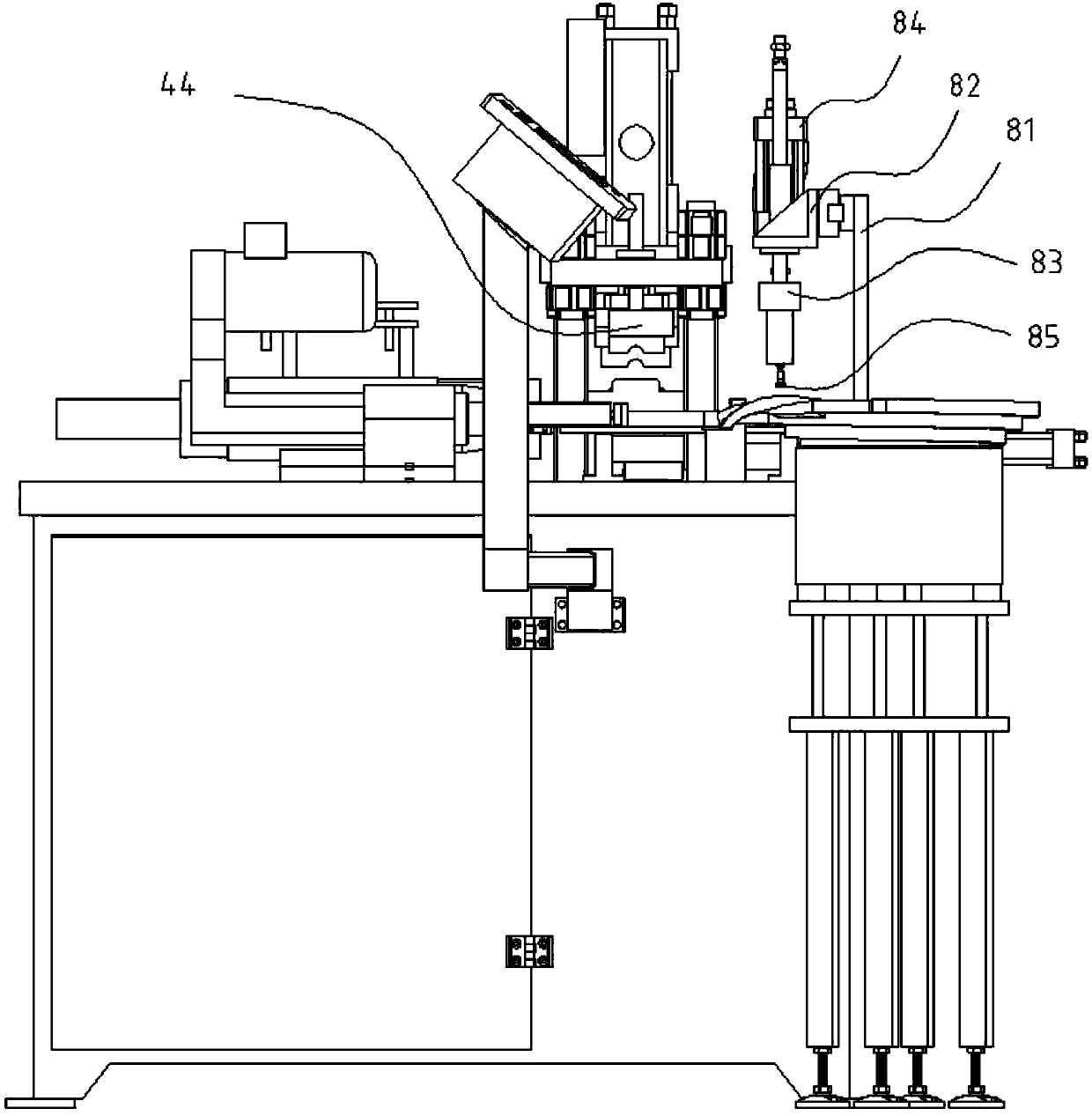

Machining equipment for three-way copper pipe fitting

ActiveCN107617673AFully automatedAchieve equidistant distributionMetal-working feeding devicesPositioning devicesPunchingAutomatic control

The invention provides machining equipment for a three-way copper pipe fitting and belongs to the technical field of automatic processing equipment. The machining equipment comprises a feeding mechanism, a punching mechanism, a flaring mechanism, a shaping mechanism and an end flatting mechanism which are arranged on a workbench and sequentially arranged in the same direction, wherein a transportmechanism is arranged perpendicular to the workbench, and all the mechanisms are connected in series through the transport mechanism. As the punching mechanism, the flaring mechanism, the shaping mechanism and the end flatting mechanism are arranged on the same workbench, and the mechanisms are connected through the transport mechanism, the machining process, including, punching, spin-flaring, shaping and end flatting, of the three-way copper pipe fitting, is finished on the same equipment, and the working efficiency is improved; the punching mode replaces a head cutting mode, so that the yield is improved, and material waste is avoided; and meanwhile, as a program controller is arranged, automatic control is achieved, the labor intensity of staff is reduced, and the production security isimproved.

Owner:NINGBO JINTIAN COPPER TUBE

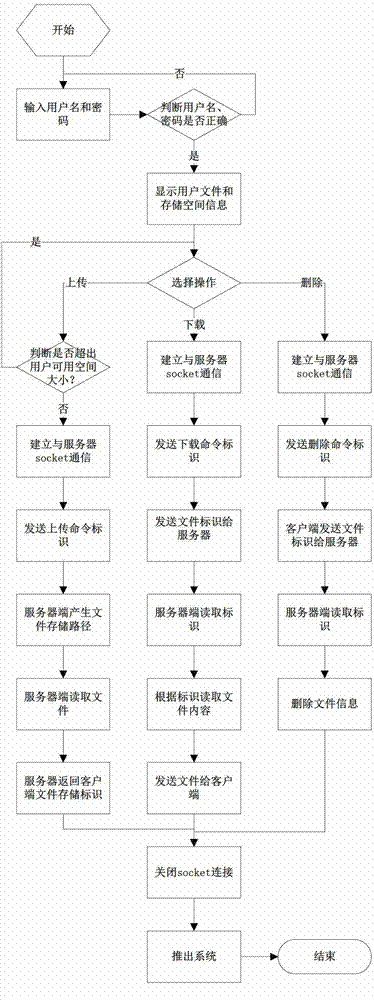

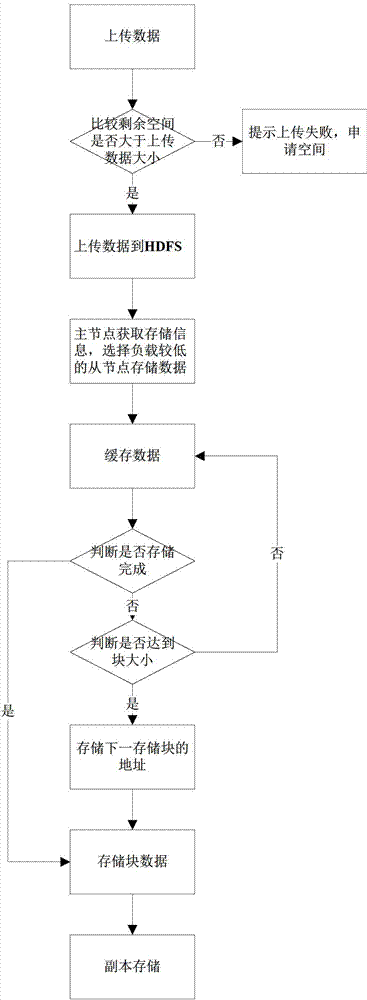

HDFS (hadoop distributed file system) cluster based distributed cloud storage system

InactiveCN102932443ARealize size customizationReasonable use of resourcesTransmissionDistributed File SystemData node

The invention discloses an HDFS (hadoop distributed file system) cluster based distributed cloud storage system which comprises a name node and a data node, wherein the name node is responsible for managing file namespaces and client access, and the data node is responsible for managing data storage. The system is characterized in that the name node comprises a registration / certification module and a user customization module, wherein the registration / certification module is used for providing users with a login service and carrying out certification on user login requests; and the user customization module is used for customizing the capacity of a storage space of a login user, and after the user logins successfully, the user sets a storage space allowance reminder. According to the method, the size of a storage space of a user is customized, therefore, an effect of distribution based on need is achieved, and resources are rationally used; the application of distributed storage improves the storage efficiency; and the application of multi-copy storage improves the data reliability of storage.

Owner:SUZHOU LIANGJIANG TECH

Household paper and preparation method thereof

ActiveCN105887567AImprove solubilityImprove antibacterialNon-fibrous pulp additionPaper coatingDecompositionProduct gas

Owner:金红叶纸业(湖北)有限公司

Path navigation method for vehicle

InactiveCN106885581AReduce the chance of double counting navigation pathsImprove navigation efficiencyInstruments for road network navigationRoad crossingMarine navigation

The invention discloses a path navigation method for a vehicle. The navigation method specifically comprises the following steps: a vehicle-mounted terminal sends a path navigation request to a processor; after the processor receives the path navigation request, path calculation is performed by taking the current real-time position of a vehicle as a start point to obtain a first navigation path; when an intersection exists on the calculated first navigation path, the processor calculates pre-estimated time to arrive at the next intersection according to the average running speed of the vehicle; and when the pre-estimated time to arrive at the next intersection is less than a preset threshold, the processor calculates multiple optimal second navigation paths by taking all divergent paths of the intersection as start points, and the processor sends the first navigation path or the second navigation paths to the vehicle-mounted terminal. The navigation method disclosed by the invention can calculate and present navigation of multiple paths in time, thereby greatly increasing the path selection probability, facilitating vehicle path selection, and enabling the vehicle to arrive at the destination in time conveniently.

Owner:HEFEI MINZHONGYIXING SOFTWARE DEV CO LTD

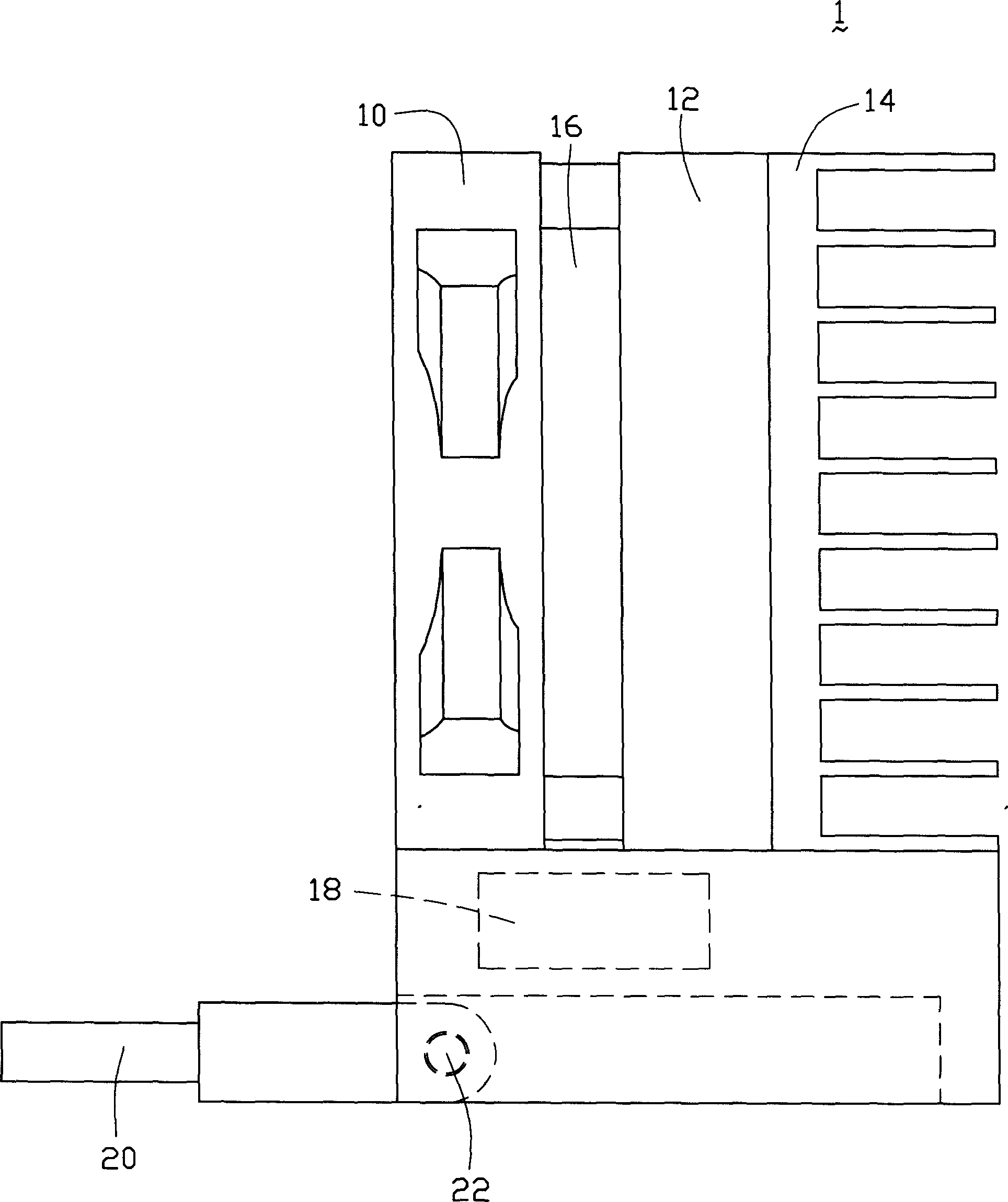

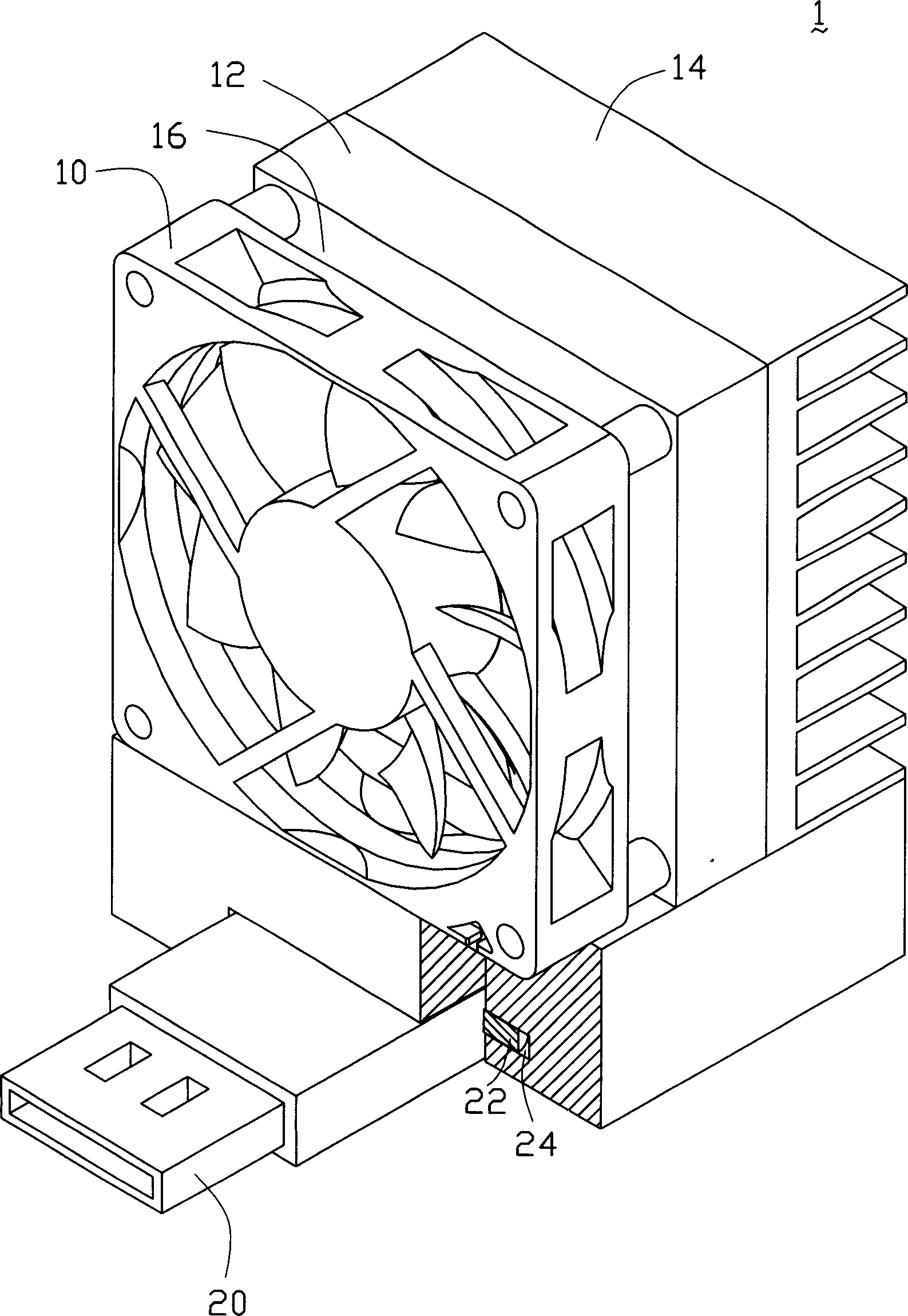

Heat sink device for electronic equipment and method therefor

InactiveCN1877488AReduce volumeImprove cooling efficiencyDigital data processing detailsMachines using electric/magnetic effectsThermoelectric coolingElectronics cooling

Disclosed is a heat dissipating device installed outside of an electronic device. The inventive device comprises a fan, a heat electronic cooling device, a processing device and an interface terminal. Wherein the heat electronic cooling device is set on the direction of fan air inlet and has an air inlet gap between the fan; the processing device is connected with the fan and the heat electronic cooling device separately to control fan rotary speed and power of the heat electronic cooling device; the heat dissipating device is connected with the electronic device via the interface terminal. Also disclosed is a heat dissipating method which comprises: the heat dissipating device obtaining necessary power source via an interface terminal; the processing device of the heat dissipating device obtaining electronic device temperature and controlling fan rotary speed of the heat dissipating device and power of the heat electronic cooling device. The inventive device and method has the advantages of having high heat dissipating efficiency.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Slow-release magnetized compound fertilizer specially used for wheat and preparation method of same

InactiveCN106187476AIncrease or decrease usageEarly administrationSuperphosphatesMagnesium fertilisersSulfateChloride

A slow-release magnetized compound fertilizer specially used for wheat and a preparation method of same. The fertilizer is prepared from, by weight, 20-30 parts of urea, 4-10 parts of calcium superphosphate, 12-18 parts of potassium chloride, 3-5 parts of a humic fertilizer, 0.5-1 part of ammonium molybdate, 0.5-1 part of manganese sulfate, 2-3 parts of plant ash, 6-10 parts of a fertilizer additive, and 32-40 parts of a magnetic carrier. Iron-beneficiating tailing sand is compounded with the fertilizer to perform magnetizing treatment, so that the fertilizer can increase productivity and yield, improves soil environment, can retain nutrients and prevent nutrient loss, is greatly improved in utilization rate, comprehensively utilizes resources, is low in emission of water liquid, waste solid and waste gas, and has good environmental benefit.

Owner:ANHUI JINLU COMPOSITE MAGNETIC FERTILIZER

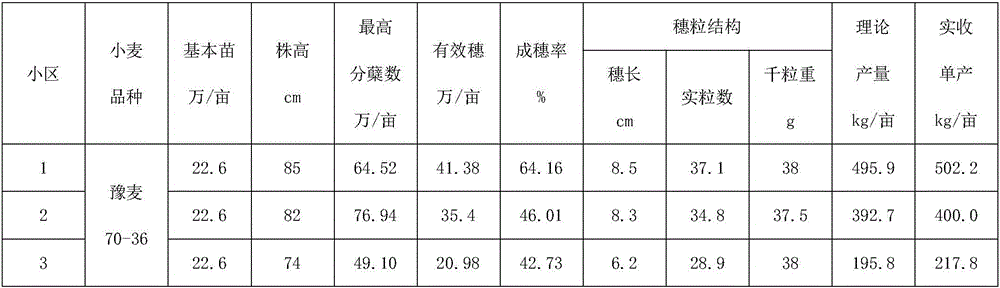

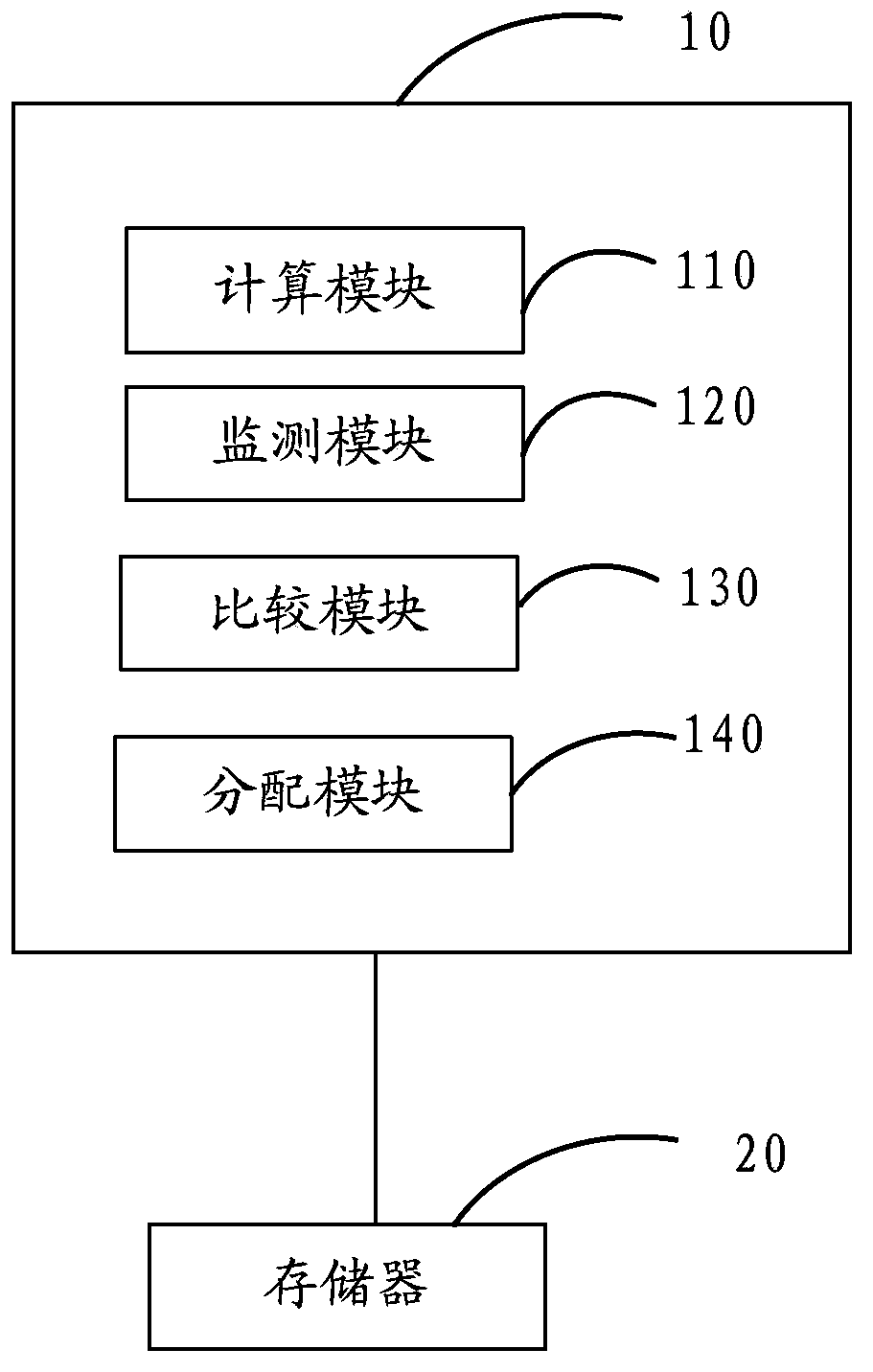

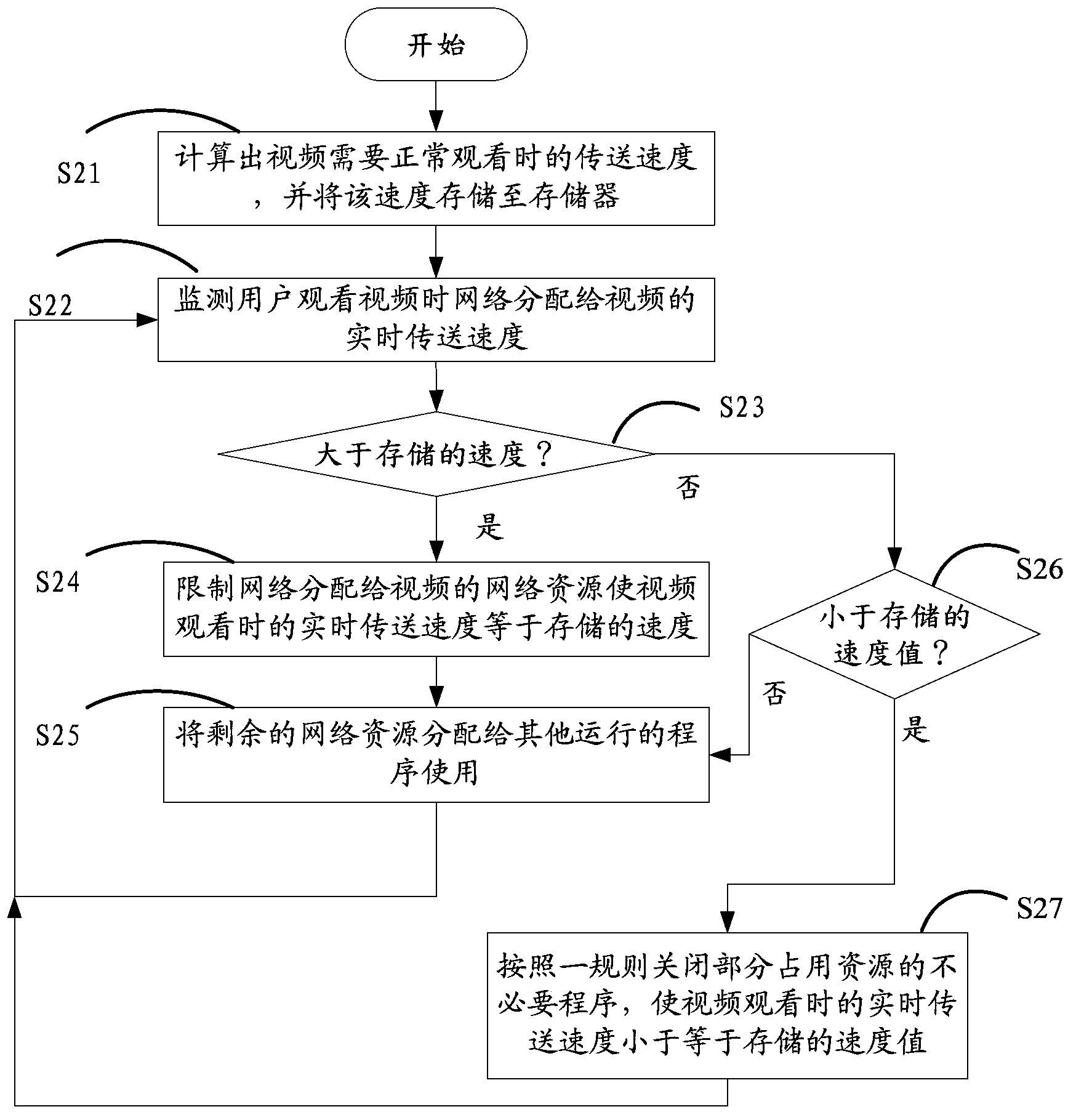

Network flow distribution system and method

InactiveCN104253766ASatisfied to watchEasy to useSelective content distributionData switching networksResource utilizationVelocity storage

The invention provides a network flow distribution system and method. The method comprises the following steps that: a transmission speed for normally watching a video is calculated and is stored; a real-time transmission speed that is distributed to the video by the network is monitored; comparison is carried out to determine whether the real-time transmission speed is larger than the stored speed; when the real-time transmission speed is larger than the stored speed, the network resources that are distributed to the video by the network are limited, so that the real-time transmission speed during video watching is equal to the stored speed; and the rest of network resources are distributed to other operating program for usage; and when the real-time transmission speed is equal to the stored speed, the rest of network resources are distributed to other operating program for usage; and when the real-time transmission speed is smaller than the stored speed, unnecessary programs of parts of occupied resources are closed according to a rule, so that the real-time transmission speed during video watching is smaller than or equal to the stored speed. With the system and method, a user can watch a video well and normal usage of other programs is not influenced based on the flow distribution controlling, so that resource utilization becomes reasonable.

Owner:FU TAI HUA IND SHENZHEN +1

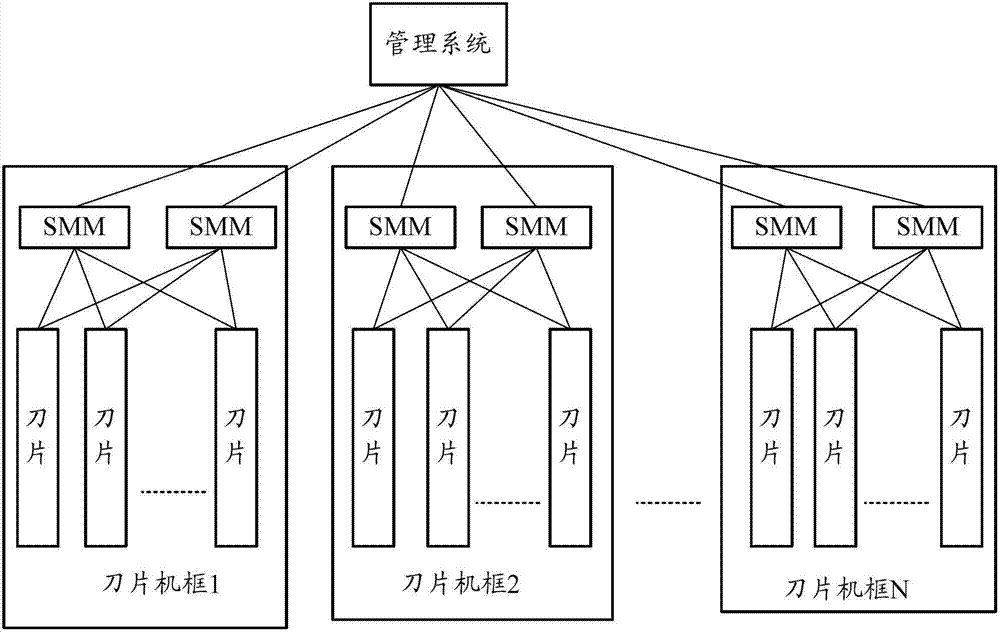

Blade server capacity expansion configuration method and management system

ActiveCN103049050AAchieve expansionHigh precisionPower supply for data processingManagement systemEmbedded system

An embodiment of the invention discloses a blade server capacity expansion configuration method and a management system. The method includes: acquiring types of blades used for capacity expansion, and the number of each type of blades; acquiring average power consumption of each type of blades in a system according to the types of the blades; calculating the number of power supply devices and the number of cooling devices, to be added, according to the number of each type of blades and the average power consumption of each type of blades in the system; displaying the number of the power supply devices and the number of the cooling devices, to be added, and configuring blade servers according to the number of the power supply devices and the number of the cooling devices, to be added, and the types of the blades used for capacity expansion and the number of each type of blades, thereby achieving capacity expansion of blade servers. Efficiency in blade server capacity expansion can be improved effectively, accuracy in capacity expansion configuration is increased, and resources can be utilized reasonably.

Owner:XFUSION DIGITAL TECH CO LTD

Universal verification platform and method for development of network core chip technology

ActiveCN105162658AEasy to set upFlexible configurationElectromagnetic transmissionData switching networksOptical ModuleResource utilization

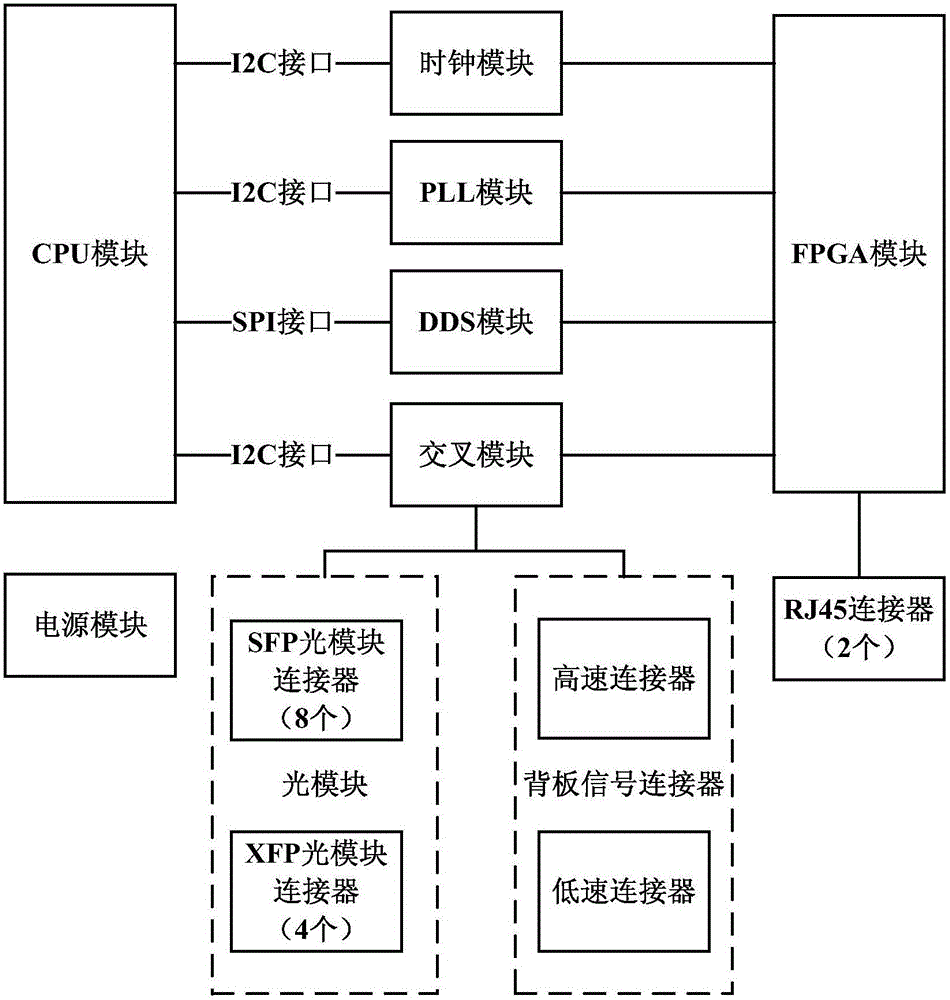

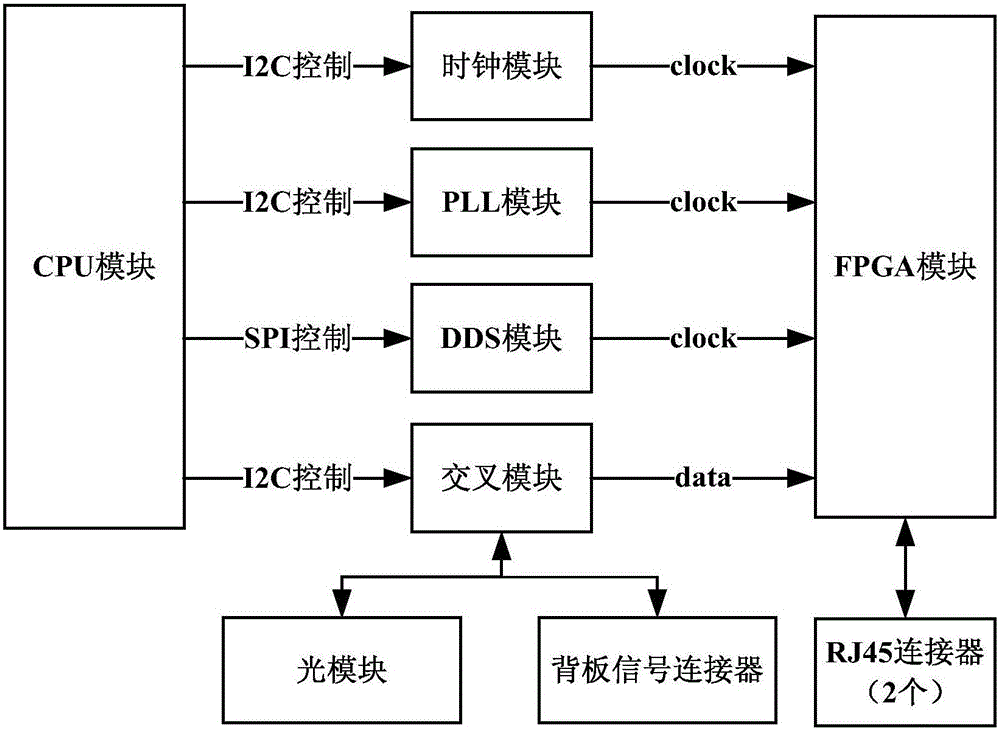

The invention discloses a universal verification platform and method for development of network core chip technology, and relates to the field of the network core chip technology. The platform comprises a power module, a CPU module, an FPGA module, a clock module, a PLL module, a DDS module, a cross module, an FPGA module, a backboard signal connector, an optical module and a RJ45 connector; the CPU module is connected with the FPGA module through the clock module, the PLL module, the DDS module and the cross module respectively; the FPGA module is connected with the RJ45 connector; and the cross module is respectively connected with the backboard signal connector and the optical module. The optical module comprises an SFP optical module connector and an XFP optical module connector; the backboard signal connector comprises a compatible high speed connector and a compatible low speed connector; and the RJ45 connector comprises two RJ45 interfaces. The universal verification platform disclosed by the invention can be used for verifying a variety of chips, so that the use cost is lower, and the resource utilization is quite reasonable.

Owner:FENGHUO COMM SCI & TECH CO LTD

Baking-free brick and preparation method thereof

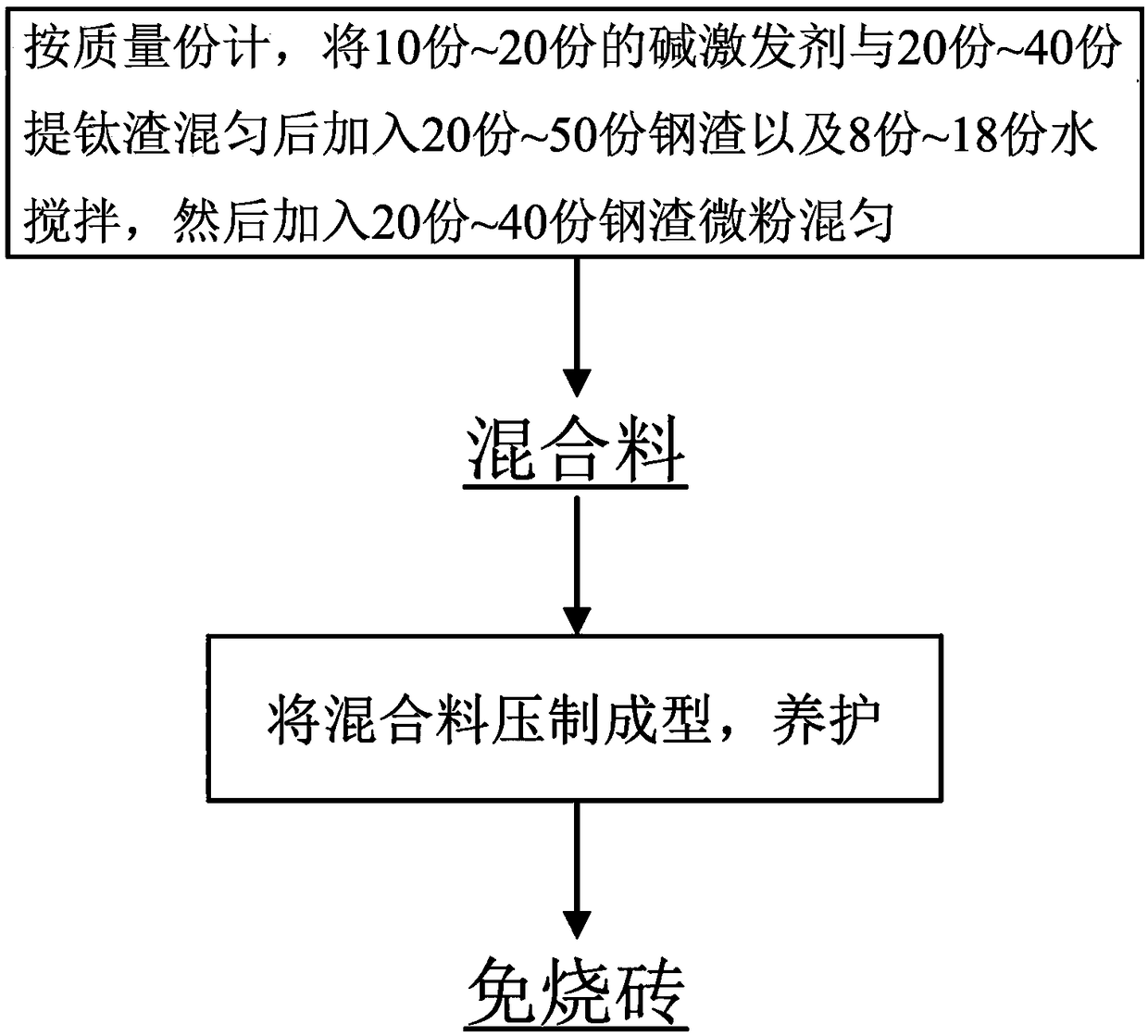

The invention provides a baking-free brick and a preparation method thereof. The preparation method comprises the following steps: based on parts by mass, uniformly mixing 10-20 parts of an alkali-activator and 20-40 parts of titanium extraction slag, adding 20-50 parts of steel slag and 8-18 parts of water to the mixture, performing stirring, then adding 20-40 parts of steel slag micro powder, performing uniform mixing to obtain a mixture, performing press forming on the mixture and performing curing to obtain the baking-free brick. The preparation method adopts the alkali-activator, the titanium extraction slag, the steel slag micro powder and the steel slag as the main raw materials, and is energy-saving and environment-friendly compared with baked bricks; and compared with other baking-free bricks, the preparation method can save a big amount of cement, consumes a big amount of industrial residue, and has low cost, convenient selection of raw materials, environmental friendliness,and higher economic and social benefits.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Paper for daily use and preparation method thereof

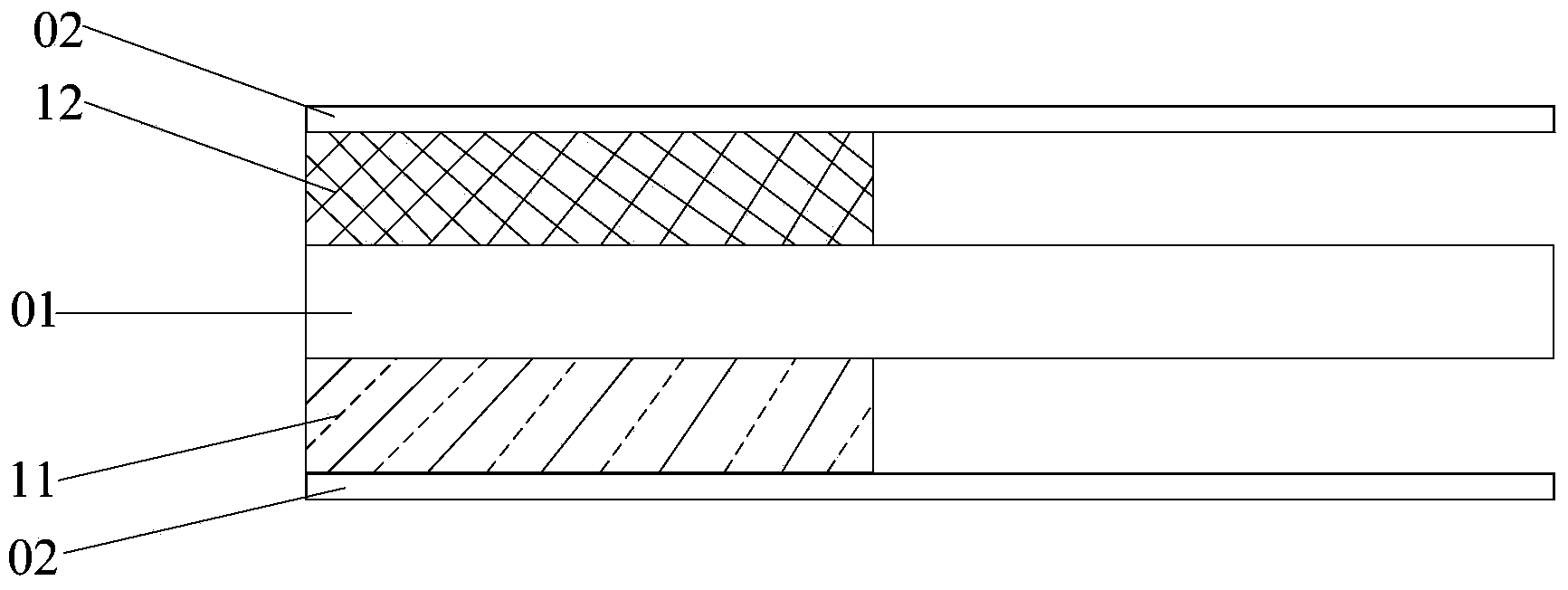

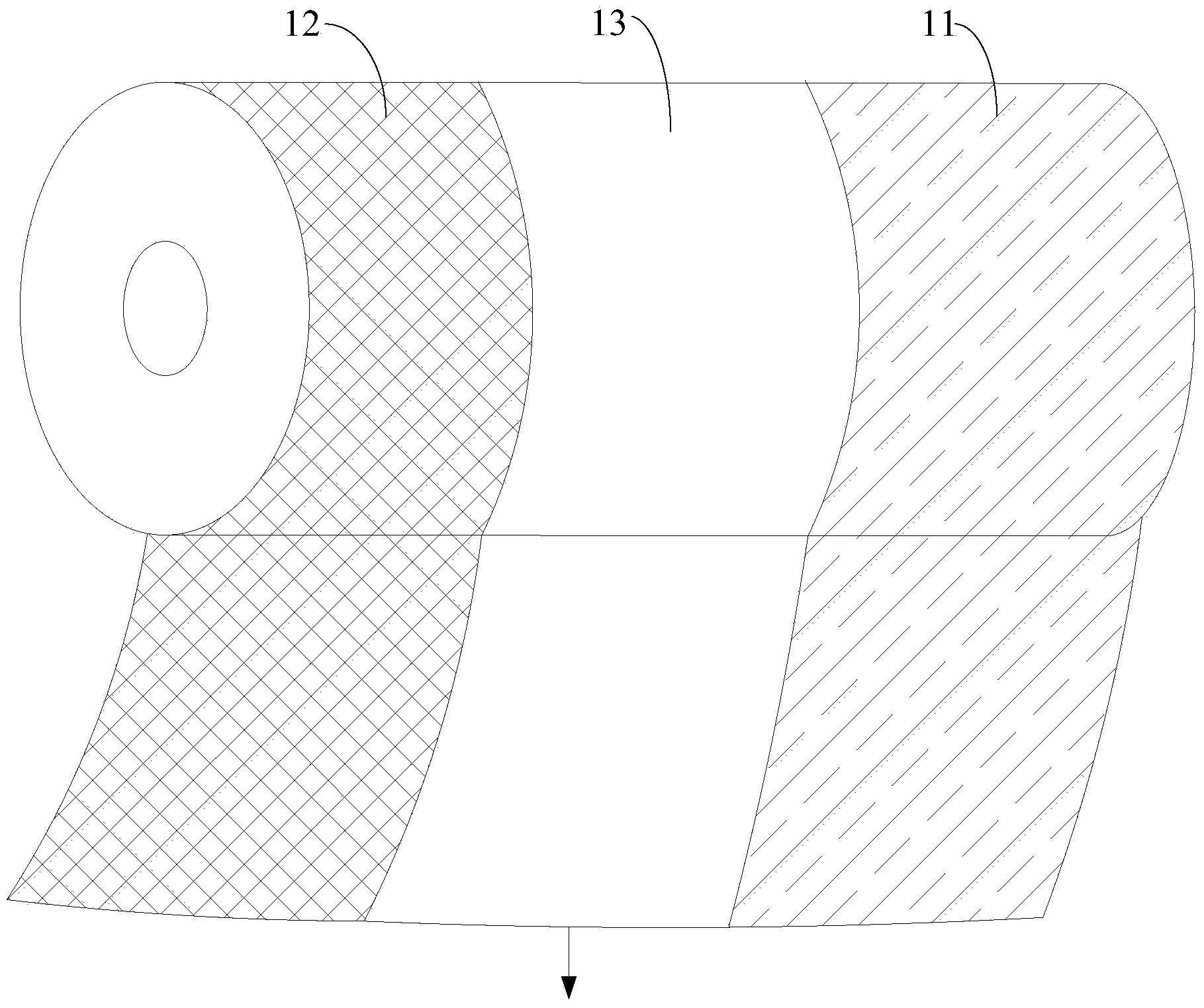

ActiveCN103821034AImprove solubilityAchieve deodorizationNon-fibrous pulp additionPaper coatingDecompositionPulp and paper industry

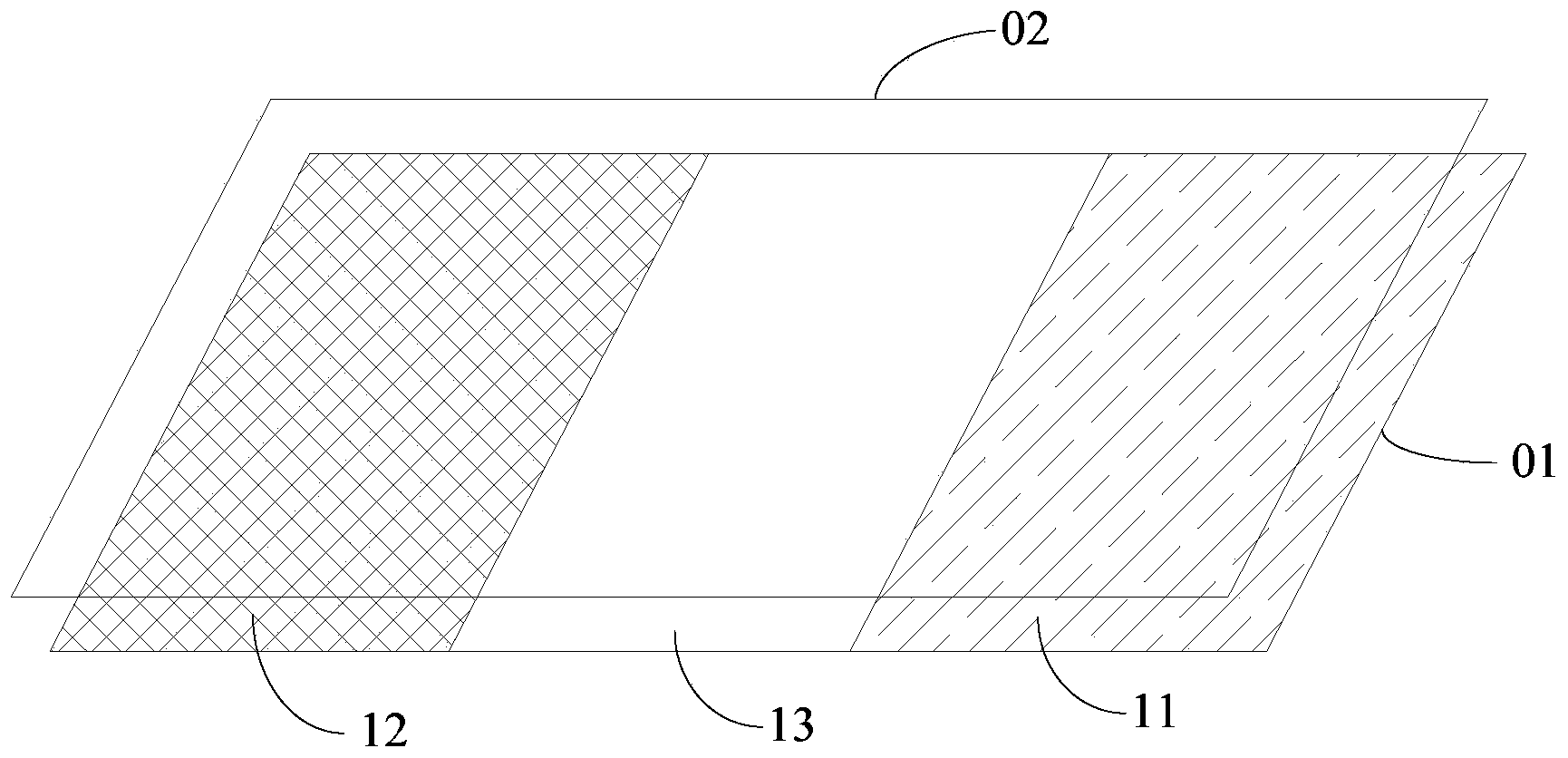

The invention discloses paper for daily use and a preparation method thereof. The paper for daily use comprises at least one paper substrate layer. A first coating and a second coating are disposed at intervals on the surface of the paper substrate layer. The first coating and the second coating react after being dissolved in water and produce at least one of a decontamination component, a gas and a deodorization component, thus accelerating decomposition of the paper for daily use and / or release of substances in the first coating and the second coating. By the technical scheme, the discarded paper for daily use can play functions of deodorization, decontamination, acceleration of paper decomposition, and the like after the paper for daily use is dissolved in water, so that the resources are utilized reasonably.

Owner:GOLD HONG YE PAPER

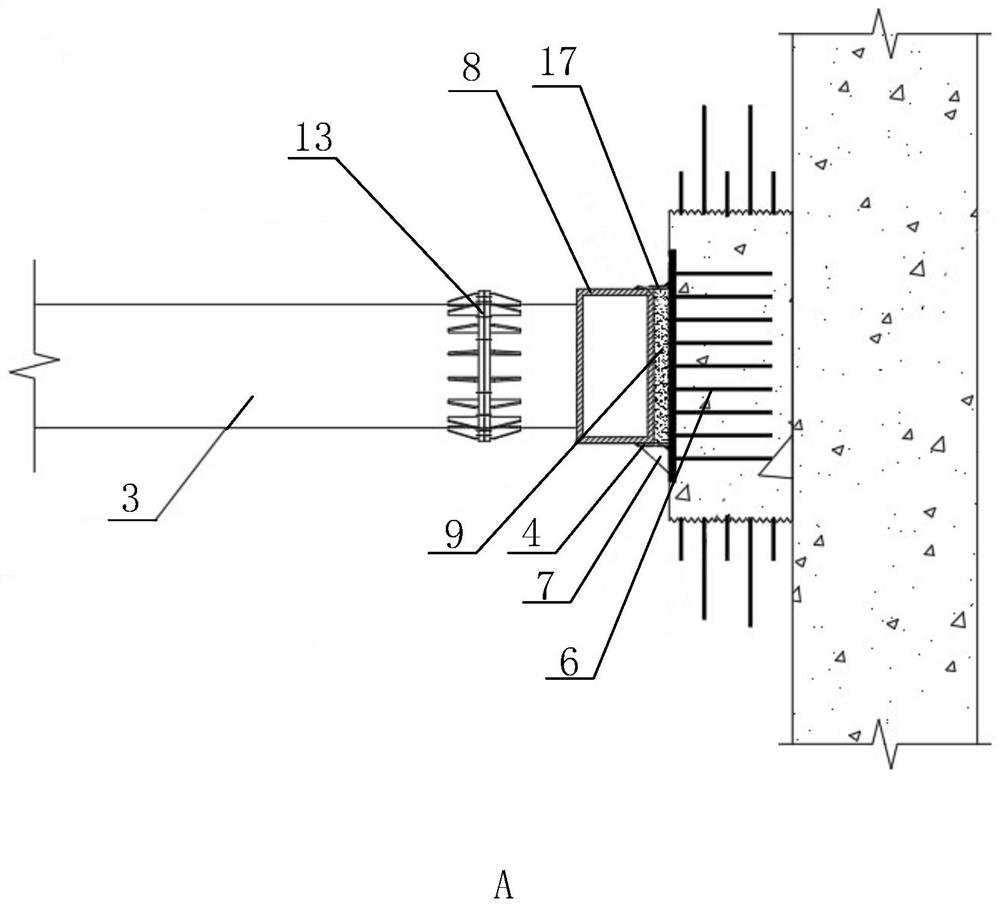

Permanent and temporary combined prefabricated internal support system and construction method

PendingCN111778990AImprove construction efficiencyShorten the construction periodExcavationsSupporting systemSlurry wall

The invention discloses a permanent and temporary combined prefabricated internal support system and a construction method, and relates to the technical field of ultra-deep foundation pit engineeringconstruction. The structure of the support system comprises a foundation pit, an underground continuous wall is arranged on the inner wall of the foundation pit, and a plurality of steel supports arearranged horizontally in the foundation pit; partial permanent structures are arranged at the positions, corresponding to the end parts of the steel supports, of the inner wall of the foundation pit,and temporary structures are connected between the end parts of the steel supports and the partial permanent structures. Aiming at the problems of multiple construction procedures, long maintenance time, slow construction speed, and being incapable of recycling utilization in the prior art, the purpose is to provide the permanent and temporary combined prefabricated internal support system and theconstruction method, and the support system and the construction method have the advantages of fast construction speed and environment-friendly recycling.

Owner:SHANGHAI MECHANIZED CONSTR GRP

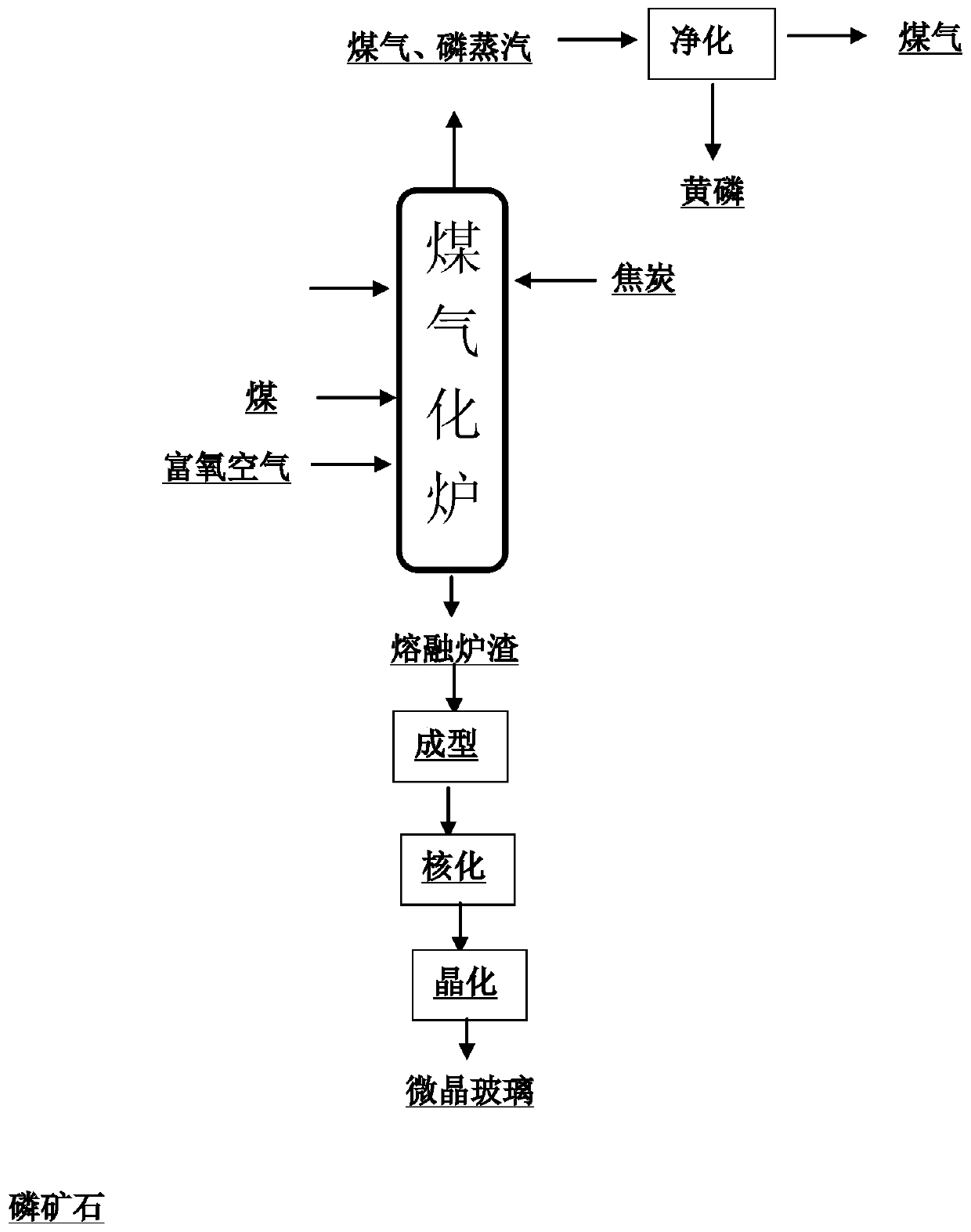

Coal gas-yellow phosphorus-building material co-production integrated method

PendingCN111548019AReasonable use of resourcesIncrease production capacityChemical industryChemical industrySlag

The invention discloses a coal gas-yellow phosphorus-building material co-production integrated production method, relates to the technical field of coal gasification, yellow phosphorus and building material production, and aims to utilize coal gasification high-level heat energy as a yellow phosphorus production heat source to improve the heat utilization efficiency. According to the method, thecharacteristic that the components of coal ash mainly contain silicon and aluminum acidic oxides is fully utilized, a fluxing agent is provided for reduction decomposition of phosphorite; the acidityvalue of a system is properly adjusted; other components such as titanium, magnesium and alkali metal in the coal ash are utilized, so that a basic glass composition suitable for preparing microcrystalline glass is obtained; and therefore, yellow phosphorus can be co-produced while coal gas is produced by a traditional oxygen-enriched pressurized gasification furnace, the microcrystalline glass isprepared from furnace slag, the resource utilization of solid waste produced by traditional coal gasification and yellow phosphorus production is realized. The method is of great practical significance for clean utilization of the coal and phosphorus chemical industry.

Owner:KUNMING UNIV OF SCI & TECH

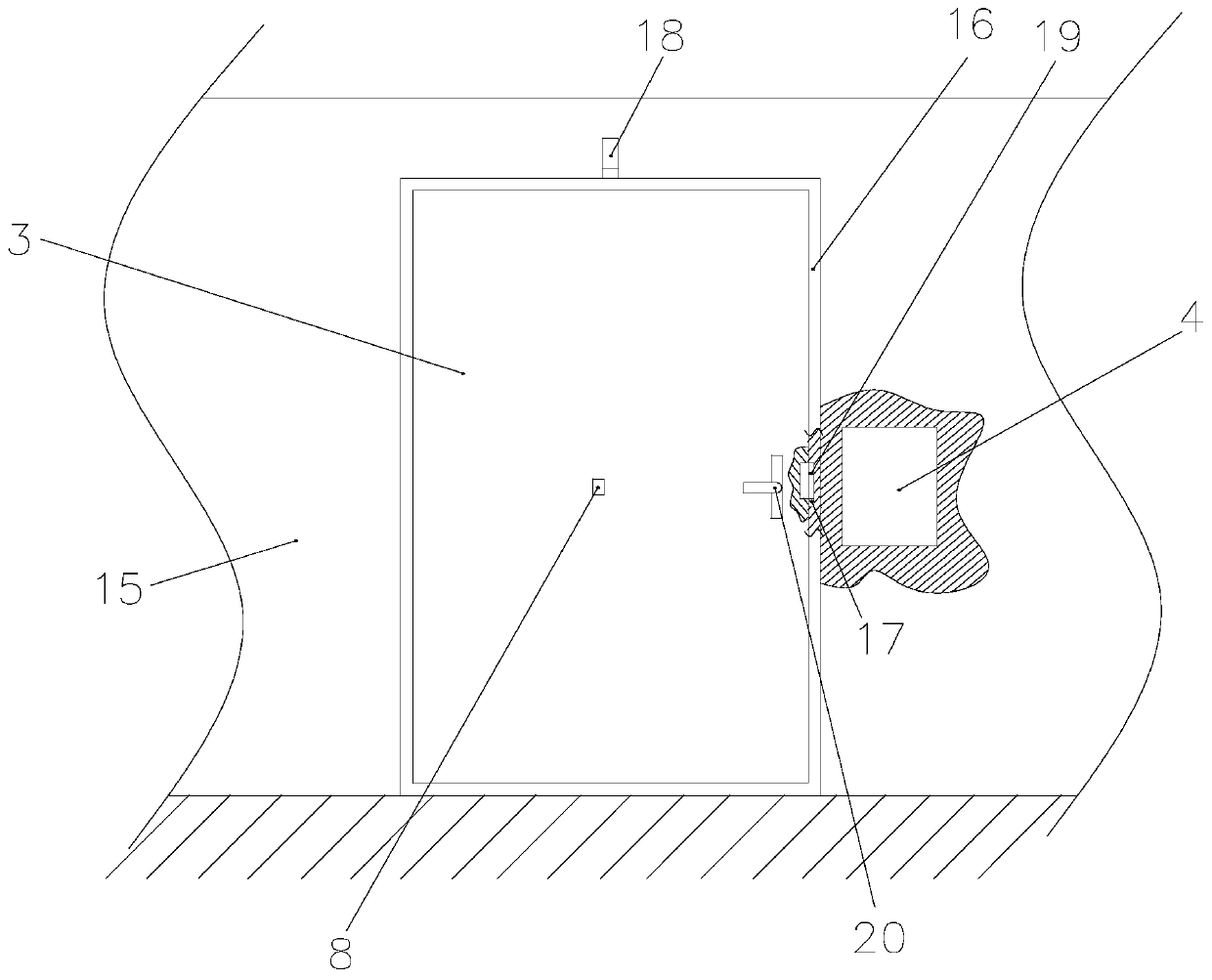

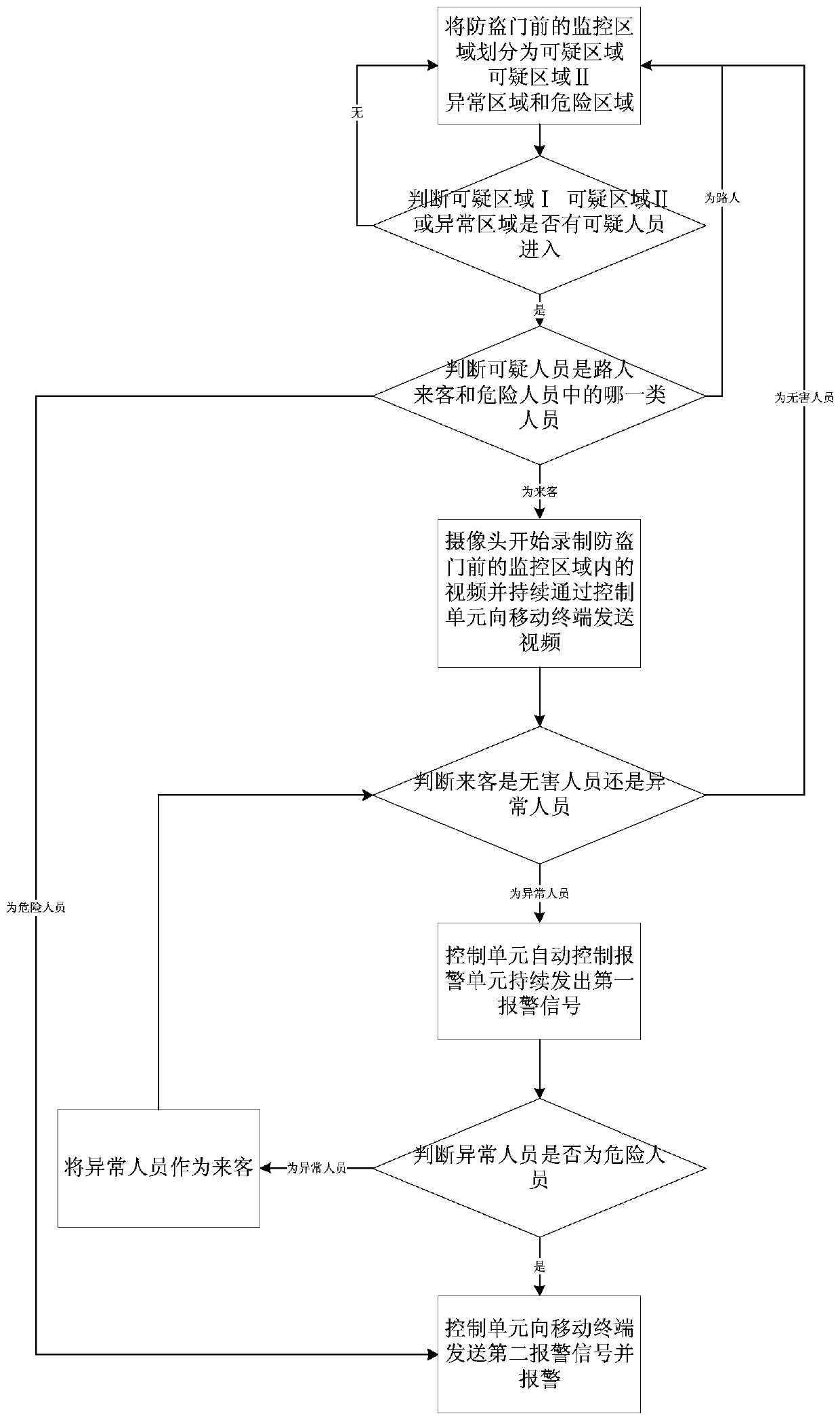

Remote anti-theft monitoring system and method for smart home

ActiveCN110211315AAccurately identify behavioral situationsReduce behavioral misjudgmentTelevision system detailsBurglar alarm by openingSurveillance cameraAnti theft

The invention provides a remote anti-theft monitoring system for smart home. The system comprises a control unit, a radar, a camera, a pressure sensor and an alarm unit. The radar is arranged in the middle of the outer side of a security door and is used for sensing a suspicious person appearing in front of the security door and sending a suspicious person position signal to the control unit. Thepressure sensor is disposed at a position, being close to a lock cylinder, of a security door frame and a force sensing surface of the pressure sensor faces the security door and; and the pressure sensor is used for sensing a pressure signal applied to the security door threshold by the security door and sending the pressure signal to the control unit. According to the invention, the behaviors ofsuspicious persons in the monitoring area in front of the security door can be identified accurately; the turning on / off of the monitoring camera are controlled accurately to realize remote anti-theftmonitoring; the automatic and hand-operated alarm controlling is realized simultaneously; while the false behavior determination of the suspicious persons is reduced, the accuracy and safety factor of anti-theft monitoring are improved; the energy consumption is reduced; and the resources are utilized reasonably.

Owner:CHONGQING UNIV

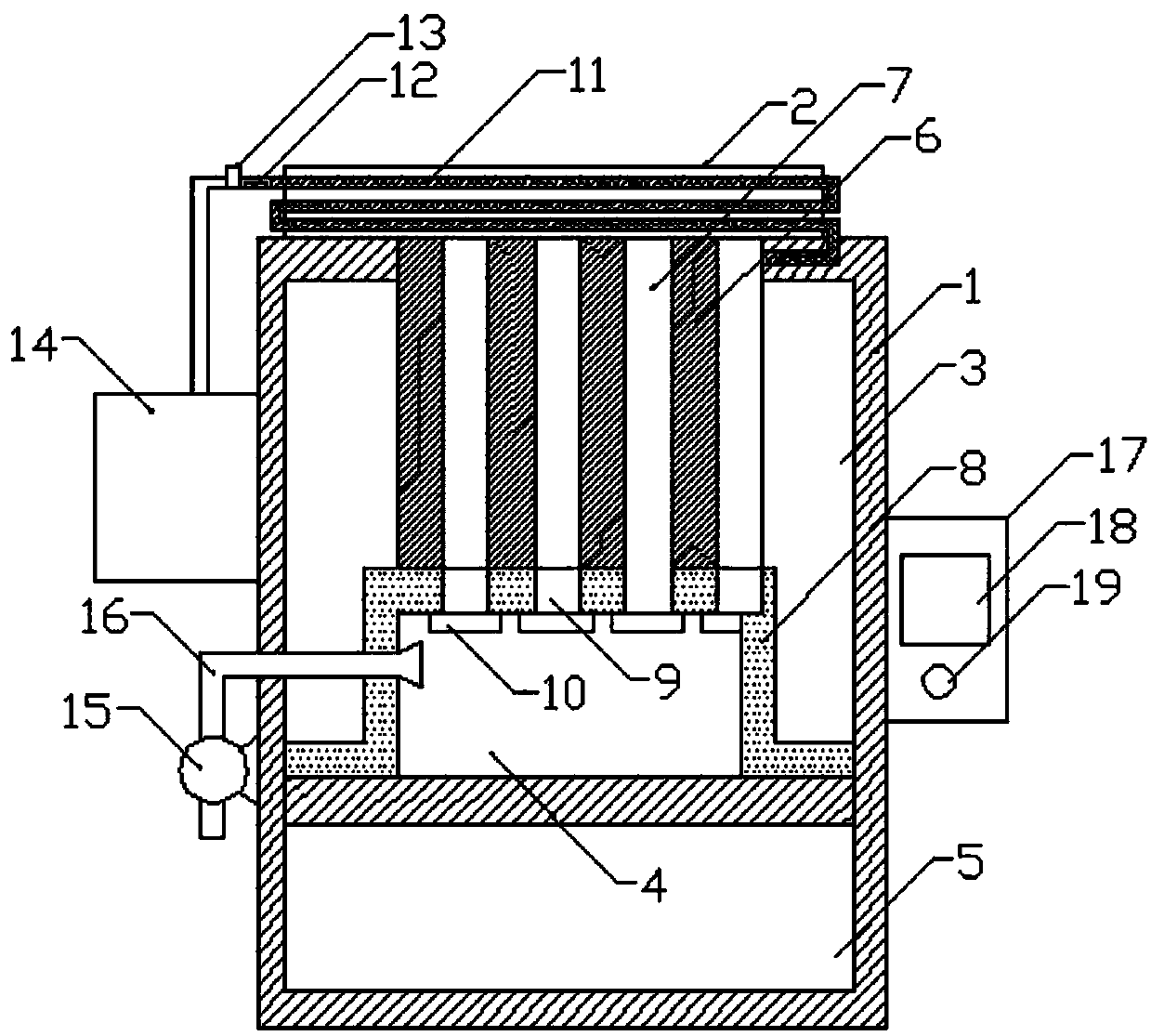

Efficient energy-saving heating boiler capable of being conveniently used by people

InactiveCN109855299AIncrease heating rateIncrease the heating areaWater heatersCombustion chamberInlet channel

The invention discloses an efficient energy-saving heating boiler capable of being conveniently used by people. The efficient energy-saving heating boiler capable of being conveniently used by peoplecomprises a boiler body and a heat-conduction pipe. A flame-airflow heat exchange chamber, a combustion chamber and an ash collection chamber are arranged in the boiler body. The flame-airflow heat exchange chamber is separated from the combustion chamber through a first partition plate. A plurality of water pipes are evenly arranged in the flame-airflow heat exchange chamber. Air inlet channels are formed between the water pipes. Air inlets of the air inlet channels communicate with through holes of the first partition plate. One end of each water pipe is fixed to the first partition plate, and the other end of each water pipe penetrates through the top end of the boiler body to be connected to the bottom end of the heat-conduction pipe. An air outlet of each air inlet channel is connected with a pre-heating pipe which is wound on the heat-conduction pipe. A pressure sensor is arranged in the pre-heating pipe, and a control valve is arranged at the tail end of the pre-heating pipe. The pre-heating pipe is connected with a tail gas treatment box through a gas delivery pipe. A combustion-supporting pump is arranged on one side of the boiler body. A control panel is fixedly arrangedat the outer end of the boiler body.

Owner:XIAN LANXIN IND AUTOMATION ENG CO LTD

Intelligent parking lock

ActiveCN108222620AReasonable use of resourcesEasy to useTransmission systemsTraffic restrictionsElectricityMicrocontroller

The invention provides an intelligent parking lock. The intelligent parking lock comprises a cassette base, a panel, a driving mechanism, a control box, a power supply, a rain shielding cloth an automatic winding mechanism. The panel is connected to the interior of the cassette base in a pivoted mode, the control box is electrically connected with the driving mechanism, the driving mechanism and the control box are separately and electrically connected with the power supply, and a portal frame of the driving mechanism is movably connected with the panel. The panel is driven by the driving mechanism to erect or lay, the automatic winding mechanism is arranged in the cassette base in a pivoted mode, one end of the rain shielding cloth is connected to the automatic winding mechanism, and theother end of the rain shielding cloth is connected to the back face of the panel. The panel is provided with a display screen and a camera, the control box comprises a single chip microcomputer, a GEMmodule, a motor drive circuit, a WIFI module and a wireless router, the GSM module, the display screen, the camera, the motor drive circuit, and the WIFI module are separately and electrically connected with the single chip microcomputer, and the WIFI module and the wireless router are connected through wireless. The intelligent parking lock is convenient to use, and resources are used reasonablyand the service life is long.

Owner:慧起点智能科技(南通)有限公司

Unit assembled magnet patch small-size LED lamp

InactiveCN109751520AAvoid enteringDoes not affect lighting performanceLighting support devicesLighting heating/cooling arrangementsLED lampStain

The invention discloses a unit assembled magnet patch small-size LED lamp, which comprises a waterproof lamp shade, an LED lamp panel, a connector, a heat conduction position limiting block, a casing,a conducting wire plug, a sealing plug, a magic patch back, a circuit board, a socket conducting wire, a conducting wire socket, a power supply conducting wire plug and a power supply. A sealed structural design is used; the inside structure is completely isolated from outside environment; meanwhile, sealing rings are used between all components of a searching lamp, so that the equipment damage due to entering of water stain and dust can be avoided. A fin heat conduction block is used, so that the heat conduction efficiency is greatly improved; the heat radiation is accelerated; a clamp buckle is added, so that the equipment can be freely combined according to the willing of a user; certain interestingness is realized; through added magic tapes, the unit assembled magnet patch small-sizeLED lamp can be pasted on most articles; the labor is saved; meanwhile, the two hands can be liberated. The dustproof waterproof and heat radiation efficiency is high; meanwhile, free assembly and pasting can be realized; the performance is much better than that of similar products.

Owner:王巧云

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com